Compact Aluminium Foam Heat Exchangers

Abstract

:1. Introduction

2. Methodology

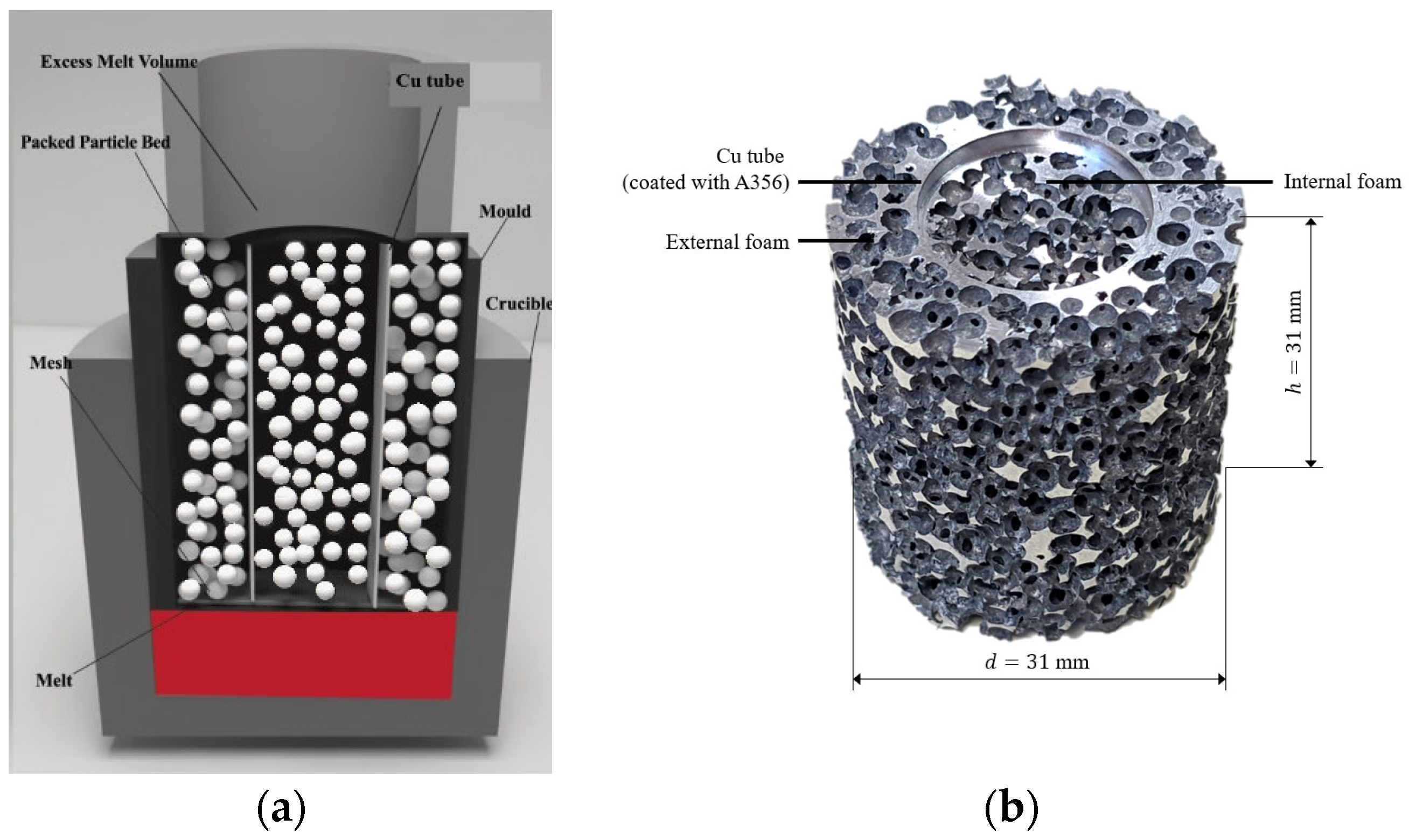

2.1. Manufacturing

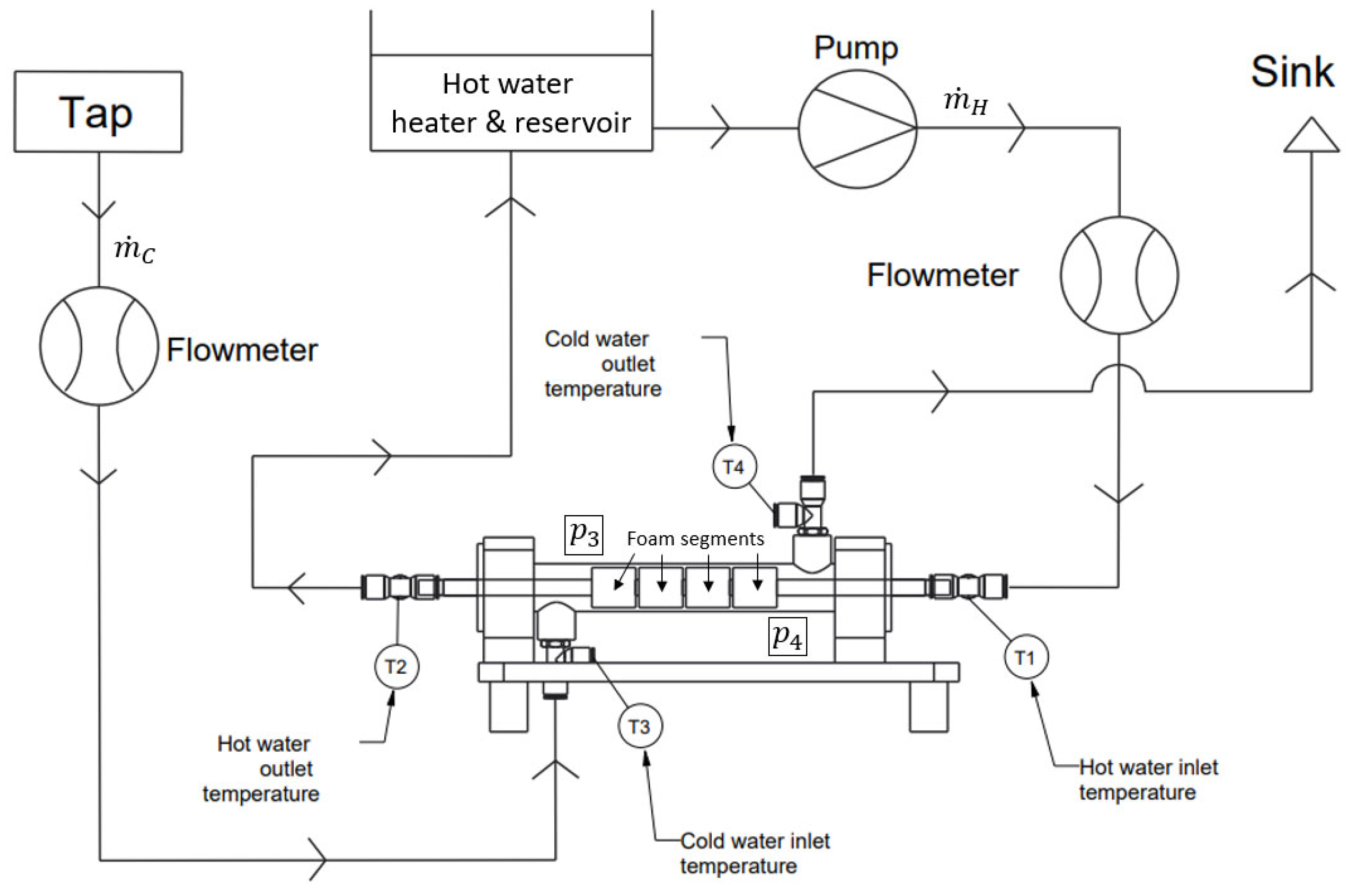

2.2. Experimentation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Analysis of Experimental Uncertainty

| Property | Sensor Type | Uncertainty |

|---|---|---|

| Temperature | Type K thermocouple | ±0.4 K |

| Mass flow | Cynergy3 UF25B | ±5% |

References

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Iasiello, M.; Bianco, N.; Chiu, W.K.; Naso, V. Anisotropic convective heat transfer in open-cell metal foams: Assessment and correlations. Int. J. Heat Mass Transf. 2020, 154, 119682. [Google Scholar] [CrossRef]

- Jeng, T.-M.; Tzeng, S.-C.; Xu, R. Experimental study of heat transfer characteristics in a 180-deg round turned channel with discrete aluminum-foam blocks. Int. J. Heat Mass Transf. 2014, 71, 133–141. [Google Scholar] [CrossRef]

- Nawaz, K.; Bock, J.; Jacobi, A.M. Thermal-hydraulic performance of metal foam heat exchangers under dry operating conditions. Appl. Therm. Eng. 2017, 119, 222–232. [Google Scholar] [CrossRef]

- Aljubury, I.M.A.; Saihood, R.G.; Farhan, A.A. Experimental study on thermo-hydraulic performance of metal foam twisted tape in a double pipe heat exchanger. Heat Transf. 2022, 51, 7910–7928. [Google Scholar] [CrossRef]

- Tamkhade, P.K.; Lande, R.D.; Gurav, R.B.; Lele, M.M. Investigations on tube in tube metal foam heat exchanger. Mater. Today Proc. 2022, 72, 951–957. [Google Scholar] [CrossRef]

- Chen, T.; Shu, G.; Tian, H.; Zhao, T.; Zhang, H.; Zhang, Z. Performance evaluation of metal-foam baffle exhaust heat exchanger for waste heat recovery. Appl. Energy 2020, 266, 114875. [Google Scholar] [CrossRef]

- Sahiti, N.; Durst, F.; Dewan, A. Strategy for selection of elements for heat transfer enhancement. Int. J. Heat Mass Transf. 2006, 49, 3392–3400. [Google Scholar] [CrossRef]

- Samudre, P.; Kailas, S.V. Thermal performance enhancement in open-pore metal foam and foam-fin heat sinks for electronics cooling. Appl. Therm. Eng. 2022, 205, 117885. [Google Scholar] [CrossRef]

- Lu, W.; Zhao, C.; Tassou, S. Thermal analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes. Int. J. Heat Mass Transf. 2006, 49, 2751–2761. [Google Scholar] [CrossRef]

- Ambrosio, G.; Bianco, N.; Chiu, W.K.; Iasiello, M.; Naso, V.; Oliviero, M. The effect of open-cell metal foams strut shape on convection heat transfer and pressure drop. Appl. Therm. Eng. 2016, 103, 333–343. [Google Scholar] [CrossRef] [Green Version]

- Nilpueng, K.; Asirvatham, L.G.; Dalkılıç, A.S.; Mahian, O.; Ahn, H.S.; Wongwises, S. Heat transfer and fluid flow characteristics in a plate heat exchanger filled with copper foam. Heat Mass Transf. 2020, 56, 3261–3271. [Google Scholar] [CrossRef]

- Tan, W.C.; Saw, L.H.; Thiam, H.S.; Garg, A.; Pambudi, N.A. Numerical study of the geometrically graded metal foam for concentrated photovoltaic solar cell cooling. Energy Procedia 2019, 158, 761–766. [Google Scholar] [CrossRef]

- Kotresha, B.; Gnanasekaran, N. Numerical Simulations of Fluid Flow and Heat Transfer through Aluminum and Copper Metal Foam Heat Exchanger—A Comparative Study. Heat Transf. Eng. 2018, 41, 637–649. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Y.; Xiao, S.; Zhao, Y.; Li, J.; Zhou, J.; Ouyang, Q. Effect of structural characteristics on the natural convective heat transfer performance of copper foam. Appl. Therm. Eng. 2022, 204, 118031. [Google Scholar] [CrossRef]

- Şahin, Y.S.; Toprak, B.I.; Solmaz, I.; Bayer, O. Investigation of flow and heat transfer behavior of integrated pin fin-aluminum foam heat sink. Appl. Therm. Eng. 2023, 219, 119504. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Rossetto, L.; Cavallini, A. Foam height effects on heat transfer performance of 20 ppi aluminum foams. Appl. Therm. Eng. 2012, 49, 55–60. [Google Scholar] [CrossRef]

- Kamath, P.M.; Balaji, C.; Venkateshan, S. Convection heat transfer from aluminium and copper foams in a vertical channel—An experimental study. Int. J. Therm. Sci. 2013, 64, 1–10. [Google Scholar] [CrossRef]

- Durmus, F.; Maiorano, L.; Molina, J. Open-cell aluminum foams with bimodal pore size distributions for emerging thermal management applications. Int. J. Heat Mass Transf. 2022, 191, 122852. [Google Scholar] [CrossRef]

- Fiedler, T.; Moore, R.; Movahedi, N. Manufacturing and Characterization of Tube-Filled ZA27 Metal Foam Heat Exchangers. Metals 2021, 11, 1277. [Google Scholar] [CrossRef]

- Hamzah, J.A.; Nima, M.A. Experimental Study of Heat Transfer Enhancement in Double-Pipe Heat Exchanger Integrated with Metal Foam Fins. Arab. J. Sci. Eng. 2020, 45, 5153–5167. [Google Scholar] [CrossRef]

- Odabaee, M.; Hooman, K. Metal foam heat exchangers for heat transfer augmentation from a tube bank. Appl. Therm. Eng. 2012, 36, 456–463. [Google Scholar] [CrossRef]

- Al-Sahlani, K.; Broxtermann, S.; Lell, D.; Fiedler, T. Effects of particle size on the microstructure and mechanical properties of expanded glass-metal syntactic foams. Mater. Sci. Eng. A 2018, 728, 80–87. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 9th ed.; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- ASM International Handbook Committee. Metals Handbook, Vol. 2—Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th ed.; ASM International: Novelty, OH, USA, 1990. [Google Scholar]

- Electronics Cooling—Design, Materials, Compounds, Adhesives, Substrates, Number 2, Technical Data, Volume 7.

| [L/min] | [L/min] | [kW] |

|---|---|---|

| 1.0 | 1.0, 2.0, 3.0 | 3.06 |

| 2.0 | 1.0 | 3.06 |

| 2.0 | 2.0, 3.0 | 6.12 |

| 3.0 | 1.0 | 3.06 |

| 3.0 | 2.0 | 6.12 |

| 3.0 | 3.0 | 9.17 |

| Copper Tube | A356 Foam | |||||

|---|---|---|---|---|---|---|

| [L/min] | 1.0 | 2.0 | 3.0 | 1.0 | 2.0 | 3.0 |

| L/min | 8.1% | 10.8% | 12.2% | 34.8% | 42.1% | 45.9% |

| L/min | 8.3% | 6.6% | 7.3% | 42.4% | 27.1% | 28.8% |

| L/min | 9.7% | 6.8% | 5.8% | 48.1% | 28.2% | 19.5% |

| Temperature | Volumetric Flow Rate | ||

|---|---|---|---|

| 1.0 L/min | 2.0 L/min | 3.0 L/min | |

| 20.0 °C | 1.14 kPa | 3.90 kPa | 7.52 kPa |

| 30.0 °C | 1.30 kPa | 4.13 kPa | 7.89 kPa |

| 40.0 °C | 1.15 kPa | 3.92 kPa | 7.34 kPa |

| 50.0 °C | 1.21 kPa | 3.78 kPa | 7.18 kPa |

| 60.0 °C | 1.13 kPa | 3.59 kPa | 6.85 kPa |

| Average | 1.19 kPa | 3.86 kPa | 7.36 kPa |

| StDev | 0.07 kPa | 0.20 kPa | 0.39 kPa |

| Hot Stream Flow Rate [L/min] | ||||

|---|---|---|---|---|

| 1.0 | 2.0 | 3.0 | ||

| Pressure drop [kPa] | 1.19 | 0.90 | 1.09 | 1.18 |

| 3.86 | 0.34 | 0.43 | 0.46 | |

| 7.36 | 0.20 | 0.23 | 0.24 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiedler, T.; Movahedi, N. Compact Aluminium Foam Heat Exchangers. Metals 2023, 13, 1440. https://doi.org/10.3390/met13081440

Fiedler T, Movahedi N. Compact Aluminium Foam Heat Exchangers. Metals. 2023; 13(8):1440. https://doi.org/10.3390/met13081440

Chicago/Turabian StyleFiedler, Thomas, and Nima Movahedi. 2023. "Compact Aluminium Foam Heat Exchangers" Metals 13, no. 8: 1440. https://doi.org/10.3390/met13081440

APA StyleFiedler, T., & Movahedi, N. (2023). Compact Aluminium Foam Heat Exchangers. Metals, 13(8), 1440. https://doi.org/10.3390/met13081440