The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microstructural Characterization

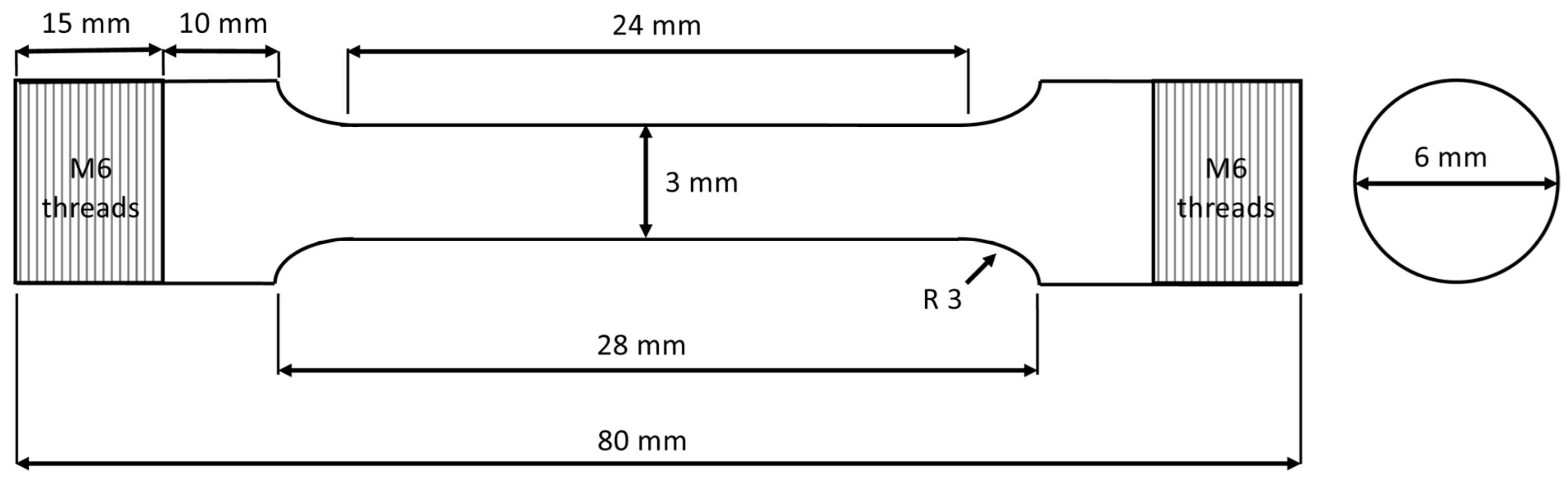

2.2. Mechanical Testing

3. Results and Discussion

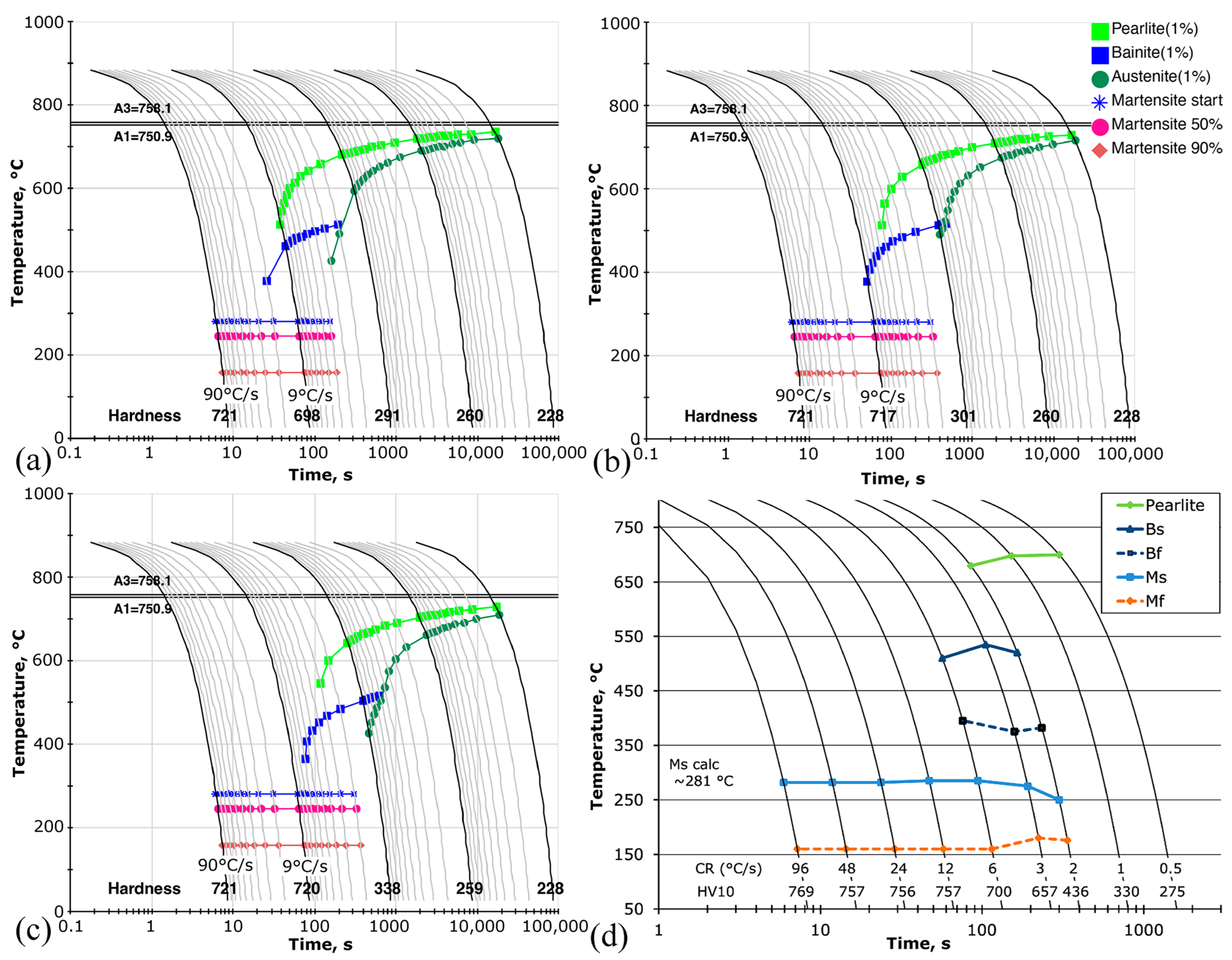

3.1. JMatPro Simulation and CCT Diagrams

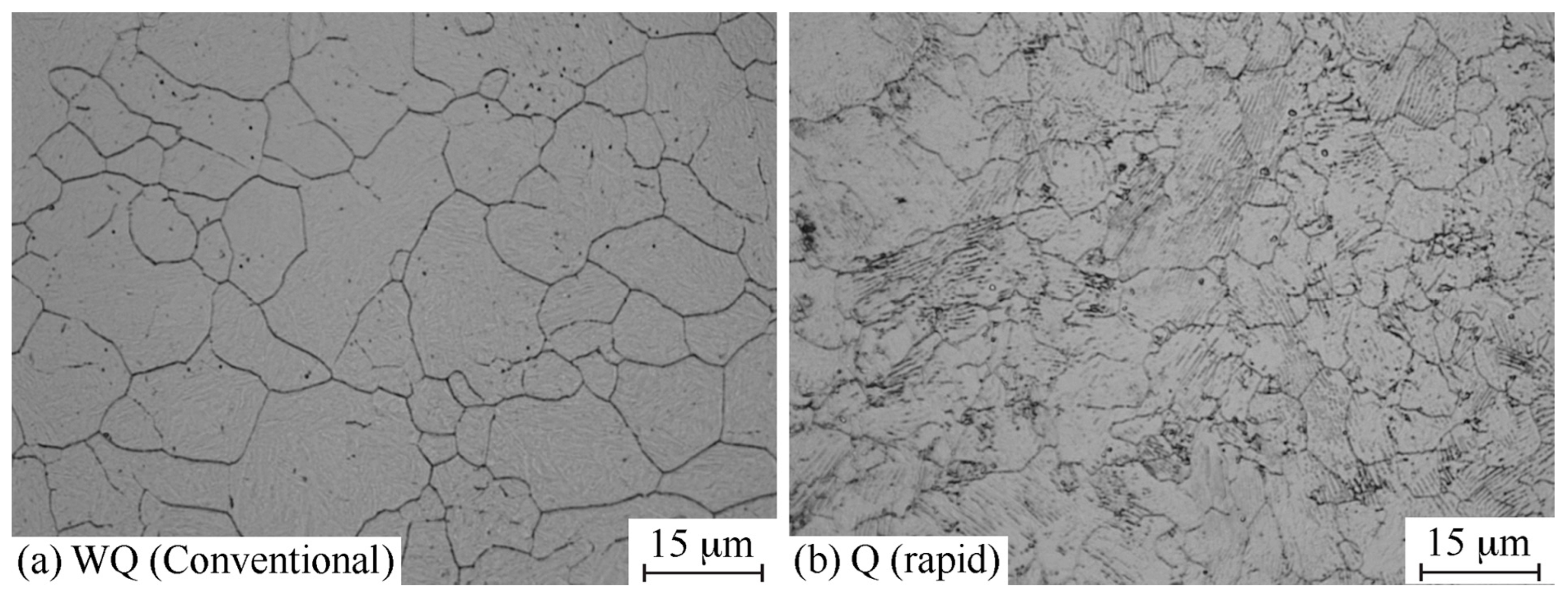

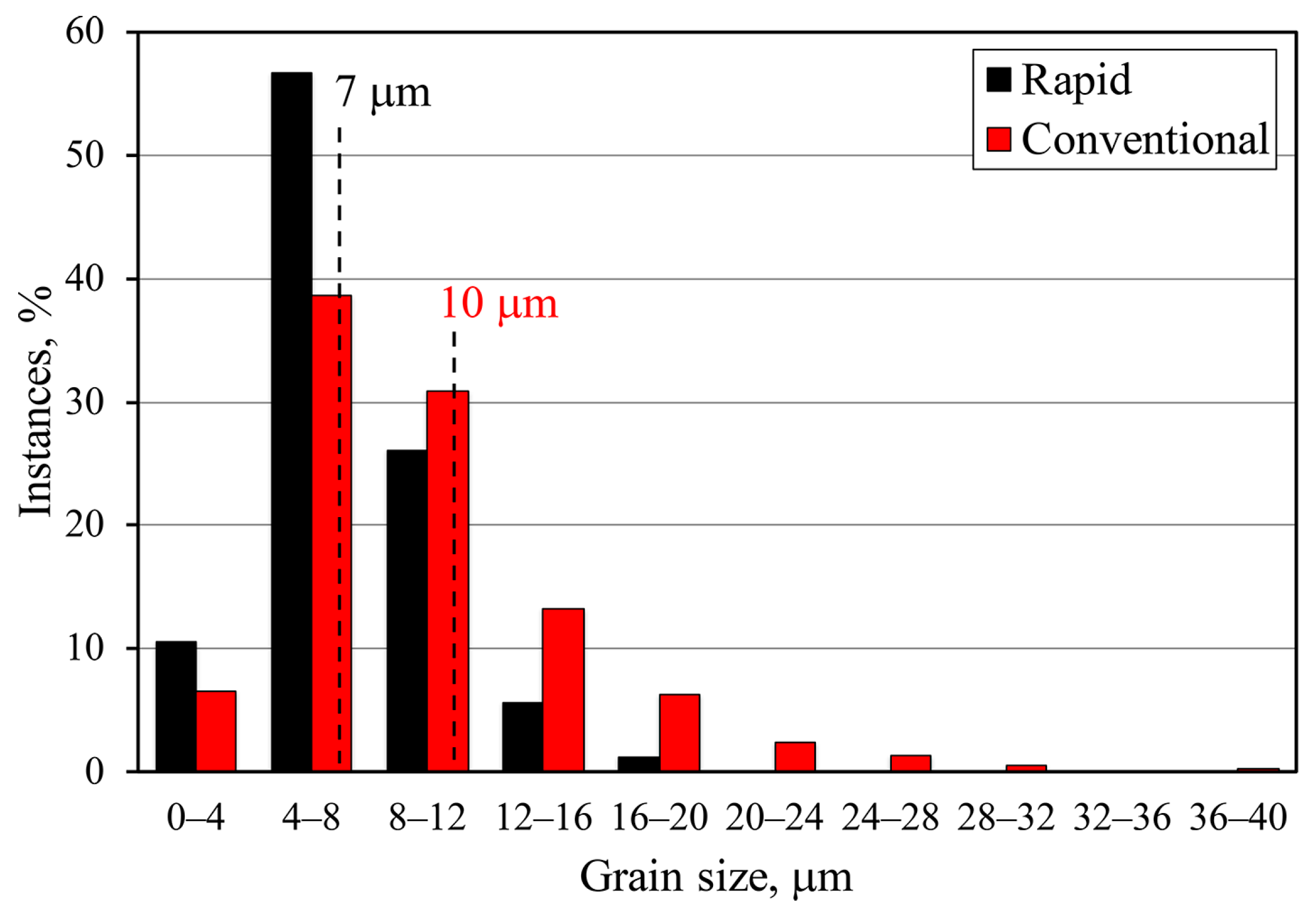

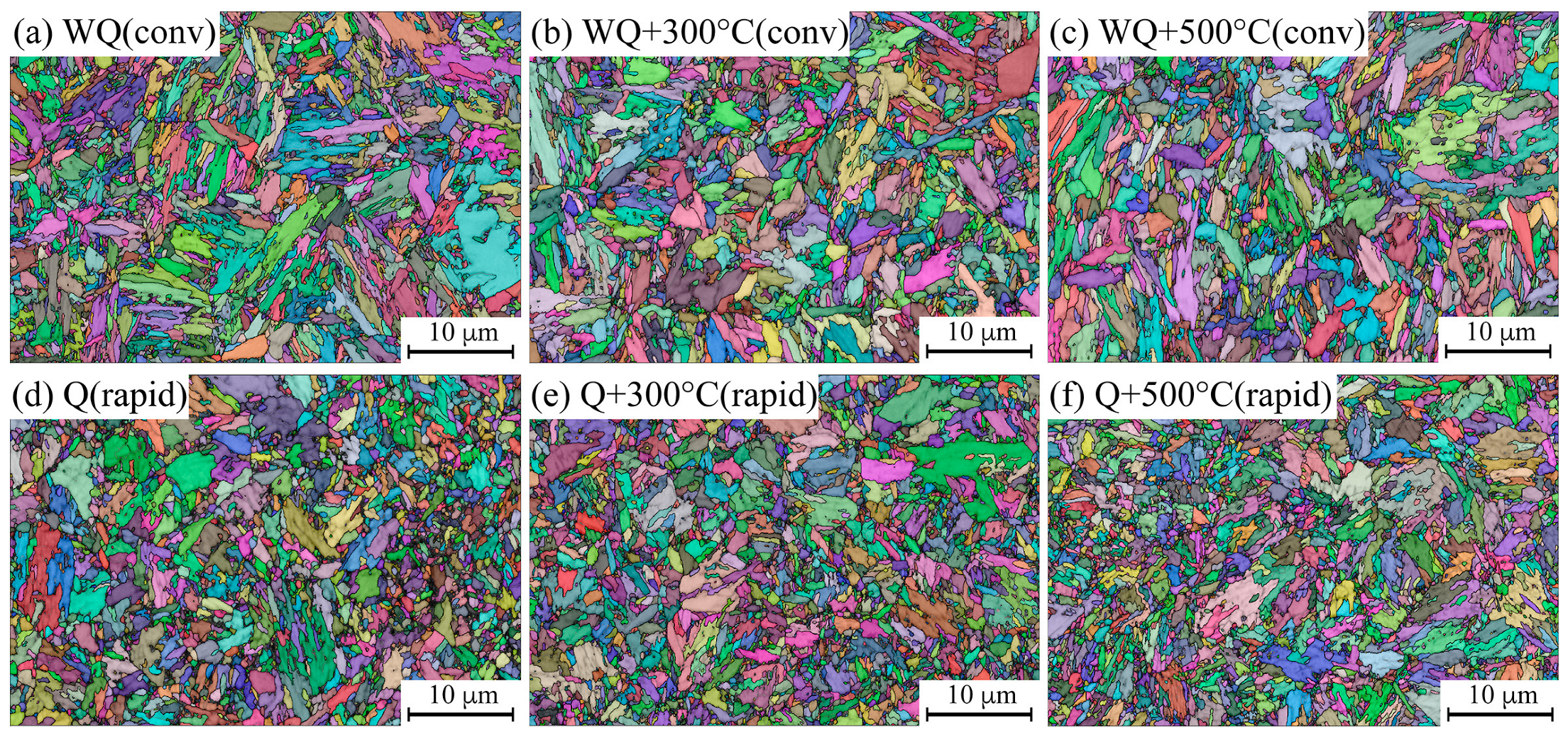

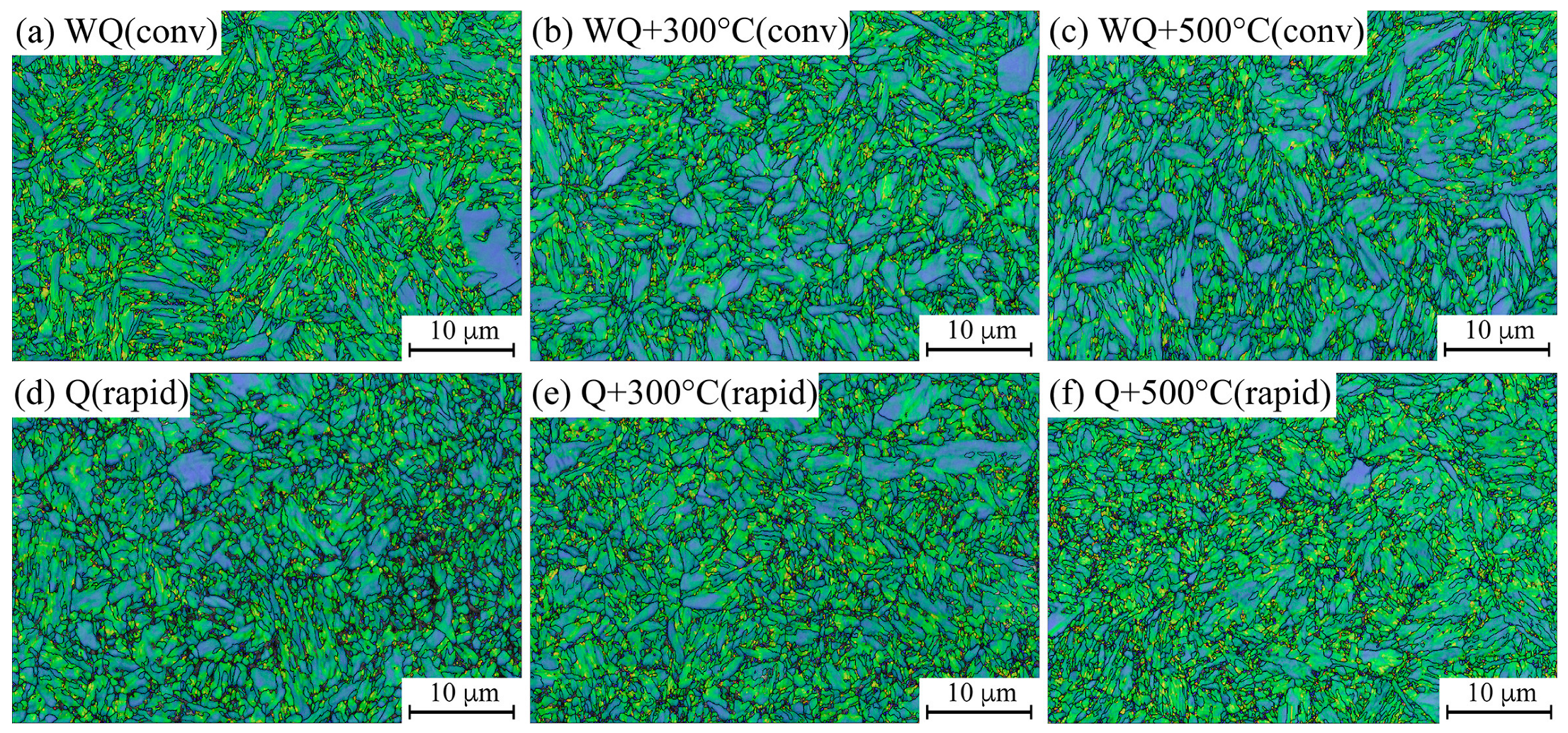

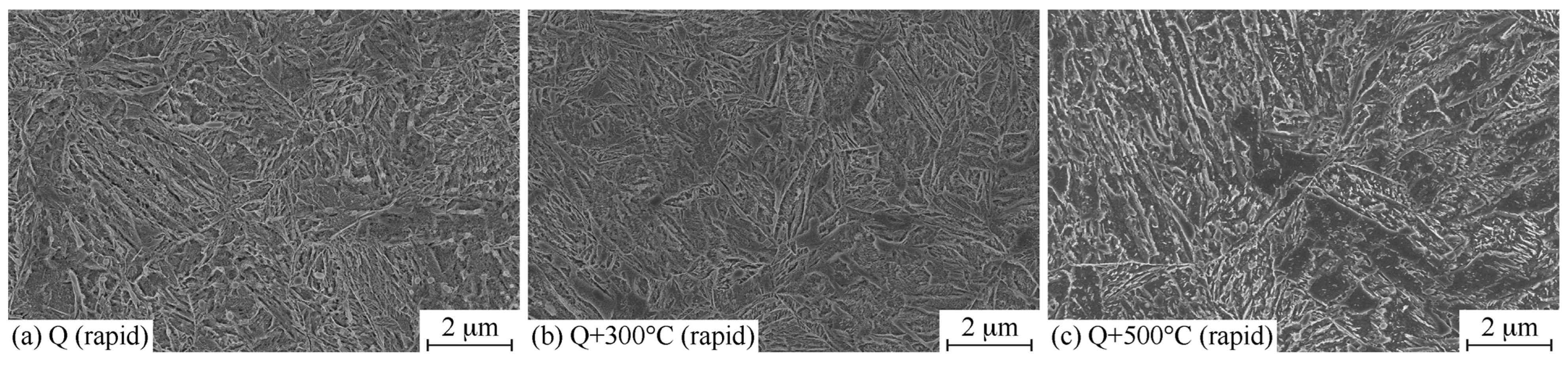

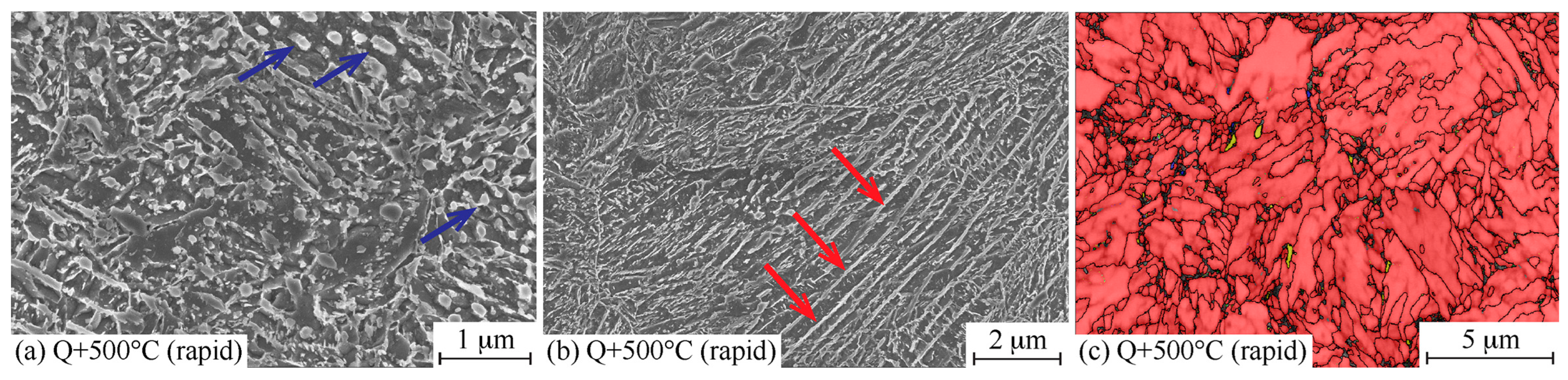

3.2. Microstructural Characterization

3.3. Mechanical Properties

3.4. Microstructure-Property Relationship

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Matlock, D.K.; Kang, S.; De Moor, E.; Speer, J.G. Applications of Rapid Thermal Processing to Advanced High Strength Sheet Steel Developments. Mater. Charact. 2020, 166, 110397. [Google Scholar] [CrossRef]

- Gaggiotti, M.; Albini, L.; Di Nunzio, P.; Di Schino, A.; Stornelli, G.; Tiracorrendo, G. Ultrafast Heating Heat Treatment Effect on the Microstructure and Properties of Steels. Metals 2022, 12, 1313. [Google Scholar] [CrossRef]

- Göken, J.; Maikranz-Valentin, M.; Steinhoff, K.; Golovin, I.S.; Ivleva, T.V.; Flejszar, A.; Riehemann, W. Mechanical Spectroscopy Study of Thermo-Mechanically Treated 51CrV4 Steel. Mater. Sci. Eng. A 2009, 521–522, 335–339. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, D.; Li, Y.; Wang, X.; Ren, X.; Wang, E. Effect of Quenching Conditions on the Microstructure and Mechanical Properties of 51CrV4 Spring Steel. Metals 2018, 8, 1056. [Google Scholar] [CrossRef]

- Lee, W.-S.; Su, T.-T. Mechanical Properties and Microstructural Features of AISI 4340 High-Strength Alloy Steel under Quenched and Tempered Conditions. J. Mater. Process. Technol. 1999, 87, 198–206. [Google Scholar] [CrossRef]

- Revilla, C.; López, B.; Rodriguez-Ibabe, J.M. Carbide Size Refinement by Controlling the Heating Rate during Induction Tempering in a Low Alloy Steel. Mater. Des. 2014, 62, 296–304. [Google Scholar] [CrossRef]

- Furuhara, T.; Kobayashi, K.; Maki, T. Control of Cementite Precipitation in Lath Martensite by Rapid Heating and Tempering. ISIJ Int. 2004, 44, 1937–1944. [Google Scholar] [CrossRef]

- Euser, V.K.; Williamson, D.L.; Clarke, A.J.; Speer, J.G. Cementite Precipitation in Conventionally and Rapidly Tempered 4340 Steel. JOM 2022, 74, 2386–2394. [Google Scholar] [CrossRef]

- Luo, Z.F.; Liang, Y.L.; Long, S.L.; Jiang, Y.; Wu, Z.L. Effects of Ultra-Refine Grain and Micro-Nano Twins on Mechanical Properties of 51CrV4 Spring Steel. Mater. Sci. Eng. A 2017, 690, 225–232. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Q.; Ren, J.; Li, R.; Wang, M.; Zhang, F.; Sun, K. Effect of Martensitic Morphology on Mechanical Properties of an As-Quenched and Tempered 25CrMo48V Steel. Mater. Sci. Eng. A 2012, 534, 339–346. [Google Scholar] [CrossRef]

- Hanamura, T.; Yin, F.; Nagai, K. Ductile-Brittle Transition Temperature of Ultrafine Ferrite/Cementite Microstructure in a Low Carbon Steel Controlled by Effective Grain Size. ISIJ Int. 2004, 44, 610–617. [Google Scholar] [CrossRef]

- Han, J.; da Silva, A.K.; Ponge, D.; Raabe, D.; Lee, S.-M.; Lee, Y.-K.; Lee, S.-I.; Hwang, B. The Effects of Prior Austenite Grain Boundaries and Microstructural Morphology on the Impact Toughness of Intercritically Annealed Medium Mn Steel. Acta Mater. 2017, 122, 199–206. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of Microstructural Refinement on the Toughness of Low Carbon Martensitic Steel. Scr. Mater. 2008, 58, 492–495. [Google Scholar] [CrossRef]

- Morris, J.W., Jr. On the Ductile-Brittle Transition in Lath Martensitic Steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef]

- Bhattacharjee, D.; Knott, J.F.; Davis, C.L. Charpy-Impact-Toughness Prediction Using an “Effective” Grain Size for Thermomechanically Controlled Rolled Microalloyed Steels. Metall. Mater. Trans. A 2004, 35, 121–130. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G.; Lee, T.-H. Correlation of Microstructure and Mechanical Properties of Thermomechanically Processed Low-Carbon Steels Containing Boron and Copper. Metall. Mater. Trans. A 2010, 41, 85–96. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G.; Kim, S.-J. Low-Temperature Toughening Mechanism in Thermomechanically Processed High-Strength Low-Alloy Steels. Metall. Mater. Trans. A 2011, 42, 717–728. [Google Scholar] [CrossRef]

- Gutiérrez, I. Effect of Microstructure on the Impact Toughness of Nb-Microalloyed Steel: Generalisation of Existing Relations from Ferrite–Pearlite to High Strength Microstructures. Mater. Sci. Eng. A 2013, 571, 57–67. [Google Scholar] [CrossRef]

- Morris, J.W.; Kinney, C.; Pytlewski, K.; Adachi, Y. Microstructure and Cleavage in Lath Martensitic Steels. Sci. Technol. Adv. Mater. 2013, 14, 014208. [Google Scholar] [CrossRef]

- Javaheri, V.; Kolli, S.; Grande, B.; Porter, D. Insight into the Induction Hardening Behavior of a New 0.40% C Microalloyed Steel: Effects of Initial Microstructure and Thermal Cycles. Mater. Charact. 2019, 149, 165–183. [Google Scholar] [CrossRef]

- Judge, V.K.; Speer, J.G.; Clarke, K.D.; Findley, K.O.; Clarke, A.J. Rapid Thermal Processing to Enhance Steel Toughness. Sci. Rep. 2018, 8, 445. [Google Scholar] [CrossRef]

- Kaiser, D.; Damon, J.; Mühl, F.; de Graaff, B.; Kiefer, D.; Dietrich, S.; Schulze, V. Experimental Investigation and Finite-Element Modeling of the Short-Time Induction Quench-and-Temper Process of AISI 4140. J. Mater. Process. Technol. 2020, 279, 116485. [Google Scholar] [CrossRef]

- Podgornik, B.; Leskovšek, V.; Godec, M.; Senčič, B. Microstructure Refinement and Its Effect on Properties of Spring Steel. Mater. Sci. Eng. A 2014, 599, 81–86. [Google Scholar] [CrossRef]

- Brownrigg, A.; Curcio, P.; Boelen, R. Etching of Prior Austenite Grain Boundaries in Martensite. Metallography 1975, 8, 529–533. [Google Scholar] [CrossRef]

- EN ISO 6892-1; Metallic Materials. Tensile Testing. Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- EN ISO 148-1; Metallic Materials, Charpy Pendulum Impact Test, Part 1: Test Method. ISO: Geneva, Switzerland, 2010.

- Stuhlmann, W. What the TTT-Diagrams Tell Us. Härterei Technische Mitteilungen 1954, 6, 31–48. (In German) [Google Scholar]

- Yuan, Q.; Ren, J.; Mo, J.; Zhang, Z.; Tang, E.; Xu, G.; Xue, Z. Effects of Rapid Heating on the Phase Transformation and Grain Refinement of a Low-Carbon Mciroalloyed Steel. J. Mater. Res. Technol. 2023, 23, 3756–3771. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Heikkala, J.; Porter, D.; Suikkanen, P. The Effect of Tempering Temperature on Microstructure, Mechanical Properties and Bendability of Direct-Quenched Low-Alloy Strip Steel. Mater. Sci. Eng. A 2018, 730, 284–294. [Google Scholar] [CrossRef]

- De Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L.A.I. Effect of Fresh Martensite on the Stability of Retained Austenite in Quenching and Partitioning Steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Kwon, E.P.; Fujieda, S.; Shinoda, K.; Suzuki, S. Characterization of Transformed and Deformed Microstructures in Transformation Induced Plasticity Steels Using Electron Backscattering Diffraction. Mater. Sci. Eng. A 2011, 528, 5007–5017. [Google Scholar] [CrossRef]

- Tervo, H. Non-Metallic Inclusions in Steels and Their Effect on the Toughness and Ductility: Ultra-High-Strength Steels and High Strength Offshore Steels. Ph.D. Thesis, University of Oulu, Oulu, Finland, 2023. [Google Scholar]

- Pickering, F.B. Towards Improved Ductility and Toughness; Climax Molybdenum Development Company: Tokyo, Japan, 1971; p. 9. [Google Scholar]

- Pickering, F.B. Some Effects of Non-Metallic Inclusions on the Properties of Steels. In Proceedings of the Mechanical Working and Steel Processing Proceedings, Chicago, IL, USA, 22–25 October 1989; pp. 381–401. [Google Scholar]

- Haiko, O.; Kaijalainen, A.; Iso-Junno, T.; Jaskari, M.; Kömi, J.I. Effect of Rapid Induction Tempering on the Mechanical Properties and Microstructure of Ultra-High Strength Steel. Mater. Sci. Forum 2023, 1105, 29–34. [Google Scholar] [CrossRef]

- Pallaspuro, S.; Kaijalainen, A.J.; Mehtonen, S.; Kömi, J.I.; Zhang, Z.L.; Porter, D.A. Estimation of Impact Toughness Transition Temperatures of As-Quenched Steels. Mater. Sci. Forum 2018, 941, 498–503. [Google Scholar] [CrossRef]

| Material | Grains pcs. | deff, μm | dmax, μm | d90%, μm | LAGB, % | HAGB, % |

|---|---|---|---|---|---|---|

| Q(Rapid) | 2110 | 0.69 ± 0.03 | 5.61 | 2.63 | 11.4 | 88.6 |

| Q + 300 °C (Rapid) | 2608 | 0.62 ± 0.02 | 7.57 | 2.39 | 11.9 | 88.1 |

| Q + 500 °C (Rapid) | 2566 | 0.62 ± 0.02 | 5.64 | 2.79 | 12.6 | 87.4 |

| WQ (Conv) | 2178 | 0.64 ± 0.03 | 8.96 | 3.28 | 12.9 | 87.1 |

| WQ + 300 °C (Conv) | 1984 | 0.68 ± 0.03 | 9.65 | 3.33 | 13.0 | 87.0 |

| WQ + 500 °C (Conv) | 1946 | 0.69 ± 0.03 | 7.34 | 3.36 | 12.9 | 87.1 |

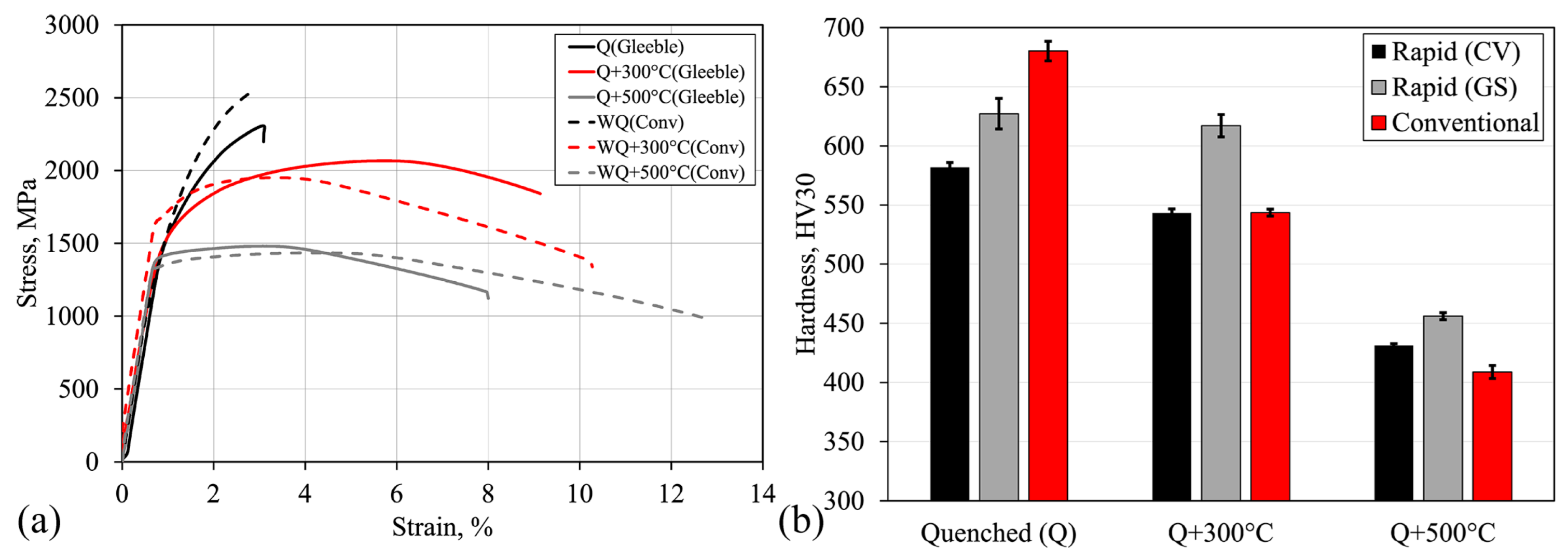

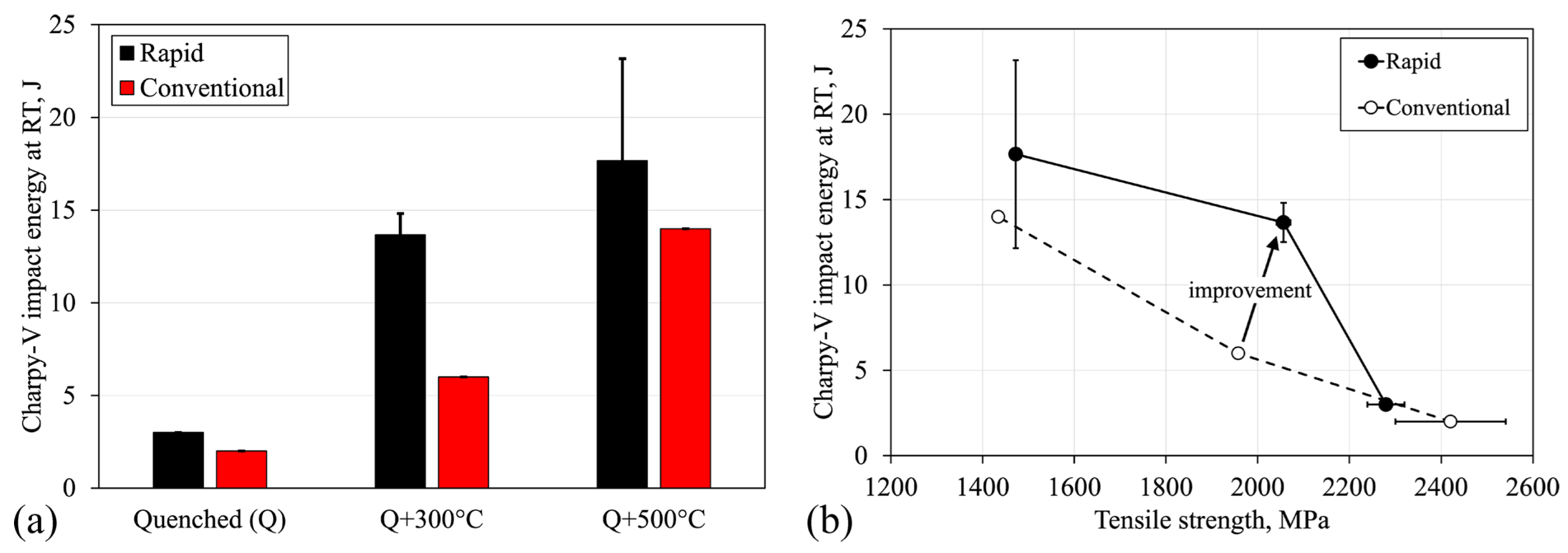

| Material | Rp0.2, MPa | Rm, MPa | A, % | Rp0.2/Rm-Ratio | Rm × A, MPa% | CV at RT, J | Hardness, HV30 (CV) | Hardness, HV30 (GS) |

|---|---|---|---|---|---|---|---|---|

| Q (Rapid) | 1643 | 2280 | 2.5 | 0.72 | 5700 | 3 | 582 ± 4 | 627 ± 13 |

| Q + 300 °C (Rapid) | 1563 | 2056 | 8.8 | 0.76 | 18,093 | 14 | 543 ± 4 | 617 ± 9 |

| Q + 500 °C (Rapid) | 1394 | 1472 | 7.9 | 0.95 | 11,629 | 18 | 431 ± 1 | 456 ± 3 |

| WQ (Conv) | 1597 | 2421 | 2.4 | 0.66 | 5810 | 2 | 680 ± 8 | - |

| WQ + 300 °C (Conv) | 1714 | 1958 | 10.0 | 0.88 | 19,580 | 6 | 544 ± 3 | - |

| WQ + 500 °C (Conv) | 1346 | 1434 | 12.2 | 0.94 | 17,495 | 14 | 409 ± 6 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaijalainen, A.; Haiko, O.; Sadeghpour, S.; Javaheri, V.; Kömi, J. The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals 2024, 14, 60. https://doi.org/10.3390/met14010060

Kaijalainen A, Haiko O, Sadeghpour S, Javaheri V, Kömi J. The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals. 2024; 14(1):60. https://doi.org/10.3390/met14010060

Chicago/Turabian StyleKaijalainen, Antti, Oskari Haiko, Saeed Sadeghpour, Vahid Javaheri, and Jukka Kömi. 2024. "The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel" Metals 14, no. 1: 60. https://doi.org/10.3390/met14010060

APA StyleKaijalainen, A., Haiko, O., Sadeghpour, S., Javaheri, V., & Kömi, J. (2024). The Influence of Rapid Tempering on the Mechanical and Microstructural Characteristics of 51CrV4 Steel. Metals, 14(1), 60. https://doi.org/10.3390/met14010060