Towards Selective Laser Melting of High-Density Tungsten

Abstract

:1. Introduction

2. Experiment

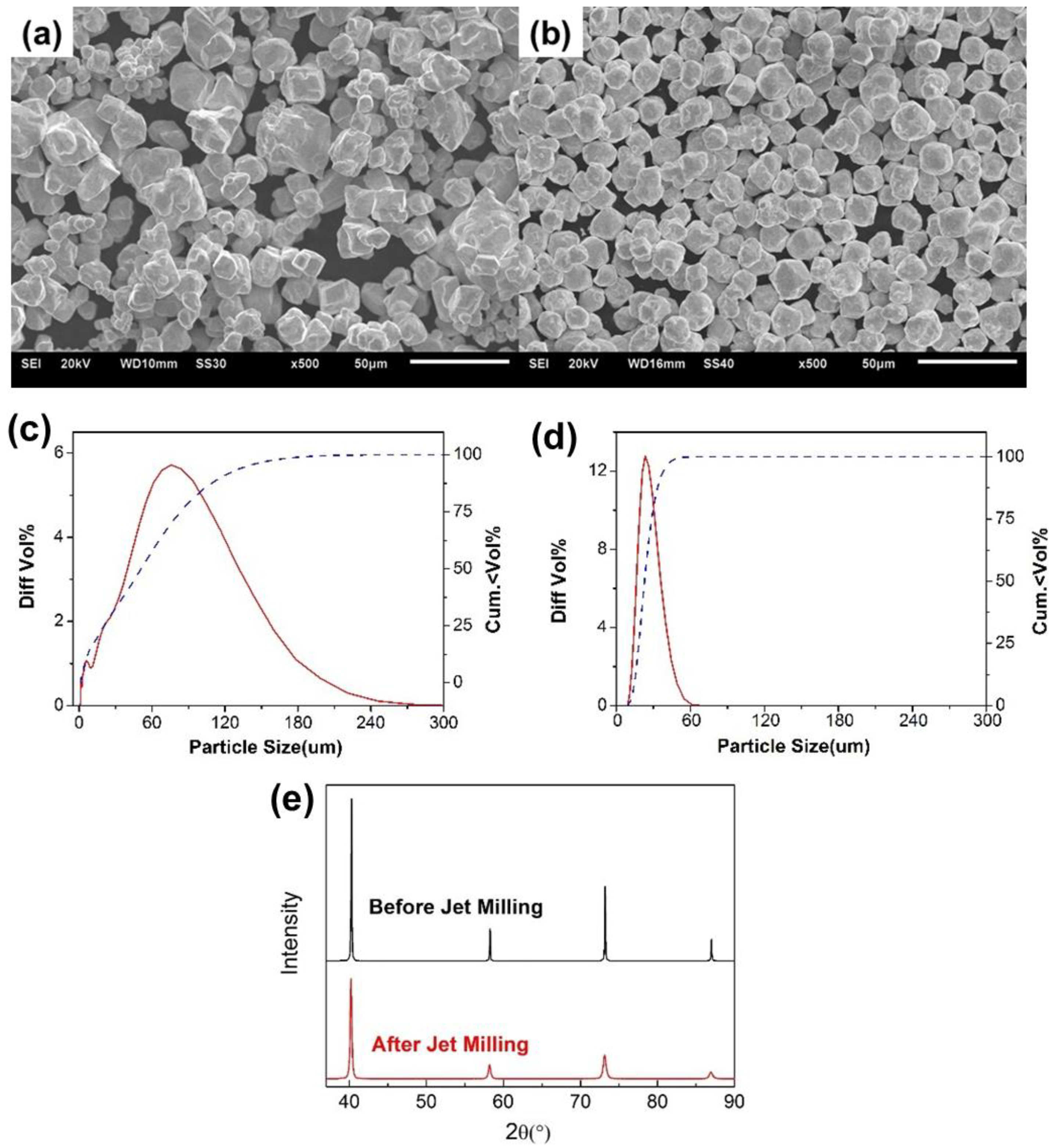

2.1. Powders and Air Jet Milling

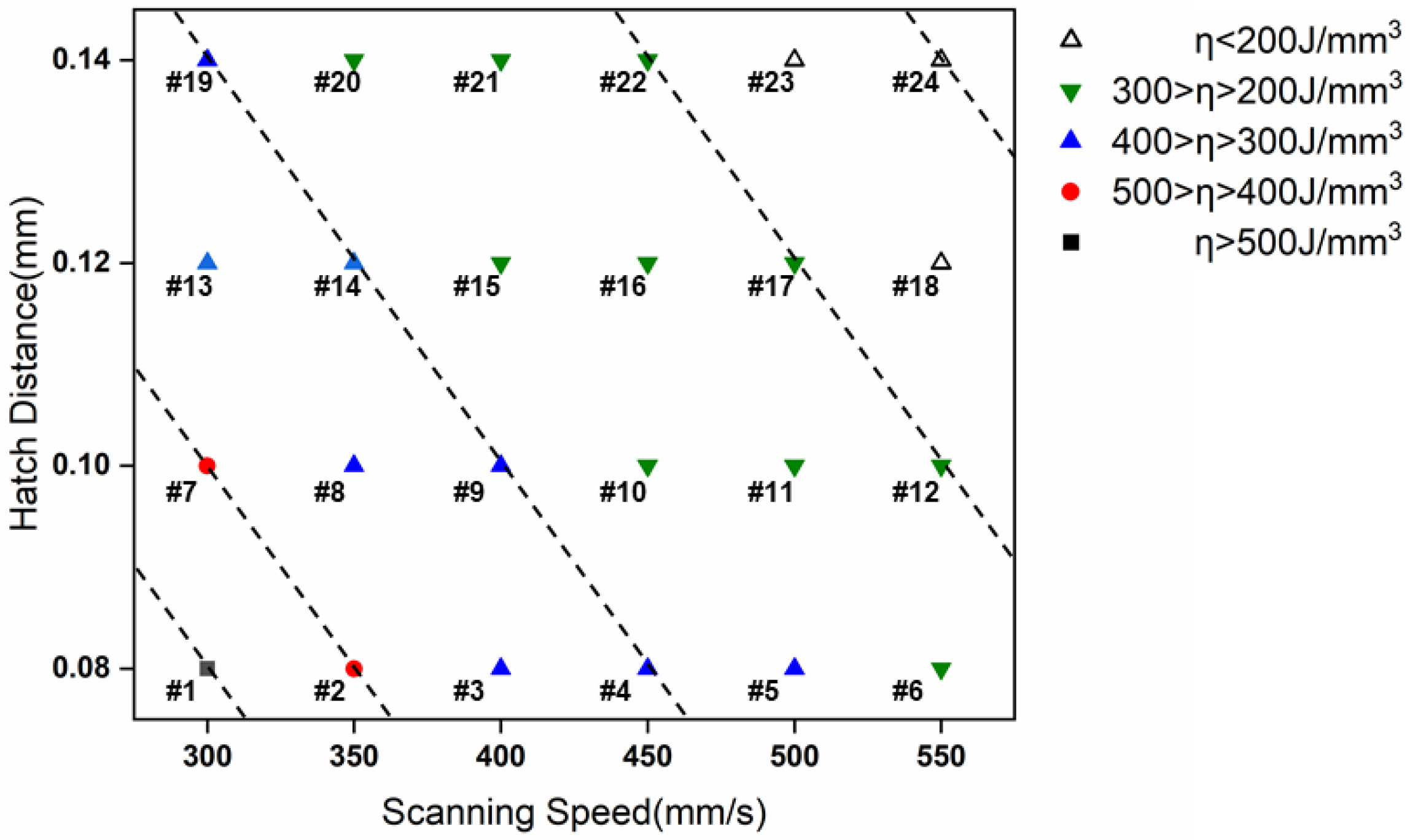

2.2. Selective Laser Melting Process

2.3. Characterization

3. Results and Discussion

3.1. Powder

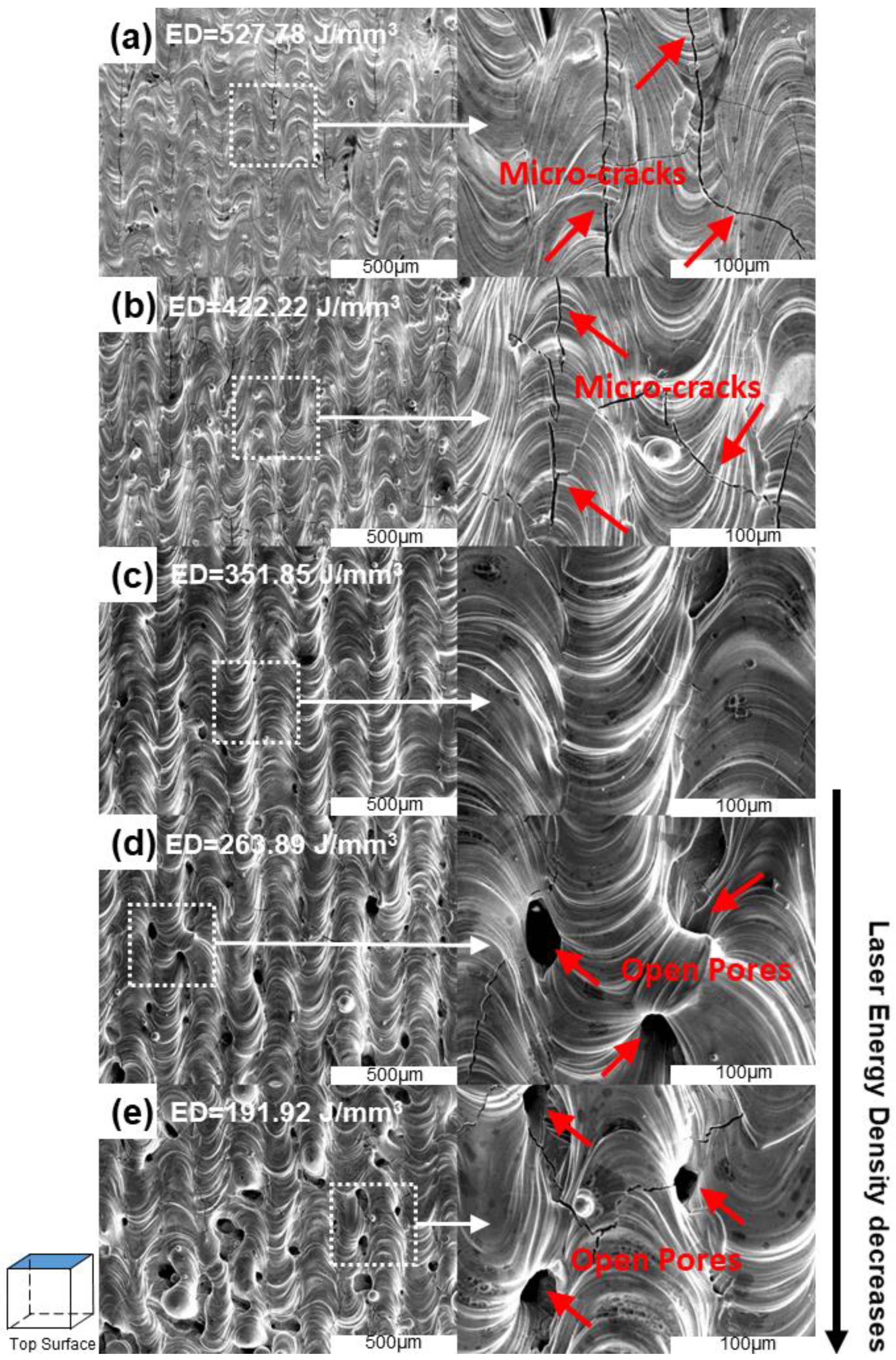

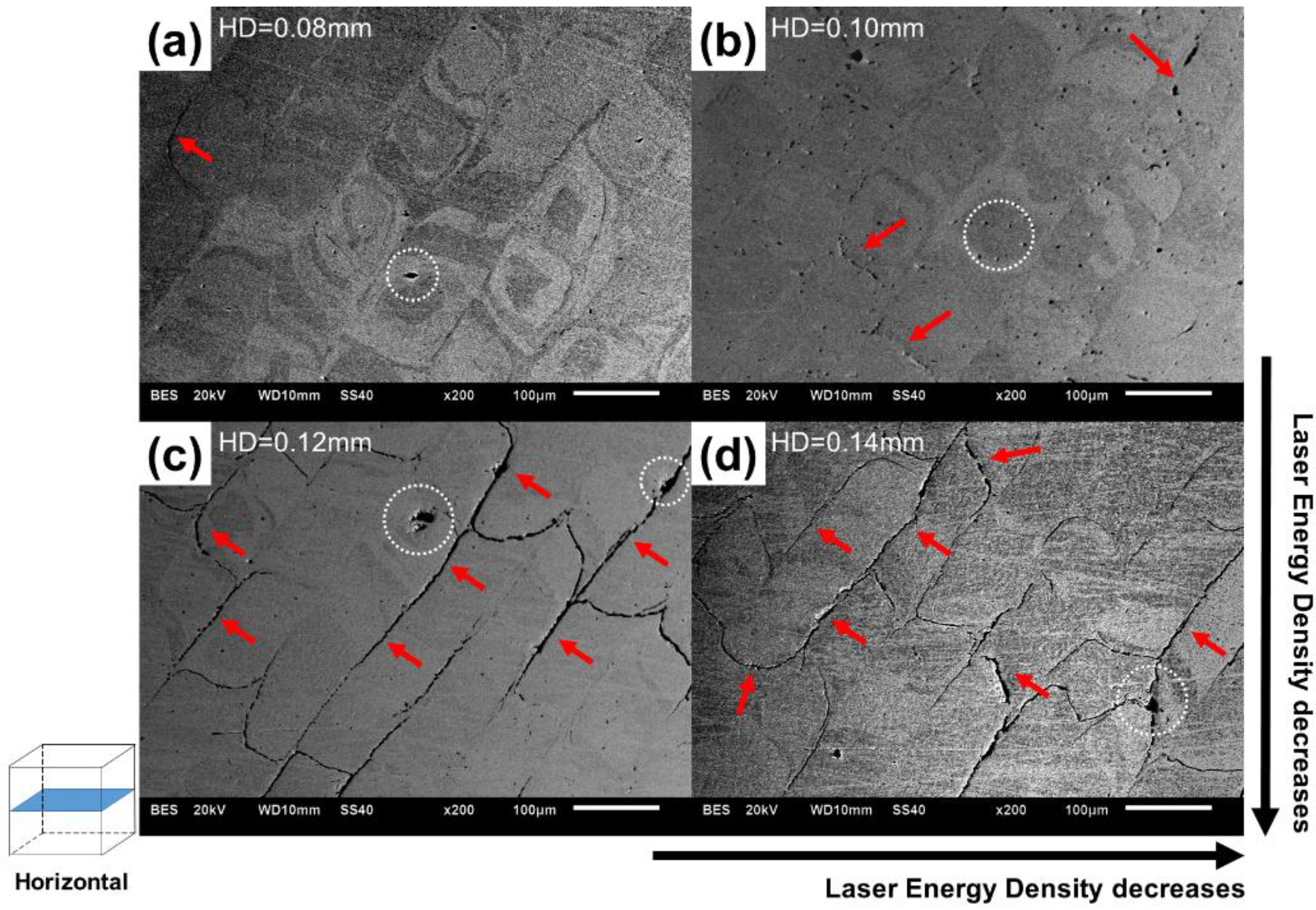

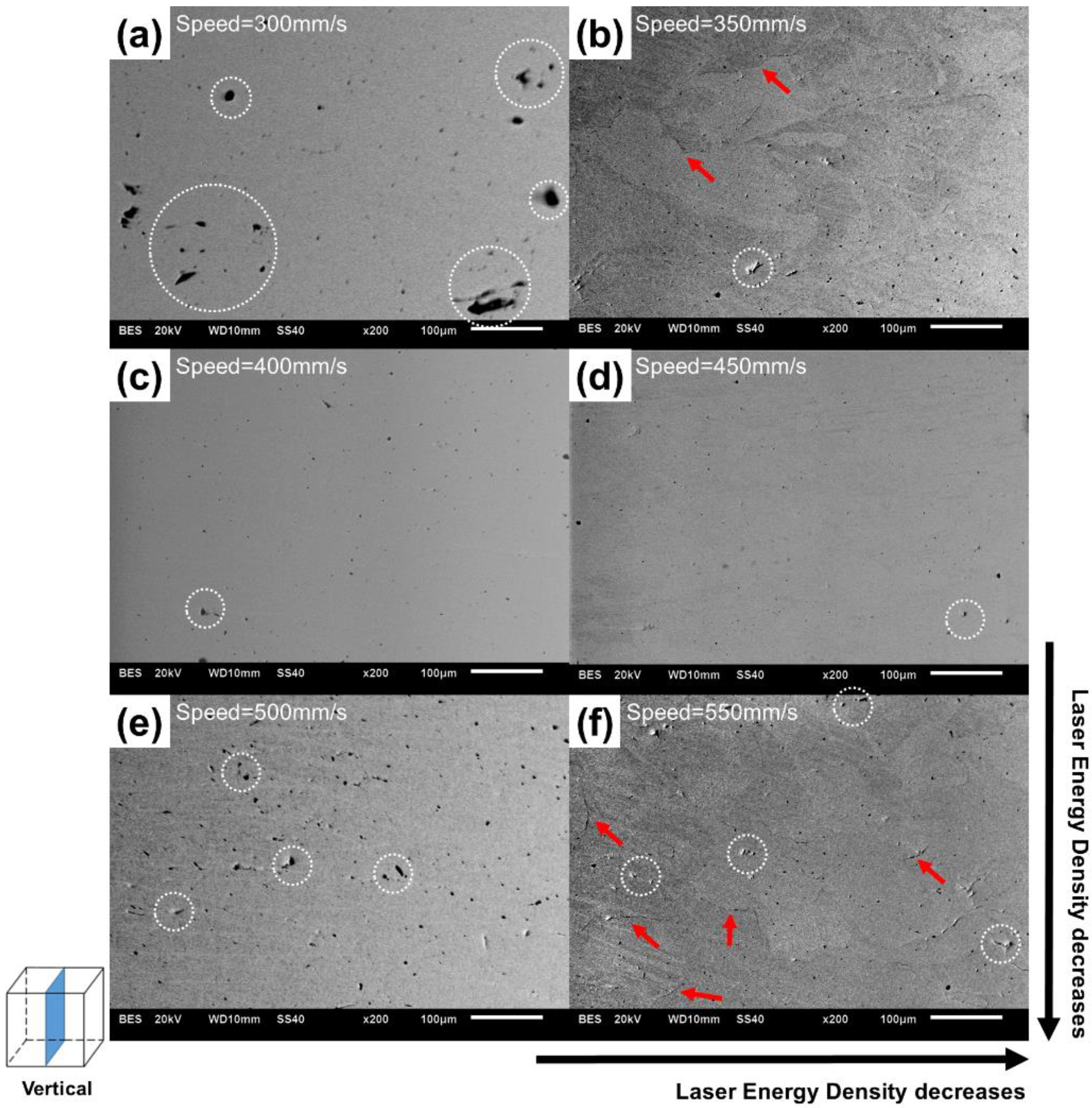

3.2. Density and Microstructure

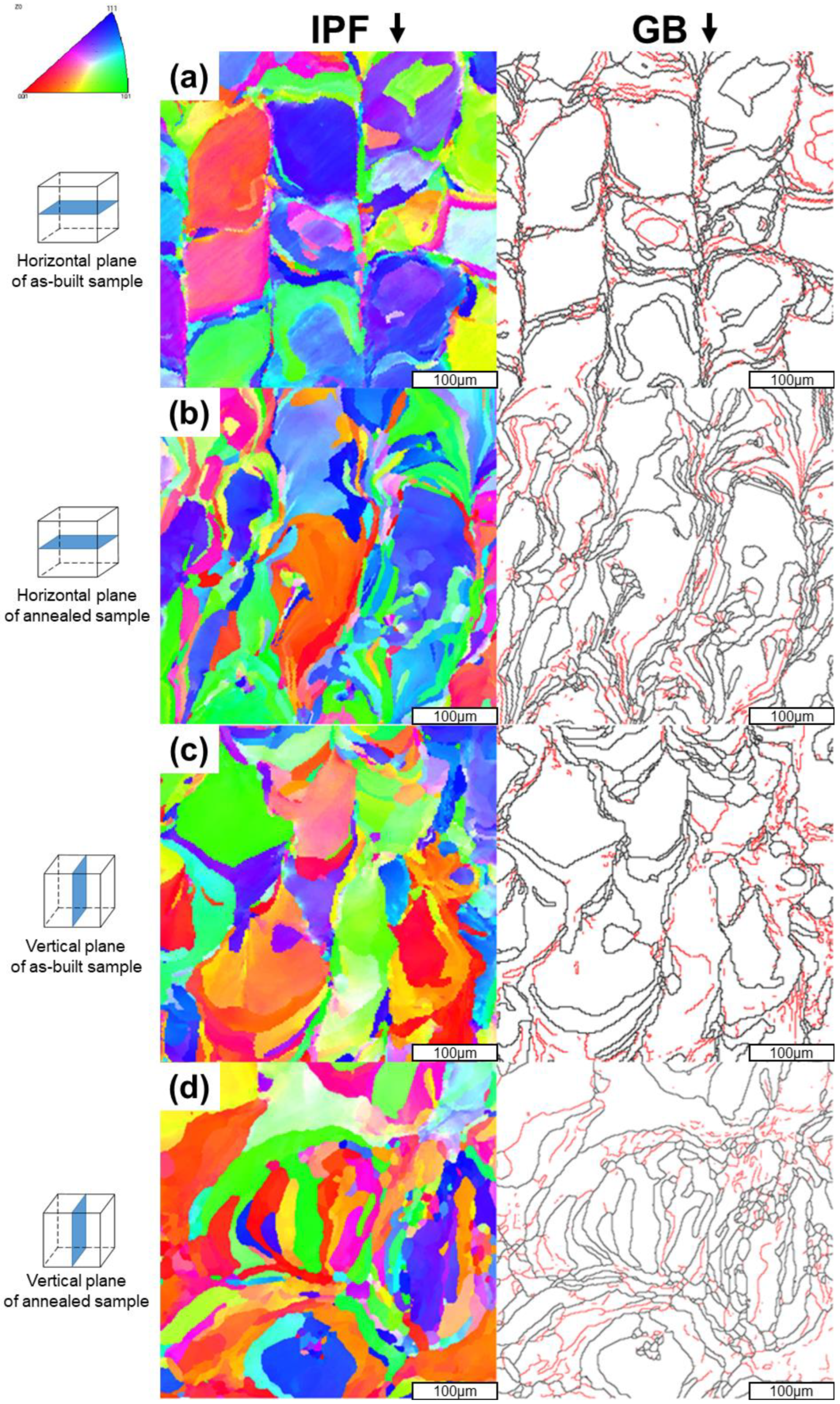

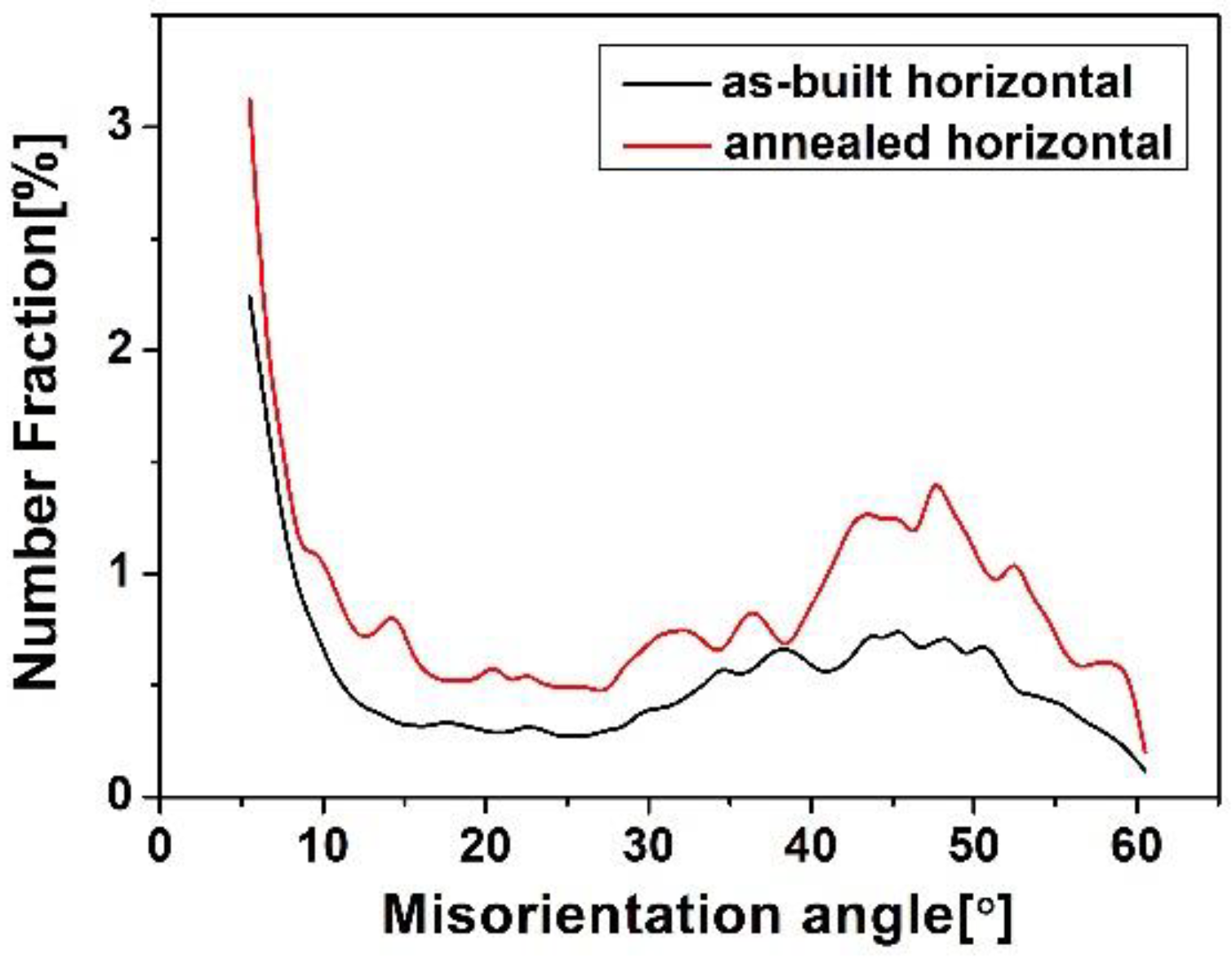

3.3. Grain Shape and Grain Boundaries

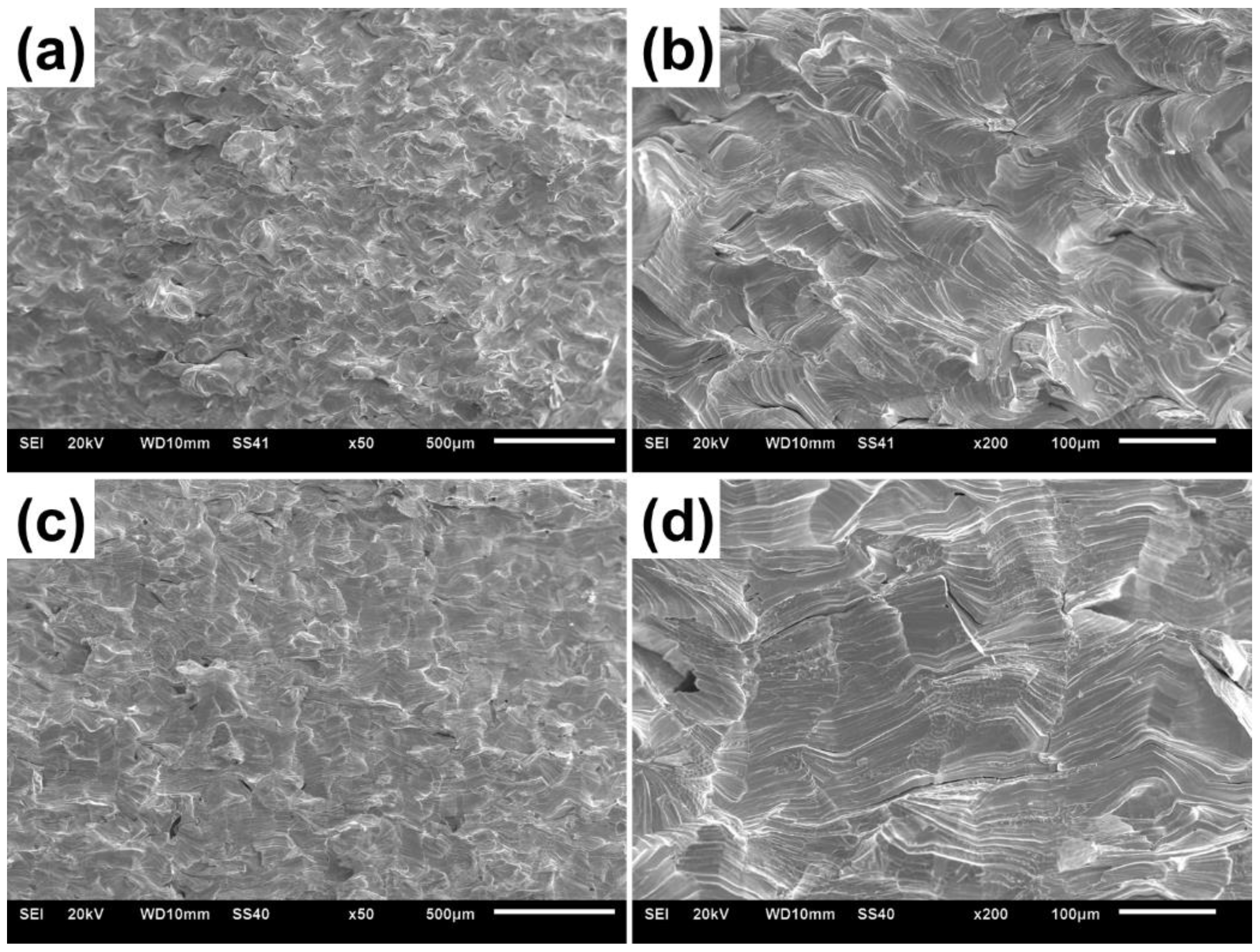

3.4. Mechanical Properties

4. Conclusions

- (1)

- The crack between the fusion line could be minimized by optimizing the laser parameter, including the laser scanning speed and hatch distance. Proper value of laser energy density results in a prior fusion outcome, rather than lack of fusion or cracking pattern. Combined efforts, including powders modification through air jet milling, 67° rotation scanning strategy, hatch distance of 0.08 mm and laser speed of 450 mm/s, lead to the higher density and less cracks;

- (2)

- The as-built W component was annealed to relive the residual stress, which homogenized the mechanical properties in the horizontal and vertical planes. EBSD results reveal the more equiaxed grain morphology and the reduced anisotropy, which are responsible for the homogenized mechanical properties. Bending strength is 155 MPa and 154 MPa in the horizontal and vertical plane, respectively. Vickers hardness is 402.7 HV and 396.4 HV in the horizontal and vertical plane, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lassner, E.; Schubert, W.D. Tungsten: Properties, Chemistry, Technology of the Element, Alloys and Chemical Compounds; Kluwer Academic and Plenum Publishers: New York, NY, USA, 1999; ISBN 0306450534. [Google Scholar]

- Linsmeier, C.; Rieth, M.; Aktaa, J.; Chikada, T.; Hoffmann, A.; Hoffmann, J.; Houben, A.; Kurishita, H.; Jin, X.; Li, M.; et al. Development of Advanced High Heat Flux and Plasma-Facing Materials. Nucl. Fusion 2017, 57, 092007. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural Materials for Fission & Fusion Energy. Mater. Today 2009, 12, 12–19. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as Material for Plasma-Facing Components in Fusion Devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Dong, Y.; Gao, R.; Qin, M.; Qu, X.; Li, J. Pressureless Two-Step Sintering of Ultrafine-Grained Tungsten. Acta Mater. 2020, 186, 116–123. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Qu, X.; Qin, M.; Que, Z.; Wei, Z.; Guo, C.; Lu, X.; Dong, Y. Powder Metallurgy Route to Ultrafine-Grained Refractory Metals. Adv. Mater. 2023, 2205807. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Dong, Y.; Qin, M.; Wei, Z.; Que, Z.; Yang, J.; Qu, X.; Li, J. Towards Pressureless Sintering of Nanocrystalline Tungsten. Acta Mater. 2021, 220, 117344. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, G.; Long, Y.; Yang, J.; Qin, M.; Qu, X.; So, K.P. Microstructure Evolution of Hot-Rolled Pure and Doped Tungsten under Various Rolling Reductions. J. Nucl. Mater. 2020, 533, 152074. [Google Scholar] [CrossRef]

- Mathaudhu, S.N.; DeRosset, A.J.; Hartwig, K.T.; Kecskes, L.J. Microstructures and Recrystallization Behavior of Severely Hot-Deformed Tungsten. Mater. Sci. Eng. A 2009, 503, 28–31. [Google Scholar] [CrossRef]

- Sheng, H.; Van Oost, G.; Zhurkin, E.; Terentyev, D.; Dubinko, V.I.; Uytdenhouwen, I.; Vleugels, J. High Temperature Strain Hardening Behavior in Double Forged and Potassium Doped Tungsten. J. Nucl. Mater. 2014, 444, 214–219. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, H.T.; Schuster, B.E.; Ramesh, K.T.; Valiev, R.Z.; Kecskes, L.J.; Dowding, R.J.; Magness, L.; Cho, K. Microstructure and Mechanical Properties of Super-Strong Nanocrystalline Tungsten Processed by High-Pressure Torsion. Acta Mater. 2006, 54, 4079–4089. [Google Scholar] [CrossRef]

- Ren, C.; Fang, Z.Z.; Koopman, M.; Butler, B.; Paramore, J.; Middlemas, S. Methods for Improving Ductility of Tungsten—A Review. Int. J. Refract. Met. Hard Mater. 2018, 75, 170–183. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning Strategy in Selective Laser Melting (SLM): A Review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective Laser Melting of Aluminum and Its Alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef]

- Karimi, J.; Suryanarayana, C.; Okulov, I.; Prashanth, K.G. Selective Laser Melting of Ti6Al4V: Effect of Laser Re-Melting. Mater. Sci. Eng. A 2021, 805, 140558. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and Mechanical Properties of Pure Copper Manufactured by Selective Laser Melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Zhou, K.; Ma, W.; Attard, B.; Zhang, P.; Kuang, T. Selective Laser Melting of High-Performance Pure Tungsten: Parameter Design, Densification Behavior and Mechanical Properties. Sci. Technol. Adv. Mater. 2018, 19, 370–380. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling Phenomena in Selective Laser Melted Tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Gu, D.; Guo, M.; Zhang, H.; Sun, Y.; Wang, R.; Zhang, L. Effects of Laser Scanning Strategies on Selective Laser Melting of Pure Tungsten. Int. J. Extrem. Manuf. 2020, 2, 025001. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on Residual Stress in Selective Laser Melting Additive Manufacturing of Alloy Parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of Process Parameters on the Selective Laser Melting (SLM) of Tungsten. Int. J. Refract. Met. Hard Mater. 2018, 71, 315–319. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, Q.; Liu, J. Formation of Nanocrystalline Tungsten by Selective Laser Melting of Tungsten Powder. Mater. Manuf. Process. 2012, 27, 1267–1270. [Google Scholar] [CrossRef]

- Wang, L.; Wu, J.; Zhang, D. Properties Evolution of Additive Manufacture Used Tungsten Powders Prepared by Radio Frequency Induction Plasma. Int. J. Refract. Met. Hard Mater. 2017, 67, 90–97. [Google Scholar] [CrossRef]

- Sun, H.; Hohl, B.; Cao, Y.; Handwerker, C.; Rushing, T.S.; Cummins, T.K.; Weiss, J. Jet Mill Grinding of Portland Cement, Limestone, and Fly Ash: Impact on Particle Size, Hydration Rate, and Strength. Cem. Concr. Compos. 2013, 44, 41–49. [Google Scholar] [CrossRef]

- Ding, W.; Tao, Q.; Chen, J.; Chen, G.; Qu, X.; Qin, M. Enhanced Mechanical Properties by Laser Powder Bed Fusion Using Cost-Effective Hydride-Dehydride Titanium Powders. J. Mater. Process. Technol. 2023, 313, 117887. [Google Scholar] [CrossRef]

- Tao, Q.; Ding, W.; Chen, G.; Qu, X.; Han, L.; Qin, M. Effect of Jet Milling on HDH CP-Ti Powders: Microstructure and Properties. JOM 2021, 73, 3102–3110. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, Z.; Chen, G.; Cai, W.; Cao, P.; Zhang, C.; Ding, W.; Lu, X.; Luo, T.; Qu, X.; et al. Selective Laser Melting of CP-Ti to Overcome the Low Cost and High Performance Trade-Off. Addit. Manuf. 2020, 34, 101198. [Google Scholar] [CrossRef]

- Rajabi, M.; Simchi, A.; Vahidi, M.; Davami, P. Effect of Particle Size on the Microstructure of Rapidly Solidified Al–20Si–5Fe–2X (X=Cu, Ni, Cr) Powder. J. Alloys Compd. 2008, 466, 111–118. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder Flowability Characterisation Methodology for Powder-Bed-Based Metal Additive Manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The Metallurgy and Processing Science of Metal Additive Manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Mussatto, A.; Groarke, R.; O’Neill, A.; Obeidi, M.A.; Delaure, Y.; Brabazon, D. Influences of Powder Morphology and Spreading Parameters on the Powder Bed Topography Uniformity in Powder Bed Fusion Metal Additive Manufacturing. Addit. Manuf. 2021, 38, 101807. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Wang, L.; Yu, A.; Li, E.; Shen, H.; Zhou, Z. Effects of Spreader Geometry on Powder Spreading Process in Powder Bed Additive Manufacturing. Powder Technol. 2021, 384, 211–222. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, J. Microwave Property of Micron and Sub-Micron Fe90Al10 Flakes Fabricated via Ball Milling and Jet Milling Routes. J. Alloys Compd. 2012, 528, 58–62. [Google Scholar] [CrossRef]

- Ghambari, M.; Emadi Shaibani, M.; Eshraghi, N. Production of Grey Cast Iron Powder via Target Jet Milling. Powder Technol. 2012, 221, 318–324. [Google Scholar] [CrossRef] [Green Version]

- Rama Rao, N.V.; Hadjipanayis, G.C. Influence of Jet Milling Process Parameters on Particle Size, Phase Formation and Magnetic Properties of MnBi Alloy. J. Alloys Compd. 2015, 629, 80–83. [Google Scholar] [CrossRef]

- Protonotariou, S.; Ritzoulis, C.; Mandala, I. Jet Milling Conditions Impact on Wheat Flour Particle Size. J. Food Eng. 2021, 294, 110418. [Google Scholar] [CrossRef]

- Lu, X.; Liu, C.; Zhu, L.; Qu, X. Influence of Process Parameters on the Characteristics of TiAl Alloyed Powders by Fluidized Bed Jet Milling. Powder Technol. 2014, 254, 235–240. [Google Scholar] [CrossRef]

- Kushimoto, K.; Suzuki, K.; Ishihara, S.; Soda, R.; Ozaki, K.; Kano, J. Analysis of the Particle Collision Behavior in Spiral Jet Milling. Adv. Powder Technol. 2023, 34, 103993. [Google Scholar] [CrossRef]

- Dhakate, M.M.; Venkatraman, A.; Khakhar, D.V. Breakage of a Single Particle in an Air Jet Mill. ACS Eng. Au 2023. [Google Scholar] [CrossRef]

- Li, R.; Qin, M.; Liu, C.; Chen, Z.; Wang, X.; Qu, X. Particle Size Distribution Control and Related Properties Improvements of Tungsten Powders by Fluidized Bed Jet Milling. Adv. Powder Technol. 2017, 28, 1603–1610. [Google Scholar] [CrossRef]

- Li, R.; Qin, M.; Liu, C.; Huang, H.; Lu, H.; Chen, P.; Qu, X. Injection Molding of Tungsten Powder Treated by Jet Mill with High Powder Loading: A Solution for Fabrication of Dense Tungsten Component at Relative Low Temperature. Int. J. Refract. Met. Hard Mater. 2017, 62, 42–46. [Google Scholar] [CrossRef]

- Shanmuganathan, P.K.; Purushothaman, D.B.; Ponnusamy, M. Effect of High Laser Energy Density on Selective Laser Melted 316L Stainless Steel: Analysis on Metallurgical and Mechanical Properties and Comparison with Wrought 316L Stainless Steel. 3D Print. Addit. Manuf. 2023, 10, 383–392. [Google Scholar] [CrossRef]

- Vivek, R.; Prakash, B.; Sivamani, S.; Selvaganapathy, V.; Kumar, S.P.; Ramesh, B.; Karthik, R.; Jayakumar, V.; Masi, C. Morphological Failure Study of Low Nickel Austenitic Grade SS: Metal Spinning. J. Nanomater. 2022, 2022, 2026210. [Google Scholar] [CrossRef]

- Kumar, S.P.; Chakkravarthy, V.; Mahalingam, A.; Rajeshshyam, R.; Sriraman, N.; Marimuthu, P.; Narayan, R.L.; Babu, P.D. Investigation of Crystallographic Orientation and Mechanical Behaviour in Laser-Welded Stainless Steel 316L Additive Components. Trans. Indian Inst. Met. 2023, 76, 527–535. [Google Scholar] [CrossRef]

- Hareharen, K.; Pradeep Kumar, S.; Panneerselvam, K.; Dinesh Babu, P.; Sriraman, N. Investigating the Effect of Laser Shock Peening on the Wear Behaviour of Selective Laser Melted 316L Stainless Steel. Opt. Laser Technol. 2023, 162, 109317. [Google Scholar] [CrossRef]

| Condition | Bending Strength/MPa | Vickers Hardness/HV50 | ||

|---|---|---|---|---|

| Horizontal | Vertical | Horizontal | Vertical | |

| As-built | 171 | 99 | 414.1 | 371.4 |

| Annealed | 155 | 154 | 402.7 | 396.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wang, D.; Li, X.; Yin, F.; Zhang, L.; Li, X.; Qu, X. Towards Selective Laser Melting of High-Density Tungsten. Metals 2023, 13, 1431. https://doi.org/10.3390/met13081431

Zhang H, Wang D, Li X, Yin F, Zhang L, Li X, Qu X. Towards Selective Laser Melting of High-Density Tungsten. Metals. 2023; 13(8):1431. https://doi.org/10.3390/met13081431

Chicago/Turabian StyleZhang, Haipo, Daokuan Wang, Xingyu Li, Fengshi Yin, Lin Zhang, Xiaodong Li, and Xuanhui Qu. 2023. "Towards Selective Laser Melting of High-Density Tungsten" Metals 13, no. 8: 1431. https://doi.org/10.3390/met13081431

APA StyleZhang, H., Wang, D., Li, X., Yin, F., Zhang, L., Li, X., & Qu, X. (2023). Towards Selective Laser Melting of High-Density Tungsten. Metals, 13(8), 1431. https://doi.org/10.3390/met13081431