Microstructure, Mechanical and Wear Properties of W-Si-C Composites Consolidated by Spark Plasma Sintering

Abstract

1. Introduction

2. Experimental Details

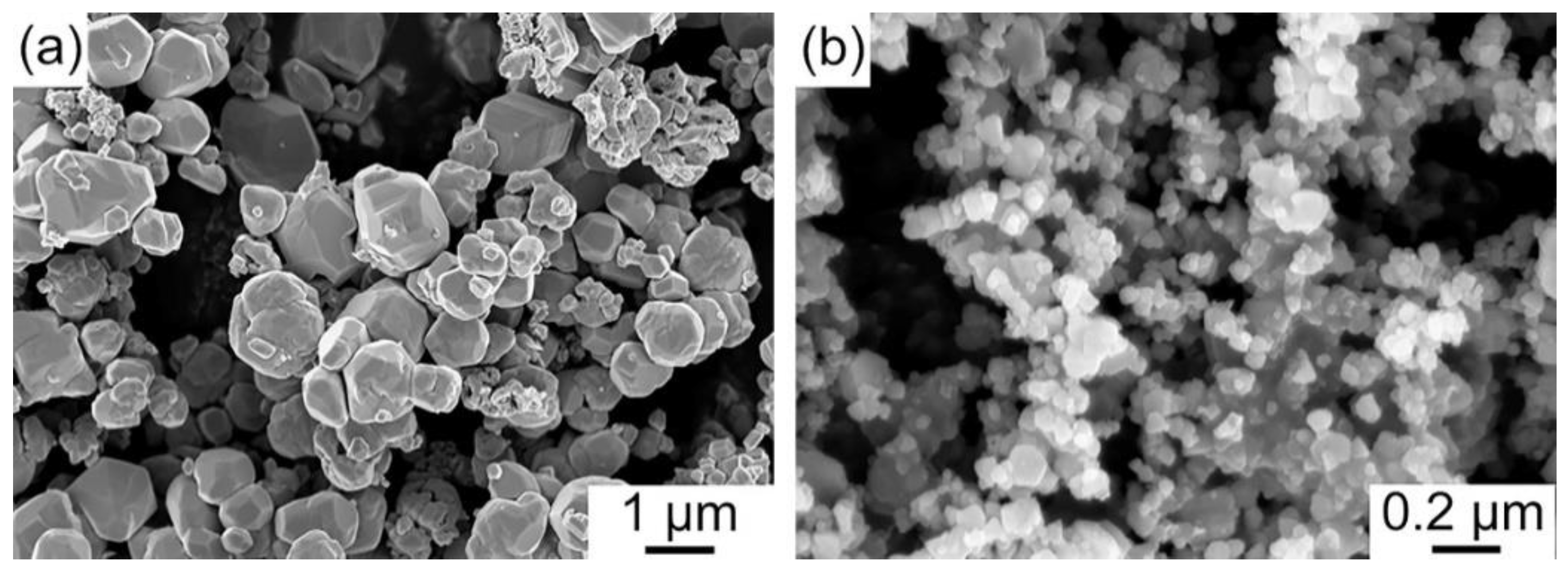

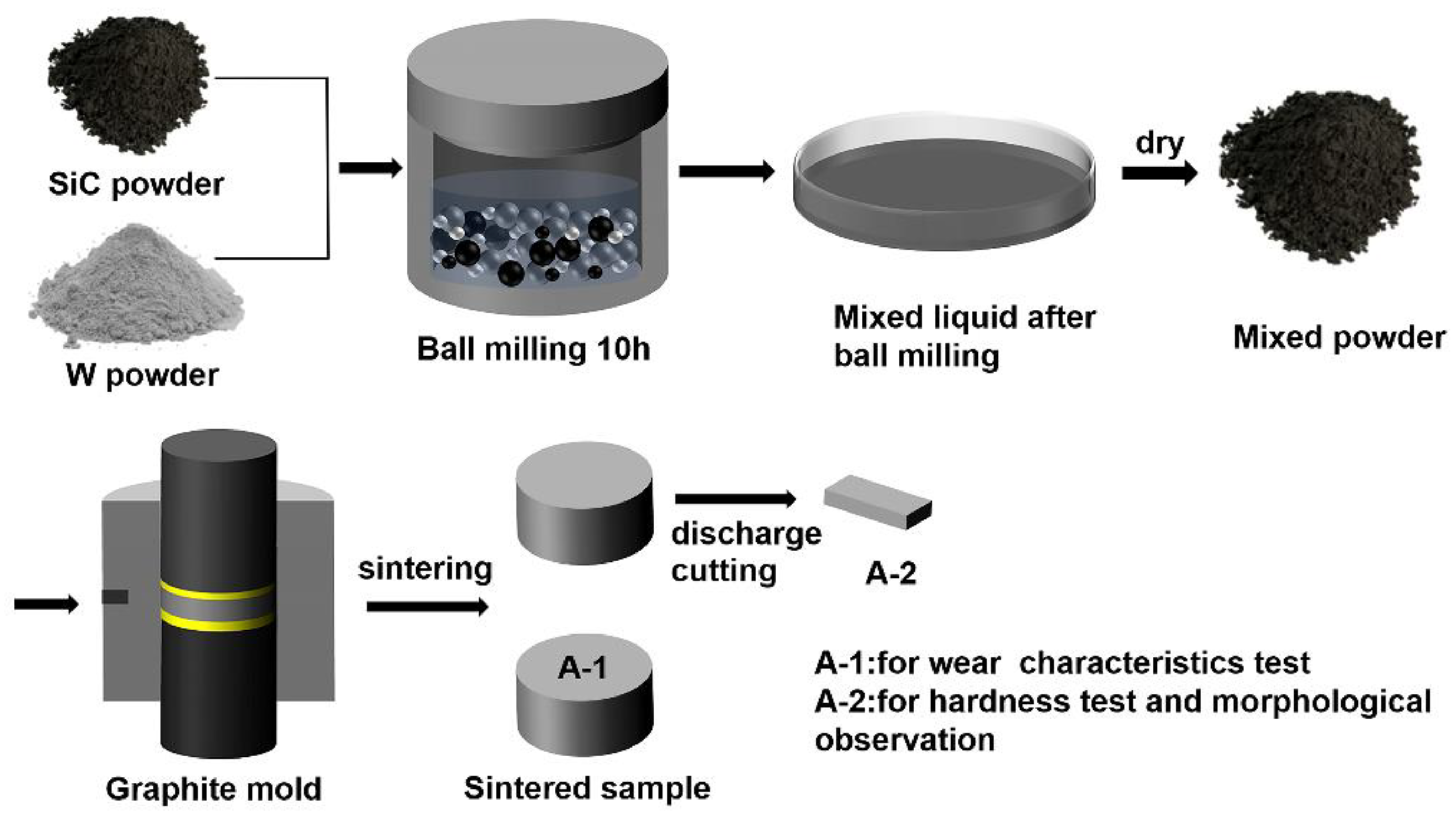

2.1. Powder and Consolidation

2.2. Microscopic and Phase Analysis

2.3. Density Measurements

2.4. Micro-Hardness Tests

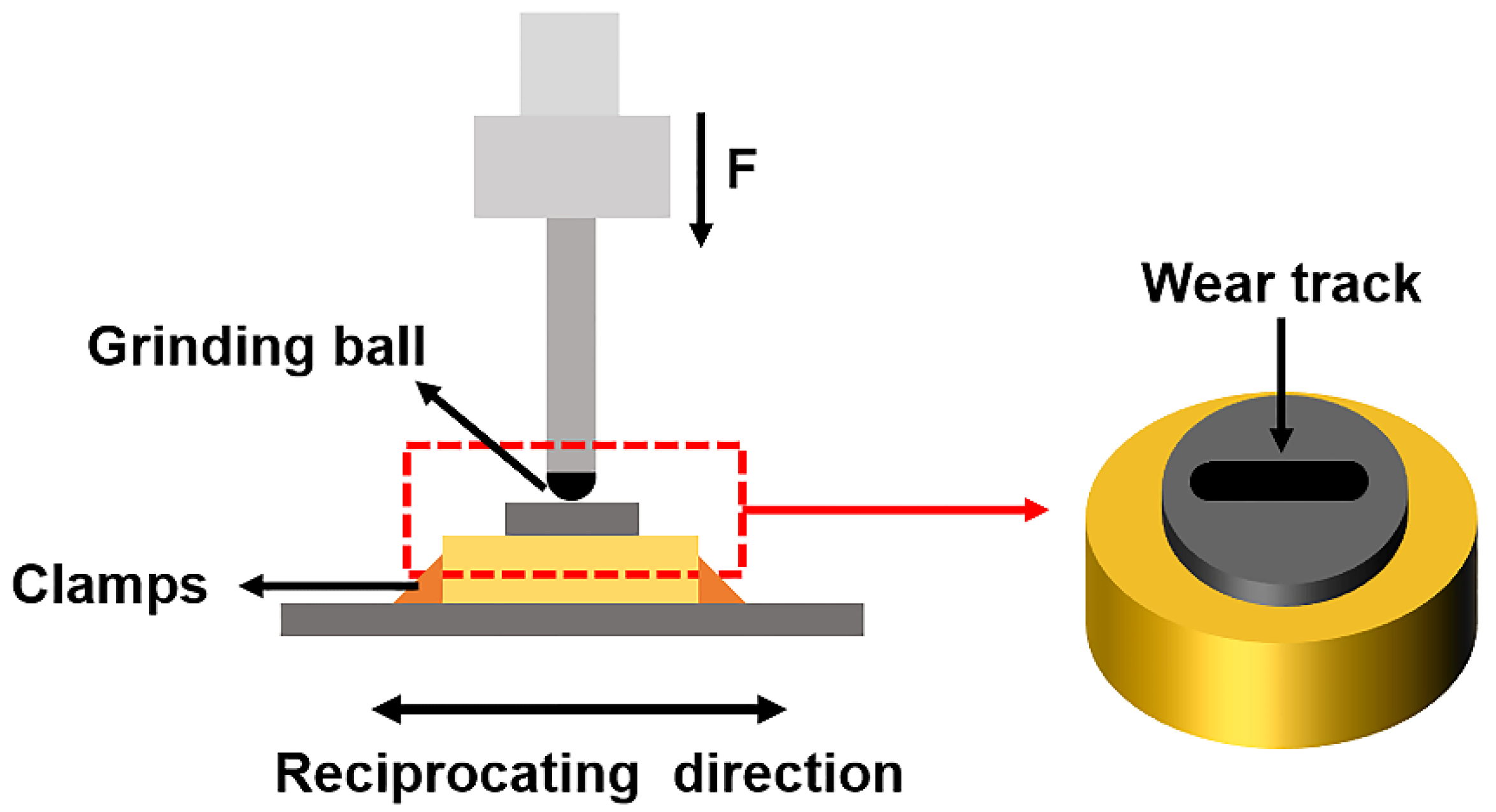

2.5. Wear Characteristics Tests

3. Results and Discussion

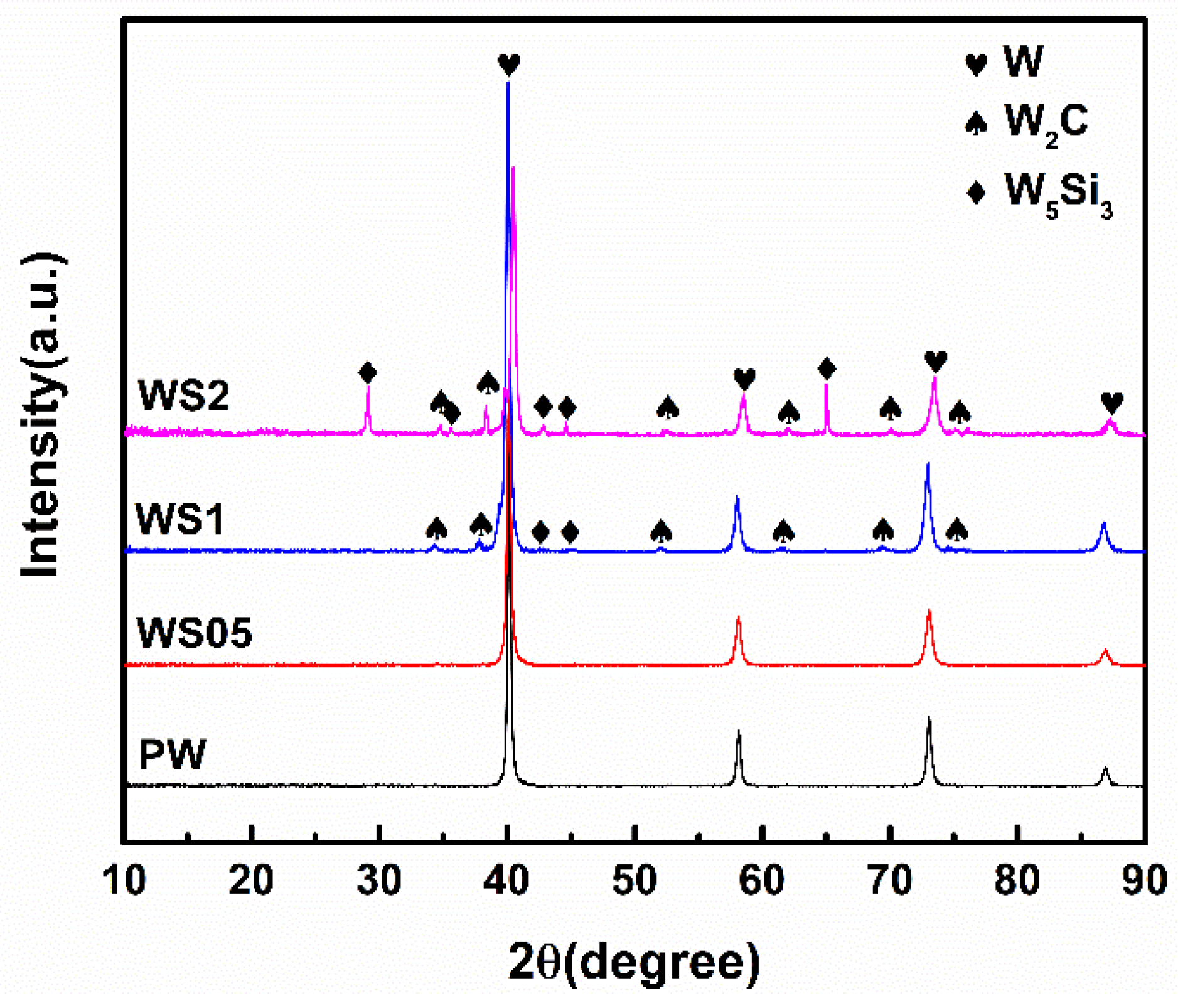

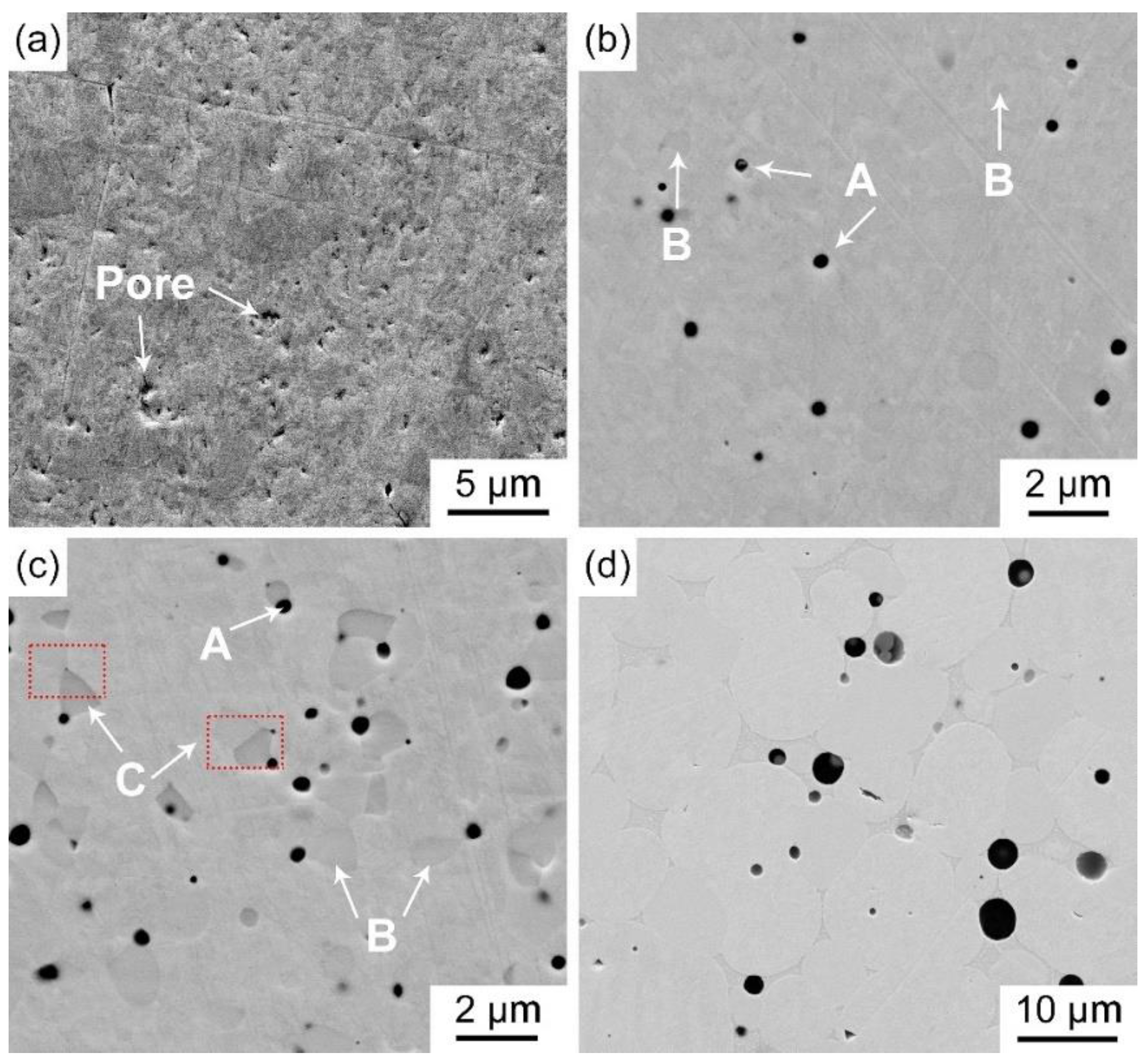

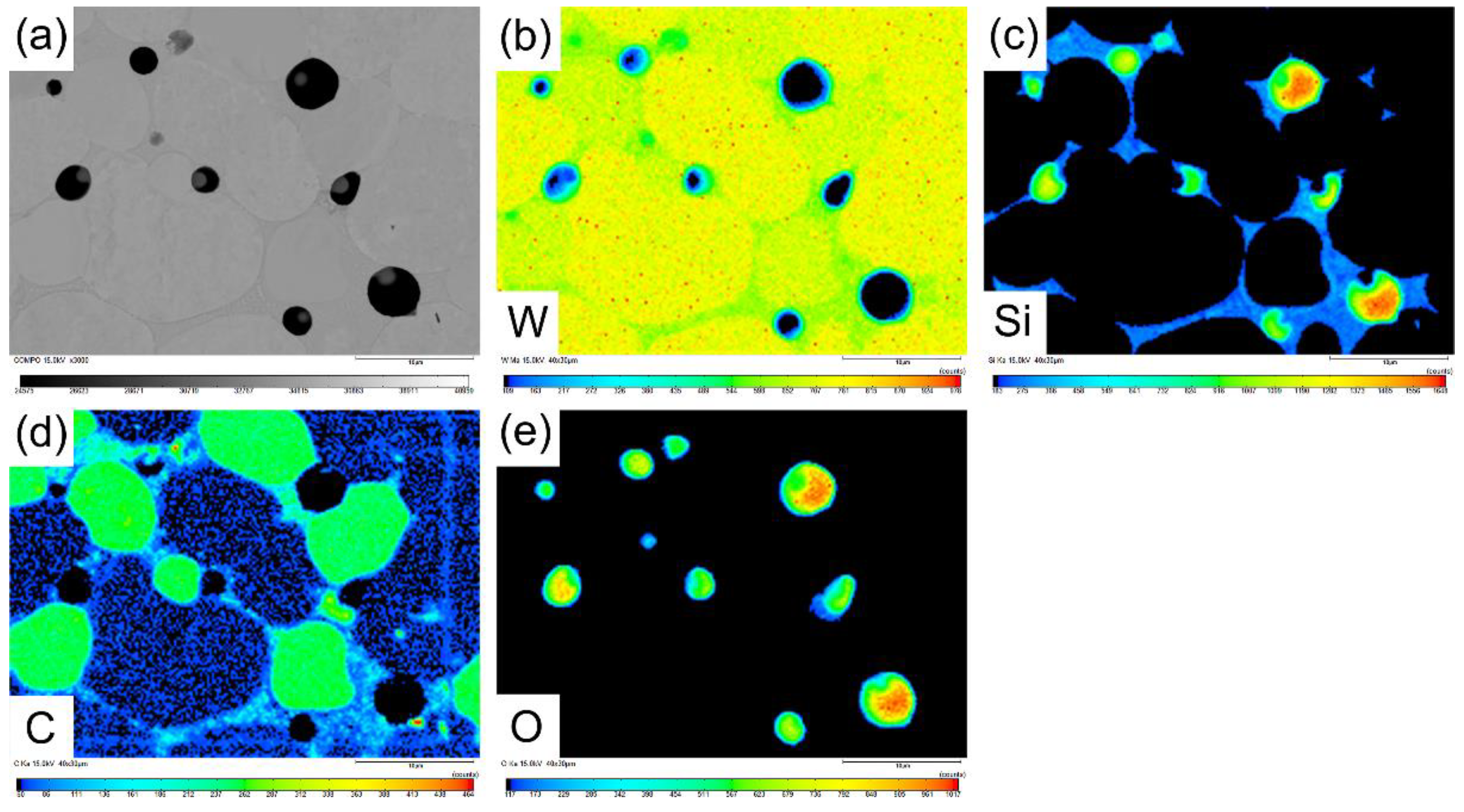

3.1. Microstructure and Phase Composition of W-Si-C Composites

3.2. Relative Density and Grain Size of W-Si-C Composites

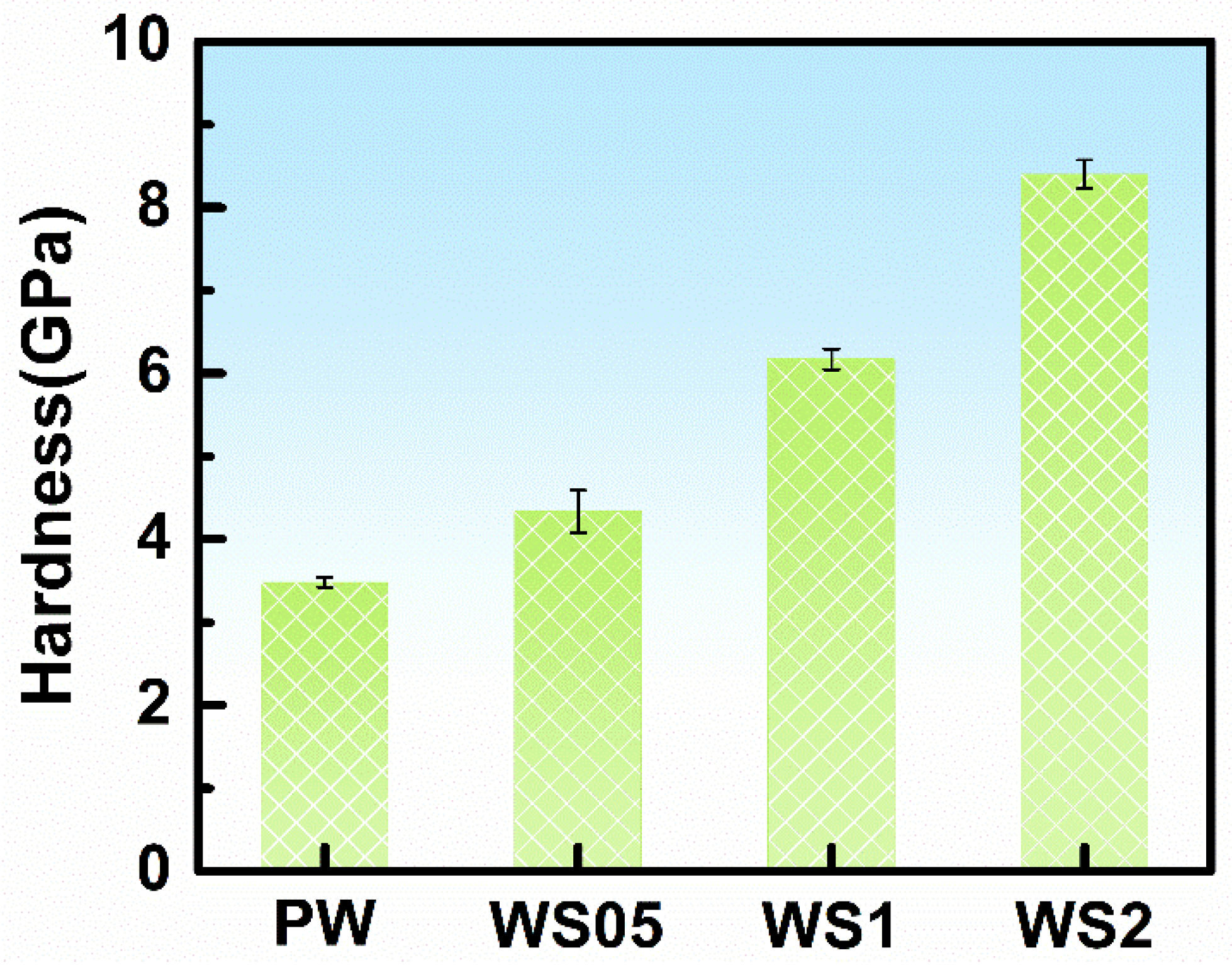

3.3. Mechanical Properties

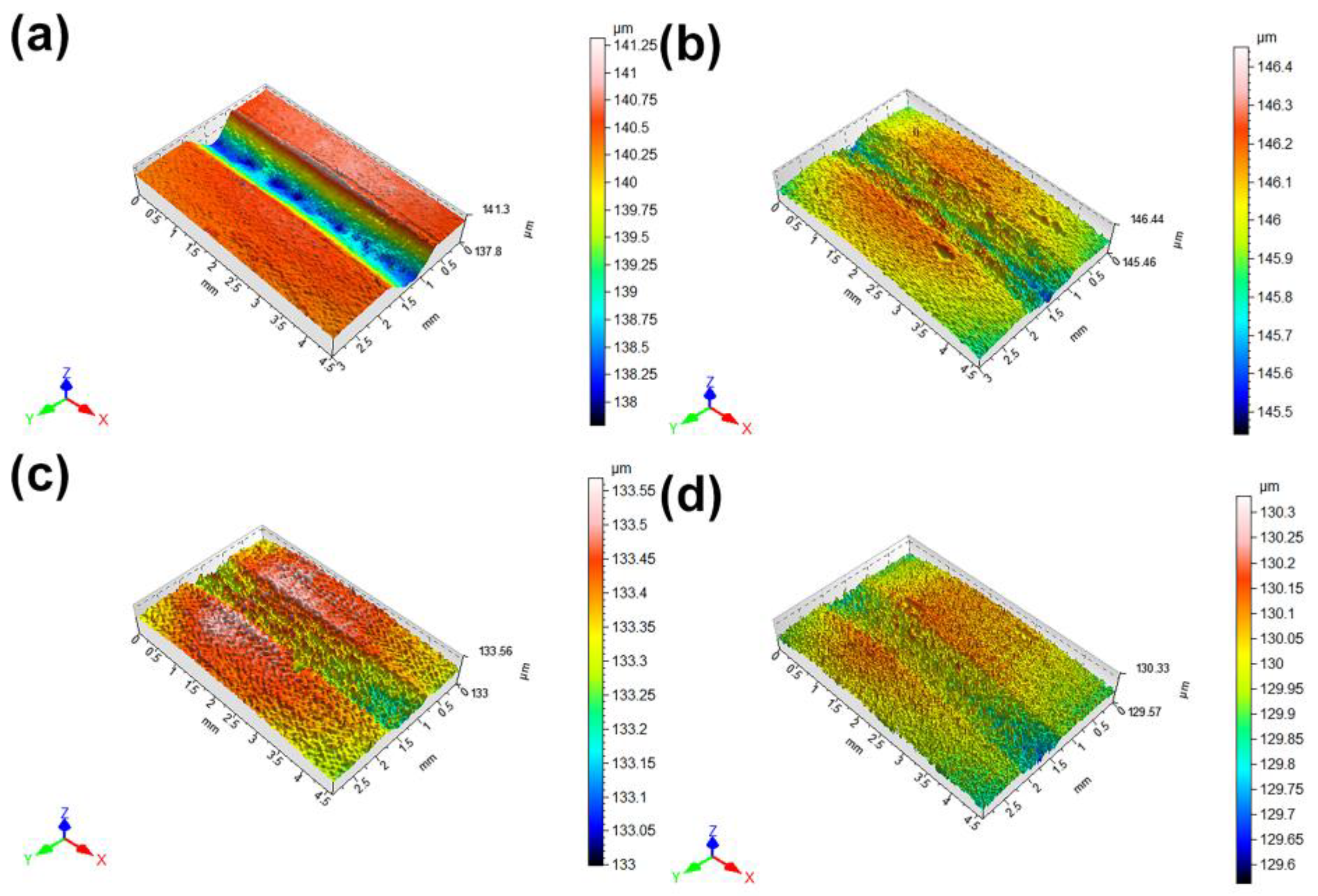

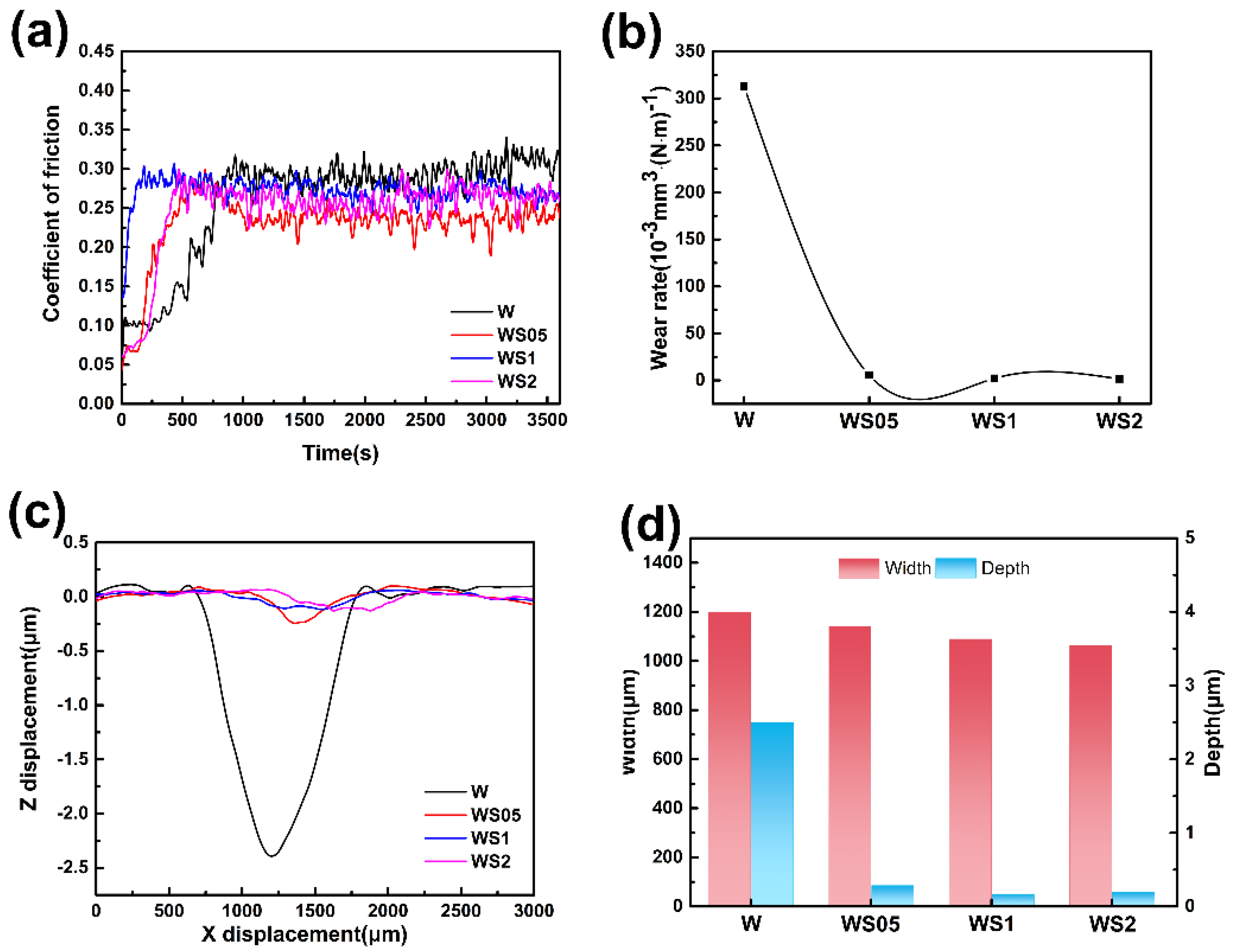

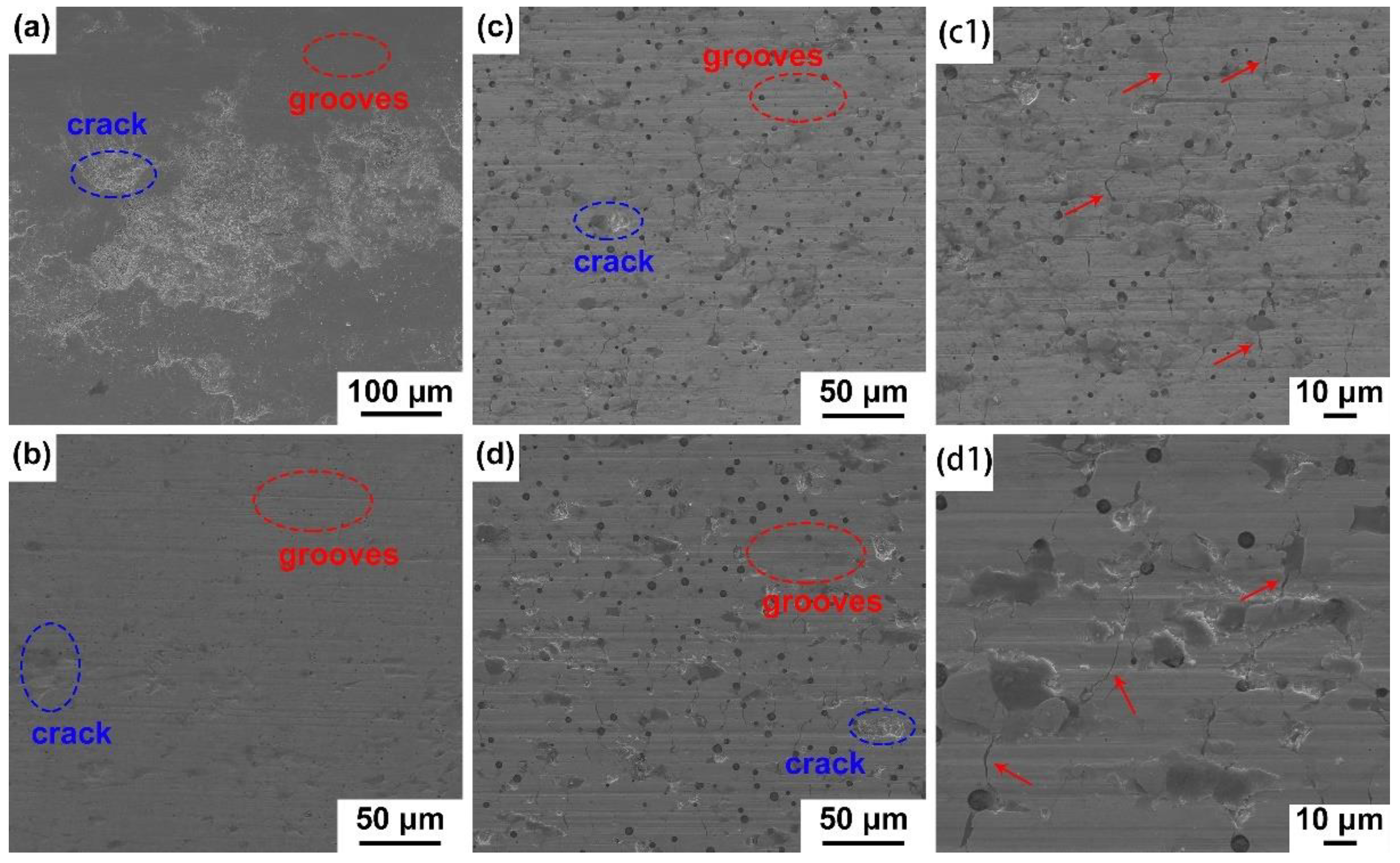

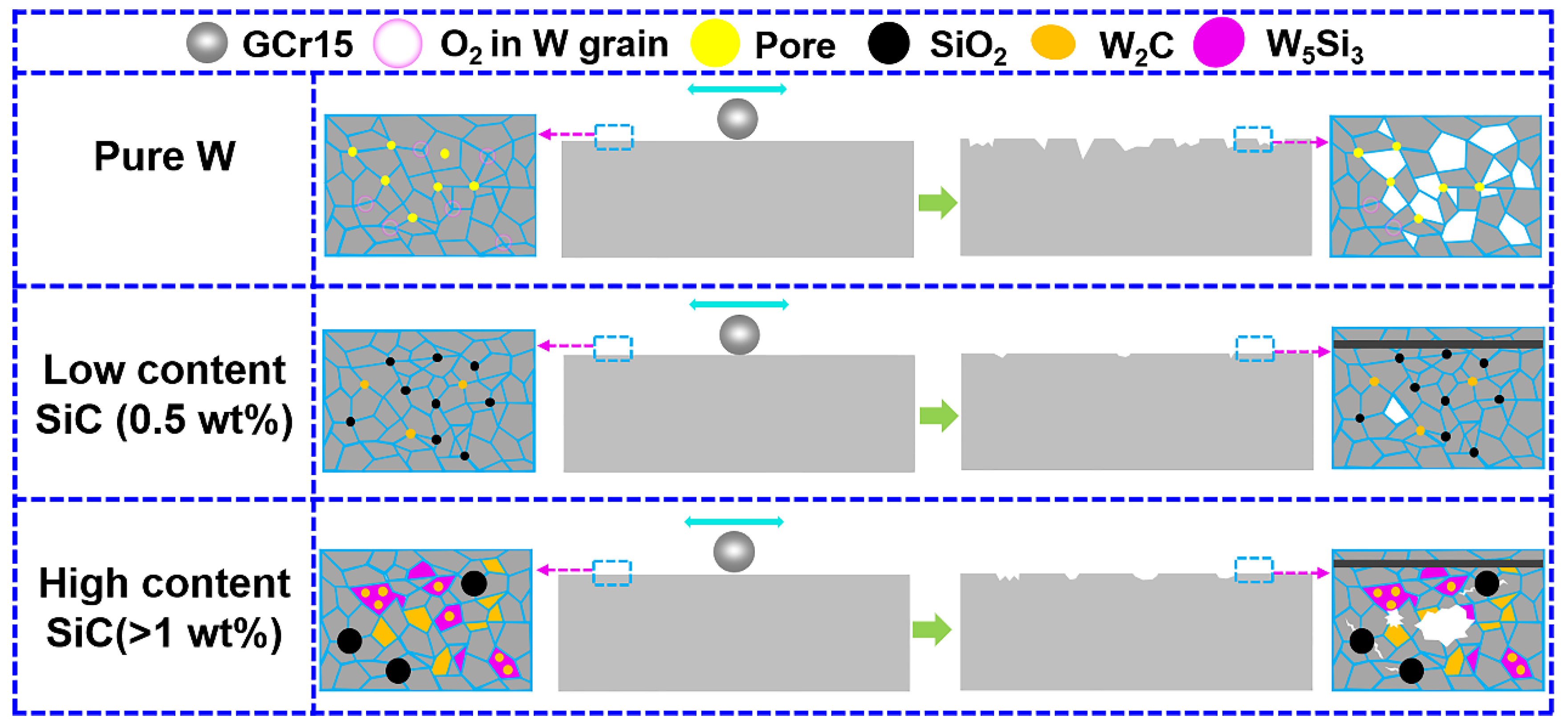

3.4. Wear Characteristics

4. Conclusions

- (1)

- The SiC reacted with the W matrix to produce in situ W2C and in situ W5Si3. SiO2 can also be formed when SiC reacts with free oxygen, improving grain boundary bonding. The content of in situ ceramic phases increased as SiC content increased. The grain size of SiO2 increases with the addition of SiC.

- (2)

- Reactive sintering promoted the densification process of W-Si-C composites. The relative density and micro-hardness of W-Si-C composites increased as SiC content increased, with maximum values of 98.12% and 8.40 GPa, respectively. The increase in hardness was due to the increase in the relative density and the reduction in grain size of W-Si-C composites, and the production of ceramic phases.

- (3)

- The wear resistance of W-Si-C composites was significantly improved with little SiC addition. Pure W and WS05 have wear rates of 313.27 × 10−3 mm3/N·m and 5.71 × 10−3 mm3/N·m, respectively. The improvement of the wear properties of W-Si-C composites was due to the increase in hardness, the purification and enhancement of grain boundaries and the generation of ceramic phases. The wear mechanisms of pure W and W-Si-C composites were attributed to abrasive wear and fatigue wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Du, Z.; Fan, J.; Lv, Y.; Lv, Y.; Ye, L.; Li, P. Microstructure and texture evolution in warm-rolled fine-grained tungsten. Int. J. Refract. Met. Hard Mater. 2021, 101, 105690. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, N.; Hu, W.; Kong, X.; Ma, Z.; Liu, Y. The effect of Y2O3 on the grain growth and densification of W matrix during low temperature sintering: Experiments and modelling. Mater. Des. 2019, 181, 108080. [Google Scholar] [CrossRef]

- Song, G.; Wang, Y.; Zhou, Y. Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles. J. Mater. Sci. 2001, 36, 4625–4631. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Livramento, V.; Nunes, D.; Correia, J.B.; Carvalho, P.A.; Mardolcar, U.; Mateus, R.; Hanada, K.; Shohoji, N.H.; Fernandes, H.; Silva, C.; et al. Tungsten–microdiamond composites for plasma facing components. J. Nucl. Mater. 2011, 416, 45–48. [Google Scholar] [CrossRef]

- Dickerson, M.B.; Wurm, P.J.; Schorr, J.R.; Hoffman, W.P.; Wapner, P.G.; Sandhage, K.H. Near net-shape, ultra-high melting, recession-resistant ZrC/W-based rocket nozzle liners via the displacive compensation of porosity (DCP) method. J. Mater. Sci. 2004, 39, 6005–6015. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- German, R.M.; Hens, K.F.; Johnson, J.L. Powder metallurgy processing of thermal management materials for microelectronic applications. Int. J. Powder Metall. 1994, 30, 205–215. [Google Scholar]

- Chen, Y.; Sun, S.; Zhang, T.; Zhou, X.; Li, S. Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater. Sci. Eng. A 2020, 771, 138545. [Google Scholar] [CrossRef]

- Chen, Y.; Mao, Y.; Lu, W.; He, P. Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt. Laser Technol. 2017, 91, 197–202. [Google Scholar]

- Zhu, Z.; Liu, Y.; Gou, G.; Gao, W.; Chen, J. Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci. Rep. 2021, 11, 10020. [Google Scholar] [CrossRef] [PubMed]

- Tayyebi, M.; Adhami, M.; Karimi, A.; Rahmatabadi, D.; Alizadeh, M.; Hashemi, R. Effects of strain accumulation and annealing on interfacial microstructure and grain structure (Mg and Al3Mg2 layers) of Al/Cu/Mg multilayered composite fabricated by ARB process. J. Mater. Res. Technol. 2021, 14, 392–406. [Google Scholar] [CrossRef]

- Dong, Z.; Ma, Z.; Dong, J.; Li, C.; Yu, L.; Liu, C.; Liu, Y. The simultaneous improvements of strength and ductility in W–Y2O3 alloy obtained via an alkaline hydrothermal method and subsequent low temperature sintering. Mater. Sci. Eng. A 2020, 784, 139329. [Google Scholar] [CrossRef]

- Kurishita, H.; Arakawa, H.; Matsuo, S.; Sakamoto, T.; Kobayashi, S.; Nakai, K.; Pintsuk, G.; Linke, J.; Tsurekawa, S.; Yardley, V.; et al. Development of nanostructured tungsten based materials resistant to recrystallization and/or radiation induced embrittlement. Mater. Trans. 2013, 54, 456–465. [Google Scholar] [CrossRef]

- Zhang, S.; Wen, Y.; Zhang, H. Low temperature preparation of tungsten nanoparticles from molten salt. Powder Technol. 2014, 253, 464–466. [Google Scholar] [CrossRef]

- Wurster, S.; Motz, C.; Romaner, L.; Ambrosch-Draxl, C.; Pippan, R. Dislocation-core symmetry and slip planes in tungsten alloys: Ab initio calculations and microcantilever bending experiments. Acta Mater. 2012, 60, 748–758. [Google Scholar]

- Gröger, R.; Bailey, A.; Vitek, V. Multiscale modeling of plastic deformation of molybdenum and tungsten: I. Atomistic studies of the core structure and glide of 1/2< 1 1 1> screw dislocations at 0 K. Acta Mater. 2008, 56, 5401–5411. [Google Scholar]

- Gludovatz, B.; Wurster, S.; Weingärtner, T.; Hoffmann, A.; Pippan, R. Influence of impurities on the fracture behaviour of tungsten. Philos. Mag. 2011, 91, 3006–3020. [Google Scholar] [CrossRef]

- Liu, K.; Gu, D.; Guo, M.; Sun, J. Effects of processing parameters on densification behavior, microstructure evolution and mechanical properties of W–Ti alloy fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2022, 829, 142177. [Google Scholar] [CrossRef]

- Cheng, X.; Jing, K.; Xie, Z.; Liu, R.; Wu, X.; Wang, X.; Fang, Q.; Liu, C. Microstructure and mechanical properties of in-situ formed ZrC nanoparticles dispersion-strengthened tungsten alloy. Int. J. Refract. Met. Hard Mater. 2022, 107, 105912. [Google Scholar] [CrossRef]

- Zhao, B.; Xie, Z.; Liu, R.; Wang, H.; Wang, M.; Zhang, L.; Gao, R.; Wu, X.; Hao, T.; Fang, Q.; et al. Fabrication of an ultrafine-grained W-ZrC-Re alloy with high thermal stability. Fusion Eng. Des. 2021, 164, 112208. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, S.; Zhu, J.; Kang, K.; Luo, G.; Wu, C.; Shen, Q.; Zhang, L. Microstructure and compression strength of W/HfC composites synthesized by plasma activated sintering. Met. Mater. Int. 2019, 25, 416–424. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.; Han, Y.; Cheng, H.; Ye, L.; Du, Z.; Li, Y. The effects of SiC addition on the sintering densification, phases, microstructure and mechanical properties of W. Int. J. Refract. Met. Hard Mater. 2021, 98, 105528. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Boride formation induced by pcBN tool wear in friction-stir-welded stainless steels. Metall. Mater. Trans. A 2009, 40, 625–636. [Google Scholar] [CrossRef]

- Wang, J.; Su, J.; Mishra, R.S.; Xu, R.; Baumann, J.A. Tool wear mechanisms in friction stir welding of Ti–6Al–4V alloy. Wear 2014, 321, 25–32. [Google Scholar] [CrossRef]

- Kang, K.; Zhang, L.; Luo, G.; Zhang, J.; Tu, R.; Wu, C.; Shen, Q. Microstructural evolution and mechanical behavior of W-Si-C multi-phase composite prepared by arc-melting. Mater. Sci. Eng. A 2018, 712, 28–36. [Google Scholar] [CrossRef]

- Lee, D.; Park, H.; Ryu, H.; Jeon, S.; Hong, S. Microstructure and mechanical properties of SiC-nanowire-augmented tungsten composites. J. Alloys Compd. 2011, 509, 9060–9064. [Google Scholar] [CrossRef]

- Coşkun, S.; Öveçoğlu, M.L.; Özkal, B.; Tanoğlu, M. Characterization investigations during mechanical alloying and sintering of W–20 vol% SiC composites. J. Alloys Compd. 2010, 492, 576–584. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Q.; Yu, Z.; Wang, H.; Zhang, T. Influence of Y2O3 addition on the microstructure of TiC reinforced Ti-based composite coating prepared by laser cladding. Mater. Charact. 2022, 189, 111962. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.; Han, Y.; Lu, Q. SiC as sintering aids: A tactic to remove impurity oxygen and reaction interface structure characterization. Int. J. Refract. Met. Hard Mater. 2021, 100, 105640. [Google Scholar] [CrossRef]

- Seng, W.F.; Barnes, P.A. Calculations of tungsten silicide and carbide formation on SiC using the Gibbs free energy. Mater. Sci. Eng. B 2000, 72, 13–18. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, Y.; Guo, B.; Zhu, L. The microstructure and mechanical properties of TiC-reinforced W-matrix composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2023, 112, 106158. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Huang, L.; Pan, Y.; Zhang, J.; Du, Y.; Zhang, Y.; Zhang, S. Densification, grain growth mechanism and mechanical properties of Mo10Nb refractory targets fabricated by SPS. Int. J. Refract. Met. Hard Mater. 2021, 99, 105575. [Google Scholar] [CrossRef]

- Venkateswarlu, K. Influence of the size and morphology of silicon particles on the physical, mechanical and tribological properties of some aluminium-silicon alloys. Mater. Sci. Lett. 1996, 15, 1773–1776. [Google Scholar]

- Zhang, F.; Zhao, W.; Zhang, W.; Liao, Z.; Xiang, X.; Gou, H.; Li, Z.; Wei, H.; Wu, X.; Shan, Q. Microstructure, mechanical properties and wear resistance of rare earth doped WC/steel matrix composites: Experimental and calculations. Ceram. Int. 2023, 49, 2638–2647. [Google Scholar] [CrossRef]

- Taimatsu, H.; Sugiyama, S.; Kodaira, Y. Synthesis of W2C by reactive hot pressing and its mechanical properties. Mater. Trans. 2008, 49, 1256–1261. [Google Scholar] [CrossRef]

- Cai, L.; Wang, H. Microstructure and dry-sliding wear resistance of laser clad tungsten reinforced W5Si3/W2Ni3Si intermetallic coatings. Appl. Surf. Sci. 2004, 235, 501–506. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, X.; Hua, N.; Que, W.; Chen, W. High temperature friction and wear behavior of tungsten–copper alloys. Int. J. Refract. Met. Hard Mater. 2018, 77, 105–112. [Google Scholar] [CrossRef]

- Huei-Long, L.; Wun-Hwa, L.; Chan, S.L.-I. Abrasive wear of powder metallurgy Al alloy 6061-SiC particle composites. Wear 1992, 159, 223–231. [Google Scholar] [CrossRef]

| Temperature/°C | 500 | 700 | 900 | 1100 | 1300 | 1500 | 1700 | 1900 |

|---|---|---|---|---|---|---|---|---|

| Reaction | ΔG/kJ⋅mol−1 | |||||||

| SiC + 8/3W → 1/3W5Si3 + WC | −22.97 | −25.86 | −28.81 | −31.80 | −34.85 | −37.96 | −41.13 | −44.37 |

| WC + W → W2C | 15.69 | 13.19 | 9.80 | 5.67 | 0.90 | −4.43 | −10.26 | −16.55 |

| SiC + O2 → SiO2 + C | −704.94 | −671.28 | −638.21 | −605.64 | −573.32 | −541.24 | −509.36 | −478.60 |

| C + 2W → W2C | −20.81 | −22.78 | −25.68 | −29.34 | −33.65 | −38.51 | −43.85 | −49.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Cheng, Y.; Hu, S.; Kang, K.; Han, Y.; Zhang, X.; Wei, R.; Luo, G. Microstructure, Mechanical and Wear Properties of W-Si-C Composites Consolidated by Spark Plasma Sintering. Metals 2023, 13, 937. https://doi.org/10.3390/met13050937

Wang C, Cheng Y, Hu S, Kang K, Han Y, Zhang X, Wei R, Luo G. Microstructure, Mechanical and Wear Properties of W-Si-C Composites Consolidated by Spark Plasma Sintering. Metals. 2023; 13(5):937. https://doi.org/10.3390/met13050937

Chicago/Turabian StyleWang, Chuanbin, Yongxin Cheng, Sumeng Hu, Kejia Kang, Yuzhe Han, Xudan Zhang, Ronghan Wei, and Guoqiang Luo. 2023. "Microstructure, Mechanical and Wear Properties of W-Si-C Composites Consolidated by Spark Plasma Sintering" Metals 13, no. 5: 937. https://doi.org/10.3390/met13050937

APA StyleWang, C., Cheng, Y., Hu, S., Kang, K., Han, Y., Zhang, X., Wei, R., & Luo, G. (2023). Microstructure, Mechanical and Wear Properties of W-Si-C Composites Consolidated by Spark Plasma Sintering. Metals, 13(5), 937. https://doi.org/10.3390/met13050937