The Potential of Cast Stock for the Forging of Aluminum Components within the Automotive Industry

Abstract

1. Introduction

2. Materials and Methods

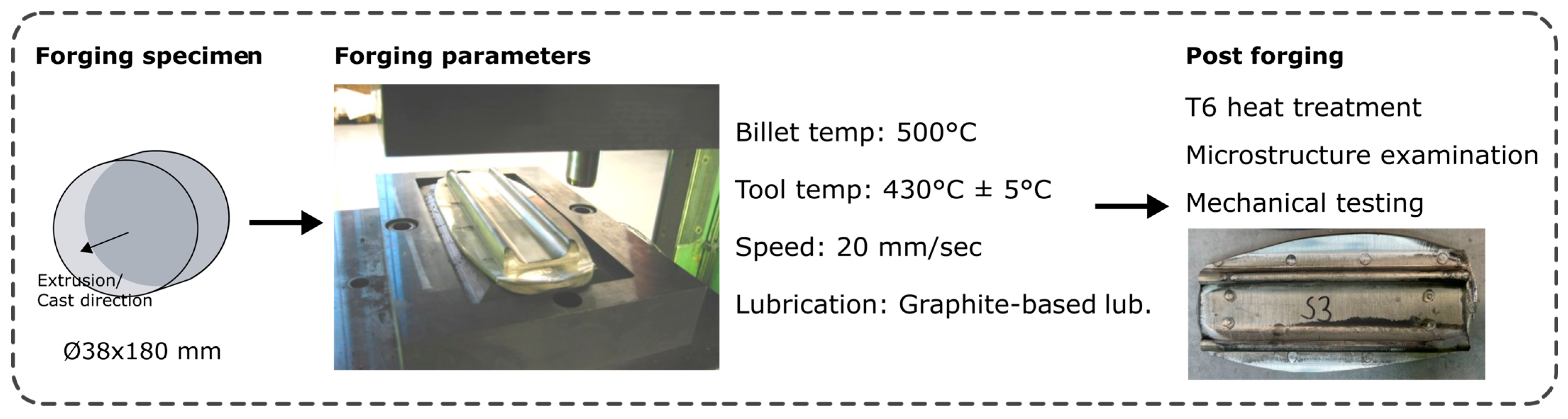

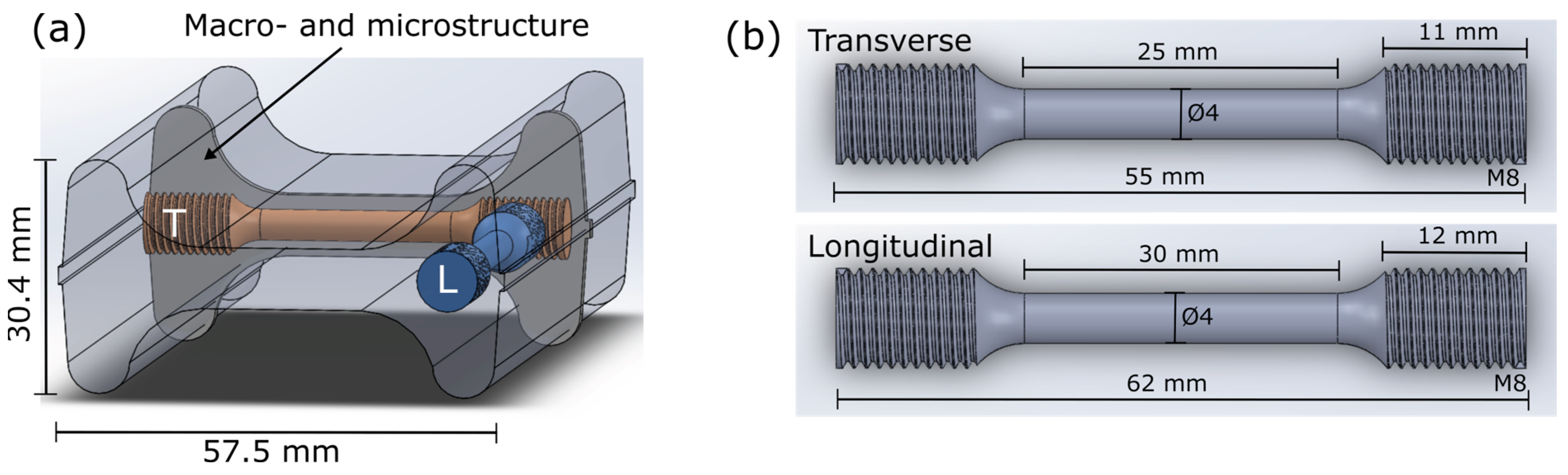

2.1. Generic Forging Trials

- As extruded: material provided by Raufoss Technology from their standard extruded forging stock.

- As cast and homogenized: 90 mm LPC material was provided by Hydro Aluminium Primary Metal, produced at the Husnes plant. Homogenization was performed at 550 °C for 2 h, followed by rapid cooling in air.

- Pre-formed cast: in this case, the homogenized LPC material was pre-formed via CWR by Raufoss Technology. The CWR component was taken out from the production line after CWR and cooled down to room temperature prior to extracting the required specimens for the forging trial.

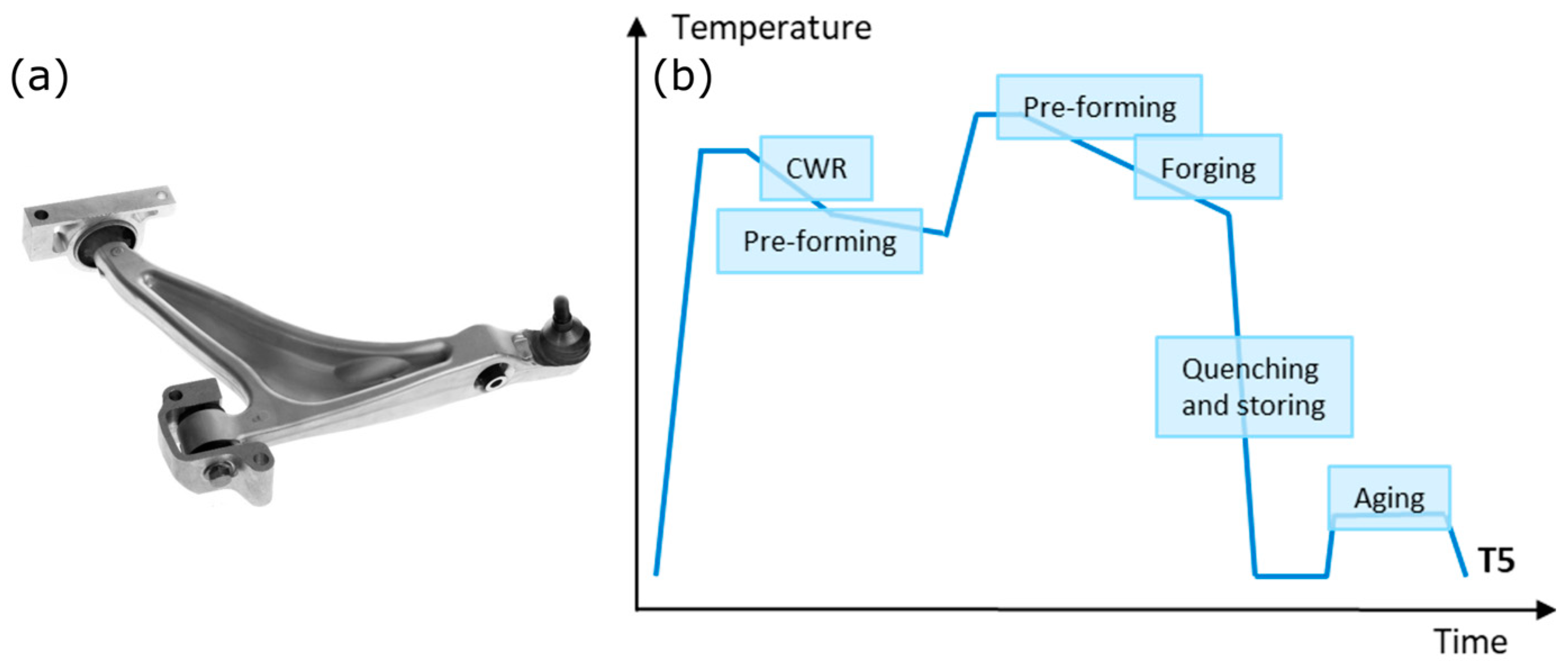

2.2. Full-Scale Production Trials of FLCA

3. Results

3.1. Generic Forging Trials

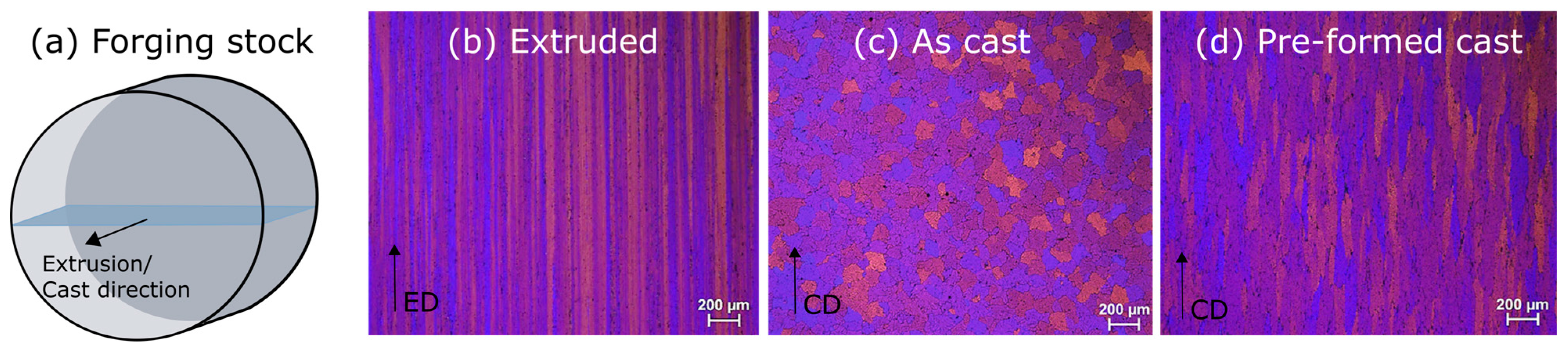

3.1.1. Initial Microstructure of the Forging Stocks

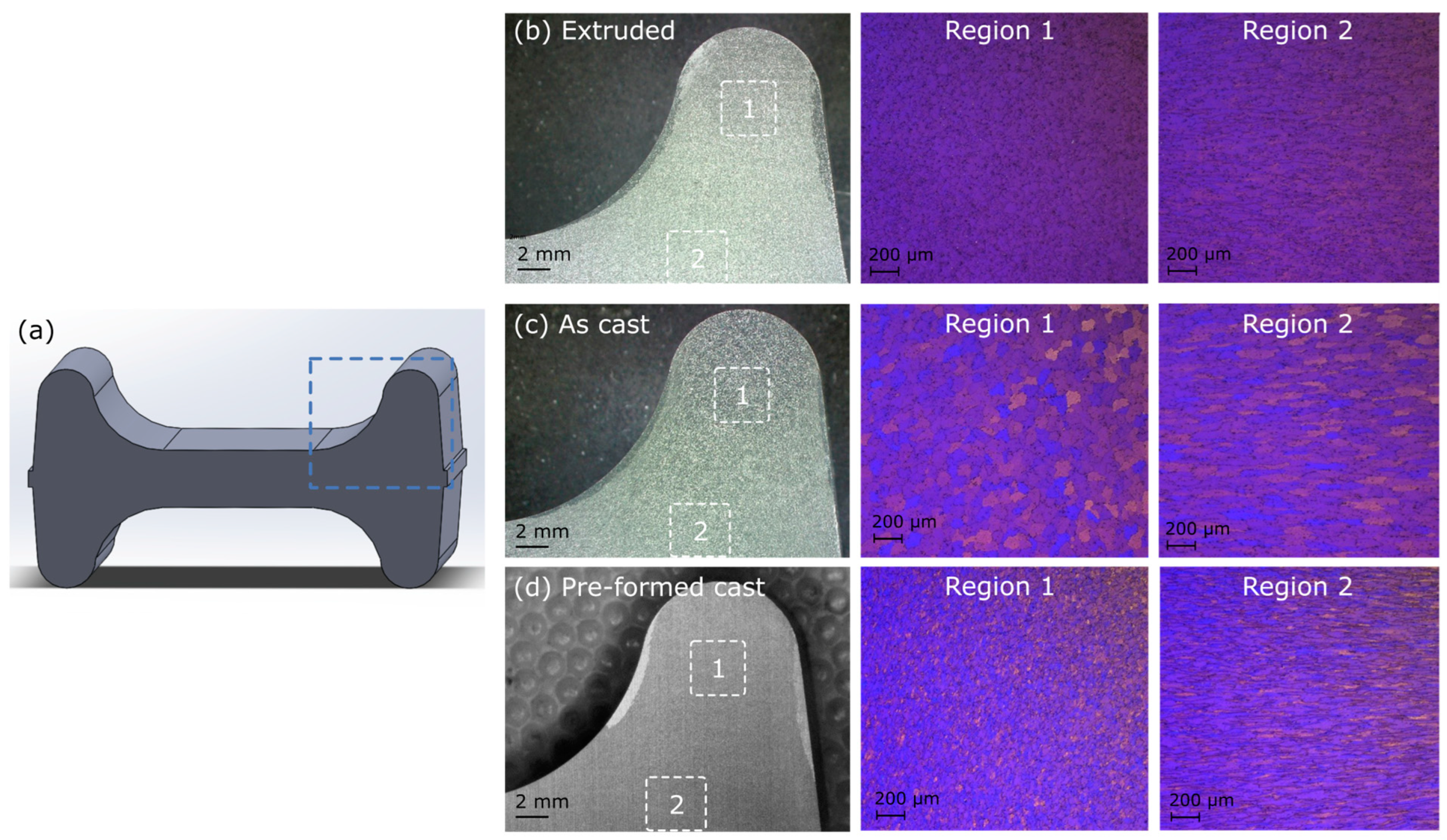

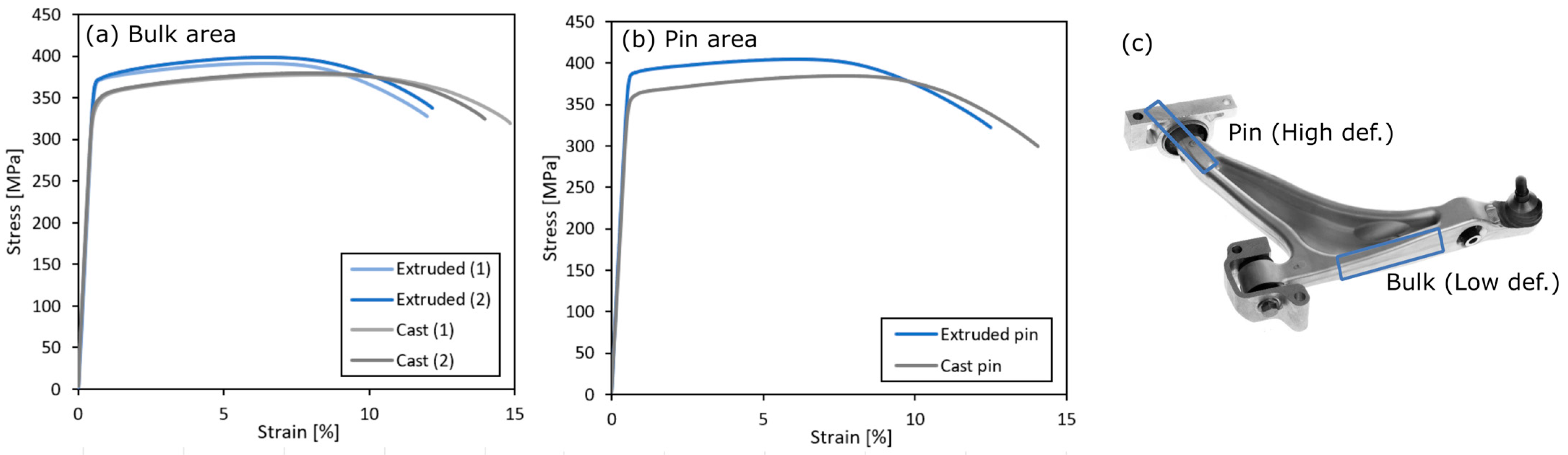

3.1.2. Microstructure and Mechanical Properties after Forging

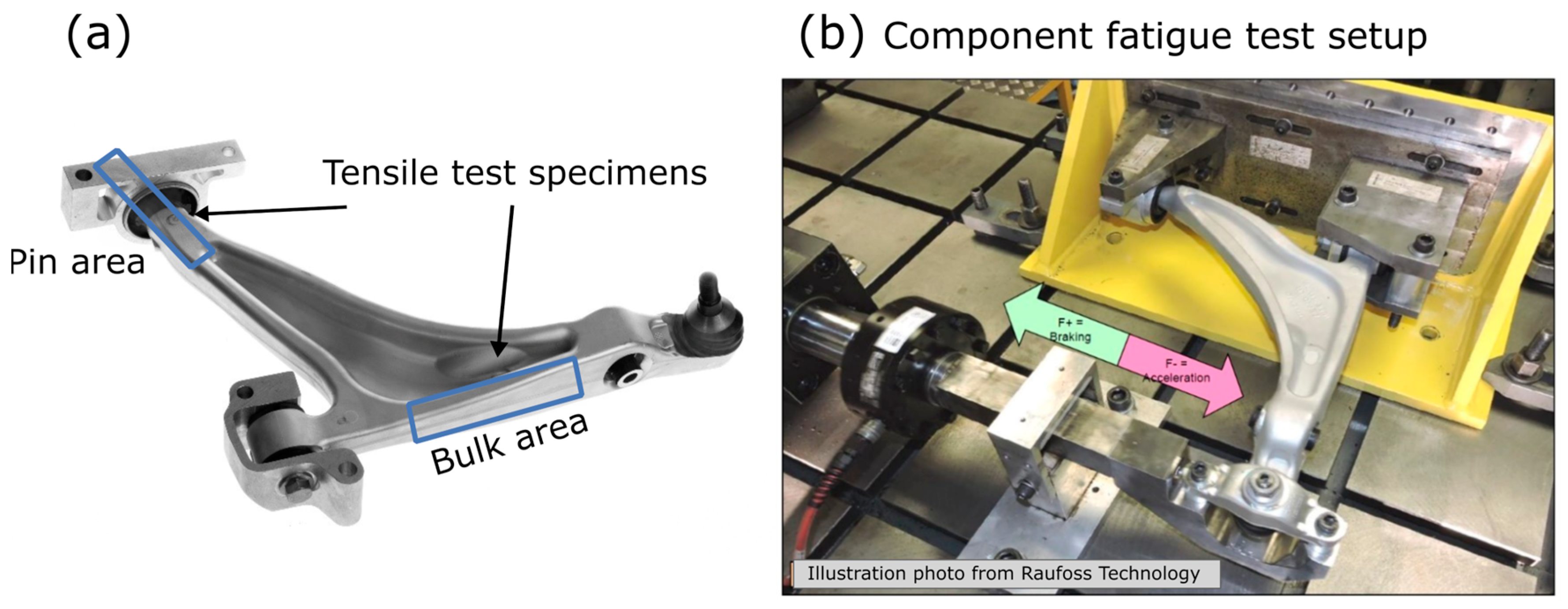

3.2. Full-Scale Production Trials of FLCA

4. Discussion

5. Conclusions

- The microstructural investigations revealed a reduced surface grain growth in the forged components produced from cast material, enhancing product reliability and robustness against pauses in a production line.

- The mechanical properties of the cast material were found to increase with the increasing degree of plastic deformation, making the LPC material well suited for the forging of complex components where the production process includes pre-forming. The variation between obtained strength in T6 temper in the generic and the full-scale industrial production trials emphasizes the influence of product design, i.e., differences in introduced deformation on the final properties.

- Directly replacing extruded forging stock with cast in the FLCA production yields comparable mechanical properties: a slightly lower strength, but with higher ductility in T5 temper. In T6 temper the properties of the cast FLCA were in line with the extruded material. Optimizing the thermomechanical process further is required to achieve the desired properties in T5 temper.

- The high ductility combined with the desirable microstructure promoted a high structural integrity and ensured a high structural integrity, as evident from FLCA fatigue trails.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ducker Worldwide. Aluminium Content in European Passenger Cars. Public Summary. European Aluminium Association. 2019. Available online: https://european-aluminium.eu/wp-content/uploads/2022/10/aluminum-content-in-european-cars_european-aluminium_public-summary_101019-1.pdf (accessed on 13 November 2023).

- Fuh, Y.K.; Shih, J.K.; Saputro, I.E.; Chen, C.P.; Huang, C.F.; Ku, H.Y.; Chan, C. Preform design with increased materials utilization and processing map analysis for aluminum hot forging process. J. Manuf. Process 2023, 90, 14–27. [Google Scholar] [CrossRef]

- Chen, X.; Shu, X.; Wang, D.; Xu, S.; Xiang, W. Multi-Step Forming Simulation and Quality Control of Aluminum Alloy Automobile Rear Upper Control Arm. Materials 2022, 15, 3610. [Google Scholar] [CrossRef]

- Kuhlman, G.W. Forging of Aluminum Alloys. In ASM Handbook Volume 14A: Metalworking: Bulk Forming; ASM International: New York, NY, USA, 2005; pp. 299–312. [Google Scholar] [CrossRef]

- Tunc, O.; Kacar, I.; Ozturk, F. Investigation of forging performance for AA6082. Int. J. Adv. Manuf. Technol. 2021, 117, 1645–1661. [Google Scholar] [CrossRef]

- Płonka, B.; Kłyszewski, A.; Senderski, J.; Lech-Grega, M. Application of Al alloys, in the form of cast billet, as stock material for the die forging in automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 149–156. [Google Scholar] [CrossRef]

- Birol, Y.; Gokcil, E.; Guvenc, M.A.; Akdi, S. Processing of high strength EN AW 6082 forgings without a solution heat treatment. Mater. Sci. Eng. A 2016, 674, 25–32. [Google Scholar] [CrossRef]

- Birol, Y.; Ilgaz, O. Effect of cast and extruded stock on grain structure of EN AW 6082 alloy forgings. Mater. Sci. Technol. 2014, 30, 860–866. [Google Scholar] [CrossRef]

- Sandvik, J.; Jensrud, O.; Gulbrandsen-Dahl, S.; Hallem, H.; Moe, J.I. Through Process Prevention of Recrystallization in Hot Formed Aluminium Structural Car Components. Mater. Sci. Forum 2010, 638–642, 315–320. [Google Scholar] [CrossRef]

- Zhao, N.; Ma, H.; Sun, Q.; Hu, Z.; Yan, Y.; Chen, T.; Hua, L. Microstructural evolutions and mechanical properties of 6082 aluminum alloy part produced by a solution-forging integrated process. J. Mater. Process Technol. 2022, 308, 117715. [Google Scholar] [CrossRef]

- Očenášek, V.; Sedláček, P. The effect of surface recrystallized layers on properties of extrusions and forgings from high strength aluminium alloys. In Conference Proceedings—Metal 2011; Tanger, Ltd.: Brno, Czech Republic, 2011. [Google Scholar]

- Pedersen, K.; Jensrud, O.; Moe, J.I.; Roven, H.J. Fatigue, fracture and microstructure relationships of an aluminium automobile component. In ECF 8 Fracture Behaviour and Design of Materials and Structures; Gruppo Italiano Frattura: Turin, Italy, 1990. [Google Scholar]

- Gokcil, E.; Akdi, S.; Birol, Y. A novel processing route for the manufacture of EN AW 6082 forged components. Mater. Res. Innov. 2015, 19, S10-311–S10-314. [Google Scholar] [CrossRef]

- Hua, L.; Yuan, P.; Zhao, N.; Hu, Z.; Ma, H. Microstructure and mechanical properties of 6082 aluminum alloy processed by preaging and hot forging. Trans. Nonferrous Met. Soc. 2022, 32, 790–800. [Google Scholar] [CrossRef]

- Hu, Z.; Zheng, J.; Pang, Q.; Sun, Q.; Zhao, N. Influence of strain rates and aging time on microstructure and hardness of integrally compressed 6082 aluminum alloy. J. Mater. Res. Technol. 2023, 27, 826–838. [Google Scholar] [CrossRef]

- Tundal, U.; Tveito, K.O.; Berg, S.S.; Moen, L.; Boge, M. Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock. Light Met. Age 2020, 12, 24–29. [Google Scholar]

- Bobba, S.; Roa, M.S.; Raj, P. Experimental Analysis on the Forging Process of Al 6061 and Al 7075 Aluminium Alloys. SunText Rev. Mater. Sci. 2021, 2, 111. [Google Scholar] [CrossRef]

- Birol, Y.; Ilgaz, O.; Akdi, S.; Unuvar, E. Comparison of Cast and Extruded Stock for the Forging of AA6082 Alloy Suspension Parts. Adv. Mater. Res. 2014, 939, 299–304. [Google Scholar] [CrossRef]

- Chang, Y.L.; Hung, F.Y.; Lui, T.S. Study of microstructure and tensile properties of infrared-heat-treated cast-forged 6082 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 173–179. [Google Scholar] [CrossRef]

- Hosoda, N.; Nakai, M.; Eto, T. The Effect of Microstructure on Mechanical Properties of Forged 6061 Aluminum Alloy. In Proceedings of the 9th International Conference on Aluminium Alloys (2004), Brisbane, Australia, 2–5 August 2004. [Google Scholar]

- Nakai, M.; Itoh, G. The Effect of Microstructure on Mechanical Properties of Forged 6061 Aluminum Alloy. Mater. Trans. 2014, 55, 114–119. [Google Scholar] [CrossRef]

- Hydro. HyForgeTM—High-Quality Forging Material from Hydro. 2023. Available online: https://www.hydro.com/en/aluminium/products/casthouse-products/hyforge/ (accessed on 1 October 2023).

- Nunes, H.; Emadinia, O.; Vieira, M.F.; Reis, A. Low- and High-Pressure Casting Aluminum Alloys: A Review. In Recent Advancements in Aluminum Alloys; IntechOpen: London, UK, 2023; Available online: https://www.intechopen.com/online-first/85913 (accessed on 30 December 2023).

- Håkonsen, A.; Ledal, R.; Hafsås, E.; Røyset, J. Game Changer for Extrusion Billet Surface Quality. In Proceedings of the Eleventh International Aluminium Extrusion Technology Seminar (ET’16), Chicago, IL, USA, 2–6 May 2016. [Google Scholar]

- NS-EN ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature, International Organization for Standardization. ISO: Geneva Switzerland, 2019.

- Arnoldt, A.R.; Schiffl, A.; Höppel, H.W.; Österreicher, J.A. Influence of different homogenization heat treatments on the microstructure and hot flow stress of the aluminum alloy AA6082. Mater. Charact. 2022, 9, 112129. [Google Scholar] [CrossRef]

- Tundal, U.; Tjøtta, S.; Li, J.; Dumoulin, S.; Arbo, S.M.; Jensrud, O. The potential for Cast Aluminum Forge Stock to Produce High-Performance Automotive Suspension Components. Light Met. Age 2022, 12, 24–28. [Google Scholar]

- Gupta, A.K.; Lloyd, D.J.; Court, S.A. Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater. Sci. Eng. A 2001, 316, 11–17. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al–Mg–Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Xu, X.; Pan, D.; Jiang, W.; Chong, X. Simultaneously Enhanced Strength and Ductility of Al–Mg–Si Alloys during Aging Process Induced by Electro-Pulsing Treatment. Materials 2019, 12, 1383. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Zheng, J.H.; Yardley, V.A.; Shi, Z.; Lin, J. A Review of Microstructural Evolution and Modelling of Aluminium Alloys under Hot Forming Conditions. Metals 2020, 10, 1516. [Google Scholar] [CrossRef]

| Identification | Position/Direction | Rp0.2 | Rm | A | Z 1 |

|---|---|---|---|---|---|

| MPa | MPa | % | % | ||

| Extruded–T6 | Longitudinal | 391.5 ± 0.5 | 406.5 ± 0.5 | 10.0 ± 0.3 | 42.0 ± 0.0 |

| Cast–T6 | Longitudinal | 356.5 ± 0.5 | 376.5 ± 0.5 | 9.7 ± 0.1 | 28.0 ± 5.0 |

| Pre-formed cast–T6 | Longitudinal | 344.8 ± 1.0 | 362.5 ± 0.1 | 11.5 ± 0.6 | 51.5 ± 1.5 |

| Extruded–T6 | Transverse | 363.3 ± 2.6 | 382.0 ± 2.9 | 8.9 ± 0.1 | 45.0 ± 0.8 |

| Cast–T6 | Transverse | 370.3 ± 0.9 | 393.3 ± 1.2 | 12.2 ± 0.8 | 48.7 ± 0.9 |

| Pre-formed cast–T6 | Transverse | 357.5 ± 2.2 | 377.7 ± 2.0 | 12.2 ± 0.3 | 50.0 ± 2.9 |

| Identification | Position | Rp0.2 | Rm | A | Z 1 |

|---|---|---|---|---|---|

| MPa | MPa | % | % | ||

| Extruded–T5, Reference from current production | Bulk area (standard) | 376.3 ± 4.0 | 399.2 ± 5.5 | 12.1 ± 0.9 | 36.8 ± 1.2 |

| Pin area | 388 | 405 | 12 | 38 | |

| Cast–T5 | Bulk area (standard) | 345.5 ± 2.5 | 378.1 ± 1 | 13.7 ± 0.8 | 42.4 ± 3.0 |

| Pin area | 369.8 ± 6.5 | 381.3 ± 6.8 | 14.1 ± 0.7 | 50.3 ± 2.9 | |

| Cast–T6 | Bulk area (standard) | 376.0 ± 2.0 | 403.5 ± 1.5 | 13.1 ± 1.2 | 45.0 ± 2.0 |

| Identification | Number of Cycles before Failure |

|---|---|

| Requirement | 18,040 |

| Extruded T5–reference average from current production | 141,466 |

| Cast T5–component (1) | 162,360 |

| Cast T5–component (2) | 135,745 |

| Cast T5–component (3) | 139,794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arbo, S.M.; Tjøtta, S.; Boge, M.H.; Tundal, U.; Li, J.; Dumoulin, S.; Jensrud, O. The Potential of Cast Stock for the Forging of Aluminum Components within the Automotive Industry. Metals 2024, 14, 90. https://doi.org/10.3390/met14010090

Arbo SM, Tjøtta S, Boge MH, Tundal U, Li J, Dumoulin S, Jensrud O. The Potential of Cast Stock for the Forging of Aluminum Components within the Automotive Industry. Metals. 2024; 14(1):90. https://doi.org/10.3390/met14010090

Chicago/Turabian StyleArbo, Siri Marthe, Stig Tjøtta, Magne H. Boge, Ulf Tundal, Jørgen Li, Stephane Dumoulin, and Ola Jensrud. 2024. "The Potential of Cast Stock for the Forging of Aluminum Components within the Automotive Industry" Metals 14, no. 1: 90. https://doi.org/10.3390/met14010090

APA StyleArbo, S. M., Tjøtta, S., Boge, M. H., Tundal, U., Li, J., Dumoulin, S., & Jensrud, O. (2024). The Potential of Cast Stock for the Forging of Aluminum Components within the Automotive Industry. Metals, 14(1), 90. https://doi.org/10.3390/met14010090