Creep Deformation Behavior, Microstructure Evolution, and Damage Mechanism of Super304H ODS Steel

Abstract

:1. Introduction

2. Experimental

2.1. Material Preparation

2.2. Creep Tests

2.3. Microstructure Observation and Analysis

3. Results and Discussion

3.1. Initial Microstructure of the As-HIPed Sample before Creep

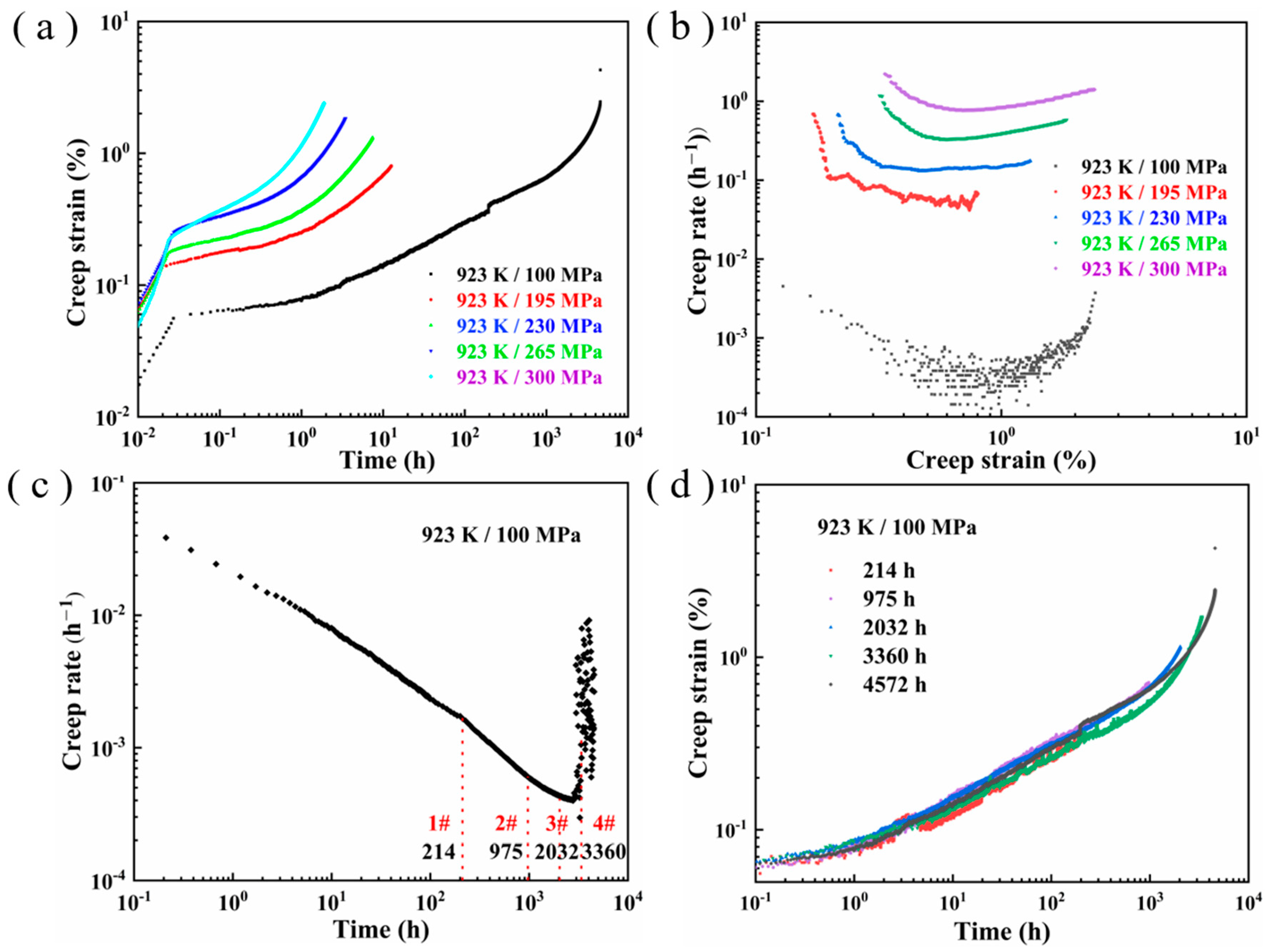

3.2. Creep Behavior

3.3. Microstructure and Microhardness Evolution during Creep

3.3.1. Evolution of Precipitates

3.3.2. Evolution of Grain Structure

3.3.3. Evolution of Microhardness

3.4. Creep Damage and Fracture Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chi, C.-y.; Yu, H.-y.; Dong, J.-x.; Liu, W.-q.; Cheng, S.-c.; Liu, Z.-d.; Xie, X.-s. The precipitation strengthening behavior of Cu-rich phase in Nb contained advanced Fe–Cr–Ni type austenitic heat resistant steel for USC power plant application. Prog. Nat. Sci. Mater. Int. 2012, 22, 175–185. [Google Scholar] [CrossRef] [Green Version]

- Vinoth Kumar, M.; Balasubramanian, V.; Gourav Rao, A. Hot tensile properties and strain hardening behaviour of Super 304HCu stainless steel. J. Mater. Res. Technol. 2017, 6, 116–122. [Google Scholar] [CrossRef] [Green Version]

- Bai, J.W.; Liu, P.P.; Zhu, Y.M.; Li, X.M.; Chi, C.Y.; Yu, H.Y.; Xie, X.S.; Zhan, Q. Coherent precipitation of copper in Super304H austenite steel. Mater. Sci. Eng. A 2013, 584, 57–62. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, J.; Gao, Y. An insight into oversaturated deformation-induced sigma precipitation in Super304H austenitic stainless steel. Mater. Des. 2019, 181, 108056. [Google Scholar] [CrossRef]

- Song, G.D.; Hwang, J.H.; Kim, D.-W.; Park, B.C.; Hahn, J.; Hong, S.-G. Coexistence of two distinct fatigue failure mechanisms in Super304H welded joint at elevated temperatures. Mater. Sci. Eng. A 2021, 819, 141465. [Google Scholar] [CrossRef]

- Huang, X.; Zhou, Q.; Wang, W.; Sheng Li, W.; Gao, Y. Microstructure and property evolutions of a novel Super304H steel during high temperature creeping. Mater. High Temp. 2017, 35, 438–450. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, L. Strengthening mechanisms of precipitates in S30432 heat-resistant steel during short-term aging. Mater. Sci. Eng. A 2012, 539, 170–176. [Google Scholar] [CrossRef]

- Ou, P.; Li, Z. Ordering of Primary Carbonitrides in an Austenitic Steel Revealed by Transmission Electron Microscopy and Atom Probe Tomography. Materials 2018, 11, 2321. [Google Scholar] [CrossRef] [Green Version]

- Zieliński, A.; Golański, G.; Sroka, M.; Dobrzański, J. Estimation of long-term creep strength in austenitic power plant steels. Mater. Sci. Technol. 2016, 32, 780–785. [Google Scholar] [CrossRef]

- Hwang, J.H.; Song, G.D.; Kim, D.-W.; Huh, Y.-H.; Park, B.C.; Hahn, J.; Hong, S.-G. Tensile and fatigue properties of Super304H welded joint at elevated temperatures. Int. J. Fatigue 2021, 143, 105989. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Chen, D.; Sun, J. Precipitate evolution during the aging of Super304H steel and its influence on impact toughness. Mater. Sci. Eng. A 2019, 754, 238–245. [Google Scholar] [CrossRef]

- Miao, Y.; Mo, K.; Zhou, Z.; Liu, X.; Lan, K.-C.; Zhang, G.; Miller, M.K.; Powers, K.A.; Almer, J.; Stubbins, J.F. In situ synchrotron tensile investigations on the phase responses within an oxide dispersion-strengthened (ODS) 304 steel. Mater. Sci. Eng. A 2015, 625, 146–152. [Google Scholar] [CrossRef] [Green Version]

- Oka, H.; Watanabe, M.; Hashimoto, N.; Ohnuki, S.; Yamashita, S.; Ohtsuka, S. Morphology of oxide particles in ODS austenitic stainless steel. J. Nucl. Mater. 2013, 442, S164–S168. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Z.; Sun, H.; Hu, H.; Li, S. Effects of plastic deformations on microstructure and mechanical properties of ODS-310 austenitic steel. J. Nucl. Mater. 2012, 430, 259–263. [Google Scholar] [CrossRef]

- Leo, J.R.O.; Pirfo Barroso, S.; Fitzpatrick, M.E.; Wang, M.; Zhou, Z. Microstructure, tensile and creep properties of an austenitic ODS 316L steel. Mater. Sci. Eng. A 2019, 749, 158–165. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, L.; Liu, Y.; Huang, Y.; Ma, Z.; Li, H.; Wu, J. Microstructure and tensile properties of a 14Cr ODS ferritic steel. Mater. Sci. Eng. A 2017, 680, 347–350. [Google Scholar] [CrossRef]

- Peng, Y.; Yu, L.; Liu, Y.; Ma, Z.; Li, H.; Liu, C.; Wu, J. Microstructures and tensile properties of an austenitic ODS heat resistance steel. Mater. Sci. Eng. A 2019, 767, 138419. [Google Scholar] [CrossRef]

- Hu, Z.-F.; Zhang, Z. Investigation the effect of precipitating characteristics on the creep behavior of HR3C austenitic steel at 650 °C. Mater. Sci. Eng. A 2019, 742, 451–463. [Google Scholar] [CrossRef]

- He, H.; Zhang, J.; Yu, L.; Gao, Q.; Liu, C.; Ma, Z.; Li, H.; Liu, Y.; Wang, H. Effects of Cu-rich phases on microstructure evolution and creep deformation behavior of a novel martensitic heat-resistant steel G115. Mater. Sci. Eng. A 2022, 855, 143937. [Google Scholar] [CrossRef]

- Ren, J.; Yu, L.; Liu, C.; Ma, Z.; Li, H.; Wang, Z.; Liu, Y.; Wang, H. Creep properties, microstructural evolution, and fracture mechanism of an Al added high Cr ODS steel during creep deformation at 600 °C. J. Nucl. Mater. 2022, 558, 153376. [Google Scholar] [CrossRef]

- Koncz, P.; Horváth, Á.; Balázsi, K.; Şahin, F.Ç.; Göller, G.; Onüralp, Y.; Balázsi, C. Correlation between Milling Parameters, Structural and Mechanical Properties of Nanostructured Austenitic Y2O3 Strengthened Steels. Mater. Sci. Forum 2012, 729, 409–414. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Z.; Sun, H.; Hu, H.; Li, S. Microstructural observation and tensile properties of ODS-304 austenitic steel. Mater. Sci. Eng. A 2013, 559, 287–292. [Google Scholar] [CrossRef]

- Neumeier, S.; Pyczak, F.; Göken, M. The temperature dependent lattice misfit of rhenium and ruthenium containing nickel-base superalloys—Experiment and modelling. Mater. Des. 2021, 198, 109362. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Y.; Wei, Q.; Dangelewicz, A.; Xu, C.; Zhu, Y.; Langdon, T.; Zhou, Y.; Lavernia, E. Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr. Mater. 2008, 59, 627–630. [Google Scholar] [CrossRef]

- Kiener, D.; Grosinger, W.; Dehm, G.; Pippan, R. A further step towards an understanding of size-dependent crystal plasticity: In situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 2008, 56, 580–592. [Google Scholar] [CrossRef]

- Latha, S.; Mathew, M.D.; Parameswaran, P.; Bhanu Sankara Rao, K.; Mannan, S.L. Thermal creep properties of alloy D9 stainless steel and 316 stainless steel fuel clad tubes. Int. J. Press. Vessel. Pip. 2008, 85, 866–870. [Google Scholar] [CrossRef]

- Ukai, S.; Mizuta, S.; Fujiwara, M.; Okuda, T.; Kobayashi, T. Development of 9Cr-ODS Martensitic Steel Claddings for Fuel Pins by means of Ferrite to Austenite Phase Transformation. J. Nucl. Sci. Technol. 2002, 39, 778–788. [Google Scholar] [CrossRef]

- Arzt, E.; Wilkinson, D.S. Threshold stresses for dislocation climb over hard particles: The effect of an attractive interaction. Acta Metall. Sin. 1986, 34, 1893–1898. [Google Scholar] [CrossRef] [Green Version]

- Praveen, C.; Christopher, J.; Ganesan, V.; Reddy, G.V.P.; Sasikala, G.; Albert, S.K. Constitutive modelling of transient and steady state creep behaviour of type 316LN austenitic stainless steel. Mech. Mater. 2019, 137, 103122. [Google Scholar] [CrossRef]

- Sakthivel, T.; Selvi, S.P.; Laha, K. An assessment of creep deformation and rupture behaviour of 9Cr–1.8W–0.5Mo–VNb (ASME grade 92) steel. Mater. Sci. Eng. A 2015, 640, 61–71. [Google Scholar] [CrossRef]

- Prat, O.; Garcia, J.; Rojas, D.; Carrasco, C.; Kaysser-Pyzalla, A.R. Investigations on coarsening of MX and M23C6 precipitates in 12% Cr creep resistant steels assisted by computational thermodynamics. Mater. Sci. Eng. A 2010, 527, 5976–5983. [Google Scholar] [CrossRef]

- Tamura, M.; Sakasegawa, H.; Kohyama, A.; Esaka, H.; Shinozuka, K. Effect of MX type particles on creep strength of ferritic steel. J. Nucl. Mater. 2003, 321, 288–293. [Google Scholar] [CrossRef]

- Godec, M.; Skobir Balantic, D.A. Coarsening behaviour of M23C6 carbides in creep-resistant steel exposed to high temperatures. Sci. Rep. 2016, 6, 29734. [Google Scholar] [CrossRef] [PubMed]

- Arzt, E. Creep of oxide-dispersion strengthened alloys. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1800–1806. [Google Scholar] [CrossRef]

- Dyson, M.F.A.B.F. Creep Damage Mechanics and Micromechanisms. In Proceedings of the 6th International Conference on Fracture, New Delhi, India, 4–10 December 1984; pp. 1–29. [Google Scholar] [CrossRef] [Green Version]

| Elements | Fe | Cr | Ni | Si | Mn | Cu | Nb | N | C | Y | O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Super304H | Bal. | 18.0 | 8.0 | 0.2 | 0.8 | 3.0 | 0.4 | 0.1 | 0.1 | -- | -- |

| Super304H ODS | Bal. | 18.4 | 8.6 | 0.57 | 0.64 | 3.06 | 0.34 | 0.108 | 0.106 | 0.416 | 0.233 |

| Stress (σ, MPa) | 100 | 195 | 230 | 265 | 300 |

|---|---|---|---|---|---|

| Creep strain (εf, %) | 4.29 | 0.80 | 1.31 | 1.85 | 2.40 |

| Creep rupture time (tr, h) | 4572.53 | 12.59 | 7.41 | 3.45 | 1.89 |

| m, h−1) | 4.48 10−4 | 0.0415 | 0.1297 | 0.3302 | 0.7677 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, W.; Zhang, Z.; Long, D.; Li, H.; Yu, L. Creep Deformation Behavior, Microstructure Evolution, and Damage Mechanism of Super304H ODS Steel. Metals 2023, 13, 1106. https://doi.org/10.3390/met13061106

Zhu W, Zhang Z, Long D, Li H, Yu L. Creep Deformation Behavior, Microstructure Evolution, and Damage Mechanism of Super304H ODS Steel. Metals. 2023; 13(6):1106. https://doi.org/10.3390/met13061106

Chicago/Turabian StyleZhu, Wan, Zeyue Zhang, Dijun Long, Huijun Li, and Liming Yu. 2023. "Creep Deformation Behavior, Microstructure Evolution, and Damage Mechanism of Super304H ODS Steel" Metals 13, no. 6: 1106. https://doi.org/10.3390/met13061106

APA StyleZhu, W., Zhang, Z., Long, D., Li, H., & Yu, L. (2023). Creep Deformation Behavior, Microstructure Evolution, and Damage Mechanism of Super304H ODS Steel. Metals, 13(6), 1106. https://doi.org/10.3390/met13061106