Microstructural Evolution and Mechanical Behavior of TA15 Titanium Alloy Fabricated by Selective Laser Melting: Influence of Solution Treatment and Aging

Abstract

:1. Introduction

2. Materials and Experimental Procedures

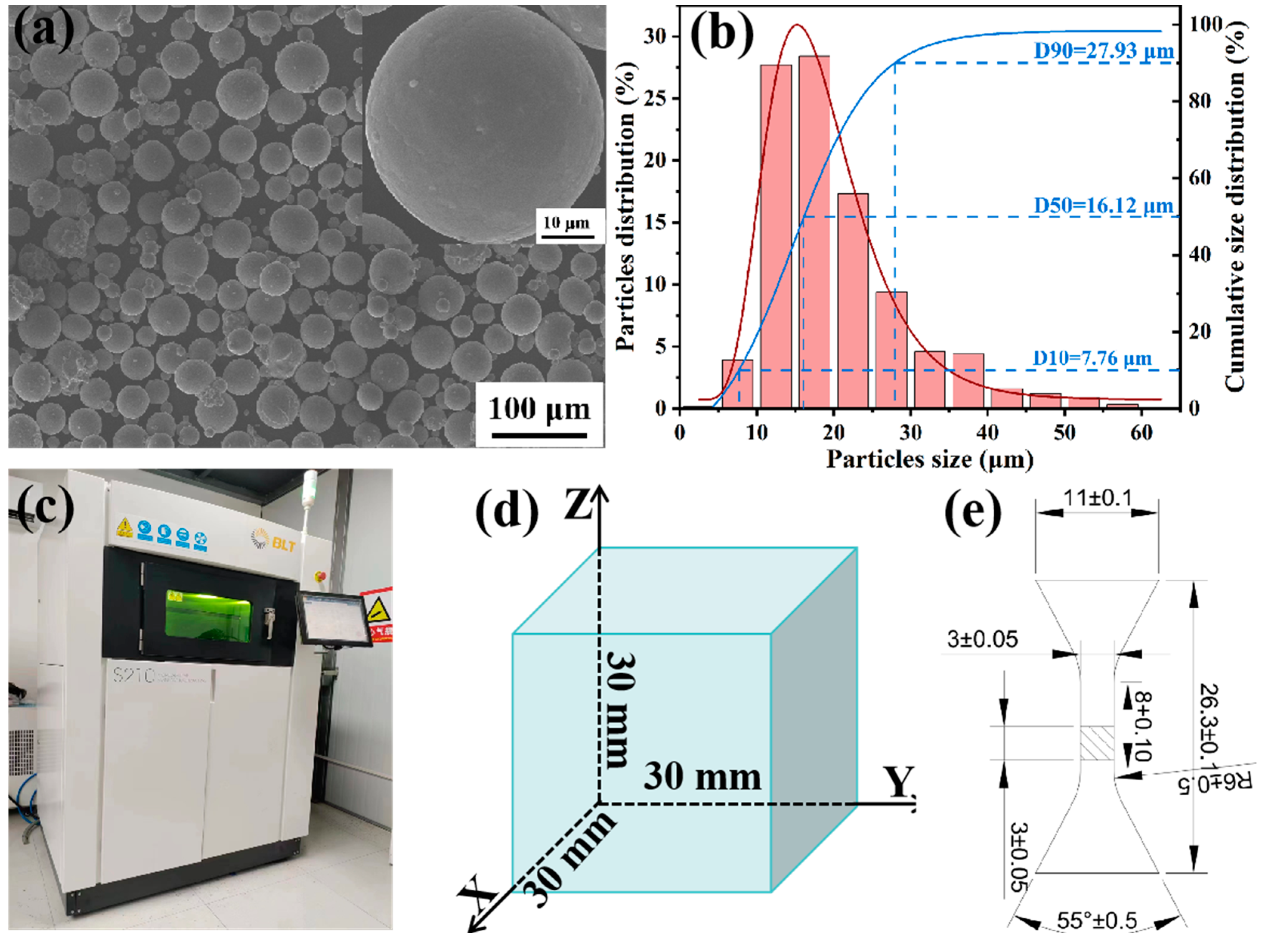

2.1. Materials

2.2. Sample Fabrications and Heat Treatment Scheme

2.3. Characterization Method

3. Results and Discussion

3.1. Influence of Heat Treatment Parameters on Microstructure of TA15 Titanium Alloy

3.2. Influence of Heat Treatment Parameters on Mechanical Properties of TA15 Titanium Alloy

4. Conclusions

- There are a lot of acicular α’ martensite crystals in the TA15 titanium alloy prepared via SLM, as well as many dislocations and twins in the martensite, which result in good mechanical properties. After solution and aging treatment, martensite is decomposed into equiaxed primary α phases and layered secondary α phases with good mechanical properties.

- In a certain range, with the increase in the solution temperature, the size of the equiaxed primary α phases gradually increases, and the plasticity of the specimen gradually increases, but the thickness of the layered secondary α phase gradually decreases, accompanied by the gradual reduction in specimen strength. After solution at 1000 °C and aging, the specimens show the best comprehensive mechanical properties, i.e., a high-temperature tensile strength of 715 MPa and corresponding elongation of 24.5%.

- Firstly, martensite is decomposed into primary and secondary α phases, and the mechanical properties of TA15 titanium alloys are improved through the formation of a phase transition interface and lattice distortion. Secondly, the equiaxed primary α phase and layered secondary α phase improve the mechanical properties and stability of TA15 titanium alloys by hindering the slip and movement of grain boundary dislocations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Wu, Z.; Wang, Q.; Zhao, L.; Zhang, X.; Gao, W.; Xu, J.; Song, Y.; Song, X.; Zhang, X. Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method. Crystals 2022, 12, 1385. [Google Scholar] [CrossRef]

- Huang, S.; Sun, B.; Guo, S. Microstructure and Property Evaluation of TA15 Titanium Alloy Fabricated by Selective Laser Melting after Heat Treatment. Opt. Laser Technol. 2021, 144, 107422. [Google Scholar] [CrossRef]

- Wang, D.; Li, H.; Zheng, W. Oxidation Behaviors of TA15 Titanium Alloy and TiBw Reinforced TA15 Matrix Composites Prepared by Spark Plasma Sintering. J. Mater. Sci. Technol. 2020, 37, 46–54. [Google Scholar] [CrossRef]

- Zhang, P.; He, A.N.; Liu, F.; Zhang, K.; Jiang, J.; Zhang, D.Z. Evaluation of Low Cycle Fatigue Performance of Selective Laser Melted Titanium Alloy Ti–6Al–4V. Metals 2019, 9, 1041. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Zou, Z.; Shi, Y.; Zang, Y. The Microstructure and Tensile Properties of Additively Manufactured Ti–6Al–2Zr–1Mo–1V with a Trimodal Microstructure Obtained by Multiple Annealing Heat Treatment. Mater. Sci. Eng. A 2022, 831, 142241. [Google Scholar] [CrossRef]

- Tao, P.; Shao, H.; Ji, Z.; Nan, H.; Xu, Q. Numerical Simulation for the Investment Casting Process of a Large-Size Titanium Alloy Thin-Wall Casing. Prog. Nat. Sci. Mater. Int. 2018, 28, 520–528. [Google Scholar] [CrossRef]

- Li, J.; Shen, J.; Hu, S.; Zhang, H.; Bu, X. Microstructure and Mechanical Properties of Ti-22Al-25Nb/TA15 Dissimilar Joint Fabricated by Dual-Beam Laser Welding. Opt. Laser Technol. 2019, 109, 123–130. [Google Scholar] [CrossRef]

- Sun, Q.J.; Xie, X. Microstructure and Mechanical Properties of TA15 Alloy after Thermo-Mechanical Processing. Mater. Sci. Eng. A 2018, 724, 493–501. [Google Scholar] [CrossRef]

- Aksa, H.C.; Hacısalihoğlu, İ.; Yıldız, F.; Varol, T.; Güler, O.; Kaya, G.; Akçay, S.B. Effects of Fabrication Parameters and Post-Processing Treatments on the Mechanical and Tribological Behavior of Surface-Enhanced Copper Based Materials by Selective Laser Melting. J. Mater. Process. Technol. 2022, 304, 117564. [Google Scholar] [CrossRef]

- Varol, T.; Hacısalihoğlu, İ.; Kaya, G.; Güler, O.; Yıldız, F.; Aksa, H.C.; Akçay, S.B. The Effect of Selective Laser Melting Process on the Microstructure, Density, and Electrical Conductivity of Silver-Coated Copper Cores. J. Mater. Eng. Perform. 2021, 30, 5216–5226. [Google Scholar] [CrossRef]

- Wu, X.; Cai, C.; Yang, L.; Liu, W.; Li, W.; Li, M.; Liu, J.; Zhou, K.; Shi, Y. Enhanced Mechanical Properties of Ti-6Al-2Zr-1Mo-1V with Ultrafine Crystallites and Nano-Scale Twins Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2018, 738, 10–14. [Google Scholar] [CrossRef]

- Cai, C.; Wu, X.; Liu, W.; Zhu, W.; Chen, H.; Qiu, J.C.D.; Sun, C.-N.; Liu, J.; Wei, Q.; Shi, Y. Selective Laser Melting of Near-α Titanium Alloy Ti-6Al-2Zr-1Mo-1V: Parameter Optimization, Heat Treatment and Mechanical Performance. J. Mater. Sci. Technol. 2020, 57, 51–64. [Google Scholar] [CrossRef]

- Jiang, J.; Ren, Z.; Ma, Z.; Zhang, T.; Zhang, P.; Zhang, D.Z.; Mao, Z. Mechanical Properties and Microstructural Evolution of TA15 Ti Alloy Processed by Selective Laser Melting before and after Annealing. Mater. Sci. Eng. A 2020, 772, 138742. [Google Scholar] [CrossRef]

- Li, L.; Pan, X.; Liu, B.; Liu, B.; Li, P.; Liu, Z. Strength and Toughness of Hot-Rolled TA15 Aviation Titanium Alloy after Heat Treatment. Aerospace 2023, 10, 436. [Google Scholar] [CrossRef]

- Sun, Z.C.; Han, F.X.; Wu, H.L.; Yang, H. Tri-Modal Microstructure Evolution of TA15 Ti-Alloy under Conventional Forging Combined with given Subsequent Heat Treatment. J. Mater. Process. Technol. 2016, 229, 72–81. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Z.; Cao, J.; Yin, Z. Formation and Evolution of Tri-Modal Microstructure during Dual Heat Treatment for TA15 Ti-Alloy. J. Alloys Compd. 2019, 786, 894–905. [Google Scholar] [CrossRef]

- Wang, L.; Ma, H.; Fan, Q.; Yao, J.; Shen, X.; Zhang, S.; Zhou, Y.; Peng, Y.; Gao, Y.; Wang, D. Simultaneously Enhancing Strength and Ductility of Ti-6Al-4V Alloy with the Hierarchical Structure via a Novel Thermal Annealing Treatment. Mater. Charact. 2021, 176, 111112. [Google Scholar] [CrossRef]

- Wang, K.; Jiao, Y.; Wu, X.; Qu, B.; Wang, X.; Liu, G. A Novel Composited Process of Solution Treatment-Hot Gas Forming and Stress Relaxation Aging for Titanium Alloys. J. Mater. Process. Technol. 2021, 288, 116904. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and Control of Martensite in Ti-6Al-4V Alloy Produced by Selective Laser Melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, D.; Guo, Y.; Zhang, T.; Liu, Z. Microstructure and Mechanical Evolution Behavior of LPBF (Laser Powder Bed Fusion)-Fabricated TA15 Alloy. J. Alloys Compd. 2021, 873, 159639. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Zou, Z.; Shi, Y. Achieving an Ideal Combination of Strength and Plasticity in Additive Manufactured Ti–6.5Al–2Zr–1Mo–1V Alloy through the Development of Tri-Modal Microstructure. Mater. Sci. Eng. A 2022, 840, 142944. [Google Scholar] [CrossRef]

- Wen, P.; Wang, C.; Zhou, P.; Yang, M.; Wang, L.; Wang, B.; Wang, H. Effect of Ultrasonic Treatment on the Microstructure and Mechanical Properties of a New Ni-Base Superalloy 4716MA0. J. Alloys Compd. 2022, 922, 166278. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Tan, H.; Zhang, G.; Lin, X.; Huang, W. Achieving Superior Ductility for Laser Solid Formed Extra Low Interstitial Ti-6Al-4V Titanium Alloy through Equiaxial Alpha Microstructure. Scr. Mater. 2018, 146, 187–191. [Google Scholar] [CrossRef]

- Motyka, M.; Baran-Sadleja, A.; Sieniawski, J.; Wierzbinska, M.; Gancarczyk, K. Decomposition of Deformed α′(α″) Martensitic Phase in Ti–6Al–4V Alloy. Mater. Sci. Technol. 2019, 35, 260–272. [Google Scholar] [CrossRef]

- Su, J.; Ji, X.; Liu, J.; Teng, J.; Jiang, F.; Fu, D.; Zhang, H. Revealing the Decomposition Mechanisms of Dislocations and Metastable α’ Phase and Their Effects on Mechanical Properties in a Ti-6Al-4V Alloy. J. Mater. Sci. Technol. 2022, 107, 136–148. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Z.; Cao, J.; Yin, Z. Microstructure and Mechanical Behavior of Heat-Treated and Thermomechanically Processed TA15 Ti Alloy Composites. J. Mater. Eng. Perform. 2019, 28, 788–799. [Google Scholar] [CrossRef]

- Cao, S.; Chu, R.; Zhou, X.; Yang, K.; Jia, Q.; Lim, C.V.S.; Huang, A.; Wu, X. Role of Martensite Decomposition in Tensile Properties of Selective Laser Melted Ti-6Al-4V. J. Alloys Compd. 2018, 744, 357–363. [Google Scholar] [CrossRef]

- Cai, C.; Gao, X.; Teng, Q.; Kiran, R.; Liu, J.; Wei, Q.; Shi, Y. Hot Isostatic Pressing of a near α-Ti Alloy: Temperature Optimization, Microstructural Evolution and Mechanical Performance Evaluation. Mater. Sci. Eng. A 2021, 802, 140426. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, W.; Zeng, L.; Cui, G.; Chen, W. Room-Temperature and High-Temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker-Reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-Pressing Sintering. Materials 2017, 10, 424. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Zhu, Y.; Yang, Y.; Zhang, R.; Zhang, Z.; Huang, A.; Zhang, K. Enhancing High-Temperature Strength and Ductility in Laser Powder Bed Fusion Ti–6.5Al–2Zr–1Mo–1V Alloy via Heat Treatment Optimization. Mater. Sci. Eng. A 2022, 859, 144201. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Qi, J.; Zou, Z.; Qian, Y. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Additive Manufactured Ti-6.5Al-2Zr-1Mo-1V Alloy. Materials 2022, 16, 160. [Google Scholar] [CrossRef] [PubMed]

- Stefansson, N.; Semiatin, S.L. Mechanisms of Globularization of Ti-6Al-4V during Static Heat Treatment. Metall. Mater. Trans. A 2003, 34, 691–698. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, M.; Guo, S.; Tao, S.; Zhou, J.; Qin, Z.; Lin, X.; Huang, W. In Situ Tensile Test of Selective Laser Melted Ti-6.5Al-2Zr-1Mo-1V Alloy at Different Stages of Martensite Decomposition. J. Mater. Sci. 2023, 58, 1798–1812. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, K.; Li, H.; Wen, X.; Xin, R. Effect of Content and Configuration of Equiaxed α and Lamellar α on Deformation Mechanism and Tensile Properties of a Near-α Titanium Alloy. Mater. Sci. Eng. A. 2023, 877, 145192. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | Zr | Mo | Si | Fe |

|---|---|---|---|---|---|---|---|

| wt.% | Balance | 5.50–7.10 | 0.80–2.50 | 1.50–2.50 | 0.50–2.00 | ≤0.15 | ≤0.25 |

| No. | Solution Conditions | Aging Conditions |

|---|---|---|

| HT1 | 950 °C/2 h/WQ | 600 °C/4 h/AC |

| HT2 | 1000 °C/2 h/WQ | 600 °C/4 h/AC |

| HT3 | 1050 °C/2 h/WQ | 600 °C/4 h/AC |

| HT4 | 1100 °C/2 h/WQ | 600 °C/4 h/AC |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Jin, B.; Zhao, L.; Liu, X.; Pan, A.; Ding, X.; Gao, W.; Song, Y.; Zhang, X. Microstructural Evolution and Mechanical Behavior of TA15 Titanium Alloy Fabricated by Selective Laser Melting: Influence of Solution Treatment and Aging. Metals 2023, 13, 1514. https://doi.org/10.3390/met13091514

Wang Q, Jin B, Zhao L, Liu X, Pan A, Ding X, Gao W, Song Y, Zhang X. Microstructural Evolution and Mechanical Behavior of TA15 Titanium Alloy Fabricated by Selective Laser Melting: Influence of Solution Treatment and Aging. Metals. 2023; 13(9):1514. https://doi.org/10.3390/met13091514

Chicago/Turabian StyleWang, Qing, Binquan Jin, Lizhong Zhao, Xiaolian Liu, Anjian Pan, Xuefeng Ding, Wei Gao, Yufeng Song, and Xuefeng Zhang. 2023. "Microstructural Evolution and Mechanical Behavior of TA15 Titanium Alloy Fabricated by Selective Laser Melting: Influence of Solution Treatment and Aging" Metals 13, no. 9: 1514. https://doi.org/10.3390/met13091514