Effect of Milling Strategy on the Surface Quality of AISI P20 Mold Steel

Abstract

1. Introduction

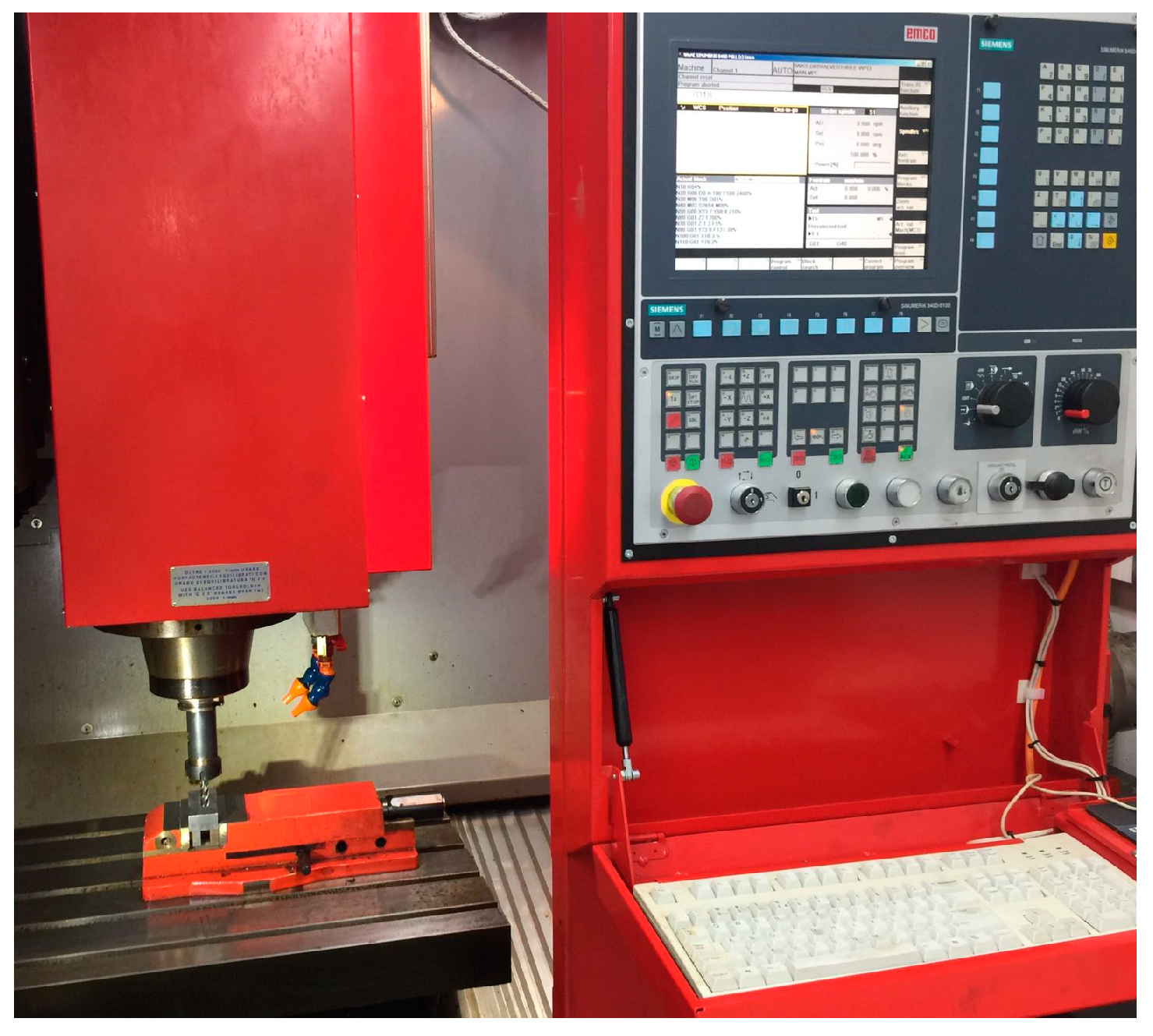

2. Materials and Methods

3. Results and Discussion

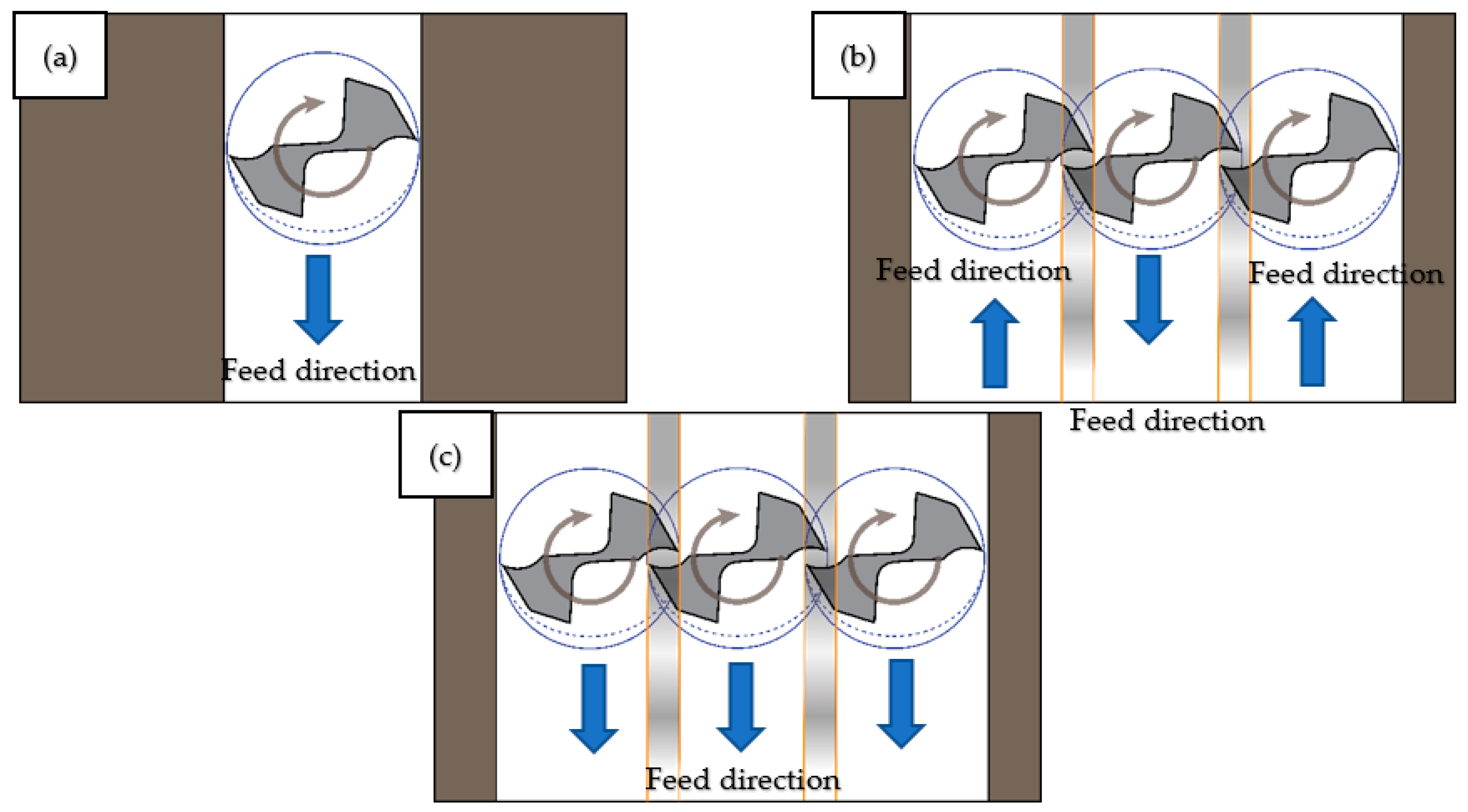

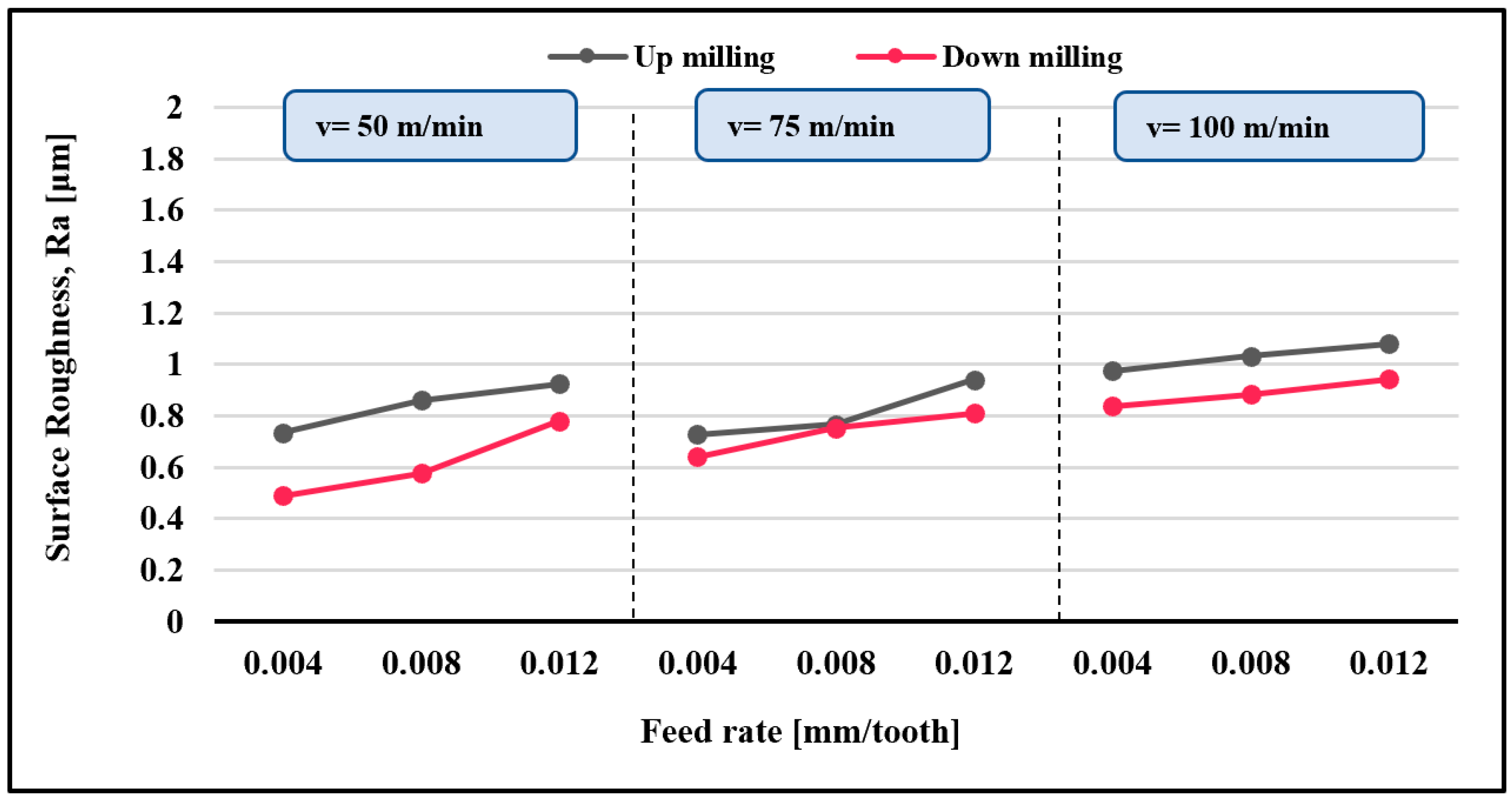

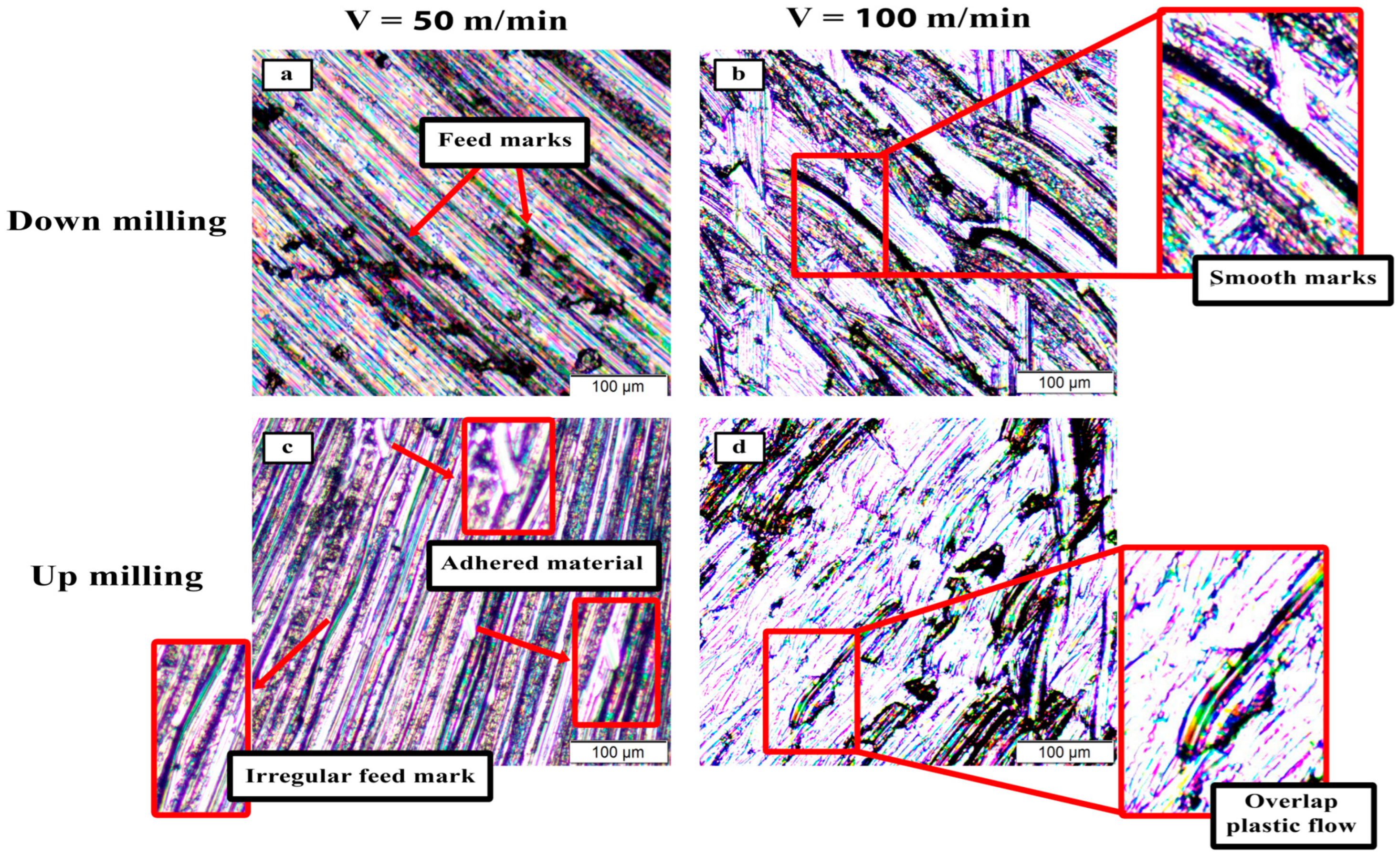

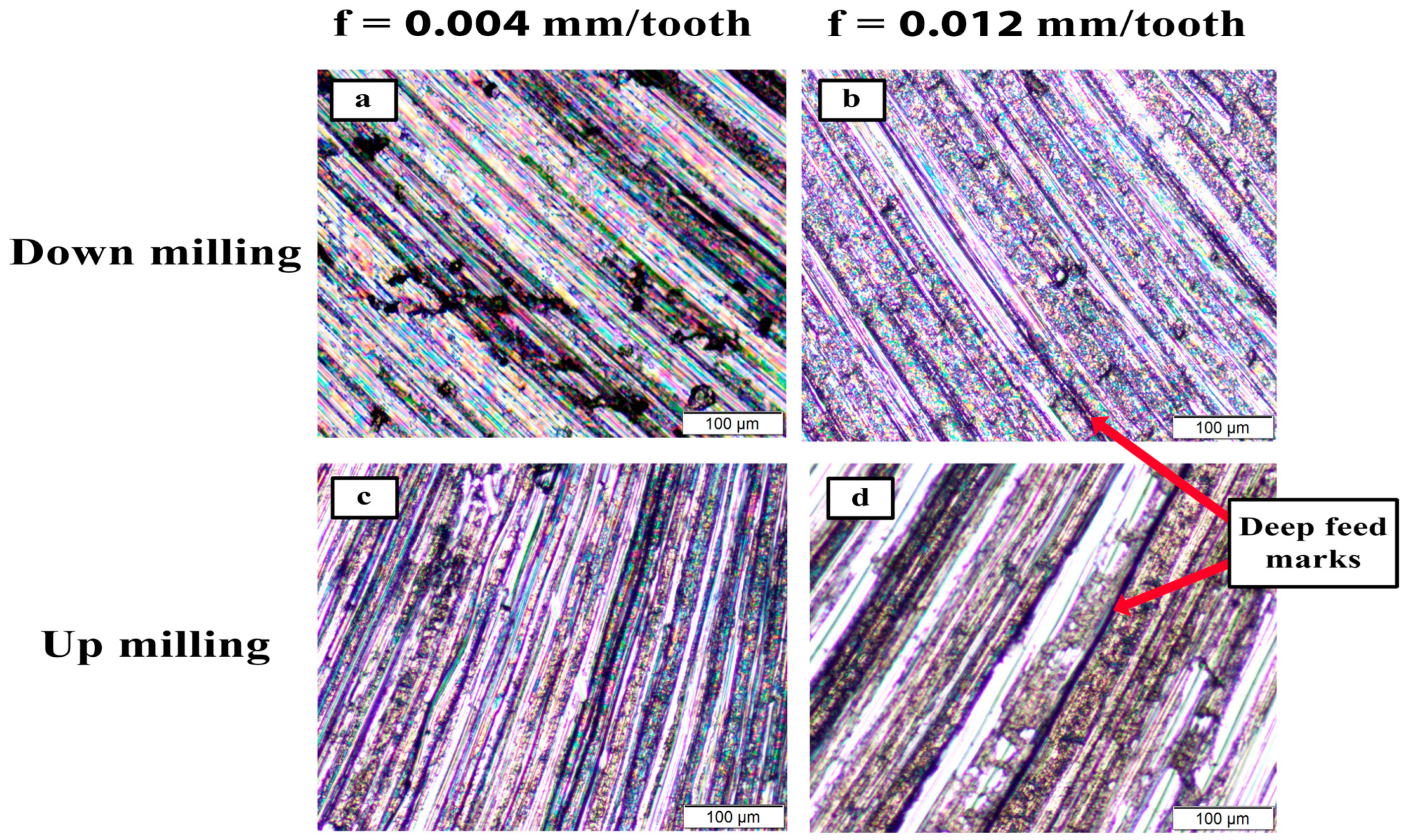

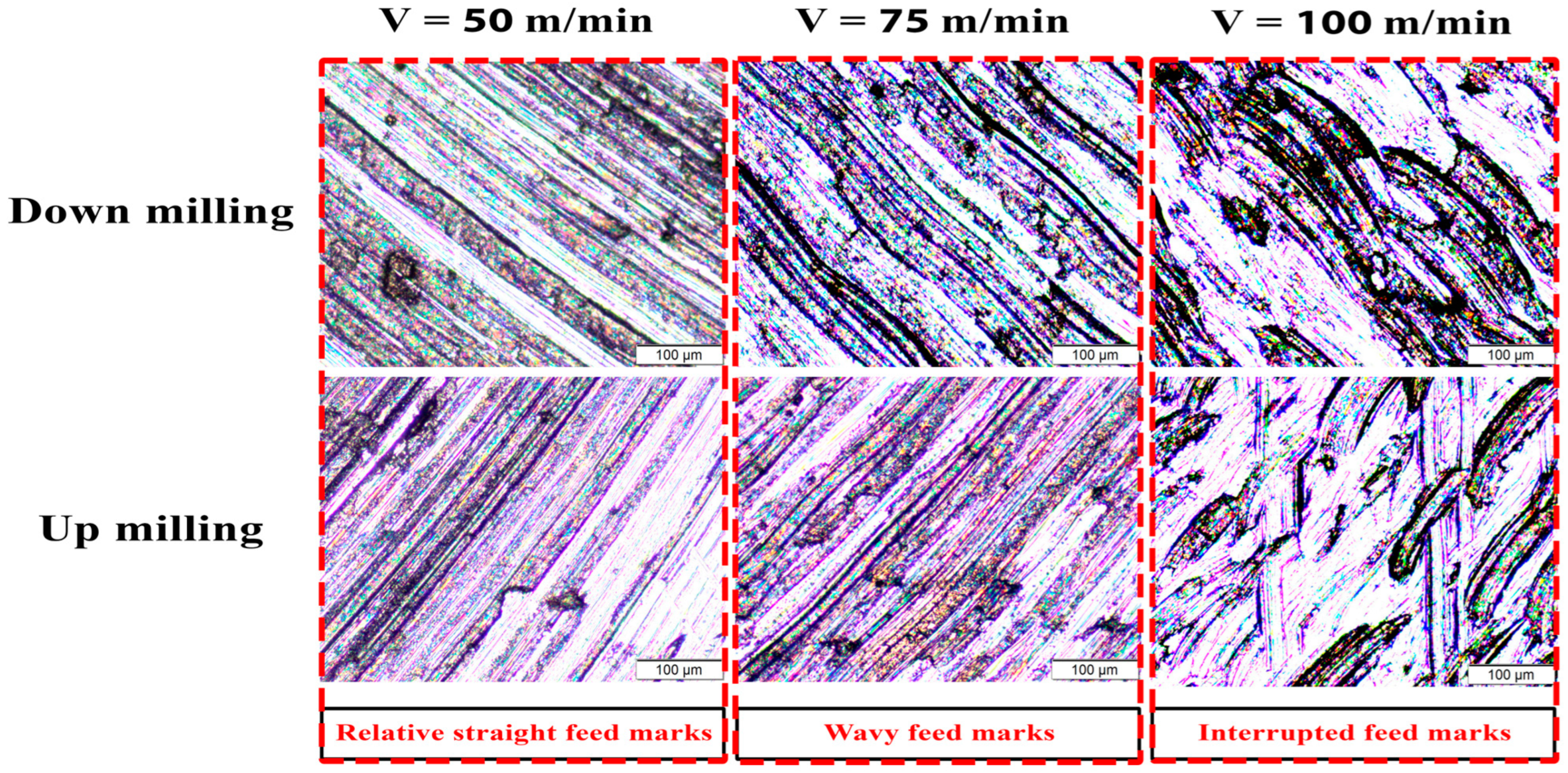

3.1. Effect of Single-Mode Milling Strategies on Surface Roughness

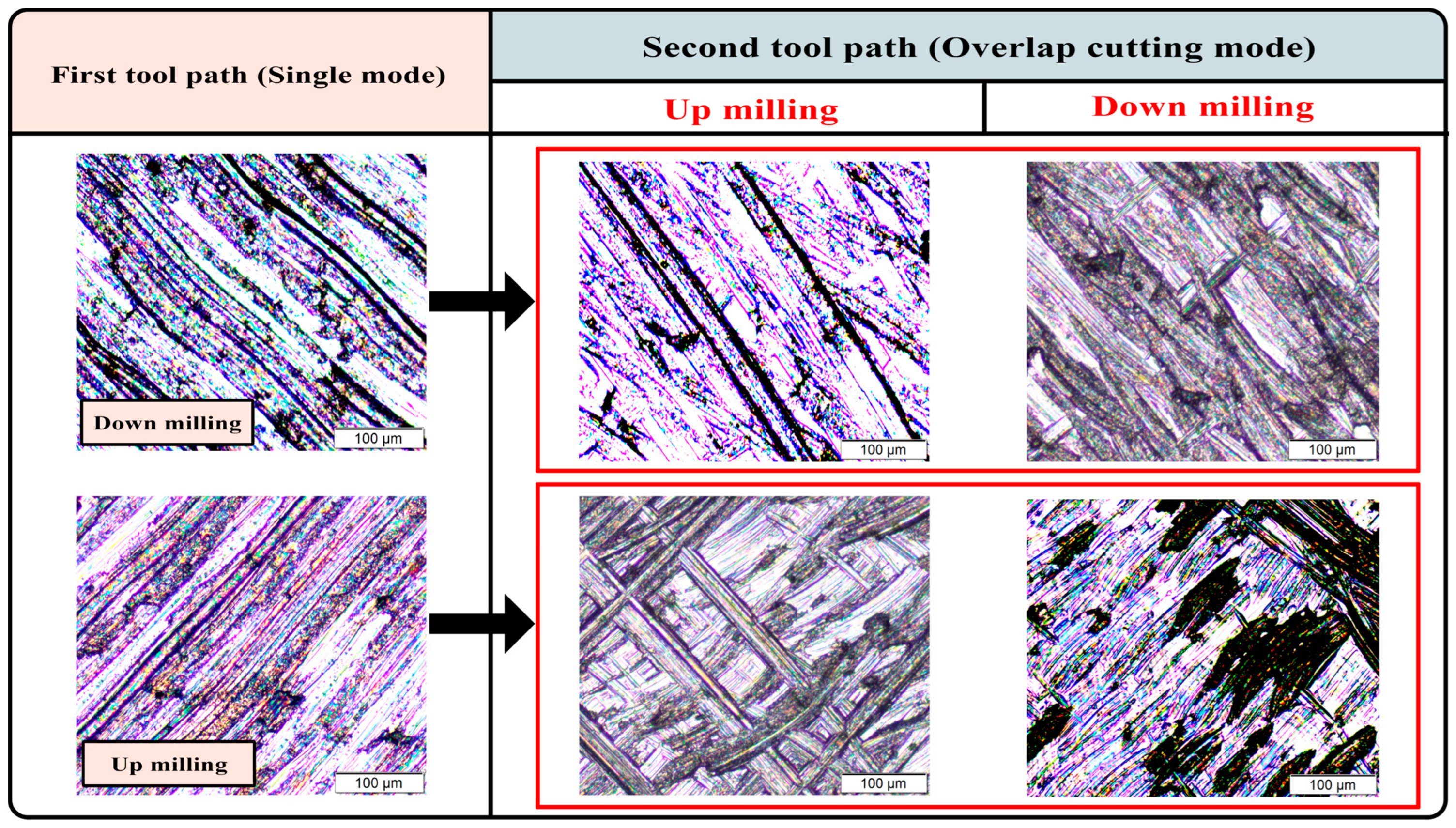

3.2. Effect of Overlap of Tool Paths with Different Strategies on Surface Roughness

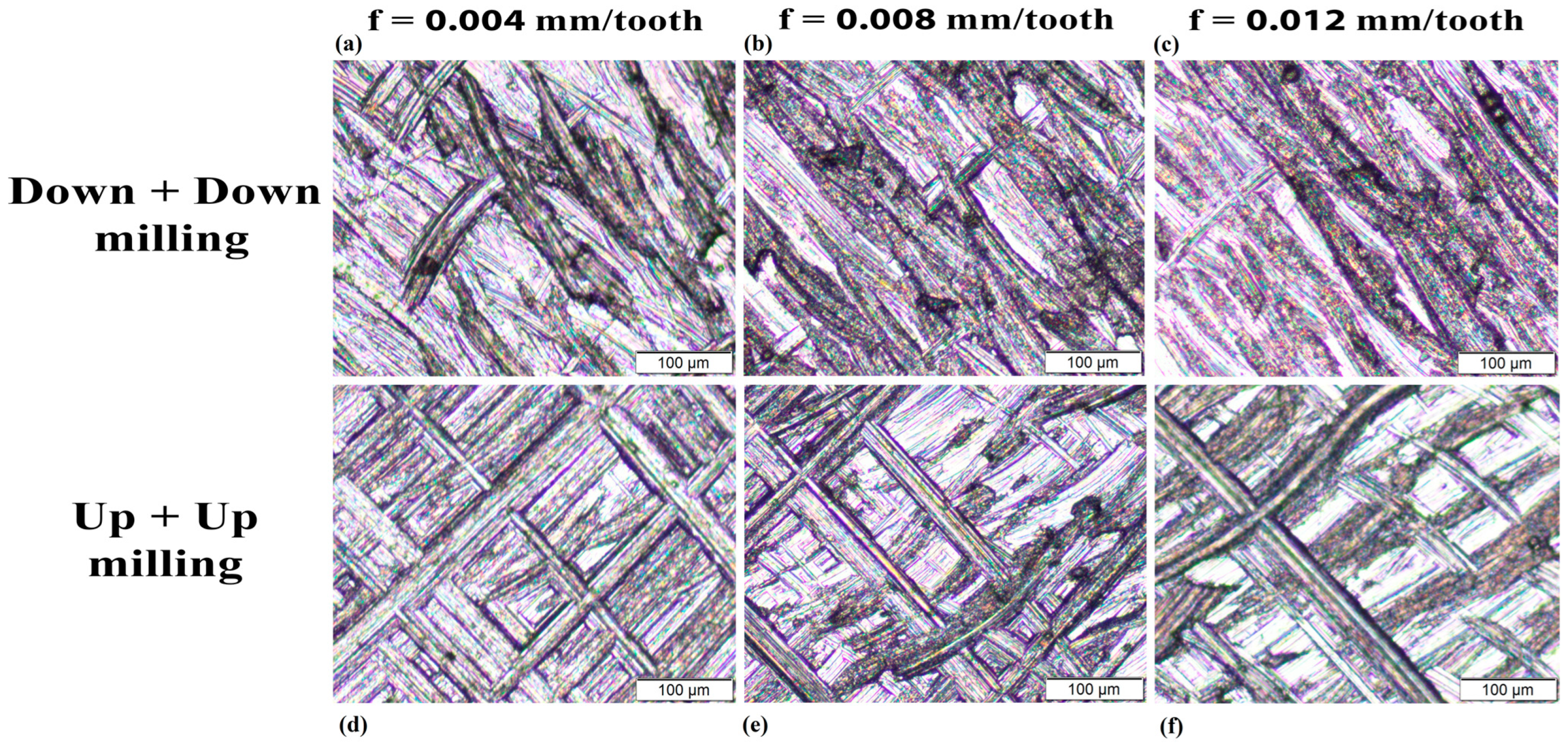

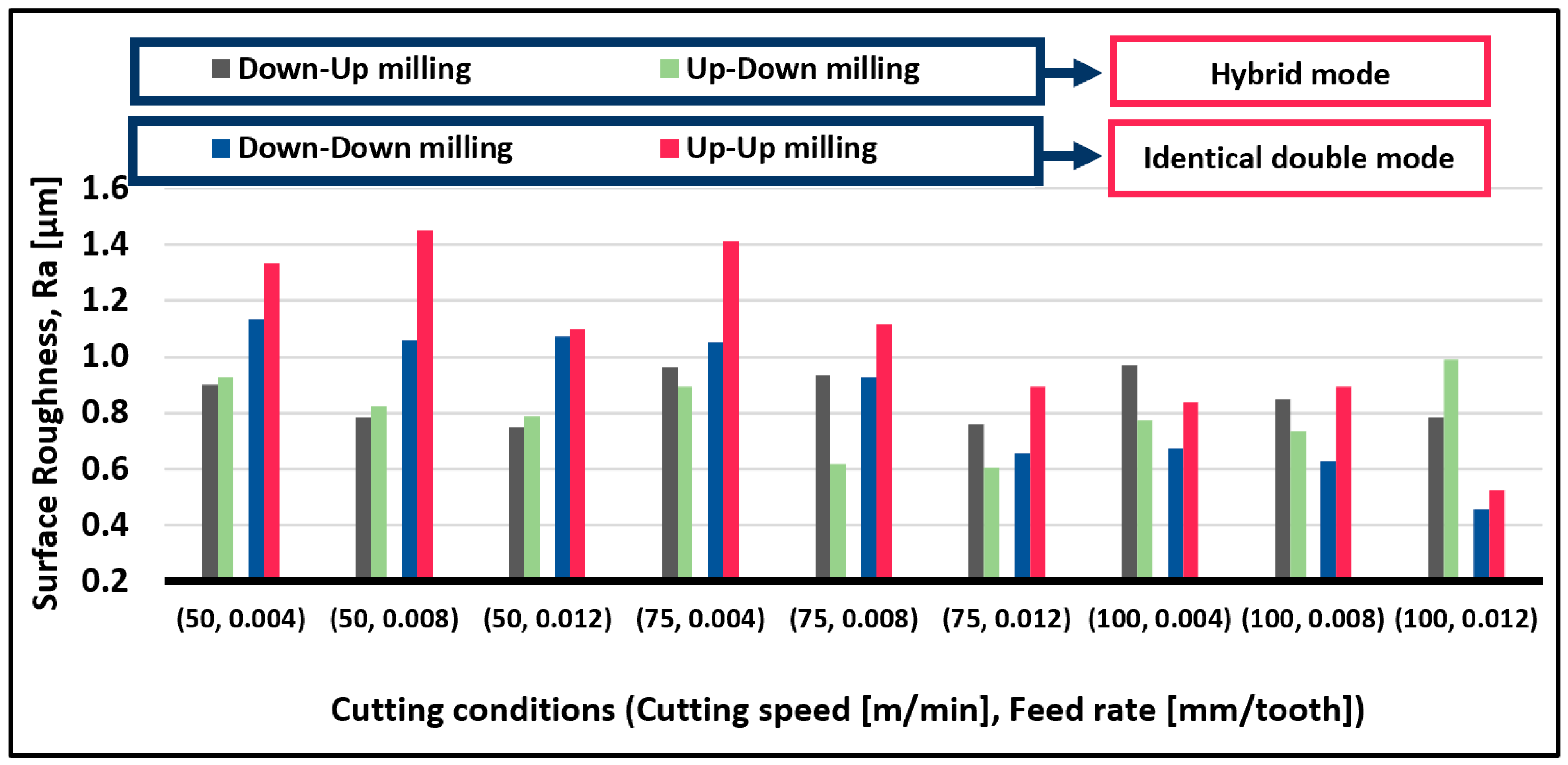

3.2.1. Effect of Identical Double-Mode Milling Strategies on Surface Roughness

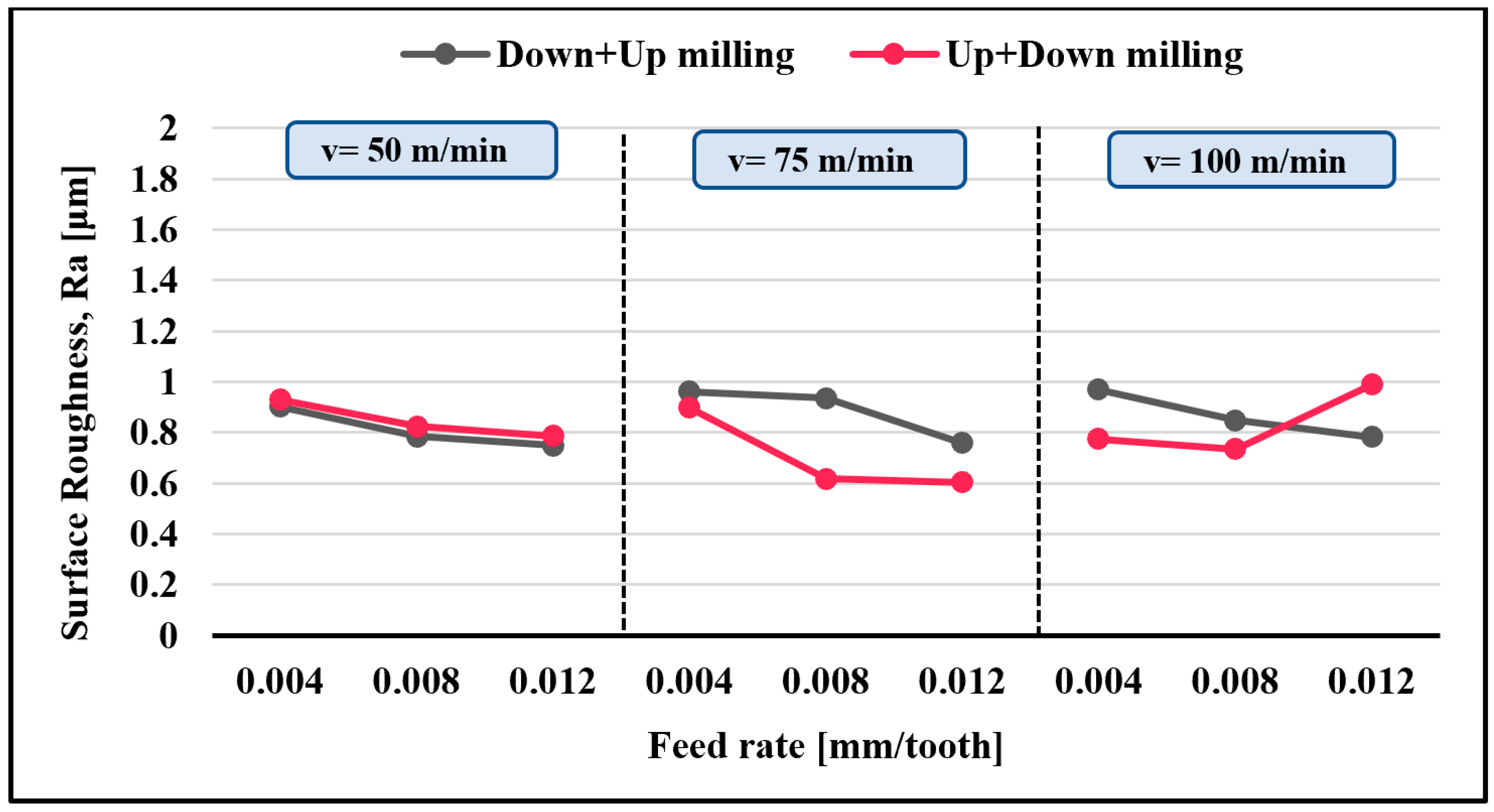

3.2.2. Effect of Hybrid-Mode Milling Strategies on Surface Roughness

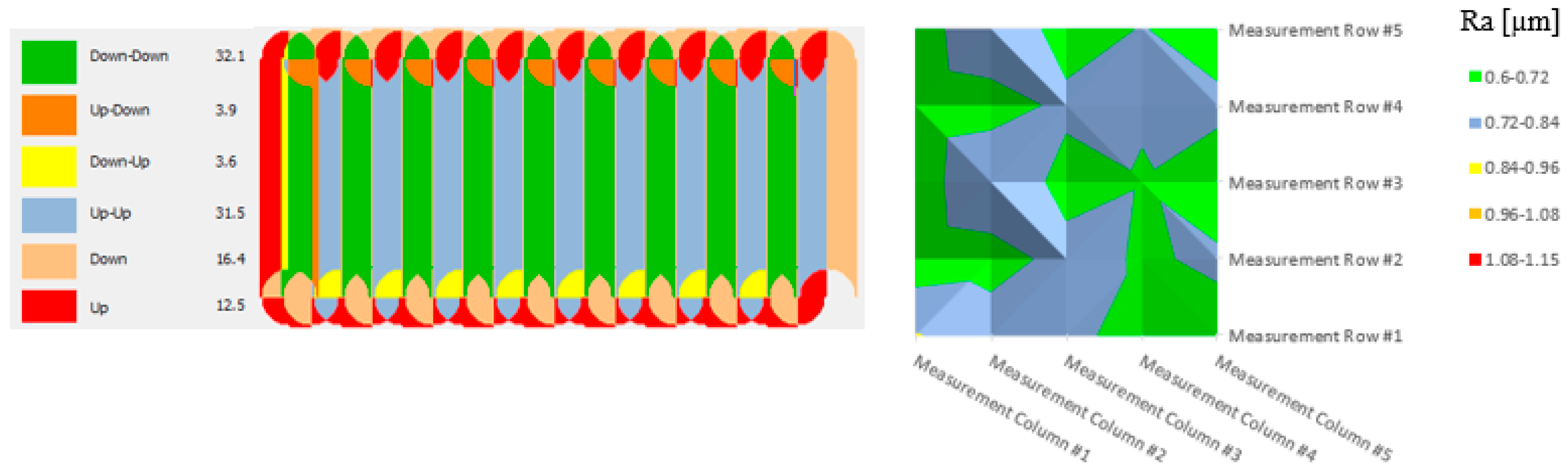

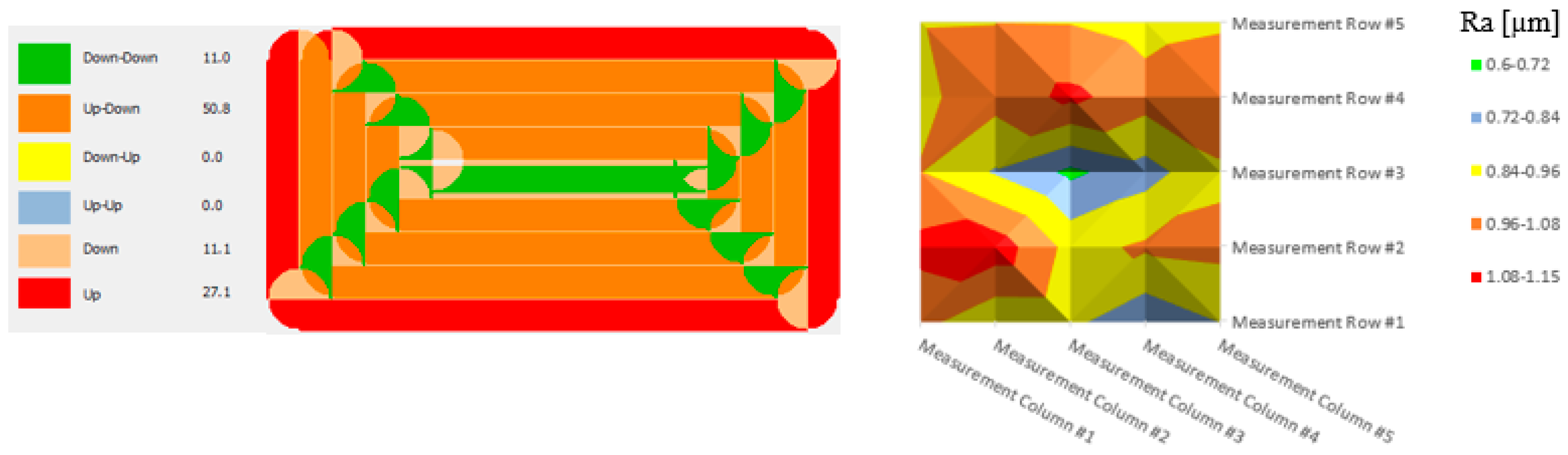

3.3. Validation Using Pocket Machining with Different Types of Toolpaths

4. Conclusions

- Our research reveals that up-milling tends to produce rougher surfaces compared to down-milling. We also found that the surface roughness generally increased with higher feed rates and cutting speeds for both up- and down-milling processes. Particularly, the double mode of the same milling direction (either up-up or down-down) showed a tendency towards rougher surfaces compared to their hybrid counterparts.

- Additionally, the study highlights that the texture of the surfaces varies significantly with the milling strategy employed. For instance, surfaces milled with consecutive up-milling showed more pronounced defects compared to those milled with consecutive down-milling.

- An interesting observation was that the differences in surface roughness between various strategies became more evident at higher cutting speeds. This indicates the influence of cutting dynamics on milling outcomes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, A.T.M.; Rahim, S.Z.A.; Al Bakri Abdullah, M.M.; Nabialek, M.; Abdellah, A.E.H.; Rennie, A.; Tahir, M.F.M.; Titu, A.M. Potential of New Sustainable Green Geopolymer Metal Composite (GGMC) Material as Mould Insert for Rapid Tooling (RT) in Injection Moulding Process. Materials 2023, 16, 1724. [Google Scholar] [CrossRef]

- De Lacalle, L.N.; Lamikiz, A.; Salgado, M.A.; Herranz, S.; Rivero, A. Process planning for reliable high-speed machining of moulds. Int. J. Prod. Res. 2010, 40, 2789–2809. [Google Scholar] [CrossRef]

- Guo, D.; Yu, D.; Zhang, P.; Song, W.; Zhang, B.; Peng, K. Laminar Plasma Jet Surface Hardening of P20 Mold Steel: Analysis on the Wear and Corrosion Behaviors. Surf. Coat. Technol. 2021, 415, 127129. [Google Scholar] [CrossRef]

- Lyu, W.; Liu, Z.; Song, Q.; Ren, X.; Wang, B.; Cai, Y. Modelling and prediction of surface topography on machined slot side wall with single-pass end milling. Int. J. Adv. Manuf. Technol. 2023, 124, 1095–1113. [Google Scholar] [CrossRef]

- Razali, S.Z.; Wong, S.V.; Ismail, N. Fuzzy logic modeling for peripheral end milling process. IOP Conf. Ser. Mater. Sci. Eng. 2011, 17, 012050. [Google Scholar] [CrossRef]

- Reddy, B.S.; Kumar, J.S.; Reddy, K.V.K. Optimization of surface roughness in CNC end milling using response surface methodology and genetic algorithm. Int. J. Eng. Sci. Technol. 2011, 3, 102–109. [Google Scholar] [CrossRef][Green Version]

- Lopes, J.G.; Machado, C.M.; Duarte, V.R.; Rodrigues, T.A.; Santos, T.G.; Oliveira, J.P. Effect of milling parameters on HSLA steel parts produced by Wire and Arc Additive Manufacturing (WAAM). J. Manuf. Process. 2020, 59, 739–749. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X. A comparative experimental study of unidirectional CFRP high-speed milling in up and down milling with varied angles. J. Manuf. Process. 2023, 101, 1147–1157. [Google Scholar] [CrossRef]

- Guo, L.; Liao, X.; Yang, W.; Sun, J. An oscillating milling strategy based on the uniform wear theory for improving service life of the ball-end cutter. J. Mater. Process. Technol. 2023, 317, 117993. [Google Scholar] [CrossRef]

- Vakondios, D.; Kyratsis, P.; Yaldiz, S.; Antoniadis, A. Influence of milling strategy on the surface roughness in ball end milling of the aluminum alloy Al7075-T6. Measurement 2012, 45, 1480–1488. [Google Scholar] [CrossRef]

- Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T. Selection of milling strategy based on surface integrity investigations of highly deformed Alloy 718 after ceramic and cemented carbide milling. J. Manuf. Process. 2020, 58, 193–207. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

- Tosello, G.; Bissacco, G.; Cao, J.; Axinte, D. Modeling and simulation of surface generation in manufacturing. CIRP Ann. 2023, 72, 753–779. [Google Scholar] [CrossRef]

- Yip-Hoi, D.; Huang, X. Cutter/workpiece engagement feature extraction from solid models for end milling. J. Manuf. Sci. Eng. 2006, 128, 249–260. [Google Scholar] [CrossRef]

- Klauer, K.; Eifler, M.; Kirsch, B.; Seewig, J.; Aurich, J.C. Micro milling of areal material measures–Study on surface generation for different up and down milling strategies. Procedia CIRP 2020, 87, 13–18. [Google Scholar] [CrossRef]

- Hadi, M.A.; Ghani, J.A.; Haron, C.C.; Kasim, M.S. Comparison between up-milling and down-milling operations on tool wear in milling Inconel 718. Procedia Eng. 2013, 68, 647–653. [Google Scholar] [CrossRef]

- Laamouri, A.; Ghanem, F.; Braham, C.; Sidhom, H. Influences of up-milling and down-milling on surface integrity and fatigue strength of X160CrMoV12 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1209–1228. [Google Scholar] [CrossRef]

- Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T.; Milesic Karlsson, A. Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718. J. Manuf. Mater. Process. 2021, 5, 48. [Google Scholar] [CrossRef]

- Abbas, A.T.; Sharma, N.; Alsuhaibani, Z.A.; Sharma, A.; Farooq, I.; Elkaseer, A. Multi-Objective Optimization of AISI P20 Mold Steel Machining in Dry Conditions Using Machine Learning—TOPSIS Approach. Machines 2023, 11, 748. [Google Scholar] [CrossRef]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Influence of additive manufacturing-induced anisotropy on tool wear in end milling of Ti6Al4V. Tribol. Int. 2020, 146, 106200. [Google Scholar] [CrossRef]

- Liang, S.; Shih, A.J. Analysis of Machining and Machine Tools; Springer: Boston, MA, USA, 2015. [Google Scholar]

- Tian, X.; Zhao, J.; Zhao, J.; Gong, Z.; Dong, Y. Effect of cutting speed on cutting forces and wear mechanisms in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int. J. Adv. Manuf. Technol. 2013, 69, 2669–2678. [Google Scholar] [CrossRef]

- Kaltenbrunner, T.; Krückl, H.P.; Schnalzger, G.; Klünsner, T.; Teppernegg, T.; Czettl, C.; Ecker, W. Differences in evolution of temperature, plastic deformation and wear in milling tools when up-milling and down-milling Ti6Al4V. J. Manuf. Process. 2022, 77, 75–86. [Google Scholar] [CrossRef]

- Uzun, M.; Usca, Ü.A.; Kuntoğlu, M.; Gupta, M.K. Influence of tool path strategies on machining time, tool wear, and surface roughness during milling of AISI X210Cr12 steel. Int. J. Adv. Manuf. Technol. 2022, 119, 2709–2720. [Google Scholar] [CrossRef]

- Bagci, E.; Yüncüoğlu, E.U. The Effects of Milling Strategies on Forces, Material Removal Rate, Tool Deflection, and Surface Errors for the Rough Machining of Complex Surfaces. J. Mech. Eng./Strojniški Vestnik 2017, 63, 643–656. [Google Scholar]

| C | Si | Mn | Cr | Mo | Cu | P | S |

|---|---|---|---|---|---|---|---|

| 0.33 | 0.65 | 0.8 | 1.75 | 0.4 | 0.25 | 0.03 | 0.03 |

| Ultimate tensile strength (MPa) | 995 |

| 0.2% yield strength, (MPa) | 845 |

| Elastic modulus E, (GPa) | 207 |

| Reduction in area % | 62.3 |

| Elongation % | 20 |

| Hardness (HRc) | 32 |

| Factor | Condition | Unit |

|---|---|---|

| Workpiece material | P20 mold steel | - |

| End-mill | Sandvik (1P240-1200-XA 1630) | - |

| Cutting speed (Vc) | 50, 75, 100 | [m/min] |

| Feed/tooth (f) | 0.004, 0.008, 0.012 | [tooth/mm] |

| Depth of cut (ap) | 0.5 | [mm] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.T.; Abdelnasser, E.; Naeim, N.; Alqosaibi, K.F.; Al-Bahkali, E.A.; Elkaseer, A. Effect of Milling Strategy on the Surface Quality of AISI P20 Mold Steel. Metals 2024, 14, 48. https://doi.org/10.3390/met14010048

Abbas AT, Abdelnasser E, Naeim N, Alqosaibi KF, Al-Bahkali EA, Elkaseer A. Effect of Milling Strategy on the Surface Quality of AISI P20 Mold Steel. Metals. 2024; 14(1):48. https://doi.org/10.3390/met14010048

Chicago/Turabian StyleAbbas, Adel T., Elshaimaa Abdelnasser, Noha Naeim, Khalid F. Alqosaibi, Essam A. Al-Bahkali, and Ahmed Elkaseer. 2024. "Effect of Milling Strategy on the Surface Quality of AISI P20 Mold Steel" Metals 14, no. 1: 48. https://doi.org/10.3390/met14010048

APA StyleAbbas, A. T., Abdelnasser, E., Naeim, N., Alqosaibi, K. F., Al-Bahkali, E. A., & Elkaseer, A. (2024). Effect of Milling Strategy on the Surface Quality of AISI P20 Mold Steel. Metals, 14(1), 48. https://doi.org/10.3390/met14010048