New Insights into the Mechanical Properties, Functional Fatigue, and Structural Fatigue of Ni-Ti Alloy Porous Structures

Abstract

:1. Introduction

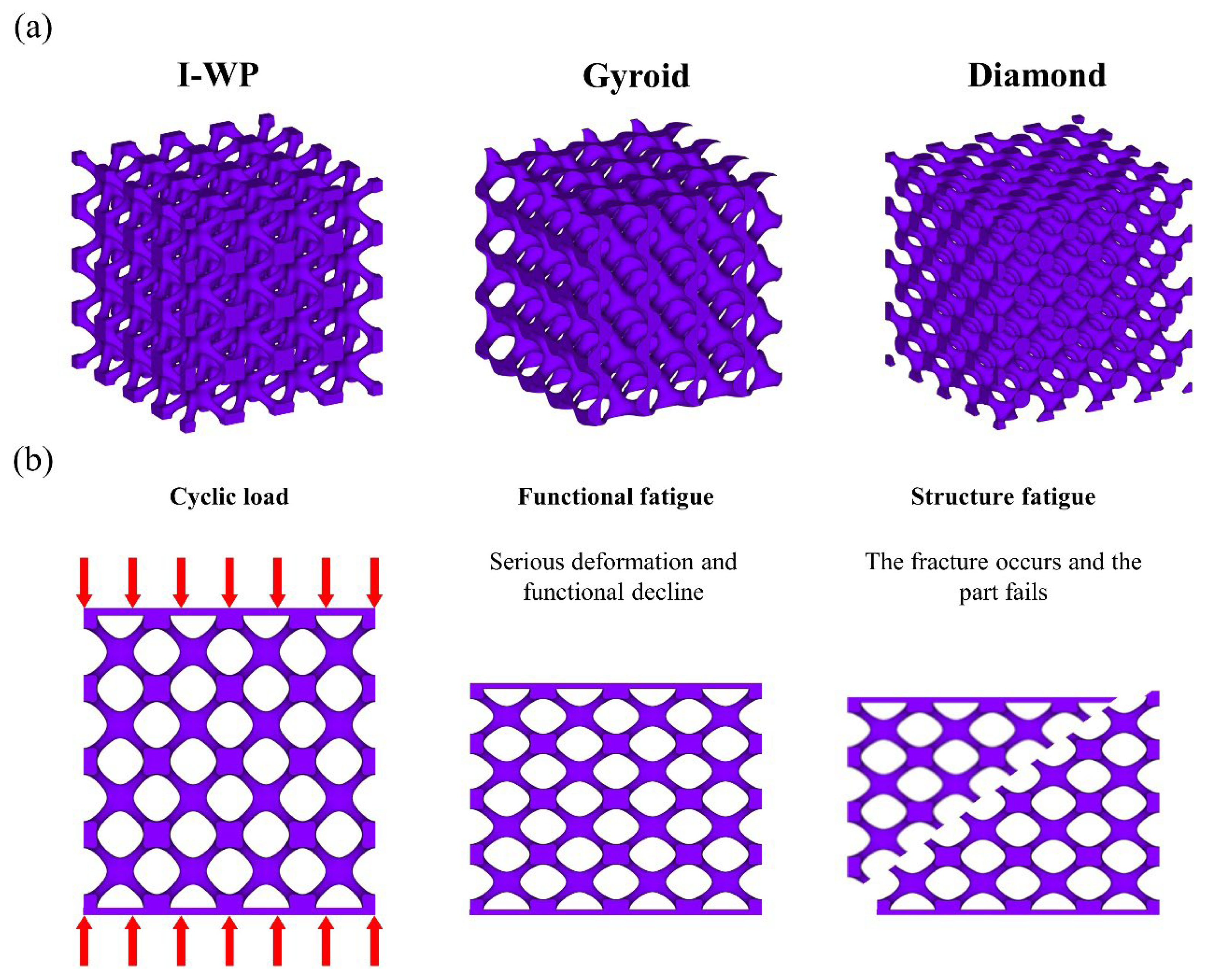

2. Mechanical Response and Structure Fatigue of Ni-Ti Lattice Structures

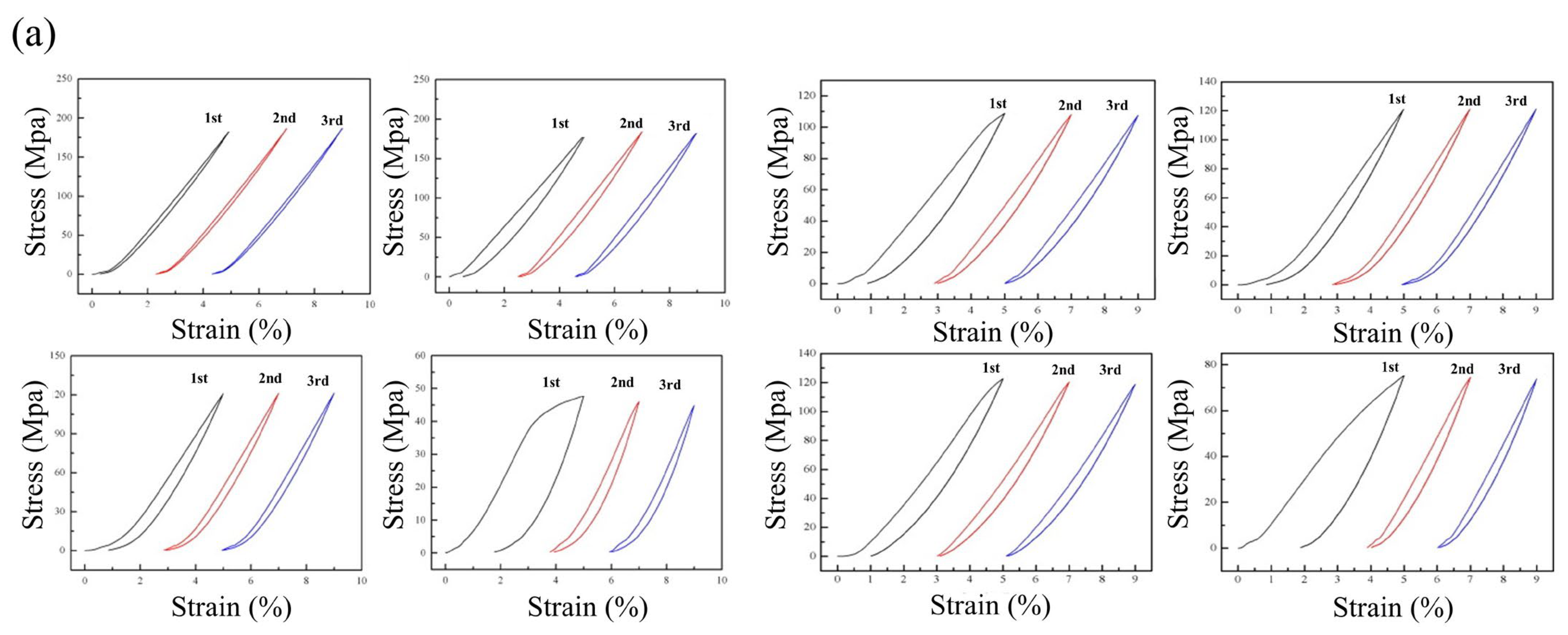

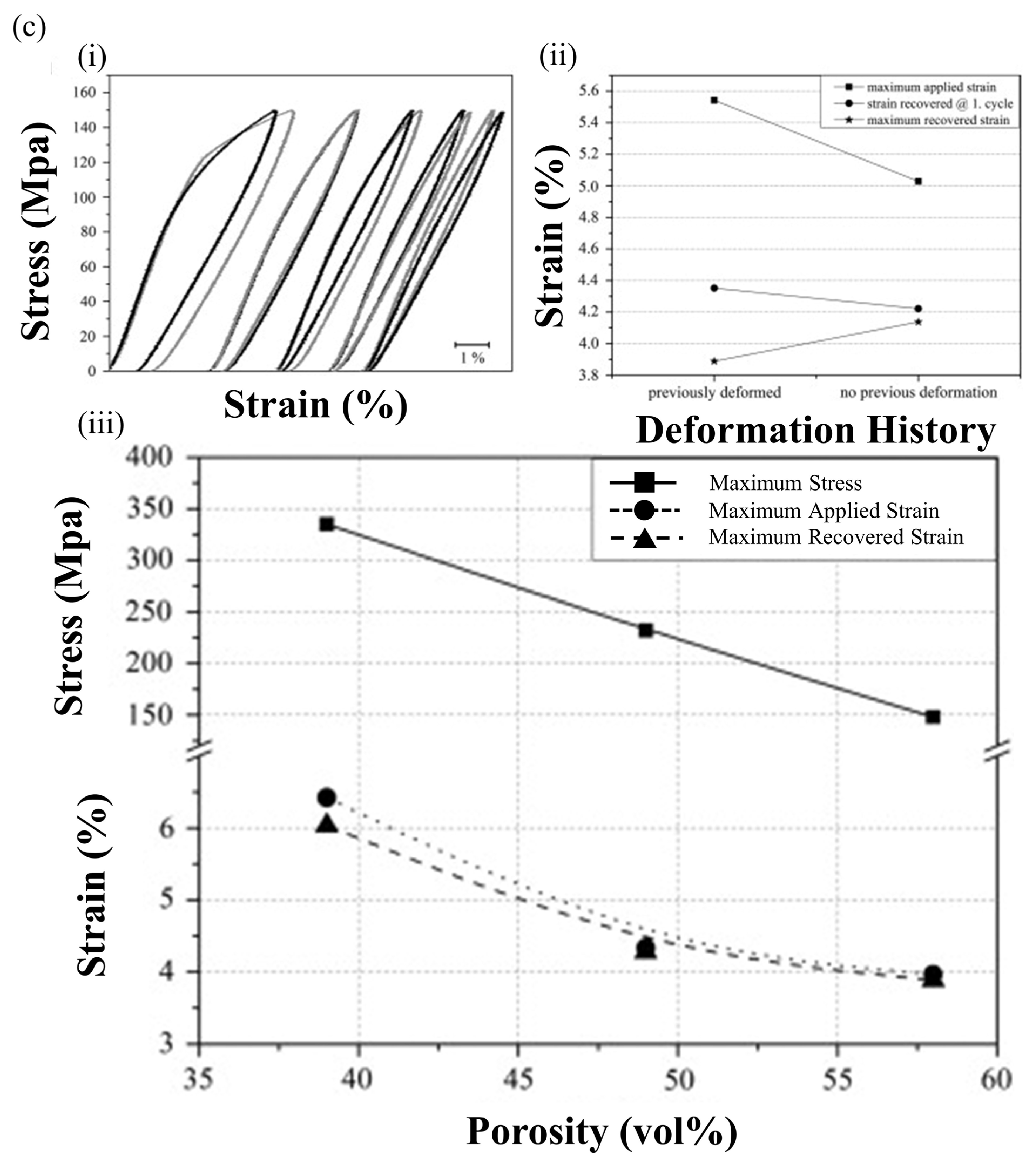

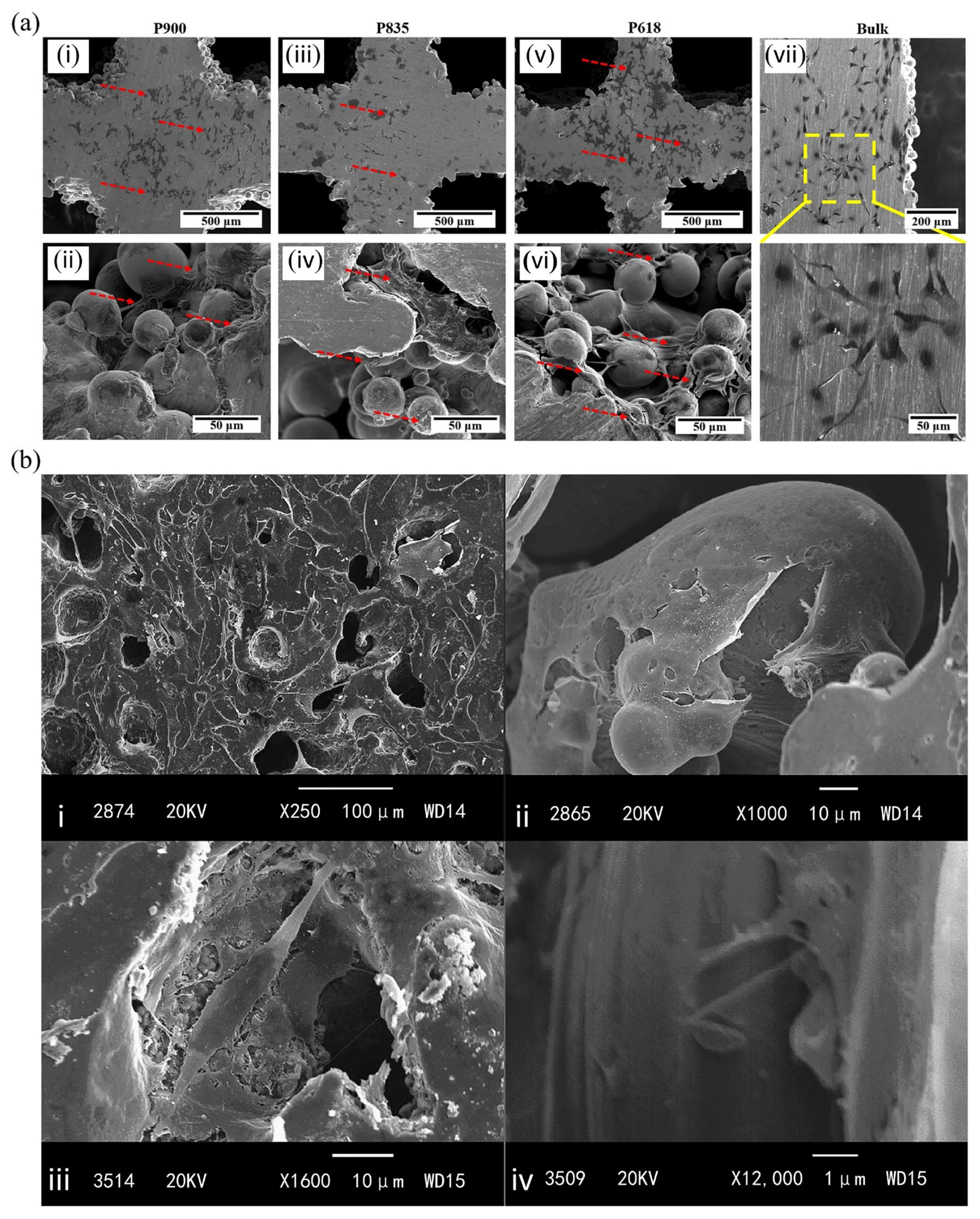

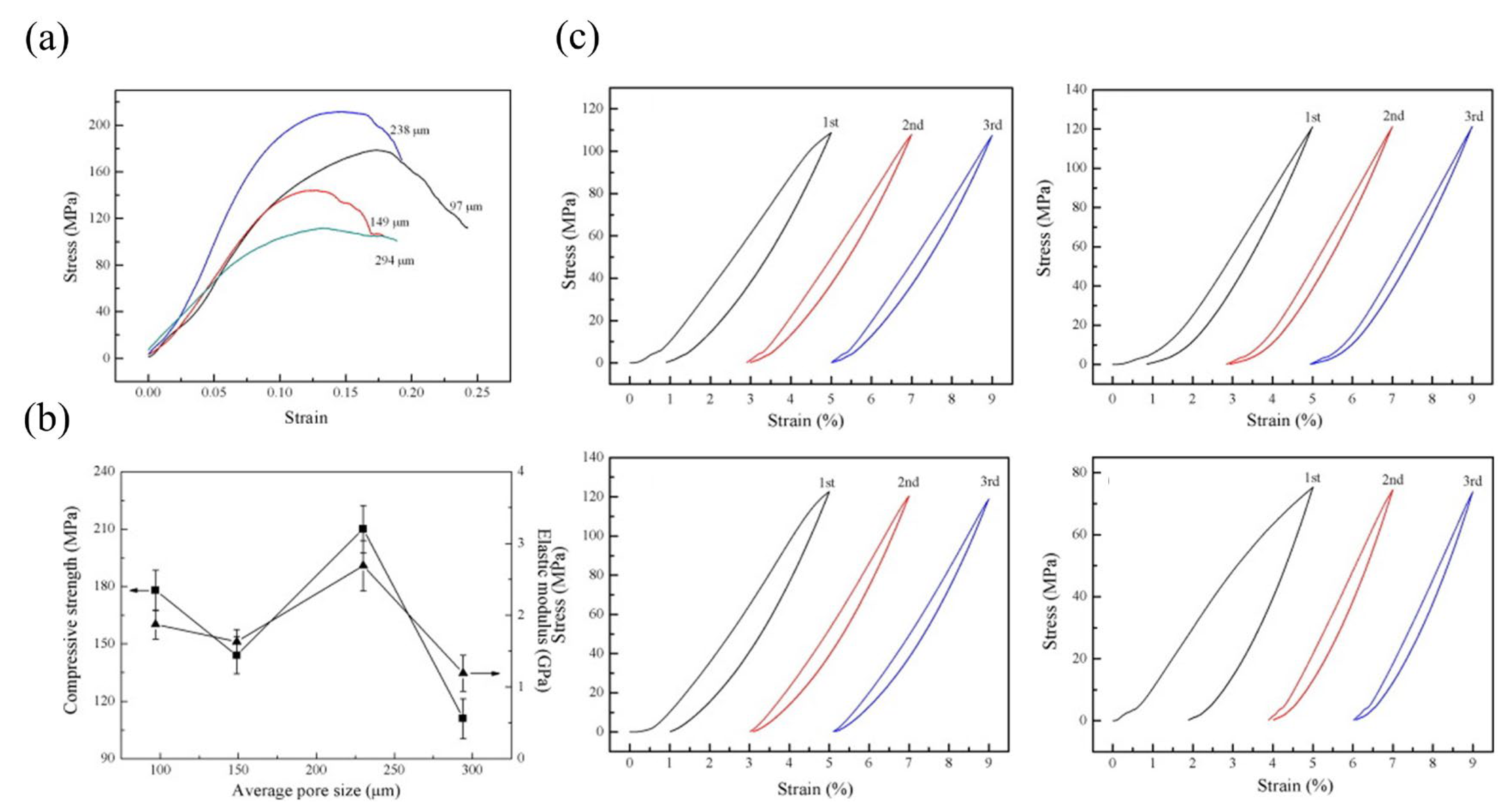

2.1. Influence of Pore Characteristics on the Mechanical Properties of Ni-Ti Porous Structures

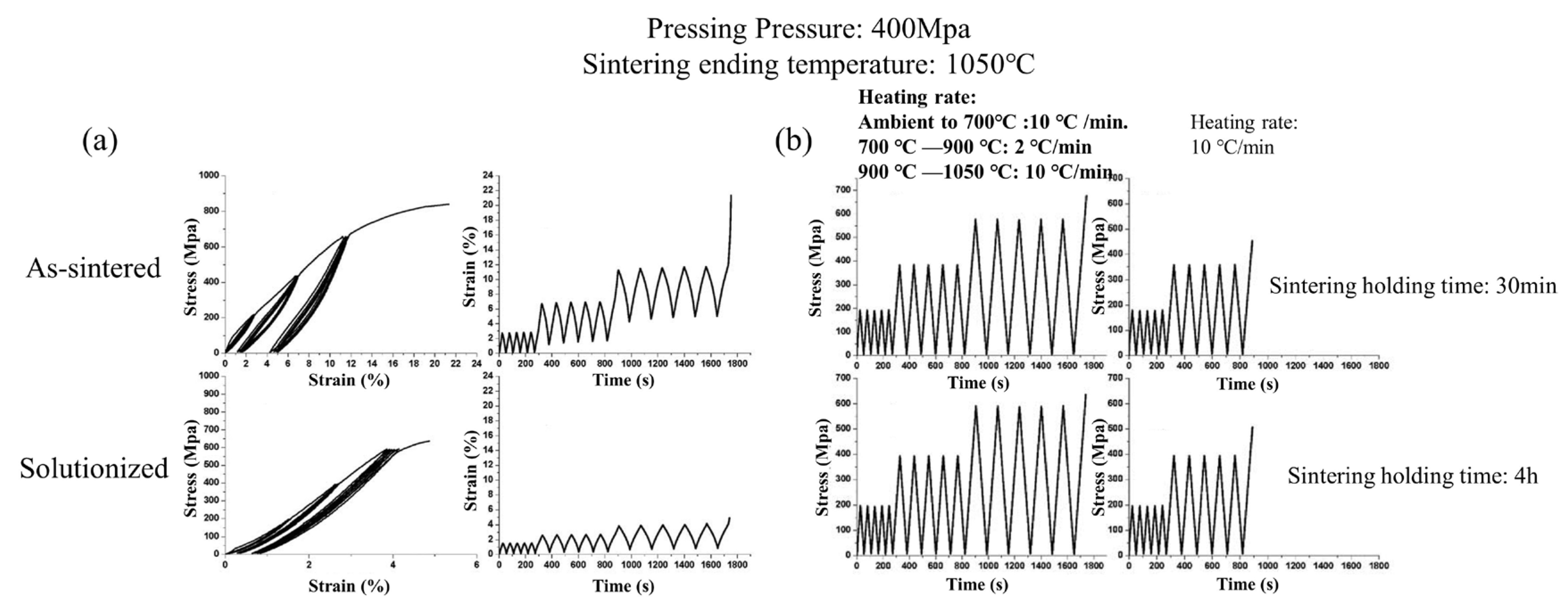

2.2. Mechanical Properties of Ni-Ti Porous Structures Influenced by the Preparation Method and Post-Treatment

2.3. Mechanical Properties of Ni-Ti Porous Structures Influenced by Additives

3. Modeling for the Mechanical Response and Structure Fatigue Simulation

3.1. Macroscopic Ni-Ti Porous Structure Simulation Study

3.2. Microscopic Ni-Ti Porous Structure Simulation Study

4. Functional Fatigue of Ni-Ti Lattice Structures

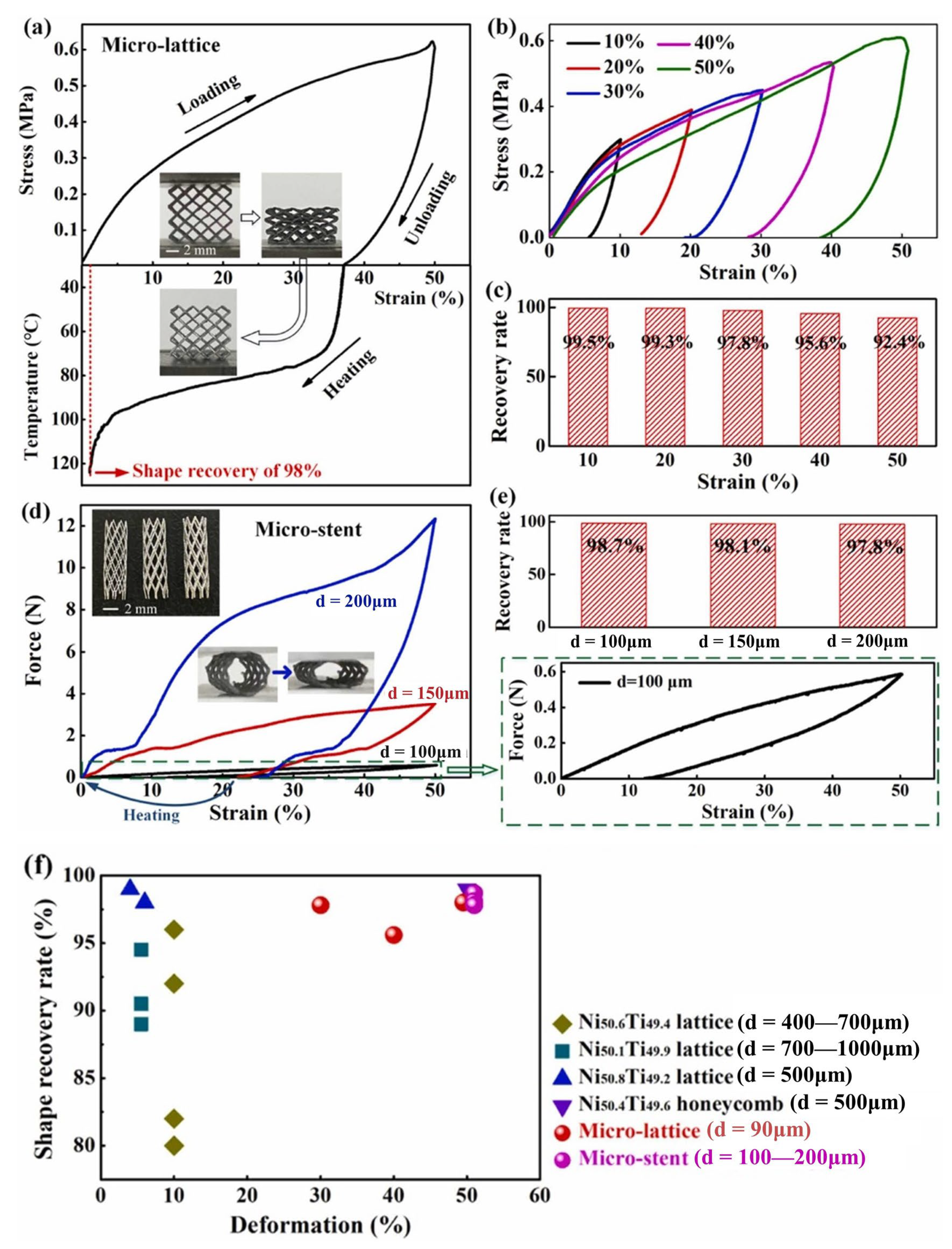

4.1. Pore Characteristics Influence the Functional Fatigue of Ni-Ti Porous Structures

4.2. Impact of Additive Manufacturing on Ni-Ti Porous Structure

5. Modeling for the Functional Fatigue Simulation

6. Application of Ni-Ti Porous Structure

7. Summaries and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiong, Z.; Li, H.; Yang, H.; Yang, Y.; Liu, Y.; Cui, L.; Li, X.; Masseling, L.; Shen, L.; Hao, S. Micro laser powder bed fusion of NiTi alloys with superior mechanical property and shape recovery function. Addit. Manuf. 2022, 57, 102960. [Google Scholar] [CrossRef]

- Farber, E.; Orlov, A.; Borisov, E.; Repnin, A.; Kuzin, S.; Golubkov, N.; Popovich, A. TiNi Alloy Lattice Structures with Negative Poisson’s Ratio: Computer Simulation and Experimental Results. Metals 2022, 12, 1476. [Google Scholar] [CrossRef]

- Chen, W.; Gu, D.; Yang, J.; Yang, Q.; Chen, J.; Shen, X. Compressive mechanical properties and shape memory effect of NiTi gradient lattice structures fabricated by laser powder bed fusion. Int. J. Extrem. Manuf. 2022, 4, ac8ef3. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, Q.; Liu, Z.; Zhang, J.; Tan, G.; Jiao, D.; Zhu, W.; Li, S.; Zhang, Z.; Yang, R. 3D printed Mg-NiTi interpenetrating-phase composites with high strength, damping capacity, and energy absorption efficiency. Sci. Adv. 2020, 6, eaba5581. [Google Scholar] [CrossRef] [PubMed]

- Valiev, R.Z.; Prokofiev, E.A.; Kazarinov, N.A.; Raab, G.I.; Minasov, T.B.; Strasky, J. Developing Nanostructured Ti Alloys for Innovative Implantable Medical Devices. Materials 2020, 13, 967. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Gu, D.; Lin, K.; Yuan, L.; Yang, J.; Chen, W. Laser powder bed fusion of diatom frustule inspired bionic NiTi lattice structures: Compressive behavior and shape memory effect. Smart Mater. Struct. 2022, 31, 074003. [Google Scholar] [CrossRef]

- Mirak, M.; Alizadeh, M.; Salahinejad, E.; Amini, R. Zn-HA-TiO2 nanocomposite coatings electrodeposited on a NiTi shape memory alloy. Surf. Interface Anal. 2015, 47, 176–183. [Google Scholar] [CrossRef]

- Frenzel, J. On the Importance of Structural and Functional Fatigue in Shape Memory Technology. Shape Mem. Superelast. 2020, 6, 213–222. [Google Scholar] [CrossRef]

- Luo, J.; Yarigarravesh, M.; Assari, A.H.; Amin, N.H.; Tayyebi, M.; Paidar, M. Investigating the solid-state diffusion at the interface of Ni/Ti laminated composite. J. Manuf. Process. 2022, 75, 670–681. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, T.; Wang, Y. Phase Transformation Graph and Transformation Pathway Engineering for Shape Memory Alloys. Shape Mem. Superelast. 2020, 6, 115–130. [Google Scholar] [CrossRef]

- Ye, Q.; Li, X.; Tayyebi, M.; Assari, A.H.; Polkowska, A.; Lech, S.; Polkowski, W.; Tayebi, M. Effect of heat treatment parameters on microstructure evolution, tensile strength, wear resistance, and fracture behavior of Ni–Ti multilayered composites produced by cross-accumulative roll bonding. Arch. Civ. Mech. Eng. 2022, 23, 27. [Google Scholar] [CrossRef]

- Amini, R.; Alijani, F.; Ghaffari, M.; Alizadeh, M.; Okyay, A.K. Formation of B19′, B2, and amorphous phases during mechano-synthesis of nanocrystalline NiTi intermetallics. Powder Technol. 2014, 253, 797–802. [Google Scholar] [CrossRef]

- Hosseini, S.; Karimidoost, M.; Emamian, M.; Mehrjoo, M.; Alishahi, M. Electrochemical dealloying of porous NiTi alloy: Porosity evolution, corrosion resistance, and biocompatibility behavior. Intermetallics 2023, 152, 107756. [Google Scholar] [CrossRef]

- Speirs, M.; Van Hooreweder, B.; Van Humbeeck, J.; Kruth, J.P. Fatigue behaviour of NiTi shape memory alloy scaffolds produced by SLM, a unit cell design comparison. J. Mech. Behav. Biomed. Mater. 2017, 70, 53–59. [Google Scholar] [CrossRef]

- Biffi, C.A.; Bassani, P.; Fiocchi, J.; Tuissi, A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals 2020, 10, 814. [Google Scholar] [CrossRef]

- Zhao, M.; Qing, H.; Wang, Y.; Liang, J.; Zhao, M.; Geng, Y.; Liang, J.; Lu, B. Superelastic behaviors of additively manufactured porous NiTi shape memory alloys designed with Menger sponge-like fractal structures. Mater. Des. 2021, 200, 109448. [Google Scholar] [CrossRef]

- Ashrafi, M.J.; Amerinatanzi, A.; Saebi, Z.; Shayesteh Moghaddam, N.; Mehrabi, R.; Karaca, H.; Elahinia, M. Shape memory response of cellular lattice structures: Unit cell finite element prediction. Mech. Mater. 2018, 125, 26–34. [Google Scholar] [CrossRef]

- Saedi, S.; Saghaian, S.E.; Jahadakbar, A.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Saghaian, S.M.; Lu, Y.C.; Elahinia, M.; Karaca, H.E. Shape memory response of porous NiTi shape memory alloys fabricated by selective laser melting. J. Mater. Sci. Mater. Med. 2018, 29, 40. [Google Scholar] [CrossRef]

- He, X.; Tong, Z.; Du, H.; Wang, D.; Wang, L.; Melnik, R. Modeling microstructure evolution in shape memory alloy rods via Legendre wavelets collocation method. J. Mater. Sci. 2019, 54, 14400–14413. [Google Scholar] [CrossRef]

- Tsouknidas, A.; Michailidis, N.; Maliaris, G.; Makkar, J.; Baxevanis, T.; Lagoudas, D. A numerical study of “functional fatigue” of closed-cell NiTi shape memory foams. Mech. Mater. 2019, 131, 11–21. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, Y.; Wang, S.; Wang, S.; Wang, Z.; Yu, Z.; Zhang, Z.; Ren, L. Compression Behavior and Failure Mechanisms of Bionic Porous NiTi Structures Built via Selective Laser Melting. In Acta Metallurgica Sinica (English Letters); Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Nargatti, K.; Ahankari, S. Advances in enhancing structural and functional fatigue resistance of superelastic NiTi shape memory alloy: A Review. J. Intell. Mater. Syst. Struct. 2021, 33, 503–531. [Google Scholar] [CrossRef]

- Parvizi, S.; Hashemi, S.M.; Asgarinia, F.; Nematollahi, M.; Elahinia, M. Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review. Prog. Mater. Sci. 2021, 117, 100739. [Google Scholar] [CrossRef]

- Sgambitterra, E.; Magarò, P.; Niccoli, F.; Renzo, D.; Maletta, C. Novel insight into the strain-life fatigue properties of pseudoelastic NiTi shape memory alloys. Smart Mater. Struct. 2019, 28, ab3df1. [Google Scholar] [CrossRef]

- Aihara, H.; Zider, J.; Fanton, G.; Duerig, T. Combustion Synthesis Porous Nitinol for Biomedical Applications. Int. J. Biomater. 2019, 2019, 4307461. [Google Scholar] [CrossRef]

- Li, Y.-H.; Li, J.-H. NiTi/PMMA Biocomposite: In Situ Polymerization, Microstructure and Mechanical Property. Trans. Indian Inst. Met. 2022, 76, 945–950. [Google Scholar] [CrossRef]

- Panton, B.; Michael, A.; Zhou, Y.N.; Khan, M.I. Effects of post-processing on the thermomechanical fatigue properties of laser modified NiTi. Int. J. Fatigue 2019, 118, 307–315. [Google Scholar] [CrossRef]

- Zhao, C.; Liang, H.; Luo, S.; Yang, J.; Wang, Z. The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting. J. Alloy. Compd. 2020, 817, 153288. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, Z.; Li, Y.; Cong, W. Excellent damping properties and their correlations with the microstructures in the NiTi alloys fabricated by laser-directed energy deposition. J. Manuf. Process. 2022, 84, 965–976. [Google Scholar] [CrossRef]

- Lv, Y.; Liu, G.; Wang, B.; Tang, Y.; Lin, Z.; Liu, J.; Wei, G.; Wang, L. Pore Strategy Design of a Novel NiTi-Nb Biomedical Porous Scaffold Based on a Triply Periodic Minimal Surface. Front. Bioeng. Biotechnol. 2022, 10, 910475. [Google Scholar] [CrossRef]

- Marchenko, E.; Baigonakova, G.; Shishelova, A. Influence of the Gas Reaction Atmosphere on the Structure, Phase Composition, Functional Properties and Cytocompatibility of Porous Titanium–Nickel Alloys. Metals 2022, 12, 2170. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Yazdani-Rad, R.; Kazemzadeh, A.; Alizadeh, M. A Comparative Study on the Mechanical Behavior of Porous Titanium and NiTi Produced by a Space Holder Technique. J. Mater. Eng. Perform. 2013, 23, 799–808. [Google Scholar] [CrossRef]

- Xu, J.L.; Bao, L.Z.; Liu, A.H.; Jin, X.F.; Luo, J.M.; Zhong, Z.C.; Zheng, Y.F. Effect of pore sizes on the microstructure and properties of the biomedical porous NiTi alloys prepared by microwave sintering. J. Alloy. Compd. 2015, 645, 137–142. [Google Scholar] [CrossRef]

- Allegretti, D.; Berti, F.; Migliavacca, F.; Pennati, G.; Petrini, L. Fatigue Assessment of Nickel–Titanium Peripheral Stents: Comparison of Multi-Axial Fatigue Models. Shape Mem. Superelast. 2018, 4, 186–196. [Google Scholar] [CrossRef]

- Wang, Z.; He, Z.; Duan, B.; Liu, X.; Wang, D. Influence of Solid Loading on the Gel-Casting of Porous NiTi Alloys. Materials 2022, 15, 8398. [Google Scholar] [CrossRef]

- Bayati, P.; Safaei, K.; Nematollahi, M.; Jahadakbar, A.; Yadollahi, A.; Mahtabi, M.; Elahinia, M. Toward understanding the effect of remelting on the additively manufactured NiTi. Int. J. Adv. Manuf. Technol. 2020, 112, 347–360. [Google Scholar] [CrossRef]

- Wan, X.; Feng, Y.; Lin, X.; Tan, H. Large superelastic recovery and elastocaloric effect in as-deposited additive manufactured Ni50.8Ti49.2 alloy. Appl. Phys. Lett. 2019, 114, 221903. [Google Scholar] [CrossRef]

- Tan, C.; Zou, J.; Li, S.; Jamshidi, P.; Abena, A.; Forsey, A.; Moat, R.J.; Essa, K.; Wang, M.; Zhou, K.; et al. Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures. Int. J. Mach. Tools Manuf. 2021, 167, 103764. [Google Scholar] [CrossRef]

- de Wild, M.; Schollbach, T.; Schumacher, R.; Schkommodau, E.; Bormann, T. Effects of laser parameters and scanning strategy on structural and mechanical properties of 3D NiTi implants fabricated with selective laser melting. Biomed. Eng. Biomed. Tech. 2013, 58 (Suppl. S1), 000010151520134088. [Google Scholar] [CrossRef]

- Khanlari, K.; Shi, Q.; Li, K.; Hu, K.; Cao, P.; Liu, X. Effects of printing volumetric energy densities and post-processing treatments on the microstructural properties, phase transformation temperatures and hardness of near-equiatomic NiTinol parts fabricated by a laser powder bed fusion technique. Intermetallics 2021, 131, 107088. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Liu, Z.; Zhao, J.; Zhang, H. Microstructure and mechanical properties of NiTi nanoporous structures fabricated with dealloying process. J. Alloy. Compd. 2023, 933, 167804. [Google Scholar] [CrossRef]

- Zhao, M.; Shao, Y.; Zheng, W.; Luo, Y.; Qiao, J.; Wu, S.; Yan, Y.; Guo, W. Tailoring the damping and mechanical properties of porous NiTi by a phase leaching process. J. Alloy. Compd. 2021, 855, 157471. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.; Xie, H.; Qu, J.; Chen, X.; Chen, F.; Song, Q.; Yin, H. Engineering the porosity and superelastic behaviors of NiTi alloys prepared by an electro-assisted powder metallurgical route in molten salts. J. Alloy. Compd. 2019, 794, 455–464. [Google Scholar] [CrossRef]

- Khanlari, K.; Ramezani, M.; Kelly, P.; Cao, P.; Neitzert, T. Mechanical and microstructural characteristics of as-sintered and solutionized porous 60NiTi. Intermetallics 2018, 100, 32–43. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Z.; Liu, X.; Wang, W.; Wang, L. Effect of sintering temperature on the microstructure and mechanical properties of Ti50Ni50 and Ti47Ni47Al6 intermetallic alloys. J. Alloy. Compd. 2013, 578, 373–379. [Google Scholar] [CrossRef]

- Monogenov, A.N.; Marchenko, E.S.; Baigonakova, G.A.; Yasenchuk, Y.F.; Garin, A.S.; Volinsky, A.A. Improved mechanical properties of porous nitinol by aluminum alloying. J. Alloy. Compd. 2022, 918, 165617. [Google Scholar] [CrossRef]

- Kaftaranova, M.; Hodorenko, V.; Anikeev, S.; Artyukhova, N.; Shabalina, A.V.; Gunther, V. Investigation of the Effect of Copper Addition on Physical and Mechanical Properties of TiNi-Cu Porous Alloy. Metals 2022, 12, 1696. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.; Tiwari, A.K.; Sharma, A.K. Enhancement of Physical and Mechanical Characteristics of NiTi Composite Containing Ag and TiC. J. Mater. Eng. Perform. 2021, 31, 2934–2945. [Google Scholar] [CrossRef]

- Anikeev, S.G.; Artyukhova, N.V.; Shabalina, A.V.; Kulinich, S.A.; Hodorenko, V.N.; Kaftaranova, M.I.; Promakhov, V.V.; Gunter, V.E. Preparation of porous TiNi-Ti alloy by diffusion sintering method and study of its composition, structure and martensitic transformations. J. Alloy. Compd. 2022, 900, 163559. [Google Scholar] [CrossRef]

- Abidi, I.H.; Khalid, F.A.; Farooq, M.U.; Hussain, M.A.; Maqbool, A. Tailoring the pore morphology of porous nitinol with suitable mechanical properties for biomedical applications. Mater. Lett. 2015, 154, 17–20. [Google Scholar] [CrossRef]

- Mehrabi, R.; Kadkhodaei, M. 3D phenomenological constitutive modeling of shape memory alloys based on microplane theory. Smart Mater. Struct. 2013, 22, 025017. [Google Scholar] [CrossRef]

- Shariat, B.S.; Bakhtiari, S.; Yang, H.; Liu, Y. Controlled initiation and propagation of stress-induced martensitic transformation in functionally graded NiTi. J. Alloy. Compd. 2021, 851, 156103. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Q.; Huang, S.; Kruzic, J.J.; Li, X. Compression Behavior of Graded NiTi Gyroid-Structures Fabricated by Laser Powder Bed Fusion Additive Manufacturing Under Monotonic and Cyclic Loading. Jom 2021, 73, 4154–4165. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Haberland, C.; Walker, J.M.; Karamooz, M.; Sadi Turabi, A.; Saedi, S.; Rahmanian, R.; Karaca, H.; Dean, D.; Kadkhodaei, M.; et al. Achieving biocompatible stiffness in NiTi through additive manufacturing. J. Intell. Mater. Syst. Struct. 2016, 27, 2661–2671. [Google Scholar] [CrossRef]

- Liu, B.; Pan, Y. Effect of Pore Shape on Mechanical Properties of Porous Shape Memory Alloy. Micromachines 2022, 13, 566. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Mokshin, A.V. Mechanical response of mesoporous amorphous NiTi alloy to external deformations. Int. J. Solids Struct. 2021, 224, 111047. [Google Scholar] [CrossRef]

- Zhu, P.; Stebner, A.P.; Catherine Brinson, L. Plastic and transformation interactions of pores in shape memory alloy plates. Smart Mater. Struct. 2014, 23, 104008. [Google Scholar] [CrossRef]

- Ravari, M.R.K.; Esfahani, S.N.; Andani, M.T.; Kadkhodaei, M.; Ghaei, A.; Karaca, H.; Elahinia, M. On the effects of geometry, defects, and material asymmetry on the mechanical response of shape memory alloy cellular lattice structures. Smart Mater. Struct. 2016, 25, 025008. [Google Scholar] [CrossRef]

- Machado, G.; Louche, H.; Alonso, T.; Favier, D. Superelastic cellular NiTi tube-based materials: Fabrication, experiments and modeling. Mater. Des. 2015, 65, 212–220. [Google Scholar] [CrossRef]

- Burr, A.; Persenot, T.; Doutre, P.-T.; Buffiere, J.-Y.; Lhuissier, P.; Martin, G.; Dendievel, R. A numerical framework to predict the fatigue life of lattice structures built by additive manufacturing. Int. J. Fatigue 2020, 139, 105769. [Google Scholar] [CrossRef]

- Lu, X.; Wang, C.; Li, G.; Liu, Y.; Zhu, X.; Tu, S. The Mechanical Behavior and Martensitic Transformation of Porous NiTi Alloys Based on Geometrical Reconstruction. Int. J. Appl. Mech. 2017, 9, 1750038. [Google Scholar] [CrossRef]

- Bagheri, A.; Yadollahi, A.; Mahtabi, M.J.; Paudel, Y.; Vance, E.; Shamsaei, N.; Horstemeyer, M.F. Microstructure-Based MultiStage Fatigue Modeling of NiTi Alloy Fabricated via Direct Energy Deposition (DED). J. Mater. Eng. Perform. 2022, 31, 4761–4775. [Google Scholar] [CrossRef]

- Resnina, N.; Belayev, S.; Voronkov, A. Influence of chemical composition and pre-heating temperature on the structure and martensitic transformation in porous TiNi-based shape memory alloys, produced by self-propagating high-temperature synthesis. Intermetallics 2013, 32, 81–89. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Natali, S. Fatigue microstructural evolution in pseudo elastic NiTi alloy. Procedia Struct. Integr. 2016, 2, 1457–1464. [Google Scholar] [CrossRef]

- Eskil, M. The effect of aging temperature on transformation parameters of porous NiTi shape memory alloy fabricated by SHS. Russ. J. Non-Ferr. Met. 2013, 54, 104–111. [Google Scholar] [CrossRef]

- Shariat, B.S.; Liu, Y.; Rio, G. Pseudoelastic behaviour of perforated NiTi shape memory plates under tension. Intermetallics 2014, 50, 59–64. [Google Scholar] [CrossRef]

- Xu, J.L.; Bao, L.Z.; Liu, A.H.; Jin, X.J.; Tong, Y.X.; Luo, J.M.; Zhong, Z.C.; Zheng, Y.F. Microstructure, mechanical properties and superelasticity of biomedical porous NiTi alloy prepared by microwave sintering. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 46, 387–393. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Superelastic behaviors of biomedical porous NiTi alloy with high porosity and large pore size prepared by spark plasma sintering. J. Alloy. Compd. 2015, 644, 513–522. [Google Scholar] [CrossRef]

- Zhang, L.; He, Z.Y.; Tan, J.; Zhang, Y.Q.; Stoica, M.; Prashanth, K.G.; Cordill, M.J.; Jiang, Y.H.; Zhou, R.; Eckert, J. Rapid fabrication of function-structure-integrated NiTi alloys: Towards a combination of excellent superelasticity and favorable bioactivity. Intermetallics 2017, 82, 1–13. [Google Scholar] [CrossRef]

- Sergey, A.; Valentina, H.; Timofey, C.; Nadezhda, A.; Victor, G.; Anatoliy, P.; Ji-hoon, K.; Ji-soon, K. Evaluation of reversible shape memory effect in porous SHS TiNi-based compounds fabricated at various ignition temperature. Mater. Res. Express 2018, 6, aaf0d4. [Google Scholar] [CrossRef]

- İpek Nakaş, G.; Dericioğlu, A.F.; Bor, Ş. Monotonic and cyclic compressive behavior of superelastic TiNi foams processed by sintering using magnesium space holder technique. Mater. Sci. Eng. A 2013, 582, 140–146. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Saedi, S.; Turabi, A.S.; Karamooz, M.R.; Haberland, C.; Karaca, H.E.; Elahinia, M. Mechanical and shape memory properties of porous Ni 50.1 Ti 49.9 alloys manufactured by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 68, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Abdollahzadeh, M.; Hoseini, S.H.; Faroughi, S. Modeling of superelastic behavior of porous shape memory alloys. Int. J. Mech. Mater. Des. 2019, 16, 109–121. [Google Scholar] [CrossRef]

- Gur, S.; Frantziskonis, G.N.; Muralidharan, K. Atomistic simulation of shape memory effect (SME) and superelasticity (SE) in nano-porous NiTi shape memory alloy (SMA). Comput. Mater. Sci. 2018, 152, 28–37. [Google Scholar] [CrossRef]

- Jahadakbar, A.; Nematollahi, M.; Safaei, K.; Bayati, P.; Giri, G.; Dabbaghi, H.; Dean, D.; Elahinia, M. Design, Modeling, Additive Manufacturing, and Polishing of Stiffness-Modulated Porous Nitinol Bone Fixation Plates Followed by Thermomechanical and Composition Analysis. Metals 2020, 10, 151. [Google Scholar] [CrossRef]

- Ravari, M.R.K.; Kadkhodaei, M.; Ghaei, A. A microplane constitutive model for shape memory alloys considering tension–compression asymmetry. Smart Mater. Struct. 2015, 24, 075016. [Google Scholar] [CrossRef]

- Karamooz-Ravari, M.R.; Taheri Andani, M.; Kadkhodaei, M.; Saedi, S.; Karaca, H.; Elahinia, M. Modeling the cyclic shape memory and superelasticity of selective laser melting fabricated NiTi. Int. J. Mech. Sci. 2018, 138–139, 54–61. [Google Scholar] [CrossRef]

- Zhu, X.; Chu, L.; Dui, G. Constitutive Modeling of Porous Shape Memory Alloys Using Gurson–Tvergaard–Needleman Model Under Isothermal Conditions. Int. J. Appl. Mech. 2020, 12, 2050038. [Google Scholar] [CrossRef]

- Yu, Z.; Xin, R.; Xu, Z.; Sha, L.; Chen, L.; Zhu, Y.; Liang, P.; Zhang, Z.; Liu, Z.; Cao, Q. Shock-Resistant and Energy-Absorbing Properties of Bionic NiTi Lattice Structure Manufactured by SLM. J. Bionic Eng. 2022, 19, 1684–1698. [Google Scholar] [CrossRef]

- Ma, C.; Gu, D.; Dai, D.; Yang, J.; Zhang, H.; Guo, M.; Wang, R.; Gao, J.; Chen, W.; Song, Y. Tailored pore canal characteristics and compressive deformation behavior of bionic porous NiTi shape memory alloy prepared by selective laser melting. Smart Mater. Struct. 2020, 29, ab9399. [Google Scholar] [CrossRef]

- Schryvers, N.; Volkov, A.E.; Evard, M.E.; Iaparova, E.N.; Van Humbeeck, J. Modeling of Functional Properties of Porous Shape Memory Alloy. MATEC Web Conf. 2015, 33, 02006. [Google Scholar] [CrossRef]

- Shariat, B.S.; Liu, Y.; Rio, G. Numerical modelling of pseudoelastic behaviour of NiTi porous plates. J. Intell. Mater. Syst. Struct. 2013, 25, 1445–1455. [Google Scholar] [CrossRef]

- Shariat, B.S.; Liu, Y.; Rio, G. Finite element computational modelling and experimental investigation of perforated NiTi plates under tension. Mater. Res. Bull. 2013, 48, 5099–5104. [Google Scholar] [CrossRef]

- Maîtrejean, G.; Terriault, P.; Brailovski, V. Density dependence of the superelastic behavior of porous shape memory alloys: Representative Volume Element and scaling relation approaches. Comput. Mater. Sci. 2013, 77, 93–101. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, B.; Wei, J.; Yang, Y.; Zhang, X.; Deng, J. Design of Porous Shape Memory Alloys with Small Mechanical Hysteresis. Crystals 2022, 13, 34. [Google Scholar] [CrossRef]

- Ibrahim, H.; Jahadakbar, A.; Dehghan, A.; Moghaddam, N.; Amerinatanzi, A.; Elahinia, M. In Vitro Corrosion Assessment of Additively Manufactured Porous NiTi Structures for Bone Fixation Applications. Metals 2018, 8, 164. [Google Scholar] [CrossRef]

- Zhou, D.; Gao, Y.; Lai, M.; Li, H.; Yuan, B.; Zhu, M. Fabrication of NiTi Shape Memory Alloys with Graded Porosity to Imitate Human Long-bone Structure. J. Bionic Eng. 2015, 12, 575–582. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, F.; Liu, B.; Deng, J. Design of Menger sponge fractal structural NiTi as bone implants. Model. Simul. Mater. Sci. Eng. 2021, 29, ac2b03. [Google Scholar] [CrossRef]

- Lu, H.Z.; Ma, H.W.; Luo, X.; Wang, Y.; Wang, J.; Lupoi, R.; Yin, S.; Yang, C. Microstructure, shape memory properties, and in vitro biocompatibility of porous NiTi scaffolds fabricated via selective laser melting. J. Mater. Res. Technol. 2021, 15, 6797–6812. [Google Scholar] [CrossRef]

- Jian, Y.T.; Yang, Y.; Tian, T.; Stanford, C.; Zhang, X.P.; Zhao, K. Effect of Pore Size and Porosity on the Biomechanical Properties and Cytocompatibility of Porous NiTi Alloys. PLoS ONE 2015, 10, e0128138. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Yeung, K.W.; Chan, Y.L.; Hu, T.; Xu, Z.; Liu, X.; Chung, J.C.; Cheung, K.M.; Chu, P.K. Relationship between osseointegration and superelastic biomechanics in porous NiTi scaffolds. Biomaterials 2011, 32, 330–338. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Raj, T.; Kumar, K. Physical and tribological characteristics of porous NiTi SMA fabricated by powder metallurgy. Part. Sci. Technol. 2016, 35, 541–546. [Google Scholar] [CrossRef]

- Zhang, X.X.; Hou, H.W.; Wei, L.S.; Chen, Z.X.; Wei, W.T.; Geng, L. High damping capacity in porous NiTi alloy with bimodal pore architecture. J. Alloy. Compd. 2013, 550, 297–301. [Google Scholar] [CrossRef]

- Kakaei, K.; Akbarpour, M.R.; Liyaghi, Z. Synthesis of partially oxidized NiTi nanostructure by high energy ball milling and its application to supercapacitor. J. Mater. Sci. Mater. Electron. 2017, 29, 2222–2227. [Google Scholar] [CrossRef]

- Bewerse, C.; Emery, A.A.; Brinson, L.C.; Dunand, D.C. NiTi porous structure with 3D interconnected microchannels using steel wire spaceholders. Mater. Sci. Eng. A 2015, 634, 153–160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, D.; Hu, Y.; Yang, L. New Insights into the Mechanical Properties, Functional Fatigue, and Structural Fatigue of Ni-Ti Alloy Porous Structures. Metals 2023, 13, 931. https://doi.org/10.3390/met13050931

Tang D, Hu Y, Yang L. New Insights into the Mechanical Properties, Functional Fatigue, and Structural Fatigue of Ni-Ti Alloy Porous Structures. Metals. 2023; 13(5):931. https://doi.org/10.3390/met13050931

Chicago/Turabian StyleTang, Dianyu, Yong Hu, and Lei Yang. 2023. "New Insights into the Mechanical Properties, Functional Fatigue, and Structural Fatigue of Ni-Ti Alloy Porous Structures" Metals 13, no. 5: 931. https://doi.org/10.3390/met13050931