Cutting Chatter in Ultrasonic Elliptical Vibration Cutting and Its Influence on Surface Roughness and Tool Wear

Abstract

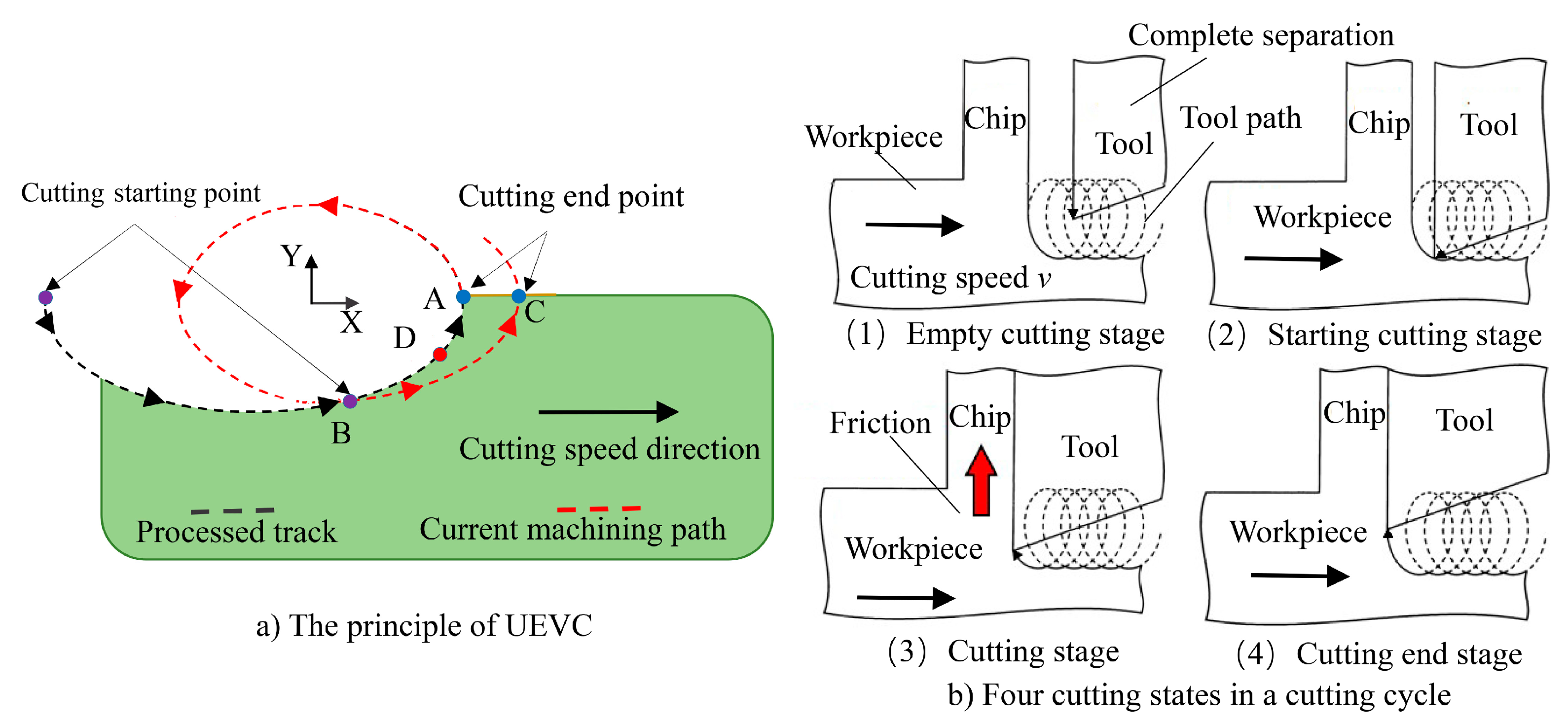

1. Introduction

2. Vibration Model of Horn and Its Influencing Factors Analysis

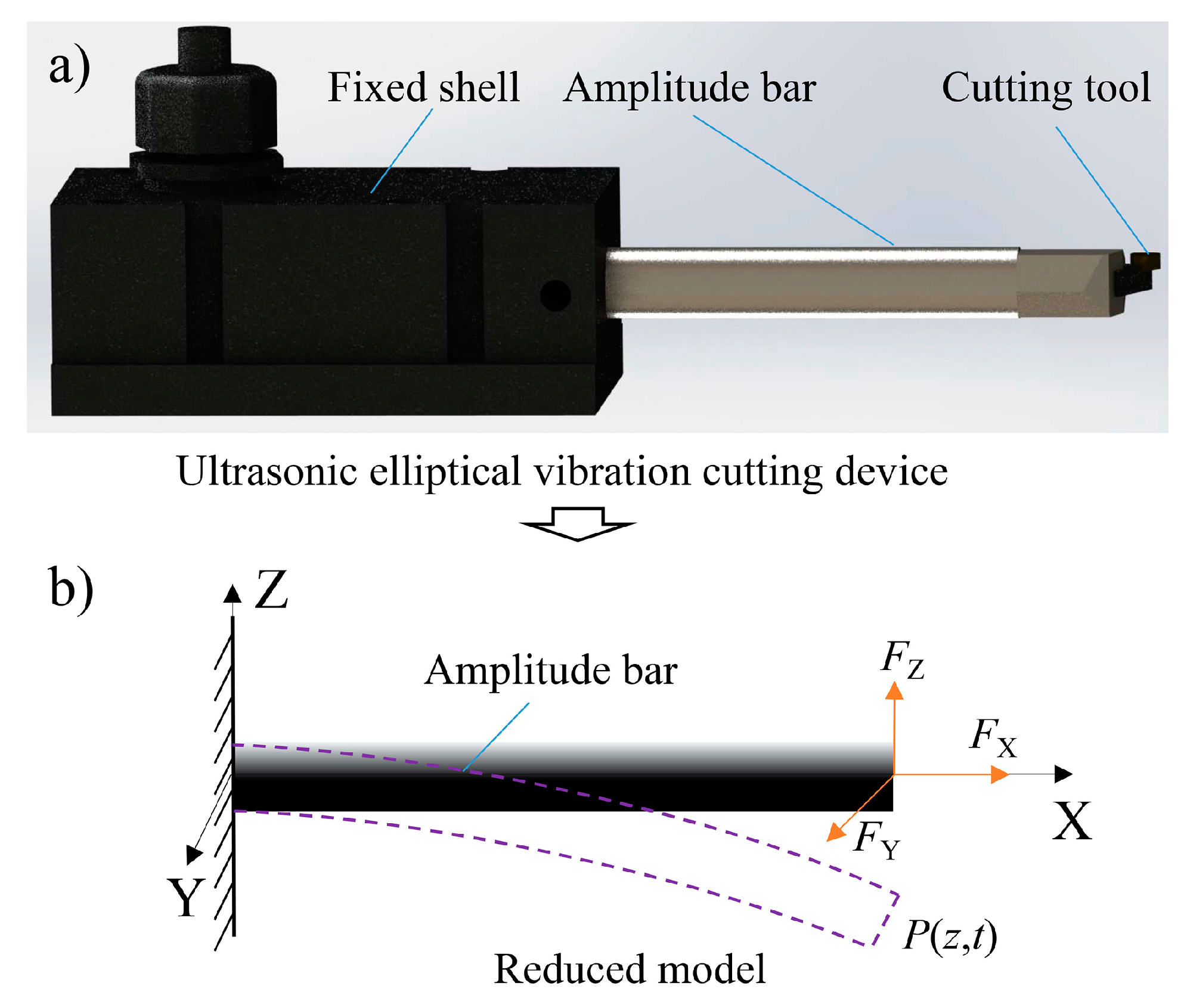

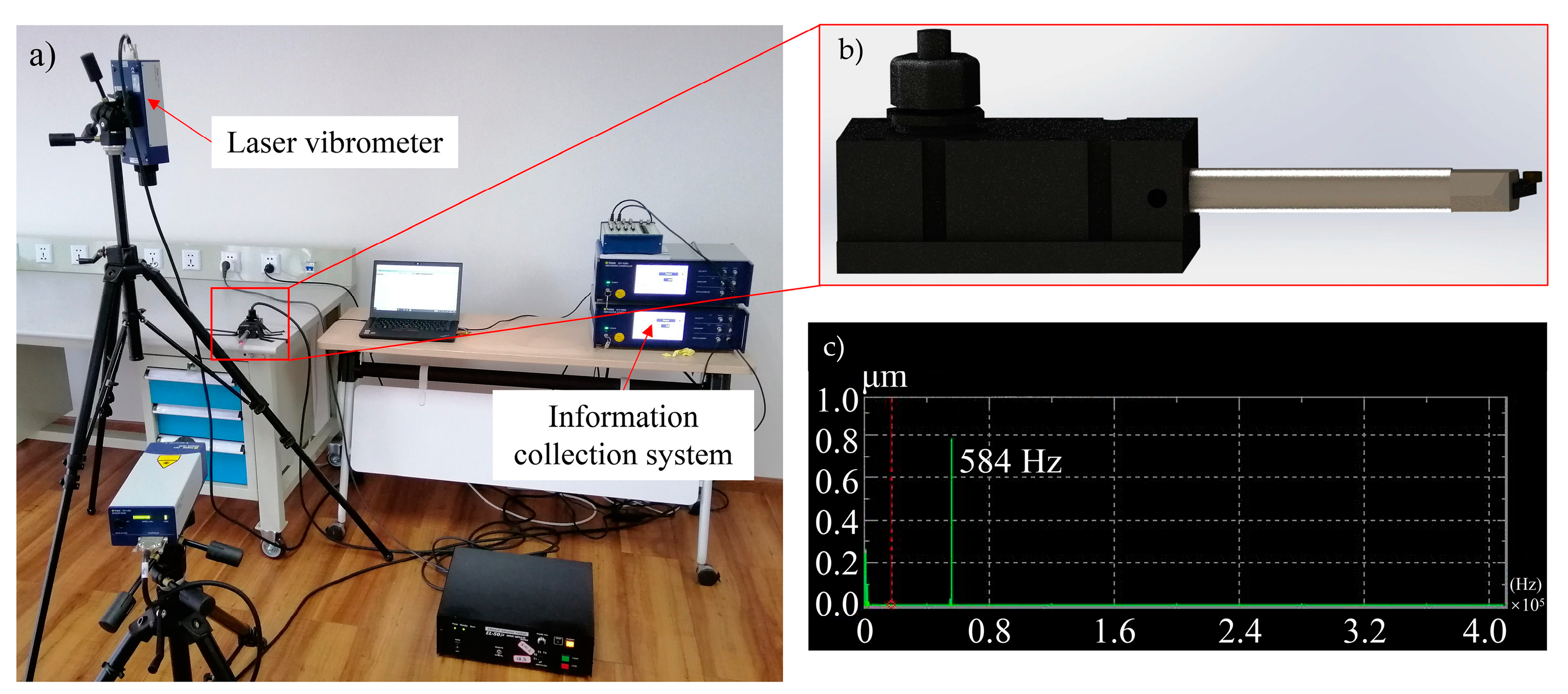

3. Experiment Scheme of UEVC

4. UEVC Experimental Device

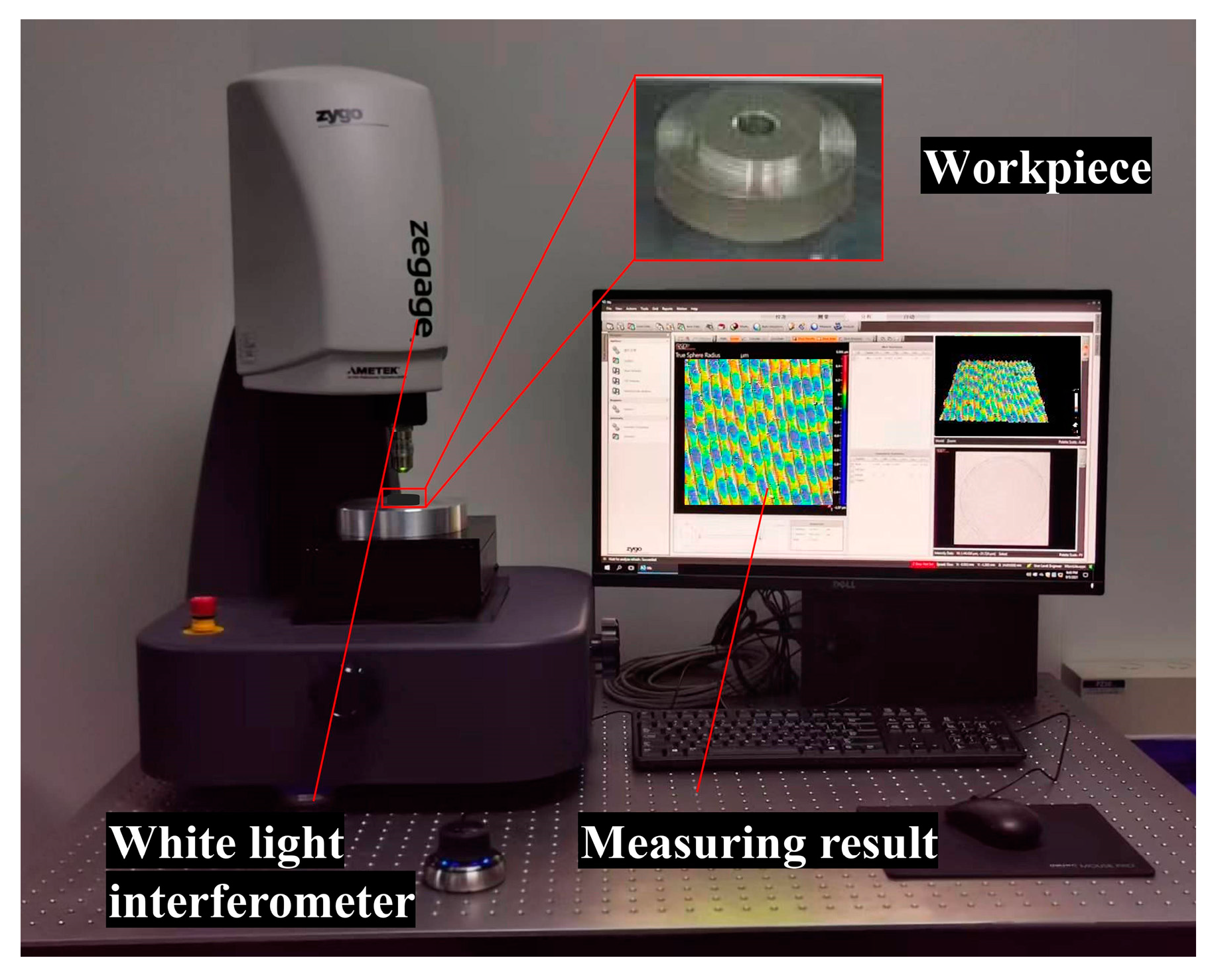

5. Experimental Results Detection and Analysis

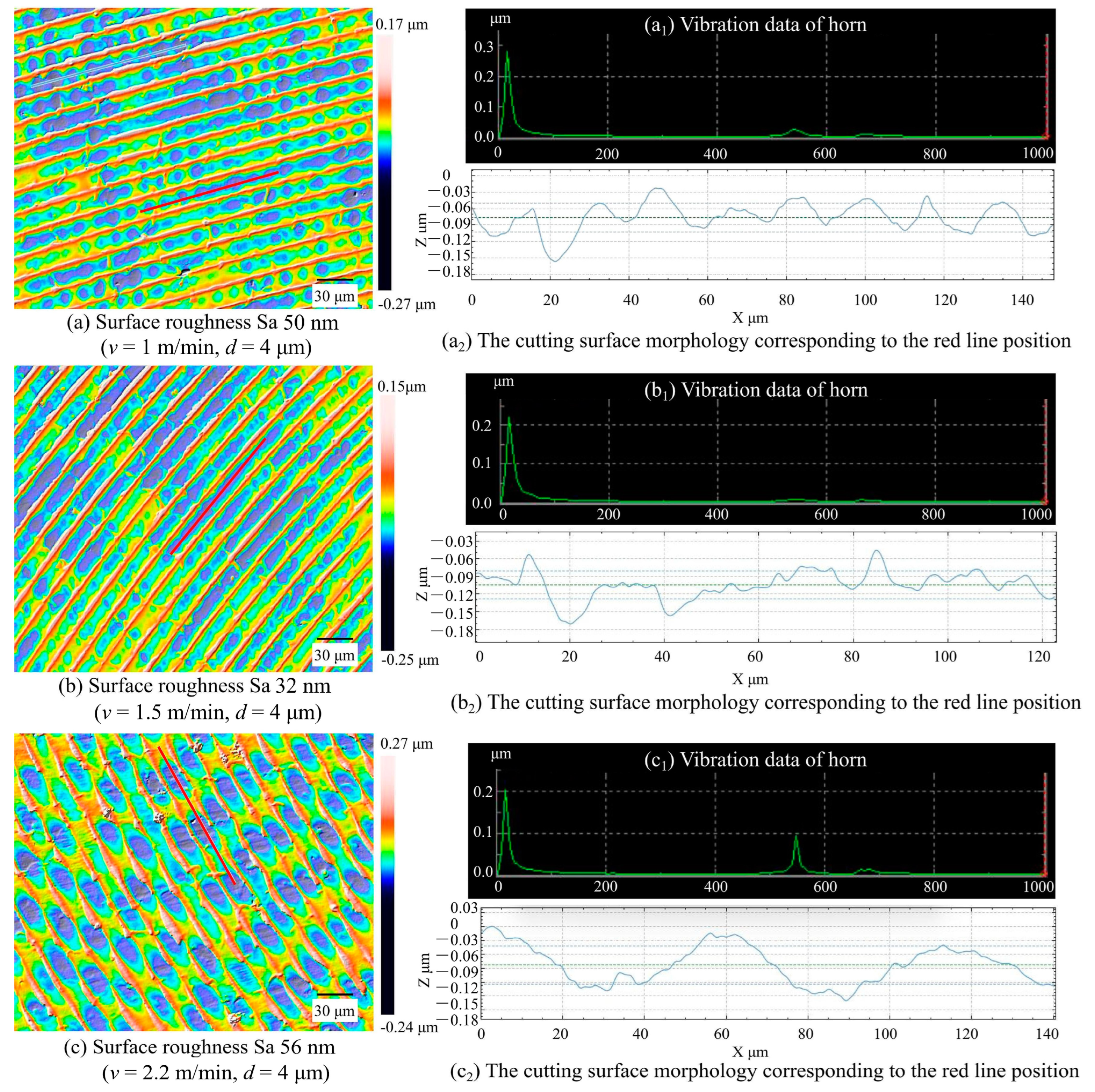

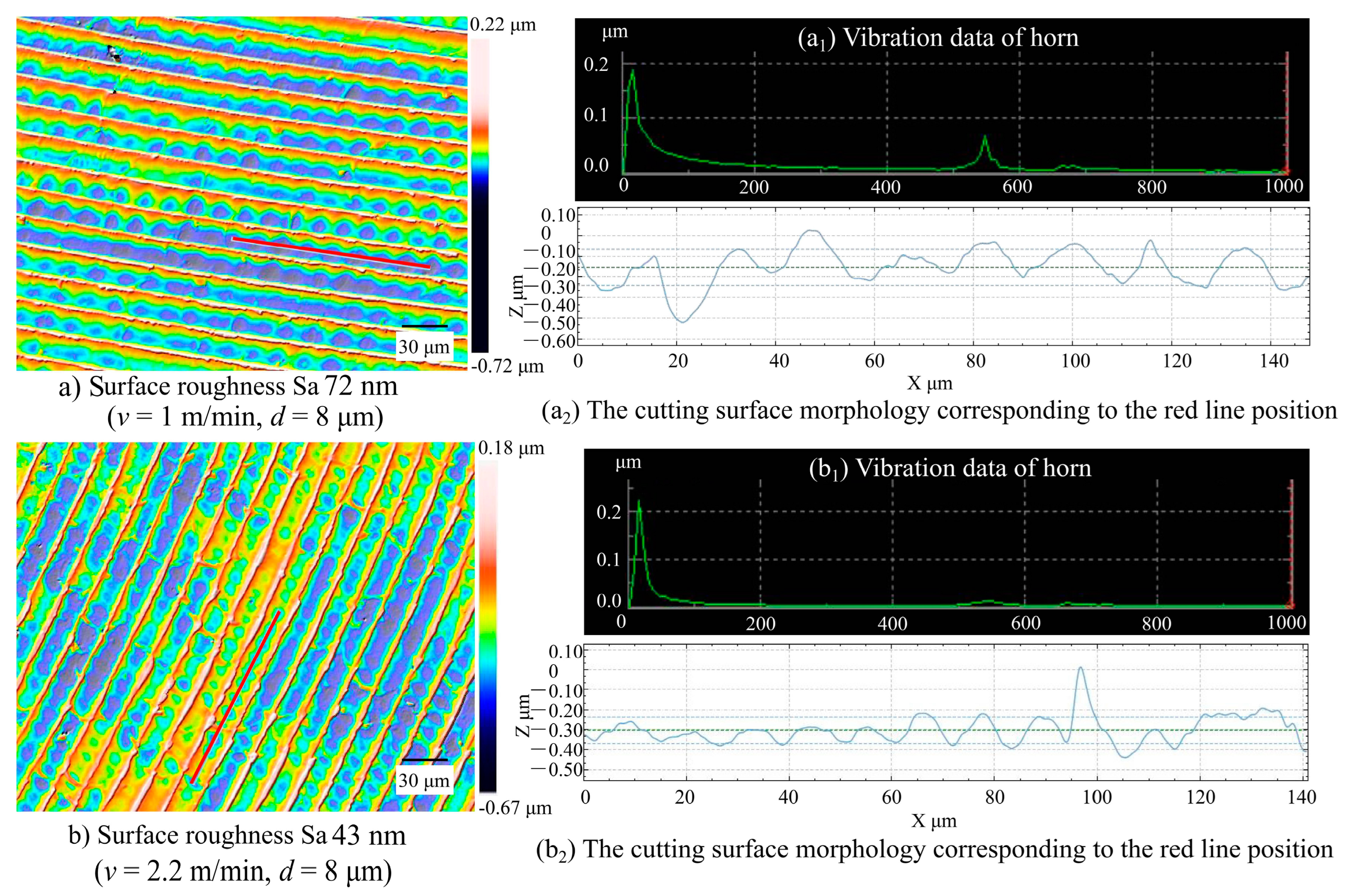

5.1. Effect of Cutting Chatter on Surface Morphology

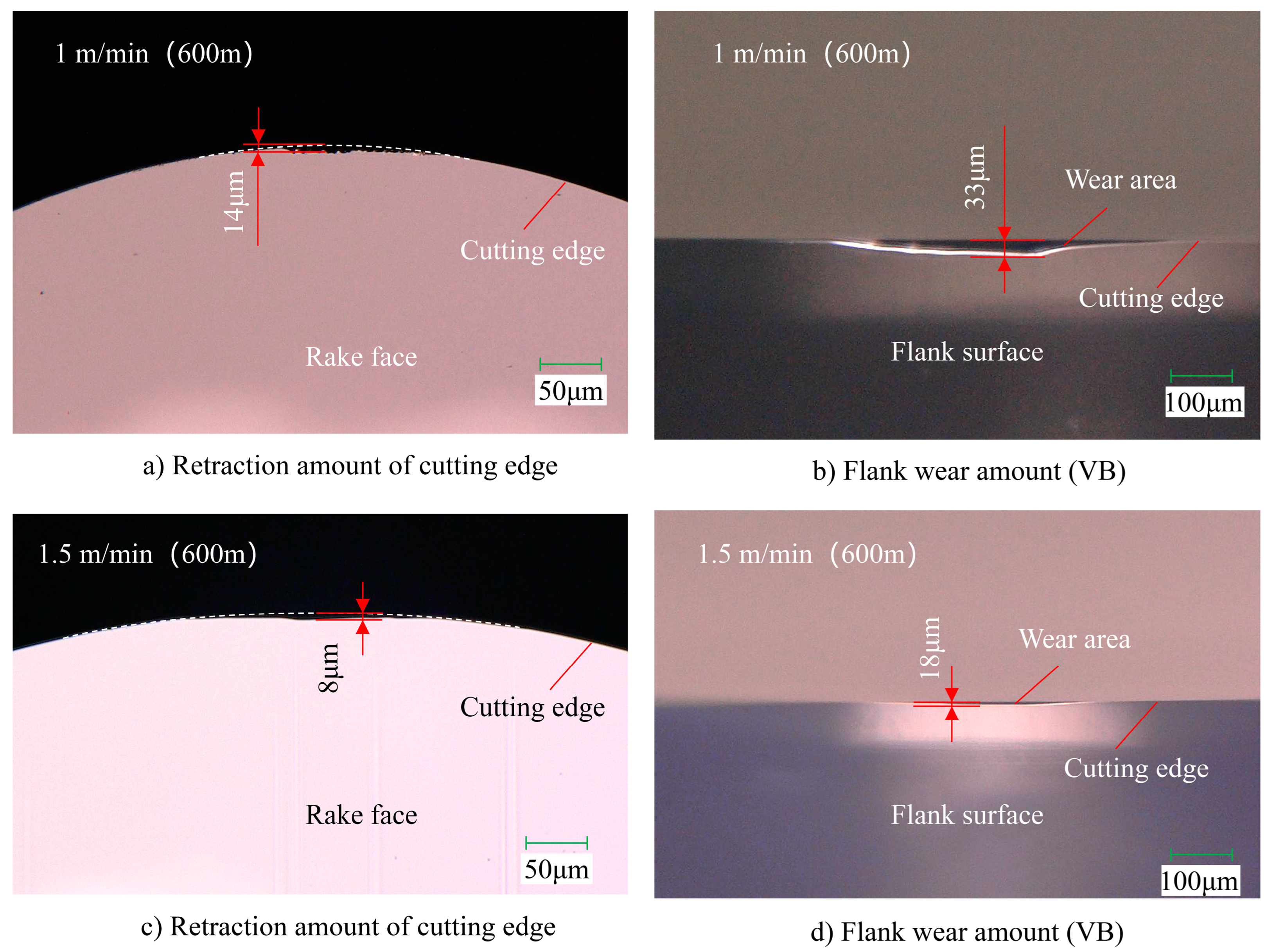

5.2. Effect of Cutting Chatter on Tool Wear

6. Conclusions

- (1)

- According to the rigid/viscoplastic rod model of horn, cutting chatter is affected by cutting speed, ultrasonic frequency, ultrasonic amplitude and other factors, and cutting speed and ultrasonic frequency influence each other. When the excitation frequency is the same as the natural frequency of the horn or its integer times, the horn will resonate, and the flutter is the most severe. The cutting chatter will form more regular pits on the cutting surface, and the pit frequency is the same as the natural frequency of the ultrasonic elliptical vibration cutting device.

- (2)

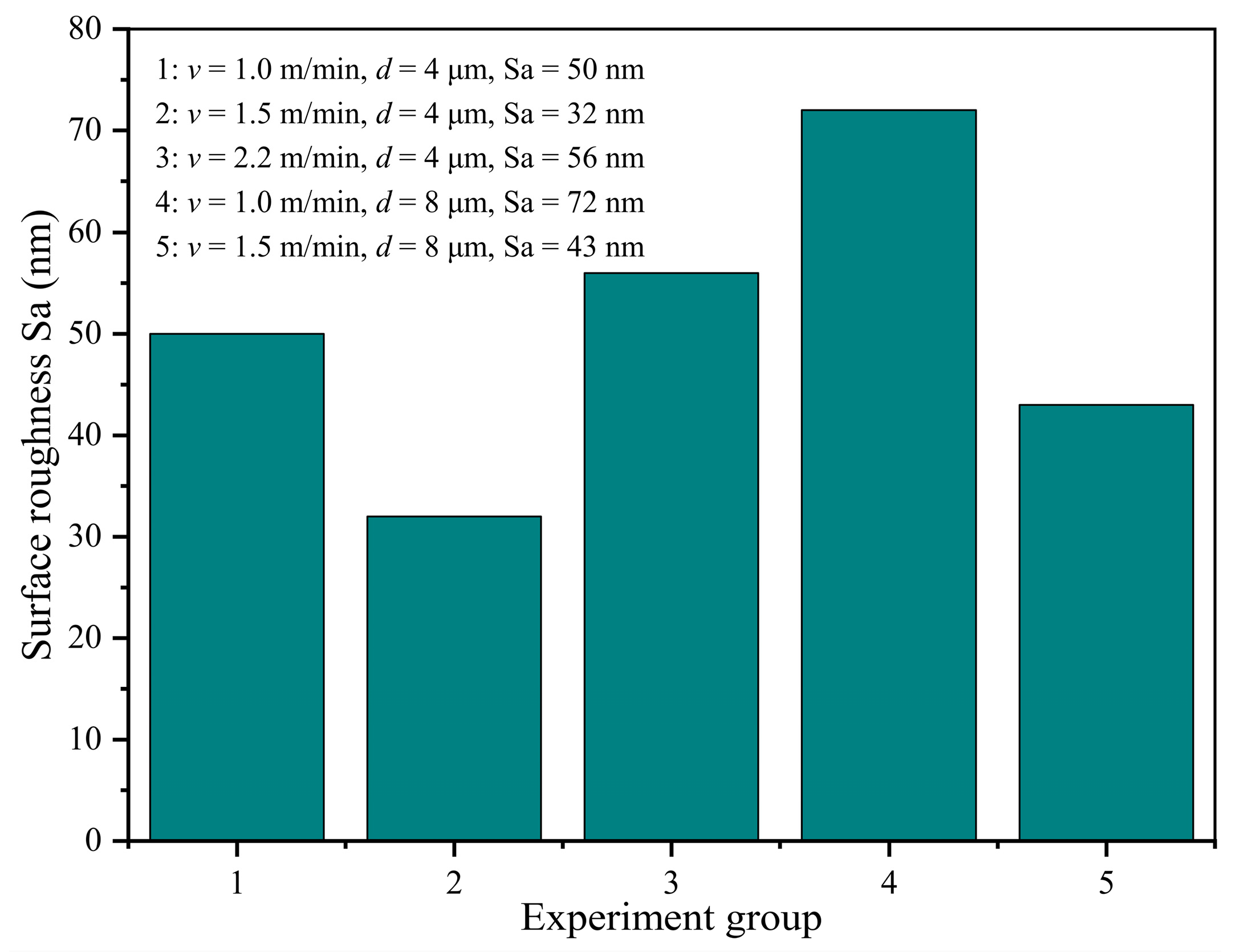

- In ultrasonic elliptical vibration cutting, by changing the cutting speed, the cutting excitation frequency in the cutting process can be changed, so that it is far away from the natural frequency of the ultrasonic elliptical vibration cutting device, thereby suppressing the cutting chatter and improving the cutting surface quality. When the cutting speed is 1 m/min, 1.5 m/min, 2.2 m/min, the cutting surface roughness Sa is 50 nm, 32 nm and 56 nm.

- (3)

- Since the cutting depth does not change the excitation frequency, it is not the cutting parameter that affects the chatter. However, increasing the cutting depth, the pits will deepen on the basis of the original cutting chatter. Under the same processing parameters, the cutting depth increases from 4 μm to 8 μm, and the surface roughness Sa changes from 50 nm to 72 nm.

- (4)

- In ultrasonic elliptical vibration cutting, inhibiting cutting chatter can significantly reduce diamond tool wear, and with the increase of cutting distance, the effect of inhibiting tool wear is more obvious. The experimental results show that when the cutting distance is 600 m, the flank wear of the single crystal diamond tool is reduced by about 45% and the rake face retreat is reduced by about 40%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shamoto, E.; Moriwaki, T. Study on Elliptical Vibration Cutting. CIRP Ann. 1994, 43, 35–38. [Google Scholar] [CrossRef]

- Moriwaki, T.; Shamoto, E. Ultrasonic Elliptical Vibration Cutting. CIRP Ann. 1995, 44, 31–34. [Google Scholar] [CrossRef]

- Shamoto, E.; Suzuki, N. Ultrasonic Vibration Diamond Cutting and Ultrasonic Elliptical Vibration Cutting. Compr. Mater. Process. 2014, 11, 405–454. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, T.; Ge, C.; Sui, Y.; Yang, H. Review of micro/nano machining by utilizing elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 106, 109–126. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Ahmed, N.; Mitrofanov, A.; Babitsky, V.; Silberschmidt, V. Analysis of forces in ultrasonically assisted turning. J. Sound Vib. 2007, 308, 845–854. [Google Scholar] [CrossRef]

- Babitsky, V.I.; Mitrofanov, A.V.; Silberschmidt, V.V. Ultrasonically assisted turning of aviation materials: Simulations and experimental study. Ultrasonics 2004, 42, 81–86. [Google Scholar] [CrossRef]

- Maeng, S.; Ito, H.; Kakinuma, Y.; Min, S. Study on Cutting Force and Tool Wear in Machining of Die Materials with Textured PCD Tools Under Ultrasonic Elliptical Vibration. Int. J. Precis. Eng. Manuf. Technol. 2022, 10, 35–44. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K. Finite Element Modeling and Experimental Validation of Tool Wear in Hot-Ultrasonic-Assisted Turning of Nimonic 90. J. Vib. Eng. Technol. 2022, 1–19. [Google Scholar] [CrossRef]

- Bai, J.; Xu, Z.; Qian, L. Precision-improving manufacturing produces ordered ultra-fine grained surface layer of tungsten heavy alloy through ultrasonic elliptical vibration cutting. Mater. Des. 2022, 220, 110859. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, R.; Dong, Z.; Du, W.; Yin, S.; Bao, Y. On-line prediction of ultrasonic elliptical vibration cutting surface roughness of tungsten heavy alloy based on deep learning. J. Intell. Manuf. 2022, 33, 675–685. [Google Scholar] [CrossRef]

- Usman, M.M.; Zou, P.; Yang, Z.; Lin, T.; Muhammad, I. Evaluation of micro-textured tool performance in ultrasonic elliptical vibration-assisted turning of 304 stainless steel. Int. J. Adv. Manuf. Technol. 2022, 121, 4403–4418. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M.; Neo, K. A study on ultrasonic elliptical vibration cutting of tungsten carbide. J. Mater. Process. Technol. 2009, 209, 4459–4464. [Google Scholar] [CrossRef]

- Pan, Y.; Bai, J.; Xu, Z. Theoretical and numerical studies of surface microstructural transformation in ultrasonic elliptical vibration cutting tungsten heavy alloys. Int. J. Adv. Manuf. Technol. 2022, 123, 3943–3953. [Google Scholar] [CrossRef]

- Kayhan, M.; Budak, E. An experimental investigation of chatter effects on tool life. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2009, 223, 1455–1463. [Google Scholar] [CrossRef]

- Ambhore, N.; Kamble, D.; Chinchanikar, S. Evaluation of Cutting Tool Vibration and Surface Roughness in Hard Turning of AISI 52100 Steel: An Experimental and ANN Approach. J. Vib. Eng. Technol. 2020, 8, 455–462. [Google Scholar] [CrossRef]

- Sahu, G.N.; Deora, P.; Law, M.; Wahi, P. Adaptive Model-Free Gain Tuning for Active Damping of Machine Tool Vibrations. J. Vib. Eng. Technol. 2022, 10, 2799–2808. [Google Scholar] [CrossRef]

- Urbikain, G.; López de Lacalle, L.; Fernández, A. Regenerative vibration avoidance due to tool tangential dynamics in interrupted turning operations. J. Sound Vib. 2014, 333, 3996–4006. [Google Scholar] [CrossRef]

- Wang, M.; Qin, P.; Zan, T.; Gao, X.; Han, B.; Zhang, Y. Improving optimal chatter control of slender cutting tool through more accurate tuned mass damper modeling. J. Sound Vib. 2021, 513, 116393. [Google Scholar] [CrossRef]

- Ye, J.; Feng, P.; Xu, C.; Ma, Y.; Huang, S. A novel approach for chatter online monitoring using coefficient of variation in machining process. Int. J. Adv. Manuf. Technol. 2018, 96, 287–297. [Google Scholar] [CrossRef]

- Xu, C.; Feng, P.; Zhang, J.; Yu, D.; Wu, Z. Milling stability prediction for flexible workpiece using dynamics of coupled machining system. Int. J. Adv. Manuf. Technol. 2016, 90, 3217–3227. [Google Scholar] [CrossRef]

- Kamada, Y.; Kitakaze, A.; Sannomiya, K.; Nakaya, T.; Sasahara, H. Mechanism to suppress regenerative chatter vibration due to the effect of air-cutting and multiple regeneration during low frequency vibration cutting. Precis. Eng. 2022, 78, 1–18. [Google Scholar] [CrossRef]

- Etxebarria, A.; Barcena, R.; Mancisidor, I. Active Control of Regenerative Chatter in Turning by Compensating the Variable Cutting Force. IEEE Access 2020, 8, 224006–224019. [Google Scholar] [CrossRef]

- Hayasaka, T.; Nam, S.; Jung, H.; Shamoto, E.; Saito, K. Proposal of ‘accelerative cutting’ for suppression of regenerative chatter. CIRP Ann. 2018, 67, 401–404. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Ahmadi, K. Finite-amplitude stability in regenerative chatter: The effect of process damping nonlinearity and intermittent cutting in turning. J. Sound Vib. 2022, 537, 117158. [Google Scholar] [CrossRef]

- Yan, B.; Zhu, L. Research on milling stability of thin-walled parts based on improved multi-frequency solution. Int. J. Adv. Manuf. Technol. 2019, 102, 431–441. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, B. Extenuating Chatter Vibration in Milling Process Using a New Ensemble Approach. J. Vib. Eng. Technol. 2022, 10, 1235–1252. [Google Scholar] [CrossRef]

| Serial Number | Cutting Speed (v) | Cutting Depth (d) |

|---|---|---|

| 1 | 1 m/min | 4 μm |

| 2 | 1.5 m/min | 4 μm |

| 3 | 2.2 m/min | 4 μm |

| 4 | 1 m/min | 8 μm |

| 5 | 1.5 m/min | 8 μm |

| Serial Number | Cutting Speed | Cutting Depth | Cutting Distance |

|---|---|---|---|

| 1 | 1 m/min | 4 μm | 600 m |

| 2 | 1.5 m/min | 4 μm | 600 m |

| Name | Tungsten Heavy Alloy (95W) |

|---|---|

| Material component | 95%W, 3%Ni, 2%Fe |

| Heat treatment | Sintering |

| Density (g/cm3) | 18.10 ± 0.15 |

| Elongation (%) | 8–22 |

| Tensile strength (MPa) | 800–1100 |

| Hardness (HRC) | 27–32 |

| Density (g/cm3) | 17.2−17.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Liu, J.; Pan, Y.; Bao, Y.; Yin, S.; Dong, Z.; Kang, R. Cutting Chatter in Ultrasonic Elliptical Vibration Cutting and Its Influence on Surface Roughness and Tool Wear. Metals 2023, 13, 1078. https://doi.org/10.3390/met13061078

Li G, Liu J, Pan Y, Bao Y, Yin S, Dong Z, Kang R. Cutting Chatter in Ultrasonic Elliptical Vibration Cutting and Its Influence on Surface Roughness and Tool Wear. Metals. 2023; 13(6):1078. https://doi.org/10.3390/met13061078

Chicago/Turabian StyleLi, Gan, Jinbo Liu, Yanan Pan, Yan Bao, Sen Yin, Zhigang Dong, and Renke Kang. 2023. "Cutting Chatter in Ultrasonic Elliptical Vibration Cutting and Its Influence on Surface Roughness and Tool Wear" Metals 13, no. 6: 1078. https://doi.org/10.3390/met13061078

APA StyleLi, G., Liu, J., Pan, Y., Bao, Y., Yin, S., Dong, Z., & Kang, R. (2023). Cutting Chatter in Ultrasonic Elliptical Vibration Cutting and Its Influence on Surface Roughness and Tool Wear. Metals, 13(6), 1078. https://doi.org/10.3390/met13061078