Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment

Abstract

:1. Introduction

2. Materials and Methods

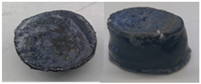

2.1. Sample Preparation

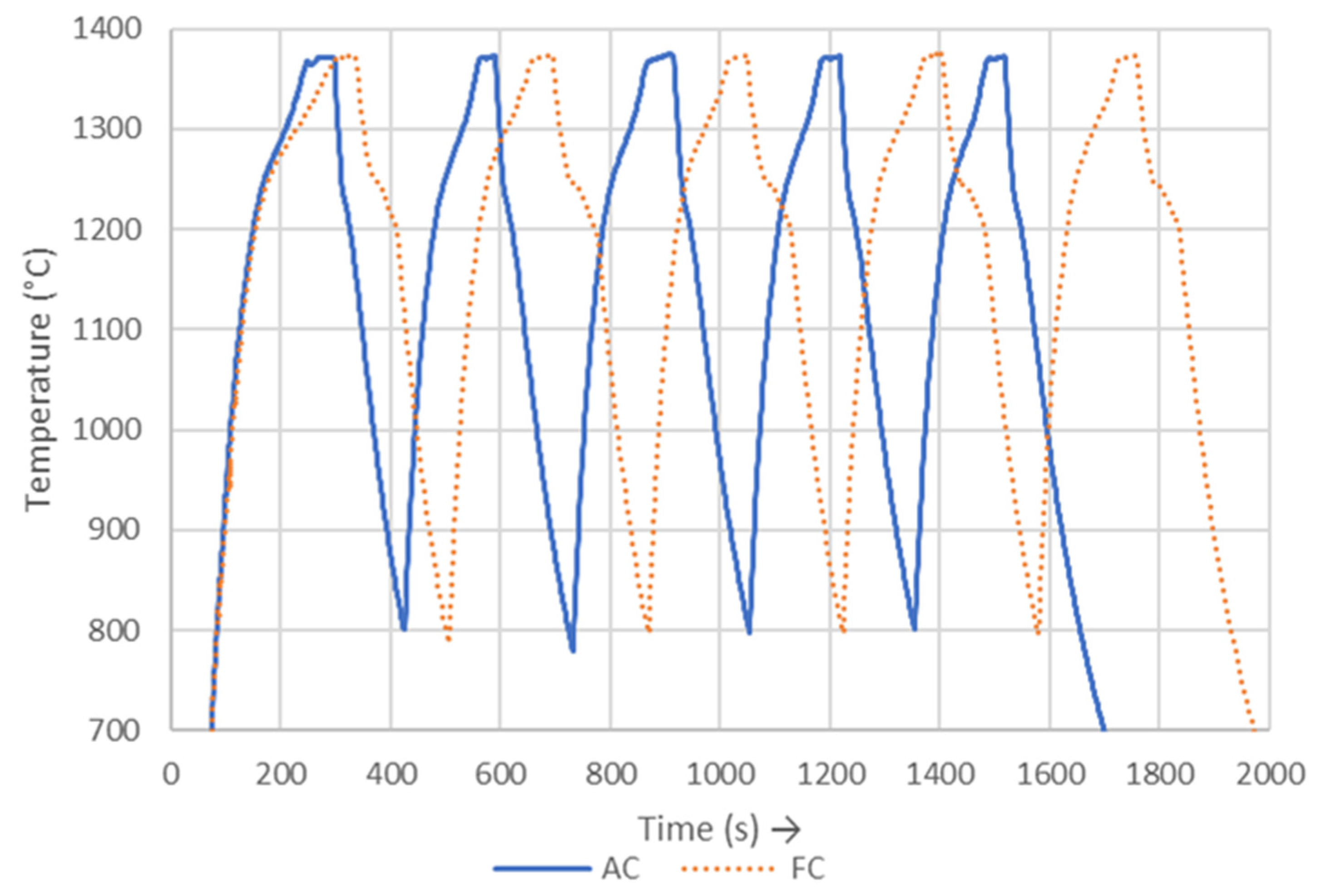

2.2. Cyclic Heat Treatment Conditions Using Induction Equipment

- Resonant frequency: ~93 kHz. Tap setting: 16.

- Capacitance: series/parallel arrangement ((2 µF × 1 µF) − (2 µF × 1 µF) -> equivalent to 1 µF).

- Starting voltage: approximately 550 V (decreased to ~350 V to prevent overshooting the target temperature at 1340 °C). The voltage settings for each sample varied due to differences in their thermal, electrical, and magnetic properties.

- Temperature control was manually achieved by adjusting the induction voltage.

2.3. Compression Testing

2.4. Microstructural Analysis

3. Results and Discussion

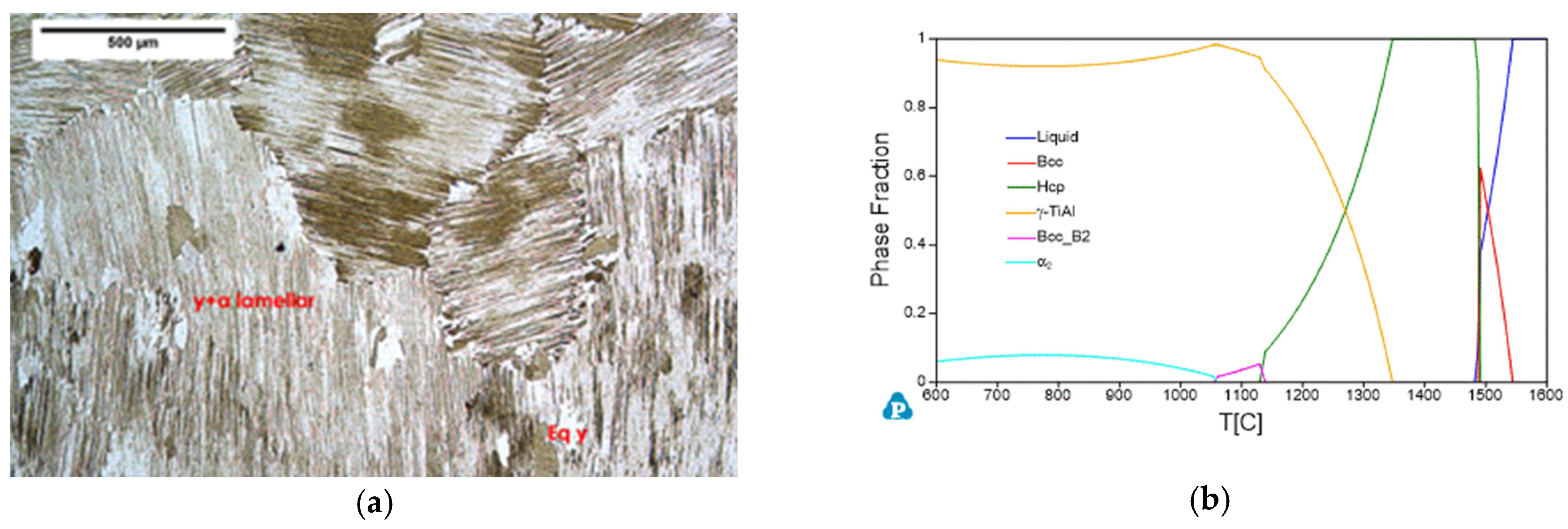

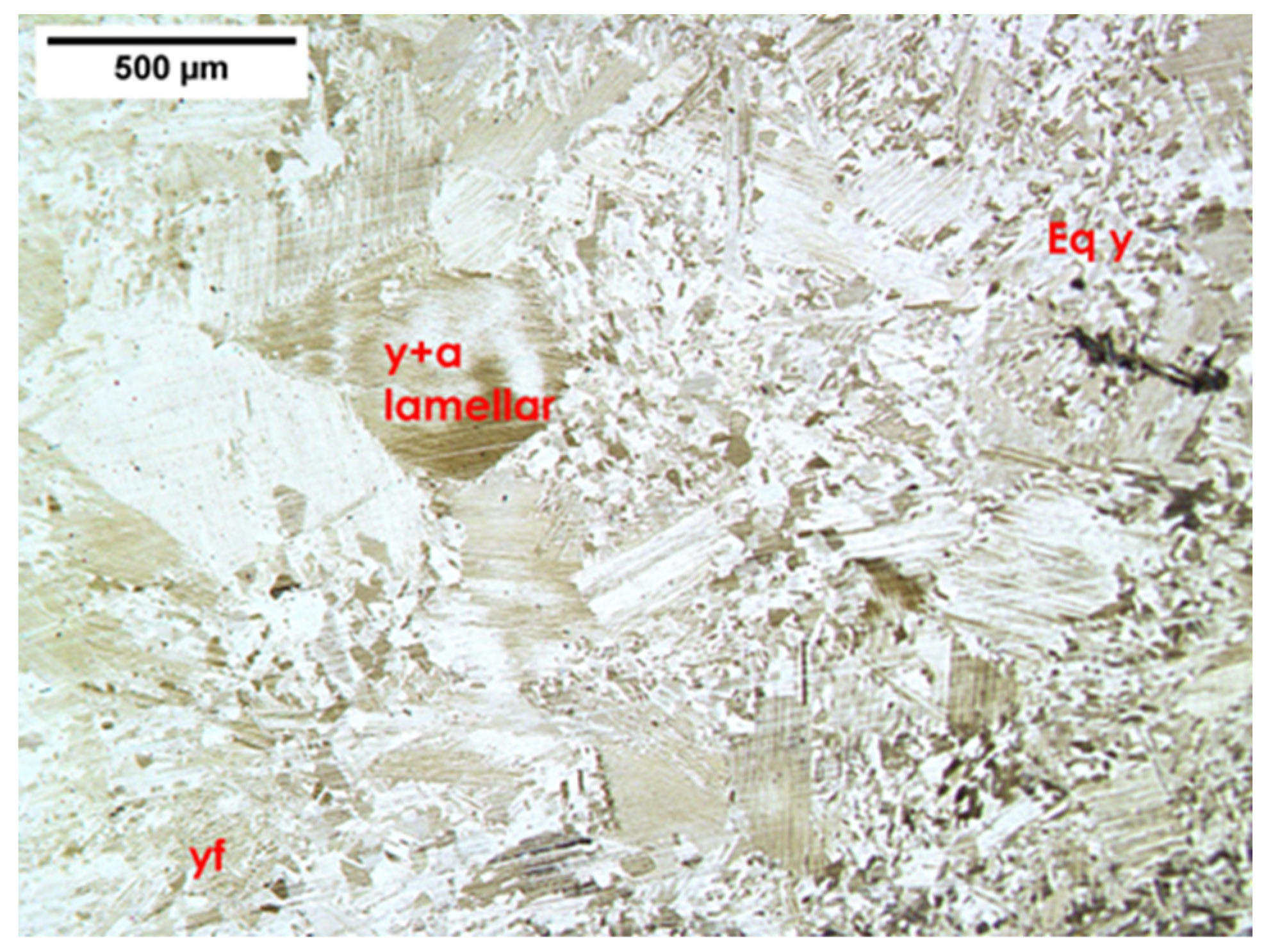

3.1. Initial Microstructure

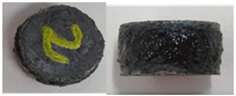

3.2. Cyclic Heat Treatment Processing with Induction Equipment

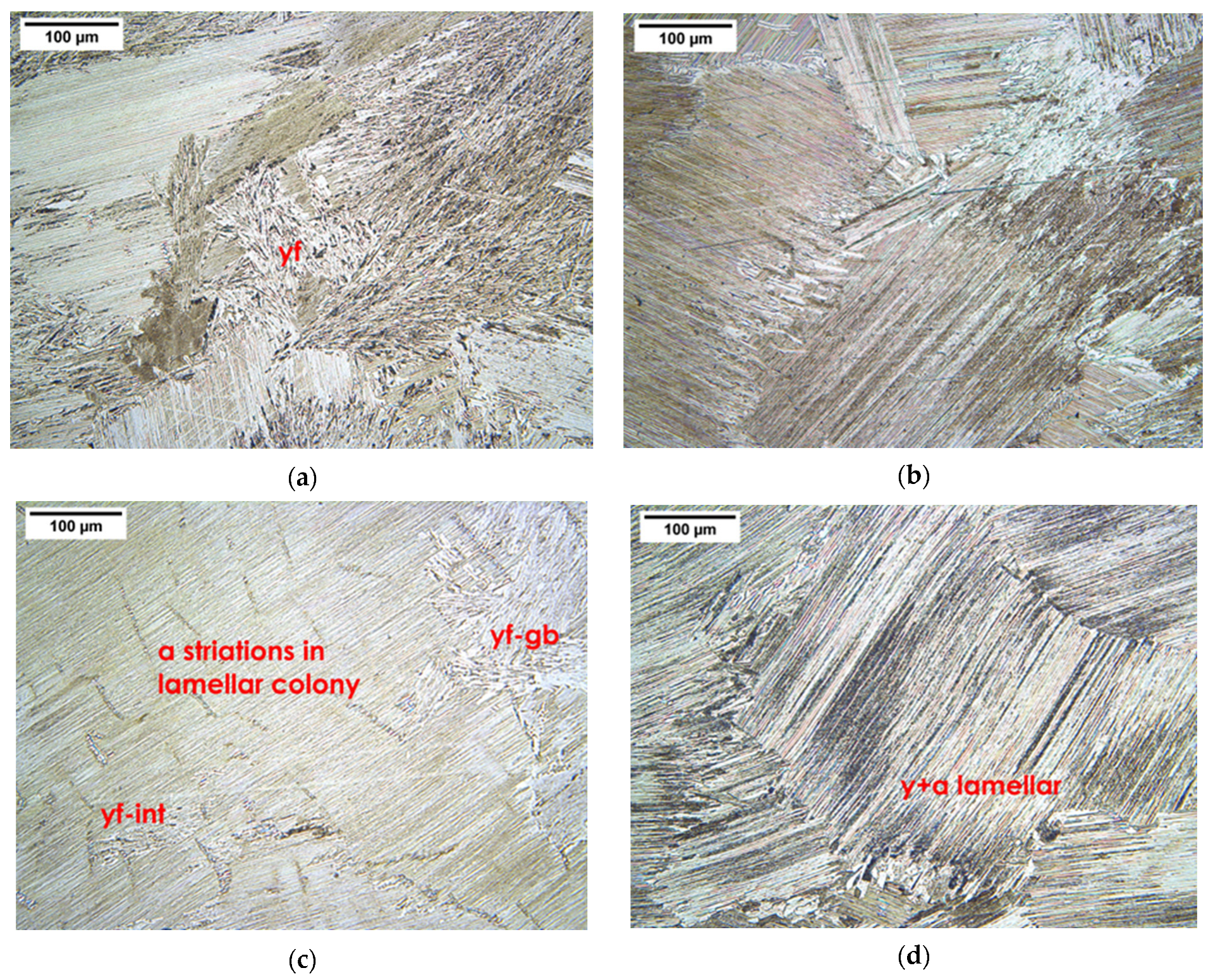

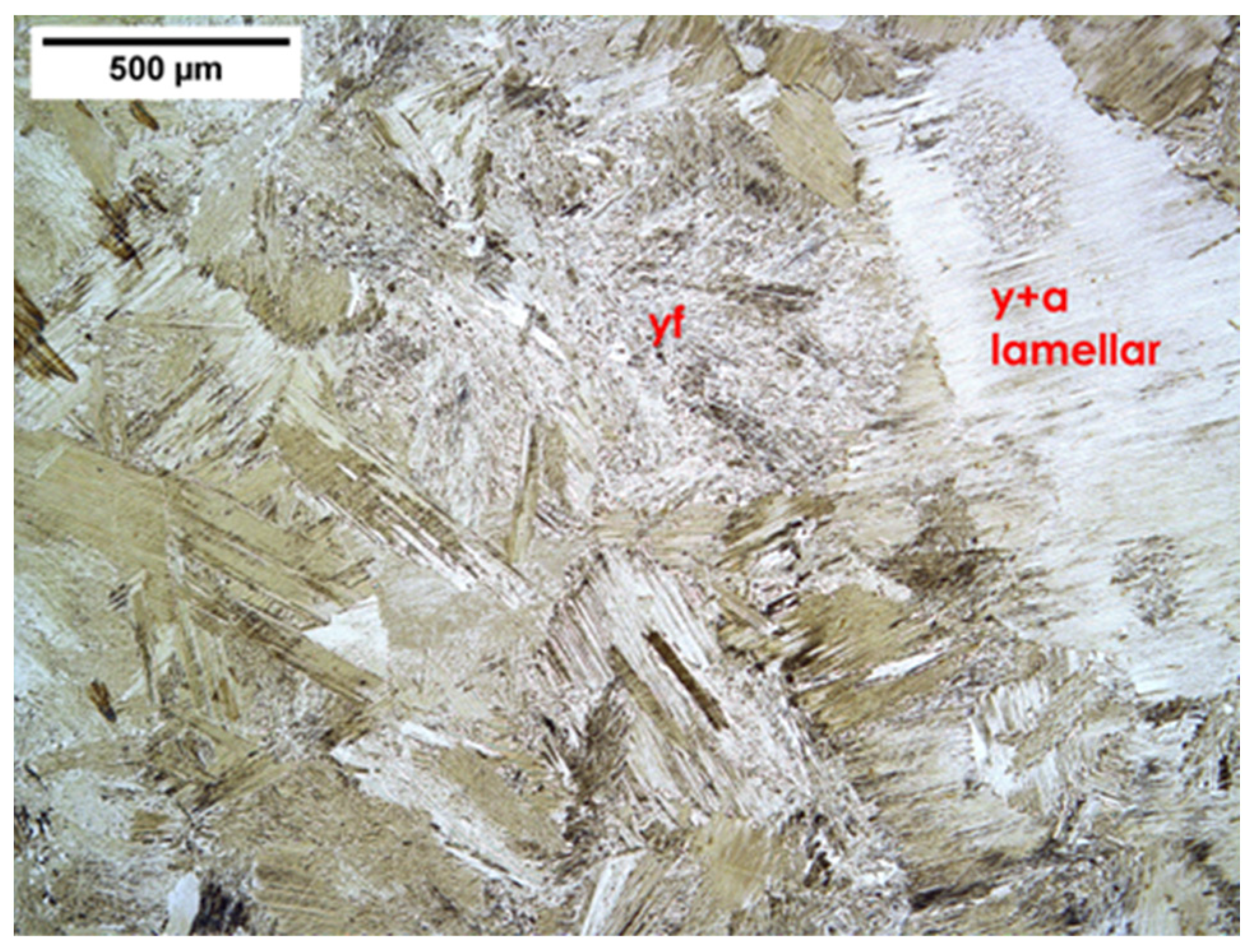

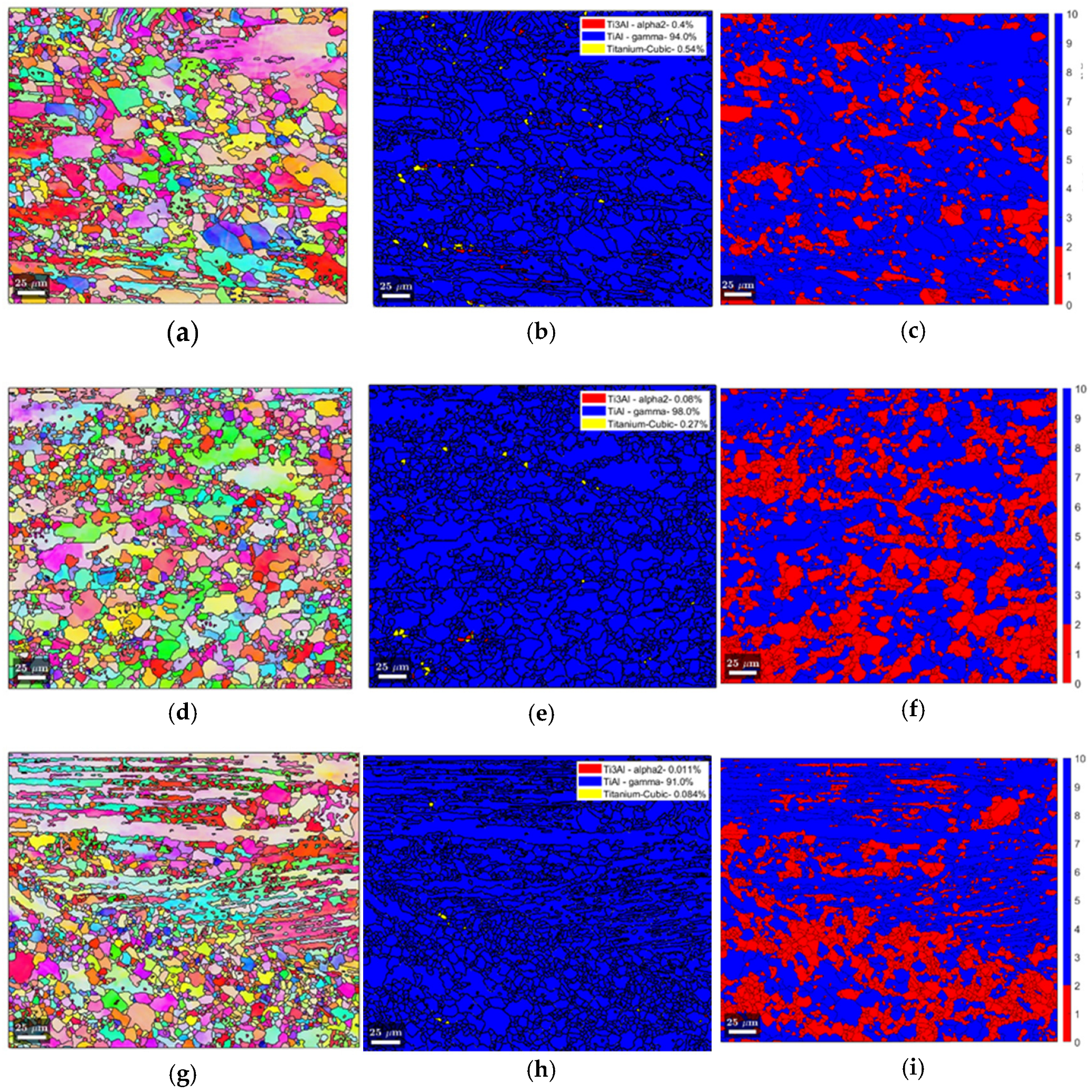

3.3. Cyclic Heat Treated Microstructures

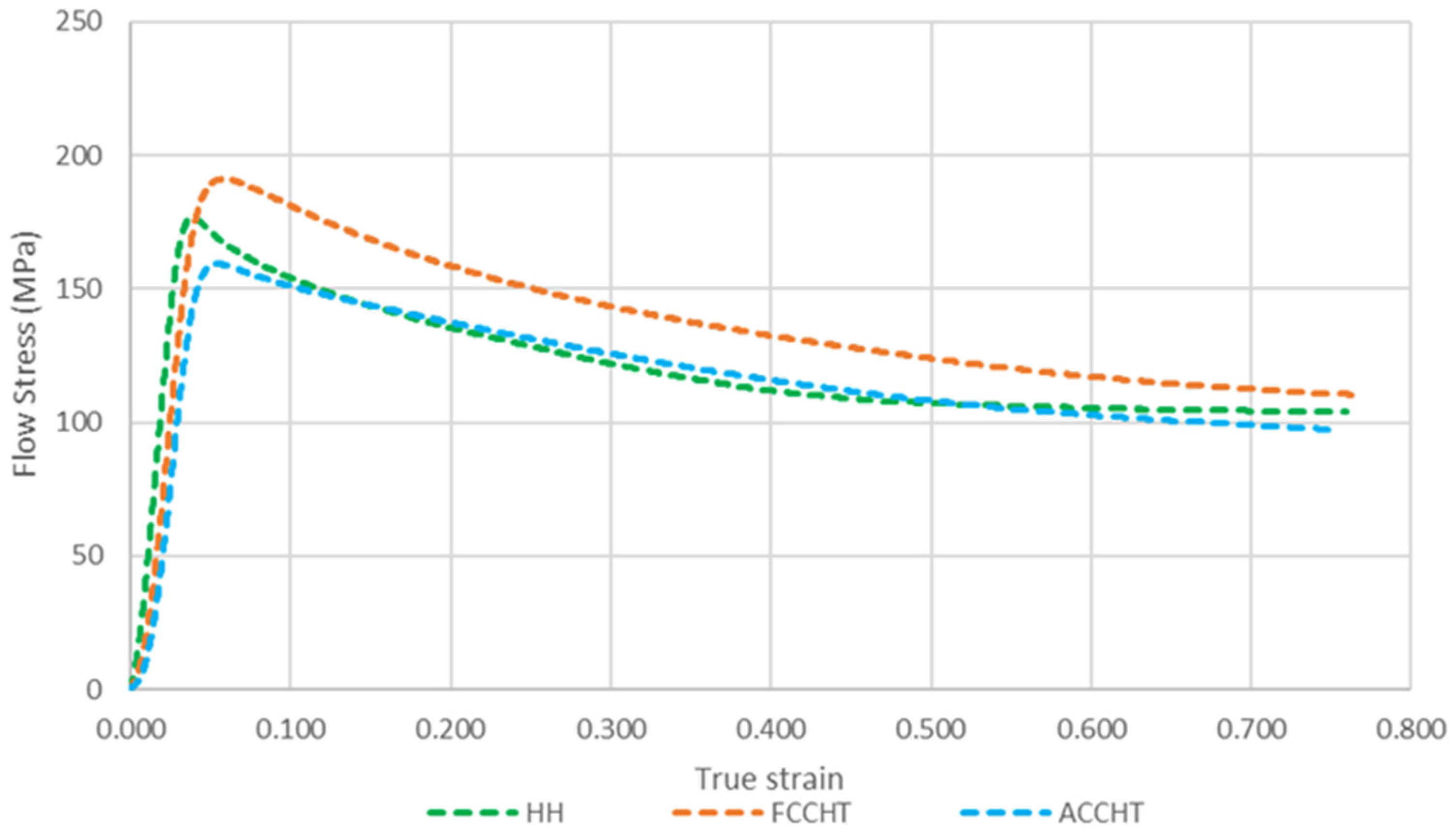

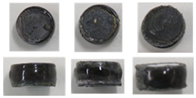

3.4. Primary Compression Behaviour

3.4.1. Behaviour of γf under Compression Conditions

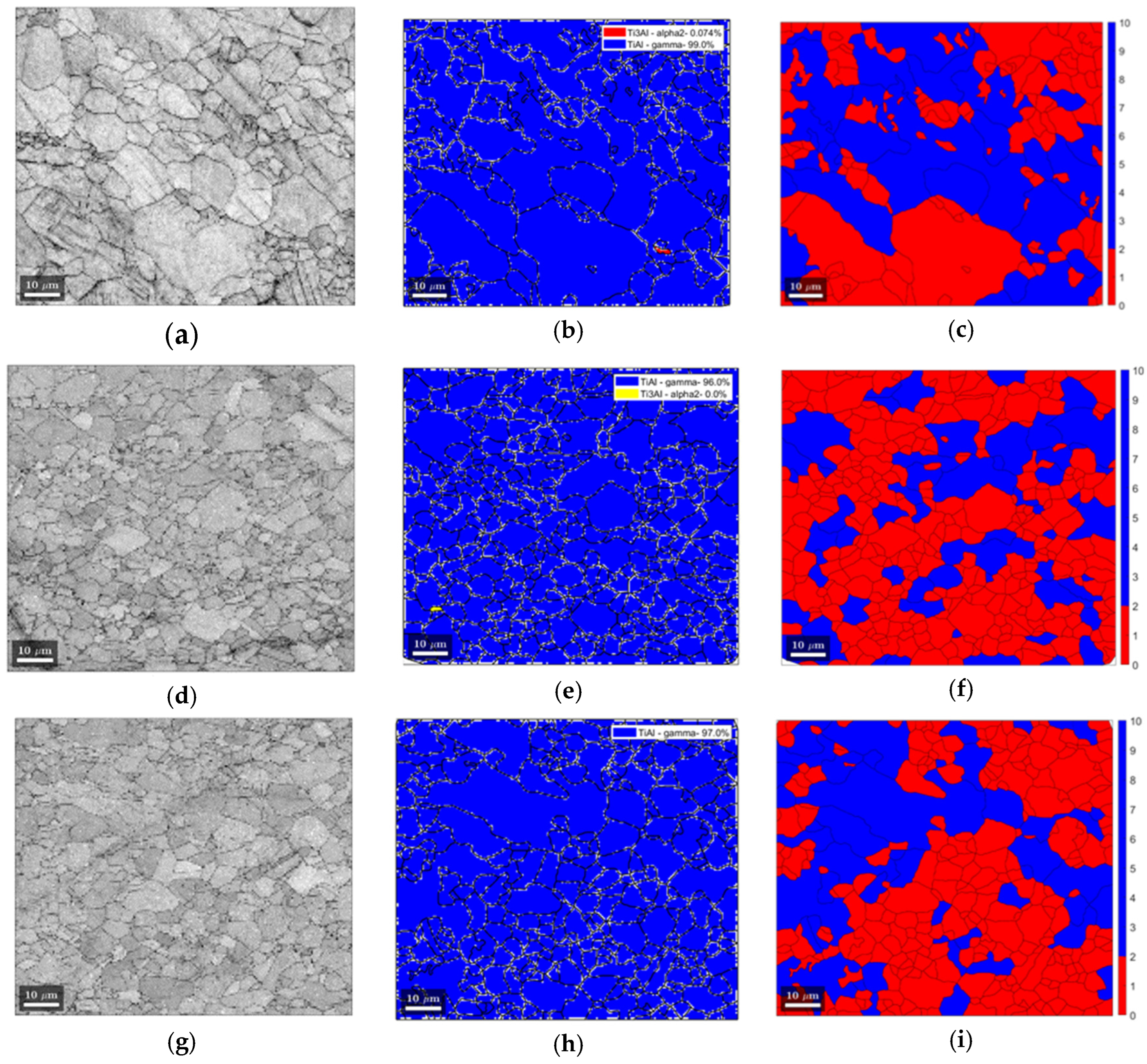

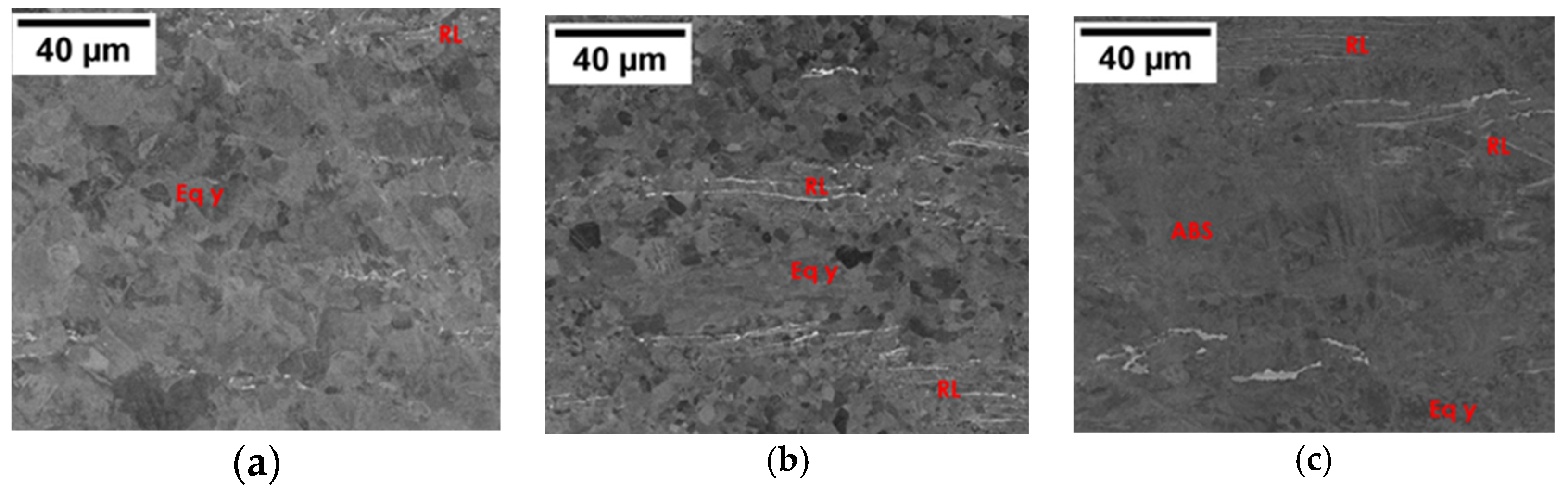

3.5. Primary Compression Microstructures

3.5.1. Primary Compression: HIP and Homogenised Microstructure

3.5.2. Primary Compression: ACCHT Microstructure

3.5.3. Primary Compression: FCCHT Microstructure

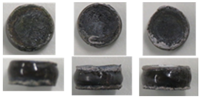

3.6. Secondary Compression Behaviour

3.7. Secondary Compression Microstructures

3.8. Summary of the CHT Process in Respect of Forging

4. Conclusions

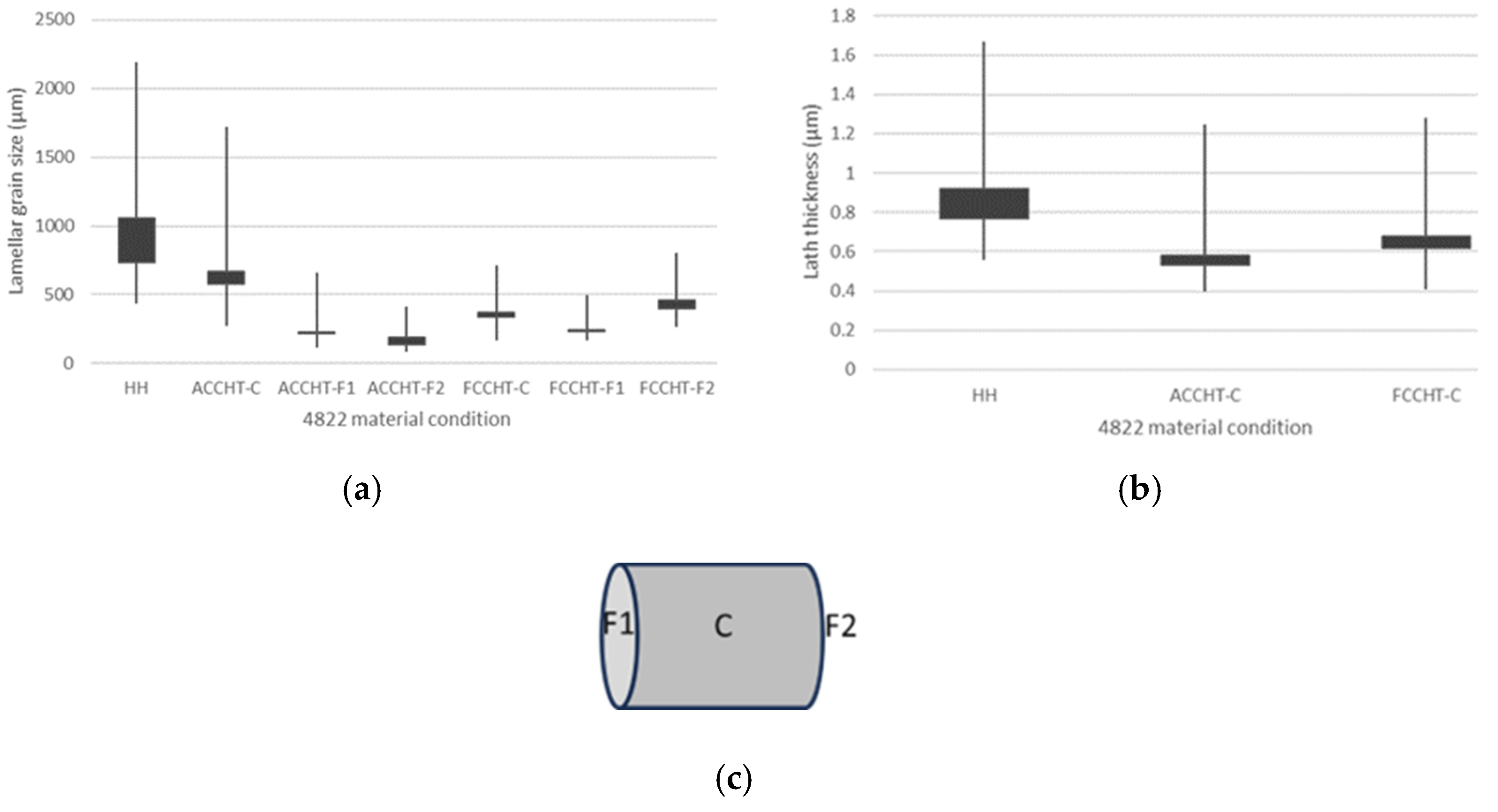

- Hot isostatic pressing and homogenisation (HH) are clearly essential processing steps but does not result in a material best placed for successful compression, with lamellar grain sizes averaging >1000 μm and low lamellar–lamellar grain boundary density restricting the globularisation of lamellar content.

- Cyclic induction heat treatment (CHT) can provide lamellar grain refinement compared with HH at a controlled furnace cooling rate (FCCHT). FCCHT results in a homogeneously refined fully lamellar microstructure with average lamellar grain size of 369.3 μm at the centre of the work piece. This grain refinement leads to successful primary compression.

- The heterogeneous microstructure under ACCHT, consisting of differing quantities of α2 + γ lamellar grains and γf across the work piece, does not appear to hinder primary or secondary compression under these conditions or at this scale, resulting in the highest dynamic recrystallised fraction values in both compression stages, 54.6% and 66.1%, respectively.

- The dominant γf in the ACCHT process transforms to γeq upon re-heating within the high γ + α2 phase region, i.e., during primary compression at 1100 °C.

- CHT material after secondary compression at a strain rate of 0.001 s−1 is free of anisotropy inducing lamellar morphologies; this material should be considered for secondary processing techniques such as hot rolling or closed-die isothermal forging.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Appel, F.J.; Paul, J.D.; Oehring, M. Gamma Titanium Aluminides; Wiley-VCH: Weinheim, Germany, 2011; ISBN 978-3-527-63622-8. [Google Scholar]

- Larsen, D.E. Status of Investment Cast Gamma Titanium Aluminides in the USA. Mater. Sci. Eng. A 1996, 213, 128–133. [Google Scholar] [CrossRef]

- Denquin, A.; Naka, S. Phase Transformation Mechanisms Involved in Two-Phase TiAl-Based Alloys—I. Lamellar Structure Formation. Acta Mater. 1996, 44, 343–352. [Google Scholar] [CrossRef]

- Ramanujan, R.V. Phase Transformations in γ Based Titanium Aluminides. Int. Mater. Rev. 2000, 45, 217–240. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Alloy Design Concepts for Refined Gamma Titanium Aluminide Based Alloys. Intermetallics 2007, 15, 451–460. [Google Scholar] [CrossRef]

- Zhang, D.; Dehm, G.; Clemens, H. Effect of Heat-Treatments and Hot-Isostatic Pressing on Phase Transformation and Microstructure in a β/B2 Containing γ-TiAl Based Alloy. Scr. Mater. 2000, 42, 1065–1070. [Google Scholar] [CrossRef]

- Kremmer, S.; Chladil, H.; Clemens, H.; Otto, A.; Güther, V. Near Conventional Forging of Titanium Aluminides. In Ti-2007 Science and Technology; The Japan Institute of Metals: Sendai, Japan, 2008; pp. 989–992. [Google Scholar]

- Fuchs, G.E. The Effect of Processing on the Hot Workability of Ti-48Al-2Nb-2Cr Alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1997, 28, 2543–2553. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Jain, V.K. Microstructure Development during Conventional and Isothermal Hot Forging of a Near-Gamma Titanium Aluminide. Metall. Mater. Trans. A 1994, 25, 2753–2768. [Google Scholar] [CrossRef]

- Wang, J.N.; Xie, K. Refining of Coarse Lamellar Microstructure of TiAl Alloys by Rapid Heat Treatment. Intermetallics 2000, 8, 545–548. [Google Scholar] [CrossRef]

- Wang, J.N.; Yang, J.; Xia, Q.; Wang, Y. On the Grain Size Refinement of TiAl Alloys by Cyclic Heat Treatment. Mater. Sci. Eng. A 2002, 329–331, 118–123. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.N.; Wang, Y.; Xia, Q. Refining Grain Size of a TiAl Alloy by Cyclic Heat Treatment through Discontinuous Coarsening. Intermetallics 2003, 11, 971–974. [Google Scholar] [CrossRef]

- Szkliniarz, A. Grain Refinement of Ti-48Al-2Cr-2Nb Alloy by Heat Treatment Method. Solid State Phenom. 2012, 191, 221–234. [Google Scholar] [CrossRef]

- Kościelna, A.; Szkliniarz, W. Effect of Cyclic Heat Treatment Parameters on the Grain Refinement of Ti–48Al–2Cr–2Nb Alloy. Mater. Charact. 2009, 60, 1158–1162. [Google Scholar] [CrossRef]

- Dey, S.R.; Bouzy, E.; Hazotte, A. Features of Feathery γ Structure in a Near-γ TiAl Alloy. Acta Mater. 2008, 56, 2051–2062. [Google Scholar] [CrossRef]

- Kamyshnykova, K.; Lapin, J. Grain Refinement of Cast Peritectic TiAl-Based Alloy by Solid-State Phase Transformations. Kov. Mater. 2018, 56, 277–287. [Google Scholar] [CrossRef] [Green Version]

- Yim, S.; Bian, H.; Aoyagi, K.; Chiba, A. Effect of Multi-Stage Heat Treatment on Mechanical Properties and Microstructure Transformation of Ti-48Al-2Cr-2Nb Alloy. Mater. Sci. Eng. A 2021, 816, 141321. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, J.H.; Kim, J.Y.; Park, S.H.; Kim, S.W.; Oh, M.H.; Kim, S.E. Producing Fine Fully Lamellar Microstructure for Cast γ-TiAl without Hot Working. Intermetallics 2020, 120, 106728. [Google Scholar] [CrossRef]

- Gupta, R.K.; Narayana Murty, S.V.S.; Pant, B.; Agarwala, V.; Sinha, P.P. Hot Workability of Γ + α2 Titanium Aluminide: Development of Processing Map and Constitutive Equations. Mater. Sci. Eng. A 2012, 551, 169–186. [Google Scholar] [CrossRef]

- Seetharaman, V.; Semiatin, S.L. Effect of the Lamellar Grain Size on Plastic Flow Behavior and Microstructure Evolution during Hot Working of a Gamma Titanium Aluminide Alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2002, 33, 3817–3830. [Google Scholar] [CrossRef]

- Nobuki, M.; Tsujimoto, T. Influene of Alloy Compostion on Hot Deformation Properties of TIAl Intermetallics. ISIJ Int. 1991, 31, 931–937. [Google Scholar] [CrossRef] [Green Version]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Flow Behavior and Globularization Kinetics during Hot Working of Ti-6Al-4V with a Colony Alpha Microstructure. Mater. Sci. Eng. A 1999, 263, 257–271. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Mokdad, F.; Wells, M.A.; Chen, D.L. A New Grain Orientation Spread Approach to Analyze the Dynamic Recrystallization Behavior of a Cast-Homogenized Mg-Zn-Zr Alloy Using Electron Backscattered Diffraction. Mater. Sci. Eng. A 2018, 709, 285–289. [Google Scholar] [CrossRef]

- Chen, X.; Tang, B.; Liu, D.; Wei, B.; Zhu, L.; Liu, R.; Kou, H.; Li, J. Dynamic Recrystallization and Hot Processing Map of Ti-48Al-2Cr-2Nb Alloy during the Hot Deformation. Mater. Charact. 2021, 179, 111332. [Google Scholar] [CrossRef]

- Wan, Z.; Sun, Y.; Hu, L.; Yu, H. Dynamic Softening Behavior and Microstructural Characterization of TiAl-Based Alloy during Hot Deformation. Mater. Charact. 2017, 130, 25–32. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Hu, L.; Shi, L.; Xiao, S.; Chen, Y.; Zhou, T. Dynamic Recrystallization, Phase Transformation and Deformation Mechanisms of a Novel Ti-43Al-6Nb-1Mo-1Cr Alloy during the Isothermal Deformation. Mater. Charact. 2023, 199, 112789. [Google Scholar] [CrossRef]

- Fecht, H.-J.; Mohr, M. Metallurgy in Space The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2022; ISBN 9783030897840. [Google Scholar]

- Rudnev, V.; Loveless, D.; Cook, R.L. Handbook of Induction Heating, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781466553972. [Google Scholar]

- Kim, Y.-W.; Sang Lan, K. Advances in Gammalloy Materials–Processes–Application Technology: Successes, Dilemmas, and Future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.Y.; Li, B.H.; Kong, F.T. Microstructural Refinement and Mechanical Properties of Y-Bearing TiAl Alloys. J. Alloys Compd. 2008, 457, 265–269. [Google Scholar] [CrossRef]

- Liu, C.T.; Schneibel, J.H.; Maziasz, P.J.; Wright, J.L.; Easton, D.S. Tensile Properties and Fracture Toughness of TiAl Alloys with Controlled Microstructures. Intermetallics 1996, 4, 429–440. [Google Scholar] [CrossRef]

- Zhang, W.J.; Lorenz, U.; Appel, F. Recovery, Recrystallization and Phase Transformations during Thermomechanical Processing and Treatment of TiAl-Based Alloys. Acta Mater. 2000, 48, 2803–2813. [Google Scholar] [CrossRef]

- Tian, S.; Jiang, H.; Guo, W.; Zhang, G.; Zeng, S. Hot Deformation and Dynamic Recrystallization Behavior of TiAl-Based Alloy. Intermetallics 2019, 112, 106521. [Google Scholar] [CrossRef]

- Bibhanshu, N.; Bhattacharjee, A.; Suwas, S. Influence of Temperature and Strain Rate on Microstructural Evolution During Hot Compression of Ti-45Al-XNb-0.2C-0.2B Titanium Aluminide Alloys. JOM 2019, 71, 3552–3564. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Ghosh, A.K. Plastic Flow, Microstructure Evolution, and Defect Formation during Primary Hot Working of Titanium and Titanium Aluminide Alloys with Lamellar Colony Microstructures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1999, 357, 1487–1512. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Hot Workability of Titanium and Titanium Aluminide Alloys—An Overview. Mater. Sci. Eng. A 1998, 243, 1–24. [Google Scholar] [CrossRef]

- Hu, R.; Wu, Y.; Yang, J.; Gao, Z.; Li, J. Phase Transformation Pathway and Microstructural Refinement by Feathery Transformation of Ru-Containing γ-TiAl Alloy. J. Mater. Res. Technol. 2022, 18, 5290–5300. [Google Scholar] [CrossRef]

- Chen, X.; Tang, B.; Chen, W.; Yang, Y.; Zheng, G.; Fan, Z.; Li, J. Effect of Inter-Pass Annealing on the Deformation Microstructure of Ti-48Al-2Cr-2Nb Alloy. J. Alloys Compd. 2023, 934, 167751. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Microstructural Evolution during Hot Working of Ti Aluminide Alloys: Influence of Phase Constitution and Initial Casting Texture. Metall. Mater. Trans. A 2005, 36, 859–867. [Google Scholar] [CrossRef]

- Ghosh, A.K. On the Measurement of Strain-Rate Sensitivity for Deformation Mechanism in Conventional and Ultra-Fine Grain Alloys. Mater. Sci. Eng. A 2007, 463, 36–40. [Google Scholar] [CrossRef]

- Palomares-García, A.J.; Pérez-Prado, M.T.; Molina-Aldareguia, J.M. Effect of Lamellar Orientation on the Strength and Operating Deformation Mechanisms of Fully Lamellar TiAl Alloys Determined by Micropillar Compression. Acta Mater. 2017, 123, 102–114. [Google Scholar] [CrossRef]

- Gao, P.; Fu, M.; Zhan, M.; Lei, Z.; Li, Y. Deformation Behavior and Microstructure Evolution of Titanium Alloys with Lamellar Microstructure in Hot Working Process: A Review. J. Mater. Sci. Technol. 2019, 39, 56–73. [Google Scholar] [CrossRef]

- Bambach, M.; Emdadi, A.; Sizova, I.; Hecht, U.; Pyczak, F. Isothermal Forging of Titanium Aluminides without Beta-Phase—Using Non-Equilibrium Phases Produced by Spark Plasma Sintering for Improved Hot Working Behavior. Intermetallics 2018, 101, 44–55. [Google Scholar] [CrossRef]

- Niu, H.Z.; Tong, R.L.; Chen, X.J.; Zhang, T.B.; Zhang, D.L. Rapid Decomposition of Lamellar Microstructure and Enhanced Hot Workability of an As-Cast Triphase Ti–45Al–6Nb–1Mo Alloy via One-Step Alpha-Extrusion & Annealing. Mater. Sci. Eng. A 2021, 801, 140438. [Google Scholar] [CrossRef]

- Tang, B.; Cheng, L.; Kou, H.; Li, J. Hot Forging Design and Microstructure Evolution of a High Nb Containing TiAl Alloy. Intermetallics 2015, 58, 7–14. [Google Scholar] [CrossRef]

| Ti | Al | Nb | Cr | Fe | Si |

|---|---|---|---|---|---|

| 49.1 | 47.2 | 1.83 | 1.83 | 0.03 | 0.03 |

| Position Analysed | Face 1 | Centre | Face 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Phase Morphology | %lam | %γeq | %γf | Avg. Lam. Size (μm) | %lam | %γeq | %γf | Avg. Lam. Size (μm) | Avg. Lath Width (μm) | %lam | %γeq | %γf | Avg. Lam. Size (μm) |

| HH | - | - | - | - | 88.4 | 11.6 | 0 | 1059.1 | 0.92 | - | - | - | - |

| ACCHT | 39.8 | 0 | 60.2 | 228.6 | 69.4 | 0 | 30.6 | 760.6 | 0.58 | 33.3 | 0 | 66.7 | 190.6 |

| FCCHT | 83.8 | 0 | 16.2 | 242.5 | 86.1 | 0 | 13.9 | 369.3 | 0.68 | 90.7 | 0 | 9.3 | 454.9 |

| Material | Max Temperature (°C) Recorded on Each Cycle | Avg. Hold Time above 1370 °C over Five Cycles (s) | Avg. Cooling Rate (°C−1) over Five Cycles | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 1370–1250 | 1250–1200 | 1200–800 | ||

| ACCHT | 1371.6 | 1372.8 | 1374.1 | 1372.2 | 1372.5 | 30.4 | 8.8 | 3.2 | 3.8 |

| FCCHT | 1373.0 | 1374.9 | 1374.0 | 1374.7 | 1373.7 | 31.0 | 3.8 | 1.2 | 4.2 |

| Material Condition | HH | ACCHT | FCCHT |

|---|---|---|---|

| σpfs—peak flow stress (MPa) | 176.6 | 159.3 | 191.1 |

| Primary compression samples |  |  |  |

| Phase Morphology | %lam | %γeq | %γf | Avg. Lam. Size (μm) |

|---|---|---|---|---|

| ACCHT Face 1 | 39.8 | 0 | 60.2 | 228.6 |

| ACCHT Face 2 | 33.3 | 0 | 66.7 | 190.6 |

| ACCHT + compression thermal cycle Face 1 | 36.6 | 56.5 | 6.9 | 183.5 |

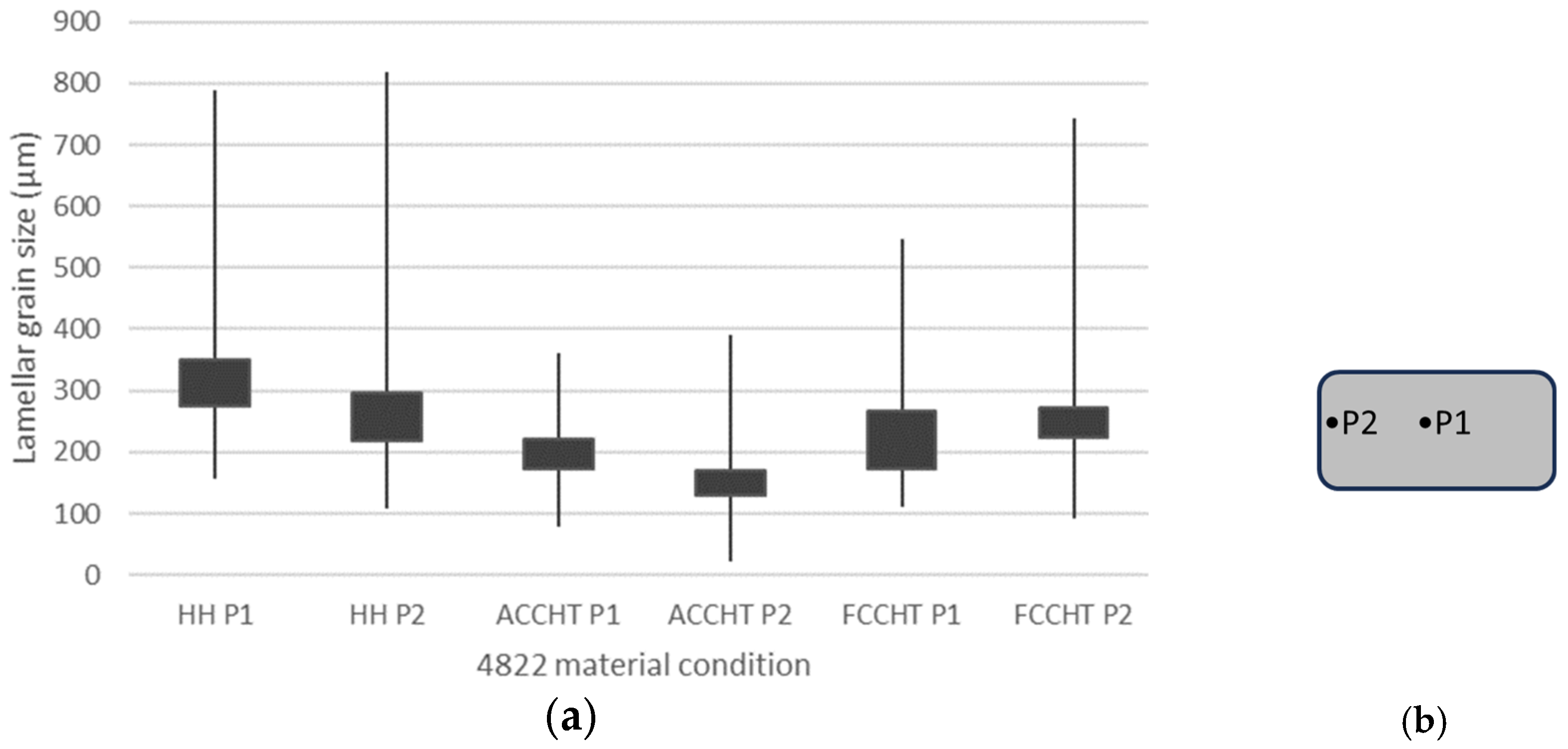

| 4822 Material Condition (s−1) | γ Equiaxed Content (%) | Lamellar Content (%) | Average Lamellar Grain Size (μm) @ 90° to Compression | Average Lamellar Grain Size (μm) @ 0° to Compression | Average Lamellar Grain Size (μm) | X-DRX (%) |

|---|---|---|---|---|---|---|

| HH 0.001 P1 | 55.6 | 44.4 | 281.7 | 418.9 | 350.3 | 22.6 |

| HH 0.001 P2 | 50.5 | 49.5 | 181.4 | 409.8 | 295.6 | 28.8 |

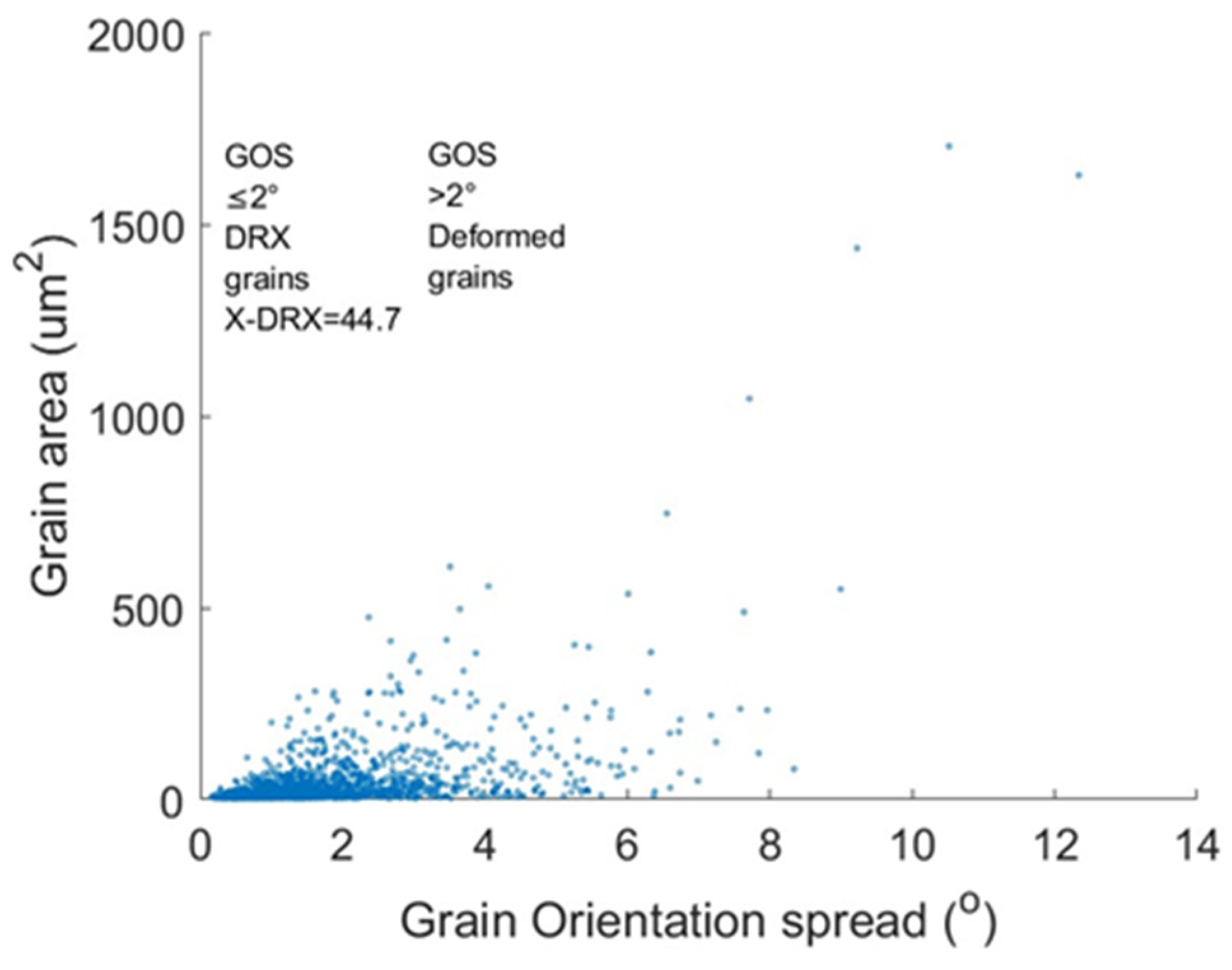

| ACCHT 0.001 P1 | 70.8 | 29.2 | 147.2 | 297.3 | 222.3 | 44.7 |

| ACCHT 0.001 P2 | 84.3 | 15.7 | 86.3 | 255.9 | 171.1 | 54.6 |

| FCCHT 0.001 P1 | 56.0 | 44.0 | 151.1 | 380.8 | 265.9 | 35.4 |

| FCCHT 0.001 P2 | 55.1 | 44.9 | 176.1 | 366.4 | 271.3 | 21.9 |

| Material Condition | HH | ACCHT | FCCHT | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Strain Rate (s−1) | 0.001 | 0.01 | 0.1 | 0.001 | 0.01 | 0.1 | 0.001 | 0.01 | 0.1 |

| σpfs—peak flow stress (MPa) | 111.7 | 218.9 | 348.5 | 111.2 | 202.8 | 341.5 | 117.3 | 212.4 | 343.6 |

| m at ε0.1 | 0.25 | 0.25 | 0.24 | ||||||

| Secondary compression samples |  |  |  | ||||||

| 4822 Material Condition (s−1) | Lamellar Content (%) | Average Lamellar Grain Size (μm, from 0° and 90°) | X-DRX (%) |

|---|---|---|---|

| HH 0.001 | 7.2 | 22.1 | 47.2 |

| HH 0.01 | 27.8 | 46.7 | 49.7 |

| HH 0.1 | 18.9 | 40.3 | 31.8 |

| ACCHT 0.001 | 0.0 | 0.0 | 66.1 |

| ACCHT 0.01 | 1.7 | 2.3 | 47.1 |

| ACCHT 0.1 | 9.0 | 15.1 | 56.7 |

| FCCHT 0.001 | 0.0 | 0.0 | 58.2 |

| FCCHT 0.01 | 0.0 | 0.0 | 60.1 |

| FCCHT 0.1 | 0.0 | 0.0 | 42.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peters, S.; Andreu, A.; Perez, M.; Blackwell, P. Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment. Metals 2023, 13, 1420. https://doi.org/10.3390/met13081420

Peters S, Andreu A, Perez M, Blackwell P. Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment. Metals. 2023; 13(8):1420. https://doi.org/10.3390/met13081420

Chicago/Turabian StylePeters, Sean, Aurik Andreu, Marcos Perez, and Paul Blackwell. 2023. "Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment" Metals 13, no. 8: 1420. https://doi.org/10.3390/met13081420

APA StylePeters, S., Andreu, A., Perez, M., & Blackwell, P. (2023). Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment. Metals, 13(8), 1420. https://doi.org/10.3390/met13081420