Evolution of Microstructure and Hardness of TC11 Titanium Alloy under Different Electroshocking Treatment Directions

Abstract

:1. Introduction

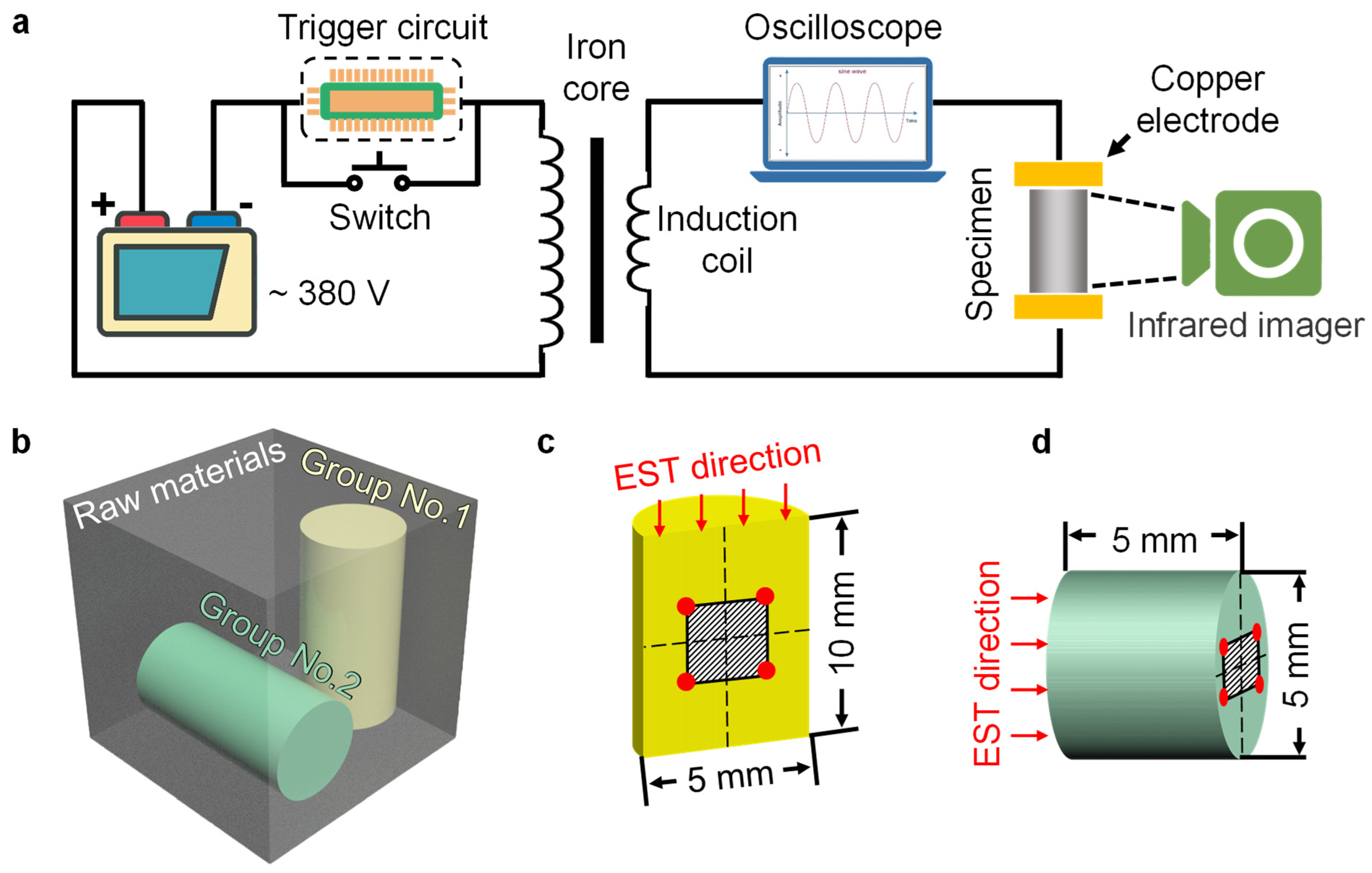

2. Experimental Procedure

2.1. EST Experiment and Specimen Preparation

2.2. Microstructure Characterization

2.3. Hardness Test

3. Results and Discussion

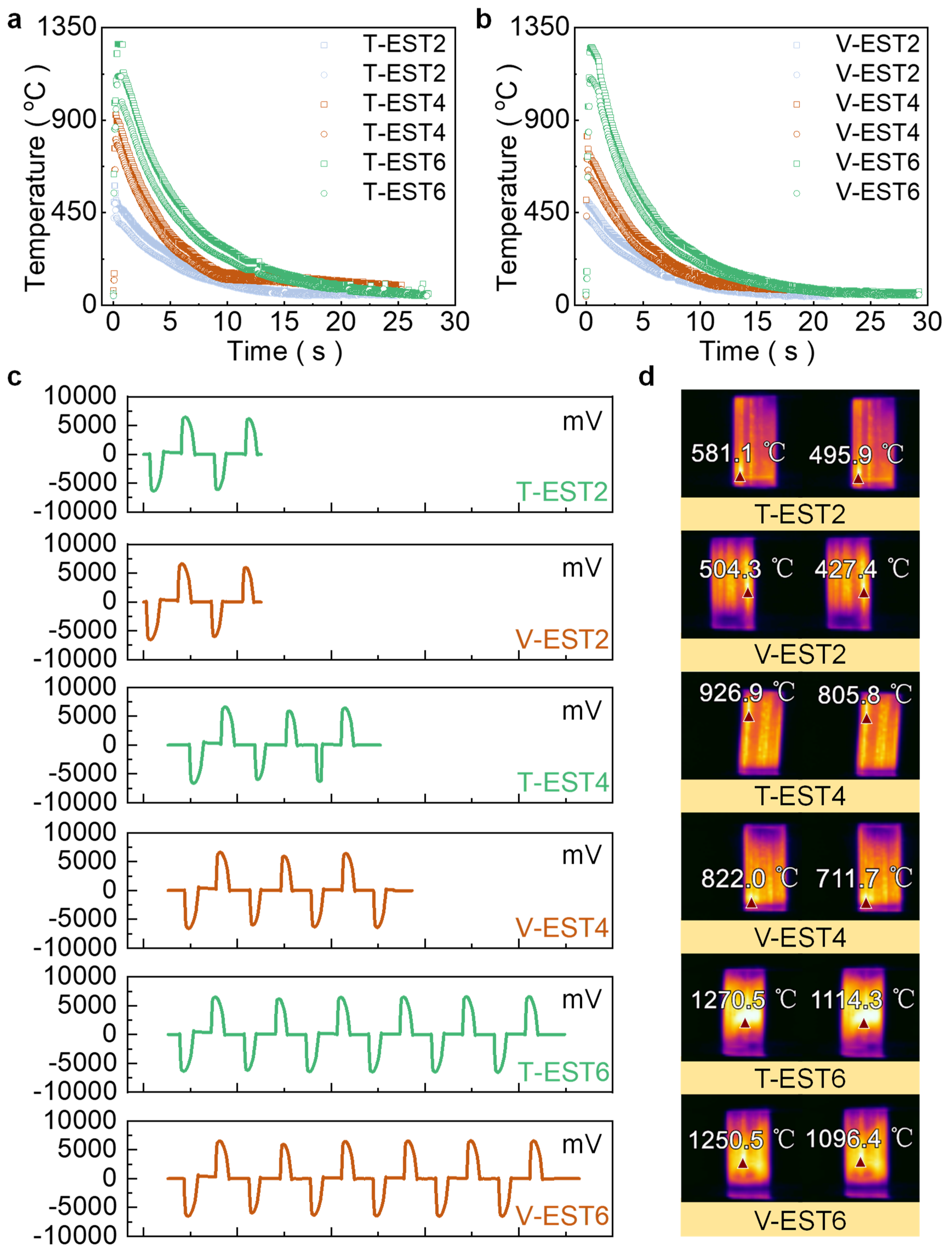

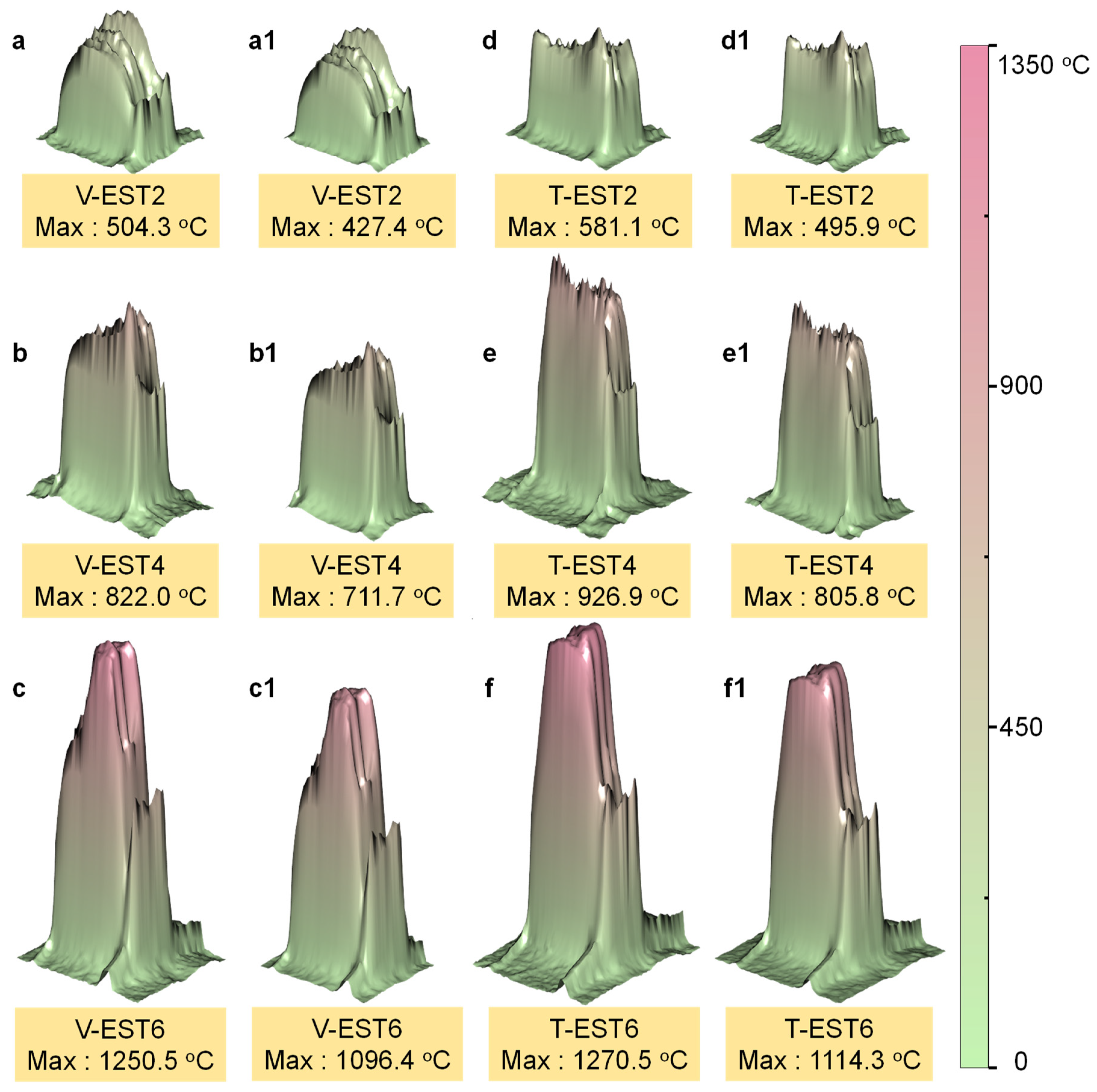

3.1. Temperature Variation of Specimen

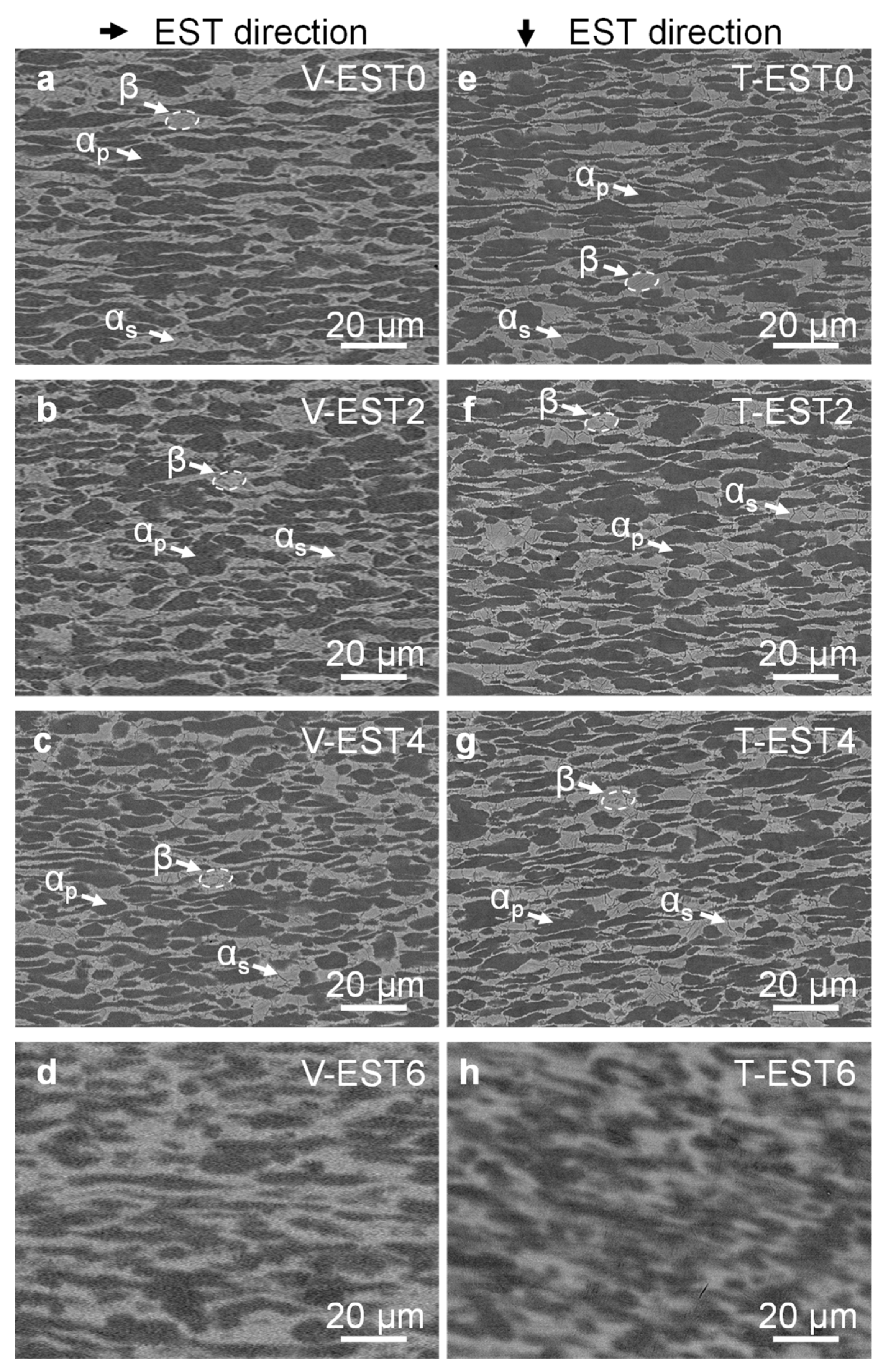

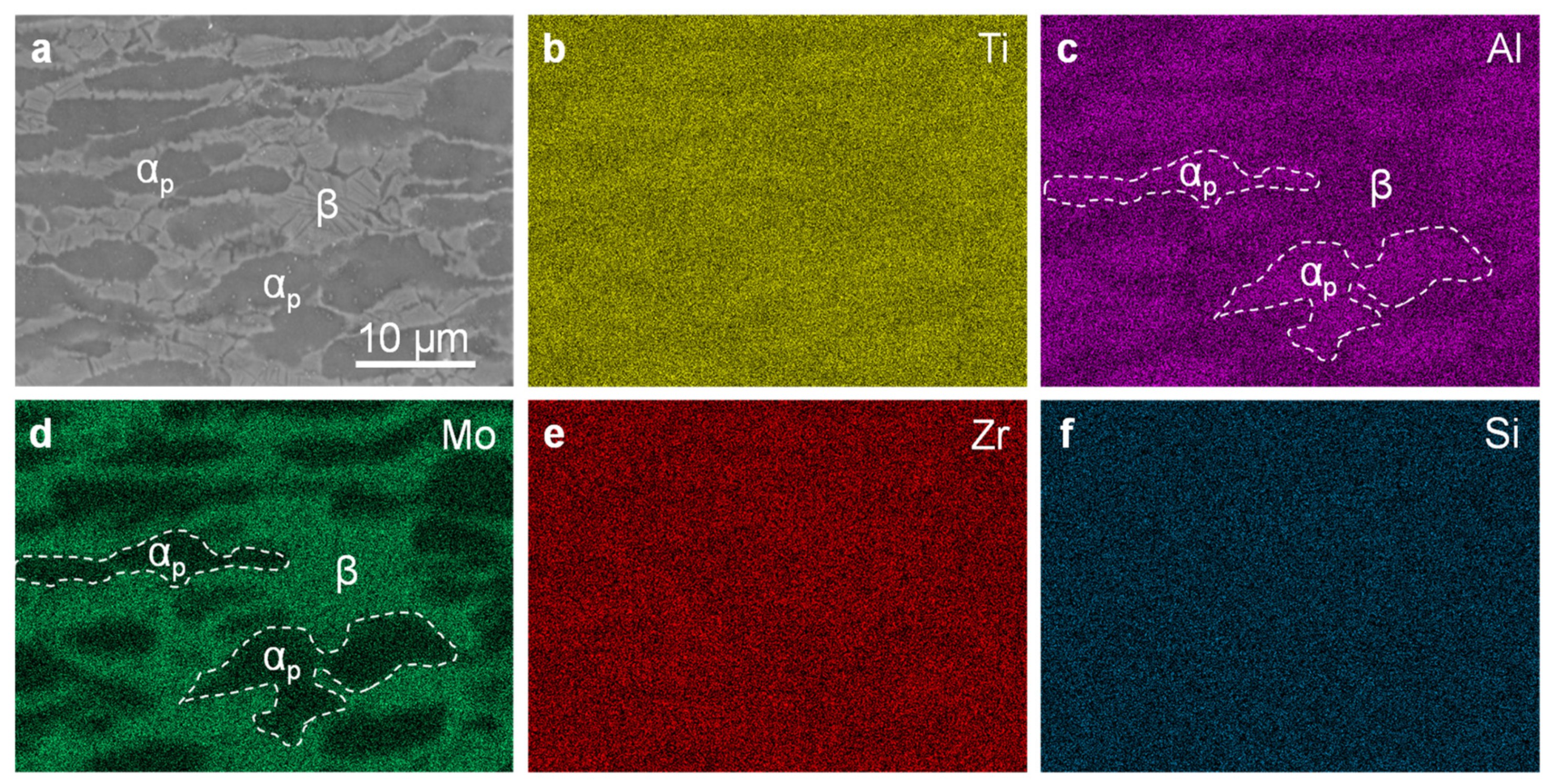

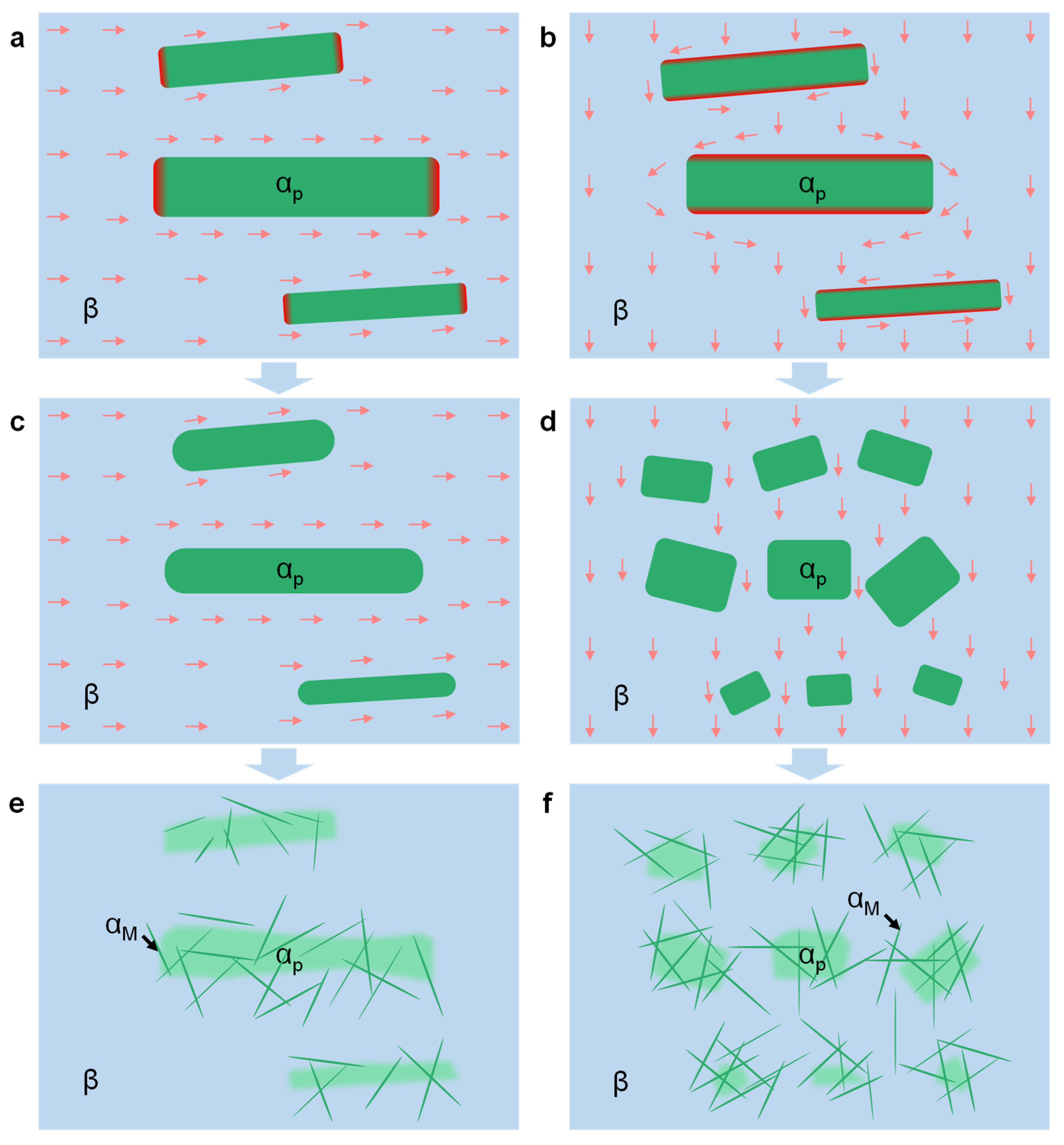

3.2. Microstructure Characterization

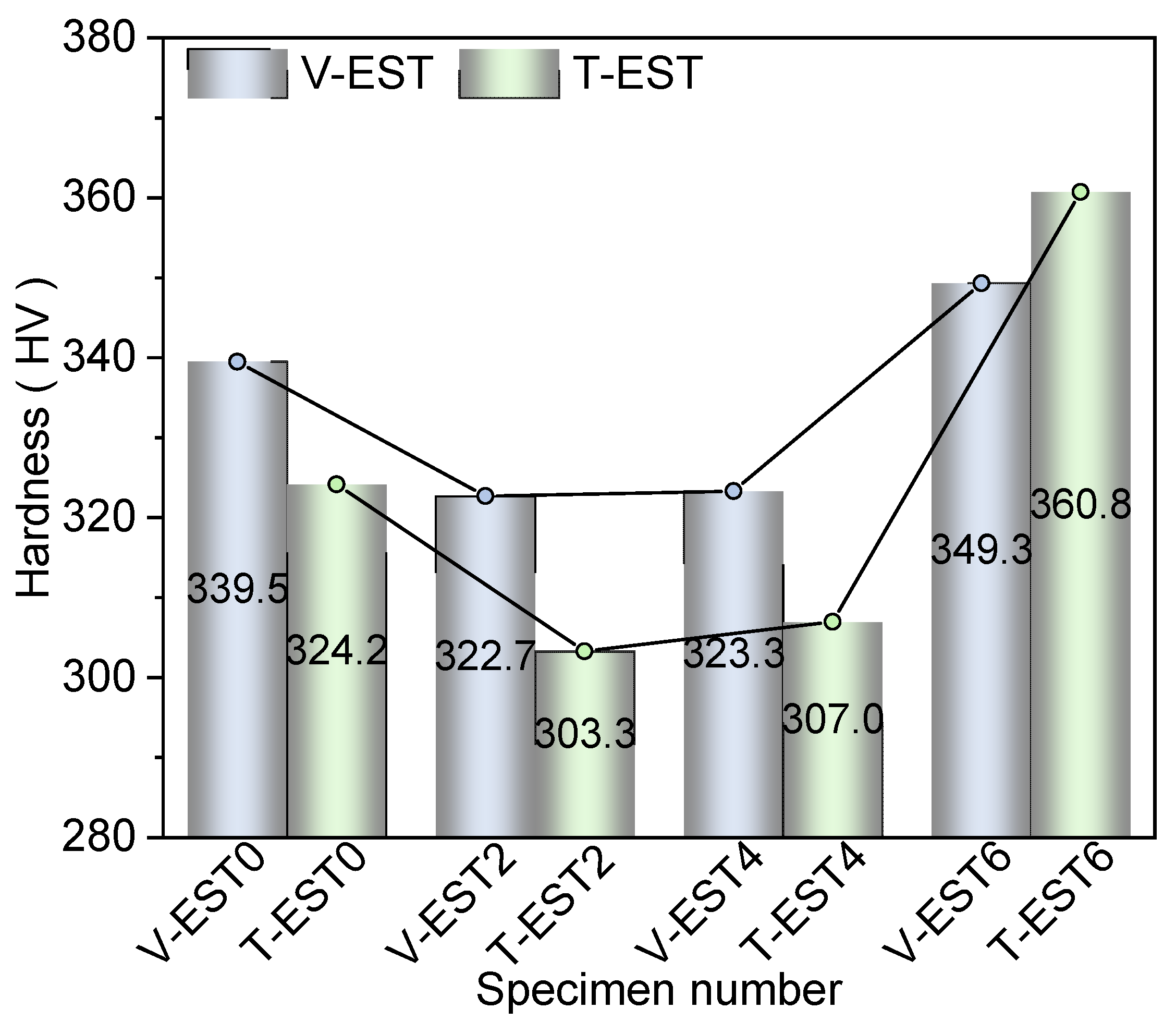

3.3. Hardness Variation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, Y.-W.; Chen, L.-Y.; Chu, Y.-H.; Zhang, L.; Li, R.; Lu, S.; Wang, L.; Zhang, L.-C. Metastable pitting corrosion behavior and characteristics of passive film of laser powder bed fusion produced Ti–6Al–4V in NaCl solutions with different concentrations. Corros. Sci. 2023, 215, 111017. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.K.; Dandekar, T.; Mahadule, D. Texture development during multi-step cross rolling of a β titanium alloy: Experiments and simulations. J. Alloys Compd. 2021, 850, 156824. [Google Scholar] [CrossRef]

- Kaseem, M.; Choe, H.-C. Simultaneous improvement of corrosion resistance and bioactivity of a titanium alloy via wet and dry plasma treatments. J. Alloys Compd. 2021, 851, 156840. [Google Scholar] [CrossRef]

- Morita, M.; Suzuki, S.; Kato, Y.; Li, W.; Umezawa, O. Tensile deformation of texture-controlled titanium with high oxygen content at room temperature. Mater. Sci. Eng. A 2020, 793, 139660. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Lv, Y.; Zhang, L.C.; Chen, L.-Y.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W. Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef] [Green Version]

- Xie, B.; Yu, Z.; Jiang, H.; Xu, B.; Wang, C.; Zhang, J.; Sun, M.; Li, D.; Li, Y. Effects of surface roughness on interfacial dynamic recrystallization and mechanical properties of Ti-6Al-3Nb-2Zr-1Mo alloy joints produced by hot-compression bonding. J. Mater. Sci. Technol. 2022, 96, 199–211. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Devaraj, A.; Joshi, V.V.; Srivastava, A.; Manandhar, S.; Moxson, V.; Duz, V.A.; Lavender, C. A low-cost hierarchical nanostructured beta-titanium alloy with high strength. Nat. Commun. 2016, 7, 11176. [Google Scholar] [CrossRef] [Green Version]

- Erdakov, I.; Glebov, L.; Pashkeev, K.; Bykov, V.; Bryk, A.; Lezin, V.; Radionova, L. Effect of the Ti6Al4V alloy track trajectories on mechanical properties in direct metal deposition. Machines 2020, 8, 79. [Google Scholar] [CrossRef]

- Feng, J.; Wei, D.; Zhang, P.; Yu, Z.; Liu, C.; Lu, W.; Wang, K.; Yan, H.; Zhang, L.; Wang, L. Preparation of TiNbTaZrMo high-entropy alloy with tunable Young’s modulus by selective laser melting. J. Manuf. Process. 2023, 85, 160–165. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, T.; Chen, C.; Hosseini, S.R.E.; Zhang, J.; Zhou, K. Anisotropy in the tensile properties of a selective laser melted Ti-5Al-5Mo-5V-1Cr-1Fe alloy during aging treatment. Materials 2022, 15, 5493. [Google Scholar] [CrossRef] [PubMed]

- Modina, I.M.; Dyakonov, G.S.; Stotskiy, A.G.; Yakovleva, T.V.; Semenova, I.P. Effect of the Texture of the Ultrafine-Grained Ti-6Al-4V Titanium Alloy on Impact Toughness. Materials 2023, 16, 1318. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, S.; Zhang, J.; Zhang, D.; Kuang, J.; Bao, X.; Liu, G.; Sun, J. Trifunctional nanoprecipitates ductilize and toughen a strong laminated metastable titanium alloy. Nat. Commun. 2023, 14, 1397. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. Effect of Heat Treatment Procedure on Mechanical Properties of Ti-15V-3Al-3Sn-3Cr Metastable β Titanium Alloy. J. Mater. Eng. Perform. 2021, 30, 1066–1074. [Google Scholar] [CrossRef]

- Zhao, P.; Wei, C.; Li, Y.; Tao, J.; Zhang, C.; Xiao, X.; Zhang, M. Effect of heat treatment on the microstructure, microhardness and impact toughness of TC11 and TC17 linear friction welded joint. Mater. Sci. Eng. A 2020, 803, 140496. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, P.; Xie, L.; Wang, Z.; Wang, L.; Lu, W.; Jiang, C.; Ji, V. Evaluation of Mechanical Behavior and Surface Morphology of Shot-Peened Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2020, 29, 182–190. [Google Scholar] [CrossRef]

- Pan, X.; Wang, X.; Tian, Z.; He, W.; Shi, X.; Chen, P.; Zhou, L. Effect of dynamic recrystallization on texture orientation and grain refinement of Ti6Al4V titanium alloy subjected to laser shock peening. J. Alloys Compd. 2020, 850, 156672. [Google Scholar] [CrossRef]

- Sun, Q.; Hua, L. Micro texture of titanium alloys excited nonlinearly by electromagnetic pulse. Scr. Mater. 2021, 200, 113828. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Yu, Y.; Wu, W.; Wang, Z.; Lu, J.; Sun, Q.; Xie, L.; Hua, L. Fatigue life improvement of TC11 titanium alloy by novel electroshock treatment. Mater. Des. 2022, 221, 110902. [Google Scholar] [CrossRef]

- Wu, W.; Song, Y.; Lu, J.; Yu, Y.; Hua, L. Novel strategy of electroshock treatment for improving mechanical performances of Al–Zn–Mg–Cu alloy by edge dislocation increment. Mater. Sci. Eng. A 2022, 854, 143805. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, R.; Chong, Y.; Li, X.; Abu-Odeh, A.; Rothchild, E.; Chrzan, D.C.; Asta, M.; Morris, J.W.; Minor, A.M. Defect reconfiguration in a Ti–Al alloy via electroplasticity. Nat. Mater. 2020, 20, 468–472. [Google Scholar] [CrossRef]

- Konovalov, S.; Komissarova, I.; Ivanov, Y.; Gromov, V.; Kosinov, D. Structural and phase changes under electropulse treatment of fatigue-loaded titanium alloy VT1-0. J. Mater. Res. Technol. 2019, 8, 1300–1307. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Zhang, Y.; Wang, Y.; Hou, H. Fast recrystallization and phase transformation in ECAP deformed Ti–6Al–4V alloy induced by pulsed electric current. J. Alloys Compd. 2019, 786, 733–741. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, X. Refining the microstructure to strengthen casting titanium alloy by electric pulse. Mater. Sci. Eng. A 2022, 849, 143519. [Google Scholar] [CrossRef]

- Gao, L.; Liu, J.; Cheng, X.; Li, S.; Luo, Y.; Guo, Q. Effects of short time electric pulse heat treatment on microstructures and mechanical properties of hot-rolled Ti–6Al–4V alloy. Mater. Sci. Eng. A 2014, 618, 104–111. [Google Scholar] [CrossRef]

- Lu, Z.; Guo, C.; Li, P.; Wang, Z.; Chang, Y.; Tang, G.; Jiang, F. Effect of electropulsing treatment on microstructure and mechanical properties of intermetallic Al3Ti alloy. J. Alloys Compd. 2017, 708, 834–843. [Google Scholar] [CrossRef]

- Yan, X.; Xu, X.; Wu, C.; Zhao, Y.; Li, D.; Zhou, Y.; Wu, Z.; Wei, L. A novel electropulsing treatment to improve the surface strength and repair the pore of additively manufactured Ti-6Al-4V alloy. Surf. Coat. Technol. 2023, 458, 129364. [Google Scholar] [CrossRef]

- Li, Y.; Wang, F.; Sun, Q.; Qian, D.; Song, Y.; Hua, L. Study on the microstructure and impact toughness of TC11 titanium alloy by a novel electromagnetic shocking treatment. Mater. Sci. Eng. A 2023, 876, 145149. [Google Scholar] [CrossRef]

- Liu, C.; Xie, L.; Qian, D.; Hua, L.; Wang, L.; Zhang, L.-C. Microstructure evolution and mechanical property response of TC11 titanium alloy under electroshock treatment. Mater. Des. 2020, 198, 109322. [Google Scholar] [CrossRef]

- Xie, L.; Guo, H.; Song, Y.; Liu, C.; Wang, Z.; Hua, L.; Wang, L.; Zhang, L.-C. Effects of electroshock treatment on microstructure evolution and texture distribution of near-β titanium alloy manufactured by directed energy deposition. Mater. Charact. 2020, 161, 110137. [Google Scholar] [CrossRef]

- Xie, L.; Guo, H.; Song, Y.; Hua, L.; Wang, L.; Zhang, L.-C. Novel approach of electroshock treatment for defect repair in near-β titanium alloy manufactured via directed energy deposition. Met. Mater. Trans. A 2021, 52, 457–461. [Google Scholar] [CrossRef]

- Xie, L.; Wu, Y.; Yao, Y.; Hua, L.; Wang, L.; Zhang, L.-C.; Lu, W. Refinement of TiB reinforcements in TiB/Ti-2Al-6Sn titanium matrix composite via electroshock treatment. Mater. Charact. 2021, 180, 111395. [Google Scholar] [CrossRef]

- Liu, C.; Yin, F.; Xie, L.; Qian, D.; Song, Y.; Wu, W.; Wang, L.; Zhang, L.-C.; Hua, L. Evolution of grain boundary and texture in TC11 titanium alloy under electroshock treatment. J. Alloy. Compd. 2022, 904, 163969. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, P.; Guo, H.; Tian, L.; Wang, L.; Wang, Z.; Hua, L.; Xie, L. Effect of electroshocking treatment on the microstructure and mechanical properties of laser melting deposited near-β Ti-55531 thin-wall. J. Alloys Compd. 2023, 936, 168187. [Google Scholar] [CrossRef]

- Guo, H.; Liu, P.; Qin, X.; Song, Y.; Qian, D.; Xie, L.; Wang, L.; Zhang, L.-C.; Hua, L. Electroshock treatment dependent microstructural evolution and mechanical properties of near-β titanium alloy manufactured by directed energy deposition. Mater. Des. 2021, 212, 110286. [Google Scholar] [CrossRef]

- González-Fernández, L.; Risueño, E.; Pérez-Sáez, R.B.; Tello, M.J. Infrared normal spectral emissivity of Ti–6Al–4V alloy in the 500–1150 K temperature range. J. Alloys Compd. 2012, 541, 144–149. [Google Scholar] [CrossRef]

- Xie, L.; Liu, C.; Song, Y.; Guo, H.; Wang, Z.; Hua, L.; Wang, L.; Zhang, L.-C. Evaluation of microstructure variation of TC11 alloy after electroshocking treatment. J. Mater. Res. Technol. 2020, 9, 2455–2466. [Google Scholar] [CrossRef]

- Fan, Z.; Jian, J.; Liu, Y.; Chen, Y.; Song, M.; Jiao, L.; Wang, H.; Zhang, X. In situ studies on superior thermal stability of bulk FeZr nanocomposites. Acta Mater. 2015, 101, 125–135. [Google Scholar] [CrossRef] [Green Version]

- Rizi, M.S.; Minouei, H.; Lee, B.J.; Toroghinejad, M.R.; Hong, S.I. Effects of carbon and molybdenum on the nanostructural evolution and strength/ductility trade-off in Fe40Mn40Co10Cr10 high-entropy alloys. J. Alloy. Compd. 2022, 911, 165108. [Google Scholar] [CrossRef]

- Dirras, G.; Tingaud, D.; Ueda, D.; Hocini, A.; Ameyama, K. Dynamic Hall-Petch versus grain-size gradient effects on the mechanical behavior under simple shear loading of β-titanium Ti-25Nb-25Zr alloys. Mater. Lett. 2017, 206, 214–216. [Google Scholar] [CrossRef]

- Ames, S.; McQuillan, A. The resistivity-temperature-concentration relationships in the system niobium-titanium. Acta Met. 1954, 2, 831–836. [Google Scholar] [CrossRef]

- Ho, J.C.; Collings, E.W. Anomalous electrical resistivity in titanium-molybdenum alloys. Phys. Rev. B 1972, 6, 3727–3738. [Google Scholar] [CrossRef]

- Ouchi, C.; Iizumi, H.; Mitao, S. Effects of ultra-high purification and addition of interstitial elements on properties of pure titanium and titanium alloy. Mater. Sci. Eng. A 1998, 243, 186–195. [Google Scholar] [CrossRef]

| Al | Mo | Zr | Si | Ti |

|---|---|---|---|---|

| 5.8–7.0 | 2.8–3.8 | 0.8–2.0 | 0.20–0.35 | others |

| Material | EST Time | Specimen Number |

|---|---|---|

| Group No. 1 | 0 s | V-EST0 |

| Group No. 2 | 0 s | T-EST0 |

| Group No. 1 | 0.02 s | V-EST2 |

| Group No. 2 | 0.02 s | T-EST2 |

| Group No. 1 | 0.04 s | V-EST4 |

| Group No. 2 | 0.04 s | T-EST4 |

| Group No. 1 | 0.06 s | V-EST6 |

| Group No. 2 | 0.06 s | T-EST6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wu, Y.; Wang, H.; Yin, F.; Qian, D.; Wang, L.; Xie, L.; Hua, L. Evolution of Microstructure and Hardness of TC11 Titanium Alloy under Different Electroshocking Treatment Directions. Metals 2023, 13, 1396. https://doi.org/10.3390/met13081396

Liu C, Wu Y, Wang H, Yin F, Qian D, Wang L, Xie L, Hua L. Evolution of Microstructure and Hardness of TC11 Titanium Alloy under Different Electroshocking Treatment Directions. Metals. 2023; 13(8):1396. https://doi.org/10.3390/met13081396

Chicago/Turabian StyleLiu, Chang, Yongjian Wu, Haoxing Wang, Fei Yin, Dongsheng Qian, Liqiang Wang, Lechun Xie, and Lin Hua. 2023. "Evolution of Microstructure and Hardness of TC11 Titanium Alloy under Different Electroshocking Treatment Directions" Metals 13, no. 8: 1396. https://doi.org/10.3390/met13081396