Testing and Numerical Simulation of the Shear Resistance of Blind-Bolted Aluminum Connections

Abstract

:1. Introduction

2. Shear Resistance Tests of BOM-Bolted Aluminum Connections

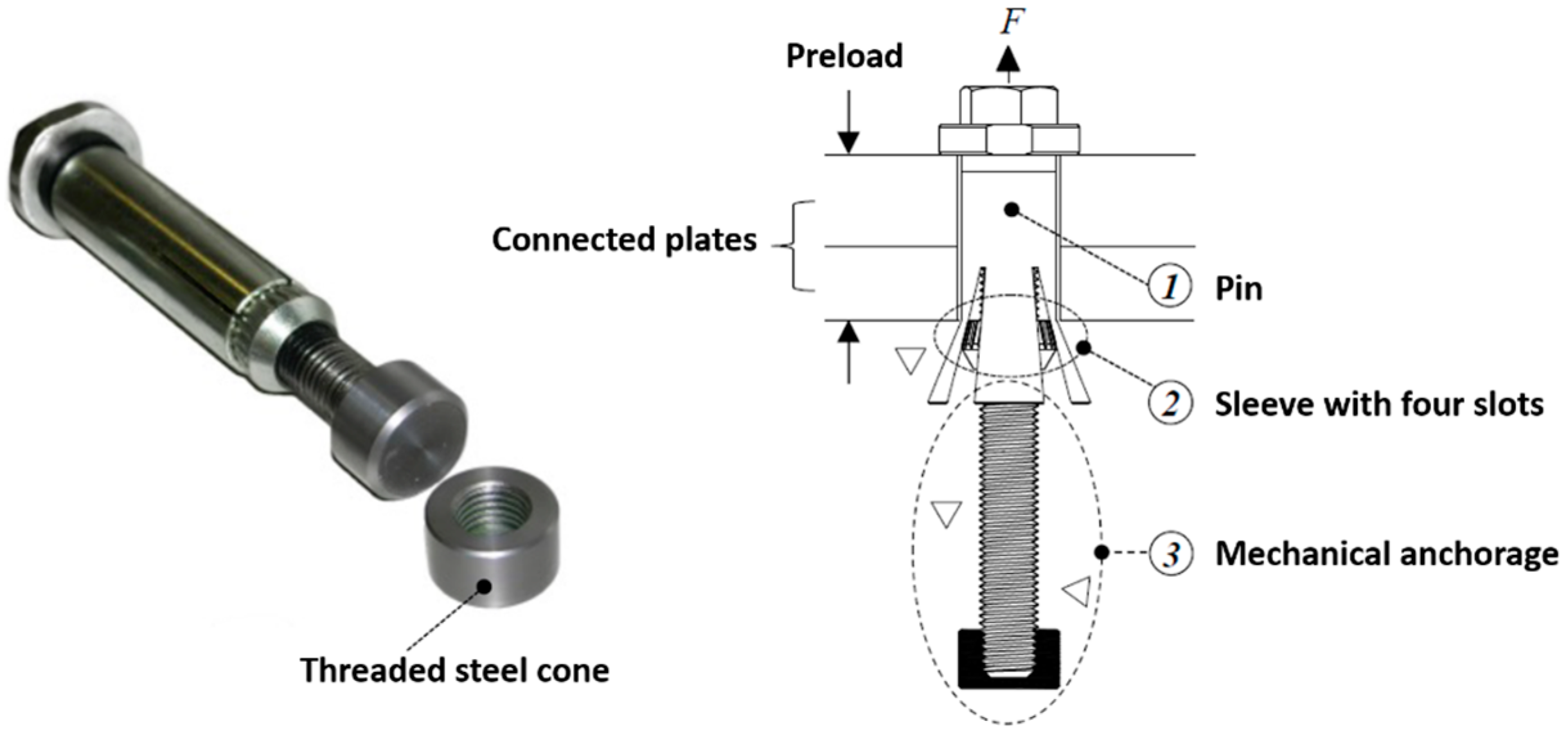

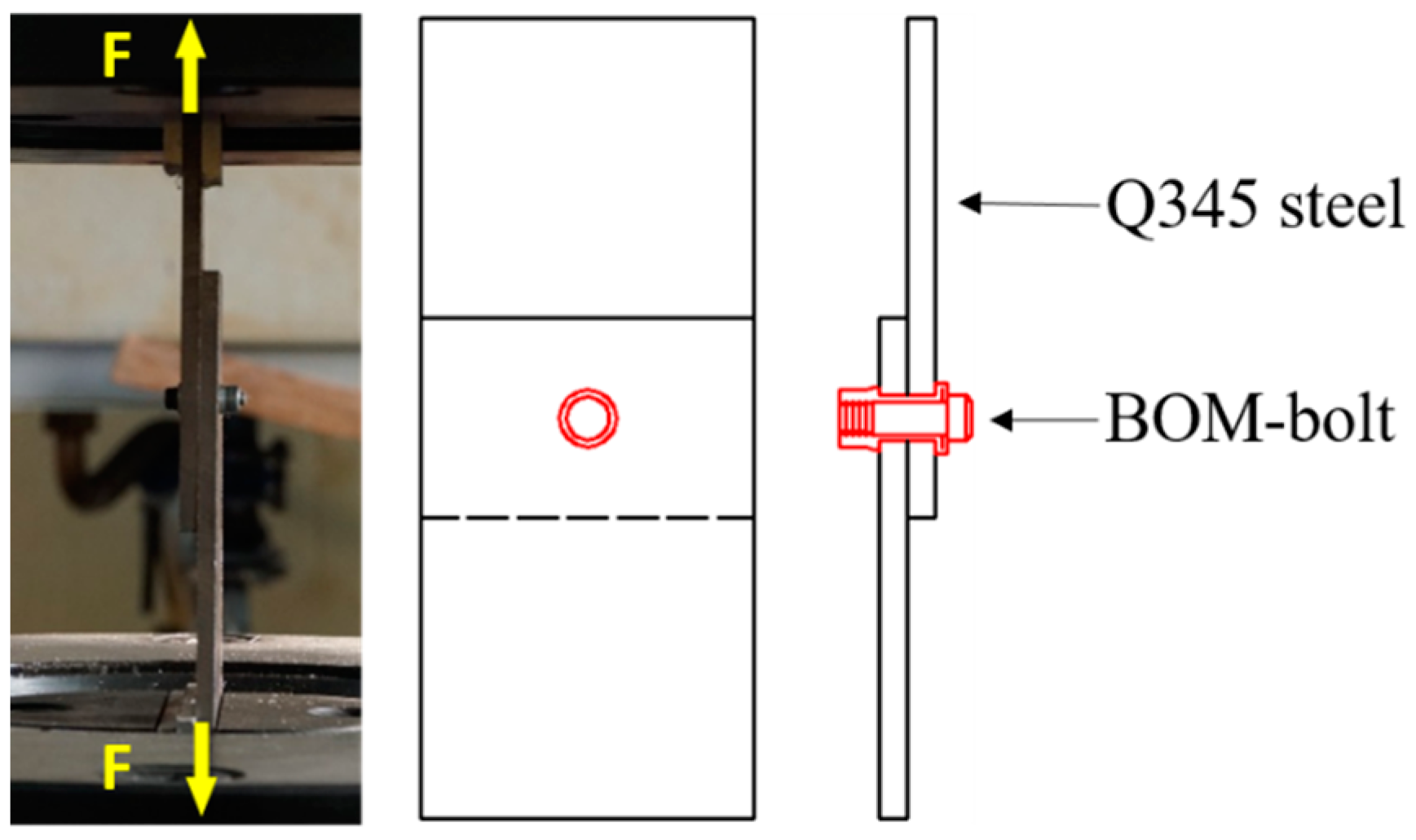

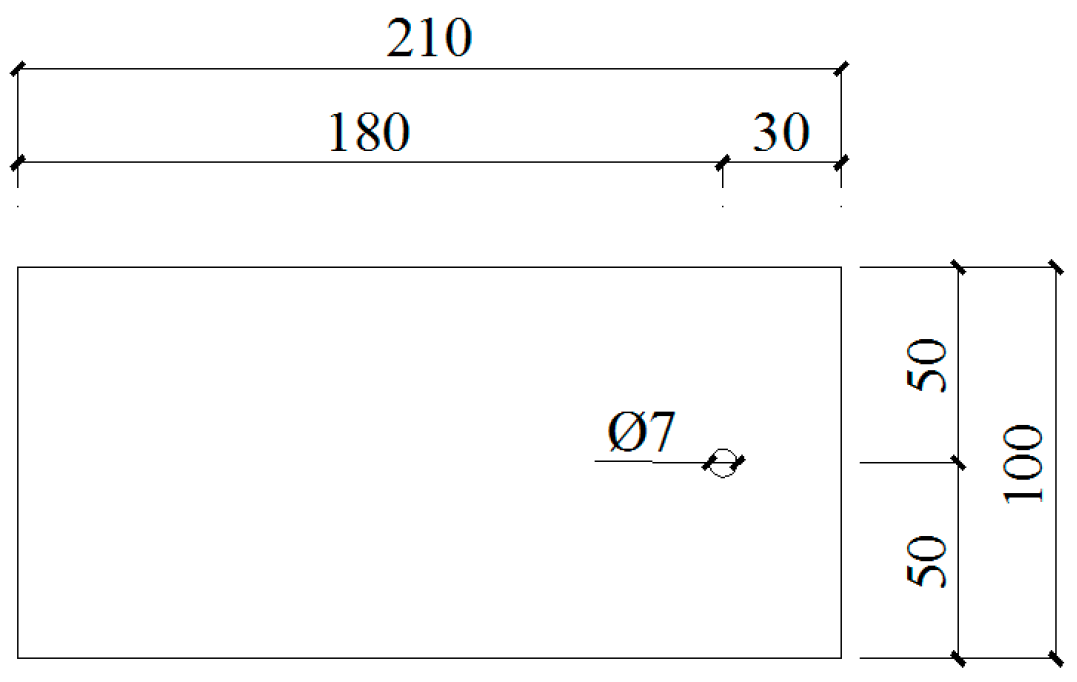

2.1. Shear Tests of Single BOM-Bolted Connections

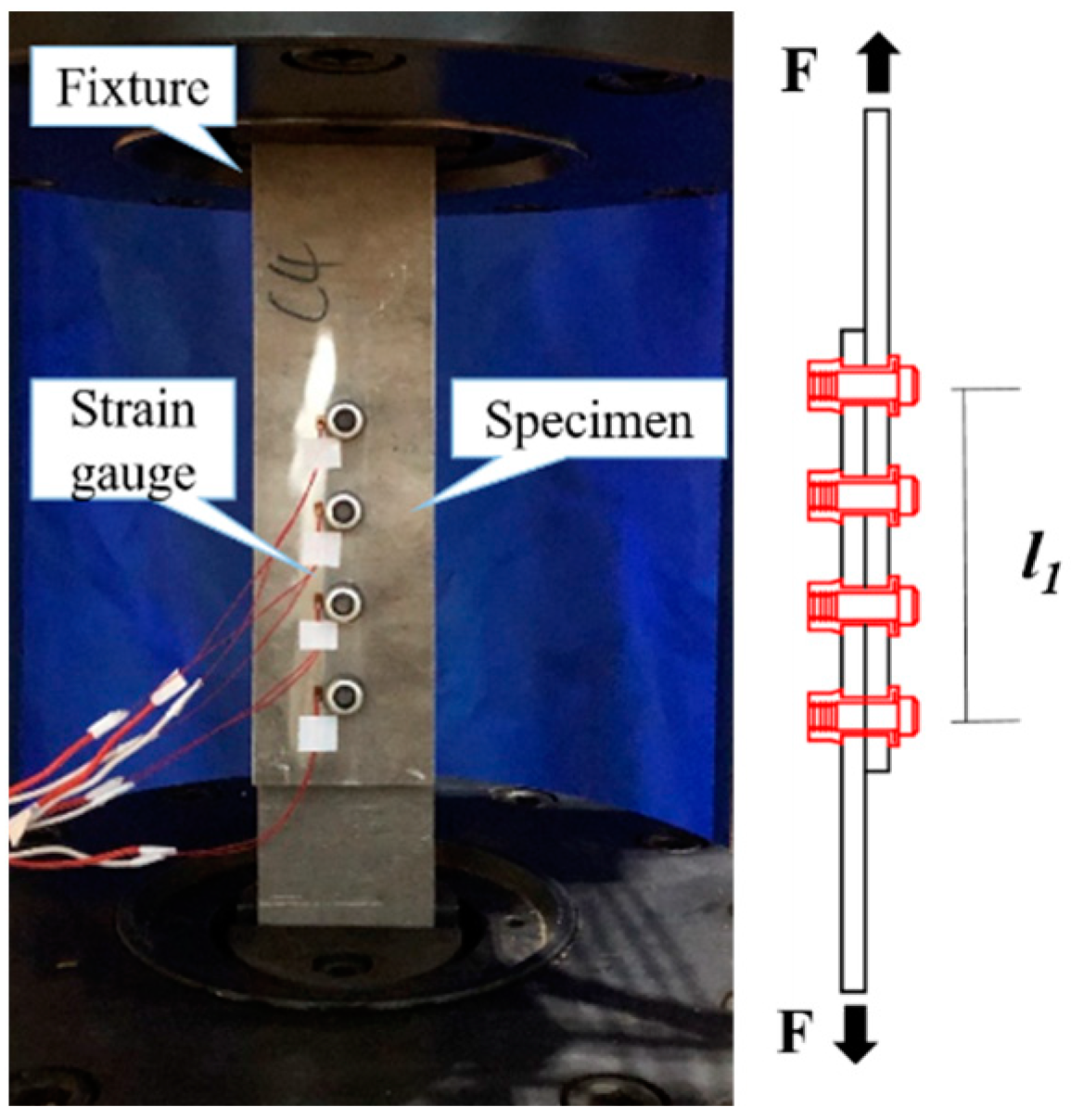

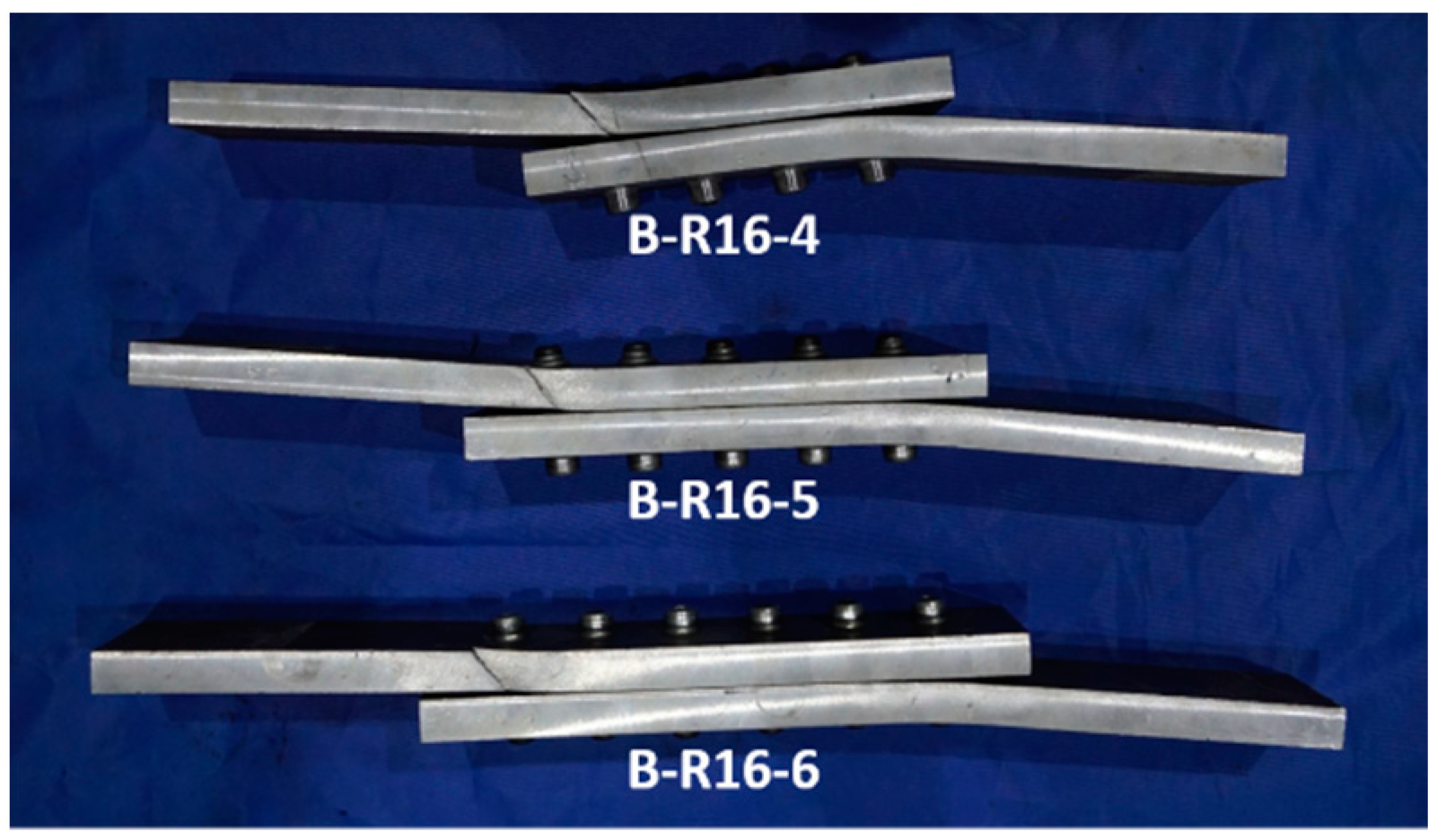

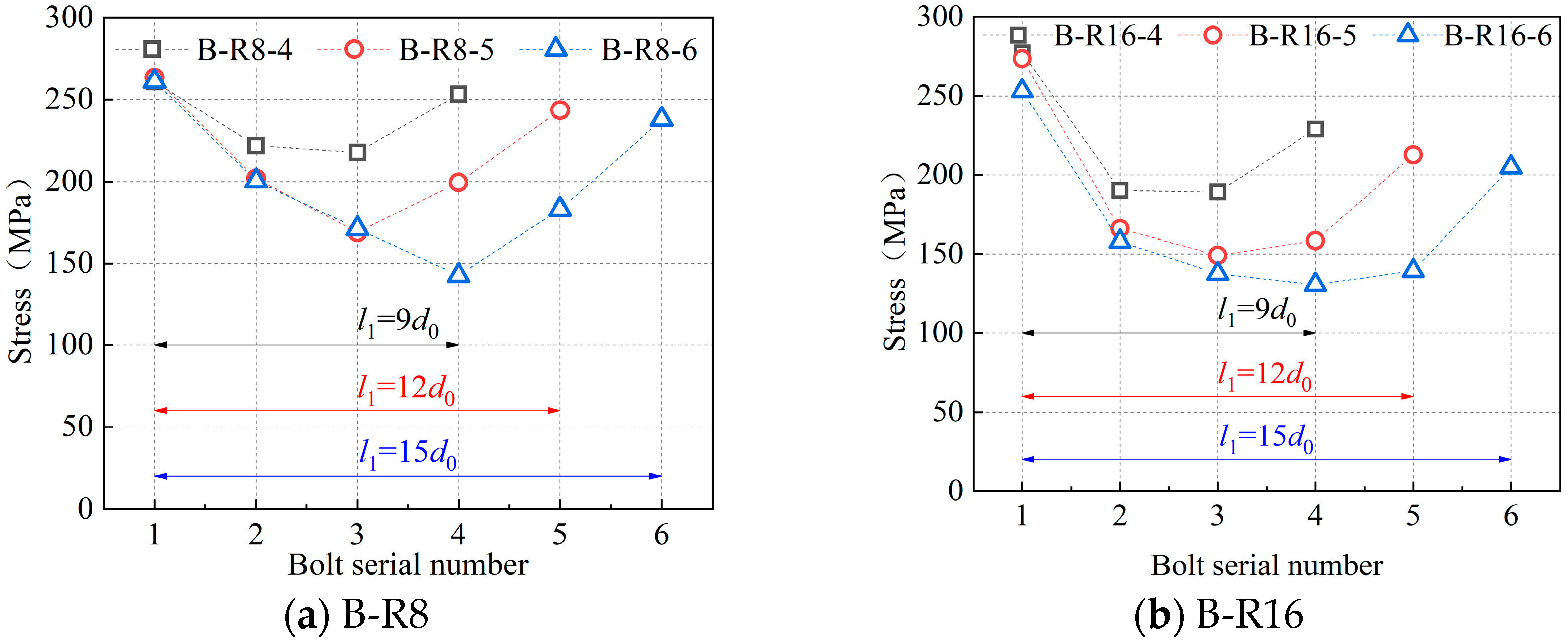

2.2. Shear Tests of BOM-Bolted Long Connections

3. Test of Bearing Resistance at Bolt Holes of BOM-Bolted Connections

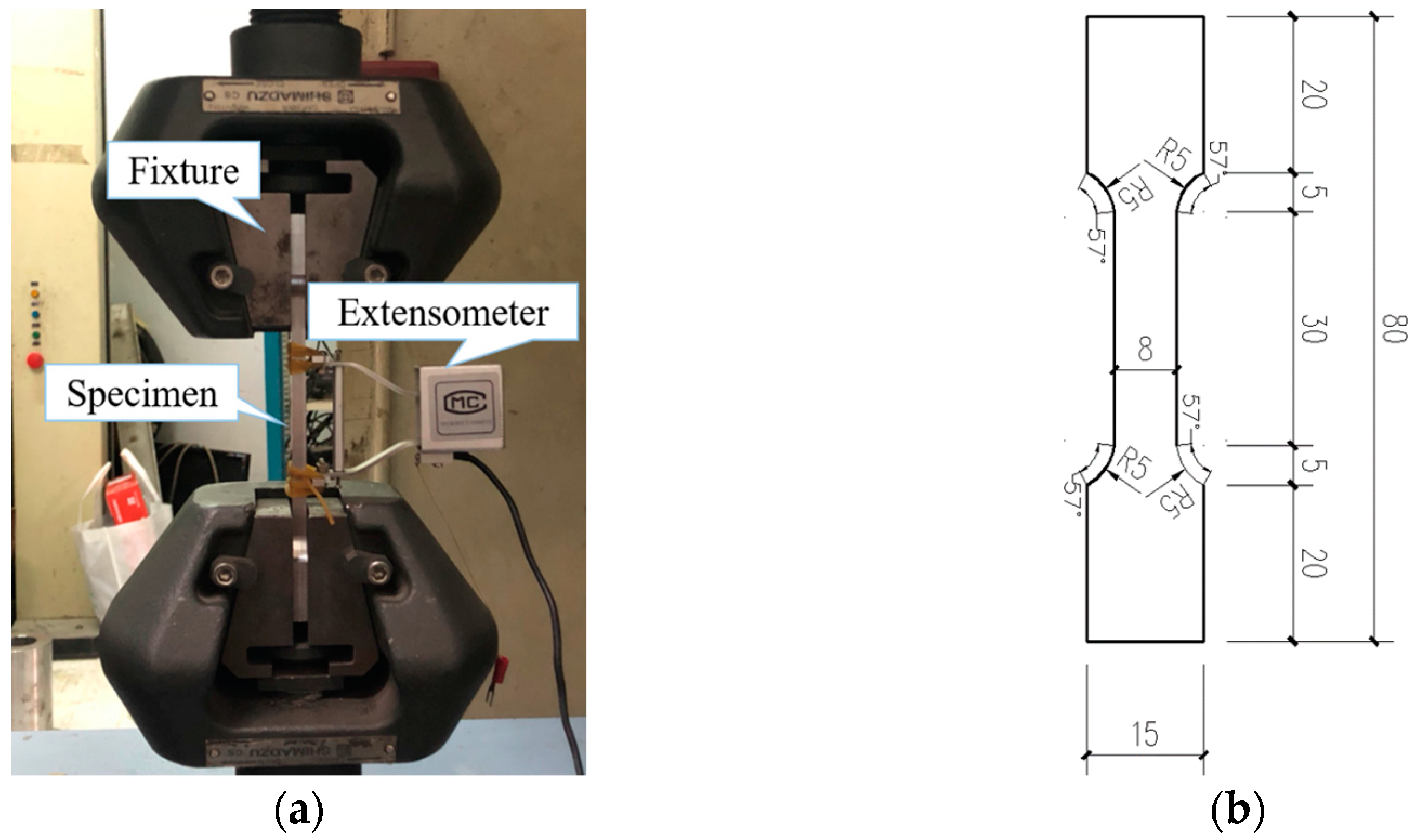

3.1. Tensile Testing of Aluminum Materials

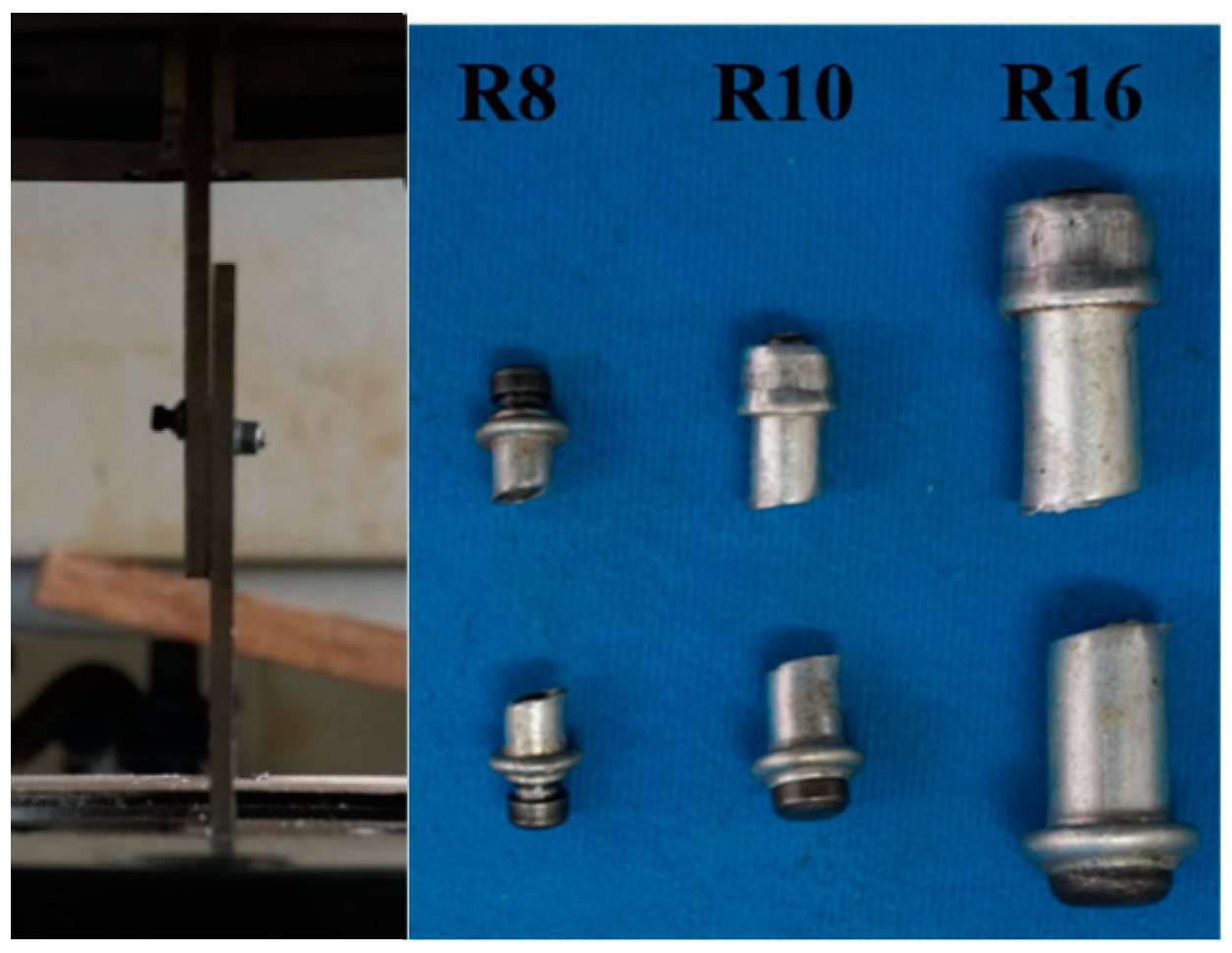

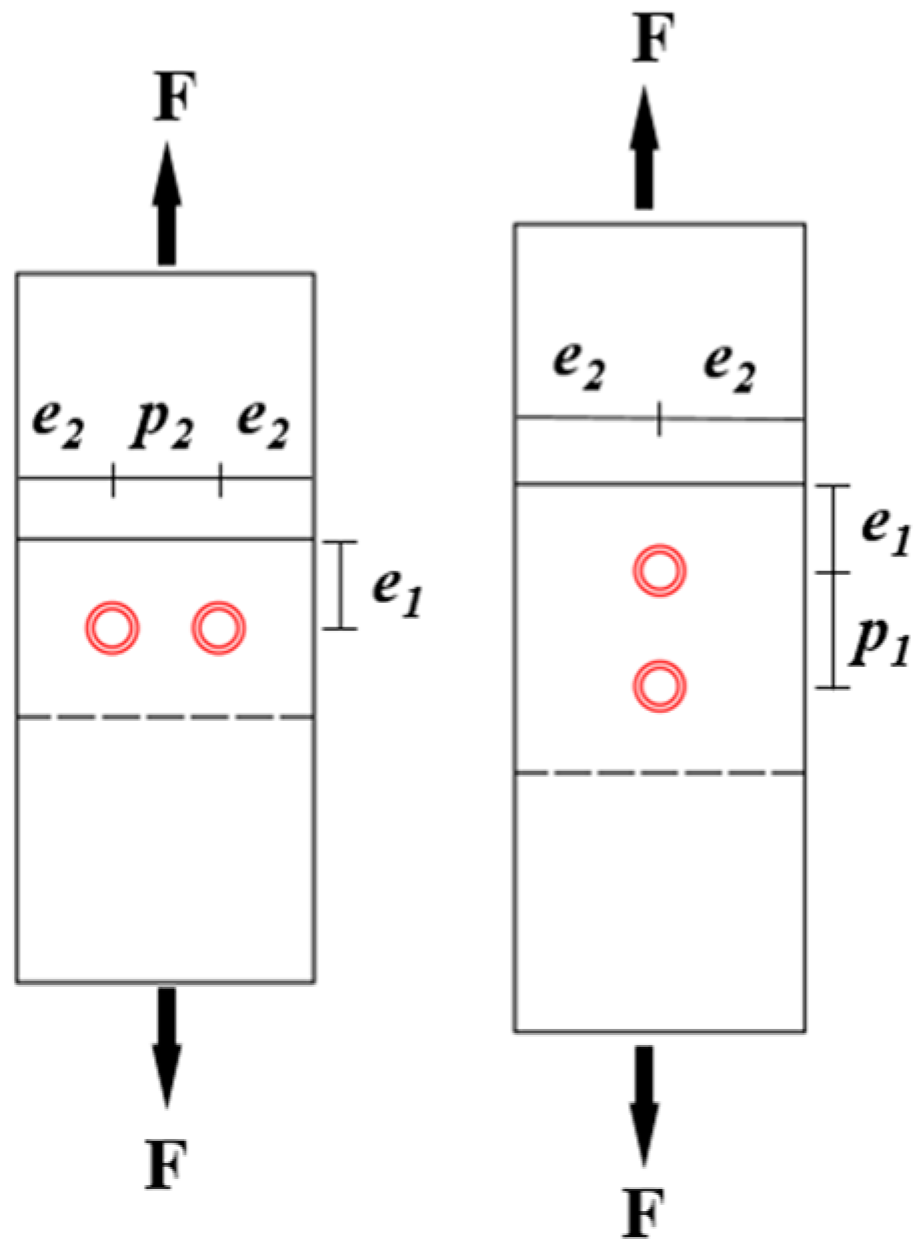

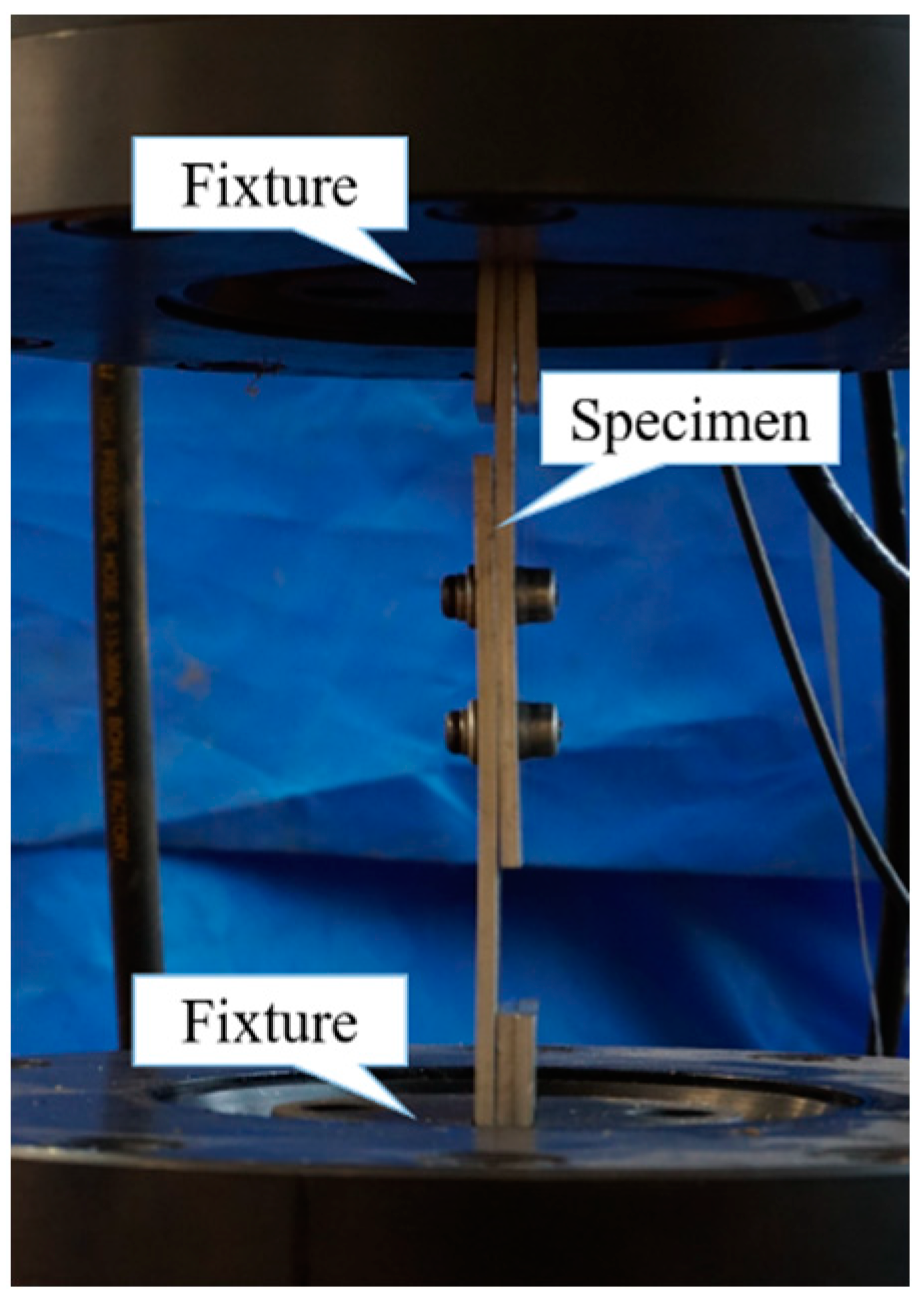

3.2. Design of the Test Setup and Parameter Scheme

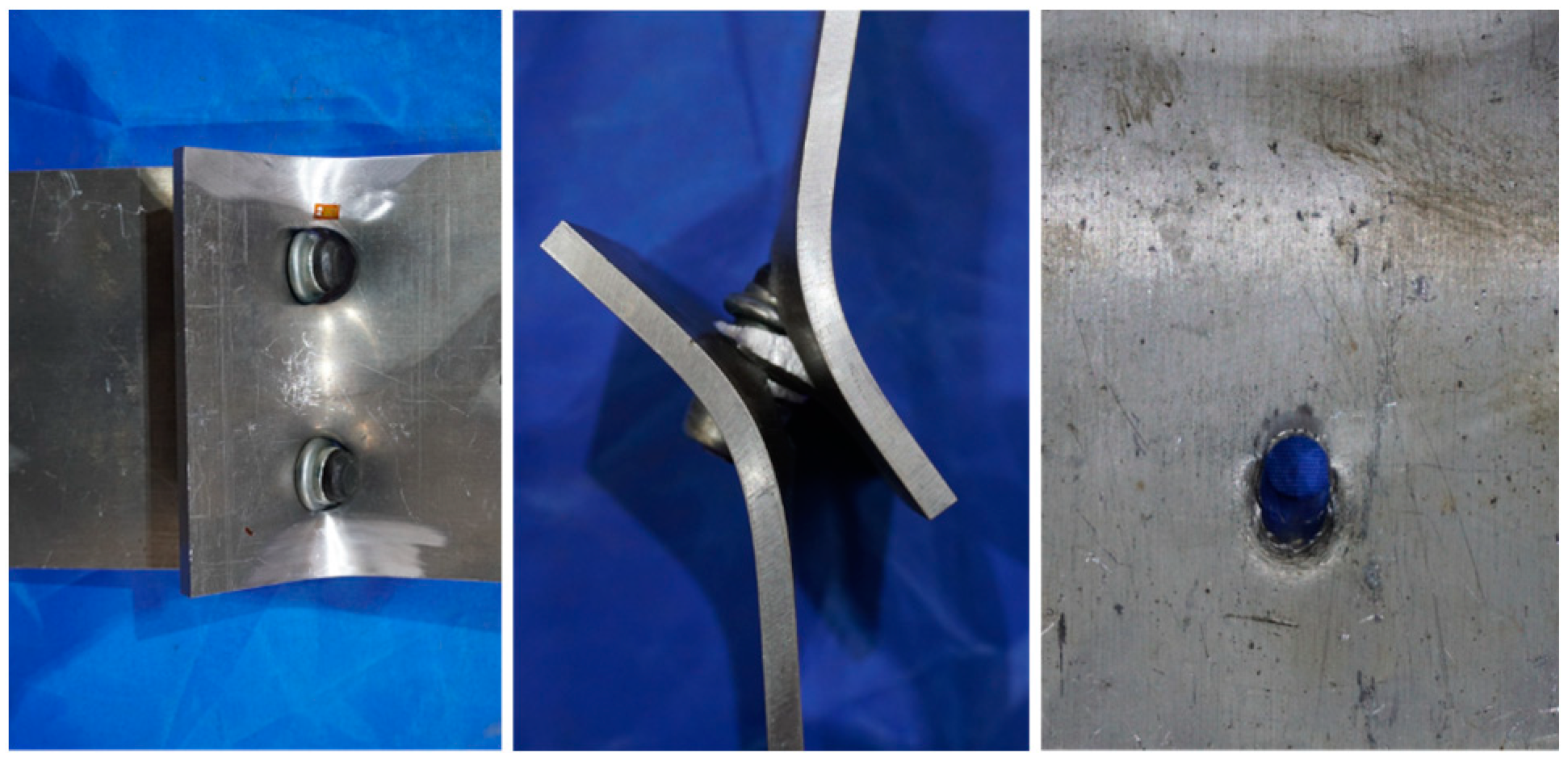

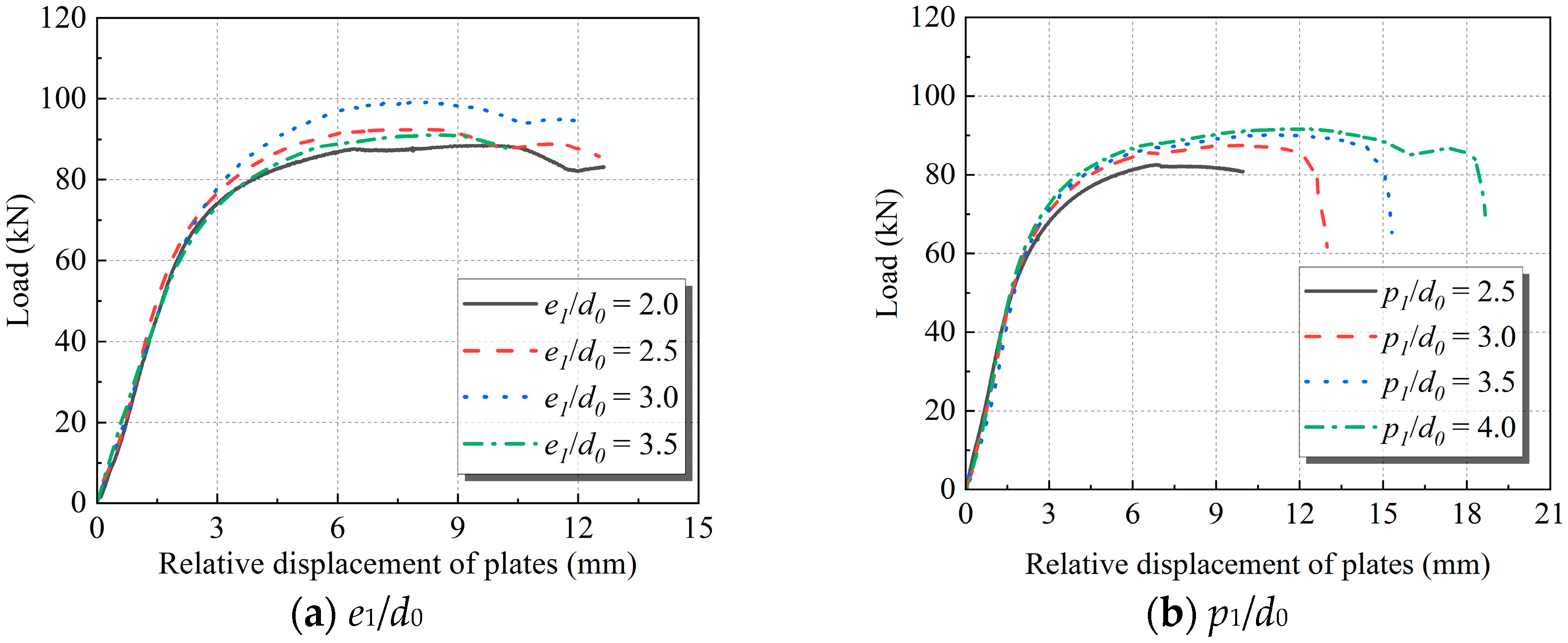

3.3. Analysis of Test Results

3.4. Comparison of Test Results and Codes

4. Finite Element Analysis of the Shear Resistance of BOM-Bolted Connections

5. Design Method of Bearing Capacity of BOM-Bolted Aluminum Connection

5.1. Calculation Formula of Bearing Strength

5.2. Reduction Formula of Shear Bearing Capacity of Long BOM-Bolted Aluminum Connection

6. Conclusions

- (1)

- Shear damage to the pin and sleeve at the shear surface is the single BOM-bolt failure mode. The BOM-bolt is still in the elastic condition of force once the shear force has reached the shear design value specified in the code. The preload force is 32.5% of the code-required minimum preload force for friction-type bolts.

- (2)

- The uneven coefficient on the bolts at both ends increases by 200% as the length of the bolt connection grows by 67%. When the connection length is 15d0, the stress on the bolts at both ends is almost twice as great as that on the central bolt, which causes the end bolts to break down more quickly. Therefore, the design value of the bolt shear bearing strength should be partially discounted when the connection length exceeds 9d0.

- (3)

- The spacing between the bolts affects the bearing strength of the connected aluminum plates, and the distances parallel to the load, e1 and p1, have less of an impact than those perpendicular to the load, e2 and p2. e2 and p2 rise by around 60%, and the specimen’s carrying capacity Pu rises by about 20%. Pu rises by 11% whereas p1 rises by 61%. Pu barely increases by 12% while e1, which has the least impact on bearing capacity, increases by 75%.

- (4)

- There is a significant discrepancy between the test results and the ones obtained according to the calculation method of bolt-bearing strength in the Chinese and European codes of aluminum structures. The results of the European code calculation are approximately 25% higher than the test findings. There may be safety risks if it is utilized to design the bearing strength of the shear connection of BOM bolts. The Chinese code’s calculation of bearing strength is typically more than 30% lower than test values, demonstrating that the design approach is cautious and prone to material waste.

- (5)

- The shear performance of BOM-bolted connections is simulated by the FEM and is confirmed by contrasting it with the outcomes of experiments. The comparison results of failure modes and F-Δ curves demonstrate that the FEM accurately simulates the shear performance of the specimens.

- (6)

- Based on the test results, the design method of the bearing strength of BOM-bolted aluminum connections and the reduction formula of the shear bearing capacity of long-bolted connections are provided. The errors between the test values and the calculated values are less than 5%, which indicates that the formula is suitable for calculating the bearing strength of BOM-bolted aluminum connections. The study of the shear properties of BOM bolts in this paper is to provide a research basis for the application of BOM bolts in aluminum alloy spatial structure joints. Subsequently, the mechanical properties of BOM-bolted aluminum joints will be investigated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Barnett, T.C.; Tizani, W.; Nethercot, D.A. The practice of blind bolting connections to structural hollow sections: A review. Steel Compos. Struct. 2001, 1, 1–16. [Google Scholar] [CrossRef]

- France, J.E.; Davison, J.B.; Kirby, P.A. Strength and rotational stiffness of simple connections to tubular columns using flowdrill connectors. J. Constr. Steel Res. 1999, 50, 15–34. [Google Scholar] [CrossRef]

- Ballerini, M.; Piazza, M.; Bozzo, E.; Occhi, F. Shear capacity of blind bolted connections for RHS steel structural elements. In Proceedings of the Seventh International Symposium, Miskolc, Hungary, 28–30 August 1996; Balkema: Rotterdam, The Netherlands, 1996; pp. 99–106. [Google Scholar]

- France, J.E.; Davison, J.B.; Kirby, P.A. Strength and rotational response of moment connections to tubular columns using flowdrill connectors. J. Constr. Steel Res. 1999, 50, 1–14. [Google Scholar] [CrossRef]

- France, J.E.; Davison, J.B.; Kirby, P.A. Moment-capacity and rotational stiffness of endplate connections to concrete-filled tubular columns with flowdrilled connectors. J. Constr. Steel Res. 1999, 50, 35–48. [Google Scholar] [CrossRef]

- Slowinski, K.; Wuwer, W. Blind-bolted shear connections for axially compressed RHS columns strengthened with open sections. J. Constr. Steel Res. 2016, 127, 15–27. [Google Scholar] [CrossRef]

- Mourad, S. Behaviour of Blind Bolted Moment Connections for Square HSS Columns. Doctoral Dissertation, McMaster University, Hamilton, ON, Canada, 1994; pp. 12–49. [Google Scholar]

- Korol, R.M.; Ghobarah, A.; Mourad, S. Blind Bolting W-Shape Beams to HSS Columns. J. Struct. Eng. 1993, 119, 3463–3481. [Google Scholar] [CrossRef]

- Mourad, S.; Ghobarah, A.; Korol, R.M. Dynamic response of hollow section frames with bolted moment connections. Eng. Struct. 1995, 17, 737–748. [Google Scholar] [CrossRef]

- Mourad, S.; Korol, R.M.; Ghobarah, A. Design of extended end-plate connections for hollow section columns. Can. J. Civ. Eng. 2011, 23, 277–286. [Google Scholar] [CrossRef]

- Ghobarah, A.; Mourad, S.; Korol, R.M. Moment-rotation relationship of blind bolted connections for HSS columns. J. Constr. Steel Res. 1996, 40, 63–91. [Google Scholar] [CrossRef]

- Mourad, S. Resistance factors for blind bolts in direct tension. Eng. Struct. 1997, 19, 995–1000. [Google Scholar]

- Tizani, W.; Cabrera, M.; Mahmood, M.; Ninic, J.; Wang, F. The behaviour of anchored extended blind bolts in concrete-filled tubes. Steel Constr. Des. Res. 2022, 15, 51–58. [Google Scholar] [CrossRef]

- Waqas, R.; Uy, B.; Thai, H.T. Experimental and numerical behaviour of blind bolted flush endplate composite connections. J. Constr. Steel Res. 2019, 153, 179–195. [Google Scholar] [CrossRef]

- Cabrera, M.; Tizani, W.; Ninic, J. A Review and Analysis of Testing and Modeling Practice of Extended Hollo-Bolt Blind Bolt Connections. J. Constr. Steel Res. 2021, 183, 106763. [Google Scholar] [CrossRef]

- Mahmood, M.; Tizani, W. A component model for column face in bending of extended HolloBolt connections. J. Constr. Steel Res. 2021, 182, 106655. [Google Scholar] [CrossRef]

- Debnath, P.P.; Chan, T.M. Tensile behaviour of headed anchored hollo-bolts in concrete filled hollow steel tube connections. Eng. Struct. 2021, 234, 111982. [Google Scholar] [CrossRef]

- Tizani, W.; Mahmood, M.; Bournas, D.A. Effect of Concrete Infill and Slenderness on Column-Face Component in Anchored Blind-Bolt Connections. J. Struct. Eng. 2020, 146, 04020041.1–04020041.18. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Pan, J.; Wang, P. Nonlinear Finite Element Analysis of Anchored Blind-Bolted Joints to Concrete-Filled Steel Tubular Columns. Int. J. Perform. Eng. 2019, 15, 676–687. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Pan, J.; Wang, P.; Qin, J.; Chen, S. Cyclic Behavior of Anchored Blind-Bolted Extended End-Plate Joints to CFST Columns. Appl. Sci. 2020, 10, 904. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Wang, J.; Wang, W.; Duan, M. Seismic evaluation and calculation models of CFDST column blind bolted to composite beam joints with partial shear interaction. Eng. Struct. 2019, 196, 109269.1–109269.20. [Google Scholar] [CrossRef]

- Kim, H.J.; Yura, J.A. The effect of ultimate-to-yield ratio on the bearing strength of bolted connections. J. Constr. Steel Res. 1999, 49, 255–269. [Google Scholar] [CrossRef]

- Rex, C.O.; Easterling, W.S. Behavior and Modeling of a Bolt Bearing on a Single Plate. J. Struct. Eng. 2003, 129, 792–800. [Google Scholar] [CrossRef]

- Kiyokawa, S.; Tateishi, K.; Hanji, T.; Shimizu, M. Slip Coefficient and Ultimate Strength of High-Strength Bolted Friction Joints with Compact Bolt Spacing and Edge Distance. Int. J. Steel Struct. 2019, 19, 1191–1201. [Google Scholar] [CrossRef]

- Bae, M.W.; Kim, S.M. A Study on Characteristics of Magnitude and Distribution Area for Contact Pressure Relative to Separated Distance from Bolt Center by Tightening Torque of Flange Bolt. Trans. Korean Soc. Mech. Eng. A 2018, 42, 621–629. [Google Scholar] [CrossRef]

- Moze, P. Bearing strength at bolt holes in connections with large end distance and bolt pitch. J. Constr. Steel Res. 2018, 147, 132–144. [Google Scholar] [CrossRef]

- Liang, G.; Guo, H.; Liu, Y.; Yang, D.; Li, S. A comparative study on tensile behavior of welded T-stub joints using Q345 normal steel and Q690 high strength steel under bolt preloading cases. Thin-Walled Struct. 2019, 137, 271–283. [Google Scholar] [CrossRef]

- Xu, Z.; Gan, Z.; Xiao, D.; Deng, C. Research on Performance of Channel Connections with Different Bolt Edge Distances. Ind. Constr. 2018, 48, 162–167. [Google Scholar]

- EN 1999-1-1: 2014; Eurocode 9: Design of Aluminum Structures. Springer: Berlin/Heidelberg, Germany, 2014.

- Shi, Y.; Zhang, G.; Wang, Y. Shear Resistance of Bolted Connection in Aluminum Structures. Prog. Steel Build. Struct. 2008, 10, 1–7. [Google Scholar]

| Specimen Number | Bolt Diameter d (mm) | Bolt Hole Diameter d0 (mm) | Thickness of Connecting Plate t (mm) |

|---|---|---|---|

| A-R8-1 | 6.8 | 7 | 6 |

| A-R8-2 | |||

| A-R8-3 | |||

| A-R10-1 | 8.6 | 9 | 10 |

| A-R10-2 | |||

| A-R10-3 | |||

| A-R16-1 | 13.6 | 14 | 20 |

| A-R16-2 | |||

| A-R16-3 |

| Specimen Number | Shear Capacity (kN) |

|---|---|

| A-R8-1 | 26.7 |

| A-R8-2 | 25.0 |

| A-R8-3 | 25.3 |

| A-R10-1 | 39.9 |

| A-R10-2 | 40.4 |

| A-R10-3 | 41.1 |

| A-R16-1 | 143.0 |

| A-R16-2 | 132.8 |

| A-R16-3 | 133.2 |

| Specimen Number | Bolt Diameter d (mm) | Bolt Hole Diameter d0 (mm) | Bolt Quantity | Connection Length l1 (mm) |

|---|---|---|---|---|

| B-R8-4 | 6.8 | 7 | 4 | 9d0 |

| B-R8-5 | 5 | 12d0 | ||

| B-R8-6 | 6 | 15d0 | ||

| B-R16-4 | 13.6 | 14 | 4 | 9d0 |

| B-R16-5 | 5 | 12d0 | ||

| B-R16-6 | 6 | 15d0 |

| Thickness of Plate | Specimen Number | Elastic Modulus | Yield Strength | Tensile Strength | f0.2/fu |

|---|---|---|---|---|---|

| 6 mm | 1 | 68,138 MPa | 263.1 MPa | 322.9 MPa | 0.81 |

| 2 | 69,027 MPa | 260.5 MPa | 323.9 MPa | 0.80 | |

| 3 | 61,615 MPa | 246.8 MPa | 319.2 MPa | 0.77 |

| Specimen Number | e1 | e2 | p1 | p2 |

|---|---|---|---|---|

| C1 | 2.0d0 | 2.5d0 | – | 4.0d0 |

| C2 | 2.5d0 | 2.5d0 | – | 4.0d0 |

| C3 | 3.0d0 | 2.5d0 | – | 4.0d0 |

| C4 | 3.5d0 | 2.5d0 | – | 4.0d0 |

| C5 | 3.0d0 | 1.5d0 | – | 4.0d0 |

| C6 | 3.0d0 | 2.0d0 | – | 4.0d0 |

| C7 | 3.0d0 | 2.5d0 | – | 2.5d0 |

| C8 | 3.0d0 | 2.5d0 | – | 3.0d0 |

| C9 | 3.0d0 | 2.5d0 | – | 3.5d0 |

| C10 | 3.0d0 | 2.5d0 | 2.5d0 | – |

| C11 | 3.0d0 | 2.5d0 | 3.0d0 | – |

| C12 | 3.0d0 | 2.5d0 | 3.5d0 | – |

| C13 | 3.0d0 | 2.5d0 | 4.0d0 | – |

| Specimen Number | Pu (kN) | σc,test (MPa) | σc,CN (MPa) | σc,EU (MPa) | σc,CN/σc,test | σc,EU/σc,test |

|---|---|---|---|---|---|---|

| C1 | 88.5 | 542.3 | 373.5 | 523.3 | 0.69 | 0.96 |

| C2 | 91.2 | 558.8 | 373.5 | 659.5 | 0.67 | 1.18 |

| C3 | 92.6 | 567.4 | 373.5 | 799.3 | 0.66 | 1.41 |

| C4 | 99.2 | 607.8 | 373.5 | 805.0 | 0.61 | 1.32 |

| C5 | 82.5 | 505.5 | 373.5 | 763.4 | 0.74 | 1.51 |

| C6 | 90.9 | 557.0 | 373.5 | 805.0 | 0.67 | 1.45 |

| C7 | 83.6 | 512.3 | 373.5 | 578.0 | 0.73 | 1.13 |

| C8 | 87.7 | 537.4 | 373.5 | 801.1 | 0.70 | 1.49 |

| C9 | 87.9 | 538.6 | 373.5 | 801.2 | 0.69 | 1.49 |

| C10 | 82.6 | 506.1 | 373.5 | 468.6 | 0.74 | 0.93 |

| C11 | 87.5 | 536.2 | 373.5 | 601.8 | 0.70 | 1.12 |

| C12 | 90.2 | 552.7 | 373.5 | 737.9 | 0.68 | 1.34 |

| C13 | 91.7 | 561.9 | 373.5 | 797.3 | 0.66 | 1.42 |

| Specimen Number | Test Values σc,test (MPa) | FEA Value σc,FEA (MPa) | σc,f/σc,test |

|---|---|---|---|

| C1 | 542.3 | 528.1 | 0.97 |

| C2 | 558.8 | 537.2 | 0.96 |

| C3 | 567.4 | 554.8 | 0.98 |

| C4 | 607.8 | 572.9 | 0.94 |

| C5 | 505.5 | 510.3 | 1.01 |

| C6 | 557.0 | 536.3 | 0.96 |

| C7 | 512.3 | 493.7 | 0.96 |

| C8 | 537.4 | 524.4 | 0.98 |

| C9 | 538.6 | 549.6 | 1.02 |

| C10 | 506.1 | 483.0 | 0.95 |

| C11 | 536.2 | 511.6 | 0.95 |

| C12 | 552.7 | 533.8 | 0.97 |

| C13 | 561.9 | 548.7 | 0.98 |

| Specimen Number | Test Values σc,test (MPa) | Formula Value σc,f (MPa) | σc,f/σc,test |

|---|---|---|---|

| C1 | 542.3 | 522.7 | 0.96 |

| C2 | 558.8 | 543.3 | 0.97 |

| C3 | 567.4 | 564.4 | 1.00 |

| C4 | 607.8 | 582.3 | 0.96 |

| C5 | 505.5 | 488.7 | 0.97 |

| C6 | 557.0 | 547.2 | 0.98 |

| C7 | 512.3 | 494.8 | 0.97 |

| C8 | 537.4 | 527.9 | 0.98 |

| C9 | 538.6 | 562.0 | 1.05 |

| C10 | 506.1 | 494.9 | 0.98 |

| C11 | 536.2 | 512.0 | 0.95 |

| C12 | 552.7 | 529.4 | 0.96 |

| C13 | 561.9 | 547.4 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Ma, H.; Zhang, Z.; Cheng, P. Testing and Numerical Simulation of the Shear Resistance of Blind-Bolted Aluminum Connections. Metals 2023, 13, 1337. https://doi.org/10.3390/met13081337

Jiang Y, Ma H, Zhang Z, Cheng P. Testing and Numerical Simulation of the Shear Resistance of Blind-Bolted Aluminum Connections. Metals. 2023; 13(8):1337. https://doi.org/10.3390/met13081337

Chicago/Turabian StyleJiang, Yuqi, Huihuan Ma, Zhiming Zhang, and Peng Cheng. 2023. "Testing and Numerical Simulation of the Shear Resistance of Blind-Bolted Aluminum Connections" Metals 13, no. 8: 1337. https://doi.org/10.3390/met13081337