Intergranular Corrosion Analysis of Austenitic Stainless Steels in Molten Nitrate Salt Using Electrochemical Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Microstructure Analysis

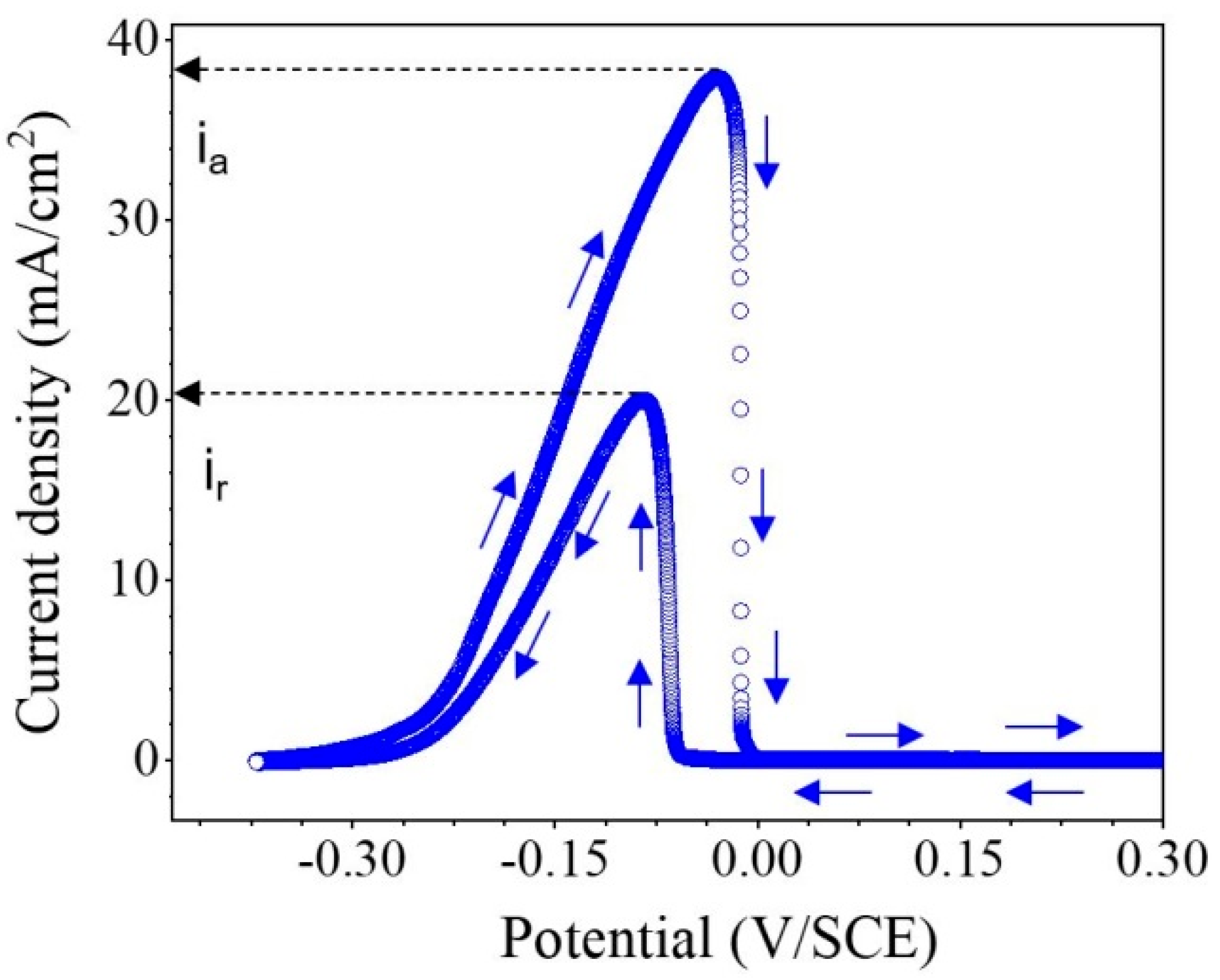

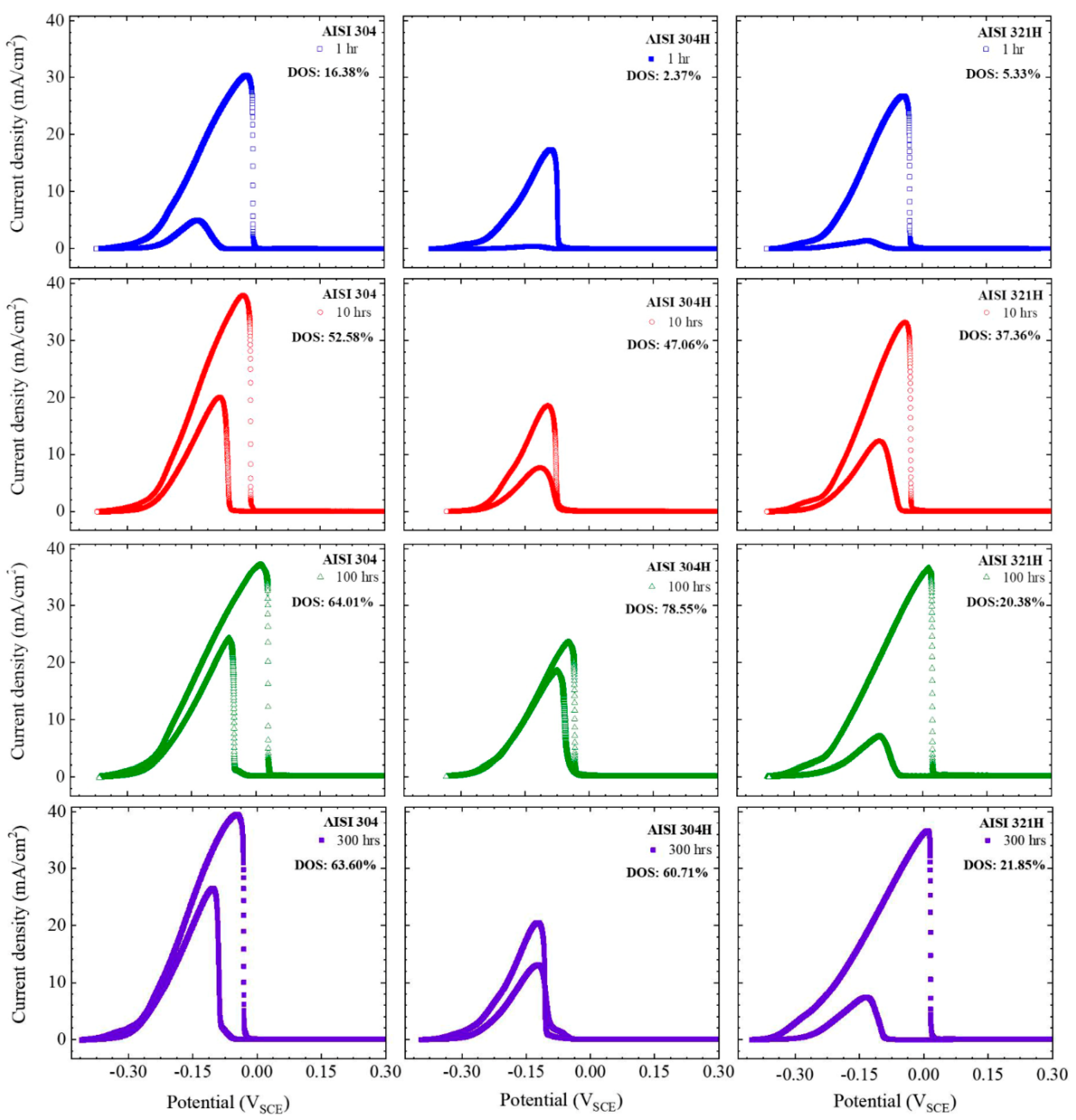

2.2. DL-EPR Measurement

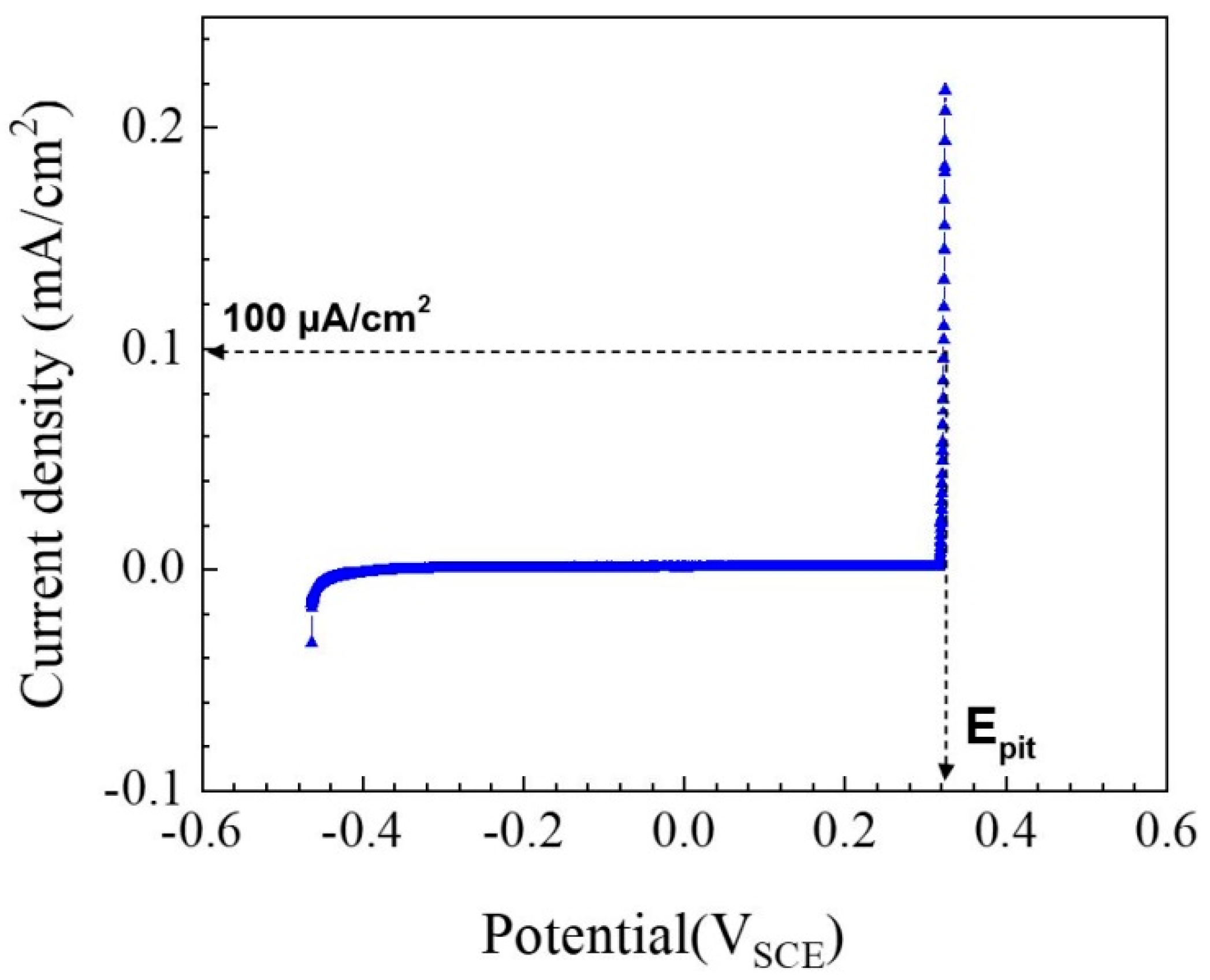

2.3. Pitting Potential Measurement

3. Results and Discussion

3.1. Microstructure Analysis

3.1.1. Chromium Carbide Formation

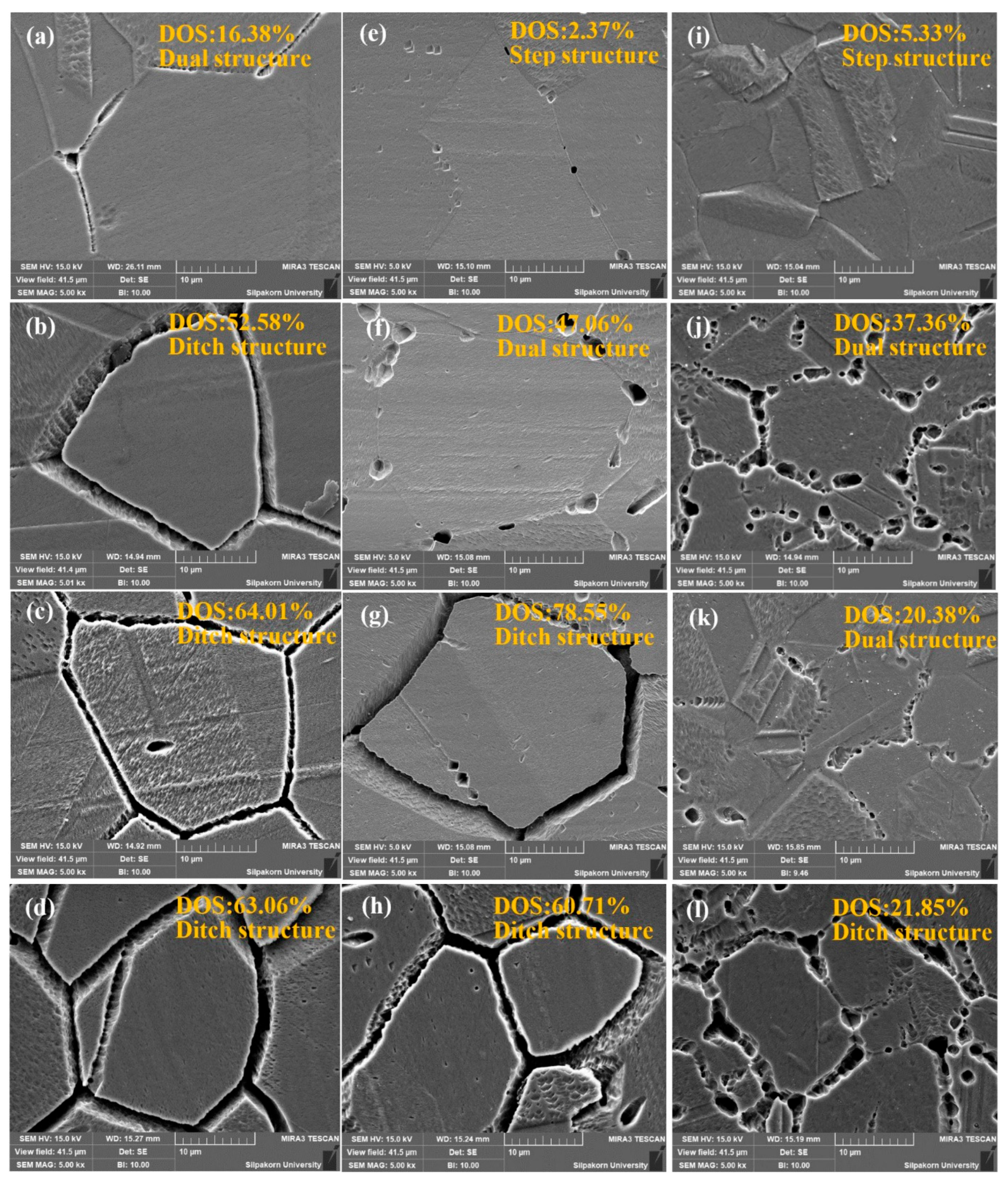

3.1.2. IGC Susceptibility Assessed by Microstructural Analysis

3.2. DL-EPR Measurement

3.3. Pitting Potential Measurement

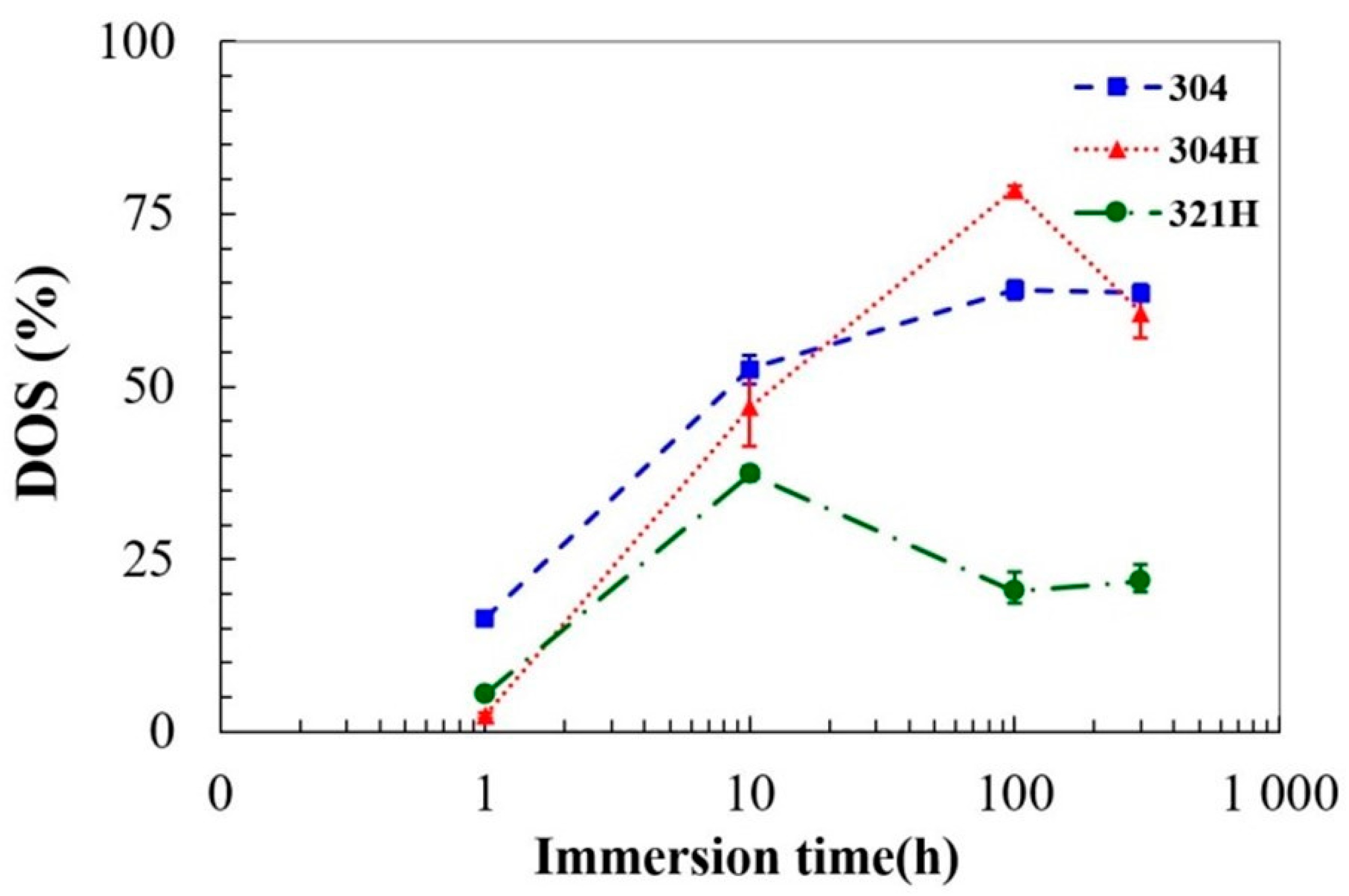

3.4. The Healing Effect after Exposure to Molten Nitrate Salt

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Belgasima, B.; Aldali, Y.; Abdunnabi, M.J.R.; Hashem, G.; Hossin, K. The potential of concentrating solar power (CSP) for electricity generation in Libya. Renew. Sustain. Energy Rev. 2018, 90, 1–15. [Google Scholar] [CrossRef]

- Ummadisingu, A.; Soni, M.S. Concentrating solar power–technology, potential and policy in India. Renew. Sustain. Energy Rev. 2011, 15, 5169–5175. [Google Scholar] [CrossRef]

- Baharoon, D.A.; Rahman, H.A.; Omar, W.Z.W.; Fadhl, S.O. Historical development of concentrating solar power technologies to generate clean electricity efficiently–A review. Renew. Sustain. Energy Rev. 2015, 41, 996–1027. [Google Scholar] [CrossRef]

- Ziuku, S.; Seyitini, L.; Mapurisa, B.; Chikodzi, D.; van Kuijk, K. Potential of concentrated solar power (CSP) in Zimbabwe. Energy Sustain. Dev. 2014, 23, 220–227. [Google Scholar] [CrossRef]

- Lovegrove, K.; Stein, W. Concentrating Solar Power Technology: Principles, Developments and Applications; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Modi, A.; Bühler, F.; Andreasen, J.G.; Haglind, F. A review of solar energy based heat and power generation systems. Renew. Sustain. Energy Rev. 2017, 67, 1047–1064. [Google Scholar] [CrossRef]

- Khorsand, S.; Sheikhi, A.; Raeissi, K.; Golozar, M.A. Hot corrosion behavior of Inconel 625 superalloy in eutectic molten nitrate salts. Oxid Met. 2018, 90, 169–186. [Google Scholar] [CrossRef]

- Dorcheh, A.S.; Durham, R.N.; Galetz, M.C. Corrosion behavior of stainless and low-chromium steels and IN625 in molten nitrate salts at 600 °C. Sol. Energy Mater. Sol. Cells 2016, 144, 109–116. [Google Scholar] [CrossRef]

- Maziasz, P.J. Developing an austenitic stainless steel for improved performance in advanced fossil power facilities. JOM 1989, 41, 14–20. [Google Scholar] [CrossRef]

- Tanaka, H.; Murata, M.; Abe, F.; Irie, H. Microstructural evolution and change in hardness in type 304H stainless steel during long-term creep. Mater. Sci. Eng. A 2001, 319, 788–791. [Google Scholar] [CrossRef]

- Wang, W.; Guan, B.; Li, X.; Lu, J.; Ding, J. Corrosion behavior and mechanism of austenitic stainless steels in a new quaternary molten salt for concentrating solar power. Sol. Energy Mater. Sol. Cells 2019, 194, 36–46. [Google Scholar] [CrossRef]

- Encinas-Sánchez, V.; Lasanta, M.I.; De Miguel, M.T.; García-Martín, G.; Pérez, F.J. Corrosion monitoring of 321H in contact with a quaternary molten salt for parabolic trough CSP plants. Corros. Sci. 2021, 178, 109070. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.; Wu, Y.; Lu, Y. Experimental research of high temperature dynamic corrosion characteristic of stainless steels in nitrate eutectic molten salt. Sol. Energy 2020, 209, 618–627. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Yin, X.; Yang, X.; Tang, J.; Gong, J. Corrosion and electrochemical investigations for stainless steels in molten Solar Salt: The influence of chloride impurity. J. Energy Storage 2021, 39, 102675. [Google Scholar] [CrossRef]

- Federsel, K.; Wortmann, J.; Ladenberger, M. High-temperature and Corrosion Behavior of Nitrate Nitrite Molten Salt Mixtures Regarding their Application in Concentrating Solar Power Plants. Energy Procedia 2015, 69, 618–625. [Google Scholar] [CrossRef]

- Ren, S.; Chen, Y.; Ye, X.X.; Jiang, L.; Yan, S.; Liang, J.; Yang, X.; Leng, B.; Li, Z.; Chen, Z.; et al. Corrosion behavior of carburized 316 stainless steel in molten chloride salts. Sol. Energy 2021, 223, 1–10. [Google Scholar] [CrossRef]

- Wilson, F.G. Mechanism of intergranular corrosion of austenitic stainless steels—Literature review. Br. Corros. J. 1971, 6, 100–108. [Google Scholar] [CrossRef]

- Aydoğdu, G.H.; Aydinol, M.K. Determination of susceptibility to intergranular corrosion and electrochemical reactivation behaviour of AISI 316L type stainless steel. Corros. Sci. 2006, 48, 3565–3583. [Google Scholar] [CrossRef]

- Liu, Q.; Qian, J.; Barker, R.; Wang, C.; Neville, A.; Pessu, F. Application of double loop electrochemical potentio-kinetic reactivation for characterizing the intergranular corrosion susceptibility of stainless steels and Ni-based alloys in solar nitrate salts used in CSP systems. Eng. Fail. Anal. 2021, 129, 105717. [Google Scholar] [CrossRef]

- ASTM E407-07; Standard Practices for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM A262-15; Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 12732:2006(E); Corrosion of Metals and Alloys—Electrochemical Potentiokinetic Reactivation Measurement Using the Double Loop Method (Based on Čihal’s Method). International Organization for Standardization: Geneva, Switzerland, 2006.

- Kannan, P.R.; Muthupandi, V.; Devakumaran, K.; Sridivya, C.; Arthi, E. Effect of grain size on self-healing behaviour of sensitized S304HCu stainless steel. Mater. Chem. Phys. 2018, 207, 203–211. [Google Scholar] [CrossRef]

- Kauss, N.; Heyn, A.; Halle, T.; Rosemann, P. Detection of sensitisation on aged lean duplex stainless steel with different electrochemical methods. Electrochim. Acta 2019, 317, 17–24. [Google Scholar] [CrossRef]

- Lopez, N.; Cid, M.; Puiggali, M.; Azkarate, I.; Pelayo, A. Application of double loop electrochemical potentiodynamic reactivation test to austenitic and duplex stainless steels. Mater. Sci. Eng. A 1997, 229, 123–128. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Carboneras, M.; Coy, A.E.; Arrabal, R. Pitting corrosion behaviour of austenitic stainless steels with Cu and Sn additions. Corros. Sci. 2007, 49, 510–525. [Google Scholar] [CrossRef]

- Parvathavarthini, N.; Mulki, S.; Dayal, R.K.; Samajdar, I.; Mani, K.V.; Raj, B. Sensitization control in AISI 316L (N) austenitic stainless steel: Defining the role of the nature of grain boundary. Corros. Sci. 2009, 51, 2144–2150. [Google Scholar] [CrossRef]

- García-Junceda, A.; Capdevila, C.; Caballero, F.G.; De Andrés, C.G. Dependence of martensite start temperature on fine austenite grain size. Scr. Mater. 2008, 58, 134–137. [Google Scholar] [CrossRef]

- Yang, H.S.; Bhadeshia, H.K.D.H. Austenite grain size and the martensite-start temperature. Scr. Mater. 2009, 60, 493–495. [Google Scholar] [CrossRef]

- Takaya, S.; Suzuki, T.; Matsumoto, Y.; Demachi, K.; Uesaka, M. Estimation of stress corrosion cracking sensitivity of type 304 stainless steel by magnetic force microscope. J. Nucl. Mater. 2004, 327, 19–26. [Google Scholar] [CrossRef]

- Lima, A.S.; Nascimento, A.M.D.; Abreu, H.F.G.D.; de Lima-Neto, P. Sensitization evaluation of the austenitic stainless steel AISI 304L, 316L, 321 and 347. J. Mater. Sci. 2005, 40, 139–144. [Google Scholar] [CrossRef]

- Gajjar, P.K.; Khatri, B.C.; Siddhpura, A.M.; Siddhpura, M.A. Sensitization and Desensitization (Healing) in Austenitic Stainless Steel: A Critical Review. Trans. Indian Inst. Met. 2022, 75, 1411–1427. [Google Scholar] [CrossRef]

- Tokunaga, T.; Ohtani, H.; Ågren, J. Evaluation of sensitization and self-healing in austenitic stainless steels based on simulations of Cr-depleted zones. ISIJ Int. 2011, 51, 965–968. [Google Scholar] [CrossRef]

- Wang, R.; Zheng, Z.; Zhou, Q.; Gao, Y. Effect of surface nanocrystallization on the sensitization and desensitization behavior of Super304H stainless steel. Corros. Sci. 2016, 111, 728–741. [Google Scholar] [CrossRef]

- Kolli, S.; Ohligschläger, T.; Kömi, J.; Porter, D. Sensitization and self-healing in austenitic stainless steel: Quantitative prediction considering carbide nucleation and growth. ISIJ Int. 2019, 59, 2090–2097. [Google Scholar] [CrossRef]

- Taji, I.; Moayed, M.H.; Mirjalili, M. Correlation between sensitisation and pitting corrosion of AISI 403 martensitic stainless steel. Corros. Sci. 2015, 92, 301–308. [Google Scholar] [CrossRef]

- Calderón-Hernández, J.W.; Hincapie-Ladino, D.; Filho, E.B.M.; Magnabosco, R.; Alonso-Falleiros, N. Relation between pitting potential, degree of sensitization, and reversed austenite in a supermartensitic stainless steel. Corrosion 2017, 73, 953–960. [Google Scholar] [CrossRef] [PubMed]

- Abou-Elazm, A.; Abdel-Karim, R.; Elmahallawi, I.; Rashad, R. Correlation between the degree of sensitization and stress corrosion cracking susceptibility of type 304H stainless steel. Corros. Sci. 2009, 51, 203–208. [Google Scholar] [CrossRef]

- Thorvaldsson, T.; Dunlop, G.L. Effect of stabilizing additions on precipitation reactions in austenitic stainless steel. Met. Sci. 1982, 16, 184–190. [Google Scholar] [CrossRef]

| Materials | Ni | C | Mo | Mn | P | S | Si | Cr | Ti | N | Cu | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 304 | 8.262 | 0.047 | 0.049 | 1.026 | 0.025 | <0.001 | 0.406 | 18.4 | <0.001 | 0.044 | 0.04 | 0.007 | Bal. |

| AISI 304H | 8.065 | 0.046 | 0.298 | 1.474 | 0.06 | 0.002 | 0.44 | 18.41 | <0.001 | 0.046 | 0.498 | 0.015 | Bal. |

| AISI 321H | 9.159 | 0.055 | 0.200 | 1.527 | 0.025 | 0.004 | 0.55 | 17.28 | 0.391 | 0.043 | 0.332 | 0.014 | Bal. |

| Materials | Immersion Time (h) | Ia (mA/cm2) | Ir (mA/cm2) | DOS (%) |

|---|---|---|---|---|

| AISI 304 | 1 | 31.26 ± 1.33 | 5.12 ± 0.21 | 16.38 ± 0.01 |

| 10 | 38.99 ± 2.17 | 20.50 ± 1.89 | 52.58 ± 2.08 | |

| 100 | 36.84 ± 0.48 | 23.58 ± 0.36 | 64.01 ± 1.80 | |

| 300 | 39.96 ± 0.33 | 25.42 ± 0.21 | 63.60 ± 0.01 | |

| AISI 304H | 1 | 17.66 ± 0.26 | 0.42 ± 0.06 | 2.37 ± 0.31 |

| 10 | 18.63 ± 0.68 | 8.79 ± 1.33 | 47.06 ± 6.05 | |

| 100 | 16.54 ± 0.45 | 12.99 ± 0.26 | 78.55 ± 0.59 | |

| 300 | 23.82 ± 0.45 | 14.46 ± 1.06 | 60.71 ± 3.47 | |

| AISI 321H | 1 | 26.68 ± 0.40 | 1.70 ± 0.51 | 6.37 ± 1.80 |

| 10 | 33.46 ± 0.46 | 12.50 ± 0.25 | 37.36 ± 1.12 | |

| 100 | 36.62 ± 0.19 | 7.46 ± 0.91 | 20.38 ± 2.49 | |

| 300 | 36.62 ± 0.20 | 8.00 ± 0.73 | 21.85 ± 2.07 |

| Materials | Pitting Potential (mV/SCE) | |||

|---|---|---|---|---|

| Sensitization Time in Molten Salt at 600 °C (h) | ||||

| 1 | 10 | 100 | 300 | |

| AISI 304 | 421.95 | 332.64 | 302.70 | 303.16 |

| AISI 304H | 435.32 | 357.44 | 308.78 | 337.50 |

| AISI 321H | 411.35 | 331.09 | 388.76 | 363.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kanjanaprayut, N.; Siripongsakul, T.; Promdirek, P. Intergranular Corrosion Analysis of Austenitic Stainless Steels in Molten Nitrate Salt Using Electrochemical Characterization. Metals 2024, 14, 106. https://doi.org/10.3390/met14010106

Kanjanaprayut N, Siripongsakul T, Promdirek P. Intergranular Corrosion Analysis of Austenitic Stainless Steels in Molten Nitrate Salt Using Electrochemical Characterization. Metals. 2024; 14(1):106. https://doi.org/10.3390/met14010106

Chicago/Turabian StyleKanjanaprayut, Noparat, Thamrongsin Siripongsakul, and Piyorose Promdirek. 2024. "Intergranular Corrosion Analysis of Austenitic Stainless Steels in Molten Nitrate Salt Using Electrochemical Characterization" Metals 14, no. 1: 106. https://doi.org/10.3390/met14010106

APA StyleKanjanaprayut, N., Siripongsakul, T., & Promdirek, P. (2024). Intergranular Corrosion Analysis of Austenitic Stainless Steels in Molten Nitrate Salt Using Electrochemical Characterization. Metals, 14(1), 106. https://doi.org/10.3390/met14010106