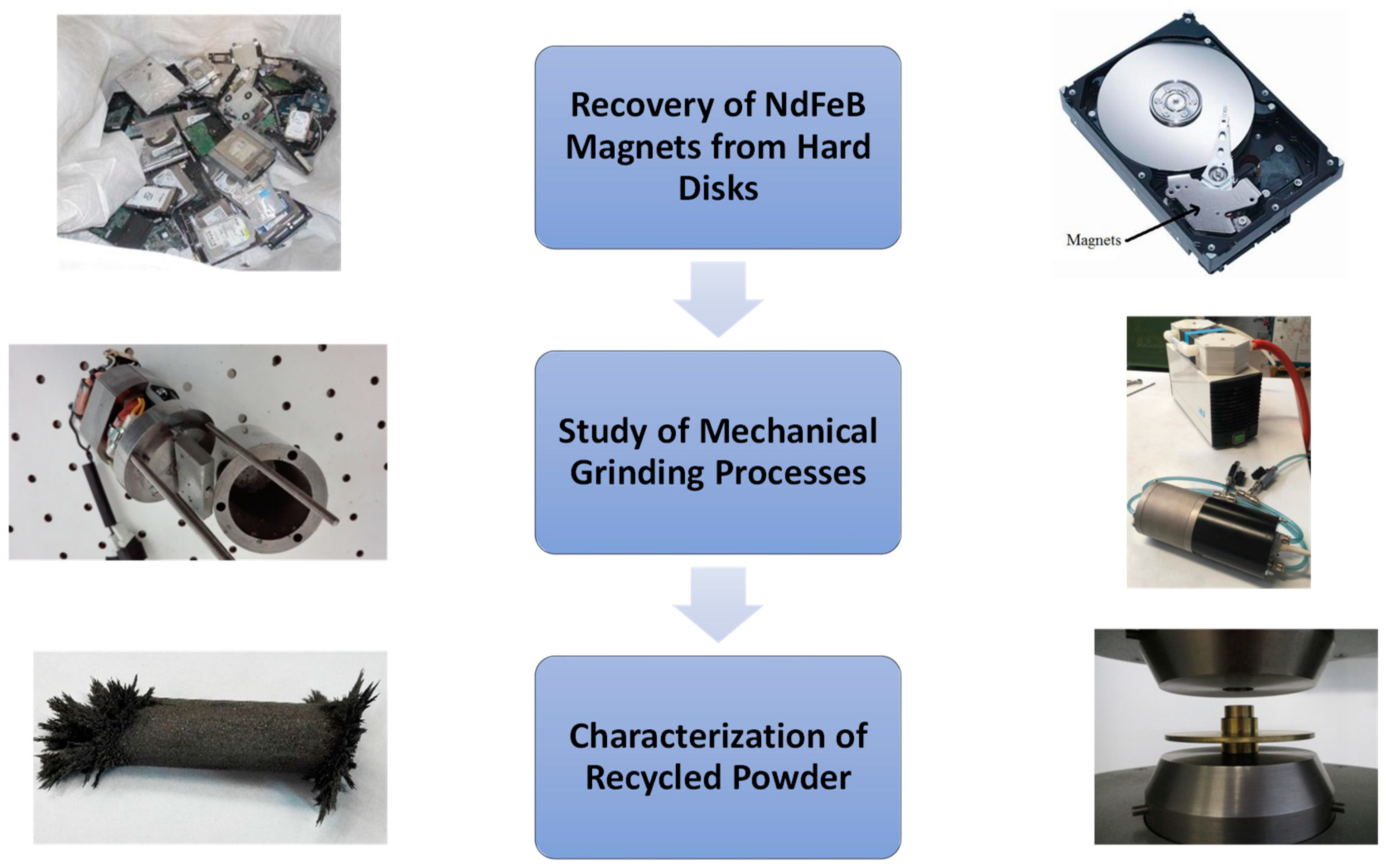

Study of an Impact Mill-Based Mechanical Method for NdFeB Magnet Recycling

Abstract

:1. Introduction

2. Materials and Methods

3. Experimental Results

3.1. Chemical and Microstructural Analyses

3.2. Magnetic Characterization and Magnetographic Observation for Recycled Powder

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lepoutre, A.; Bouscayrol, A.; Irimia, C.; Husar, C.; Kalogiannis, T.; Ahmed, M.; Martis, C.; Zuber, D.; Phetsinorath, D.; Gao, F.; et al. Calculation of the GHG emissions of a European research project on electrified vehicles. In Proceedings of the 2021 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 25–28 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Freire, F.; Marques, P. Electric vehicles in Portugal: An integrated energy, greenhouse gas and cost life-cycle analysis. In Proceedings of the 2012 IEEE International Symposium on Sustainable Systems and Technology (ISSST), Boston, MA, USA, 16–18 May 2012; pp. 1–6. [Google Scholar]

- Helmers, E.; Dietz, J.; Hartard, S. Electric car life cycle assessment based on real-world mileage and the electric conversion scenario. Int. J. Life Cycle Assess. 2015, 22, 15–30. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing environmental impacts of additive manufacturing vs traditional machining via life-cycle assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef] [Green Version]

- Schillingmann, H.; Gehler, S.; Henke, M. Life cycle assessment of electrical machine production considering resource requirements and sustainability. In Proceedings of the 2021 11th International Electric Drives Production Conference (EDPC), Erlangen, Germany, 7–9 December 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Tintelecan, A.; Dobra, A.C.; Martis, C. Literature Review—Electric Vehicles Life Cycle Assessment. In Proceedings of the 2020 ELEKTRO, Taormina, Italy, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Ayyappan, G.; Narayanan, N.K.; Raghavan, M.R.; Pandi, V.R.; Angel, T.; Babu, B.R. Electrical Motor Maintenance Techniques and Life Cycle Assessment—A Review with Case Studies. In Proceedings of the 2019 2nd International Conference on Power and Embedded Drive Control (ICPEDC), Chennai, India, 21–23 August 2019; pp. 167–172. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Kallaste, A.; Orlova, S.; Gevorkov, L.; Vaimann, T.; Belahcen, A. Re-Use and Recycling of Different Electrical Machines. Latv. J. Phys. Tech. Sci. 2018, 55, 13–23. [Google Scholar]

- Andersson, M.; Ljunggren Söderman, M.; Sandén, B. Are scarce metals in cars functionally recycled? Waste Manag. 2017, 60, 407–416. [Google Scholar] [CrossRef]

- Efstratiadis, V.S.; Michailidis, N. Sustainable Recovery, Recycle of Critical Metals and Rare Earth Elements from Waste Electric and Electronic Equipment (Circuits, Solar, Wind) and Their Reusability in Additive Manufacturing Applications: A Review. Metals 2022, 12, 794. [Google Scholar] [CrossRef]

- Isfahani, A.H.; Vaez-Zadeh, S. Line start permanent magnet synchronous motors: Challenges and opportunities. Energy 2009, 34, 1755–1763. [Google Scholar] [CrossRef]

- Tintelecan, A.; Dobra, A.C.; Martis, C. Life Cycle Assessment Comparison of Synchronous Motor and Permanent Magnet Synchronous Motor. In Proceedings of the 2020 International Conference and Exposition on Electrical And Power Engineering (EPE), Iasi, Romania, 22–23 October 2020; pp. 205–210. [Google Scholar] [CrossRef]

- Nordelöf, A.; Grunditz, E.; Lundmark, S.; Tillman, A.-M.; Alatalo, M.; Thiringer, T. Life cycle assessment of permanent magnet electric traction motors. Transp. Res. Part D: Transp. Environ. 2019, 67, 263–274. [Google Scholar] [CrossRef]

- Grunditz, E.A.; Lundmark, S.T.; Alatalo, M.; Thiringer, T.; Nordelöf, A. Three traction motors with different magnet materials—Influence on cost, losses, vehicle performance, energy use and environmental impact. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; pp. 1–13. [Google Scholar]

- Ilankoon, I.M.S.K.; Dushyantha, N.P.; Mancheri, N.; Edirisinghe, P.M.; Neethling, S.J.; Ratnayake, N.P.; Rohitha, L.P.S.; Dis-sanayake, D.M.D.O.K.; Premasiri, H.M.R.; Abeysinghe, A.M.K.B.; et al. Constraints to rare earth elements supply diversification: Evidence from an industry survey. J. Clean. Prod. 2021, 331, 129932. [Google Scholar] [CrossRef]

- Massari, S.; Ruberti, M. Rare earth elements as critical raw materials: Focus on international markets and future strategies. Resour. Policy 2013, 38, 36–43. [Google Scholar] [CrossRef]

- Baldi, L.; Peri, M.; Vandone, D. Clean energy industries and rare earth materials: Economic and financial issues. Energy Policy 2014, 66, 53–61. [Google Scholar] [CrossRef] [Green Version]

- Habib, K. A product classification approach to optimize circularity of critical resources – the case of NdFeB magnets. J. Clean. Prod. 2019, 230, 90–97. [Google Scholar] [CrossRef]

- Zhanheng, C. Global rare earth resources and scenarios of future rare earth industry. J. Rare Earths 2011, 29, 1–6. [Google Scholar]

- Kontos, S.; Ibrayeva, A.; Leijon, J.; Mörée, G.; Frost, A.E.; Schönström, L.; Gunnarsson, K.; Svedlindh, P.; Leijon, M.; Eriksson, S. An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines. Energies 2020, 13, 5549. [Google Scholar] [CrossRef]

- Ferraris, L.; Ferraris, P.; Poskovic, E.; Tenconi, A. Theoretic and Experimental Approach to the Adoption of Bonded Magnets in Fractional Machines for Automotive Applications. IEEE Trans. Ind. Electron. 2011, 59, 2309–2318. [Google Scholar] [CrossRef]

- Ferraris, L.; Franchini, F.; La Cascia, D.; Poskovic, E. Adoption of bonded magnets in place of sintered NdFeB: Performance and economic considerations on a small power generator. In Proceedings of the IEEE EPE ECCE Europe Conference, Geneva, Switzerland, 8–10 September 2015. [Google Scholar] [CrossRef]

- Riba, J.-R.; López-Torres, C.; Romeral, L.; Garcia, A. Rare-earth-free propulsion motors for electric vehicles: A technology review. Renew. Sustain. Energy Rev. 2016, 57, 367–379. [Google Scholar] [CrossRef] [Green Version]

- Schulze, R.; Buchert, M. Estimates of global REE recycling potentials from NdFeB magnet material. Resour. Conserv. Recycl. 2016, 113, 12–27. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Liu, R.; Buchert, M.; Dittrich, S.; Manhart, A.; Merz, C.; Schuler, D. Application of rare earths in consumer electronics and challenges for recycling. In Proceedings of the IEEE ICCE Conference, Berlin, Germany, 6–8 September 2011; pp. 286–290. [Google Scholar] [CrossRef]

- Zakotnik, M.; Tudor, C.O.; Talens Peiró, L.; Afiuny, P.; Skomski, R.; Hatch, G.P. Analysis of energy usage in Nd–Fe–B magnet to magnet recycling. Environ. Technol. Innov. 2016, 5, 117–126. [Google Scholar] [CrossRef]

- Jin, H.; Song, B.D.; Yih, Y.; Sutherland, J. A bi-objective network design for value recovery of neodymium-iron-boron magnets: A case study of the United States. J. Clean. Prod. 2018, 211, 257–269. [Google Scholar] [CrossRef]

- Lixandru, A.; Poenaru, I.; Güth, K.; Gauß, R.; Gutfleisch, O. A systematic study of HDDR processing conditions for the recycling of end-of-life Nd-Fe-B magnets. J. Alloys Compd. 2017, 724, 51–61. [Google Scholar] [CrossRef]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Multiple recycling of NdFeB-type sintered magnets. J. Alloys Compd. 2009, 469, 314–321. [Google Scholar] [CrossRef]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Possible methods of recycling NdFeB-type sintered magnets using the HD/degassing process. J. Alloys Compd. 2008, 450, 525–531. [Google Scholar] [CrossRef]

- Horikawa, T.; Miura, K.; Itoh, M.; Machida, K.I. Effective recycling for Nd-Fe-B sintered magnet scraps. J. Alloys Compd. 2006, 408–412, 1386–1390. [Google Scholar] [CrossRef]

- Itoh, M.; Masuda, M.; Suzuki, S.; Machida, K.-I. Recycling of rare earth sintered magnets as isotropic bonded magnets by melt-spinning. J. Alloys Compd. 2004, 374, 393–396. [Google Scholar] [CrossRef]

- Tanvar, H.; Dhawan, N. Microwave-Assisted Carbothermic Reduction of Discarded Rare Earth Magnets for Recovery ofNeodymium and Iron Values. J. Miner. Met. Mater. Soc. 2021, 73, 54–62. [Google Scholar] [CrossRef]

- Di Piazza, S.; Cecchi, G.; Cardinale, A.M.; Carbone, C.; Mariotti, M.G.; Giovine, M.; Zotti, M. Penicillium expansum Link strain for a biometallurgical method to recover REEs from WEEE. Waste Manag. 2017, 60, 596–600. [Google Scholar] [CrossRef]

- Emil-Kaya, E.; Stopic, S.; Gürmen, S.; Friedrich, B. Production of rare earth element oxide powders by solution combustion: A new approach for recycling of NdFeB magnets. RSC Adv. 2022, 12, 31478–31488. [Google Scholar] [CrossRef]

- Chung, H.; Prasakti, L.; Stopic, S.R.; Feldhaus, D.; Cvetković, V.S.; Friedrich, B. Recovery of Rare Earth Elements from Spent NdFeB Magnets: Metal Extraction by Molten Salt Electrolysis (Third Part). Metals 2023, 13, 559. [Google Scholar] [CrossRef]

- Orefice, M.; Eldosouky, A.; Škulj, I.; Binnemans, K. Removal of metallic coatings from rare-earth permanent magnets by solutions of bromine in organic solvents. RSC Adv. 2019, 9, 14910–14915. [Google Scholar] [CrossRef] [Green Version]

- Meakin, J. Targeted Hydrogen Decrepitation of Ndfeb Magnets from Large Commercial Assemblies. Master’s Thesis, School of Metallurgy and Materials, University of Birmingham, Birmingham, UK, 2013. [Google Scholar]

- Fidler, J.; Schrefl, T.; Hoefinger, S.; Hajduga, M. Recent developments in hard magnetic bulk materials. J. Phys. Condens. Matter 2004, 16, S455–S470. [Google Scholar] [CrossRef] [Green Version]

- Method for Producing Sintered Ndfeb Magnet. European Patent EP2071597B1, 23 July 2007.

- Corfield, M.R.; Harris, I.R.; Williams, A.J. Influence of oxygen content on grain growth in Pr–Fe–B/Nd–Fe–B sintered magnets. J. Alloys Compd. 2008, 463, 180–188. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, F.; Su, Z.; Liu, S.; Anderson, C.; Jiang, T. Hydrometallurgical Recovery of Rare Earth Elements from NdFeB Permanent Magnet Scrap: A Review. Metals 2020, 10, 841. [Google Scholar] [CrossRef]

- Li, D.; Horikawa, T.; Liu, J.; Itoh, M.; Machida, K.-I. Electromagnetic wave absorption properties of iron/rare earth oxide composites dispersed by amorphous carbon powder. J. Alloys Compd. 2006, 408–412, 1429–1433. [Google Scholar] [CrossRef]

- Nlebedim, I.; Ucar, H.; Hatter, C.B.; McCallum, R.; McCall, S.K.; Kramer, M.; Paranthaman, M.P. Studies on in situ magnetic alignment of bonded anisotropic Nd-Fe-B alloy powders. J. Magn. Magn. Mater. 2017, 422, 168–173. [Google Scholar] [CrossRef] [Green Version]

| Type of Impact Mill Operation | Oxygen Content wt.% |

|---|---|

| Operation in a glove box (Argon) | 1.59 |

| Operation in Vacuum Impact Mill | 0.375 |

| Elements | Composition % |

|---|---|

| Fe | 63.394 |

| Nd | 28.514 |

| Ni | 5.653 |

| V | 1.053 |

| La | 0.987 |

| Cu | 0.182 |

| Ca | 0.087 |

| Nb | 0.057 |

| Zr | 0.039 |

| Os | 0.020 |

| Mo | 0.013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pošković, E.; Franchini, F.; Ceroni, M.; Innocenti, C.; Ferraris, L.; Sangregorio, C.; Caneschi, A.; Actis Grande, M. Study of an Impact Mill-Based Mechanical Method for NdFeB Magnet Recycling. Metals 2023, 13, 1103. https://doi.org/10.3390/met13061103

Pošković E, Franchini F, Ceroni M, Innocenti C, Ferraris L, Sangregorio C, Caneschi A, Actis Grande M. Study of an Impact Mill-Based Mechanical Method for NdFeB Magnet Recycling. Metals. 2023; 13(6):1103. https://doi.org/10.3390/met13061103

Chicago/Turabian StylePošković, Emir, Fausto Franchini, Marta Ceroni, Claudia Innocenti, Luca Ferraris, Claudio Sangregorio, Andrea Caneschi, and Marco Actis Grande. 2023. "Study of an Impact Mill-Based Mechanical Method for NdFeB Magnet Recycling" Metals 13, no. 6: 1103. https://doi.org/10.3390/met13061103

APA StylePošković, E., Franchini, F., Ceroni, M., Innocenti, C., Ferraris, L., Sangregorio, C., Caneschi, A., & Actis Grande, M. (2023). Study of an Impact Mill-Based Mechanical Method for NdFeB Magnet Recycling. Metals, 13(6), 1103. https://doi.org/10.3390/met13061103