Occurrence Form of Potassium Vapor in Sinter and Its Effect on Reduction Degradation Indexes

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

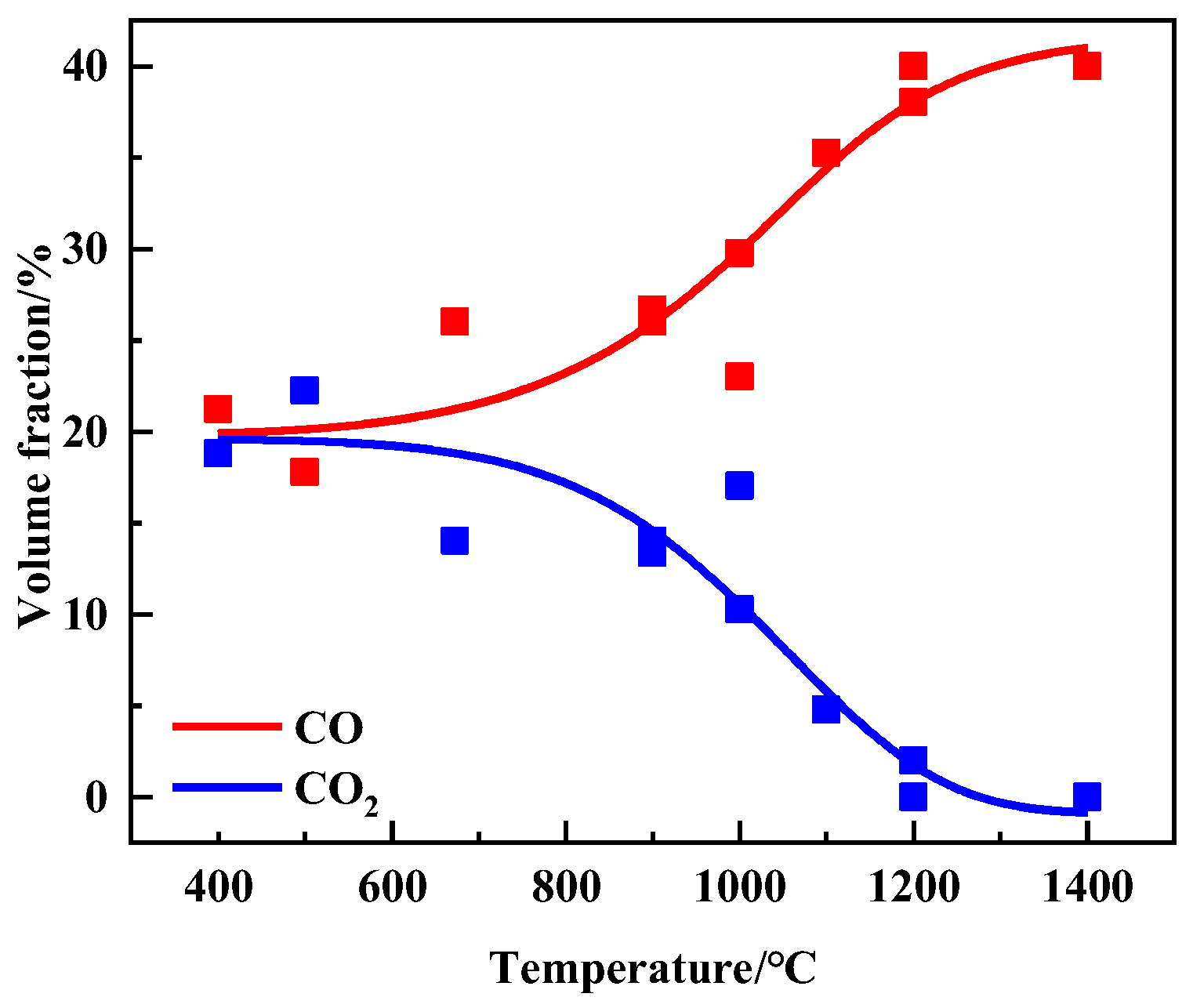

2.2. The Alkali Metal Adsorption of Sinter

2.3. Characterization Methods

3. Results and Discussion

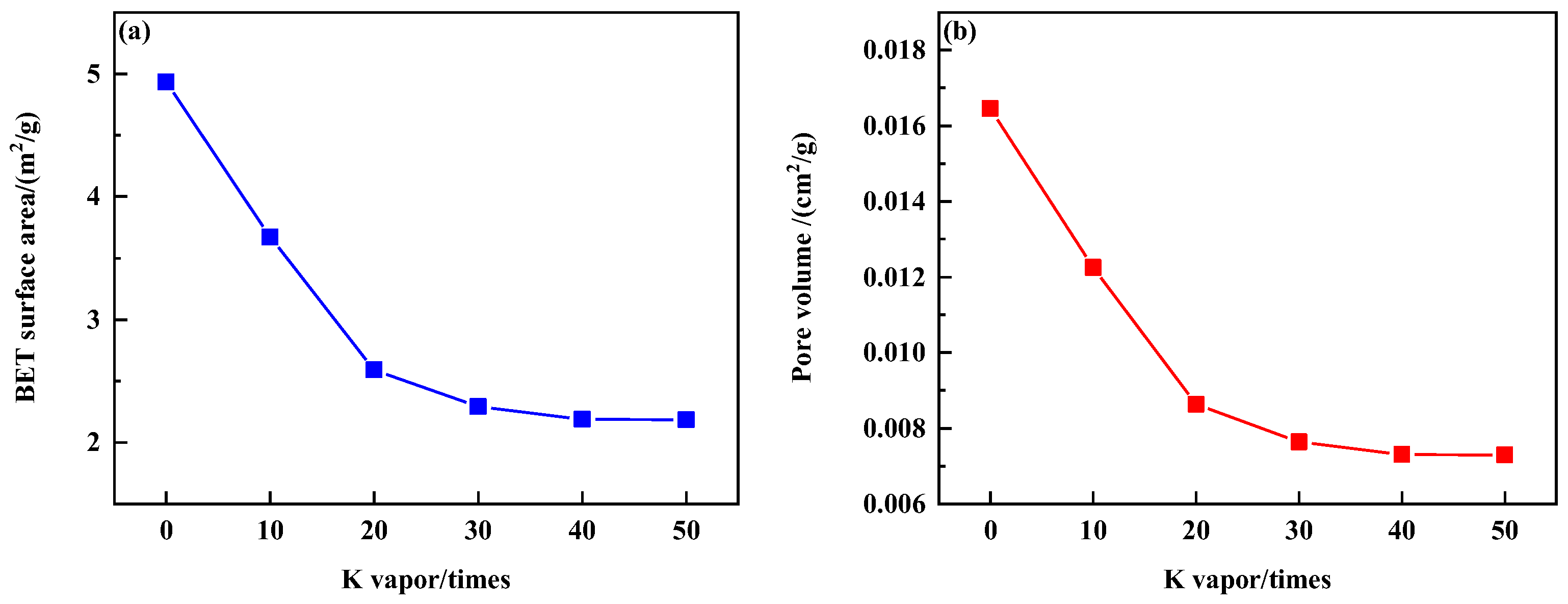

3.1. Effect of Potassium Vapor on Potassium Enrichment Ratio and Adsorption Rate of Sinter

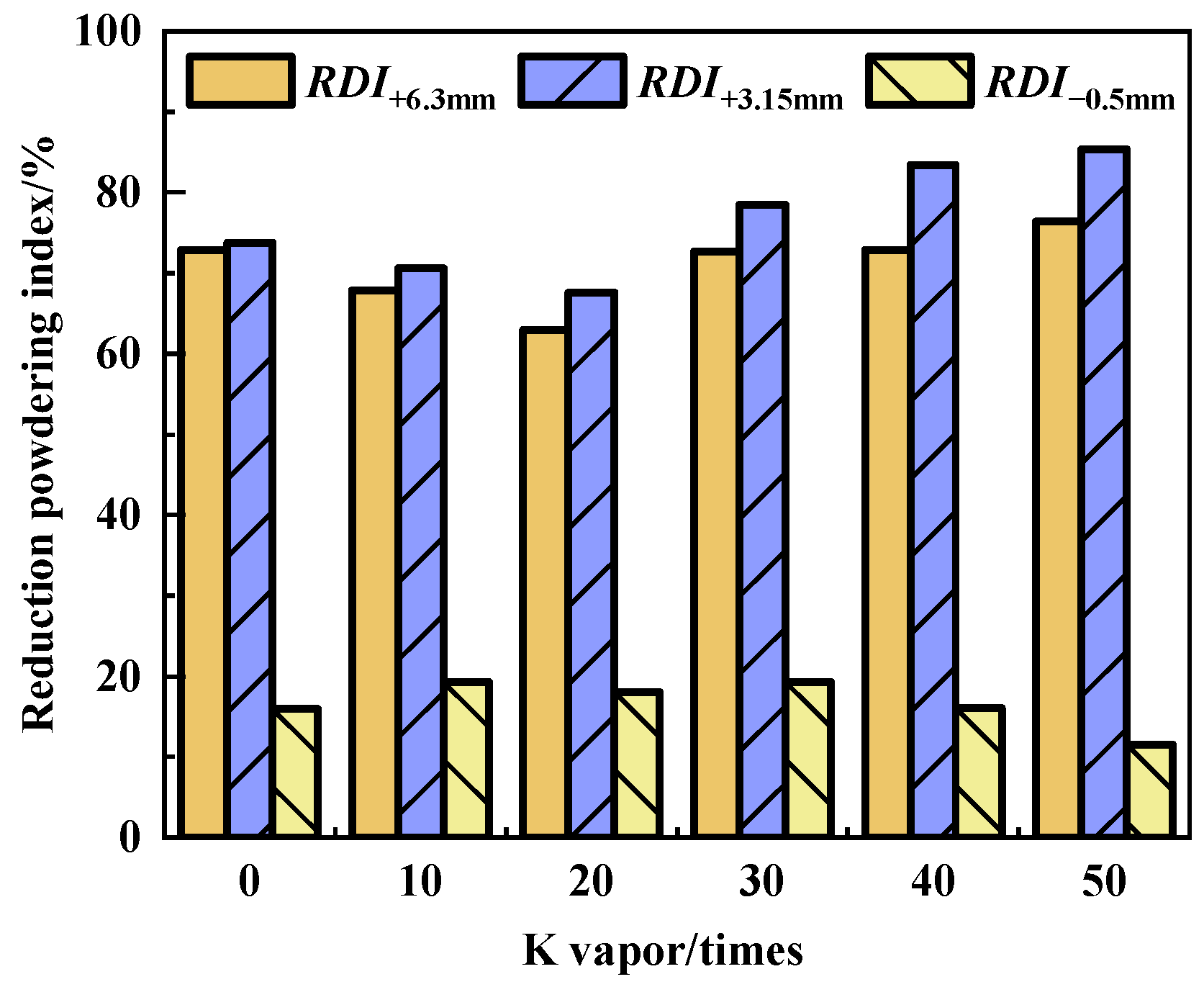

3.2. Effect of Potassium Vapor on Sinter Reduction Chalking Index

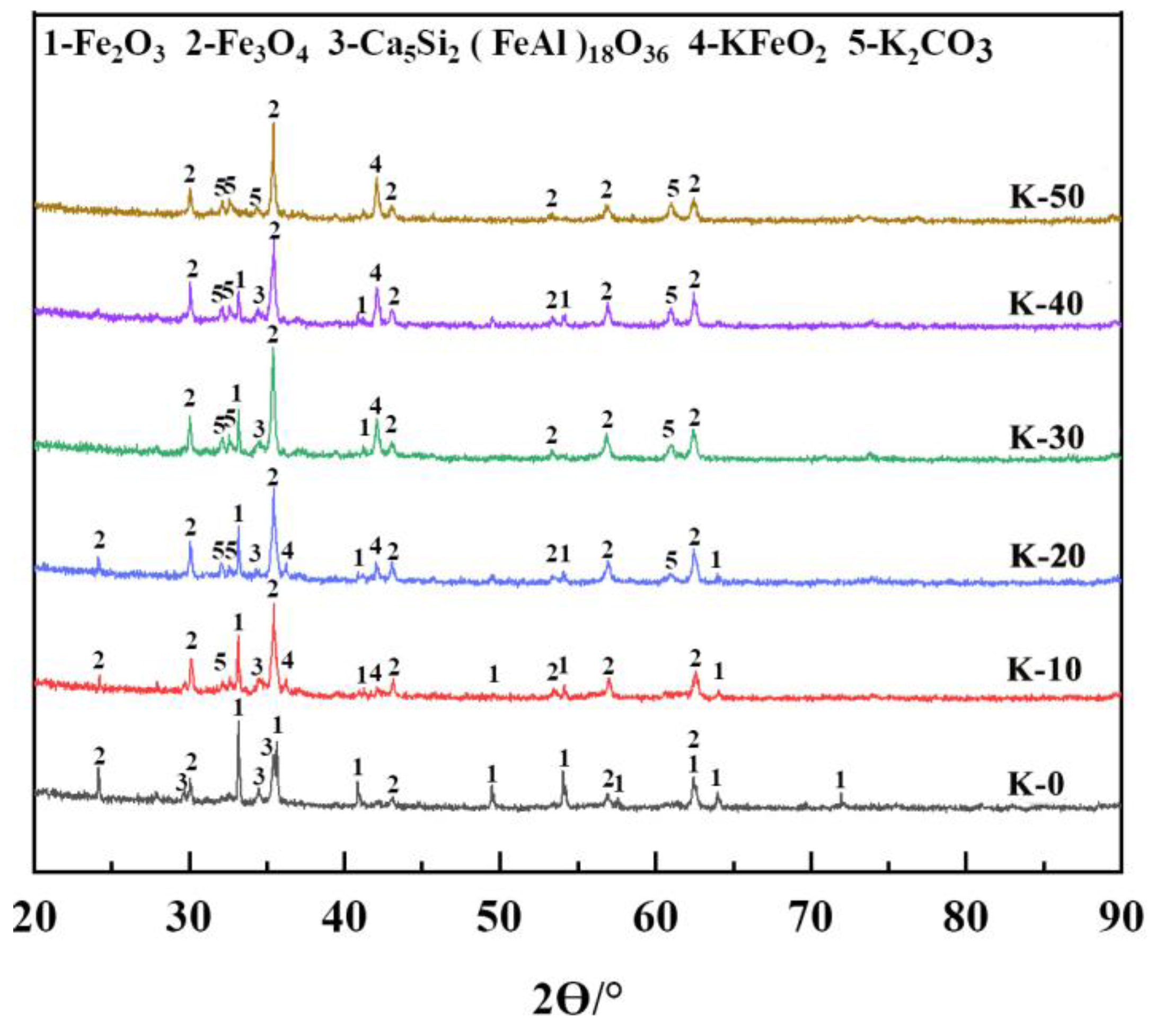

3.3. Occurrence Form of Potassium in Sinter Mine

3.3.1. Phase Analysis of Potassium-Rich Sinter

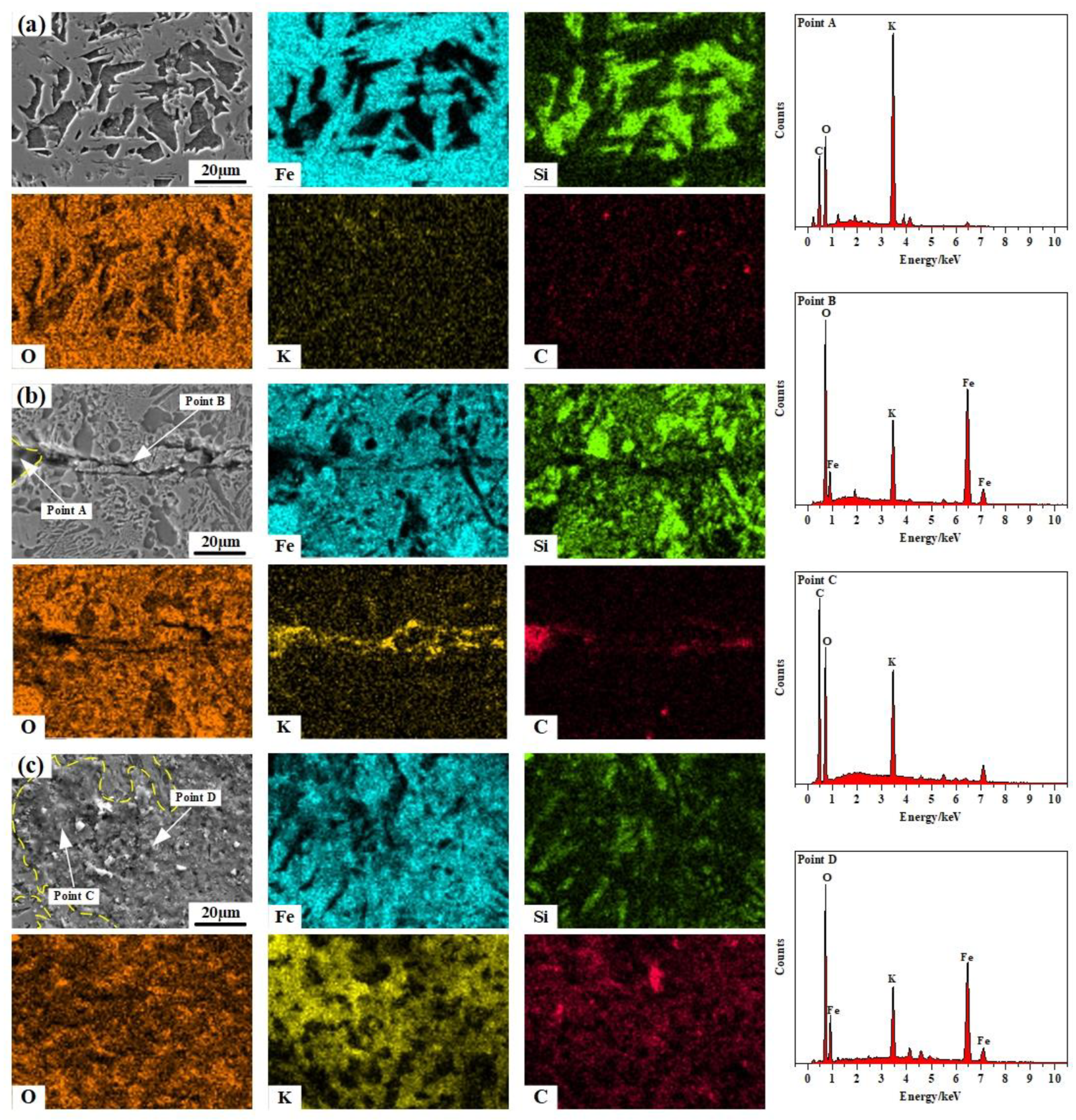

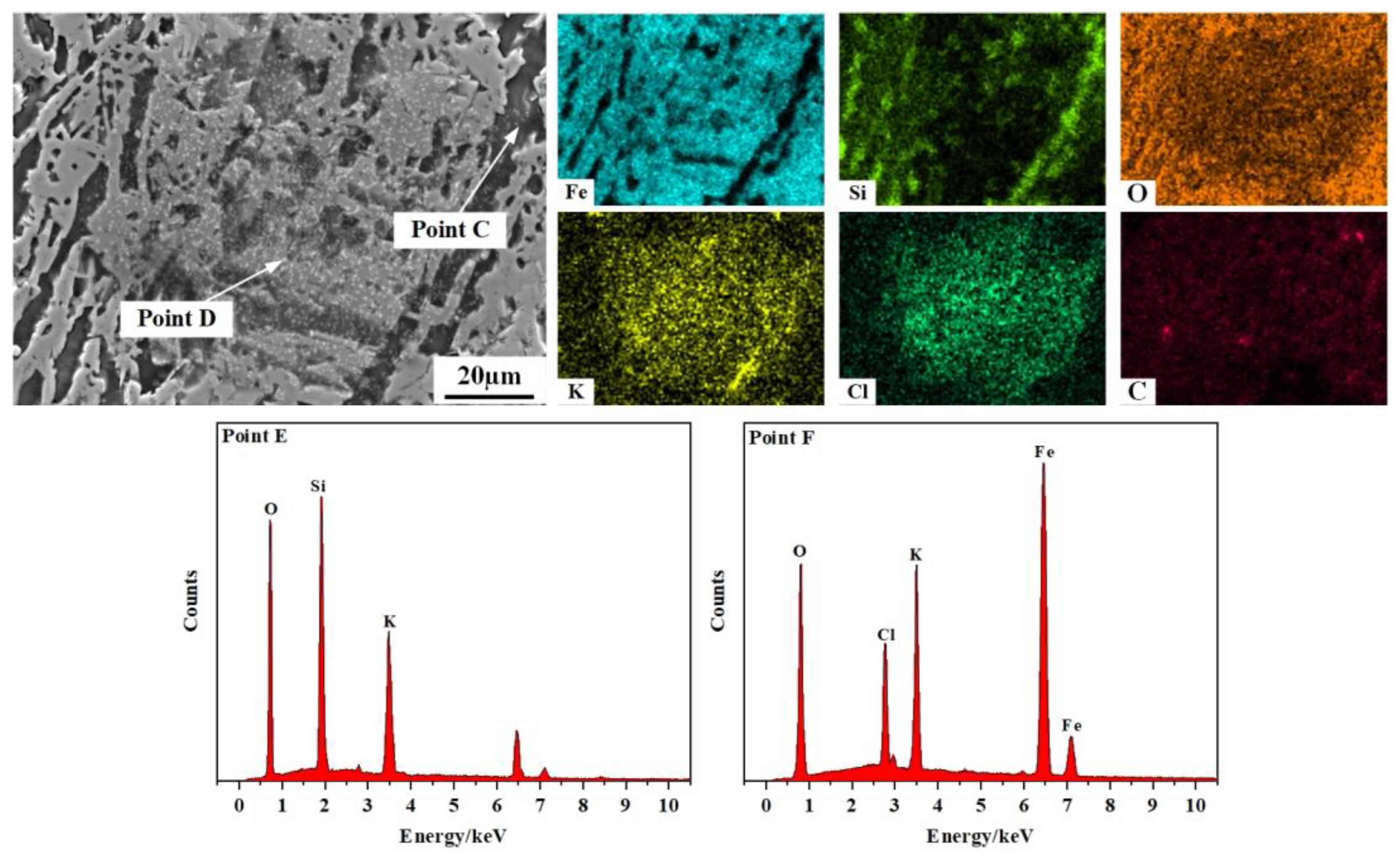

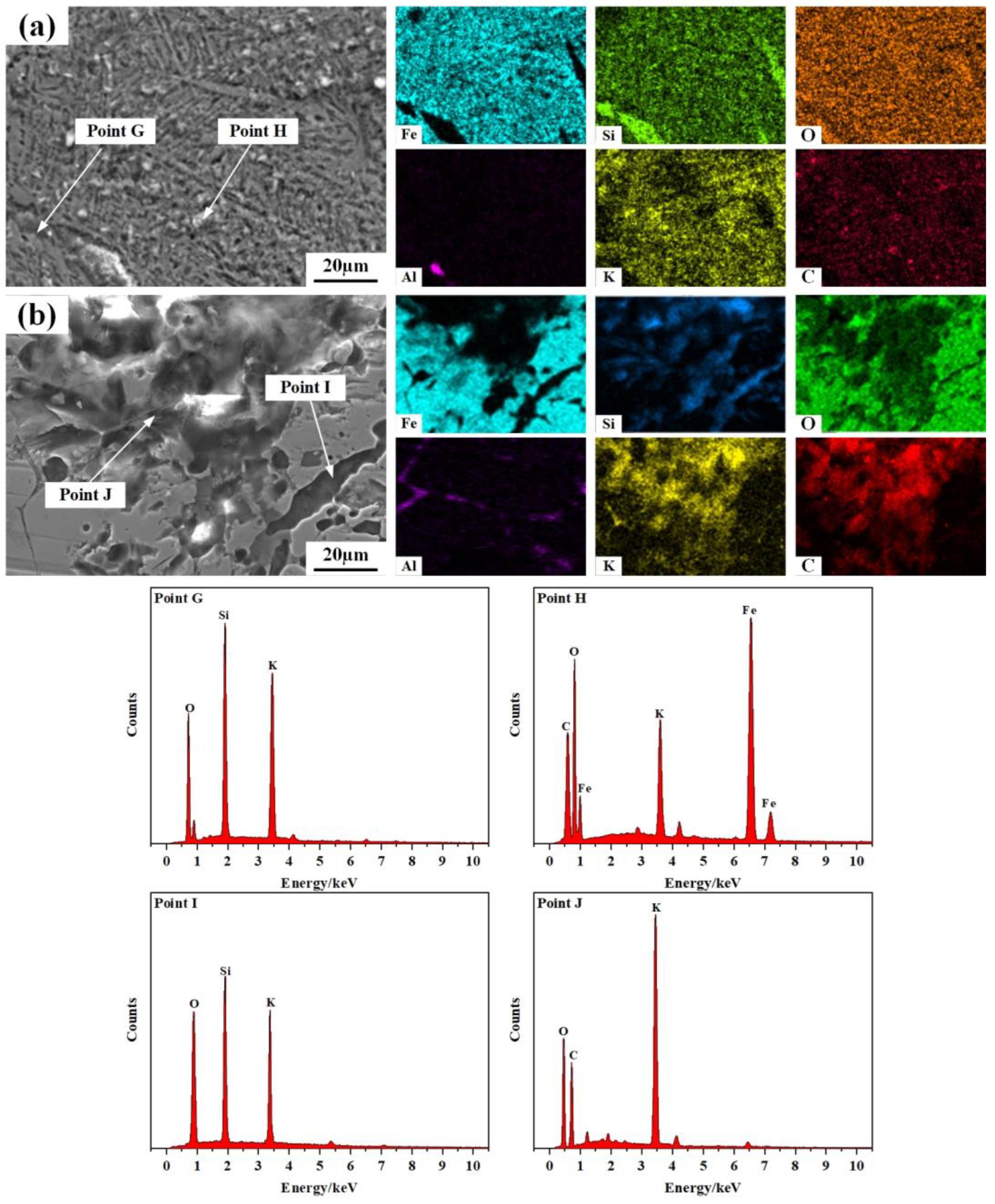

3.3.2. Microstructure Evolution and Element distributions

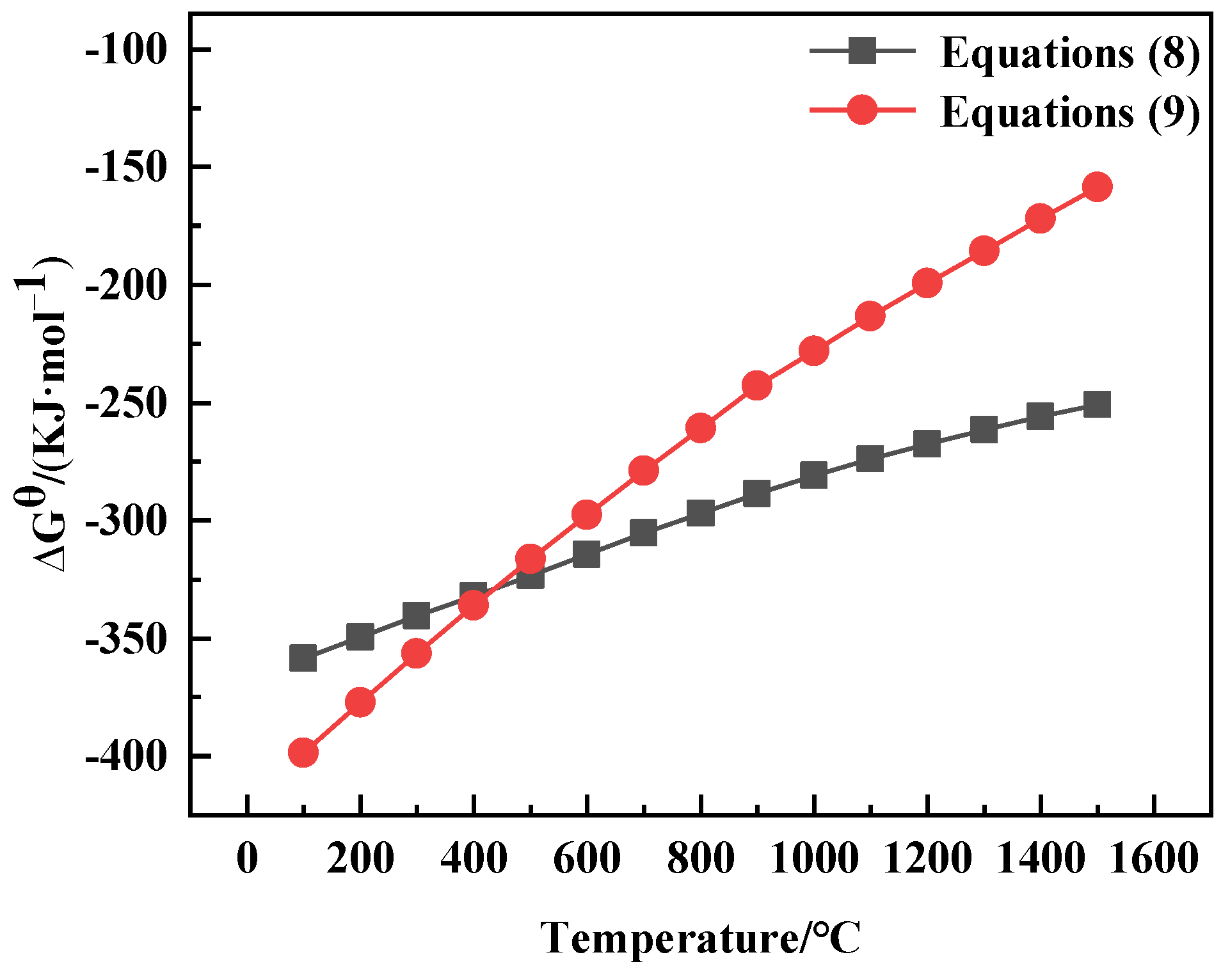

3.4. Transformation of Potassium Vapor Enrichment Form on Sinter

4. Conclusions

- (1)

- With the increase in potassium vapor content, the adsorption rate of potassium in the sinter first increases and then decreases. When the content of potassium vapor content is 50 times higher, the enrichment ratio of K is 2576%, and the adsorption rate of potassium is the lowest, which is 51.5%.

- (2)

- The main methods of potassium vapor adsorption by sinter are physical adsorption and chemical adsorption. When the potassium vapor content is less than 30 times higher, the potassium vapor is mainly adsorbed on the sinter surface in the form of K2CO3, while the potassium vapor diffuses to the sinter and reacts with Fe3O4 to form KFeO2, which results in the decrease of RDI+3.15mm. With the continuous increase of potassium vapor content, the KFeO2 distribution is uniform, and the RDI+3.15mm improves.

- (3)

- In the process of potassium vapor rising with gas, at 1200 °C and 1000 °C, potassium vapor mainly exists in the sinter in the form of KAlSiO3 and K2SiO3. At 800 °C, the potassic phases of the sinter are KCl, K2SiO3, and KFeO2. At 600 °C, potassium vapor mainly exists in the form of K2CO3, K2SiO3, and KFeO2. At 400 °C, potassium vapor is mainly adsorbed on the sinter in the form of K2CO3.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, C.Q.; Su, X.C.; Huang, B. Recycling of dust removal ash in iron and steel production process. China Met. Bull. 2022, 1074, 102–104. [Google Scholar]

- Wang, C.H.; Jiang, X.T. Property analysis and utilization technology of dust ash in Jiusteel. Metallurgy 2019, 29, 57–62. [Google Scholar]

- Lanzerstorfer, C.; Bamberger-Strassmayr, B.; Pilz, K. Recycling of blast furnace dust in the iron ore sintering process: Investigation of coke breeze substitution and the influence on off-gas emissions. ISIJ Int. 2015, 55, 758–764. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Feng, C.Y.; Li, D.X. The Major Ore Clusters of Super-Large Iron Deposits in the World, Present Situation of Iron Resources in China and Prospect. Acta Geol. Sin. Engl. Ed. 2014, 88, 1895–1915. [Google Scholar] [CrossRef]

- Kurunov, L.F.; Titov, V.N.; Emel’yanov, V.L. Analysis of the behavior of alkalis in a blast furnace. Metallurgist 2009, 53, 9–10. [Google Scholar] [CrossRef]

- Gridasov, V.P.; Logachev, G.N.; Pishnograev, S.N. Behavior of Alkalis in Blast Furnaces. Metallurgist 2016, 59, 9–10. [Google Scholar] [CrossRef]

- Zhao, H.; Cheng, S. New cognition on coke degradation by potassium and sodium in alkali enriched regions and quantificational control model for BF. J. Univ. Sci. Technol. Beijing 2012, 34, 333–341. [Google Scholar]

- Hilding, T.; Gupta, S.; Sahajwalla, V. Degradation behaviour of a high CSR coke in an experimental blast furnace: Effect of carbon structure and alkali reactions. ISIJ Int. 2005, 45, 1041–1050. [Google Scholar] [CrossRef]

- Wang, M.C.; Wei, G.S.; Yang, S.F. Effect of alkali (K/Na) metal vapor on the metallurgical properties of coke in CO2–O2–N2 mixed atmosphere. Energy 2022, 257, 124748–124763. [Google Scholar] [CrossRef]

- Wang, G.W.; Ren, S.; Zhang, J.L. Influence mechanism of alkali metals on CO2 gasification properties of metallurgical coke. Chem. Eng. J. 2020, 387, 124093–124106. [Google Scholar] [CrossRef]

- Wang, Y.B.; Luo, G.P. Effect of MgO, fluorine and alkali metals on mineral phase of pellets. Iron Steel 2022, 57, 34–42. [Google Scholar]

- Wang, S.J.; Wang, W.; Chen, R.G. Research on effect of potassium on metallurgical properties of pellets. Sintered Pellet 2021, 46, 44–49. [Google Scholar]

- Wang, Z.X.; Feng, S.; Wang, Y.L. Influence on blast furnace burden by alkali metals. Sichuan Metall. 2020, 42, 29–32. [Google Scholar]

- Fang, M.X.; Hou, X.J.; Hou, Z.Y. Alkali vapor corrosion of refractories at high temperatures. Refractories 2021, 55, 296–301. [Google Scholar]

- Jiao, K.X.; Zhang, J.L.; Liu, Z.J. Analysis of Blast Furnace Hearth Sidewall Erosion and Protective Layer Formation. ISIJ Int. 2016, 56, 1956–1963. [Google Scholar] [CrossRef]

- Jin, Y.L.; He, Z.J.; Wang, C. Analysis on low carbon emission of blast furnace with different raw materials structure. Iron Steel 2019, 54, 8–16. [Google Scholar]

- Zhou, D.D.; Cheng, S.S.; Wang, Y.S. The production of large blast furnaces during 2016 and future development of ironmaking in China. Ironmak. Steelmak. 2017, 44, 714–720. [Google Scholar] [CrossRef]

- Bahgat, M.; Halim, K.S.A.; El-Kelesh, H.A. Metallic iron whisker formation and growth during iron oxide reduction: K2O effect. Ironmak. Steelmak. 2019, 36, 379–387. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, X.; Wang, X.B. Experimental study on influence of K2O on strength of sinter. Iron Steel 2020, 55, 49–55. [Google Scholar]

- Yan, Z.L.; Li, X.Y.; Liu, Z.J. Study on influence of gas phase potassium adsorption on metallurgical properties of sinter. J. Sintered Pellets 2016, 9, 1–5, discussion 31. [Google Scholar]

- Kang, Z.P.; Li, J.C.; Si, J.C. Effect of harmful trace elements on metallurgical properties of blast furnace burden in Hansteel. Iron Steel Res. 2014, 42, 10–12, discussion 15. [Google Scholar]

- Wang, X.Z.; Yan, Z.W.; Wang, R.R. Study of the enrichment characteristics of sinter by alkali metal vapors. Metall. Res. Technol. 2018, 115, 310–319. [Google Scholar] [CrossRef]

- Cheng, G.J. Study on Kinetics of High Chromia Vanadium-Titanium Magnetite Reduction and Migration Behavior of Valuable Elements in Lumpy Zone. Master’s Thesis, Northeastern University, Liaoning, China, 2013. [Google Scholar]

- Li, P.; Liu, W.; Zhang, H.X. Impact of Potassium on Gasification Reaction and Post-Reaction Strength of Ferro-coke. ISIJ Int. 2017, 57, 1947–1954. [Google Scholar] [CrossRef]

- Fan, X.Y. Study on the Formation and Evolution of the Slag Phase in the Cohesive Zone of the Blast Furnace. Ph.D. Thesis, Beijing University of Science and Technology, Beijing, China, 2022. [Google Scholar]

- Chen, S.P.; Wang, W.; Xu, R.S. Influence of multiple factors on the alkali metal enrichment in blast furnaces by a thermodynamic model. Ironmak. Steelmak. 2020, 47, 219–227. [Google Scholar] [CrossRef]

- Li, K.J.; Zhang, J.L.; Barati, M. Influence of alkaline (Na, K) vapors on carbon and mineral behavior in blast furnace cokes. Fuel 2015, 145, 202–213. [Google Scholar] [CrossRef]

- Zhu, B.; Zhou, J.D.; Zhao, L.C. Occurrence form of zinc in blast furnace and its influence on sinter performance. Iron Steel 2020, 55, 130–139. [Google Scholar]

- Zhu, B.; Zhou, J.D.; Pan, Y. Study on enrichment and occurrence form of zinc on coke in upper part of blast furnace. J. Iron Steel Res. 2020, 32, 690–699. [Google Scholar]

- GB/T 6730.49-2017; Iron Ores Determination of Potassium Content Flame Atomic Absorption Spectrometric Method. General Administration of Quality Supervision, Inspection and Quarantine of China: Beijing, China, 2017.

- GB/T 13241-2017; Iron Ores Determination of Reducibility. General Administration of Quality Supervision, Inspection and Quarantine of China: Beijing, China, 2017.

- Andou, Y.; Kawahara, A. The renfinement of the structure of synthetic kalsilite. Mineral. J. 1984, 12, 153–161. [Google Scholar] [CrossRef]

| TFe | FeO | CaO | SiO2 | Al2O3 | MgO | ZnO | K | Na2O |

|---|---|---|---|---|---|---|---|---|

| 49.95 | 9.25 | 14.28 | 7.41 | 1.84 | 2.69 | 0.22 | 0.28 | 0.32 |

| Temperature/°C | CO2/mL·min−1 | CO/mL·min−1 | N2/mL·min−1 |

|---|---|---|---|

| 400 | 200 | 200 | 600 |

| 500 | 200 | 200 | 600 |

| 600 | 190 | 210 | 600 |

| 800 | 170 | 230 | 600 |

| 1000 | 100 | 300 | 600 |

| 1200 | 20 | 380 | 600 |

| Sample | Sinter Mass/g | K/g | K2CO3/g | Activated Carbon/g |

|---|---|---|---|---|

| K-0 | 57.1 | - | - | - |

| K-10 | 58.2 | 1.63 | 2.88 | 0.75 |

| K-20 | 60.1 | 3.37 | 5.95 | 1.55 |

| K-30 | 60.3 | 5.07 | 8.96 | 2.34 |

| K-40 | 56.1 | 6.28 | 11.12 | 2.90 |

| K-50 | 59.3 | 8.30 | 14.69 | 3.83 |

| L-400 | 58.5 | 6.55 | 11.59 | 3.02 |

| L-600 | 59 | 6.61 | 11.69 | 3.05 |

| L-800 | 58.4 | 6.54 | 11.57 | 3.02 |

| L-1000 | 56.4 | 6.32 | 11.18 | 2.92 |

| L-1200 | 54.7 | 6.13 | 10.84 | 2.83 |

| Sample | Original Content/wt% | Enrichment Content/wt% | Enrichment Ratio/% | Adsorption Rate/% |

|---|---|---|---|---|

| K-0 | 0.28 | 0.26 | - | - |

| K-10 | 0.28 | 1.79 | 538 | 53.8 |

| K-20 | 0.28 | 4.18 | 1391 | 69.5 |

| K-30 | 0.28 | 6.42 | 2191 | 73.0 |

| K-40 | 0.28 | 6.83 | 2338 | 58.5 |

| K-50 | 0.28 | 7.49 | 2576 | 51.5 |

| Sample | Drum Mass/g | |||

|---|---|---|---|---|

| m+6.3mm | m3.15–6.3mm | m0.5–3.15mm | m−0.5mm | |

| K-0 | 41.6 | 0.5 | 1.4 | 9.1 |

| K-10 | 39.5 | 1.6 | 1.8 | 11.2 |

| K-20 | 37.8 | 2.8 | 4.9 | 10.8 |

| K-30 | 43.8 | 3.5 | 5.9 | 11.6 |

| K-40 | 40.9 | 5.9 | 6.3 | 9.0 |

| K-50 | 45.3 | 5.3 | 8.7 | 6.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, J.; Wang, H.; Xing, X.; Liu, M.; Zhao, G.; Jiang, X. Occurrence Form of Potassium Vapor in Sinter and Its Effect on Reduction Degradation Indexes. Metals 2023, 13, 1010. https://doi.org/10.3390/met13061010

Ju J, Wang H, Xing X, Liu M, Zhao G, Jiang X. Occurrence Form of Potassium Vapor in Sinter and Its Effect on Reduction Degradation Indexes. Metals. 2023; 13(6):1010. https://doi.org/10.3390/met13061010

Chicago/Turabian StyleJu, Jiantao, Huayong Wang, Xiangdong Xing, Manbo Liu, Guiqing Zhao, and Xintai Jiang. 2023. "Occurrence Form of Potassium Vapor in Sinter and Its Effect on Reduction Degradation Indexes" Metals 13, no. 6: 1010. https://doi.org/10.3390/met13061010

APA StyleJu, J., Wang, H., Xing, X., Liu, M., Zhao, G., & Jiang, X. (2023). Occurrence Form of Potassium Vapor in Sinter and Its Effect on Reduction Degradation Indexes. Metals, 13(6), 1010. https://doi.org/10.3390/met13061010