Abstract

In this work, the technique of Direct Laser Interference Patterning (DLIP) was used to fabricate micrometric structures at the surface of Cobalt-Chromium-Molybdenum and AZ91D magnesium alloys. Line-like patterns with spatial periods of 5 μm were textured using an ultra-short pulsed laser (10 ps pulse duration and 1064 nm wavelength) with a two-beam interference setup. The surface topography, morphology, and chemical modifications were analysed using Confocal Microscopy, Scanning Electron Microscopy, and Energy Dispersive Spectroscopy (EDS), respectively. Laser fluence and pulse overlap were varied to evaluate their influence on the final structure. Homogeneous structures were achieved for the CoCrMo alloy for every condition tested, with deeper structures (up to 0.85 μm) being achieved for higher energy levels (higher overlap and/or fluence). For high energy, sub-micrometric secondary structures, so-called LIPSS, could also be observed on the CoCrMo. The EDS analysis showed some oxidation after the laser texturing. Regarding the AZ91D alloy, deeper structures could be achieved (up to 2.5 μm), but more melting and oxidation was observed, forming spherical oxide particles. Nonetheless, these results bring new perspectives on the fabrication of microtextures on the surface of CoCrMo and AZ91D using DLIP.

1. Introduction

Surface microstructure plays an important role in regulating the material behaviour on its environment, and it can be tailored to improve the performance of its application. Surface topology can influence the wettability, adhesive and frictional properties, cosmetic appearance, and susceptibility to wear and surface damage of materials, and, at the same time, maintain the desirable bulk properties of the material [1]. For instance, controlled surface roughness can improve bonding between two materials, creating an interlocking mechanical effect. Surface modifications can also introduce hydrophobic or hydrophilic characteristics to a surface [2]. In biomaterials, features with different size levels with controlled orientations can improve the interaction between implant and tissue, simulating a natural cellular environment [3].

Conventional techniques to introduce micro- and nanofeatures include acid etching, micromachining, grinding, and grit-blasting. Although widely used, these techniques present drawbacks that limit their use in advanced engineering applications. Acid etching, grinding, and grit-blasting only allow the fabrication of random structures with low dimensional control [4]. The fabrication of patterns smaller than 100 μm can be challenging using micromachining, as well as the processing of hard and brittle materials using this technique. For advanced engineering applications, controlling the size and orientation of the features are crucial. For example, studies have shown that random roughness on an implant’s surface can increase bacteria proliferation, while a controlled nanostructured surface can decrease bacteria adhesion and biofilm formation [5,6]. Texture direction can also guide cell growth [7]. Surface texturing can also influence the wear behaviour and the coefficient of friction when it is in contact with another material. Grooves fabricated on the surface can act as lubricant reservoirs and decrease friction. However, if the grooves are too large, the oil drains through them. Thus, the channels must be small enough to increase flow resistance and avoid displacement of the lubricant, forming a thin film over the entire contact surface [8]. In this context, a versatile approach to produce high-resolution features is laser-based microprocessing, where a laser beam with sufficient energy produces controlled and localised ablation on the surface. Laser techniques allow a fast and accurate fabrication of micro- and nanofeatures, inducing little or even no damage on the material surface. Ultra-short pulsed lasers (pico- and femtosecond lasers) have especially shown great potential to texture almost defect-free surfaces (no microcracking or resolidified layer) due to their ability to ablate very thin surface layers and significantly reduce heat-affected zones and melt generation [9].

Direct Laser Writing (DLW) has emerged as a powerful technique to introduce microfeatures on the material’s surface by precisely moving the laser beam to selectively ablate the material. However, in this technique, the feature resolution is limited by the laser beam diameter (spot sizes smaller than 5–10 μm are very difficult to obtain) [10]. On the other hand, the Direct Laser Interference Patterning (DLIP) technique takes advantage of the physical principle of light interference to produce features with spatial resolution similar to that of the laser wavelength. In this method, the laser is split into two or more beams, which are superposed on the material surface, creating an interference pattern. At the maxima regions, the high energy density causes ablation, while the material is not directly affected at the minima regions, resulting in periodic structures on the surface [11]. Overlapping two beams generates a line-like pattern whose dimensions are controlled by the angle between beams and the laser wavelength. The resulting patterning is also influenced by the laser fluence, pulse duration, number of pulses, pulse overlap (distance between subsequent pulses), and interaction between laser and material.

DLIP has been studied in several different materials, especially metals. However, research is still scarce regarding DLIP in CoCrMo and AZ91D magnesium alloys. The AZ91D alloy (9% aluminium and 1% zinc) is one of the most commonly used magnesium based-alloys due to its high strength, ductility, and corrosion resistance [12,13]. The addition of aluminium and zinc in the magnesium alloy results in intermetallic compounds (such as Mg17Al11.5Zn0.5 or Mg17(Al,Zn)12) responsible for substantially increasing the oxidation resistance [14]. The CoCrMo alloy also exhibits attractive properties, such as high mechanical strength, wear resistance, ductility, biocompatibility, and corrosion resistance due to the presence of Chromium, which forms a protective oxide layer over the material’s surface [15]. Molybdenum is also added to the alloy to improve its mechanical resistance due to a solid-solution hardening effect [16]. On the CoCr alloy, Schieber et al. showed that DLIP could potentially accelerate endothelium recovery and avoid surface thrombosis on cardiovascular bare-metal stents [17], but no work was found about DLIP in AZ91D. Thus, this work aimed at the texture of CoCrMo and AZ91D alloys’ surfaces using DLIP while assessing the influence of different parameters (fluence and distance between pulses) on the surface morphology.

2. Materials and Methods

2.1. Materials

Laser structuring experiments were carried out on polished CoCrMo alloy (composition: 63% Co, 24% Cr, 3% Mo, 8% W, 1% Si, and 1% Nb) disks with 10 mm diameter and 4 mm thickness, and on AZ91D alloy (composition: 90% Mg, 9% Al, 1% Zn) 3 mm thick plates. Prior to laser texturing, the samples were subjected to ultrasonic cleaning in isopropyl alcohol for 10 min and then rinsed in distilled water to remove contaminants.

2.2. Laser Structuring

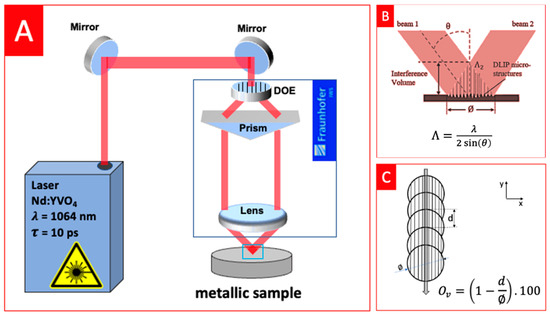

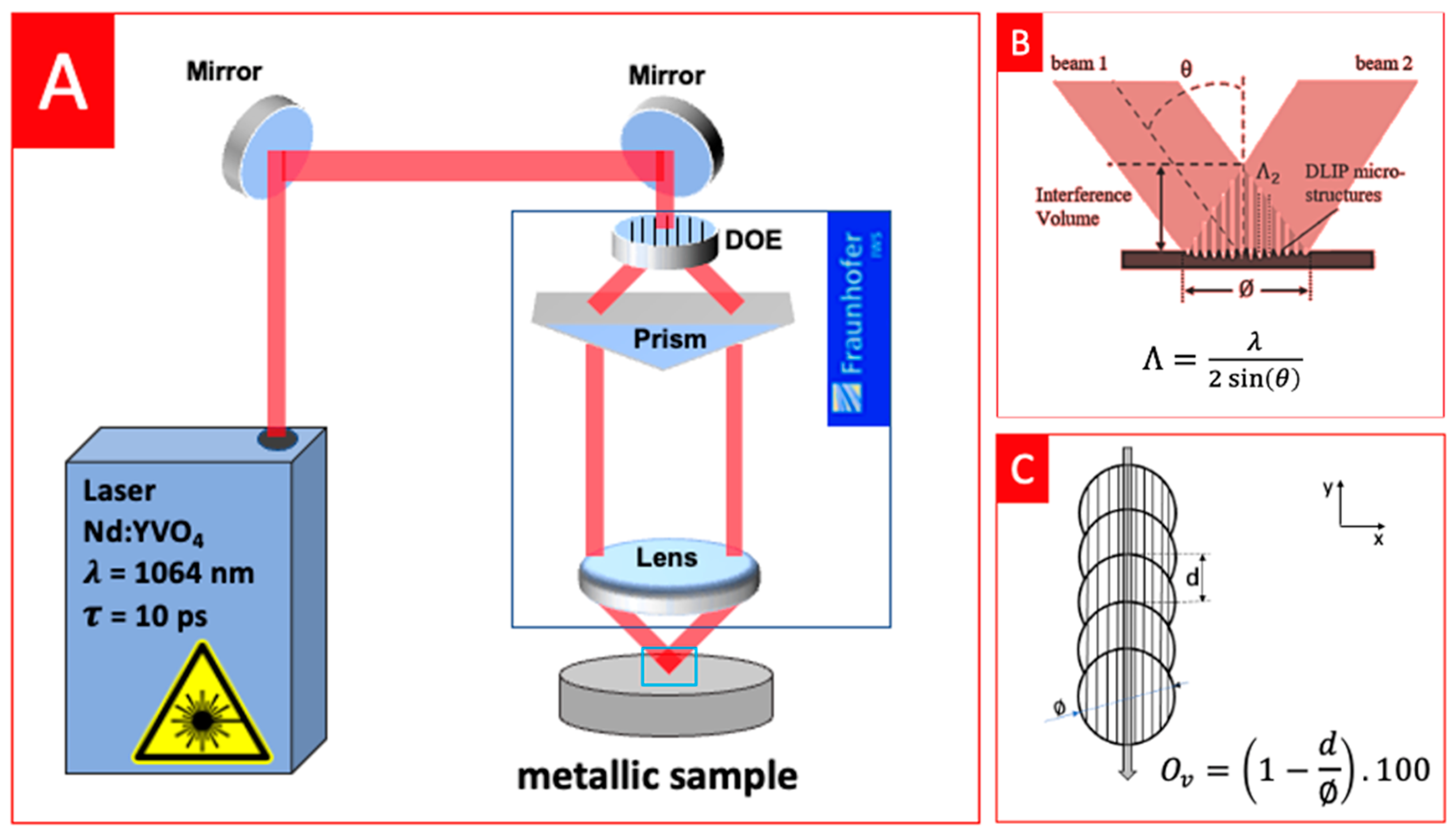

The structuring of the substrates was performed using Direct Laser Interference Patterning (DLIP) technology. The DLIP system (developed by TU Dresden and Fraunhofer IWS, Dresden, Germany) used was equipped with a 10 ps solid-state Nd:YVO4 laser (PX200, EdgeWave, Würselen, Germany) with a maximum output power of 10 W, working at a wavelength of 1064 nm, with a fixed repetition rate of 10 kHz and a Gaussian beam. The optical setup used a diffractive optical element (DOE) to split the main laser beam into two sub-beams with equal angles to the optical axis, which were parallelised using a prism and then focused and overlapped on the sample surface using a 60 mm focal length aspheric lens, as illustrated in Figure 1A, resulting in a spot size of ~116 µm in diameter ⌀. Using this configuration, a line-like interference profile was obtained, following the intensity distribution described by Equation (1):

where I0 is the intensity of the laser beam, λ is the laser wavelength, and α is half angle between the interfering beams, as shown in Figure 1B.

Using the optical setup described above, the two beams overlapped with a full angle 2θ of 24° on the sample’s surface, leading to the generation of an interference pattern with line-like geometry within the laser spot and a spatial period Λ = 5.0 µm. The relationship between periodicity Λ of the generated pattern and the angle between the laser sub-beams can be calculated according to the following Equation (2):

The interference pattern was directly transferred to the material surface through selective ablation at the maxima positions. The spatial period is defined as the distance between maxima regions, which translates to the distance between two subsequent grooves (Figure 1B). In order to texture full lines larger than the laser spot size, or even entire areas, the samples were translated in x- and y-directions using high-precision positioning axes (Aerotech PRO165-300, Pittsburgh, PA, USA) with an accuracy of ±2.5 μm [18]. In this work, long lines were textured by moving the sample in the y-direction each time a pulse was fired. The pulse-to-pulse overlap (Ov) was controlled by the distance between subsequent pulses, as shown in Figure 1C, and it translates to the number of pulses hitting the same area. For example, 98% overlap resulted in 50 pulses hitting the same spot. Different values of laser fluence (between 3.8 J/cm2 and 13.3 J/cm2 for the CoCrMo alloy and between 0.9 J/cm2 and 18.2 J/cm2 for the AZ91D alloy) and pulse-to-pulse overlap (between 85% and 98% for both materials) were tested to evaluate the changes in the surface structure. The laser experiments were performed in ambient environment and no post treatments were carried out.

Figure 1.

(A) DLIP system optical setup; (B) interference pattern created by the overlap of the sub-beams: ablation occurred mainly at the maxima regions, creating line-like patterns with period Λ; (C) line-like texturing strategy used on this work: overlap (Ov) ranged between 85% and 98%. Adapted from [19].

Figure 1.

(A) DLIP system optical setup; (B) interference pattern created by the overlap of the sub-beams: ablation occurred mainly at the maxima regions, creating line-like patterns with period Λ; (C) line-like texturing strategy used on this work: overlap (Ov) ranged between 85% and 98%. Adapted from [19].

2.3. Surface Analysis

Confocal Microscopy (S-Neox, Sensofar, Barcelona, Spain) employing 150× objective was used to analyse the surface topography, resulting in a vertical resolution of 2 nm and a lateral resolution of 140 nm. The acquired topographical data were processed using the software MountainsMap 7.4 (Digital Surf, Besançon, France), which calculated the average depth of the fabricated structures. The surface morphology of the specimens was also analysed using a Scanning Electron Microscope (JSM-6010 LV, JEOL, Tokyo, Japan) operating at an accelerating voltage of 5.0 kV with magnifications between 5000× and 20,000× and using Secondary Electrons. Furthermore, the chemical composition of the samples (before and after laser texturing) was analysed using Energy Dispersive Spectroscopy (EDS) accessory at an accelerating voltage of 15 kV. These analyses were performed approximately at the centre of the textured region.

3. Results and Discussion

3.1. CoCrMo Alloy

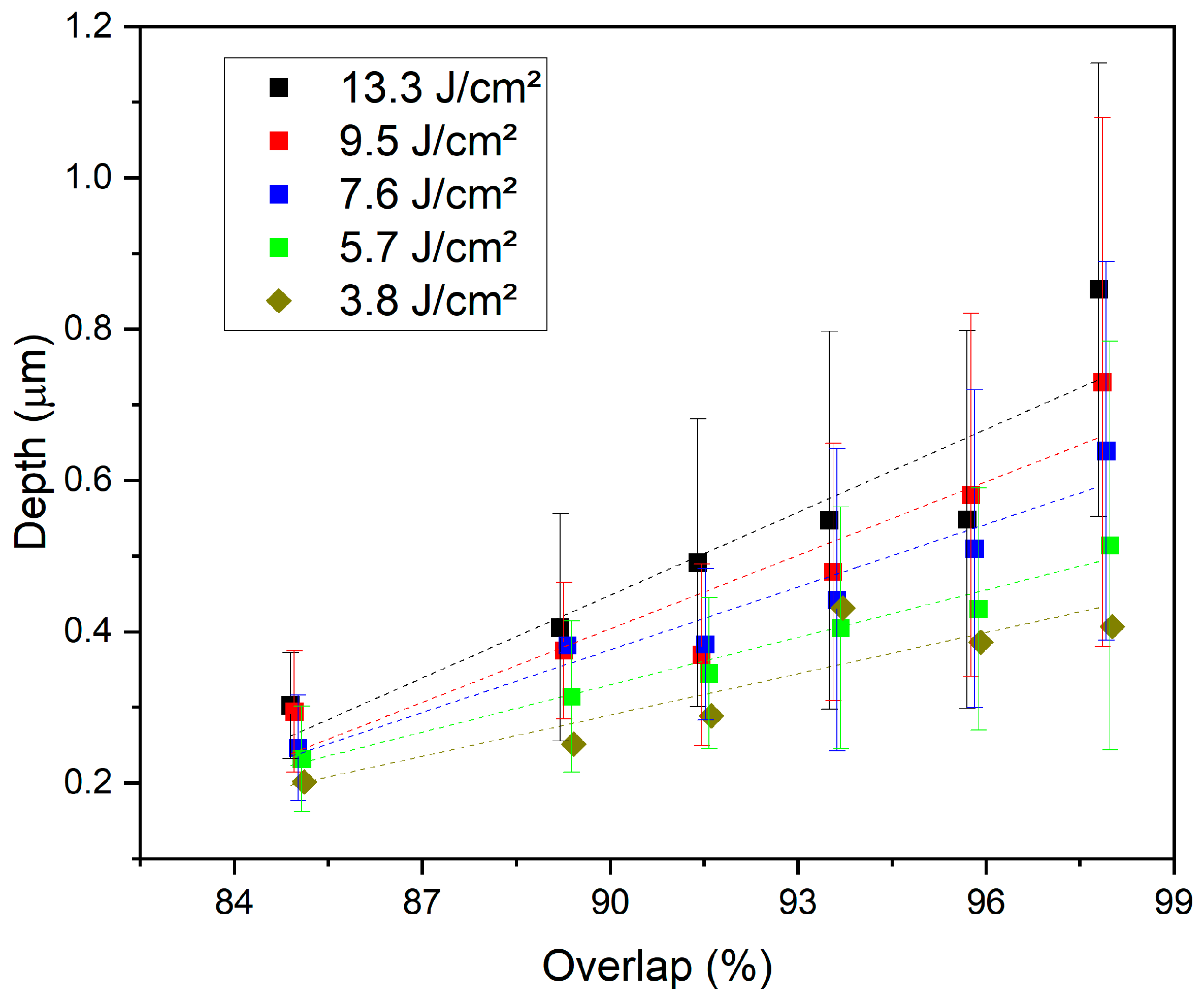

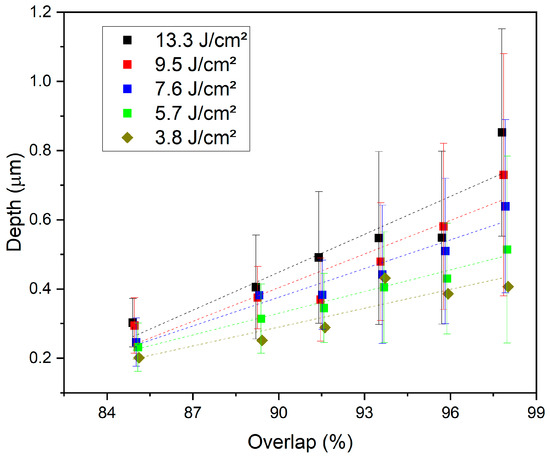

Line-like structures with period Λ = 5.0 µm with different laser parameters were successfully fabricated. The experiments were designed to evaluate the influence of the deposited energy on the average depth of the fabricated structures and on the surface morphology. For that, the influence of the laser fluence (energy density of a single pulse) and the pulse overlap (which relates to the number of pulses hitting the same spot) was analysed. The average depths of the structures obtained for the different values of fluence and pulse overlaps for the CoCrMo alloy are shown in Figure 2. As a general trend (represented on the graph by the dashed lines), increasing either the pulse fluence and/or the overlap leads to an increase in the depth of the features, which means that, for the tested conditions, if more energy is applied over the same area, deeper structures can be achieved. For example, at a fluence of 13.3 J/cm2, the average depth increases from 0.30 μm for an overlap of 85% to 0.85 μm when an overlap of 98% is used. Similarly, fixing the overlap at 98%, the structure depth increases from 0.40 μm for a fluence of 3.8 J/cm2 to 0.85 μm for a fluence of 13.3 J/cm2. A similar trend can also be observed in other works for different materials [19,20,21]. The depths achieved in this research are in line with those presented in the work by Schieber et al.; however, they showed that the conditions to achieve such depths remelted the entire surface [17]. Although not observed for the conditions tested on the CoCrMo alloy, if the laser energy was further increased, the depths of the grooves could start to decrease or even be destroyed. Excessive energy can also heat and melt the surface layer at the destructive interference zones, resulting in molten material flowing to the grooves and accumulating inside the cavities. It is important to state that these depths were measured at the centre of the laser beam. Due to its Gaussian nature, the depth tended to decrease close to its outer edge.

Figure 2.

Average depth and standard deviation of line-like structures obtained by DLIP on CoCrMo surfaces for different combinations of pulse overlaps and laser fluence.

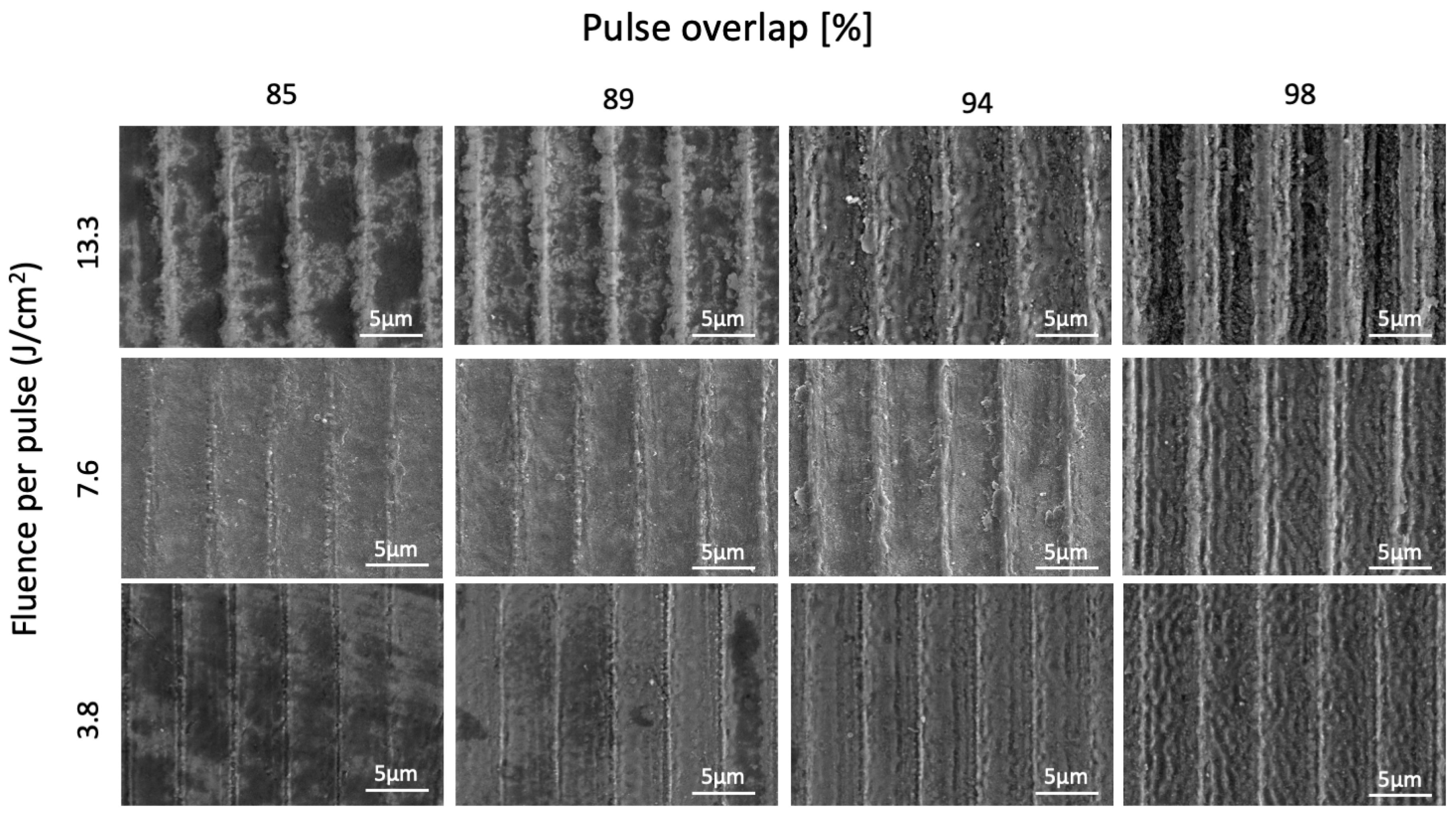

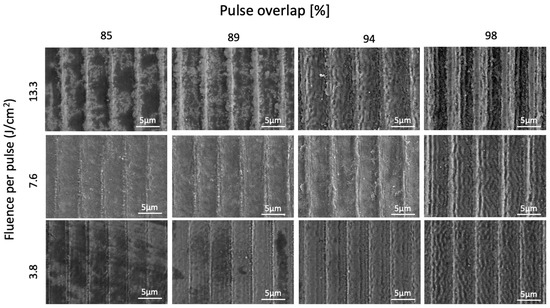

Scanning electron microscopy (SEM) images of the surface of the DLIP-modified CoCrMo samples with different laser processing conditions are shown in Figure 3. The images reveal that for low energy levels (low fluence and/or overlap), besides the small depth of the structures as seen in Figure 2, it is also evident that the grooves (where the interference pattern is maximum) are very narrow compared with the ridges. Increasing the fluence and/or the overlap, the width of the grooves increased along with their depth, resulting in more well-defined structures. It can also be seen that ablation occurred over the entire region under the laser beam, including at the minima positions (ridges) of the interference pattern. This means that the heat deposited on the maxima regions and transferred via conduction to the surroundings was excessively high to the point of surpassing the material ablation threshold. If ablation was required only at the maxima positions, lower energy levels should be used, but at a cost of decreasing depth and definition of the features. Nevertheless, homogeneous structures were fabricated for all conditions tested, with no signs of thermal cracking or resolidified material, which means that the feature’s geometry can be tailored using any condition tested, resulting in well-defined textures.

Figure 3.

SEM images from the textured surface of the CoCrMo samples for different conditions tested.

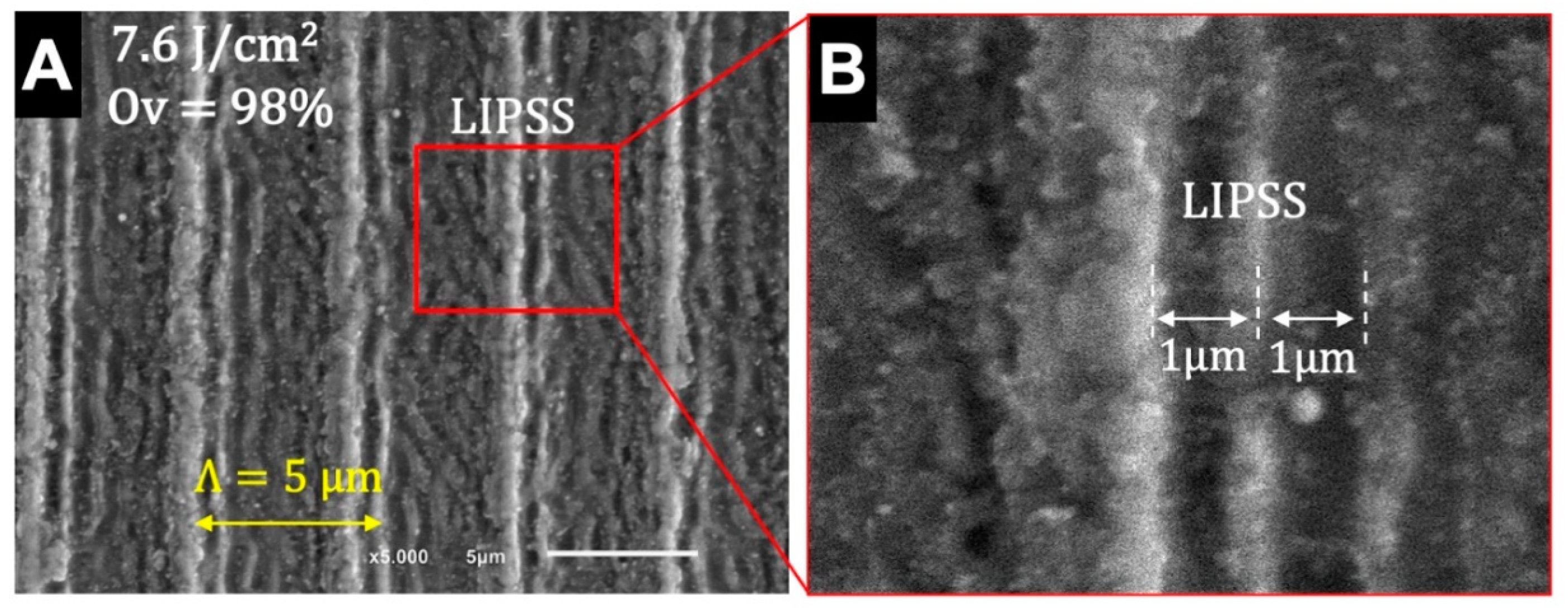

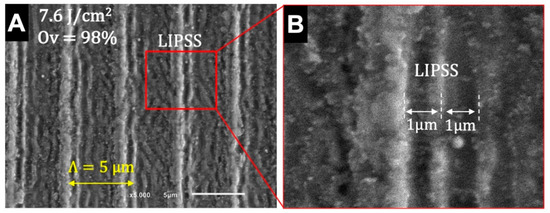

The SEM images also reveal the presence of smaller features in the format of ripples on the sample’s surface, especially for high-overlap conditions (>94%). Higher magnification images of the sample with 7.6 J/cm2 of laser fluence and 98% overlap (Figure 4) allow the identification of these secondary sub-micrometric structures that are present on the entire textured surface. These structures, parallel to the DLIP structures, can be classified as laser-induced periodic surface structures (LIPSS), as they have a spatial frequency of ~1000 nm, which is similar to the laser wavelength (1064 nm) [22]. Moreover, considering their spatial frequency and orientation (perpendicular to the laser beam polarisation), these structures can be classified as low-spatial-frequency LIPSS (LSFL), which are more common for strong absorbing materials, such as metals [23]. LSFL are generated by a complex sequence of inter- and intrapulse physical processes that are not yet fully understood, creating these periodic submicrometric features in format of “ripples” [24]. Despite the small size, these structures can change the optical, mechanical, and chemical surface properties. LIPSS have been shown to decrease bacterial adhesion to titanium implant surfaces and, at the same time, improve cell differentiation, which can lead to enhanced performance of implants [6,25]. Batal et al. showed that laser texturing in CoCrMo implants can improve initial cell adhesion due to the higher roughness, but submicrometric features (LIPSS) improves both cell adhesion and proliferation [26]. In the present work, the presence of multiscale surface structures can potentially improve the cells’ response to an implant surface via a possible collaborative effect between the grooves and the LIPSS. Further biological studies must be performed to validate this hypothesis and understand the biological response to multiscale texturing. Surface texturing can also significantly influence the tribological properties of a material. Studies have shown that textured grooves can store lubricant and trap wear debris, decreasing the coefficient of friction and wear rate [27,28]. Furthermore, smaller feature sizes (period smaller than 10 μm), such as those produced using the DLIP technique, seem to have a more positive effect on decreasing friction compared with those produced using the traditional DLW (periods greater than 30 μm) [8].

Figure 4.

Details of the multi-scale structures developed on DLIP-structured CoCrMo at 7.6 J/cm2 of laser fluence and 98% overlap: (A) periodic structures of Λ = 5 µm spacing are combined with (B) sub-micrometric features with 1 µm spacing (LIPSS).

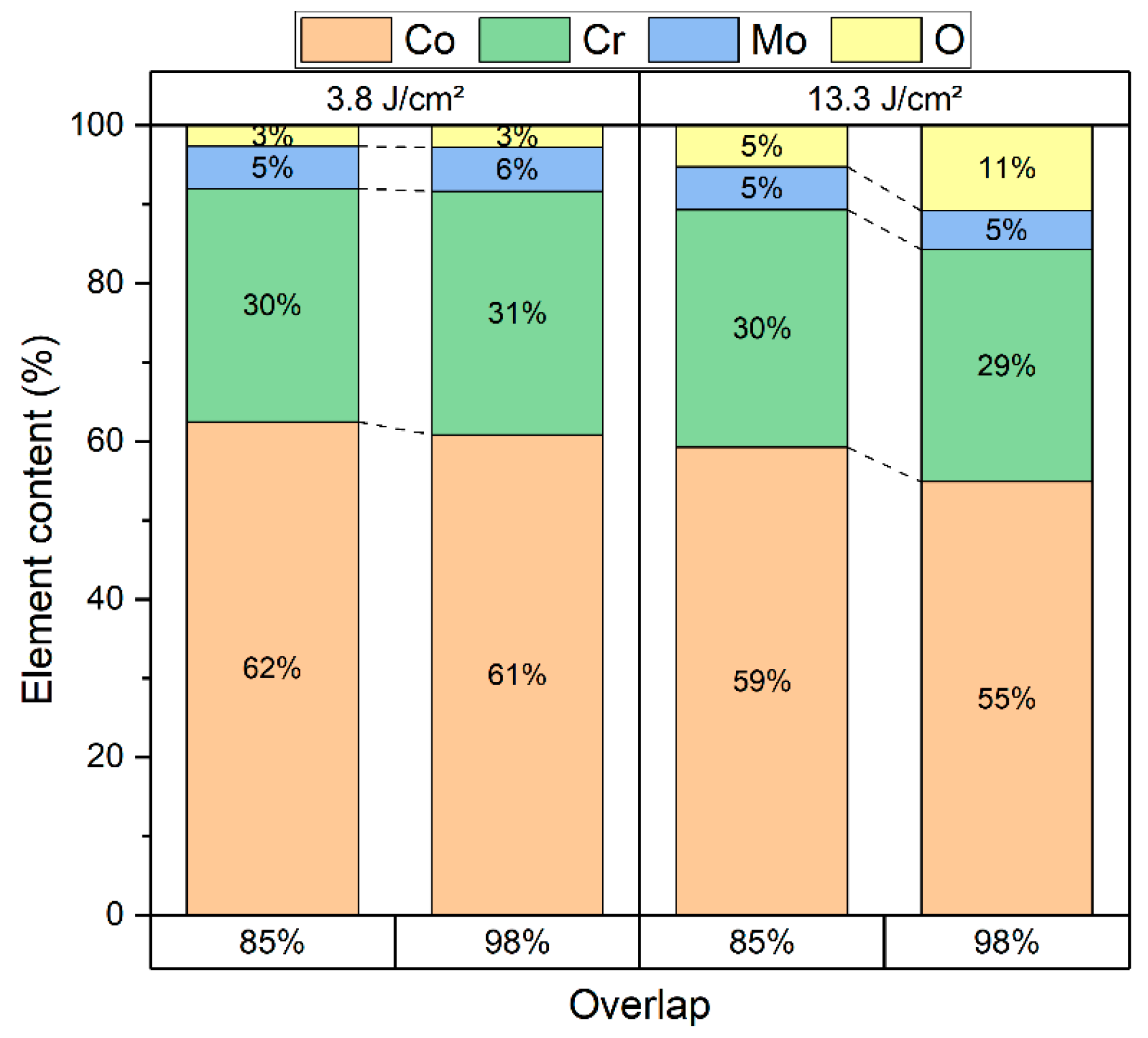

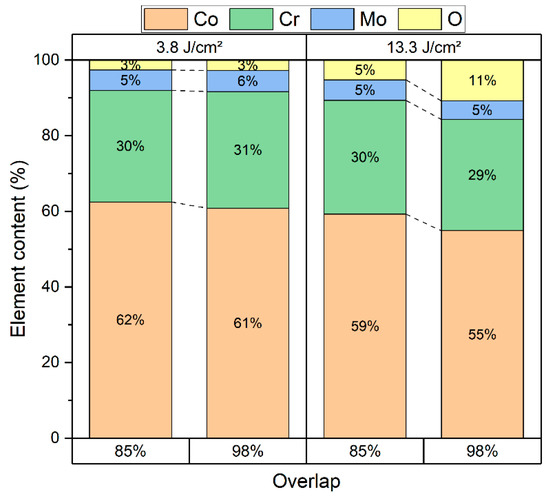

EDS analysis of the surfaces (Figure 5) shows a slight increase in the oxygen content after the laser texturing, indicating some oxidation. For low fluence (3.8 J/cm2) and low overlap (85%) conditions, the oxygen content is approximately 2% and reaches 4% when the overlap is increased to 98%. For the high fluence conditions, the oxygen content varies between 5% (for 85% overlap) and 8% (for 98% overlap). Oxidation can hinder the material’s properties, and its influence should be carefully evaluated based on the application. For example, oxygen can increase the size and frequency of glossy inclusions in CoCrMo alloys, which act as a stress concentrator and decrease the alloy’s mechanical strength [29]. Thus, the influence of these chemical changes on the material’s properties should be evaluated in future works. Moreover, the chemical composition of the laser-treated surface can still change over time. Thus, further EDS analysis after some period of time should be performed [30]. Despite using a slightly different alloy, Schieber et al. showed a more intense change in chemical composition after DLIP texturing in CoCr, probably due to the higher heating produced by the ns laser, which can cause chemical changes due to thermal effects [17]. The mechanism behind the oxidation of CoCrMo is probably related to the localised heating during the laser treatment. At elevated temperatures, the surface of the alloy can react with the oxygen from the surrounding atmosphere, resulting in the formation of oxides, such as CoO and MoO3 [27,31]. Chemical changes can be minimised using ultra-short pulsed lasers due to the athermal mechanism of ablation with low heat diffusion to the surroundings.

Figure 5.

Element content measured using EDS analysis for different values of fluence and overlap.

3.2. AZ91D Alloy

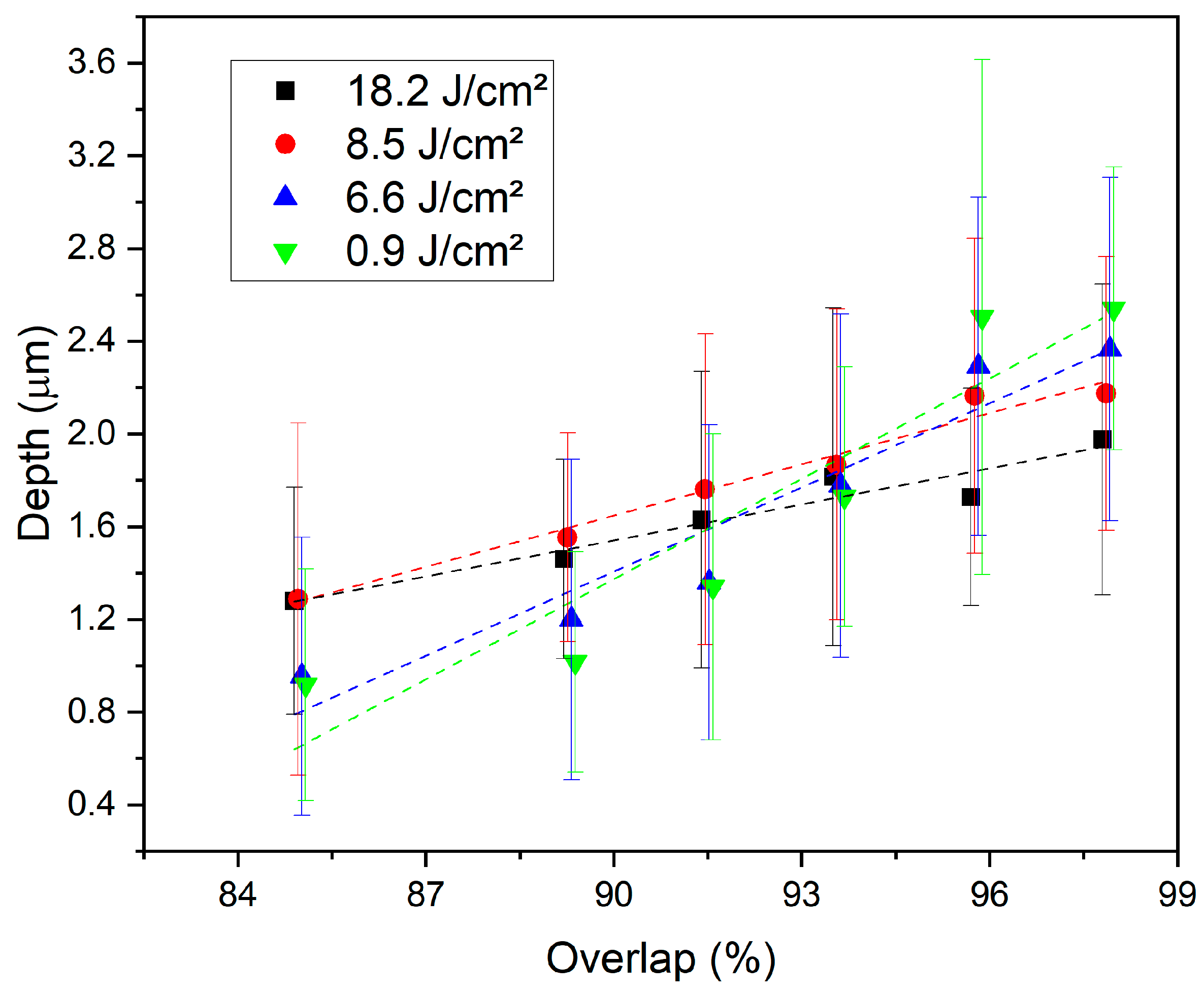

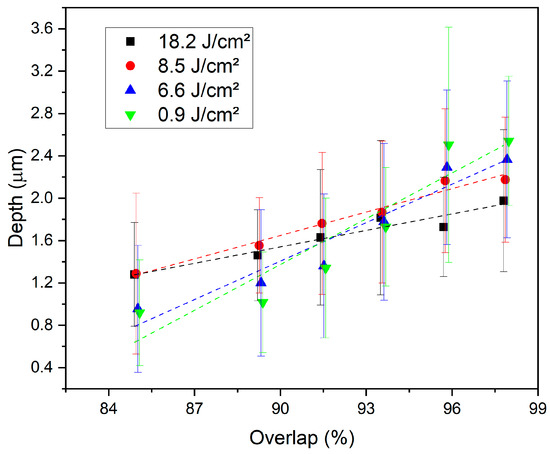

The texturing of the AZ91D magnesium alloy was also successfully performed using the DLIP technique. Figure 6 shows the depth of the different DLIP structures obtained for different combinations of laser fluences and pulse-to-pulse overlaps. It can be noticed that structures’ depth increases for increasing values of pulse overlaps, regardless of the level of laser fluence. For example, at 0.9 J/cm2, the structures’ depths increased from 0.9 µm to 2.5 µm (the maximum depth registered) when overlap changed from 85% to 98%, respectively. Also, it can be observed that at low overlaps, lower depths resulted from lower laser fluences and higher depths resulted from higher laser fluences, as expected and observed for the CoCrMo alloy. However, for higher overlaps (above 96%), a change was seen in this trend, with the higher depth values being obtained for lower laser fluences (e.g., 0.9 J/cm2 and 6.6 J/cm2). The linear fitting lines (dashed lines on the graph) also allowed us to observe this trend, showing the higher slope for lower fluence values. This finding suggests that for high levels of energy (high fluence and/or high overlap), melting is also occurring on the ridges, which flows to the surrounding region and accumulates inside the grooves, decreasing the total average depth. Thus, unlike the CoCrMo alloy, increasing the energy further will not necessarily increase the depth of the features. Despite this, the grooves fabricated on the magnesium alloy were deeper than those fabricated on the CoCrMo alloy, regardless of the laser conditions.

Figure 6.

Average depth and standard deviation of the periodic structures as function of the pulse-to-pulse overlap for different values of laser fluences.

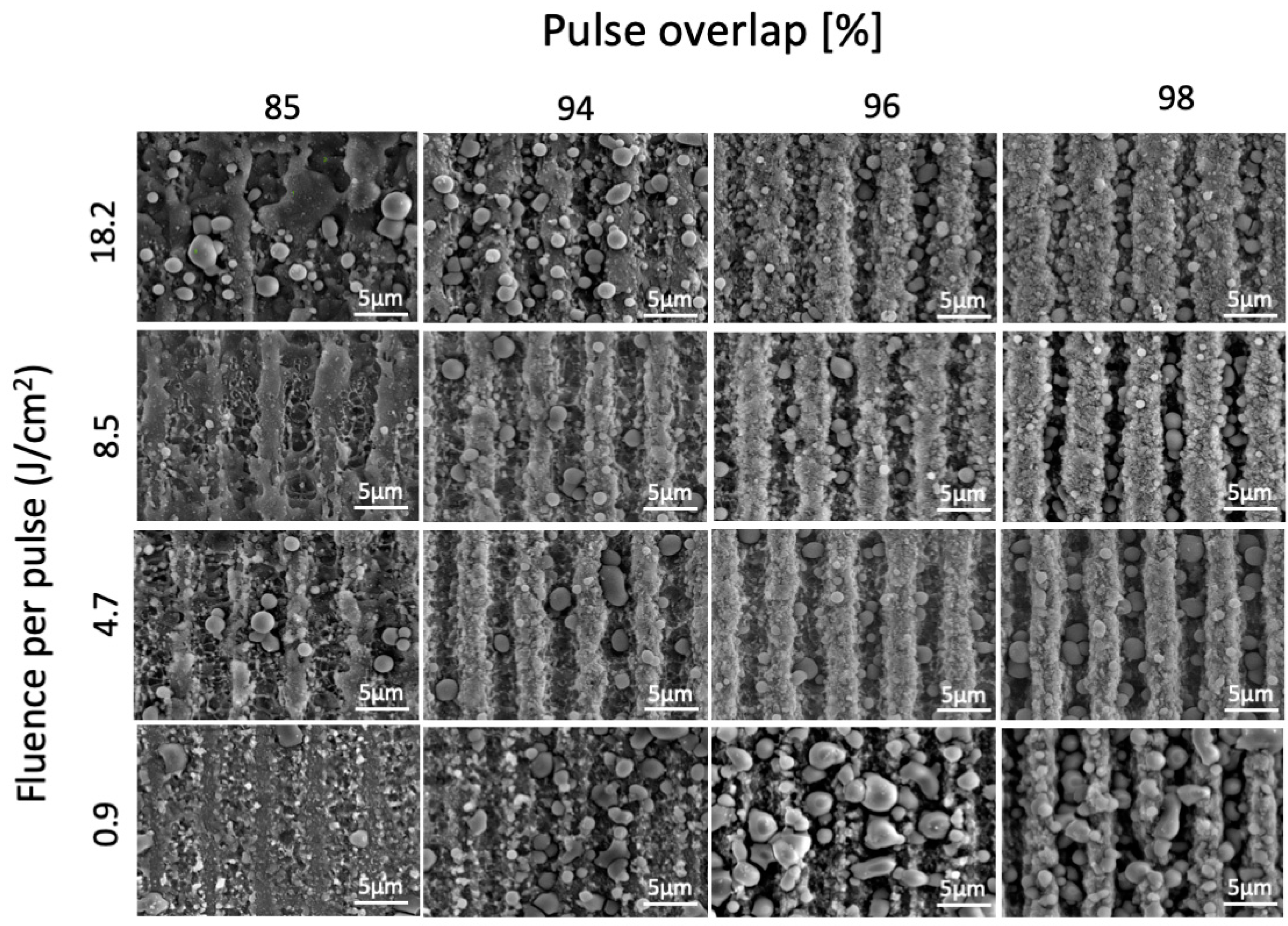

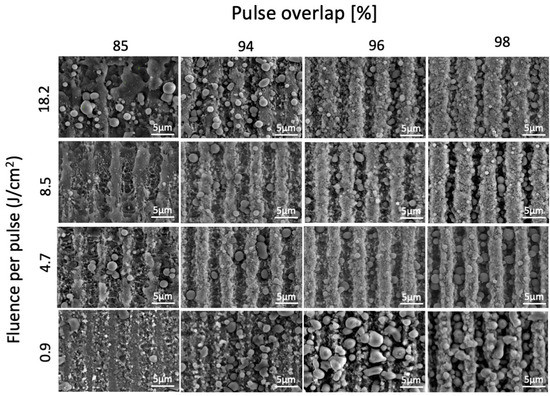

Figure 7 shows the SEM images with morphological details of the DLIP-structured surfaces. At low overlap (85%) and low fluence (0.9 J/cm2), the structures start to develop but still lack definition. The irregular shape of the lines, especially at higher values of fluence, indicates that melting occurred on the ridges, impairing the texture’s definition. For higher overlaps (>94%), line-like periodic structures with periodicity Λ = 5 µm and with good definition and homogeneity were successfully formed. The morphology of the samples textured with higher values of fluence and overlap also corroborates with the discussion above about melting accumulating on the grooves. For high fluence (18.2 J/cm2) and low overlap (85%), the lines were not straight due to the melting on the ridges. Indeed, for the highest energy condition (fluence 18.2 J/cm2 and overlap 98%), the grooves were starting to lose definition again, which shows that they were probably ablating and melting. Apparently, there was also more material, in the form of particles, inside the groove. The melting observed on the AZ91D alloy, as well as its deeper ablated grooves, was probably related to its lower melting point (~530 °C) compared with the CoCrMo (~1350 °C). However, despite the melting, relatively homogeneous structures could be achieved for moderate values of fluence (4.7–8.5 J/cm2) and high overlaps (>94%). Spherical particles, identified in the EDS analysis as metal oxides (Figure 8), could also be observed for almost every condition tested. The formation of bigger particles was particularly noticed under laser conditions of low energy (0.9 J/cm2) and high overlap (96% and 98%). The influence of these particles on the material properties, as well as their formation mechanism, should be further studied in future works. Unlike the CoCrMo alloy, no signs of LIPSS could be observed, probably due to the high melting that can potentially destroy the submicrometric structures.

Figure 7.

SEM images of the sample’s surfaces for each fluence and pulse overlap tested.

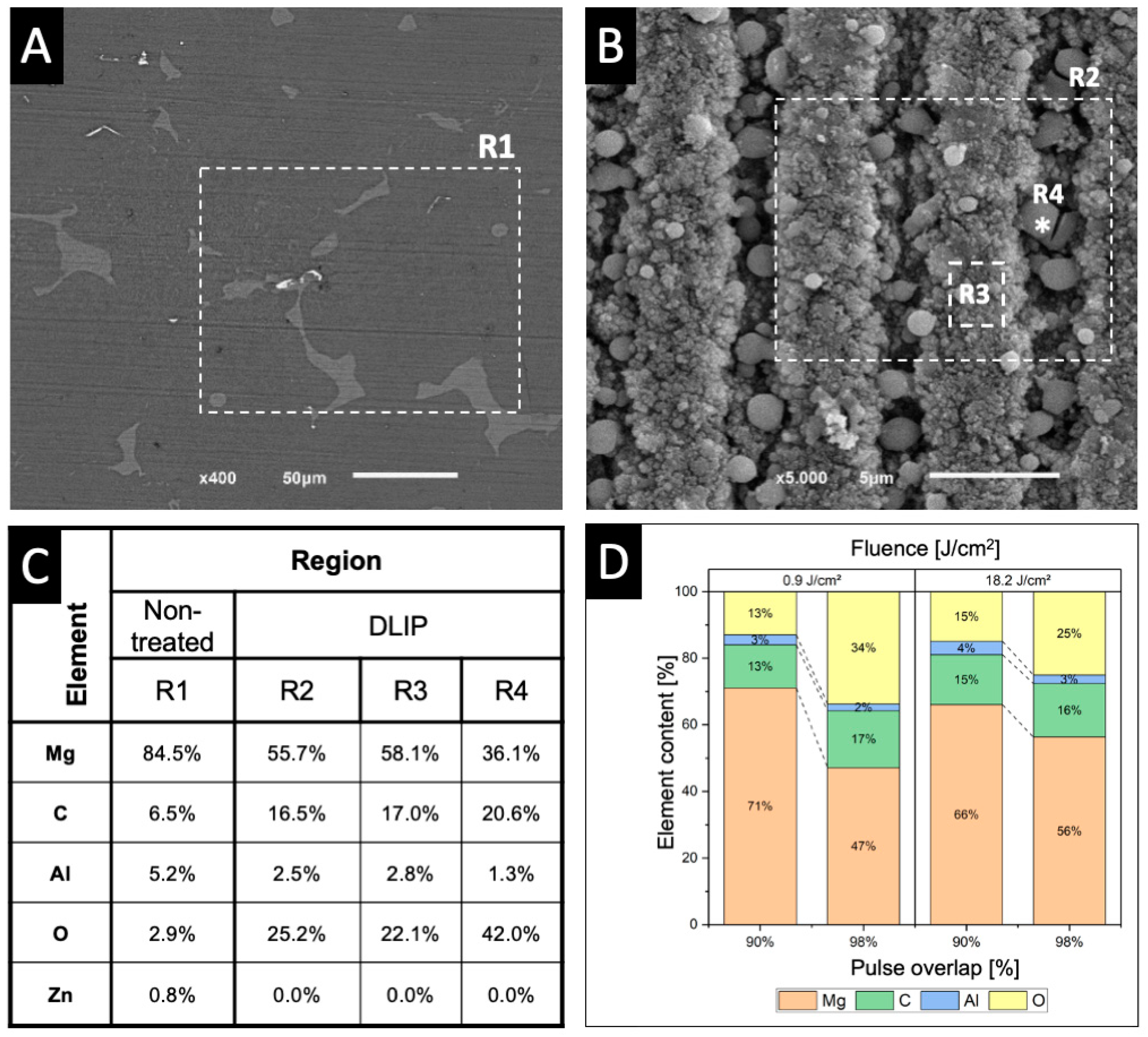

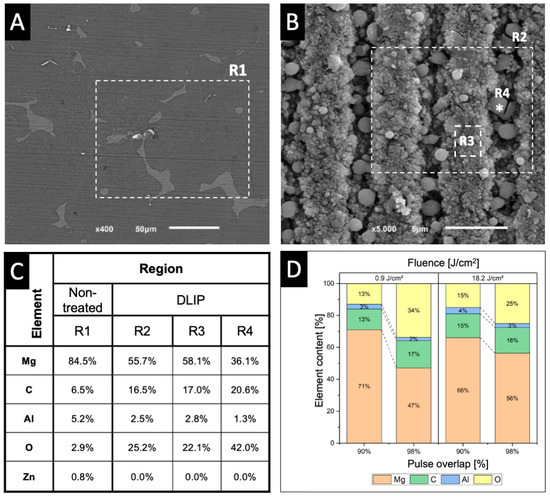

Figure 8.

SEM micrographs of (A) non-treated and (B) laser textured surfaces. (C) EDS chemical composition of the non-treated surface (R1), textured surface at 18.2 J/cm2 and 98% overlap (R2), ridge region (R3), and an oxide particle (R4). (D) Chemical composition variation on textured surfaces for different values of fluence and overlap.

The results of the EDS analysis presented in Figure 8 show a generalised oxidation of the laser-structured surface (R2) in relation to the untreated surface (R1), along with a reduction of Mg and Al contents and the volatilisation of Zn. The analysis of the spherical particles (R4) revealed a high content of oxygen (>40%), which allowed us to conclude that it was a metallic oxide containing Mg and Al. Changes in surface chemical composition can lead to different behaviour of biomaterials. For example, MgO has been reported to display improved antibacterial and angiogenic properties when incorporated in bone substitutes [32]. As well as the CoCrMo alloy, the oxidation of AZ91D can be attributed to the heating caused by the laser, resulting in reactions between magnesium and oxygen from the air. Furthermore, magnesium can also react with carbon dioxide in the atmosphere, forming carbon granules, which explains the increase in this element on the EDS analysis after laser texturing [33].

Figure 8 also shows the variation in Mg, Al, and O contents (Zn was not detected) on the laser-structured surfaces for different overlaps (90% and 98%) and laser fluences (0.9 J/cm2 and 18.2 J/cm2). The results revealed a trend of decreasing Mg content and increasing O content for increasing overlap values, verified for both energy levels. Surface oxidation, however, appeared to be higher when lower energy levels were used, which is in agreement with the SEM images (Figure 7), where a higher number of oxide particles can be observed for high overlap and low fluence laser processing conditions. Surface oxidation was also noticed in another work in AZ91D after laser texturing, although oxide particles were not observed [34].

4. Conclusions

In this work, the fabrication of DLIP structures using an infrared (1064 nm) ultra-short pulse laser source (10 ps) on the AZ91D magnesium and CoCrMo alloys and the influence of the laser parameters on the morphology of the structures have been evaluated and reported for the first time. The following conclusions can be drawn from this work:

- DLIP allowed the production of homogeneous line-like structures with a spatial period of 5 μm and with depths up to 0.85 μm for the CoCrMo alloy. Furthermore, sub-micrometric secondary structures, which can be reported as LIPSS, were also present at high energy conditions. Although ablation occurred over the entire surface, not only at the maxima interference regions, homogeneous and well-defined surfaces were achieved at every condition tested (fluence between 3.8 J/cm2 and 13.3 J/cm2 and overlap between 85% and 98%).

- Regarding the AZ91D alloy, fabrication of line-like structures with a periodicity of 5 μm and an average depth between 0.9 μm and 2.5 μm, deeper than the CoCrMo, was also successfully achieved. However, the high temperatures generated by the laser caused some melting, especially at high values of fluence, and oxidation of the surface, with the formation of spherical Mg-Al-O oxide particles. For high energy conditions (high fluence and/or overlap), the molten material started to accumulate inside the grooves, decreasing their depth.

- Although the influence of the oxidised surface and the multiscale surface topography must be further studied, these results bring optimistic perspectives to the possibility of the fabrication of micrometric periodic structures for the functionalisation of AZ91D magnesium and CoCrMo alloys for different engineering applications.

Author Contributions

Conceptualisation, B.H. and A.F.L.; methodology, B.H.; formal analysis, B.H.; investigation, B.H. and B.V.; resources, A.F.L.; writing—original draft preparation, B.H. and D.F.; writing—review and editing, B.V. and A.F.L.; visualisation, D.F.; supervision, A.F.L.; project administration, B.H. and A.F.L.; funding acquisition, B.H. and A.F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Capes-Humboldt Research Fellowship Programme (Ref: 88881.197684/2018-01), FCT-Portugal (through the reference projects UIDB/04436/2020 and UIDP/04436/2020), by the Capes/DAAD PROBRAL Programme (Ref: 88887.628082/2021-00) and by FINEP-Brazil (Project BIOMIO—01.22.0180.00 (0027/21)).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, B.H., upon reasonable request.

Acknowledgments

The authors acknowledge Fábio Antonio Xavier (EMC/UFSC) for providing the material used in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brown, M.S.; Arnold, C.B. Fundamentals of Laser-Material Interaction and Application to Multiscale Surface Modification. In Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 135, pp. 91–120. [Google Scholar]

- Watanabe, H.; Saito, K.; Kokubun, K.; Sasaki, H.; Yoshinari, M. Change in Surface Properties of Zirconia and Initial Attachment of Osteoblastlike Cells with Hydrophilic Treatment. Dent. Mater. J. 2012, 31, 806–814. [Google Scholar] [CrossRef] [PubMed]

- Dumas, V.; Rattner, A.; Vico, L.; Audouard, E.; Dumas, J.C.; Naisson, P.; Bertrand, P. Multiscale Grooved Titanium Processed with Femtosecond Laser Influences Mesenchymal Stem Cell Morphology, Adhesion, and Matrix Organization. J. Biomed. Mater. Res. A 2012, 100, 3108–3116. [Google Scholar] [CrossRef] [PubMed]

- Le Guéhennec, L.; Soueidan, A.; Layrolle, P.; Amouriq, Y. Surface Treatments of Titanium Dental Implants for Rapid Osseointegration. Dent. Mater. 2007, 23, 844–854. [Google Scholar] [CrossRef] [PubMed]

- Bohinc, K.; Dražić, G.; Fink, R.; Oder, M.; Jevšnik, M.; Nipič, D.; Godič-Torkar, K.; Raspor, P. Available Surface Dictates Microbial Adhesion Capacity. Int. J. Adhes. Adhes. 2014, 50, 265–272. [Google Scholar] [CrossRef]

- Cunha, A.; Elie, A.M.; Plawinski, L.; Serro, A.P.; Botelho Do Rego, A.M.; Almeida, A.; Urdaci, M.C.; Durrieu, M.C.; Vilar, R. Femtosecond Laser Surface Texturing of Titanium as a Method to Reduce the Adhesion of Staphylococcus Aureus and Biofilm Formation. Appl. Surf. Sci. 2016, 360, 485–493. [Google Scholar] [CrossRef]

- Lukaszewska-Kuska, M.; Wirstlein, P.; Majchrowski, R.; Dorocka-Bobkowska, B. Osteoblastic Cell Behaviour on Modified Titanium Surfaces. Micron 2018, 105, 55–63. [Google Scholar] [CrossRef]

- Stark, T.; Alamri, S.; Aguilar-Morales, A.I.; Kiedrowski, T.; Lasagni, A.F. Positive Effect of Laser Structured Surfaces on Tribological Performance. J. Laser Micro/Nanoeng. 2019, 14, 13–18. [Google Scholar] [CrossRef]

- Bauer, F.; Michalowski, A.; Kiedrowski, T.; Nolte, S. Heat Accumulation in Ultra-Short Pulsed Scanning Laser Ablation of Metals. Opt. Express 2015, 23, 1035. [Google Scholar] [CrossRef]

- El-Khoury, M.; Alamri, S.; Voisiat, B.; Kunze, T.; Lasagni, A.F. Fabrication of Hierarchical Surface Textures Using Multi-Pulse Direct Laser Interference Patterning with Nanosecond Pulses. Mater. Lett. 2020, 258, 126743. [Google Scholar] [CrossRef]

- Mücklich, F.; Lasagni, A.; Daniel, C. Laser Interference Metallurgy—Using Interference as a Tool for Micro/Nano Structuring. Int. J. Mater. Res. 2006, 97, 1337–1344. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium Properties—Applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Pinela, V.M.; De Oliveira, L.A.; De Oliveira, M.C.L.; Antunes, R.A. Study of the Corrosion Process of AZ91D Magnesium Alloy during the First Hours of Immersion in 3.5 Wt.% NaCl Solution. Int. J. Corros. 2018, 2018, 8785154. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N. Discontinuous and Continuous Precipitation in Magnesium–Aluminium Type Alloys. J. Alloys Compd. 2009, 477, 870–876. [Google Scholar] [CrossRef]

- Henriques, B.; Soares, D.; Silva, F.S. Microstructure, Hardness, Corrosion Resistance and Porcelain Shear Bond Strength Comparison between Cast and Hot Pressed CoCrMo Alloy for Metal-Ceramic Dental Restorations. J. Mech. Behav. Biomed. Mater. 2012, 12, 83–92. [Google Scholar] [CrossRef]

- Matković, T.; Matković, P.; Malina, J. Effects of Ni and Mo on the Microstructure and Some Other Properties of Co–Cr Dental Alloys. J. Alloys Compd. 2004, 366, 293–297. [Google Scholar] [CrossRef]

- Schieber, R.; Lasserre, F.; Hans, M.; Fernández-Yagüe, M.; Díaz-Ricart, M.; Escolar, G.; Ginebra, M.P.; Mücklich, F.; Pegueroles, M. Direct Laser Interference Patterning of CoCr Alloy Surfaces to Control Endothelial Cell and Platelet Response for Cardiovascular Applications. Adv. Healthc. Mater. 2017, 6, 1700327. [Google Scholar] [CrossRef]

- Milles, S.; Soldera, M.; Voisiat, B.; Lasagni, A.F. Fabrication of Superhydrophobic and Ice-Repellent Surfaces on Pure Aluminium Using Single and Multiscaled Periodic Textures. Sci. Rep. 2019, 9, 13944. [Google Scholar] [CrossRef]

- Henriques, B.; Fabris, D.; Voisiat, B.; Lasagni, A.F. Multi-Scale Textured PEEK Surfaces Obtained by Direct Laser Interference Patterning Using IR Ultra-Short Pulses. Mater. Lett. 2023, 339, 134091. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Lasagni, A.F. Micro-Fabrication of High Aspect Ratio Periodic Structures on Stainless Steel by Picosecond Direct Laser Interference Patterning. J. Mater. Process. Technol. 2018, 252, 313–321. [Google Scholar] [CrossRef]

- Mulko, L.; Soldera, M.; Lasagni, A.F. Structuring and Functionalization of Non-Metallic Materials Using Direct Laser Interference Patterning: A Review. Nanophotonics 2022, 11, 203–240. [Google Scholar] [CrossRef]

- Alamri, S.; Fraggelakis, F.; Kunze, T.; Krupop, B.; Mincuzzi, G.; Kling, R.; Lasagni, A.F. On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation. Materials 2019, 12, 1018. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond Laser-Induced Periodic Surface Structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Bonse, J.; Hohm, S.; Kirner, S.V.; Rosenfeld, A.; Kruger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Cunha, A.; Zouani, O.F.; Plawinski, L.; Botelho do Rego, A.M.; Almeida, A.; Vilar, R.; Durrieu, M.-C. Human Mesenchymal Stem Cell Behavior on Femtosecond Laser-Textured Ti-6Al-4V Surfaces. Nanomedicine 2015, 10, 725–739. [Google Scholar] [CrossRef] [PubMed]

- Batal, A.; Sammons, R.; Dimov, S. Response of Saos-2 Osteoblast-like Cells to Laser Surface Texturing, Sandblasting and Hydroxyapatite Coating on CoCrMo Alloy Surfaces. Mater. Sci. Eng. C 2019, 98, 1005–1013. [Google Scholar] [CrossRef]

- Cuao Moreu, C.A.; Maldonado Cortés, D.; Lara Banda, M.d.R.; García Sánchez, E.O.; Zambrano Robledo, P.; Hernández Rodríguez, M.A.L. Surface, Chemical, and Tribological Characterization of an ASTM F-1537 Cobalt Alloy Modified through an Ns-Pulse Laser. Metals 2021, 11, 1719. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Hans, M.; Gachot, C.; Thome, A.; Bonk, S.; Mücklich, F. Direct Laser Interference Patterning: Tailoring of Contact Area for Frictional and Antibacterial Properties. Lubricants 2016, 4, 2. [Google Scholar] [CrossRef]

- Fleming, T.J.; Kavanagh, A.; Duggan, G. The Effect of Melt Temperature on the Mechanical Properties of Cast ASTM F75 CoCrMo Alloy as Explained by Nitrogen and Oxygen Content. J. Mater. Res. Technol. 2020, 9, 9479–9486. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Voisiat, B.; Kunze, T.; Lasagni, A.F. The Role of the Surface Nano-Roughness on the Wettability Performance of Microstructured Metallic Surface Using Direct Laser Interference Patterning. Materials 2019, 12, 2737. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A.; Rondinella, A.; Sordetti, F.; Magnan, M.; Honma, T.; Yoshida, Y.; Zhu, W.; Pezzotti, G.; Fedrizzi, L. Multi-Spectroscopic Analysis of High Temperature Oxides Formed on Cobalt-Chrome-Molybdenum Alloys. J. Mater. Res. Technol. 2022, 20, 3061–3073. [Google Scholar] [CrossRef]

- Coelho, C.C.; Padrão, T.; Costa, L.; Pinto, M.T.; Costa, P.C.; Domingues, V.F.; Quadros, P.A.; Monteiro, F.J.; Sousa, S.R. The Antibacterial and Angiogenic Effect of Magnesium Oxide in a Hydroxyapatite Bone Substitute. Sci. Rep. 2020, 10, 19098. [Google Scholar] [CrossRef]

- Jafari, H.; Idris, M.H.; Ourdjini, A. High Temperature Oxidation of AZ91D Magnesium Alloy Granule during In-Situ Melting. Corros. Sci. 2011, 53, 655–663. [Google Scholar] [CrossRef]

- Aulakh, S.S.; Kaushal, G. Laser Texturing as an Alternative to Grit Blasting for Improved Coating Adhesion on AZ91D Magnesium Alloy. Trans. IMF 2019, 97, 100–108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).