Rapid Alloy Development Using Calphad Simulation and Powder Blends in Direct Energy Deposition

Abstract

:1. Introduction

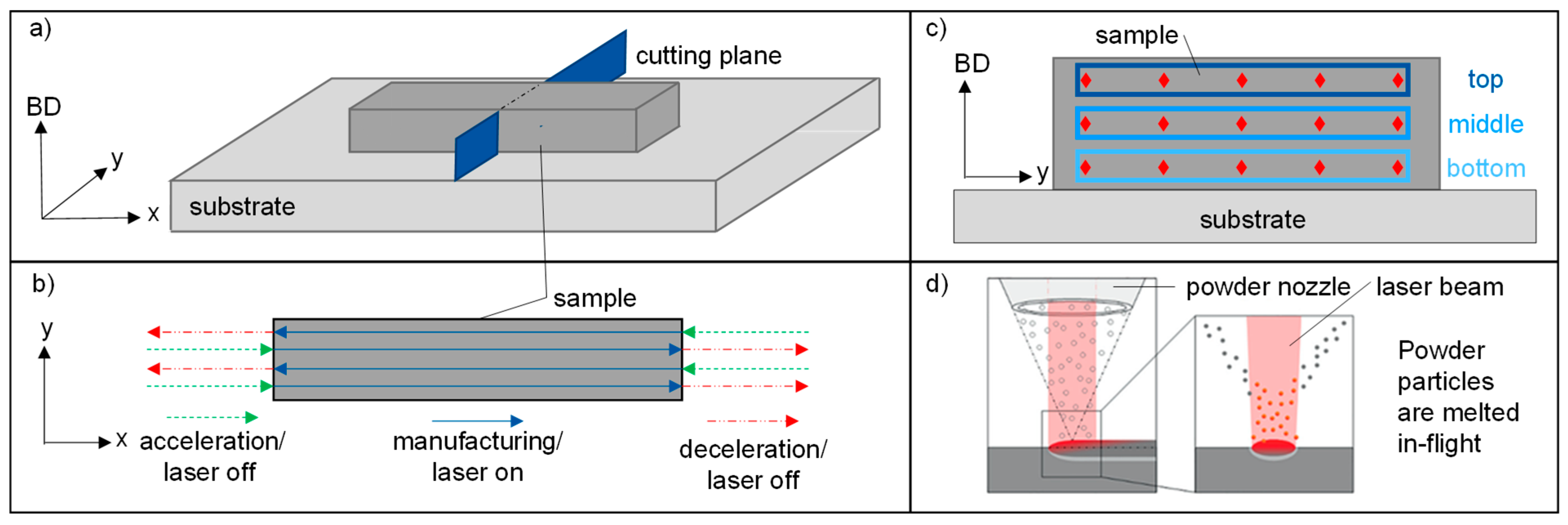

2. Materials and Methods

3. Results

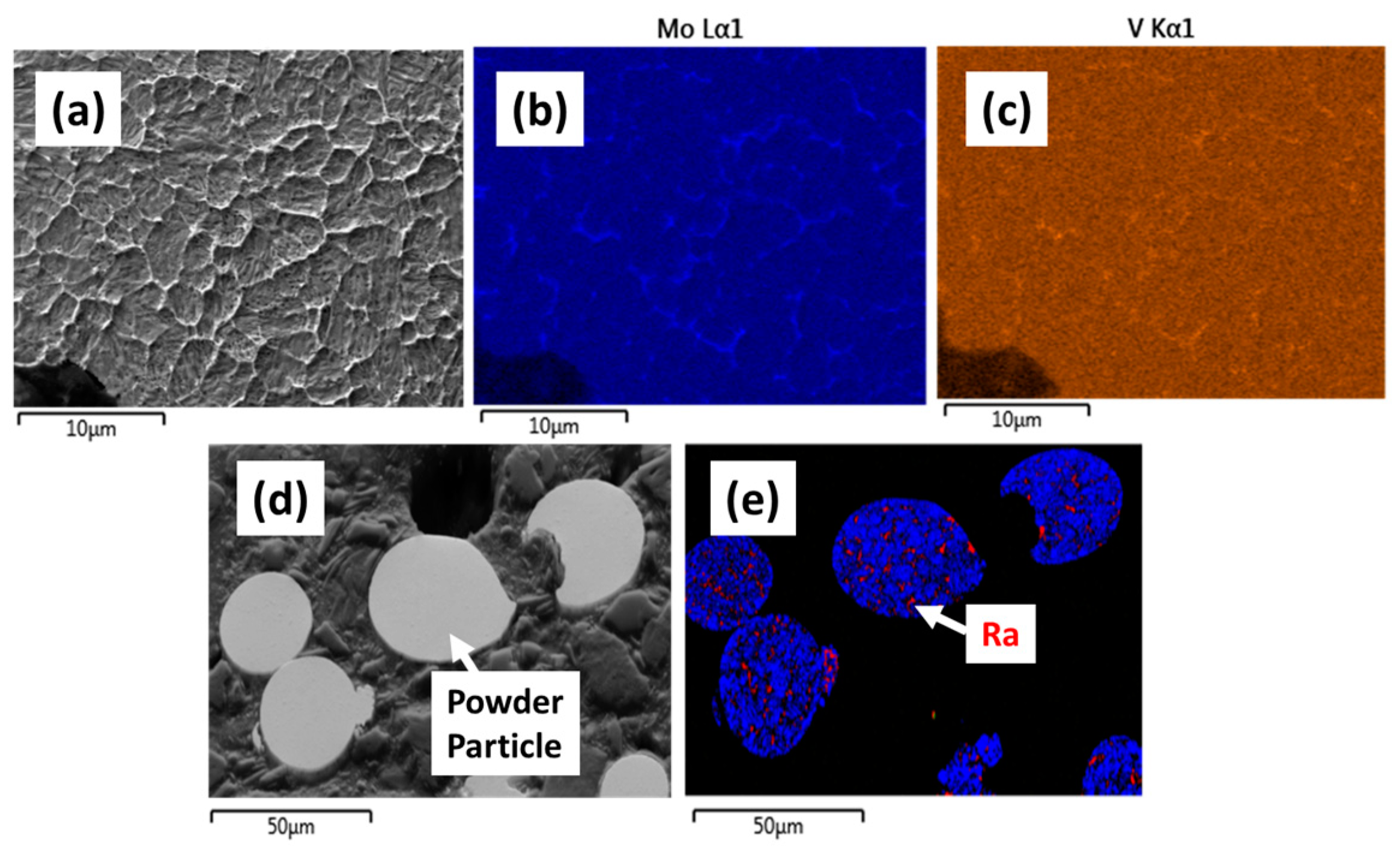

3.1. Powder Particle Characterization

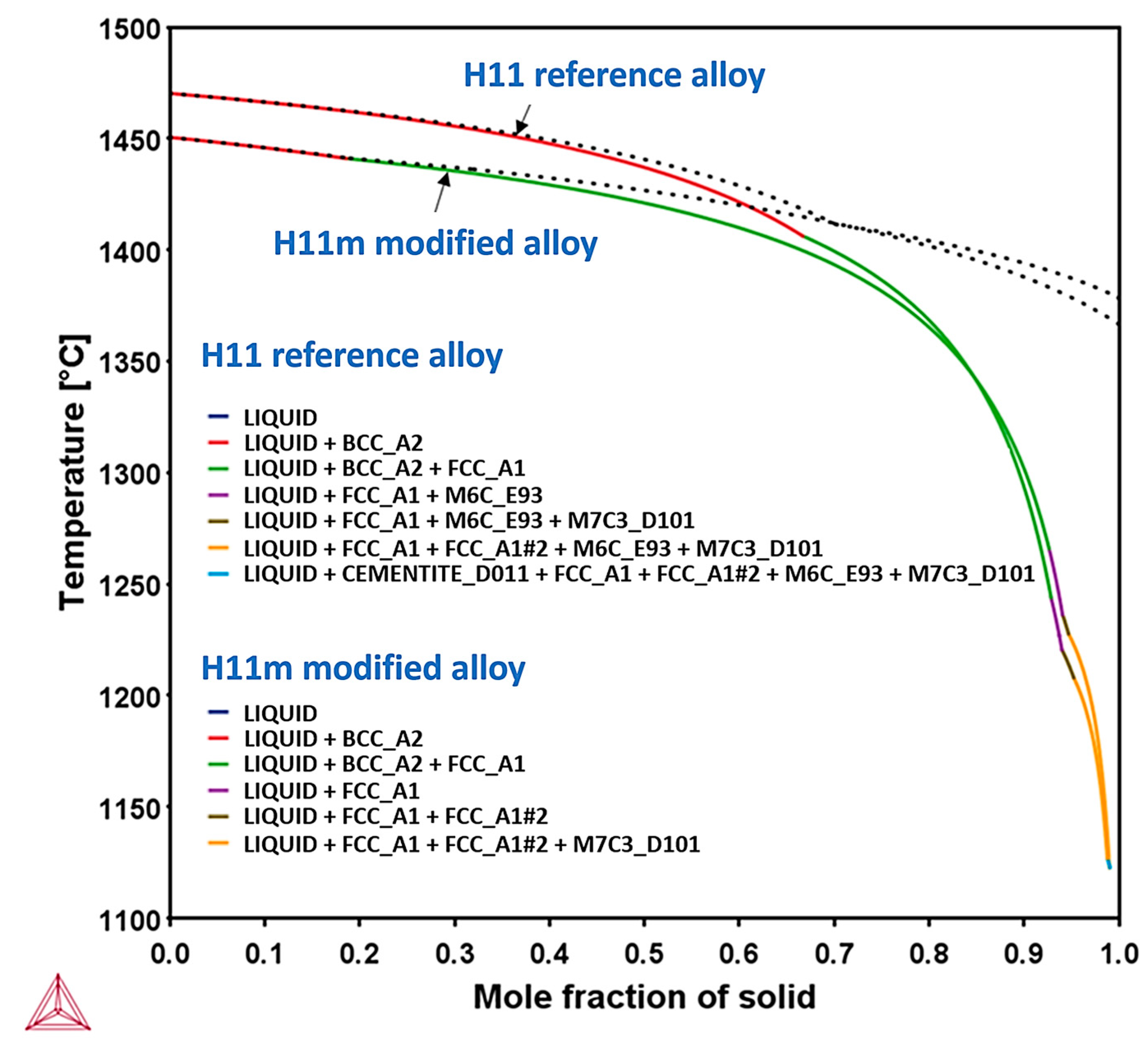

3.2. Scheil-Simulation

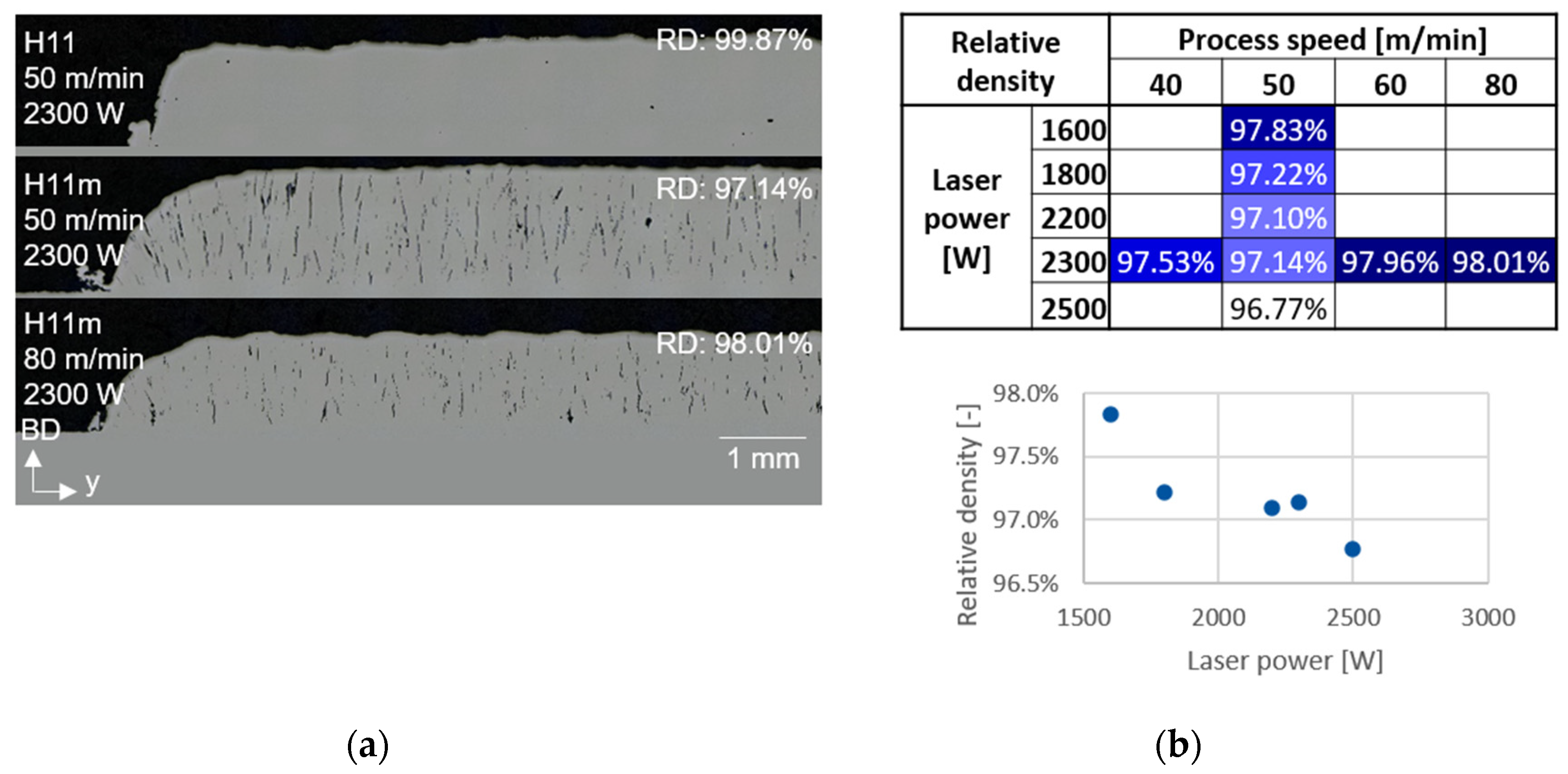

3.3. Process Parameters and Relative Density

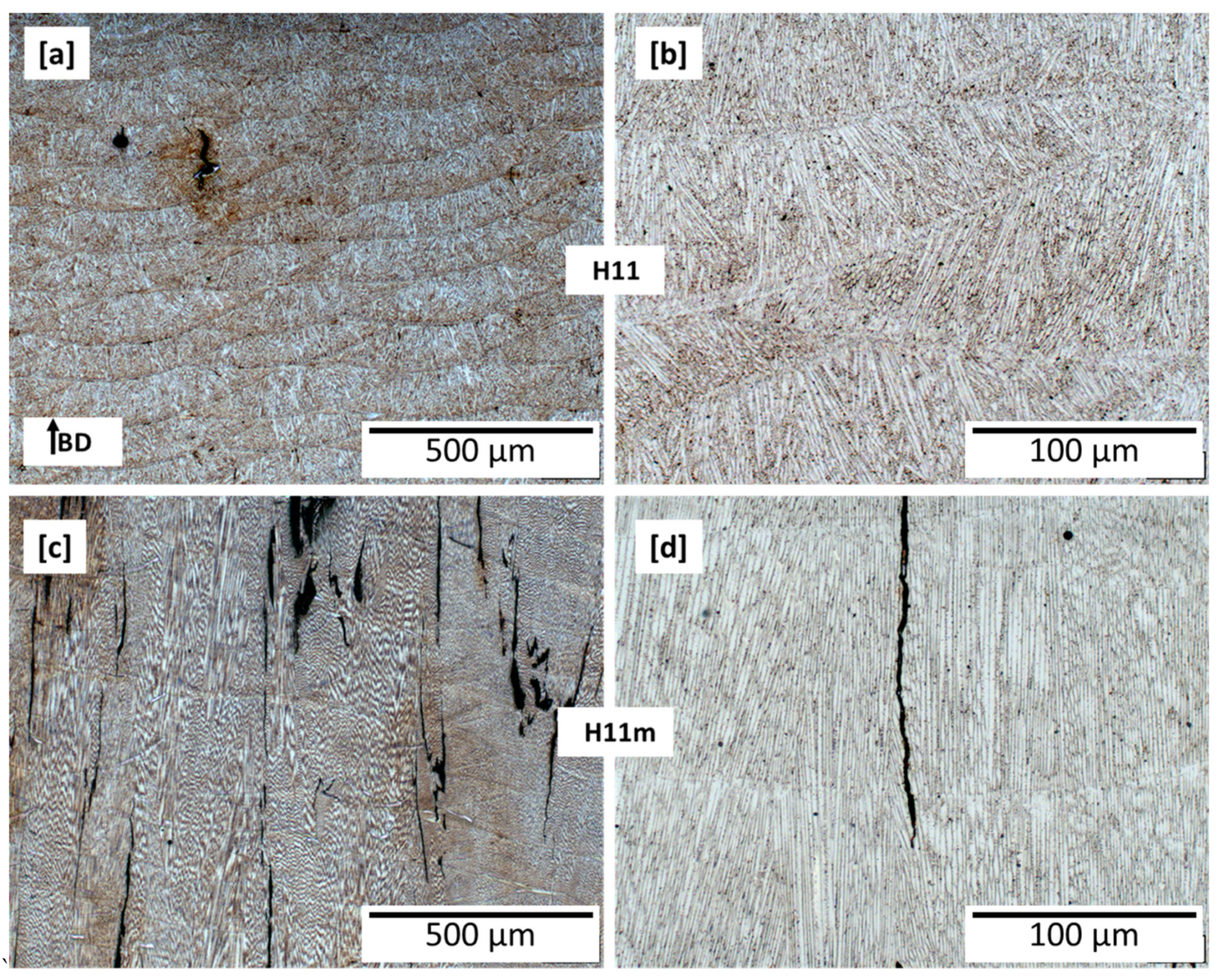

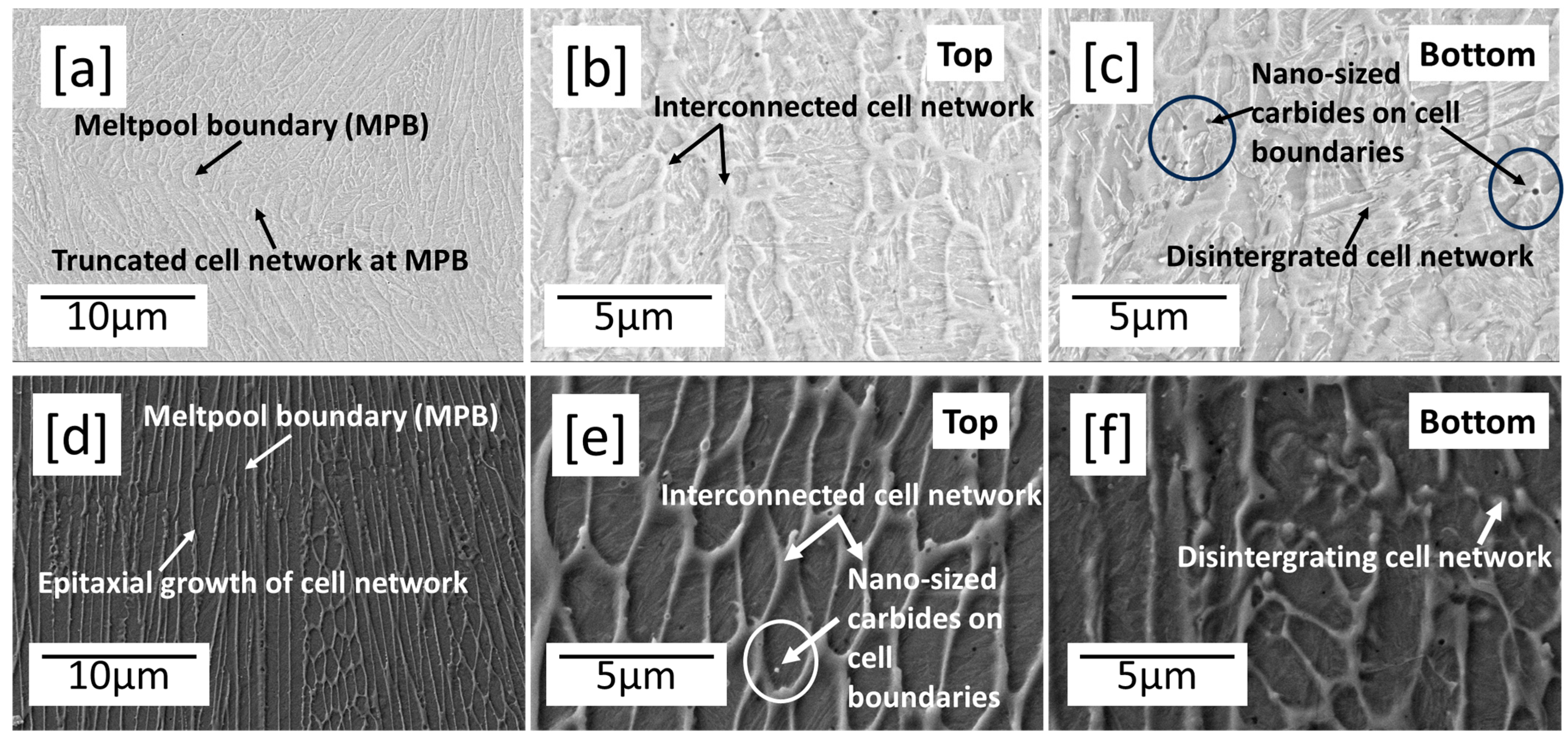

3.4. Microstructure, Segregation and Phase Characterization of HS DED-LB/M-Samples

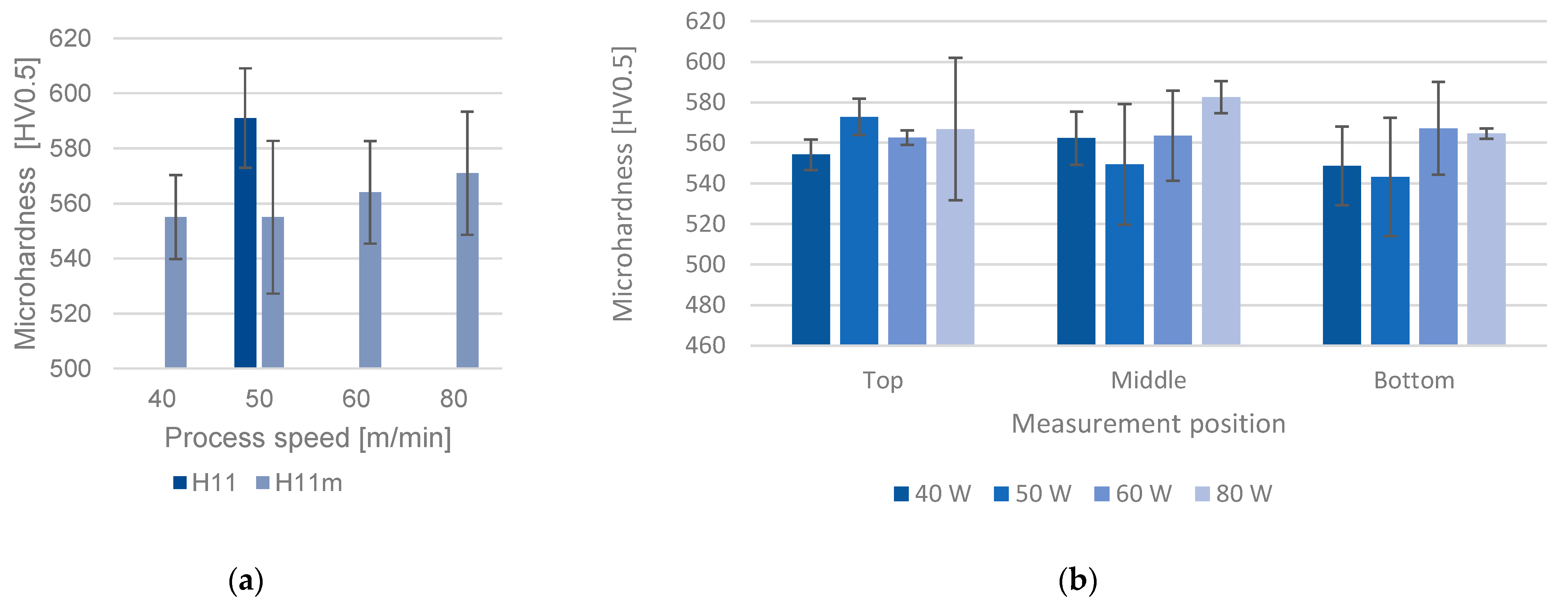

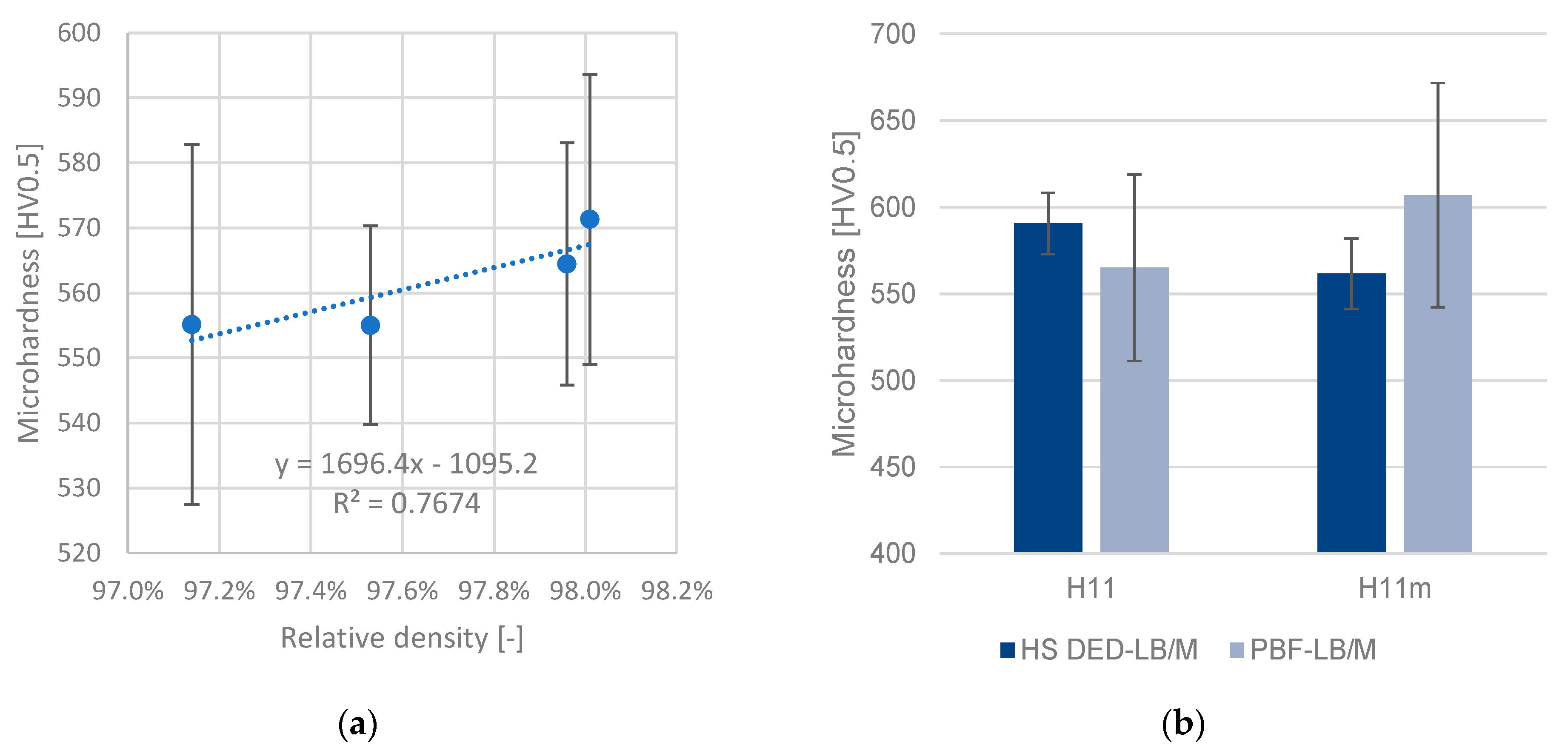

3.5. Microhardness Tests

4. Discussion

4.1. Scheil, Solidification and Powder

4.2. Discussion Microstructure Analysis: Phase Characterization, Segregations, Relative Density

4.3. Microhardness

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, B.; Lu, D.; Zhou, R.; Li, Z.; Guan, J. Preparation and mechanical properties of selective laser melted H13 steel. J. Mater. Res. 2019, 34, 1415–1425. [Google Scholar] [CrossRef]

- ISO/TC 261; Additive Manufacturing: General Principles, Fundamentals and Vocabulary. 2nd ed. ISO: Geneva, Switzerland, 2021; 25.030 01.040.25 (52900:2021).

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Yan, J.J.; Zheng, D.L.; Li, H.X.; Jia, X.; Sun, J.F.; Li, Y.L.; Qian, M.; Yan, M. Selective laser melting of H13: Microstructure and residual stress. J. Mater. Sci. 2017, 52, 12476–12485. [Google Scholar] [CrossRef]

- Jain, A.; Ong, S.P.; Hautier, G.; Chen, W.; Richards, W.D.; Dacek, S.; Cholia, S.; Gunter, D.; Skinner, D.; Ceder, G.; et al. Commentary: The Materials Project: A materials genome approach to accelerating materials innovation. APL Mater. 2013, 1, 011002. [Google Scholar] [CrossRef]

- Lachmayer, R.; Rettschlag, K.; Kaierle, S. Konstruktion für die Additive Fertigung 2020; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Haase, C.; Tang, F.; Wilms, M.B.; Weisheit, A.; Hallstedt, B. Combining thermodynamic modeling and 3D printing of elemental powder blends for high-throughput investigation of high-entropy alloys—Towards rapid alloy screening and design. Mater. Sci. Eng. A 2017, 688, 180–189. [Google Scholar] [CrossRef]

- Raffeis, I.; Adjei-Kyeremeh, F.; Ewald, S.; Schleifenbaum, J.H.; Bührig-Polaczek, A. A Combination of Alloy Modification and Heat Treatment Strategies toward Enhancing the Properties of LPBF Processed Hot Working Tool Steels (HWTS). J. Manuf. Mater. Process 2022, 6, 63. [Google Scholar] [CrossRef]

- Megahed, S.; Koch, R.; Schleifenbaum, J.H. Laser Powder Bed Fusion Tool Repair: Statistical Analysis of 1.2343/H11 Tool Steel Process Parameters and Microstructural Analysis of the Repair Interface. J. Manuf. Mater. Process. 2022, 6, 139. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Li, D.; Xie, M.; Kollo, L.; Luo, Z.; Zhang, W.; Prashanth, K.G. Comparison of additively manufacturing samples fabricated from pre-alloyed and mechanically mixed powders. J. Alloys Compd. 2020, 830, 154603. [Google Scholar] [CrossRef]

- Koptyug, A.; Popov, V.V.; Botero Vega, C.A.; Jiménez-Piqué, E.; Katz-Demyanetz, A.; Rännar, L.-E.; Bäckström, M. Compositionally-tailored steel-based materials manufactured by electron beam melting using blended pre-alloyed powders. Mater. Sci. Eng. A 2020, 771, 138587. [Google Scholar] [CrossRef]

- Garrard, R.; Lynch, D.; Carter, L.N.; Adkins, N.J.; Gie, R.; Chouteau, E.; Pambaguian, L.; Attallah, M.M. Comparison of LPBF processing of AlSi40 alloy using blended and pre-alloyed powder. Addit. Manuf. Lett. 2022, 2, 100038. [Google Scholar] [CrossRef]

- Ewald, S.; Kies, F.; Hermsen, S.; Voshage, M.; Haase, C.; Schleifenbaum, J.H. Rapid Alloy Development of Extremely High-Alloyed Metals Using Powder Blends in Laser Powder Bed Fusion. Materials 2019, 12, 1706. [Google Scholar] [CrossRef] [PubMed]

- Marchese, G.; Garmendia Colera, X.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition. Adv. Eng. Mater. 2017, 19, 1600635. [Google Scholar] [CrossRef]

- Ewald, S.; Schaukellis, M.; Koehnen, P.; Schleifenbaum, J.H. Laser Powder Bed Fusion of Advanced High-Strength Steels—Modification of Deformation Mechanisms by Increasing Stacking Fault Energy. Berg. Huettenmaenn Monatsh 2019, 164, 127–132. [Google Scholar] [CrossRef]

- Schneck, M.; Horn, M.; Schmitt, M.; Seidel, C.; Schlick, G.; Reinhart, G. Review on additive hybrid- and multi-material-manufacturing of metals by powder bed fusion: State of technology and development potential. Prog. Addit. Manuf. 2021, 6, 881–894. [Google Scholar] [CrossRef]

- Koß, S.; Ewald, S.; Bold, M.-N.; Koch, J.H.; Voshage, M.; Ziegler, S.; Schleifenbaum, J.H. Comparison of the EHLA and LPBF Process in Context of New Alloy Design Methods for LPBF. Adv. Mater. Res. 2021, 1161, 13–25. [Google Scholar] [CrossRef]

- Kolli, S.; Javaheri, V.; Ohligschläger, T.; Kömi, J.; Porter, D. The importance of steel chemistry and thermal history on the sensitization behavior in austenitic stainless steels: Experimental and modeling assessment. Mater. Today Commun. 2020, 24, 101088. [Google Scholar] [CrossRef]

- Costa e Silva, A. Challenges and opportunities in thermodynamic and kinetic modeling microalloyed HSLA steels using computational thermodynamics. Calphad 2020, 68, 101720. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Park, S.; Huynh, T.; Mehta, A.; Thapliyal, S.; Mishra, R.S.; Sohn, Y. Elimination of extraordinarily high cracking susceptibility of aluminum alloy fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2022, 103, 50–58. [Google Scholar] [CrossRef]

- Vecchio, K.S.; Dippo, O.F.; Kaufmann, K.R.; Liu, X. High-throughput rapid experimental alloy development (HT-READ). Acta Mater. 2021, 221, 117352. [Google Scholar] [CrossRef]

- Steen, W.M.; Vilar, R.M.; Watkins, K.G.; Ferreira, M.G.S.; Carvalho, P.; Sexton, C.L.; Pontinha, M.; McMahon, M. Alloy System Analysis by Laser Cladding; AIP Publishing: Melville, NY, USA, 1992; pp. 278–287. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018, 20, 1700952. [Google Scholar] [CrossRef]

- Gokuldoss, P.K. Design of next-generation alloys for additive manufacturing. Mater. Des. Process. Commun. 2019, 1, 34. [Google Scholar] [CrossRef]

- Boyce, B.L.; Uchic, M.D. Progress toward autonomous experimental systems for alloy development. MRS Bull. 2019, 44, 273–280. [Google Scholar] [CrossRef]

- Bold, M.-N.; Schmitt, N.; Schleifenbaum, J.H. Application of the 3D-EHLA Process for Agile Alloy Development; Universitätsbibliothek der RWTH Aachen: Aachen, Germany, 2022. [Google Scholar] [CrossRef]

- Li, T.; Zhang, L.; Chen, G.; Pirch, N.; Schopphoven, T.; Gasser, A.; Poprawe, R. A combined heat source model for the prediction of residual stress post extreme high-speed laser material deposition. J. Manuf. Process. 2022, 78, 265–277. [Google Scholar] [CrossRef]

- Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Suwanpinij, P.; Ewald, S.; Bührig-Polazcek, A. Investigation of the Lithium-Containing Aluminum Copper Alloy (AA2099) for the Laser Powder Bed Fusion Process [L-PBF]: Effects of Process Parameters on Cracks, Porosity, and Microhardness. JOM 2019, 71, 1543–1553. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Parvez, M.M.; Liou, F. A Review on Metallic Alloys Fabrication Using Elemental Powder Blends by Laser Powder Directed Energy Deposition Process. Materials 2020, 13, 3562. [Google Scholar] [CrossRef] [PubMed]

- Petschow, U.; Ferdinand, J.P.; Dickel, S.; Flämig, H.; Steinfeldt, M.; Worobei, A. Dezentrale Produktion, 3D-Druck und Nachhaltigkeit: Trajektorien und Potenziale Innovativer Wertschöpfungsmuster Zwischen Maker-Bewegung und Industrie 4.0; neue Ausg; Institut für Ökologische Wirtschaftsforschung Berlin: Berlin, Germany, 2014. [Google Scholar]

- Wang, K.; Du, D.; Liu, G.; Pu, Z.; Chang, B.; Ju, J. High-temperature oxidation behaviour of high chromium superalloys additively manufactured by conventional or extreme high-speed laser metal deposition. Corros. Sci. 2020, 176, 108922. [Google Scholar] [CrossRef]

- Wang, K.; Du, D.; Liu, G.; Pu, Z.; Chang, B.; Ju, J. A study on the additive manufacturing of a high chromium Nickel-based superalloy by extreme high-speed laser metal deposition. Opt. Laser Technol. 2021, 133, 106504. [Google Scholar] [CrossRef]

- Fang, P.; Xu, Y.; Li, X.; Chen, Y. Influence of Atomizing Gas and Cooling Rate on Solidification Characterization of Nickel-based Superalloy Powders. Rare Met. Mater. Eng. 2018, 47, 423–430. [Google Scholar] [CrossRef]

- Mohammadpour, P.; Yuan, H.; Phillion, A.B. Microstructure evolution of Inconel 625 alloy during single-track Laser Powder Bed Fusion. Addit. Manuf. 2022, 55, 102824. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Knoll, H.; Ocylok, S.; Weisheit, A.; Springer, H.; Jägle, E.; Raabe, D. Combinatorial Alloy Design by Laser Additive Manufacturing. Steel Res. Int. 2017, 88, 1600416. [Google Scholar] [CrossRef]

- Schopphoven, T. Experimental and Model-Theoretical Investigations on Extreme High-Speed Laser Material Deposition; Fraunhofer Verlag: Aachen, Germany, 2020. [Google Scholar]

- Khorasani, M.; Ghasemi, A.; Leary, M.; Cordova, L.; Sharabian, E.; Farabi, E.; Gibson, I.; Brandt, M.; Rolfe, B. A comprehensive study on meltpool depth in laser-based powder bed fusion of Inconel 718. Int. J. Adv. Manuf. Technol. 2022, 120, 2345–2362. [Google Scholar] [CrossRef]

| HWTS | C | Si | Cr | Mo | Mn | V | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| H11 (reference) | 0.41 | 2.07 | 6.14 | 1.49 | <0.01 | 0.46 | - | Bal. |

| H11m (modified) | 0.38 | 2.06 | 5.61 | 1.19 | 1.11 | 0.41 | 3.07 | Bal. |

| Process Speed [m/min] | Laser Power [W] | Alloy |

|---|---|---|

| 50 | 2300 | H11 |

| 40 | 2300 | H11m |

| 50 | 1600 | H11m |

| 50 | 1800 | H11m |

| 50 | 2200 | H11m |

| 50 | 2300 | H11m |

| 50 | 2500 | H11m |

| 60 | 2300 | H11m |

| 80 | 2300 | H11m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bold, M.-N.; Raffeis, I.; Adjei-Kyeremeh, F.; Schleifenbaum, J.H.; Bührig-Polaczek, A. Rapid Alloy Development Using Calphad Simulation and Powder Blends in Direct Energy Deposition. Metals 2024, 14, 79. https://doi.org/10.3390/met14010079

Bold M-N, Raffeis I, Adjei-Kyeremeh F, Schleifenbaum JH, Bührig-Polaczek A. Rapid Alloy Development Using Calphad Simulation and Powder Blends in Direct Energy Deposition. Metals. 2024; 14(1):79. https://doi.org/10.3390/met14010079

Chicago/Turabian StyleBold, Marie-Noemi, Iris Raffeis, Frank Adjei-Kyeremeh, Johannes Henrich Schleifenbaum, and Andreas Bührig-Polaczek. 2024. "Rapid Alloy Development Using Calphad Simulation and Powder Blends in Direct Energy Deposition" Metals 14, no. 1: 79. https://doi.org/10.3390/met14010079

APA StyleBold, M.-N., Raffeis, I., Adjei-Kyeremeh, F., Schleifenbaum, J. H., & Bührig-Polaczek, A. (2024). Rapid Alloy Development Using Calphad Simulation and Powder Blends in Direct Energy Deposition. Metals, 14(1), 79. https://doi.org/10.3390/met14010079