Model-Based Decision Support System for Electric Arc Furnace (EAF) Online Monitoring and Control

Abstract

:1. Introduction

2. Materials and Methods

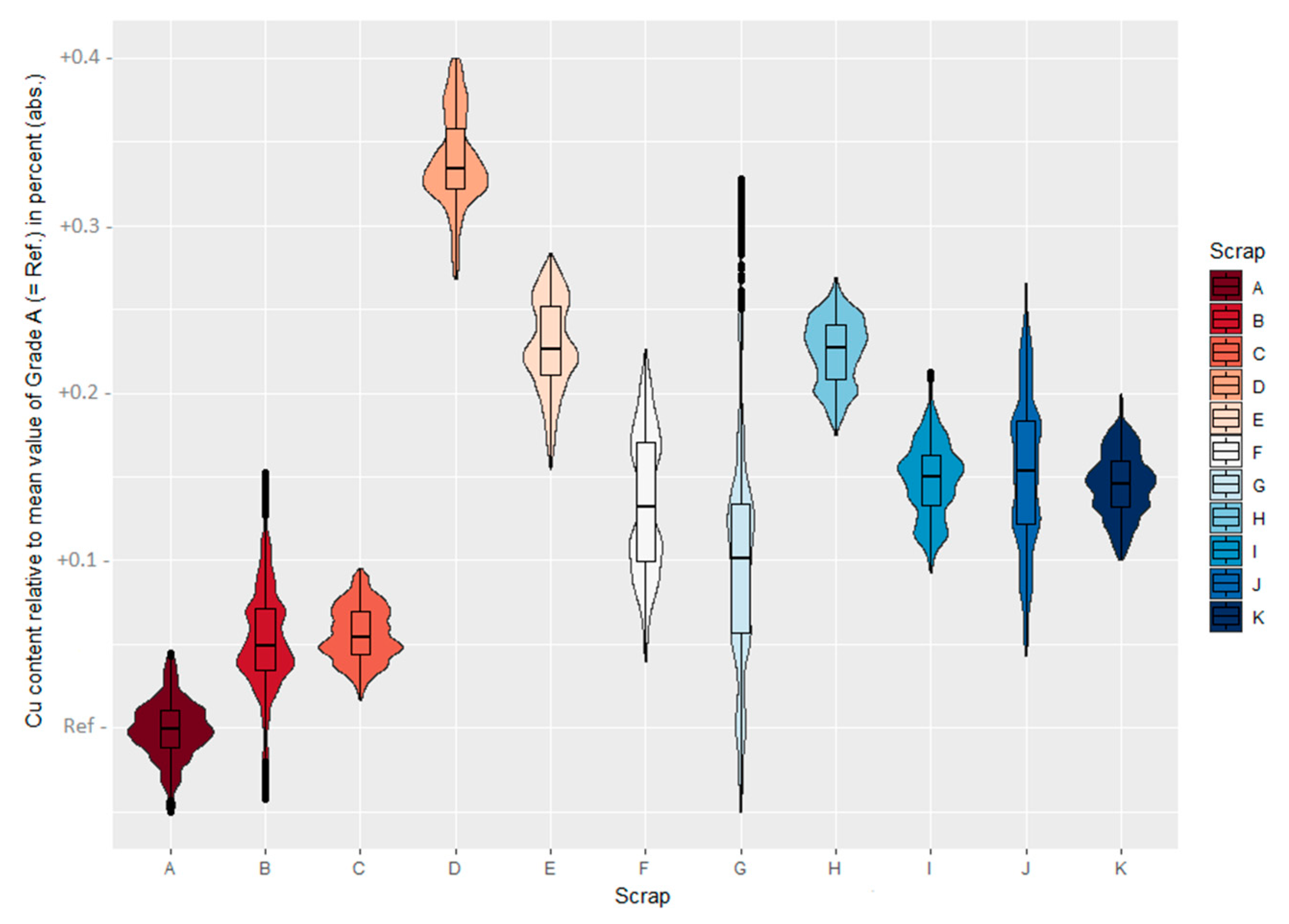

2.1. Characterisation of Steel Scrap

- Post-consumer scrap: Old scrap from the demolition of the metal structure of industrial buildings, machinery, railway and naval scrap, used cars, etc.;

- Pre-consumer scrap: Industrial or new scrap that is generated in processing industries that use steel as raw material in their manufacturing processes;

- Internal recoveries: Scrap generated along the steelmaking process itself, in melt shops, rolling mills and other processes inside Sidenor premises.

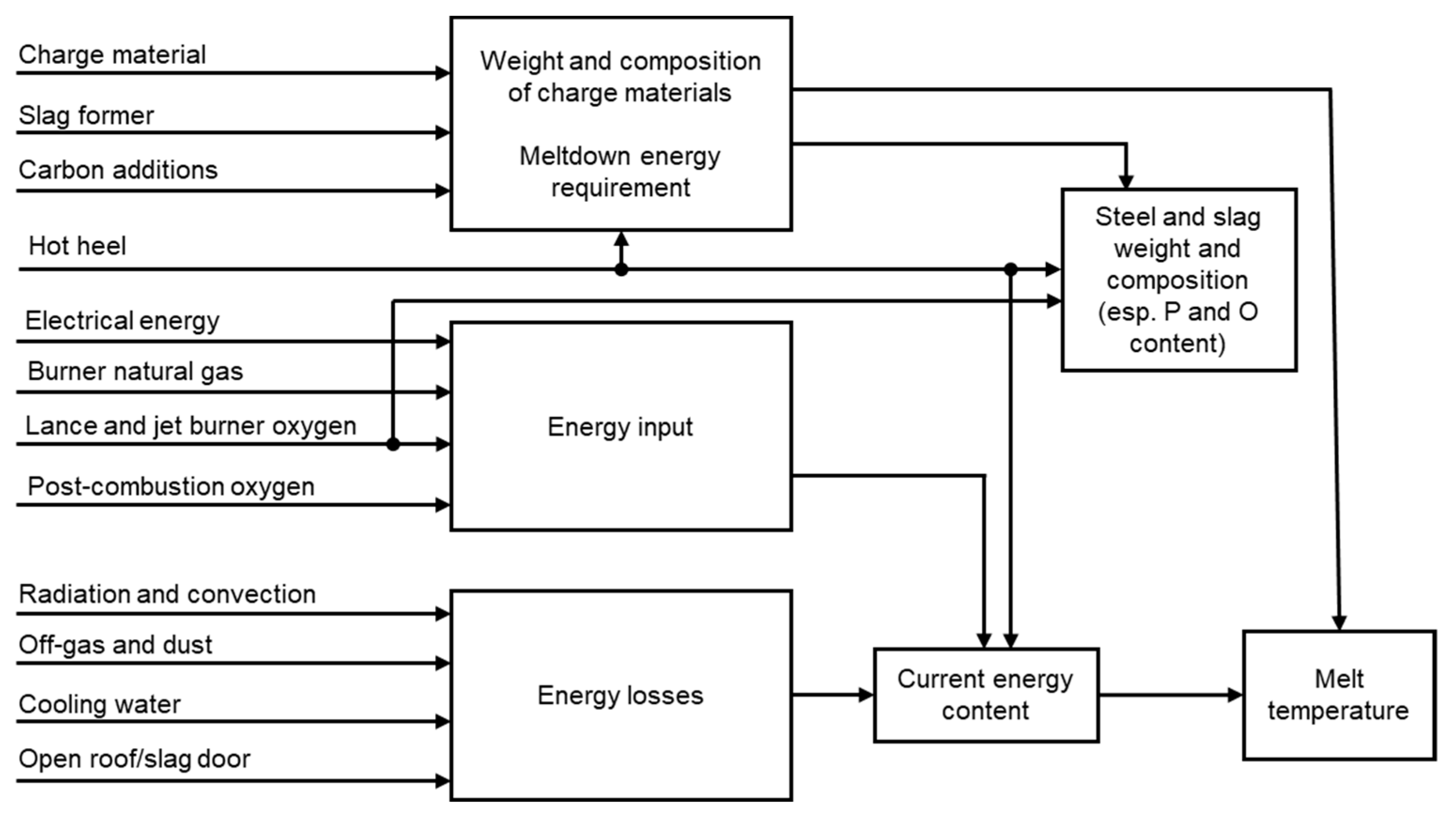

2.2. Dynamic EAF Process Model

3. Results and Discussion

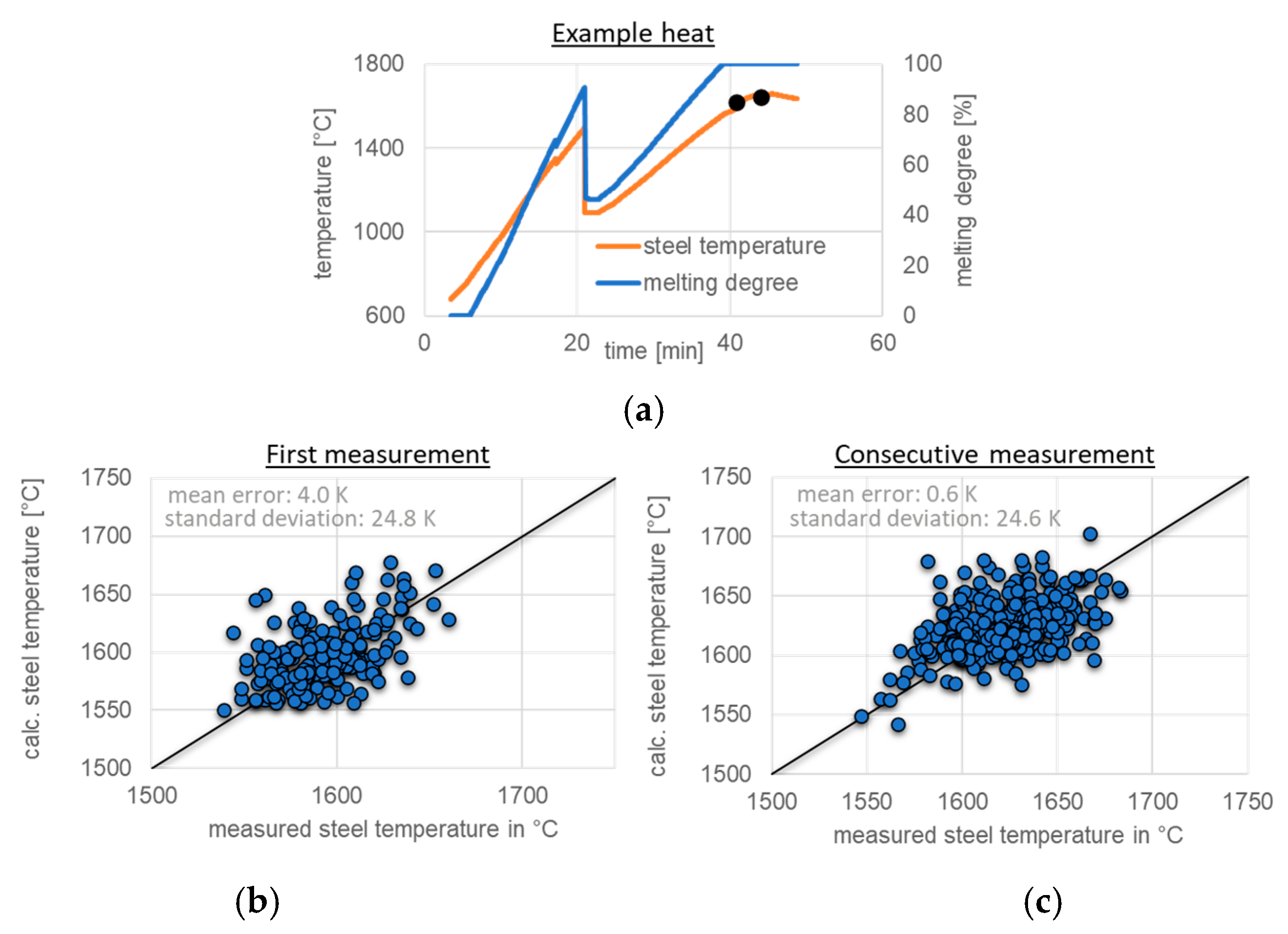

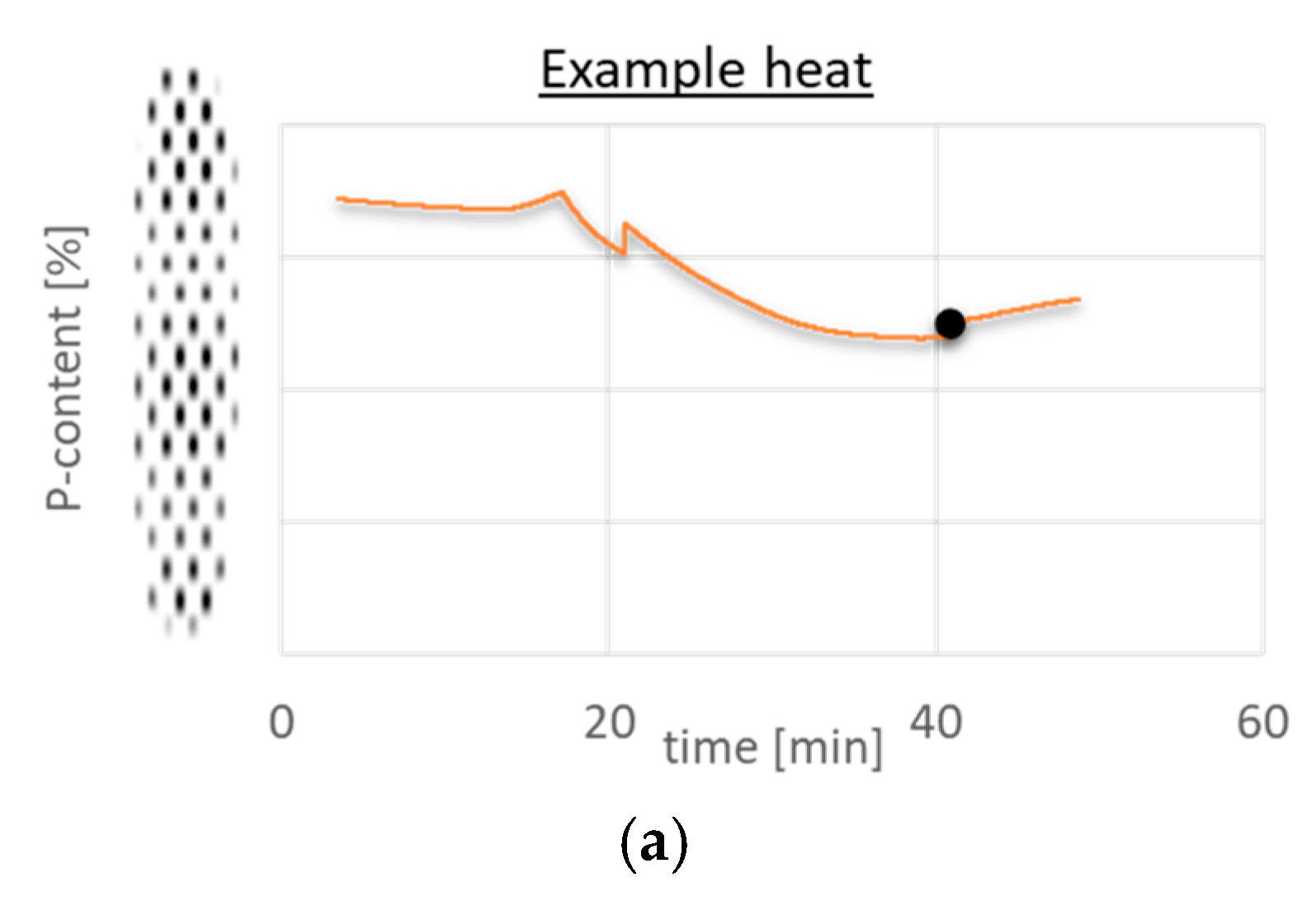

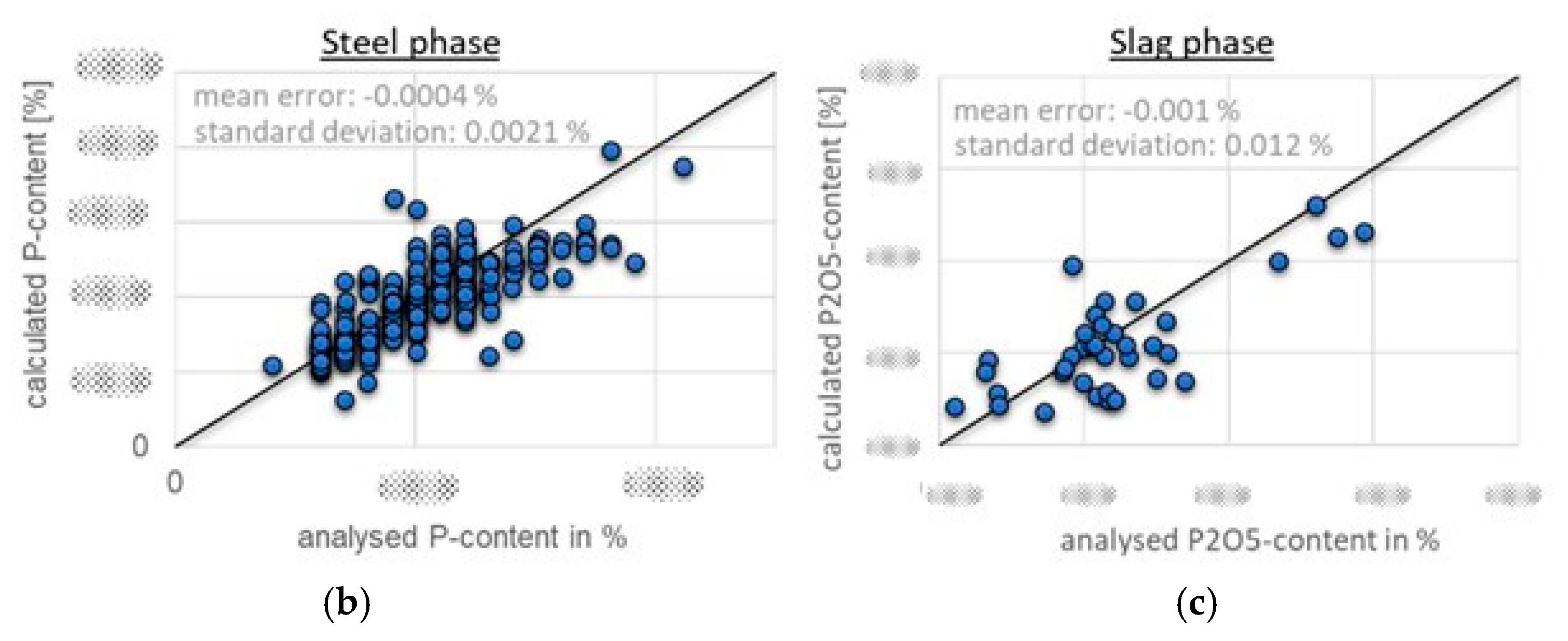

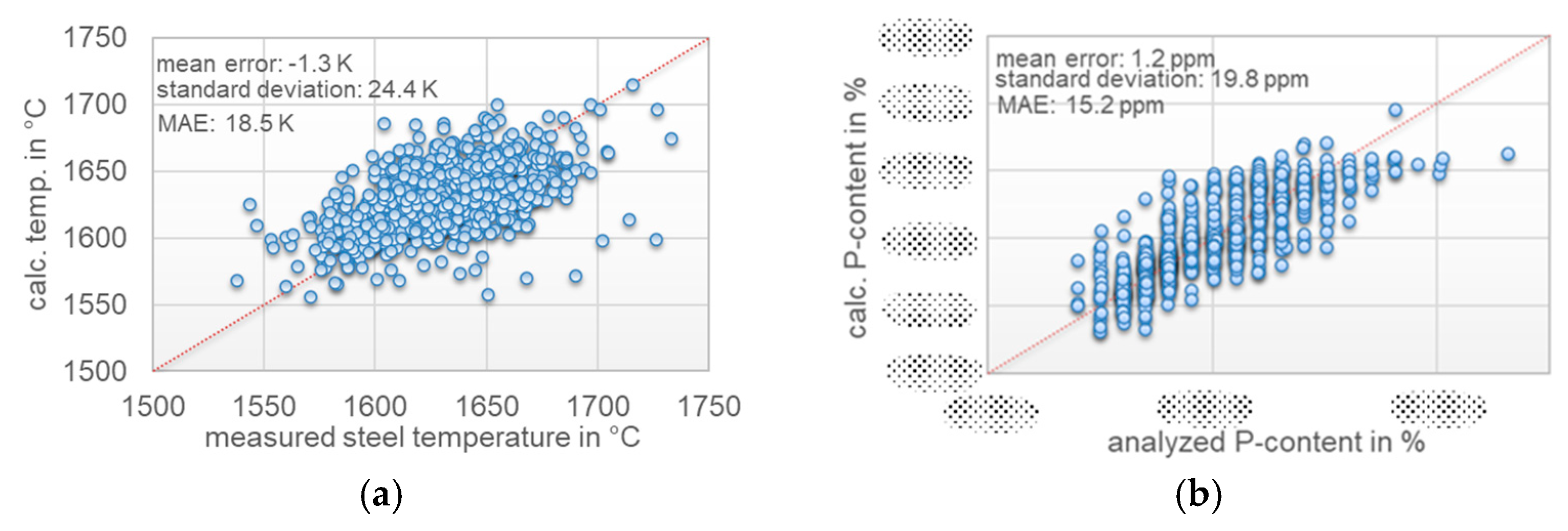

3.1. Validation of the EAF Process Model

3.2. Online Implementation for Process Monitoring

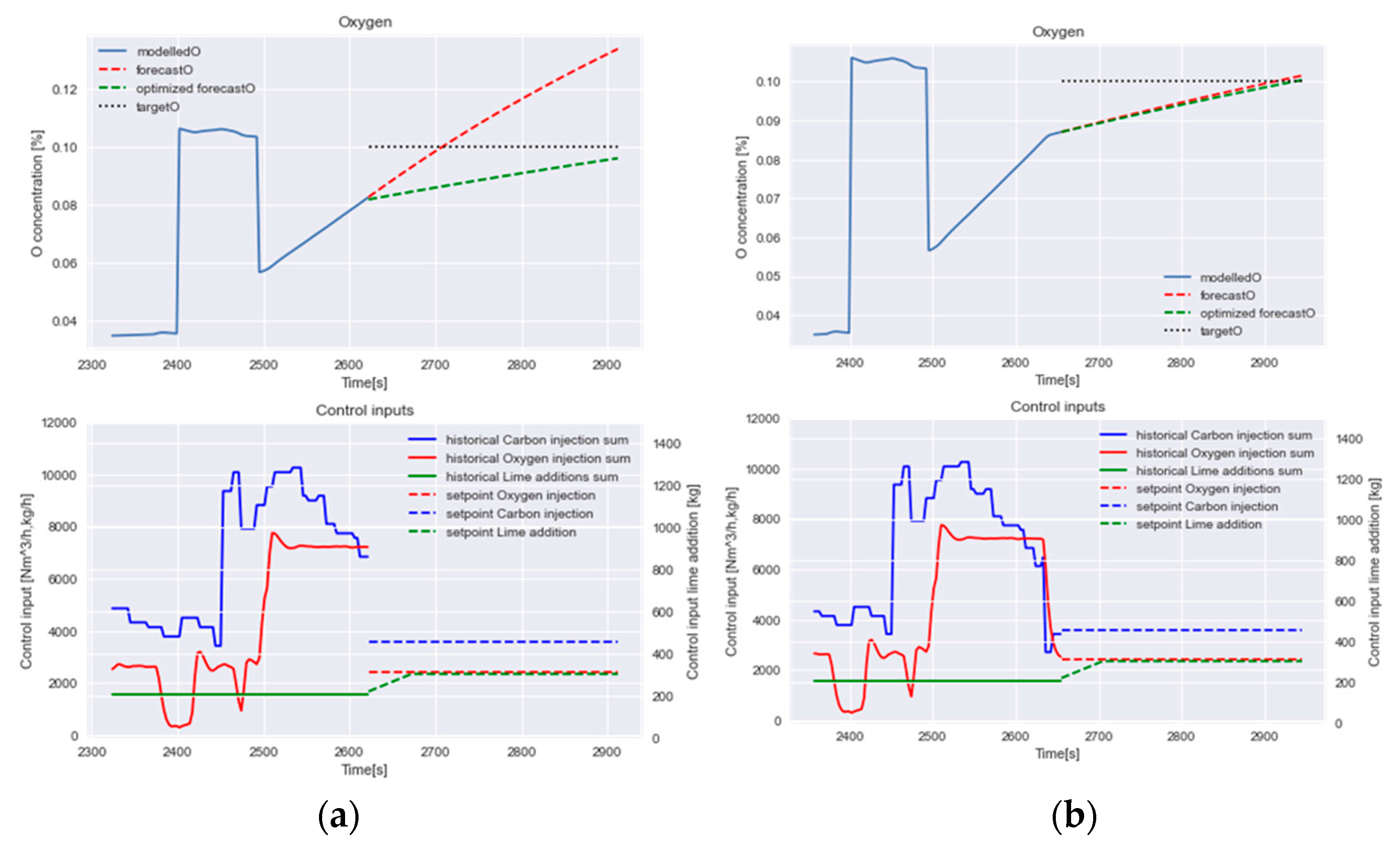

3.3. Model-Based Decision Support

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malfa, E.; Nyssen, P.; Fillipini, E.; Dettmer, B.; Unamuno, I.; Gustafsson, A.; Sandberg, E.; Kleimt, B. Cost and Energy Effective Management of EAF with Flexible Charge Material Mix. BHM 2013, 158, 3–12. [Google Scholar] [CrossRef]

- Gyllenram, R.; Westerberg, O. The impact of scrap upgrading on EAF production cost and environmental performance. Stahl Eisen 2016, 136, 32–36. [Google Scholar]

- Bets, S.; Cesareo, E.; Rolando, A.; Venturi, F.; Fontana, P.; Mazarrello, B. OPTIMET: An advanced Charge Optimizing Model for EAF steelmaking. In Proceedings of the 11th European Electric Steelmaking Conference, Venice, Italy, 25–27 May 2016. [Google Scholar]

- Sandberg, E. Improved material efficiency utilizing cloud-based novel tools for on-lien supervision of EAF raw materials pro-perties. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Kleimt, B.; Mier, D.; Maza, D. Early detection of deviations in charge material properties and adjustment for optimal scrap usage in the EAF. In Proceedings of the 5th European Steel Technology and Application Days, ESTAD 2021, Stockholm, Sweden, 2 September 2021. [Google Scholar]

- Kleimt, B.; Pierre, R.; Dettmer, B.; Deng, J.; Schlinge, L.; Schliephake, H. Continuous dynamic EAF process control for increased energy and resource efficiency. In Proceedings of the 10th European Electric Steelmaking Conference, Graz, Austria, 25–28 September 2012. [Google Scholar]

- Kleimt, B.; Pierre, R.; Gellert, S.; Kier, K.; Die, N.; Berg, P. Dynamic process control for energy efficiency improvement at an EAF with DRI feeding. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Gassner, G.; Fuchs, P.; Schlautmann, M.; Stubbe, G.; Jendryssek, U.; Niehues, P.; Leyva, C.; Ojeda, A. Development and application of model-based software tools for raw material and energy optimization at Cast Steel production—MORSE project. In Proceedings of the 5th European Steel Technology and Application Days, ESTAD 2021, Stockholm, Sweden, 2 September 2021. [Google Scholar]

- Hay, T.; Visuri, V.-V.; Aula, M.; Echterhof, T. A Review of Mathematical Process Models for the Electric Arc Furnace Process. Steel Res. Int. 2021, 92, 2000395. [Google Scholar] [CrossRef]

- Hernandez, J.; Onofri, L.; Engell, S. Modelling and Energy Efficiency Analysis of the Steelmaking Process in an Electric Arc Furnace. Metall. Mater. Trans. B 2022, 53, 3413–3441. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modelling and validation of an electric arc furnace: Part 1, heat and mass transfer. ISIJ Int. 2012, 52, 402–413. [Google Scholar] [CrossRef] [Green Version]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modelling and validation of an electric arc furnace: Part 2, thermo-chemistry. ISIJ Int. 2012, 52, 414–424. [Google Scholar]

- Nyssen, P.; Ojeda, C.; Baumert, J.C.; Picco, M.; Thibaut, J.C.; Sun, S.; Waterfall, S.; Ranger, M.; Lowry, M. Implementation and on-line use of a dynamic process model at the ArcelorMittal-Dofasco Electric Arc Furnace. In Proceedings of the METEC InSteelCon, SteelSim 2011, Düsseldorf, Germany, 27 June–1 July 2011. [Google Scholar]

- Placier, E. EAF Optimisation Technology for Stainless Steel Production with Dynamic Model Applications. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Baumert, J.-C.; Engel, R.; Weiler, C. Dynamic modelling of the electric arc furnace process using artificial neural networks. Metall. Res. Technol. 2002, 99, 839–884. [Google Scholar] [CrossRef]

- Carlsson, L.; Samuelsson, P.; Jönsson, P. Using Statistical Modelling to predict the Electrical Energy Consumption of an Electric Arc Furnace producing Stainless Steel. Metals 2020, 10, 36. [Google Scholar] [CrossRef] [Green Version]

- Wessels, T. Precise temperature Control with Artificial Intelligence. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Kirk, T. Deep learning applied to online EAF process optimization: Challenges, results and possibilities. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Tomažic, S.; Andonovski, G.; Škrjanc, I.; Logar, V. Data-Driven Modelling and Optimization of Energy Consumption in EAF. Metals 2022, 12, 816. [Google Scholar] [CrossRef]

- Schlautmann, M.; Wolff, A.; Pierret, J.C.; Ansseau, O.; Zagrebin, V.; Illichmann, M.; Küster, O. Auto-calibration of model parameters for long-term reliability of process control along the electric steelmaking route. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Frittella, P. Monitoring and control of EAF process through KPI’s approach with self-learning strategies for autocalibration and autoadaptation of process control rules. In Proceedings of the 12th European Electric Steelmaking Conference, Sheffield, UK, 13–15 September 2021. [Google Scholar]

- Hay, T.; Echterhof, T. Use of a comprehensive electric arc furnace process model in the investigation of alternative and optimized operating strategies. In Proceedings of the 5th European Steel Technology and Application Days, ESTAD 2021, Stockholm, Sweden, 2 September 2021. [Google Scholar]

- Li, Q.; Hong, X. Dynamic model and simulation of EAF steelmaking process. Acta Metall. Sin. 2003, 16, 197–203. [Google Scholar]

- Borovsky, T.; Kijac, J.; Domovec, M. The slag composition influence on the dephosphorization and on the lifetime of Electric Arc Furnace hearth refractory lining. Acta Met. Slovaca 2010, 16, 165–171. [Google Scholar]

- Tayeb, M.A.; Fruehan, R.; Sridhar, S.; Pistorius, C. Dephosphorization model for a continuous DRI EAF process. In Proceedings of the Materials Science & Technology (MS&T) Conference, Pittsburgh, PA, USA, 12–16 October 2014; pp. 143–151. [Google Scholar]

- Pierre, R.; Kleimt, B.; Dettmer, B.; Schliephake, H. Quality and cost optimal charge material selection for the EAF. In Proceedings of the 10th European Electric Steelmaking Conference, Graz, Austria, 25–28 September 2012. [Google Scholar]

- RFCS Project “Optimization of Scrap Charge Management and Related Process Adaptation for Performance Improvement and Cost Reduction” EUR 30537 EN. 2020. Available online: https://op.europa.eu/en/publication-detail/-/publication/f45c7766-5a0c-11eb-b59f-01aa75ed71a1/language-en/format-PDF/source-289948522 (accessed on 23 July 2023).

- Assis, A.; Fruehan, R.; Sridhar, S. Phosphorus Equilibrium between Liquid Iron and CaO-SiO2-MgO-FeO Slags. In Proceedings of the AISTech, Atlanta, GA, USA, 7–10 May 2012; pp. 861–870. [Google Scholar]

- Available online: https://s-x-aipi-project.eu/ (accessed on 1 June 2023).

- Available online: https://alchimia-project.eu/ (accessed on 1 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kleimt, B.; Krieger, W.; Mier Vasallo, D.; Arteaga Ayarza, A.; Unamuno Iriondo, I. Model-Based Decision Support System for Electric Arc Furnace (EAF) Online Monitoring and Control. Metals 2023, 13, 1332. https://doi.org/10.3390/met13081332

Kleimt B, Krieger W, Mier Vasallo D, Arteaga Ayarza A, Unamuno Iriondo I. Model-Based Decision Support System for Electric Arc Furnace (EAF) Online Monitoring and Control. Metals. 2023; 13(8):1332. https://doi.org/10.3390/met13081332

Chicago/Turabian StyleKleimt, Bernd, Waldemar Krieger, Diana Mier Vasallo, Asier Arteaga Ayarza, and Inigo Unamuno Iriondo. 2023. "Model-Based Decision Support System for Electric Arc Furnace (EAF) Online Monitoring and Control" Metals 13, no. 8: 1332. https://doi.org/10.3390/met13081332