The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Microstructural Characterization

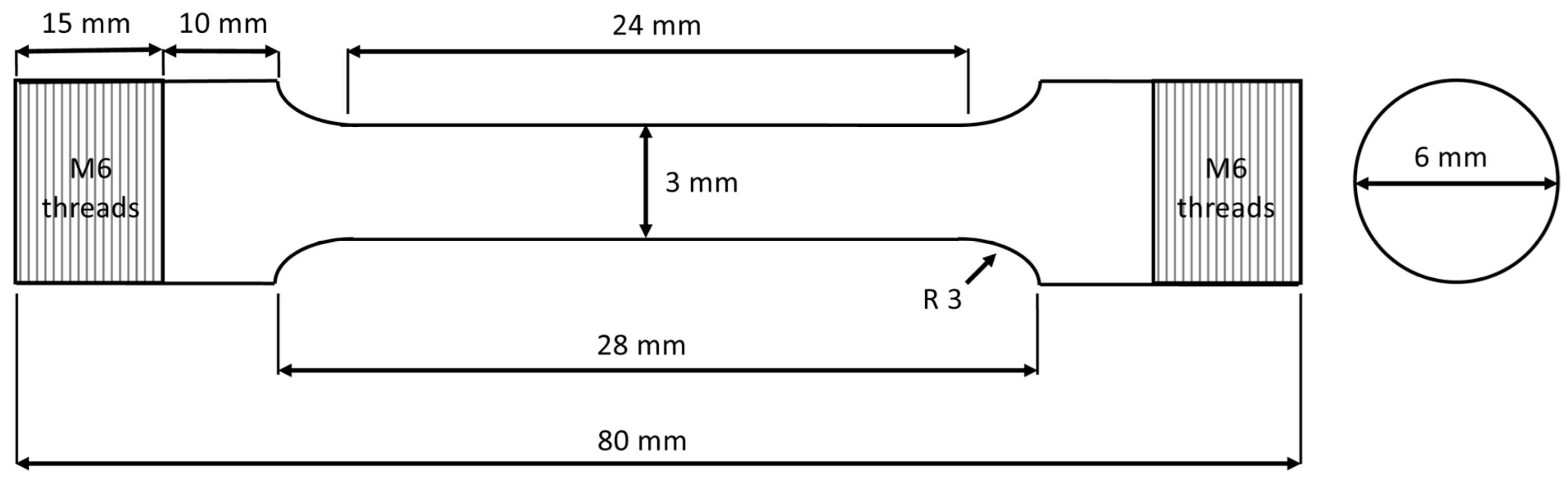

2.2. Mechanical Testing

3. Results and Discussion

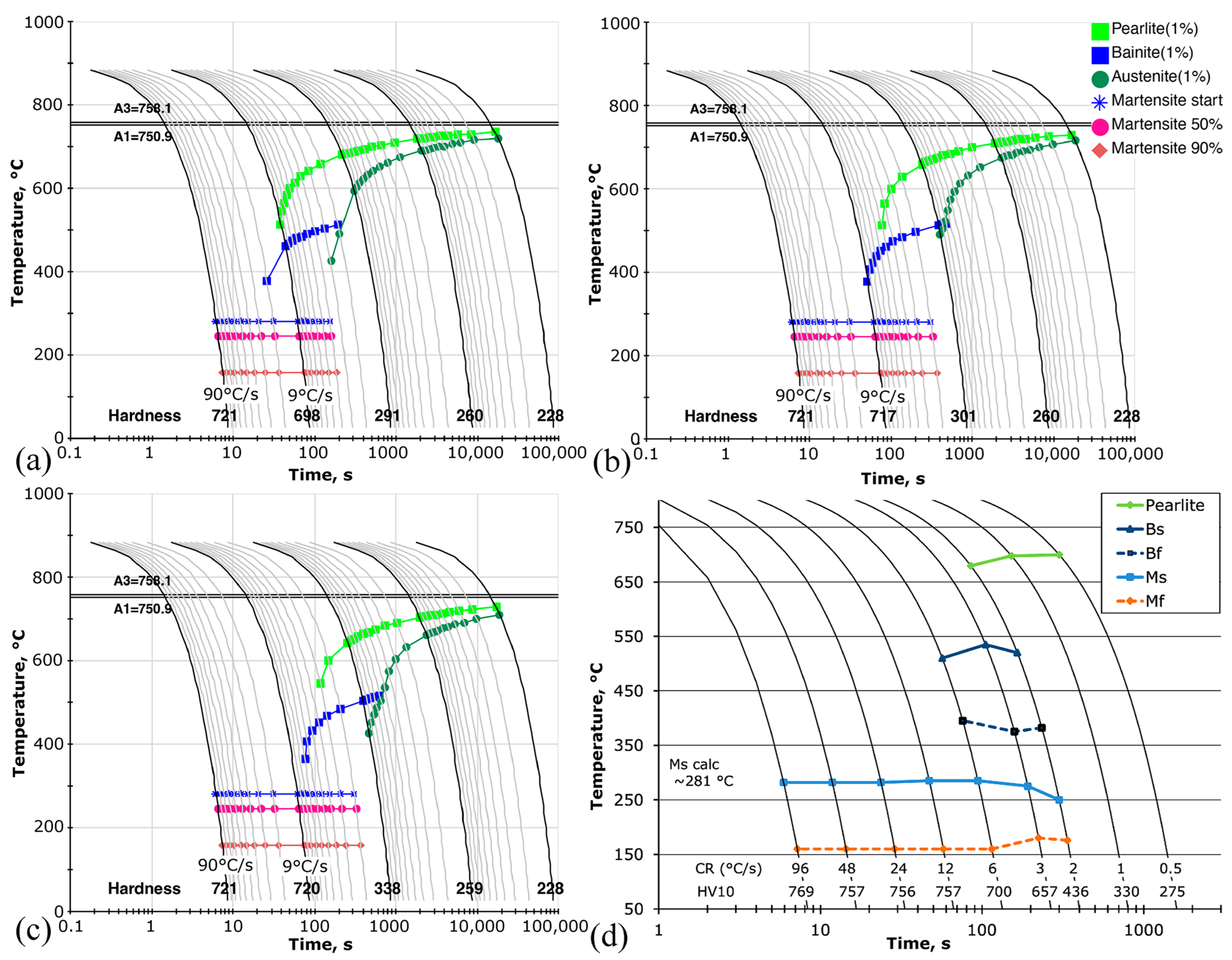

3.1. JMatPro Simulation and CCT Diagrams

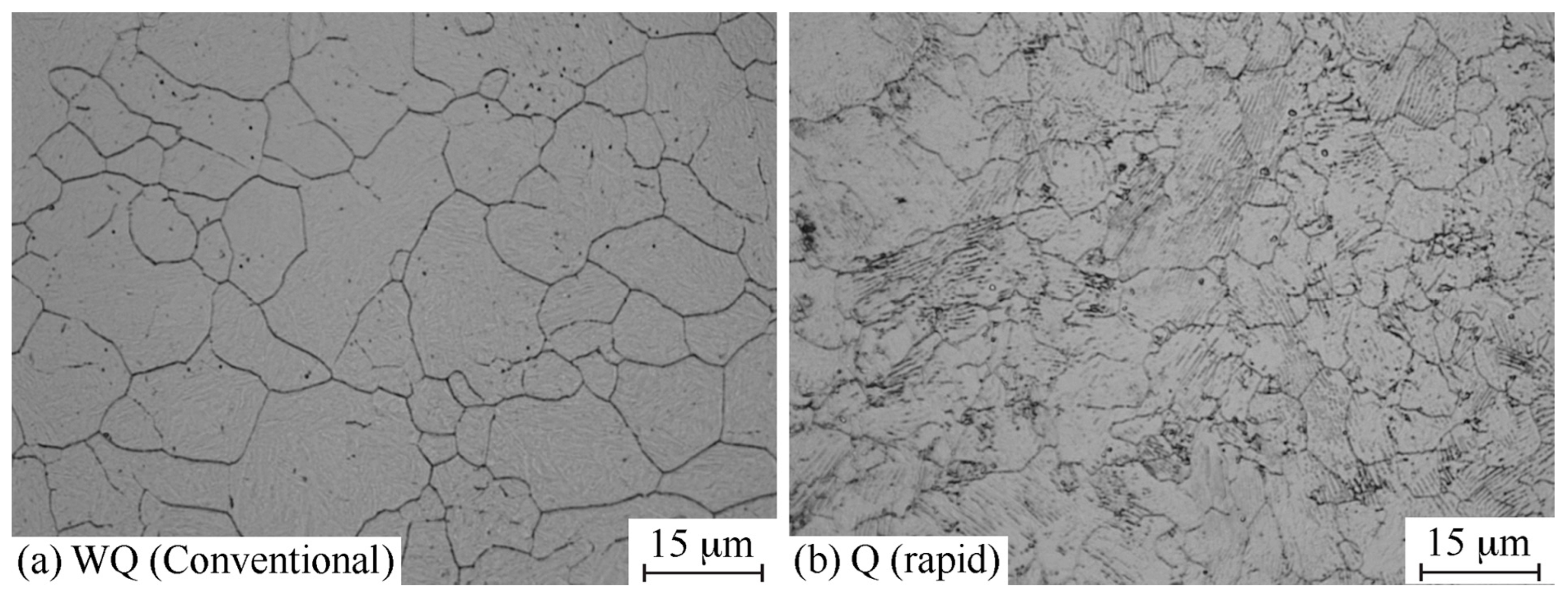

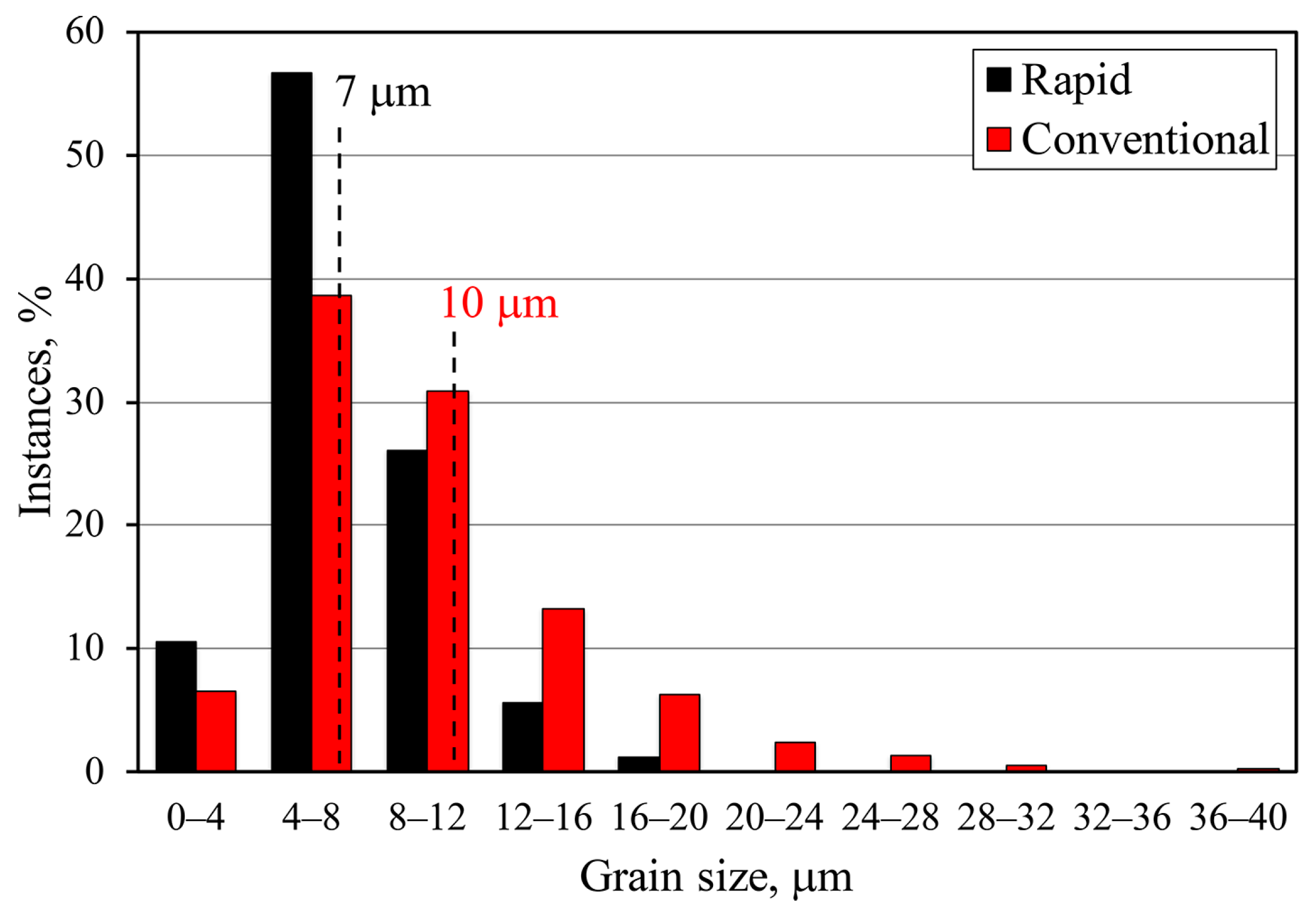

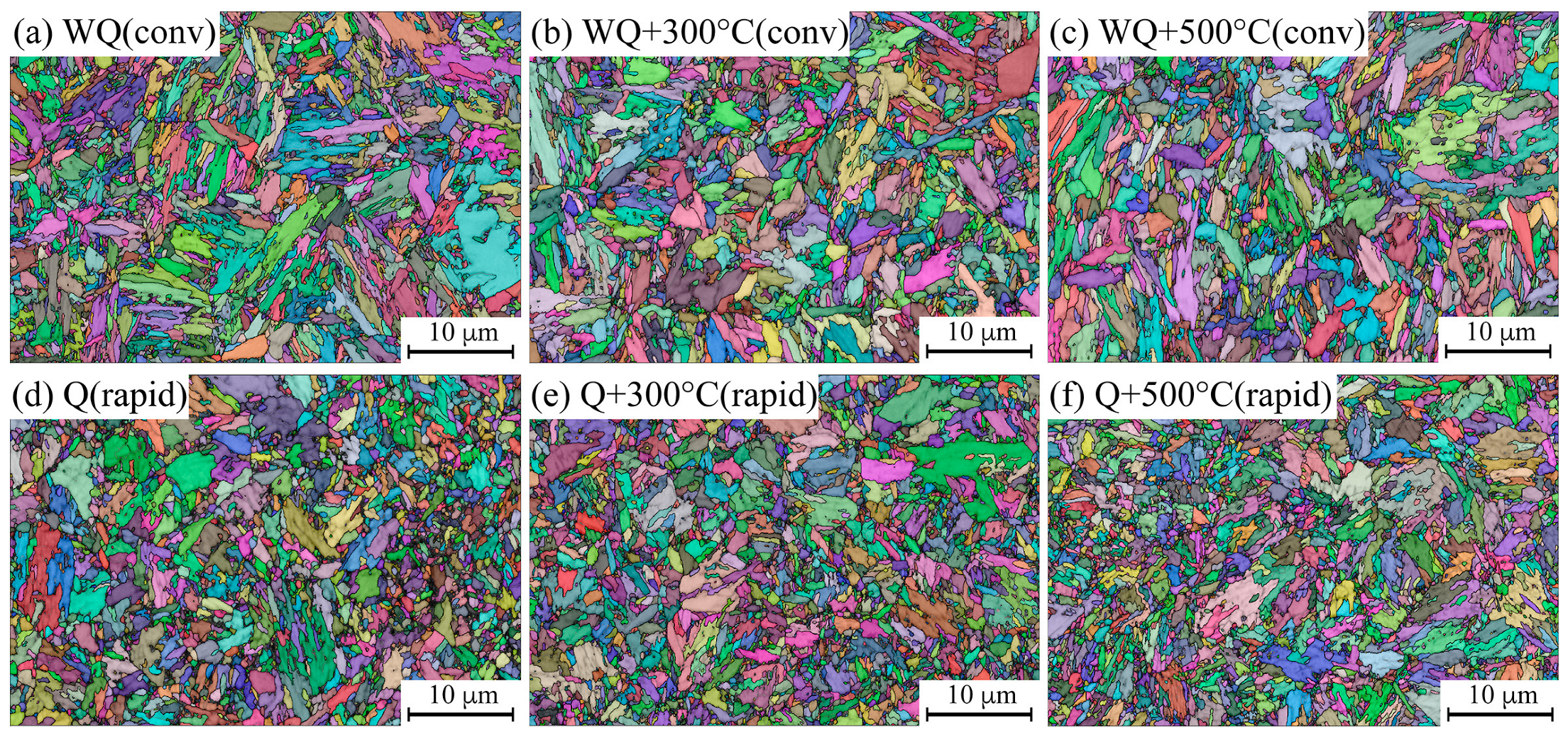

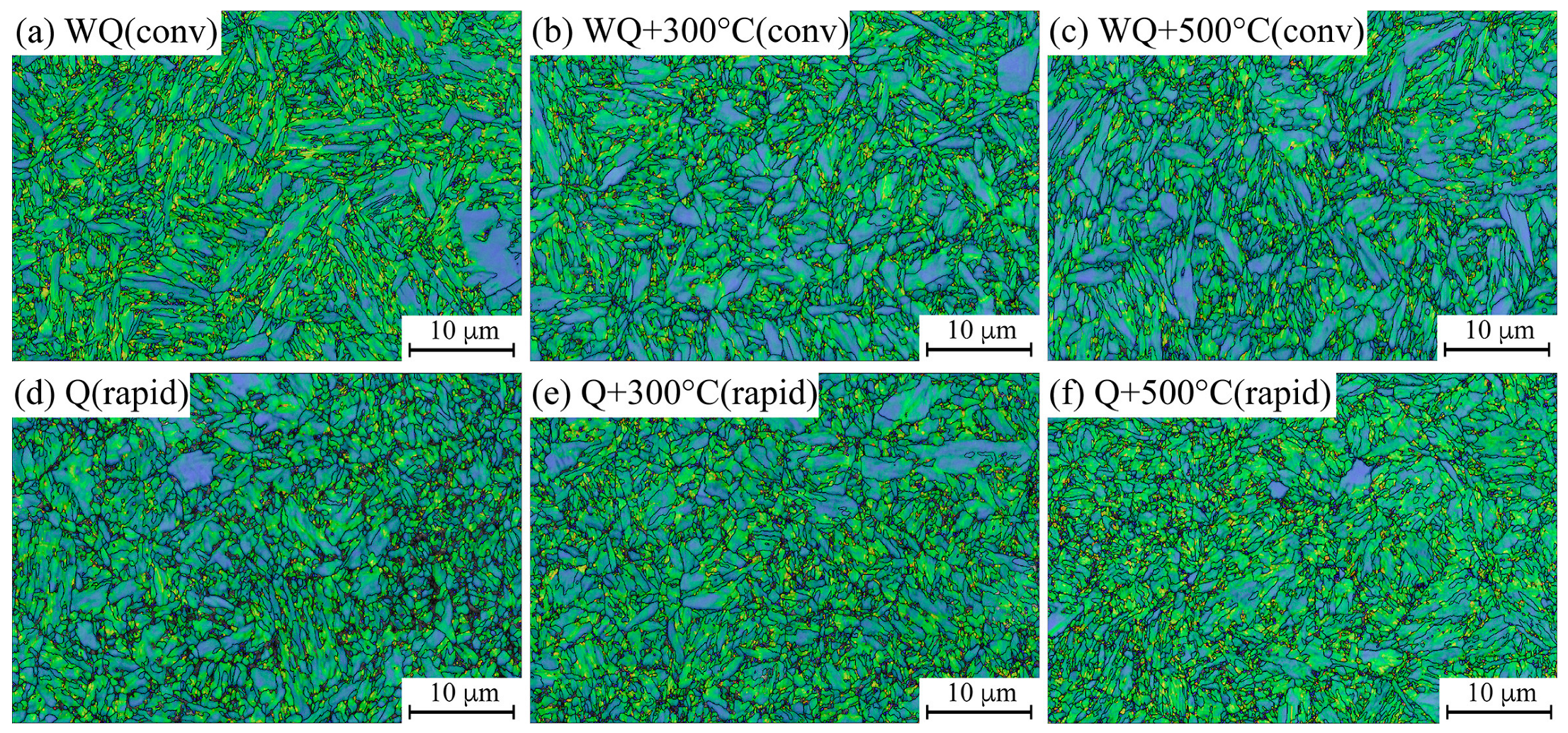

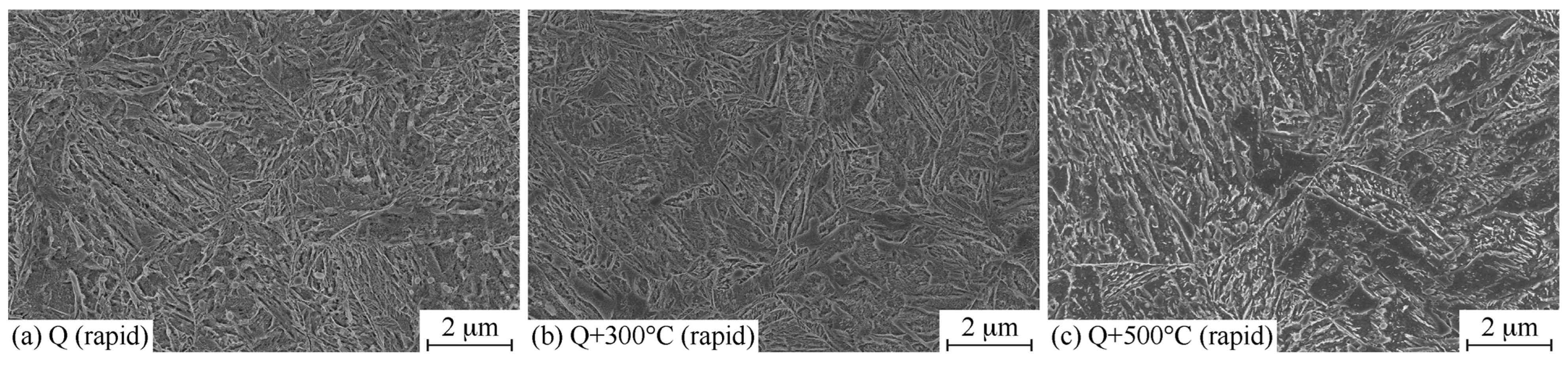

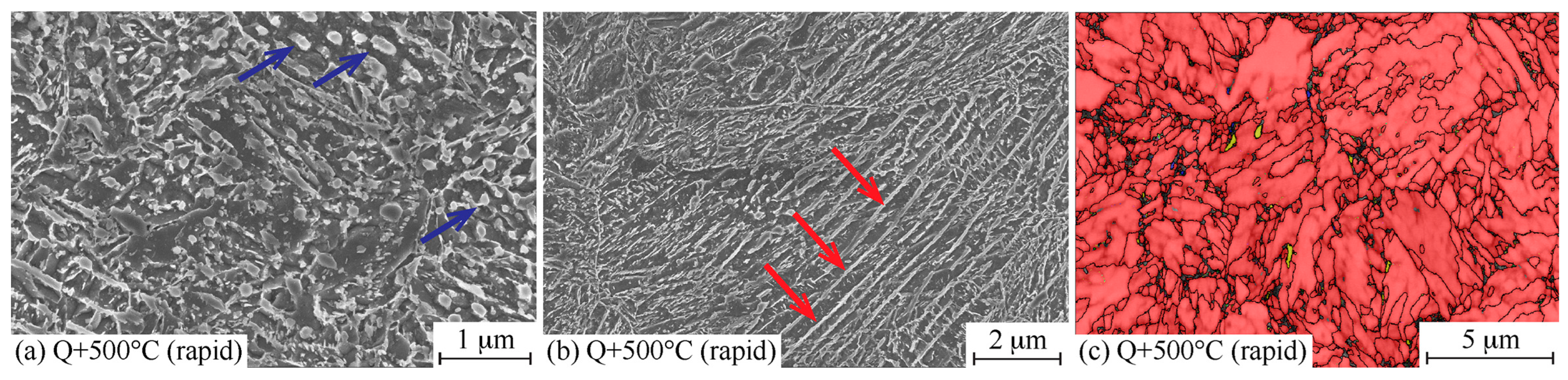

3.2. Microstructural Characterization

3.3. Mechanical Properties

3.4. Microstructure-Property Relationship

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Matlock, D.K.; Kang, S.; De Moor, E.; Speer, J.G. Applications of Rapid Thermal Processing to Advanced High Strength Sheet Steel Developments. Mater. Charact. 2020, 166, 110397. [Google Scholar] [CrossRef]

- Gaggiotti, M.; Albini, L.; Di Nunzio, P.; Di Schino, A.; Stornelli, G.; Tiracorrendo, G. Ultrafast Heating Heat Treatment Effect on the Microstructure and Properties of Steels. Metals 2022, 12, 1313. [Google Scholar] [CrossRef]

- Göken, J.; Maikranz-Valentin, M.; Steinhoff, K.; Golovin, I.S.; Ivleva, T.V.; Flejszar, A.; Riehemann, W. Mechanical Spectroscopy Study of Thermo-Mechanically Treated 51CrV4 Steel. Mater. Sci. Eng. A 2009, 521–522, 335–339. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, D.; Li, Y.; Wang, X.; Ren, X.; Wang, E. Effect of Quenching Conditions on the Microstructure and Mechanical Properties of 51CrV4 Spring Steel. Metals 2018, 8, 1056. [Google Scholar] [CrossRef]

- Lee, W.-S.; Su, T.-T. Mechanical Properties and Microstructural Features of AISI 4340 High-Strength Alloy Steel under Quenched and Tempered Conditions. J. Mater. Process. Technol. 1999, 87, 198–206. [Google Scholar] [CrossRef]

- Revilla, C.; López, B.; Rodriguez-Ibabe, J.M. Carbide Size Refinement by Controlling the Heating Rate during Induction Tempering in a Low Alloy Steel. Mater. Des. 2014, 62, 296–304. [Google Scholar] [CrossRef]

- Furuhara, T.; Kobayashi, K.; Maki, T. Control of Cementite Precipitation in Lath Martensite by Rapid Heating and Tempering. ISIJ Int. 2004, 44, 1937–1944. [Google Scholar] [CrossRef]

- Euser, V.K.; Williamson, D.L.; Clarke, A.J.; Speer, J.G. Cementite Precipitation in Conventionally and Rapidly Tempered 4340 Steel. JOM 2022, 74, 2386–2394. [Google Scholar] [CrossRef]

- Luo, Z.F.; Liang, Y.L.; Long, S.L.; Jiang, Y.; Wu, Z.L. Effects of Ultra-Refine Grain and Micro-Nano Twins on Mechanical Properties of 51CrV4 Spring Steel. Mater. Sci. Eng. A 2017, 690, 225–232. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Q.; Ren, J.; Li, R.; Wang, M.; Zhang, F.; Sun, K. Effect of Martensitic Morphology on Mechanical Properties of an As-Quenched and Tempered 25CrMo48V Steel. Mater. Sci. Eng. A 2012, 534, 339–346. [Google Scholar] [CrossRef]

- Hanamura, T.; Yin, F.; Nagai, K. Ductile-Brittle Transition Temperature of Ultrafine Ferrite/Cementite Microstructure in a Low Carbon Steel Controlled by Effective Grain Size. ISIJ Int. 2004, 44, 610–617. [Google Scholar] [CrossRef]

- Han, J.; da Silva, A.K.; Ponge, D.; Raabe, D.; Lee, S.-M.; Lee, Y.-K.; Lee, S.-I.; Hwang, B. The Effects of Prior Austenite Grain Boundaries and Microstructural Morphology on the Impact Toughness of Intercritically Annealed Medium Mn Steel. Acta Mater. 2017, 122, 199–206. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of Microstructural Refinement on the Toughness of Low Carbon Martensitic Steel. Scr. Mater. 2008, 58, 492–495. [Google Scholar] [CrossRef]

- Morris, J.W., Jr. On the Ductile-Brittle Transition in Lath Martensitic Steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef]

- Bhattacharjee, D.; Knott, J.F.; Davis, C.L. Charpy-Impact-Toughness Prediction Using an “Effective” Grain Size for Thermomechanically Controlled Rolled Microalloyed Steels. Metall. Mater. Trans. A 2004, 35, 121–130. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G.; Lee, T.-H. Correlation of Microstructure and Mechanical Properties of Thermomechanically Processed Low-Carbon Steels Containing Boron and Copper. Metall. Mater. Trans. A 2010, 41, 85–96. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G.; Kim, S.-J. Low-Temperature Toughening Mechanism in Thermomechanically Processed High-Strength Low-Alloy Steels. Metall. Mater. Trans. A 2011, 42, 717–728. [Google Scholar] [CrossRef]

- Gutiérrez, I. Effect of Microstructure on the Impact Toughness of Nb-Microalloyed Steel: Generalisation of Existing Relations from Ferrite–Pearlite to High Strength Microstructures. Mater. Sci. Eng. A 2013, 571, 57–67. [Google Scholar] [CrossRef]

- Morris, J.W.; Kinney, C.; Pytlewski, K.; Adachi, Y. Microstructure and Cleavage in Lath Martensitic Steels. Sci. Technol. Adv. Mater. 2013, 14, 014208. [Google Scholar] [CrossRef]

- Javaheri, V.; Kolli, S.; Grande, B.; Porter, D. Insight into the Induction Hardening Behavior of a New 0.40% C Microalloyed Steel: Effects of Initial Microstructure and Thermal Cycles. Mater. Charact. 2019, 149, 165–183. [Google Scholar] [CrossRef]

- Judge, V.K.; Speer, J.G.; Clarke, K.D.; Findley, K.O.; Clarke, A.J. Rapid Thermal Processing to Enhance Steel Toughness. Sci. Rep. 2018, 8, 445. [Google Scholar] [CrossRef]

- Kaiser, D.; Damon, J.; Mühl, F.; de Graaff, B.; Kiefer, D.; Dietrich, S.; Schulze, V. Experimental Investigation and Finite-Element Modeling of the Short-Time Induction Quench-and-Temper Process of AISI 4140. J. Mater. Process. Technol. 2020, 279, 116485. [Google Scholar] [CrossRef]

- Podgornik, B.; Leskovšek, V.; Godec, M.; Senčič, B. Microstructure Refinement and Its Effect on Properties of Spring Steel. Mater. Sci. Eng. A 2014, 599, 81–86. [Google Scholar] [CrossRef]

- Brownrigg, A.; Curcio, P.; Boelen, R. Etching of Prior Austenite Grain Boundaries in Martensite. Metallography 1975, 8, 529–533. [Google Scholar] [CrossRef]

- EN ISO 6892-1; Metallic Materials. Tensile Testing. Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- EN ISO 148-1; Metallic Materials, Charpy Pendulum Impact Test, Part 1: Test Method. ISO: Geneva, Switzerland, 2010.

- Stuhlmann, W. What the TTT-Diagrams Tell Us. Härterei Technische Mitteilungen 1954, 6, 31–48. (In German) [Google Scholar]

- Yuan, Q.; Ren, J.; Mo, J.; Zhang, Z.; Tang, E.; Xu, G.; Xue, Z. Effects of Rapid Heating on the Phase Transformation and Grain Refinement of a Low-Carbon Mciroalloyed Steel. J. Mater. Res. Technol. 2023, 23, 3756–3771. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Heikkala, J.; Porter, D.; Suikkanen, P. The Effect of Tempering Temperature on Microstructure, Mechanical Properties and Bendability of Direct-Quenched Low-Alloy Strip Steel. Mater. Sci. Eng. A 2018, 730, 284–294. [Google Scholar] [CrossRef]

- De Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L.A.I. Effect of Fresh Martensite on the Stability of Retained Austenite in Quenching and Partitioning Steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Kwon, E.P.; Fujieda, S.; Shinoda, K.; Suzuki, S. Characterization of Transformed and Deformed Microstructures in Transformation Induced Plasticity Steels Using Electron Backscattering Diffraction. Mater. Sci. Eng. A 2011, 528, 5007–5017. [Google Scholar] [CrossRef]

- Tervo, H. Non-Metallic Inclusions in Steels and Their Effect on the Toughness and Ductility: Ultra-High-Strength Steels and High Strength Offshore Steels. Ph.D. Thesis, University of Oulu, Oulu, Finland, 2023. [Google Scholar]

- Pickering, F.B. Towards Improved Ductility and Toughness; Climax Molybdenum Development Company: Tokyo, Japan, 1971; p. 9. [Google Scholar]

- Pickering, F.B. Some Effects of Non-Metallic Inclusions on the Properties of Steels. In Proceedings of the Mechanical Working and Steel Processing Proceedings, Chicago, IL, USA, 22–25 October 1989; pp. 381–401. [Google Scholar]

- Haiko, O.; Kaijalainen, A.; Iso-Junno, T.; Jaskari, M.; Kömi, J.I. Effect of Rapid Induction Tempering on the Mechanical Properties and Microstructure of Ultra-High Strength Steel. Mater. Sci. Forum 2023, 1105, 29–34. [Google Scholar] [CrossRef]

- Pallaspuro, S.; Kaijalainen, A.J.; Mehtonen, S.; Kömi, J.I.; Zhang, Z.L.; Porter, D.A. Estimation of Impact Toughness Transition Temperatures of As-Quenched Steels. Mater. Sci. Forum 2018, 941, 498–503. [Google Scholar] [CrossRef]

| Material | Grains pcs. | deff, μm | dmax, μm | d90%, μm | LAGB, % | HAGB, % |

|---|---|---|---|---|---|---|

| Q(Rapid) | 2110 | 0.69 ± 0.03 | 5.61 | 2.63 | 11.4 | 88.6 |

| Q + 300 °C (Rapid) | 2608 | 0.62 ± 0.02 | 7.57 | 2.39 | 11.9 | 88.1 |

| Q + 500 °C (Rapid) | 2566 | 0.62 ± 0.02 | 5.64 | 2.79 | 12.6 | 87.4 |

| WQ (Conv) | 2178 | 0.64 ± 0.03 | 8.96 | 3.28 | 12.9 | 87.1 |

| WQ + 300 °C (Conv) | 1984 | 0.68 ± 0.03 | 9.65 | 3.33 | 13.0 | 87.0 |

| WQ + 500 °C (Conv) | 1946 | 0.69 ± 0.03 | 7.34 | 3.36 | 12.9 | 87.1 |

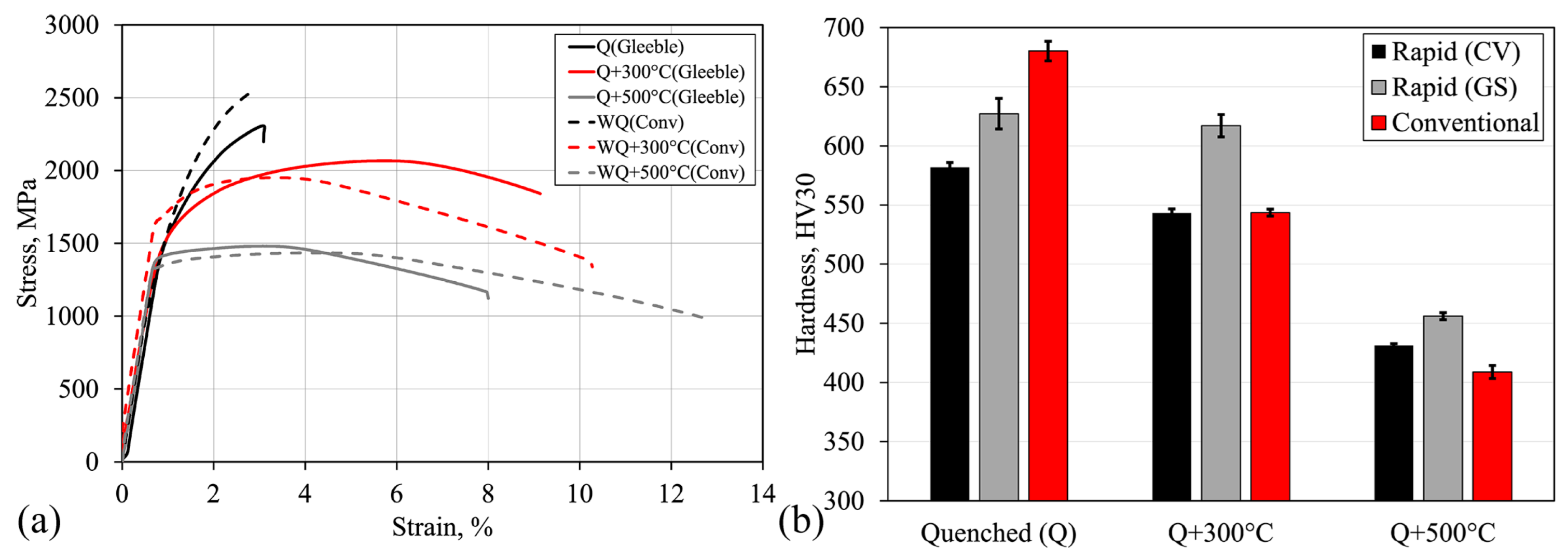

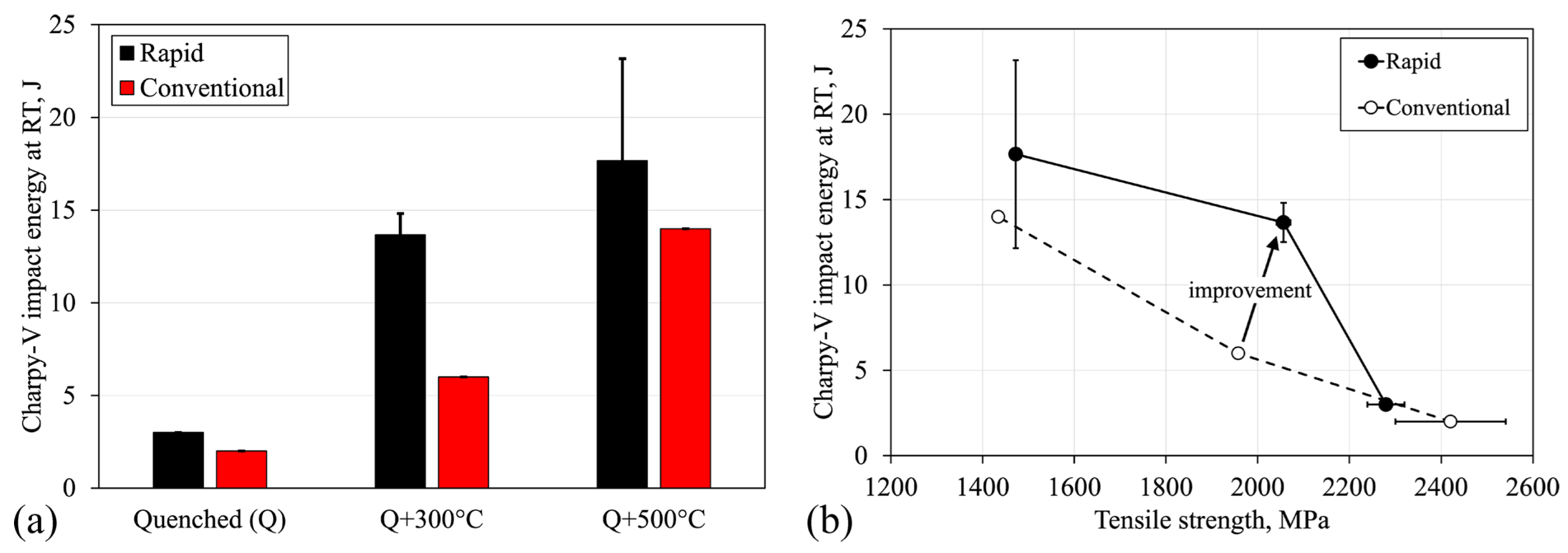

| Material | Rp0.2, MPa | Rm, MPa | A, % | Rp0.2/Rm-Ratio | Rm × A, MPa% | CV at RT, J | Hardness, HV30 (CV) | Hardness, HV30 (GS) |

|---|---|---|---|---|---|---|---|---|

| Q (Rapid) | 1643 | 2280 | 2.5 | 0.72 | 5700 | 3 | 582 ± 4 | 627 ± 13 |

| Q + 300 °C (Rapid) | 1563 | 2056 | 8.8 | 0.76 | 18,093 | 14 | 543 ± 4 | 617 ± 9 |

| Q + 500 °C (Rapid) | 1394 | 1472 | 7.9 | 0.95 | 11,629 | 18 | 431 ± 1 | 456 ± 3 |

| WQ (Conv) | 1597 | 2421 | 2.4 | 0.66 | 5810 | 2 | 680 ± 8 | - |

| WQ + 300 °C (Conv) | 1714 | 1958 | 10.0 | 0.88 | 19,580 | 6 | 544 ± 3 | - |

| WQ + 500 °C (Conv) | 1346 | 1434 | 12.2 | 0.94 | 17,495 | 14 | 409 ± 6 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaijalainen, A.; Haiko, O.; Sadeghpour, S.; Javaheri, V.; Kömi, J. The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals 2024, 14, 60. https://doi.org/10.3390/met14010060

Kaijalainen A, Haiko O, Sadeghpour S, Javaheri V, Kömi J. The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals. 2024; 14(1):60. https://doi.org/10.3390/met14010060

Chicago/Turabian StyleKaijalainen, Antti, Oskari Haiko, Saeed Sadeghpour, Vahid Javaheri, and Jukka Kömi. 2024. "The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel" Metals 14, no. 1: 60. https://doi.org/10.3390/met14010060

APA StyleKaijalainen, A., Haiko, O., Sadeghpour, S., Javaheri, V., & Kömi, J. (2024). The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals, 14(1), 60. https://doi.org/10.3390/met14010060