Study of Cooling Medium Variables during Quenching in SAE 4340 Steel Using Statistical and Modeling Tools

Abstract

:1. Introduction

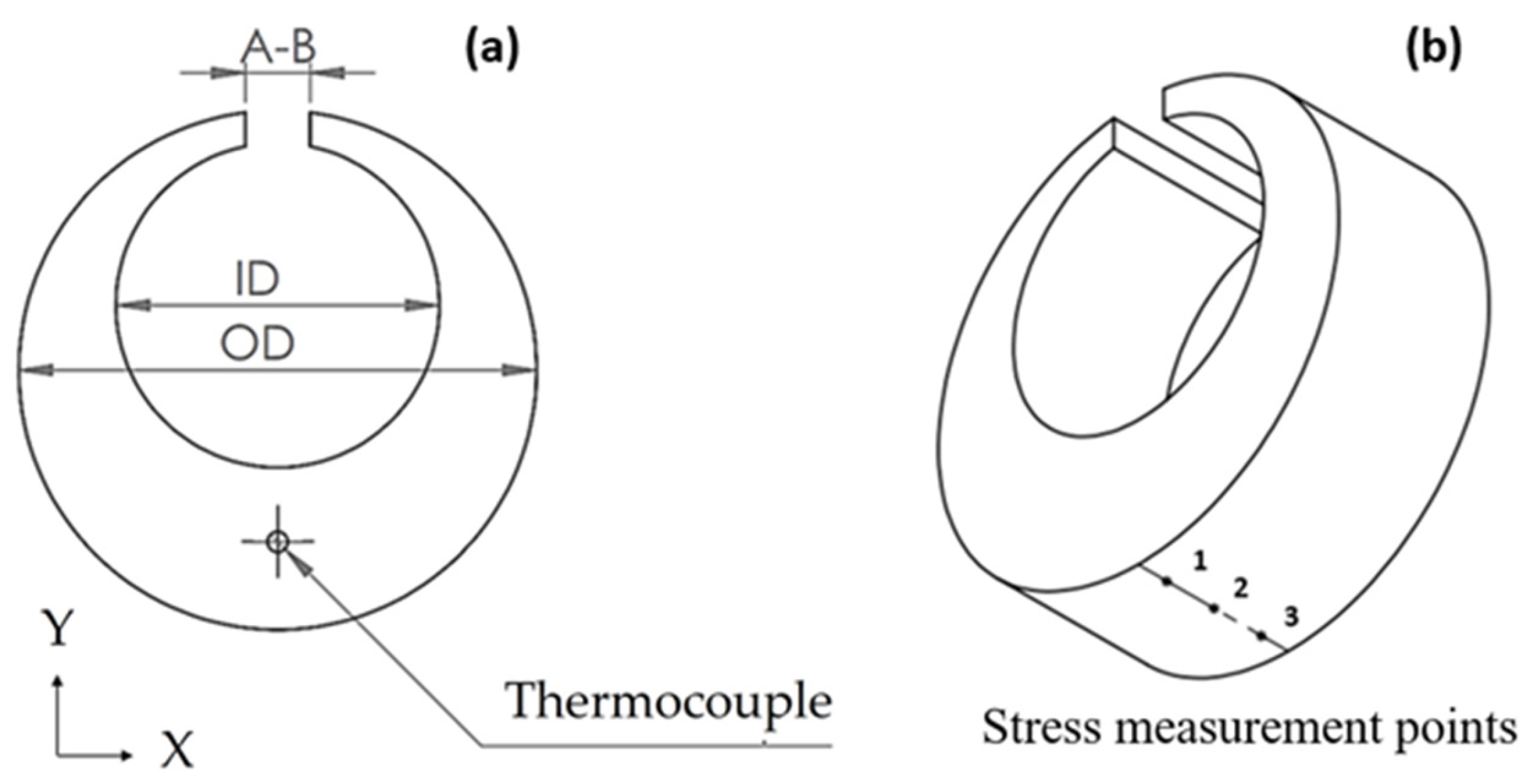

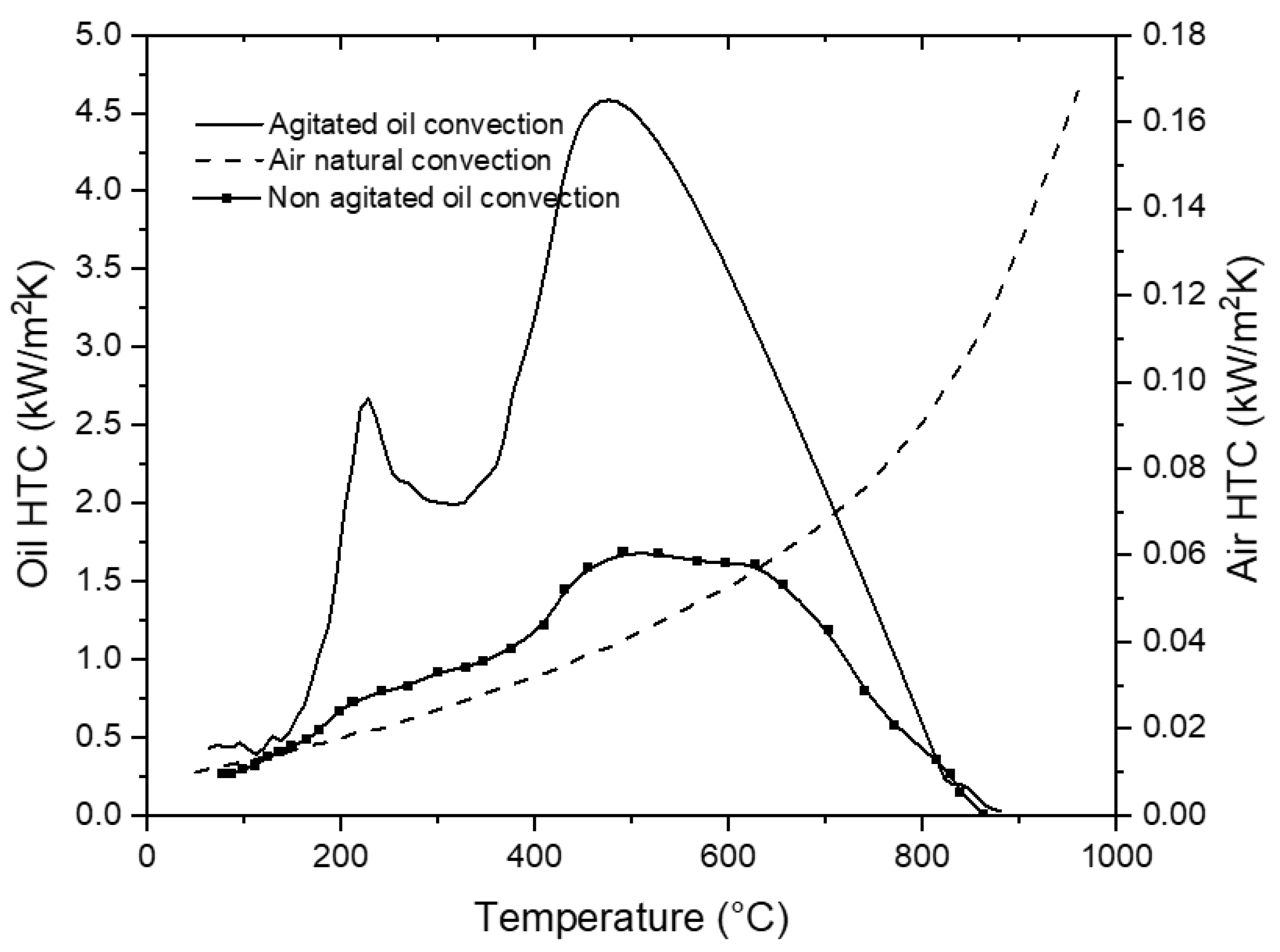

2. Materials and Methods

3. Results

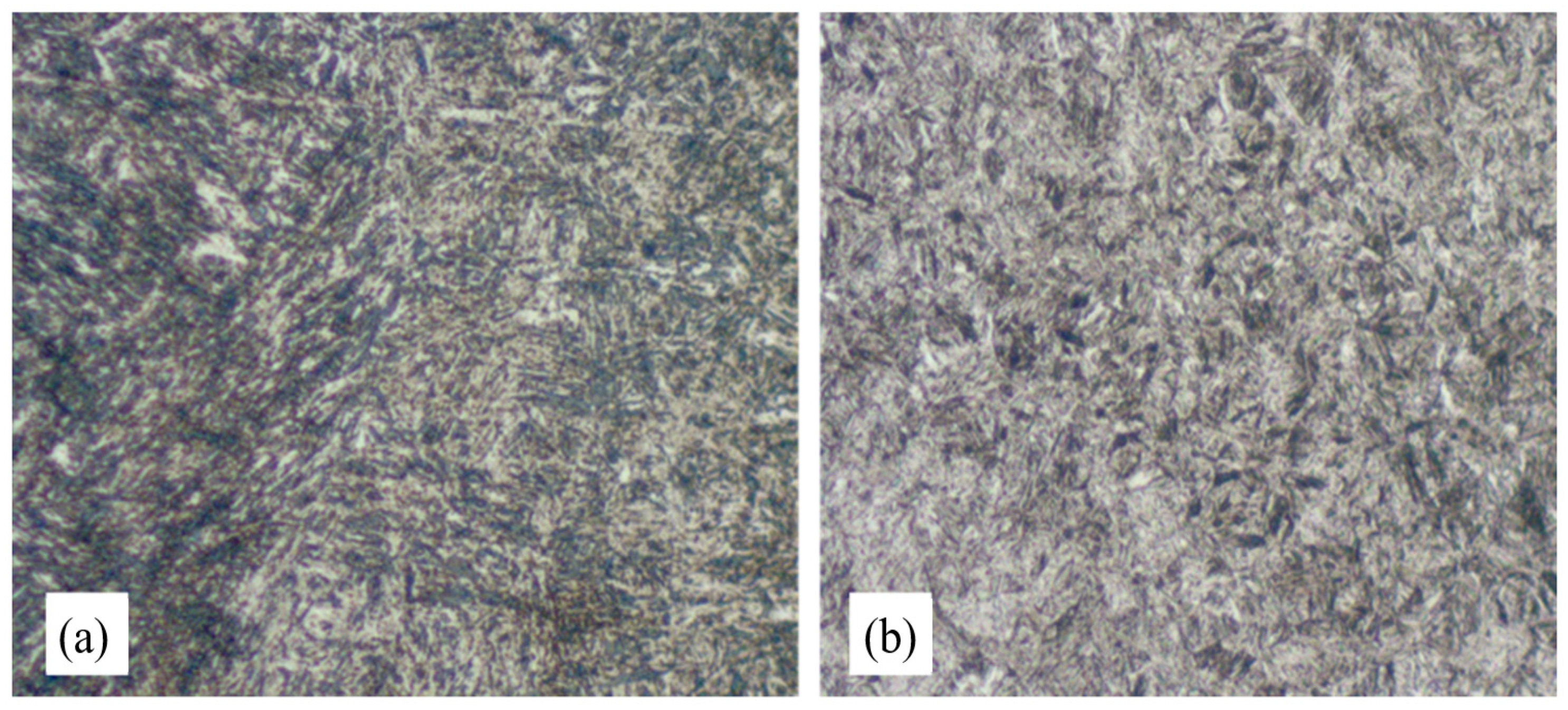

3.1. Microstructure

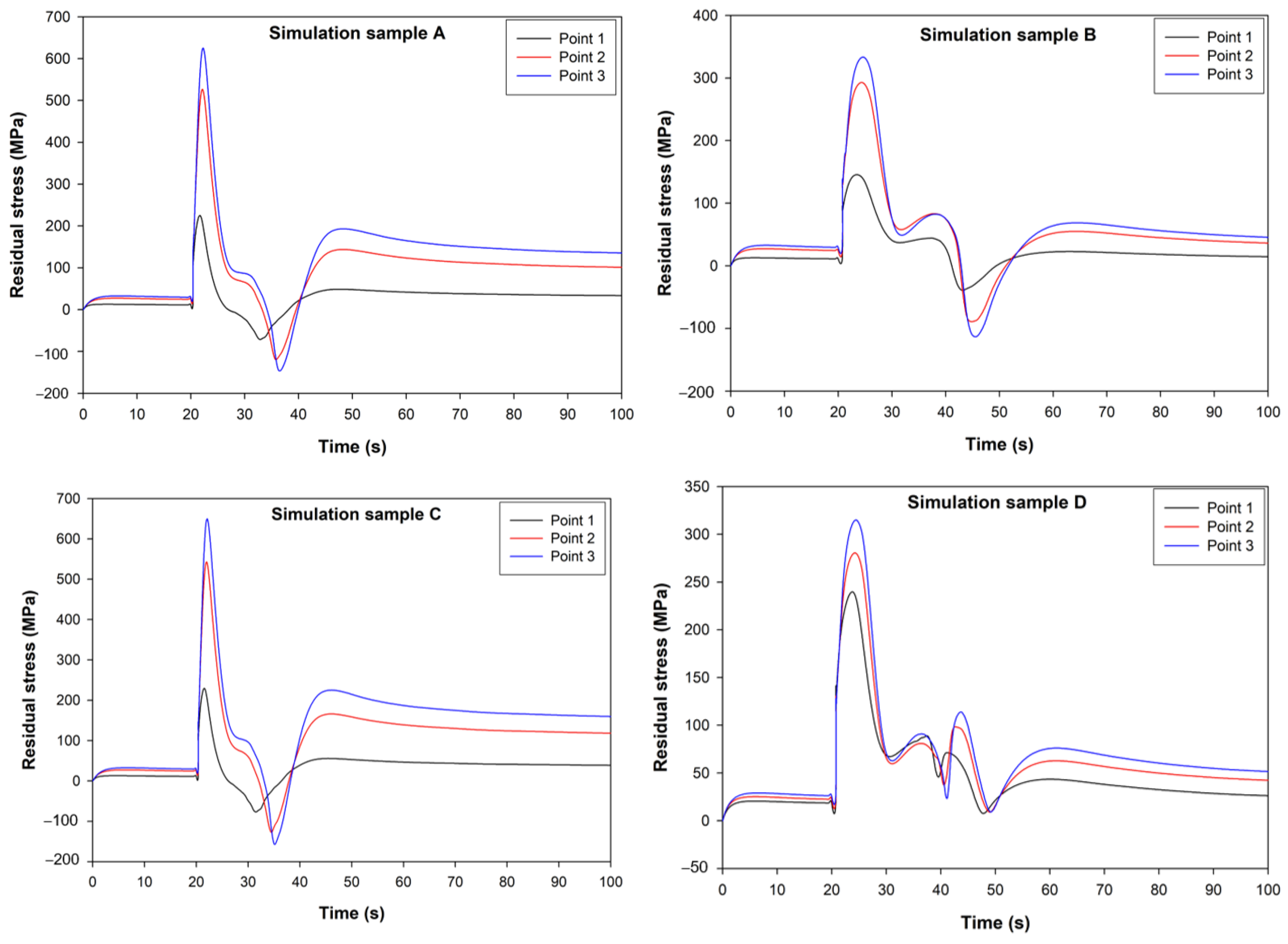

3.2. Residual Stresses

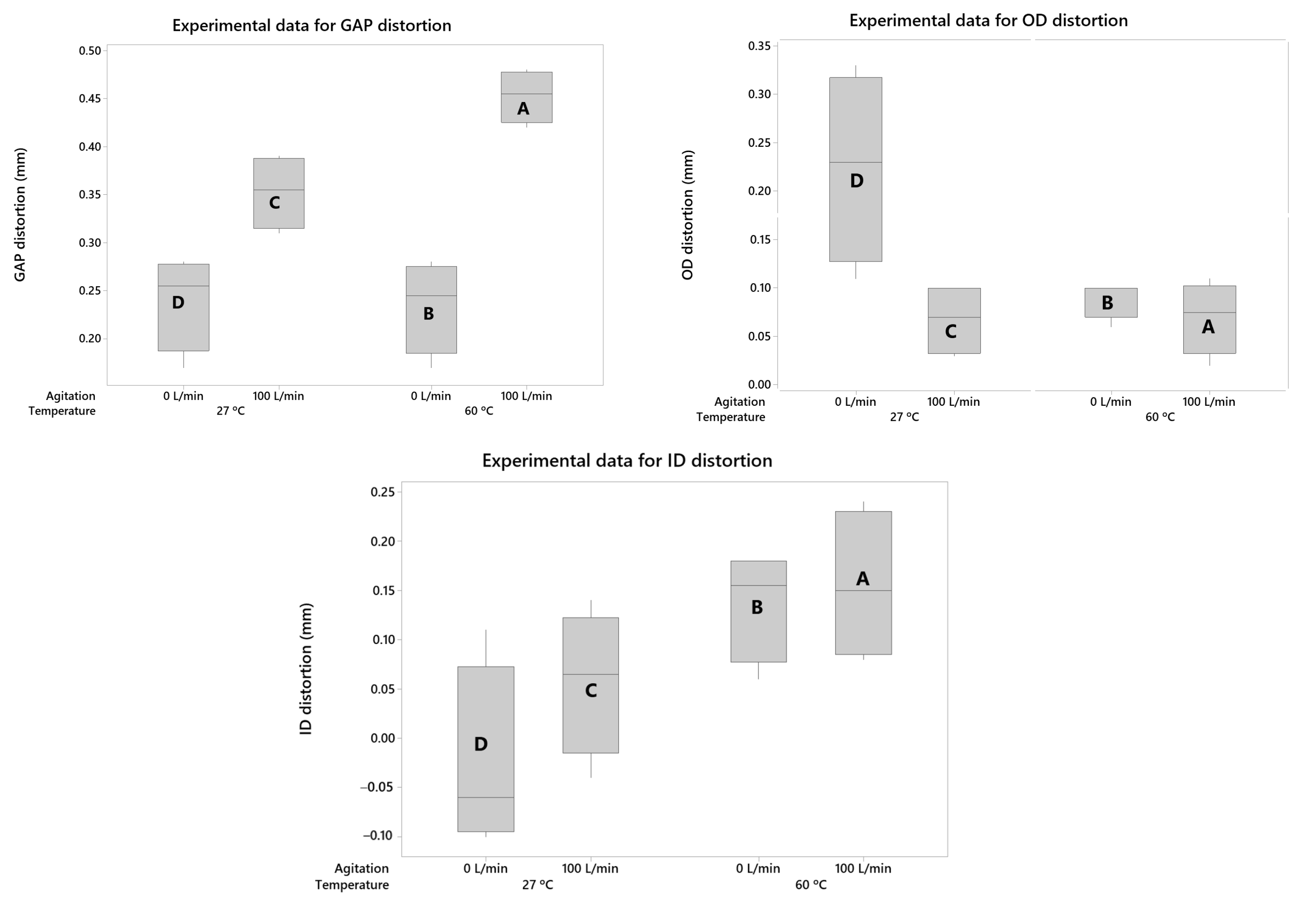

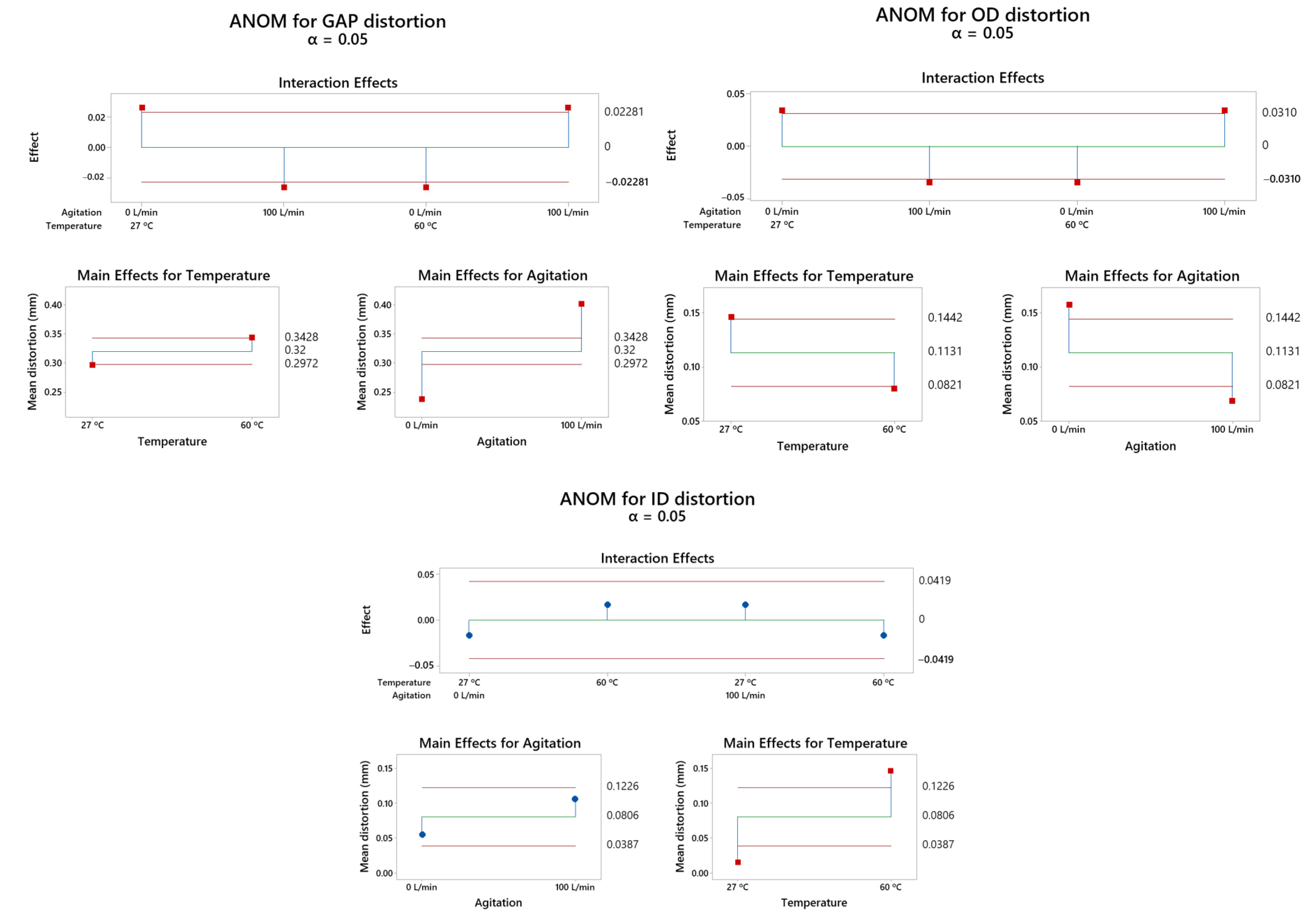

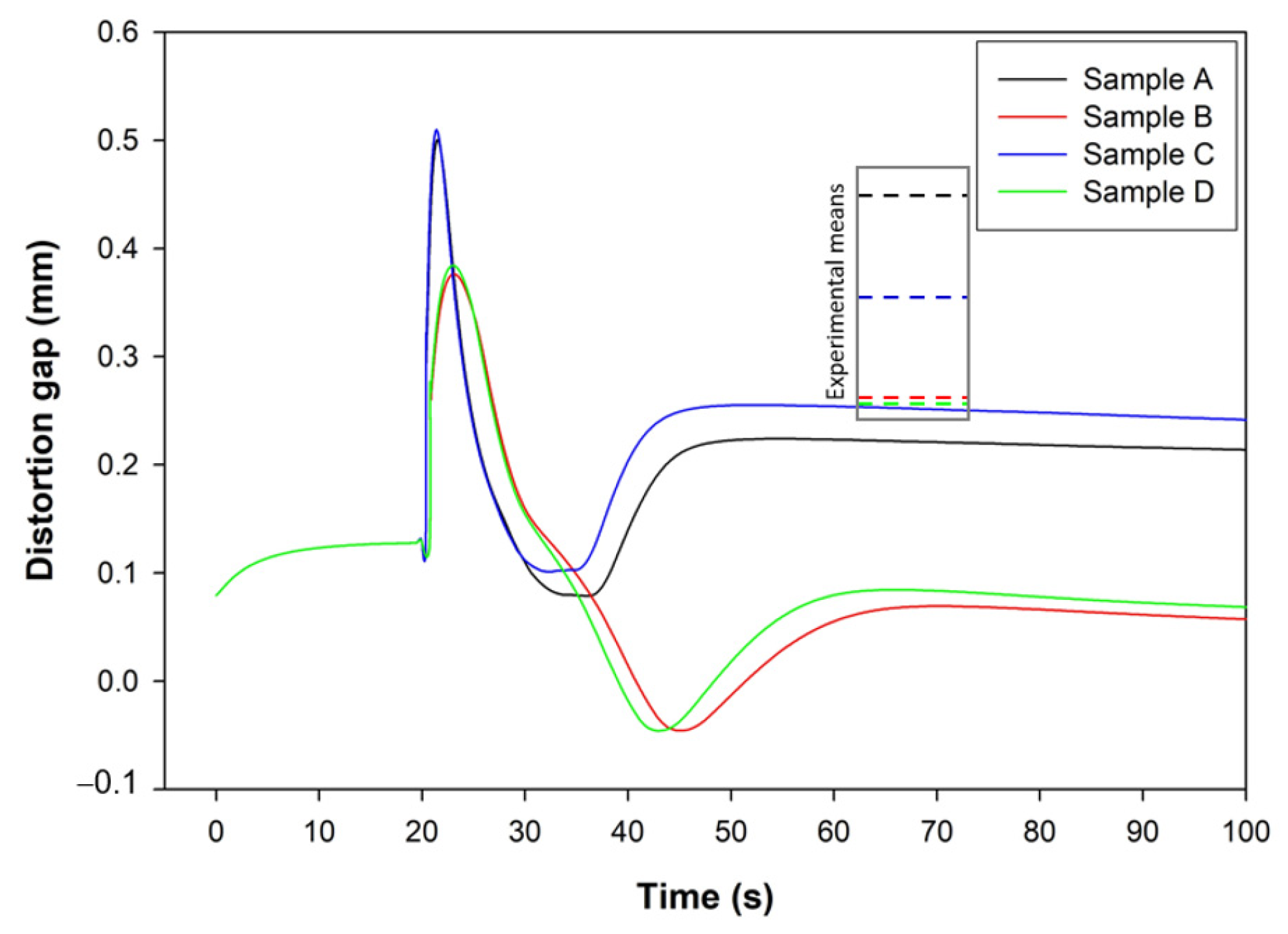

3.3. Distortion of the C-Rings

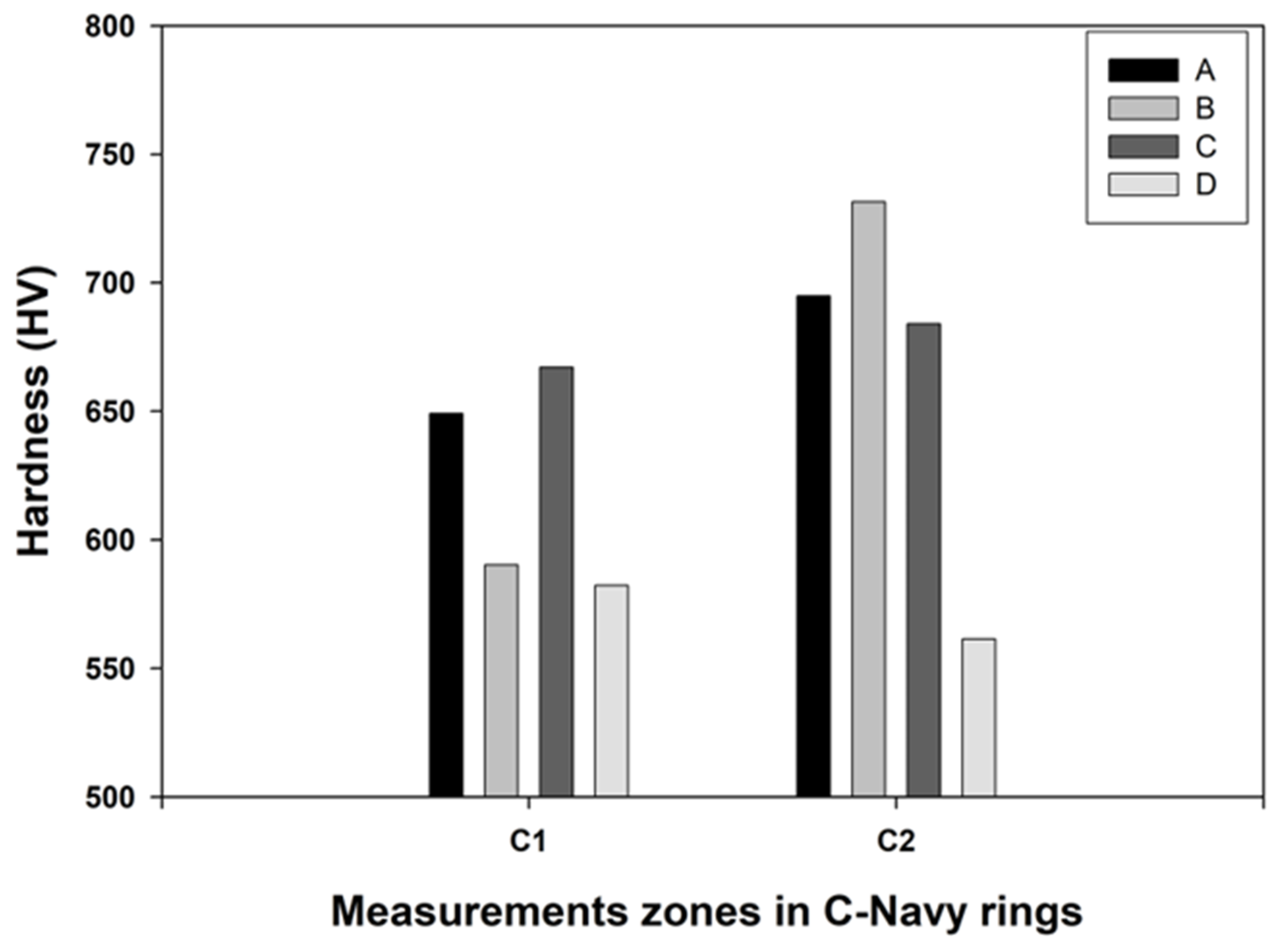

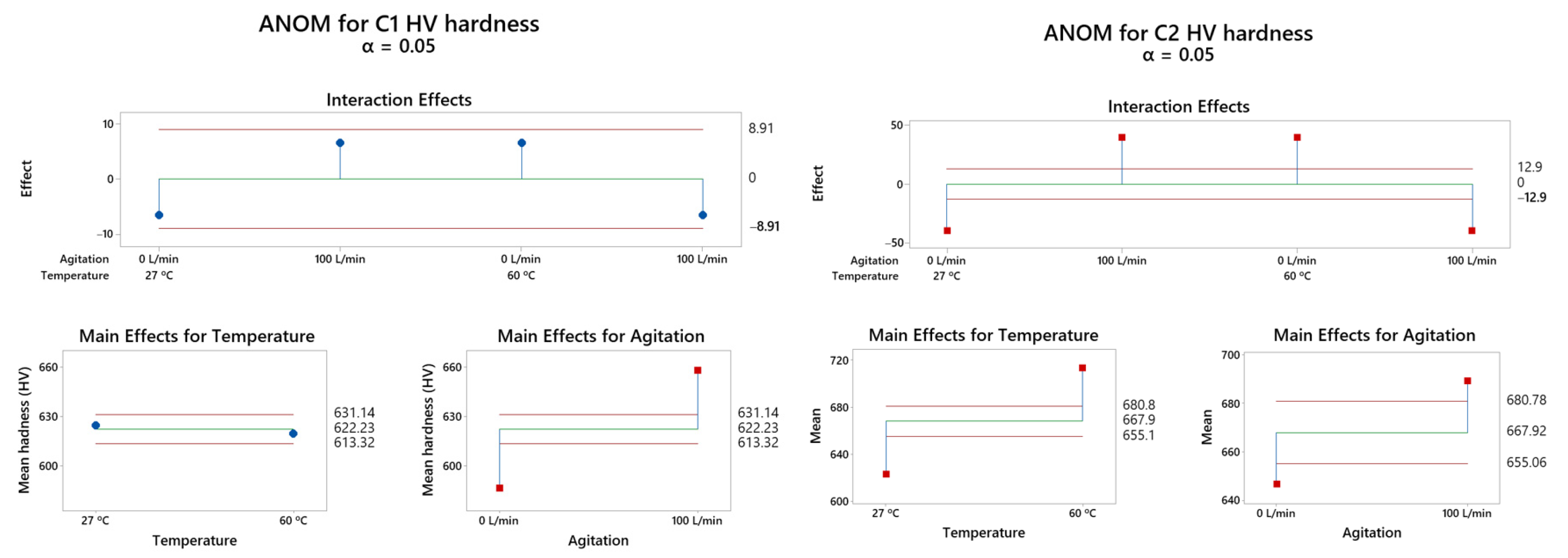

3.4. Analysis of Hardness

4. Discussion of Results

4.1. Residual Stress

4.2. ANOM for Distortion

4.3. ANOM for Hardness

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehrabi, A.; Sharifi, H.; Asadabad, M.A.; Najafabadi, R.A.; Rajaee, A. Improvement of AISI 4340 Steel Properties by Intermediate Quenching–Microstructure, Mechanical Properties, and Fractography. Int. J. Mater. Res. 2020, 111, 771–779. [Google Scholar] [CrossRef]

- Bates, C.E. Predicting Properties and Minimizing Residual Stress in Quenched Steel Parts. J. Heat Treat. 1988, 6, 27–45. [Google Scholar] [CrossRef]

- Li, Z.; Freborg, A.M.; Hansen, B.D.; Srivatsan, T.S. Modeling the Effect of Carburization and Quenching on the Development of Residual Stresses and Bending Fatigue Resistance of Steel Gears. J. Mater. Eng. Perform. 2012, 22, 664–672. [Google Scholar] [CrossRef]

- Schröder, R. Influences on Development of Thermal and Residual Stresses in Quenched Steel Cylinders of Different Dimensions. Mater. Sci. Technol. 1985, 1, 754–764. [Google Scholar] [CrossRef]

- Apichai, P. Effects of Quenchants on Microstructures and Mechanical Properties of Steel Grade AISI 5160. J. Met. Mater. Min. 2020, 30, 15–23. [Google Scholar] [CrossRef]

- Ghazali, S.; Algarni, M.; Bai, Y.; Choi, Y. A Study on the Plasticity and Fracture of the AISI 4340 Steel Alloy under Different Loading Conditions and Considering Heat-Treatment Effects. Int. J. Fract. 2020, 225, 69–87. [Google Scholar] [CrossRef]

- Fakir, R.; Barka, N.; Brousseau, J. Mechanical Properties Analysis of 4340 Steel Specimen Heat Treated in Oven and Quenching in Three Different Fluids. Met. Mater. Int. 2018, 24, 981–991. [Google Scholar] [CrossRef]

- Medina-Juárez, I.; Araujo De Oliveira, J.; Moat, R.J.; García-Pastor, F.A. On the Accuracy of Finite Element Models Predicting Residual Stresses in Quenched Stainless Steel. Metals 2019, 9, 1308. [Google Scholar] [CrossRef]

- Sonar, T.; Lomte, S.; Gogte, C.; Balasubramanian, V. Minimization of Distortion in Heat Treated AISI D2 Tool Steel: Mechanism and Distortion Analysis. Procedia Manuf. 2018, 20, 113–118. [Google Scholar] [CrossRef]

- Jami, M.; Gil, E.; Ushiña, E.; Cabrera, V.H.; Cartagena, A. Determine Hardness and Torsional Resistance of AISI/SAE 4340 Steel, Treated by Quenching at 860 °C and Tempering at 300 °C, 350 °C and 400 °C. Mater. Today Proc. 2021, 49, 35–42. [Google Scholar] [CrossRef]

- Clark, A.; Bowers, R.J.; Northwood, D.O. Heat Treatment Effects on Distortion, Residual Stress, and Retained Austenite in Carburized 4320 Steel. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; Volume 783–786, pp. 692–697. [Google Scholar]

- García-Navas, V.; Gonzalo, O.; Quintana, I.; Pirling, T. Residual Stresses and Structural Changes Generated at Different Steps of the Manufacturing of Gears: Effect of Banded Structures. Mater. Sci. Eng. A 2011, 528, 5146–5157. [Google Scholar] [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Wimpory, R.C.; Dear, J.P.; Davies, C.M. Prediction and Measurement of Residual Stresses and Distortion in fibre laser welded Ti-6Al-4V Considering Phase Transformation. Mater. Des. 2017, 115, 441–457. [Google Scholar] [CrossRef]

- Guo, J.; Fu, H.; Pan, B.; Kang, R. Recent Progress of Residual Stress Measurement Methods: A Review. Chin. J. Aeronaut. 2021, 34, 54–78. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of Measuring Residual Stresses in Components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Z.; Xie, H. Recent Progress in Residual Stress Measurement Techniques. Acta Mech. Solida Sin. 2013, 26, 570–583. [Google Scholar] [CrossRef]

- Yi, J.; Gharghouri, M.; Bocher, P.; Medraj, M. Distortion and Residual Stress Measurements of Induction Hardened AISI 4340 Discs. Mater. Chem. Phys. 2013, 142, 248–258. [Google Scholar] [CrossRef]

- Manivannan, M.; Northwood, D.O.; Stoilov, V. Use of Navy C-Rings to Study and Predict Distortion in Heat Treated Components: Experimental Measurements and Computer Modelling. Int. Heat Treat. Surf. Eng. 2014, 8, 168–175. [Google Scholar] [CrossRef]

- Yu, H.; Yang, M.; Sisson, R.D. Application of C-Ring Specimen for Controlling the Distortion of Parts During Quenching. Met. Sci. Heat Treat. 2021, 63, 220–228. [Google Scholar] [CrossRef]

- Hernández-Morales, B.; Barba-Méndez, O.; Ingalls-Cruz, A.; Barrera-Godínez, J.A. Mathematical Modelling of Temperature and Stress Evolution during Cooling of a Stainless Steel Navy C-Ring Probe. Int. J. Mater. Prod. Technol. 2005, 24, 306–318. [Google Scholar] [CrossRef]

- Da Silva, A.; Pedrosa, T.; Gonzalez-Mendez, J.; Jiang, X.; Cetlin, P.; Altan, T. Distortion in Quenching an AISI 4140 C-Ring—Predictions and Experiments. Mater. Des. 2012, 42, 55–61. [Google Scholar] [CrossRef]

- Boyle, E.; Bowers, R.; Northwood, D.O. The Use of Navy C-Ring Specimens to Investigate the Effects of Initial Microstructure and Heat Treatment on the Residual Stress, Retained Austenite, and Distortion of Carburized Automotive Steels. SAE Technol. Pap. 2007, 1, 31–39. [Google Scholar]

- Klein, D.; Seifert, M.; Thoben, K.D. Taking the Distortion of Component Parts along a Manufacturing Chain into Consideration during Planning. Mater. Sci. Eng. Technol. 2009, 40, 349–353. [Google Scholar] [CrossRef]

- Zoch, H.W. Distortion Engineering: Vision or Ready to Application? Mater. Sci. Eng. Technol. 2009, 40, 342–348. [Google Scholar] [CrossRef]

- Pizetta Zordão, L.H.; Oliveira, V.A.; Totten, G.E.; Canale, L.C.F. Quenching Power of Aqueous Salt Solution. Int. J. Heat Mass Transf. 2019, 140, 807–818. [Google Scholar] [CrossRef]

- Lopez-Garcia, R.D.; Medina-Juárez, I.; Maldonado-Reyes, A. Effect of Quenching Parameters on Distortion Phenomena in AISI 4340 Steel. Metals 2022, 12, 759. [Google Scholar] [CrossRef]

- Kobasko, N.I.; Marques, A.; Canale, L.C.F.; Totten, G.E.; Dobryvechir, V.V. Cooling Capacity of Petroleum Oil Quenchants as a Function of Bath Temperature. Mater. Perform. Charact. 2013, 2, 468–488. [Google Scholar] [CrossRef]

- Buczek, A.; Telejko, T. Investigation of heat transfer coefficient during quenching in various cooling agents. Int. J. Heat Fluid Flow. 2013, 44, 358–364. [Google Scholar] [CrossRef]

- Taraba, B.; Duehring, S.; Španielka, J.; Hajdu, Š. Effect of Agitation Work on Heat Transfer during Cooling in Oil ISORAPID 277HM. Stroj. Vestn. J. Mech. Eng. 2012, 58, 102–106. [Google Scholar] [CrossRef]

- Sedighi, M.; McMahon, C.A. The Influence of Quenchant Agitation on the Heat Transfer Coefficient and Residual Stress Development in the Quenching of Steels. Proc. IMechE Part B J. Eng. Manuf. 2000, 214, 555–567. [Google Scholar] [CrossRef]

- Li, Z.; Grandhi, R.V.; Shivpuri, R. Optimum Design of the Heat-Transfer Coefficient during Gas Quenching Using the Response Surface Method. Int. J. Mach. Tools Manuf. 2002, 42, 549–558. [Google Scholar] [CrossRef]

- Sugianto, A.; Narazaki, M.; Kogawara, M.; Shirayori, A. Validity of Heat Transfer Coefficient Based on Cooling Time, Cooling Rate, and Heat Flux on Jominy End Quench Test. In Proceedings of the MS&T 2007, Materials Science and Technology, Detroit, MI, USA, 16–20 September 2007; pp. 171–180. [Google Scholar]

- Jung, M.; Kang, M.; Lee, Y.-K. Finite-element simulation of quenching incorporating improved transformation kinetics in a plain medium-carbon steel. Acta Mater. 2012, 60, 525–536. [Google Scholar] [CrossRef]

- Lopez-Garcia, R.D.; Garcia-Pastor, F.A.; Castro-Roman, M.J.; Alfaro-Lopez, E.; Acosta-Gonzalez, F.A. Effect of Immersion Routes on the Quenching Distortion of a Long Steel Component Using a Finite Element Model. Trans. Indian Inst. Met. 2016, 69, 1645–1656. [Google Scholar] [CrossRef]

- Şimşir, C.; Gür, C.H. 3D FEM simulation of steel quenching and investigation of the effect of asymmetric geometry on residual stress distribution. J. Mater. Process. Technol. 2008, 207, 211–221. [Google Scholar] [CrossRef]

- Wang, R.; Jiang, H.; Shao, W.; Yang, S.; Sun, X.; Cao, J.; Zhen, L. Quenching Induced Residue Stress in M50 Steel Ring: A FEM Simulation. J. Mater. Res. Technol. 2023, 24, 5298–5308. [Google Scholar] [CrossRef]

- Cho, J.R.; Kang, W.J.; Kim, M.G.; Lee, J.H.; Lee, Y.S.; Bae, W.B. Distortions Induced by Heat Treatment of Automotive Bevel Gears. J. Mater. Process. Technol. 2004, 153–154, 476–481. [Google Scholar] [CrossRef]

- Slovácek, M. Application of Numerical Simulation of Heat Treatment in Industry. J. Phys. IV Fr. 2004, 120, 753–760. [Google Scholar] [CrossRef]

- Yuce, B.E.; Nielsen, P.V.; Wargocki, P. The Use of Taguchi, ANOVA, and GRA Methods to Optimize CFD Analyses of Ventilation Performance in Buildings. Build. Environ. 2022, 225, 109587. [Google Scholar] [CrossRef]

- Madani, T.; Boukraa, M.; Aissani, M.; Chekifi, T.; Ziadi, A.; Zirari, M. Experimental Investigation and Numerical Analysis using Taguchi and ANOVA Methods for Underwater Friction Stir Welding of Aluminium Alloy 2017 Process Improvement. Int. J. Press. Vessel. Pip. 2023, 201, 104879. [Google Scholar] [CrossRef]

- Agboola, O.O.; Ikubanni, P.P.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S.; Aliyu, S.J.; Olabamiji, T.S. Optimization of Heat Treatment Parameters of Medium Carbon Steel Quenched in Different Media Using Taguchi Method and Grey Relational Analysis. Heliyon 2020, 6, e04444. [Google Scholar] [CrossRef] [PubMed]

- Nunes, M.M.; Da Silva, E.M.; Renzetti, R.A.; Brito, T.G. Analysis of Quenching Parameters in AISI 4340 Steel by Using Design of Experiments. Mater. Res. 2018, 22. [Google Scholar] [CrossRef]

- The Japan Society of Mechanical Engineers. JSME Data Book: Heat Transfer, 4th ed.; The Japan Society of Mechanical Engineers, Maruzen: Tokyo, Japan, 1986. [Google Scholar]

- Understanding Analysis of Means, Minitab 21 Support. Available online: https://support.minitab.com/en-us/minitab/21/help-and-how-to/statistical-modeling/anova/supporting-topics/basics/understanding-analysis-of-means (accessed on 2 July 2021).

| Sample | Agitation (L/min) | Austenitizing Temp. (°C) | Soaking Time (min) | Oil Temp. (°C) | Immersion Rate (mm/s) | Immersion Direction |

|---|---|---|---|---|---|---|

| A | 100 | 860 | 30 | 60 | 53 | -Y |

| B | 0 | 860 | 30 | 60 | 53 | -Y |

| C | 100 | 860 | 30 | 27 | 53 | -Y |

| D | 0 | 860 | 30 | 27 | 53 | -Y |

| Simulation Parameters | Value(s) |

|---|---|

| Number of simulation steps | 400 |

| Number of elements | 30,000 |

| Number of nodes | 43,500 |

| Initial temperature of the nodes (°C) | 860 |

| Environment temperature (°C) | 27 |

| Quenching oil temperature (°C) | 27 and 60 |

| Iteration method | Newton–Raphson |

| Heat transfer coefficient (kW/m2K) | Temperature dependent, see Figure 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puga-Patlán, C.; Lopez-Garcia, R.D.; Medina-Juárez, I.; Maldonado-Reyes, A.; Reyes-Gallegos, M.M. Study of Cooling Medium Variables during Quenching in SAE 4340 Steel Using Statistical and Modeling Tools. Metals 2023, 13, 1627. https://doi.org/10.3390/met13091627

Puga-Patlán C, Lopez-Garcia RD, Medina-Juárez I, Maldonado-Reyes A, Reyes-Gallegos MM. Study of Cooling Medium Variables during Quenching in SAE 4340 Steel Using Statistical and Modeling Tools. Metals. 2023; 13(9):1627. https://doi.org/10.3390/met13091627

Chicago/Turabian StylePuga-Patlán, Carlos, Ricardo Daniel Lopez-Garcia, Israel Medina-Juárez, Araceli Maldonado-Reyes, and María Magdalena Reyes-Gallegos. 2023. "Study of Cooling Medium Variables during Quenching in SAE 4340 Steel Using Statistical and Modeling Tools" Metals 13, no. 9: 1627. https://doi.org/10.3390/met13091627