Understanding the Fatigue Notch Sensitivity of High-Strength Steels through Fracture Toughness

Abstract

:1. Introduction

2. Materials and Methods

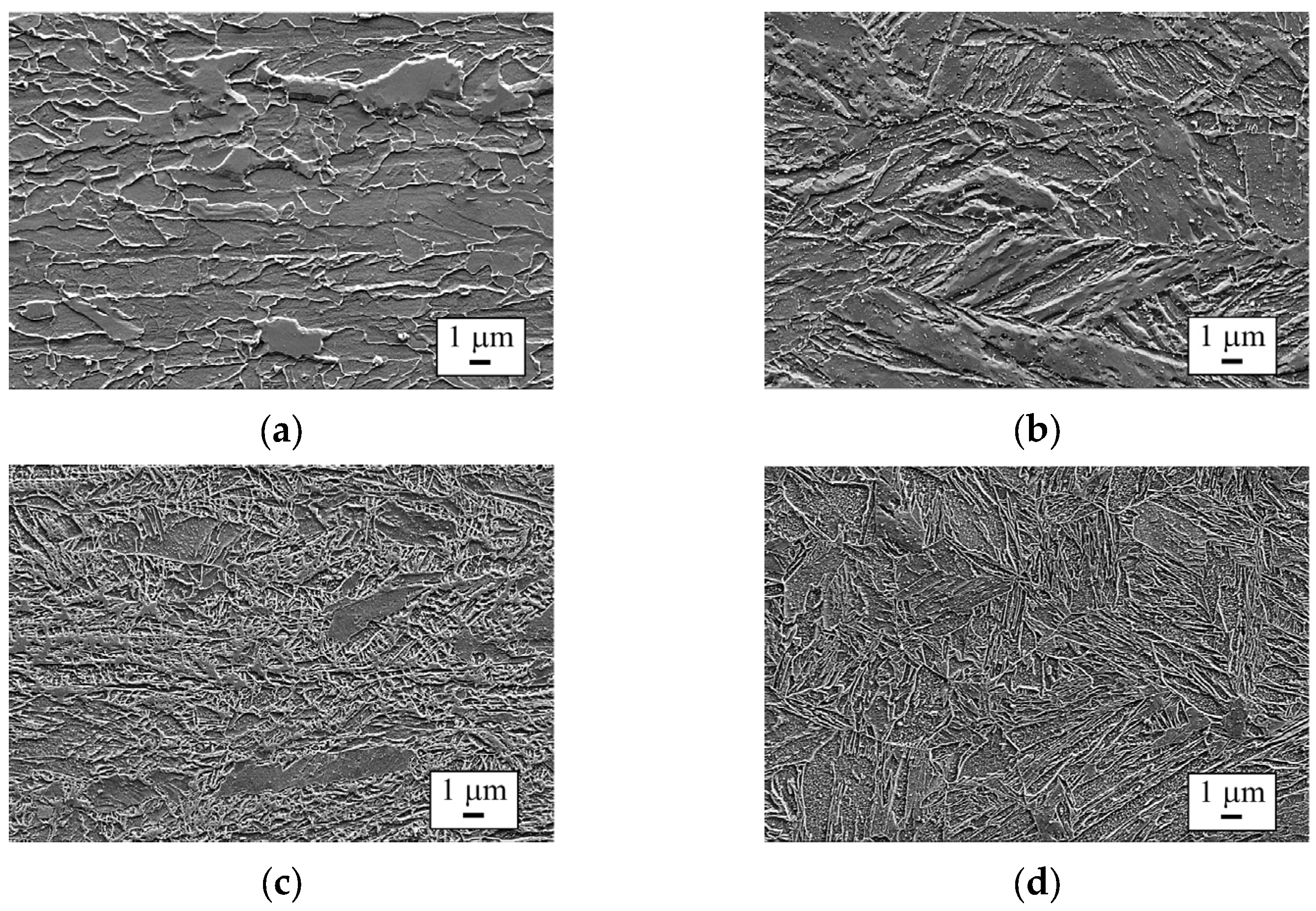

2.1. Materials

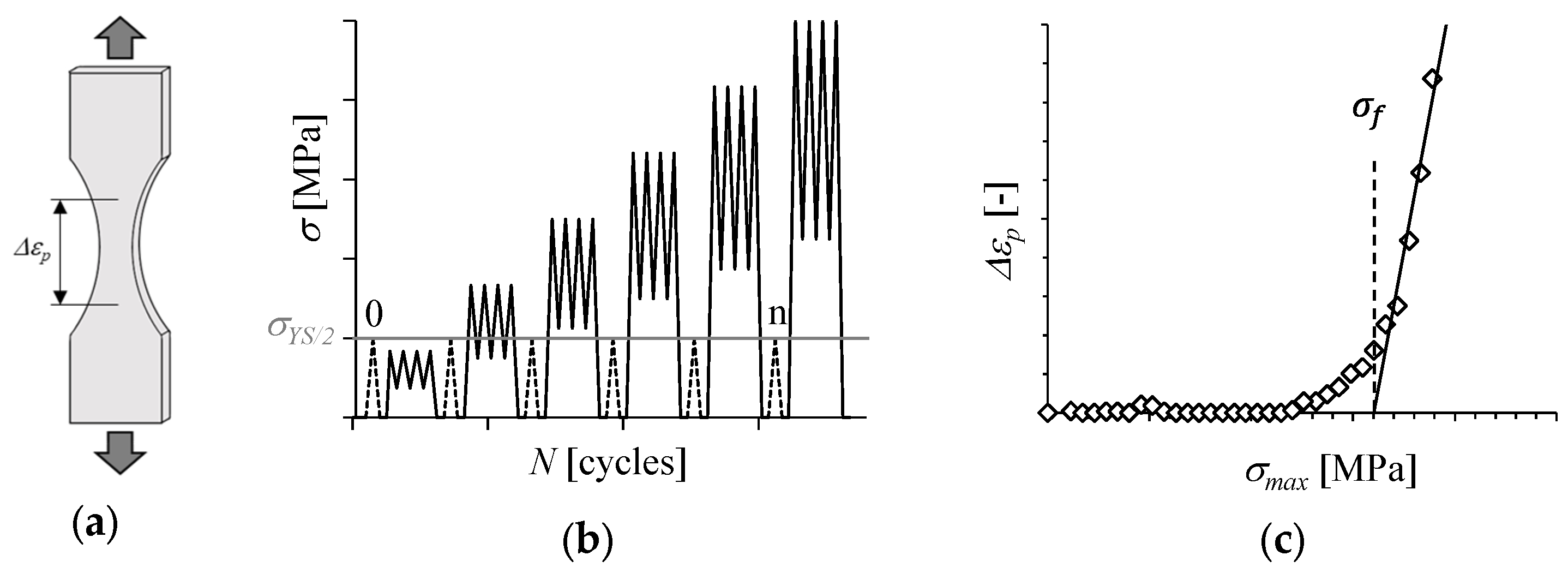

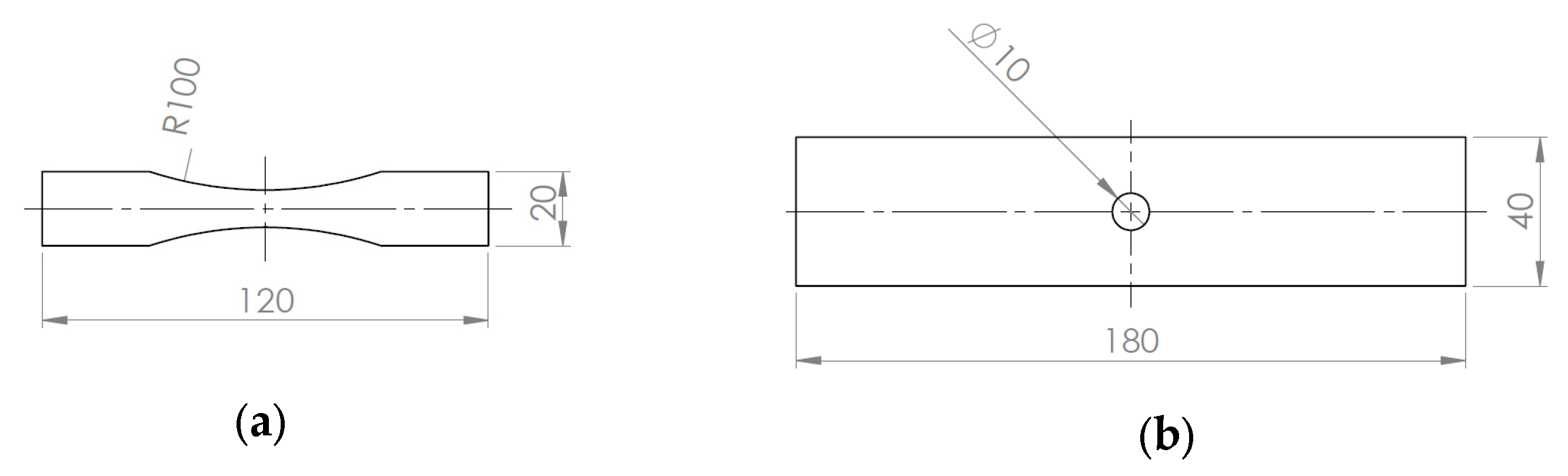

2.2. Fatigue Tests

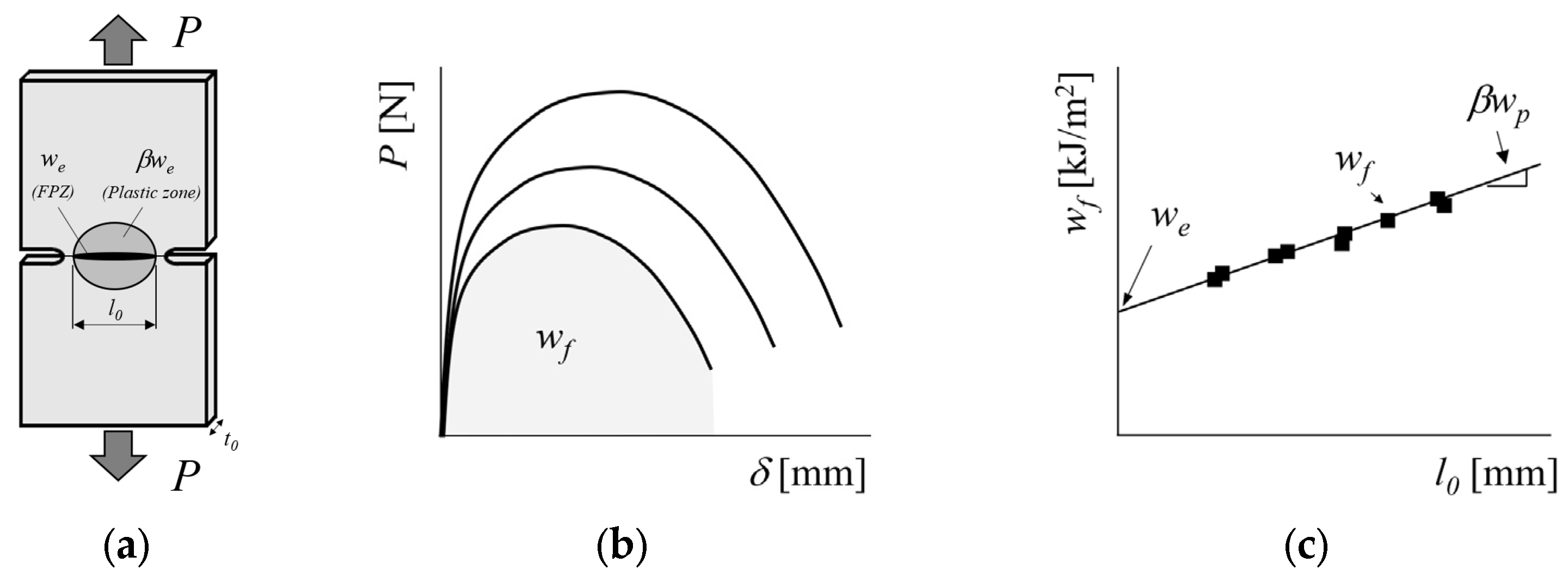

2.3. Fracture Toughness Tests

3. Results and Discussion

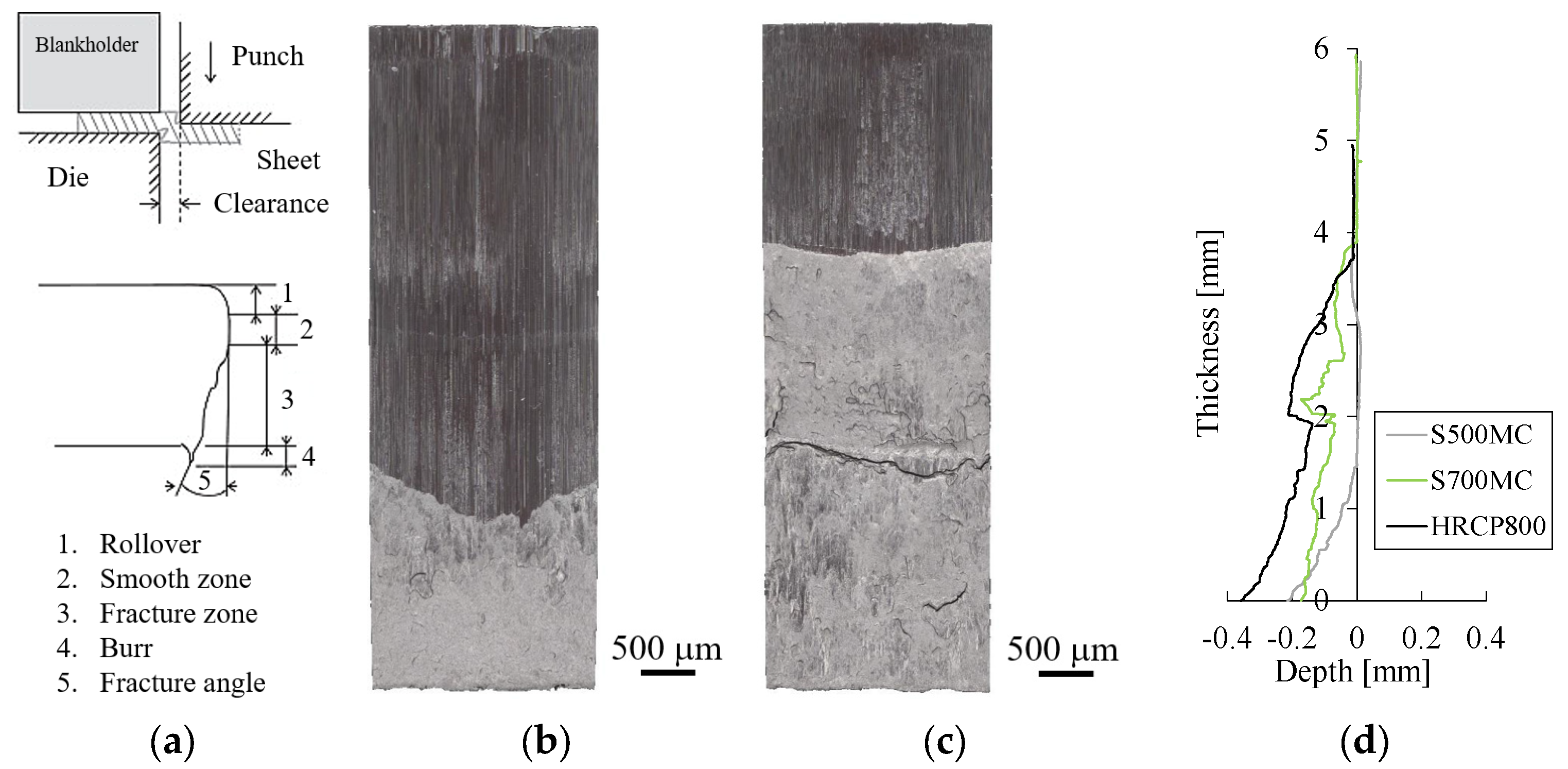

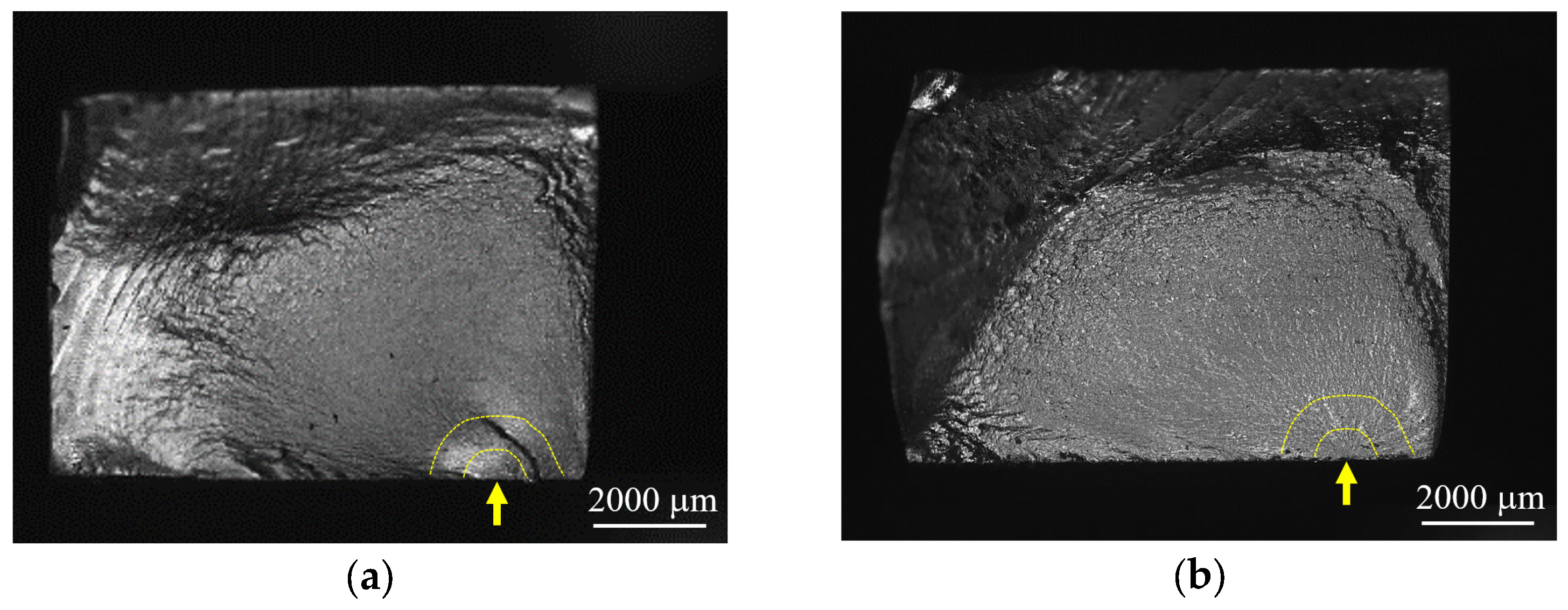

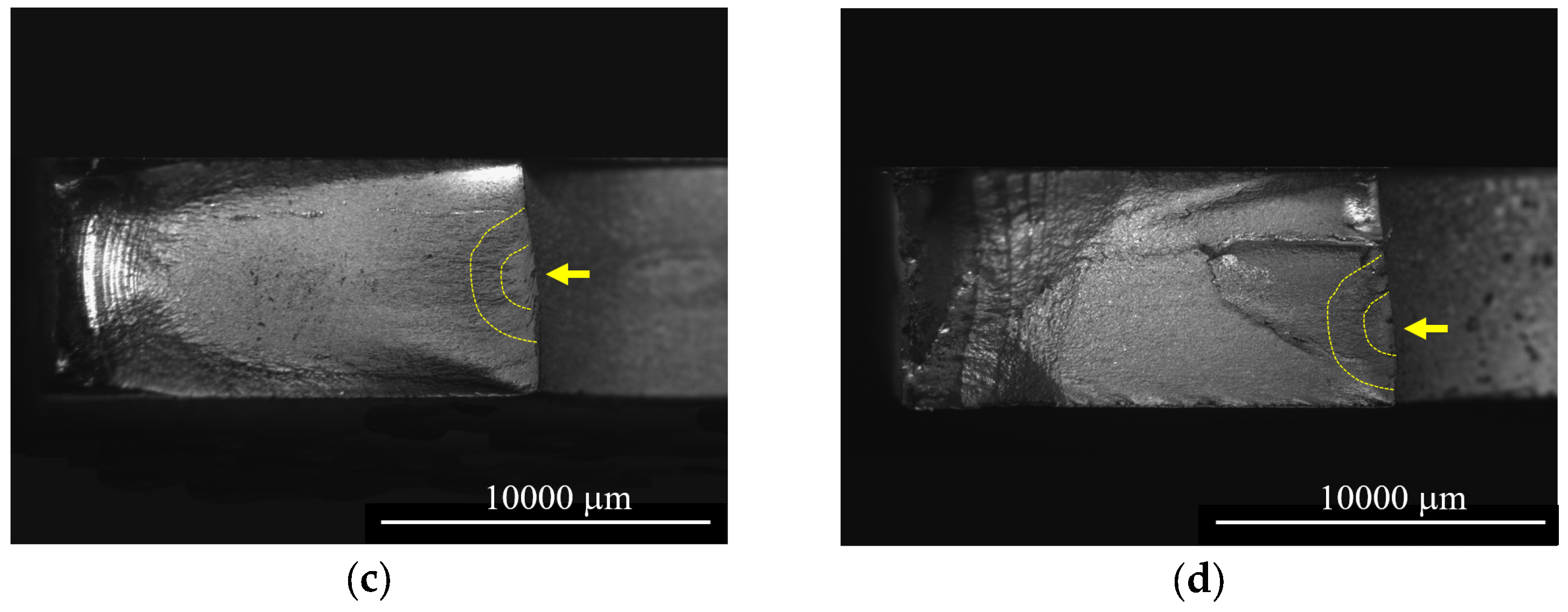

3.1. Influence of Sheared Edge Defects on Fatigue Resistance

| Steel Grade | Edge Condition | σf [MPa] | kf | we [kJ/m2] |

|---|---|---|---|---|

| MS300 | Polished | 113 ± 5 | 1.00 | 289 ± 12 |

| Trimmed, Cl = 10% | 113 ± 6 | |||

| S500MC | Polished | 265 ± 10 | 0.98 | 367 ± 67 |

| Punched, Cl = 6% | 260 ± 24 | |||

| WL750 | Polished | 371 ± 14 | 0.95 | 344 ± 49 |

| Punched, Cl = 10% | 353 ± 11 | |||

| HR800CP | Polished | 270 ± 23 | 0.94 | 302 ± 60 |

| Punched, Cl = 10% | 253 ± 19 | |||

| S700MC | Polished | 251 ± 22 | 0.67 | 191 ± 15 |

| Punched, Cl = 6% | 168 ± 12 | |||

| WL980 | Polished | 412 ± 16 | 0.92 | 241 ± 56 |

| Punched, Cl = 10% | 378 ± 2 | |||

| DP1000 | Polished | 317 ± 3 | 0.75 | 203 ± 17 |

| Trimmed, Cl = 6% | 239 ± 40 | |||

| WL1150 | Polished | 453 ± 22 | 0.87 | 192 ± 22 |

| Trimmed, Cl = 6% | 395 ± 12 | |||

| 22MnB5 | Polished | 343 ± 38 | 0.57 | 159 ± 11 |

| Trimmed, Cl = 6% | 197 ± 23 |

3.2. Damage-Tolerant Fatigue Design Approach

3.3. Relationship between Fracture Toughness and Fatigue Notch Sensitivity

3.4. Implications on the Design of Fatigue-Relevant Parts

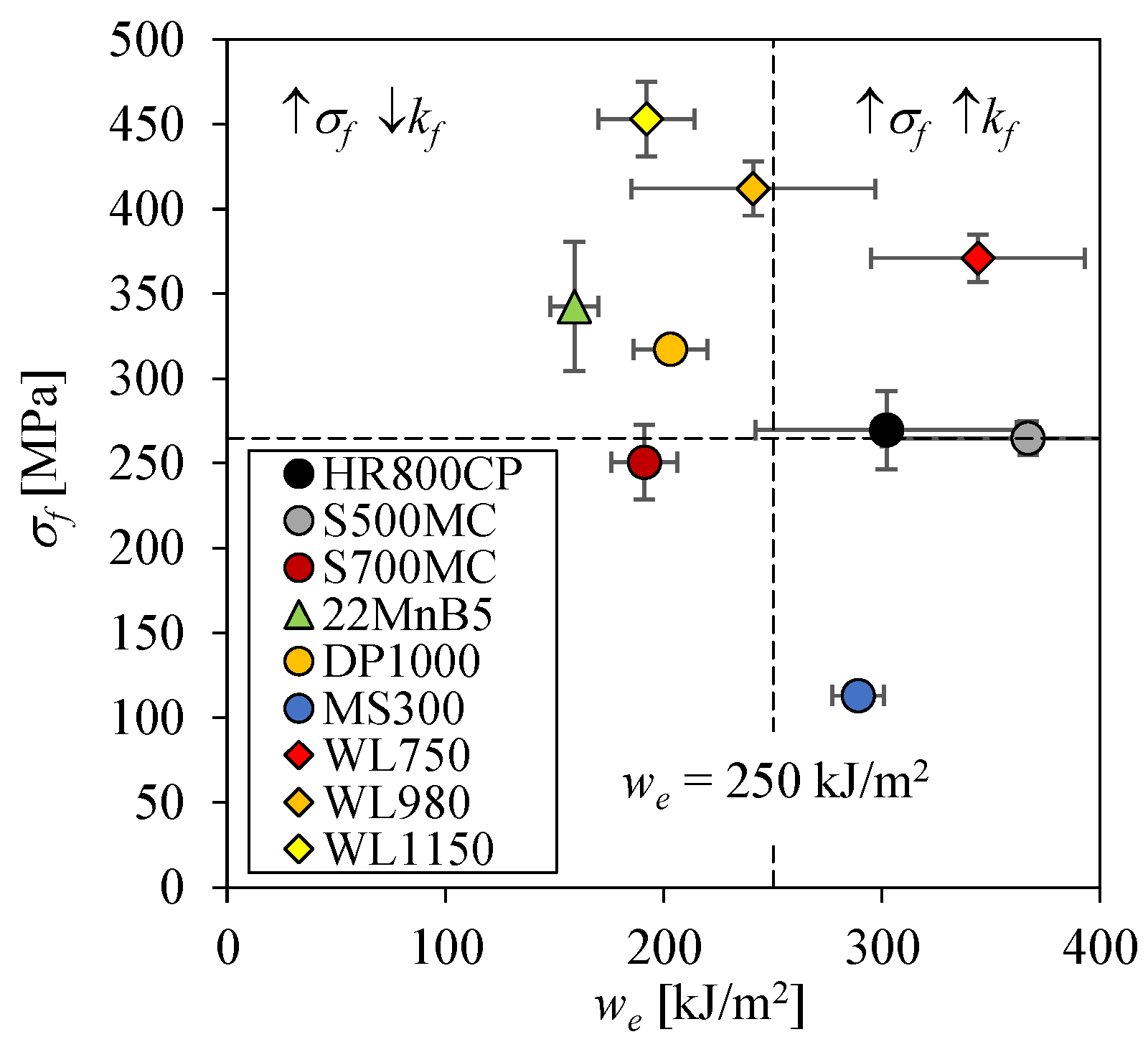

- DP1000 and S700MC have high fatigue limits but low toughness (<250 kJ/m2), resulting in low damage tolerance or high fatigue notch sensitivity;

- The 22MnB5 steel shows excellent formability in hot conditions and superior fatigue resistance, making it a good candidate for lightweighting. However, its high sensitivity to defects (low fracture toughness) indicates that special attention must be paid during component designing and manufacturing. Similar behaviour is found for WL1150;

- WL750, WL980, HR800CP, and S500MC exhibit high fatigue limits and low fatigue notch sensitivity, which postulate them as good candidates for chassis lightweighting strategies. In general, warm-formed steels (WL780, WL980, WL1150) show a good combination of high fatigue limit and fracture toughness. This optimised performance, together with the high formability of these steel grades at the manufacturing temperatures, even for thick sheets, poses them as excellent candidates for truck chassis parts.

4. Conclusions

- -

- The fatigue resistance of both edge-polished and sheared specimens can be measured in 3–4 h using the stiffness method;

- -

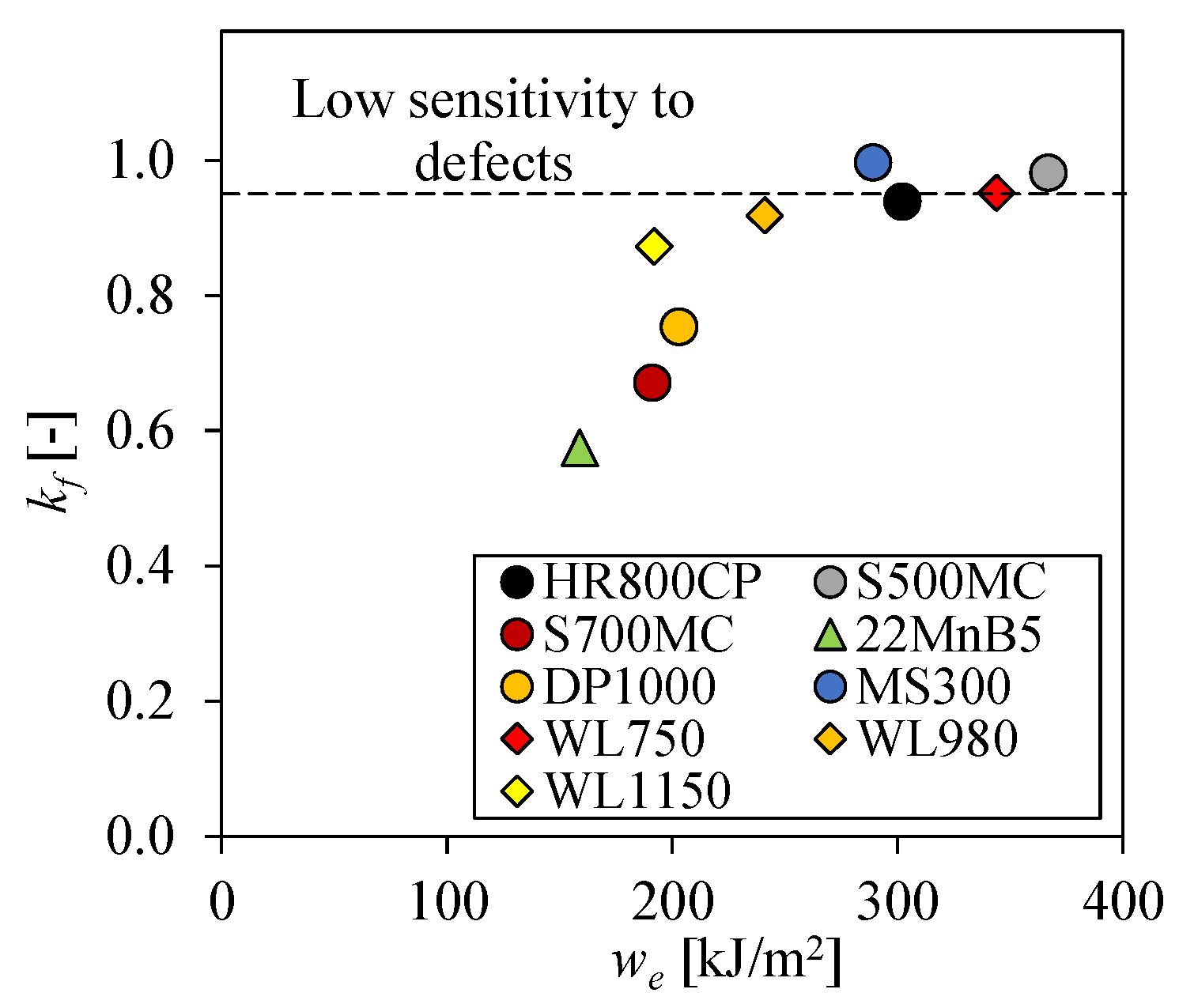

- The influence of the sheared edge quality on the fatigue resistance can be quantified by a fatigue strength reduction factor (kf). Such factor accounts for the fatigue notch sensitivity; low values of kf around 0.5 mean high fatigue notch sensitivity or low fatigue damage tolerance, meanwhile values of kf close to 1 indicate low fatigue notch sensitivity or high fatigue damage tolerance;

- -

- The kf factor correlates well with the fracture toughness, determined by the essential work of fracture methodology, reporting a correlation coefficient (r) value of 0.83. Accordingly, tough materials such as the WL750 (we = 344 ± 49 kJ/m2) show low fatigue notch sensitivity, while low-toughness materials such as the 22MnB5 (we = 159 ± 11 kJ/m2) have high fatigue notch sensitivity. A we of 250 kJ/m2 can be defined as a threshold for a low fatigue sensitivity to surface defects, for the studied materials;

- -

- Despite the moderate correlation between fatigue and fracture toughness parameters (r = −0.31), the plot permits ranking of the material candidates to be used for a lightweight fatigue design of chassis parts. Following such results, the warm-formed steels stand out as one of the best candidates, showing good fatigue resistance above the reference material and fracture toughness higher than the we threshold.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Decker, M. Vibration fatigue analysis using response spectra. Int. J. Fatigue 2021, 148, 106192. [Google Scholar] [CrossRef]

- Bellec, E.; Facchinetti, M.; Doudard, C.; Calloch, S.; Moyne, S.; Silvestri, M. Modelling and identification of fatigue load spectra: Application in the automotive industry. Int. J. Fatigue 2021, 149, 106222. [Google Scholar] [CrossRef]

- Sonsino, C. Consideration of salt-corrosion fatigue for lightweight design and proof of aluminium safety components in vehicle applications. Int. J. Fatigue 2021, 154, 106406. [Google Scholar] [CrossRef]

- Sonsino, C.; Breitenberger, M.; Krause, I.; Pötter, K.; Schröder, S.; Jürgens, K. Required Fatigue Strength (RFS) for evaluating of spectrum loaded components by the example of cast-aluminium passenger car wheels. Int. J. Fatigue 2020, 145, 105975. [Google Scholar] [CrossRef]

- Stellmach, S.; Braun, L.; Wächter, M.; Esderts, A.; Diekhaus, S. On load assumptions for self-propelled forage harvesters. Int. J. Fatigue 2021, 147, 106114. [Google Scholar] [CrossRef]

- De Almeida, D.T.; Bianchi, K.E.; de Souza, J.H.C.; de Lima, M.S.F.; Clarke, T.G.R.; da Silva, F.P.; Mohrbacher, H. Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels. Metals 2022, 12, 580. [Google Scholar] [CrossRef]

- Cecchel, S. Materials and Technologies for Lightweighting of Structural Parts for Automotive Applications: A Review. SAE Int. J. Mater. Manuf. 2020, 14, 81–98. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Hattalli, V.L.; Srivatsa, S.R. Sheet Metal Forming Processes—Recent Technological Advances. Mater. Today Proc. 2018, 5, 2564–2574. [Google Scholar] [CrossRef]

- Diaz-Infante, D.; Narayanan, A.; Groseclose, A.; Altan, T. FE Simulations of Piercing and Trimming of AL and AHSS Alloys; Springer: Berlin/Heidelberg, Germany, 2021; pp. 2925–2938. [Google Scholar] [CrossRef]

- Nothhaft, K.; Suh, J.; Golle, M.; Picas, I.; Casellas, D.; Volk, W. Shear cutting of press hardened steel: Influence of punch chamfer on process forces, tool stresses and sheared edge qualities. Prod. Eng. 2012, 6, 413–420. [Google Scholar] [CrossRef]

- Senn, S.; Liewald, M. Experimental investigation of piercing of high-strength steels within a critical range of slant angle. J. Physics Conf. Ser. 2017, 896, 12099. [Google Scholar] [CrossRef] [Green Version]

- Sandin, O.; Hammarberg, S.; Parareda, S.; Frómeta, D.; Casellas, D.; Jonsén, P. Prediction of sheared edge characteristics of advanced high strength steel. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1238, 012034. [Google Scholar] [CrossRef]

- Frómeta, D.; Lara, A.; Grifé, L.; Dieudonné, T.; Dietsch, P.; Rehrl, J.; Suppan, C.; Casellas, D.; Calvo, J. Fracture Resistance of Advanced High-Strength Steel Sheets for Automotive Applications. Met. Mater. Trans. A 2021, 52, 840–856. [Google Scholar] [CrossRef]

- Casellas, D.; Lara, A.; Frómeta, D.; Gutiérrez, D.; Molas, S.; Pérez, L.; Rehrl, J.; Suppan, C. Fracture Toughness to Understand Stretch-Flangeability and Edge Cracking Resistance in AHSS. Met. Mater. Trans. A 2016, 48, 86–94. [Google Scholar] [CrossRef]

- Lipiäinen, K.; Kaijalainen, A.; Ahola, A.; Björk, T. Fatigue strength assessment of cut edges considering material strength and cutting quality. Int. J. Fatigue 2021, 149, 106263. [Google Scholar] [CrossRef]

- Thomas, D.J. A Review of Fatigue Failure Properties from Edge Defects. J. Fail. Anal. Prev. 2017, 17, 802–811. [Google Scholar] [CrossRef]

- Meurling, F.; Melander, A.; Linder, J.; Larsson, M. The influence of mechanical and laser cutting on the fatigue strengths of carbon and stainless sheet steels. Scand. J. Met. 2001, 30, 309–319. [Google Scholar] [CrossRef]

- Thum, M.; Basavarajappa, V.; Haefele, P. Influence of edge cutting process on fatigue behaviour of spectrum loaded aluminum sheets. Int. J. Fatigue 2021, 150, 106330. [Google Scholar] [CrossRef]

- Zhang, K.; Hamada, S.; Yokoi, T.; Noguchi, H. Significant reduction of fatigue crack non-propagation limit caused by damage accumulation mode fatigue crack propagation in a precipitation-hardened punched steel plate. Mater. Sci. Eng. A 2023, 871, 144871. [Google Scholar] [CrossRef]

- Stahl, J.; Pätzold, I.; Golle, R.; Sunderkötter, C.; Sieurin, H.; Volk, W. Effect of One- and Two-Stage Shear Cutting on the Fatigue Strength of Truck Frame Parts. J. Manuf. Mater. Process. 2020, 4, 52. [Google Scholar] [CrossRef]

- Remes, H.; Korhonen, E.; Lehto, P.; Romanoff, J.; Niemelä, A.; Hiltunen, P.; Kontkanen, T. Influence of surface integrity on the fatigue strength of high-strength steels. J. Constr. Steel Res. 2013, 89, 21–29. [Google Scholar] [CrossRef]

- Lillemäe-Avi, I.; Liinalampi, S.; Lehtimäki, E.; Remes, H.; Lehto, P.; Romanoff, J.; Ehlers, S.; Niemelä, A. Fatigue strength of high-strength steel after shipyard production process of plasma cutting, grinding, and sandblasting. Weld. World 2018, 62, 1273–1284. [Google Scholar] [CrossRef] [Green Version]

- Jin, Z.; Mallick, P.K. Enhancement of Fatigue Life of Self-Piercing Riveted Joints by Coining. Manufacturing 2002, 2002, 417–429. [Google Scholar] [CrossRef]

- Diekhoff, P.; Hensel, J.; Nitschke-Pagel, T.; Dilger, K. Investigation on fatigue strength of cut edges produced by various cutting methods for high-strength steels. Weld. World 2020, 64, 545–561. [Google Scholar] [CrossRef] [Green Version]

- Lipiäinen, K.; Ahola, A.; Skriko, T.; Björk, T. Fatigue strength characterization of high and ultra-high-strength steel cut edges. Eng. Struct. 2020, 228, 111544. [Google Scholar] [CrossRef]

- Stenberg, T.; Lindgren, E.; Barsoum, Z.; Barmicho, I. Fatigue assessment of cut edges in high strength steel—Influence of surface quality. Mater. Werkst. 2017, 48, 556–569. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.-P.; Ye, W.-L.; Correia, J.A.; Jesus, A.M.; Wang, Q. Stress gradient effect in metal fatigue: Review and solutions. Theor. Appl. Fract. Mech. 2022, 121, 103513. [Google Scholar] [CrossRef]

- Liu, M.; Miranda, A.C.D.O.; Antunes, M.A.; Meggiolaro, M.A.; de Castro, J.T.P. Plastic stress concentration effects in fatigue strength. Int. J. Fatigue 2023, 168, 107394. [Google Scholar] [CrossRef]

- Pirinu, A.; Panella, F.W. A new approach for rapid fatigue limit assessment for C45 steel based on contrast damage parameters. Mech. Res. Commun. 2023, 127, 104039. [Google Scholar] [CrossRef]

- Foti, P.; Santonocito, D.; Ferro, P.; Risitano, G.; Berto, F. Determination of Fatigue Limit by Static Thermographic Method and Classic Thermographic Method on Notched Specimens. Procedia Struct. Integr. 2020, 26, 166–174. [Google Scholar] [CrossRef]

- De Finis, R.; Palumbo, D.; Pirinu, A.; Saponaro, A.; Panella, F.W.; Nobile, R.; Galietti, U. Fatigue behaviour assessment of C45 steel by means of energy-based methods. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1038, 012015. [Google Scholar] [CrossRef]

- Giudice, F.; La Rosa, G.; Savio, F.L.; Clienti, C. Comparison between thermal energy and acoustic emission for the fatigue behavior of steels. Procedia Struct. Integr. 2019, 18, 886–890. [Google Scholar] [CrossRef]

- Parareda, S.; Casellas, D.; Frómeta, D.; Martínez, M.; Lara, A.; Barrero, A.; Pujante, J. Fatigue resistance of press hardened 22MnB5 steels. Int. J. Fatigue 2019, 130, 105262. [Google Scholar] [CrossRef]

- Mughrabi, H. On ‘multi-stage’ fatigue life diagrams and the relevant life-controlling mechanisms in ultrahigh-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 755–764. [Google Scholar] [CrossRef]

- Bellec, E.; Doudard, C.; Facchinetti, M.; Calloch, S.; Moyne, S. Loading Classification Proposal for Fatigue Design of Automotive Chassis-Parts: A Relevant Process for Variable Amplitude and Multi-Input Load Cases. Int. J. Fatigue 2022, 166, 107284. [Google Scholar] [CrossRef]

- Dixon, W.J.; Mood, A.M. A Method for Obtaining and Analyzing Sensitivity Data. J. Am. Stat. Assoc. 1948, 43, 109–126. [Google Scholar] [CrossRef]

- Parareda, S.; Casellas, D.; Lara, A.; Mateo, A. Fatigue resistance evaluation of high Mn-TWIP steel through damage mechanics: A new method based on stiffness evolution. Int. J. Fatigue 2021, 156, 106643. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Sandin, O.; Jonsén, P.; Frómeta, D.; Casellas, D. Stating Failure Modelling Limitations of High Strength Sheets: Implications to Sheet Metal Forming. Materials 2021, 14, 7821. [Google Scholar] [CrossRef]

- Parareda, S.; Lara, A.; Sieurin, H.; D´armas, H.; Casellas, D. Increasing fatigue performance in AHSS thick sheet by surface treatments. MATEC Web Conf. 2018, 165, 22015. [Google Scholar] [CrossRef]

- Frómeta, D.; Parareda, S.; Lara, A.; Casellas, D.; Pujante, J.; Jonsén, P.; Golling, S.; Sieurin, H.; Oldenburg, M. Fracture toughness evaluation of thick press hardened 22MnB5 sheets for high crash performance applications in trucks. In Proceedings of the 7th International Conference on Hot Sheet Metal Forming of High Performance Steel (CHS2 2019), Luleå, Sweden, 2–5 June 2019. [Google Scholar]

- Frómeta, D.; Lara, A.; Molas, S.; Casellas, D.; Rehrl, J.; Suppan, C.; Larour, P.; Calvo, J. On the correlation between fracture toughness and crash resistance of advanced high strength steels. Eng. Fract. Mech. 2018, 205, 319–332. [Google Scholar] [CrossRef]

- Frómeta, D.; Parareda, S.; Lara, A.; Molas, S.; Casellas, D.; Jonsén, P.; Calvo, J. Identification of fracture toughness parameters to understand the fracture resistance of advanced high strength sheet steels. Eng. Fract. Mech. 2020, 229, 106949. [Google Scholar] [CrossRef]

- European Committee for Standardization. Test Method for Determination of the Essential Work of Fracture of Thin Ductile Metallic Sheets; CEN-CENELE: Brussels, Belgium, 2021. [Google Scholar]

- Tarhouni, I.; Frómeta, D.; Casellas, D. Essential work of fracture method for toughness evaluation of thick press hardened 22MnB5 plates. In Proceedings of the 8th International Conference on Hot Sheet Metal Forming of High Performance Steel (CHS2 2022), Wissenschaftliche Scripten, Barcelona, Spain, 30 May–2 June 2022. [Google Scholar]

- The Association of German Engineers. VDI 2906-2: Quality of Cut Faces of (Sheet) Metal Parts after Cutting, Blanking, Trimming or Piercing; General Introduction, Characteristic Values, Materials: Berlin, Germany, 1994. [Google Scholar]

- Lara, A.; Picas, I.; Casellas, D. Effect of the cutting process on the fatigue behaviour of press hardened and high strength dual phase steels. J. Mater. Process. Technol. 2013, 213, 1908–1919. [Google Scholar] [CrossRef]

- Murakami, Y. Material defects as the basis of fatigue design. Int. J. Fatigue 2012, 41, 2–10. [Google Scholar] [CrossRef]

- Schönbauer, B.M.; Mayer, H. Effect of small defects on the fatigue strength of martensitic stainless steels. Int. J. Fatigue 2019, 127, 362–375. [Google Scholar] [CrossRef]

- Davidson, D.; Chan, K.; McClung, R.; Hudak, S. Small Fatigue Cracks. Compr. Struct. Integr. 2003, 4, 129–164. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Tanaka, K. Fatigue Crack Propagation. Compr. Struct. Integr. 2003, 4, 95–127. [Google Scholar] [CrossRef]

- Yukitaka, M.; Masahiro, E. Quantitative evaluation of fatigue strength of metals containing various small defects or cracks. Eng. Fract. Mech. 1983, 17, 1–15. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Li, S.; Li, G.; Wang, Q.; Hui, W.; Weng, Y. On the critical inclusion size of high strength steels under ultra-high cycle fatigue. Mater. Sci. Eng. A 2006, 427, 167–174. [Google Scholar] [CrossRef]

- Dowling, N.; Begley, J. Fatigue Crack Growth During Gross Plasticity and the J-Integral. In Mechanics of Crack Growth; American Society for Testing and Materials: West Conshohocken, PA, USA, 1976; pp. 82–103. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Vormwald, M.; Beier, H. Fatigue strength and fracture mechanics—A general perspective. Eng. Fract. Mech. 2018, 198, 2–23. [Google Scholar] [CrossRef]

- Lesiuk, G.; Szata, M.; Rozumek, D.; Marciniak, Z.; Correia, J.; De Jesus, A. Energy response of S355 and 41Cr4 steel during fatigue crack growth process. J. Strain Anal. Eng. Des. 2018, 53, 663–675. [Google Scholar] [CrossRef]

- Ngoula, D.T.; Madia, M.; Beier, H.; Vormwald, M.; Zerbst, U. Cyclic J-integral: Numerical and analytical investigations for surface cracks in weldments. Eng. Fract. Mech. 2018, 198, 24–44. [Google Scholar] [CrossRef]

- Rice, J.R. A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef] [Green Version]

- Oh, G. A simplified toughness estimation method based on standard tensile data. Int. J. Press. Vessel. Pip. 2022, 199, 104733. [Google Scholar] [CrossRef]

- Görzen, D.; Ostermayer, P.; Lehner, P.; Blinn, B.; Eifler, D.; Beck, T. A New Approach to Estimate the Fatigue Limit of Steels Based on Conventional and Cyclic Indentation Testing. Metals 2022, 12, 1066. [Google Scholar] [CrossRef]

| Steel Grade | C | Si | Mn | Cr | Al |

|---|---|---|---|---|---|

| MS300 | 0.09 | 0.01 | 0.3 | 0.02 | 0.03 |

| S500MC | 0.16 | 0.5 | 1.2 | - | - |

| WL750 | 0.06 | - | 1.9 | - | - |

| HR800CP | 0.18 | 1.0 | 2.2 | - | - |

| S700MC | 0.12 | 0.5 | 1.6 | - | - |

| WL980 | 0.09 | - | 1.6 | ~1 | - |

| DP1000 | 0.17 | 0.48 | 1.56 | 0.05 | 0.05 |

| WL1150 | 0.18 | - | - | - | - |

| 22MnB5 | 0.25 | 0.29 | 1.23 | 0.2 | 0.04 |

| Steel Grade | t [mm] | σYS [MPa] | σUTS [MPa] | A80 [%] | Microstructure |

|---|---|---|---|---|---|

| MS300 | 1.5 | 217 | 299 | 28 | F matrix-P islands |

| S500MC | 6 | 641 | 651 | 27 | F matrix-P islands |

| WL750 | 7 | 806 | 807 | 17 | B |

| HR800CP | 5 | 819 | 881 | 18 | F/B matrix-M/A islands |

| S700MC | 6 | 825 | 935 | 19 | F-B |

| WL980 | 7 | 1051 | 1054 | 11 | Tempered M |

| DP1000 | 2 | 798 | 1059 | 6 | F-M |

| WL1150 | 7 | 1201 | 1203 | 9 | Tempered M |

| 22MnB5 | 1.8 | 1346 | 1543 | 6 | M |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parareda, S.; Frómeta, D.; Casellas, D.; Sieurin, H.; Mateo, A. Understanding the Fatigue Notch Sensitivity of High-Strength Steels through Fracture Toughness. Metals 2023, 13, 1117. https://doi.org/10.3390/met13061117

Parareda S, Frómeta D, Casellas D, Sieurin H, Mateo A. Understanding the Fatigue Notch Sensitivity of High-Strength Steels through Fracture Toughness. Metals. 2023; 13(6):1117. https://doi.org/10.3390/met13061117

Chicago/Turabian StyleParareda, Sergi, David Frómeta, Daniel Casellas, Henrik Sieurin, and Antonio Mateo. 2023. "Understanding the Fatigue Notch Sensitivity of High-Strength Steels through Fracture Toughness" Metals 13, no. 6: 1117. https://doi.org/10.3390/met13061117

APA StyleParareda, S., Frómeta, D., Casellas, D., Sieurin, H., & Mateo, A. (2023). Understanding the Fatigue Notch Sensitivity of High-Strength Steels through Fracture Toughness. Metals, 13(6), 1117. https://doi.org/10.3390/met13061117