The Influence of the Hot-Rolling Temperature on the Microstructure and Mechanical Properties of Ti-Nb Microalloyed 21%Cr Ferritic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Testing Methods

3. Results

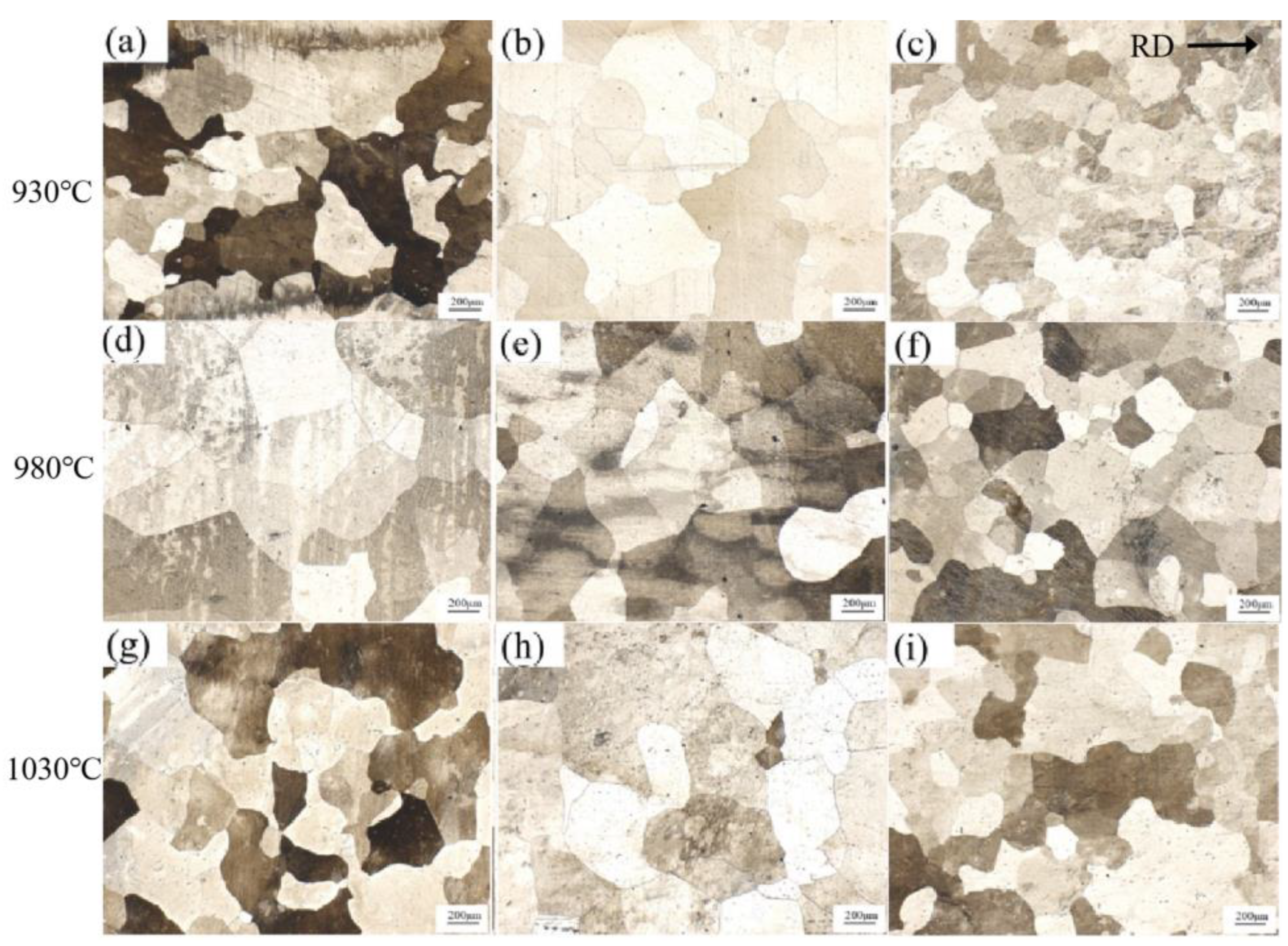

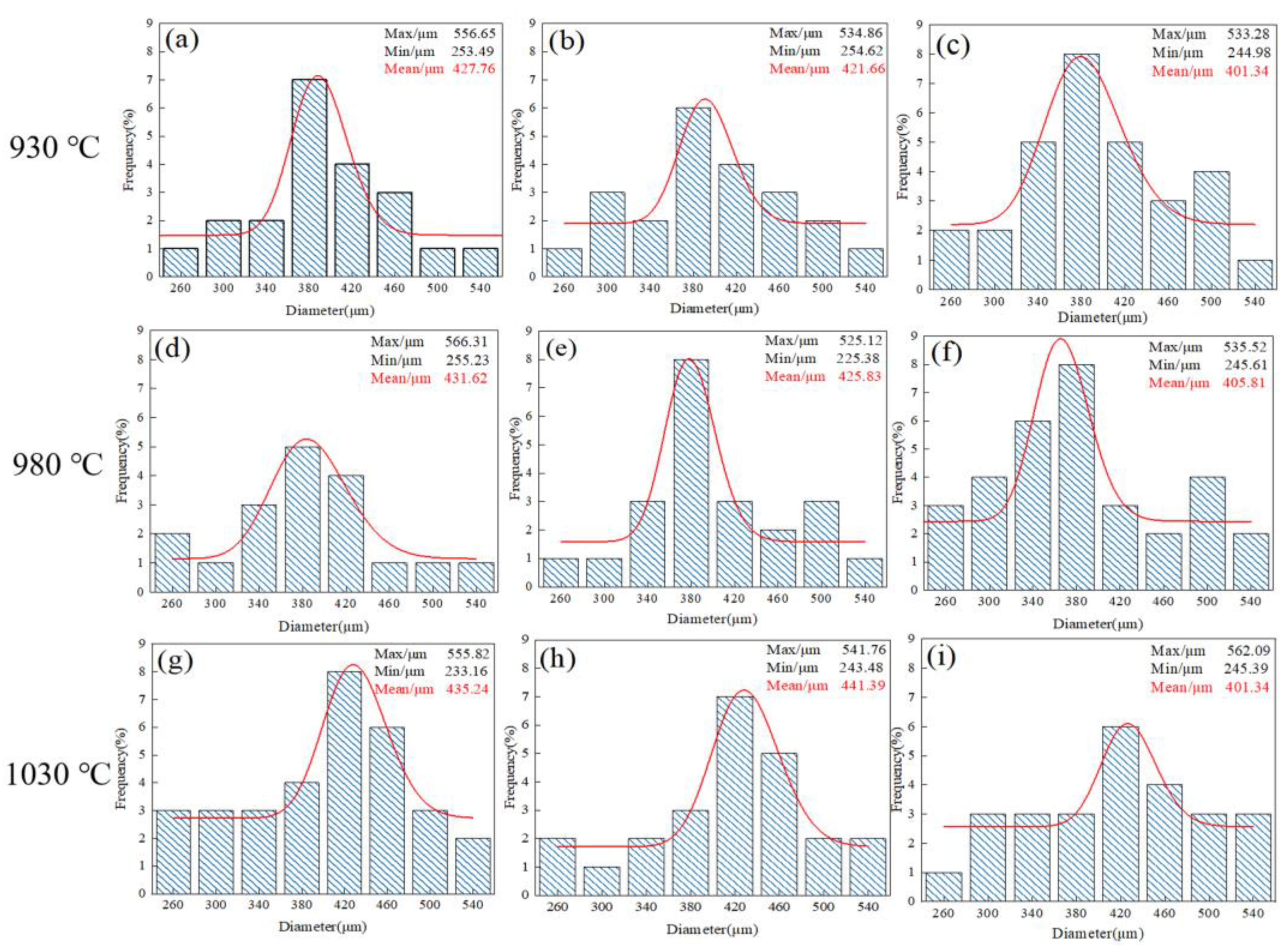

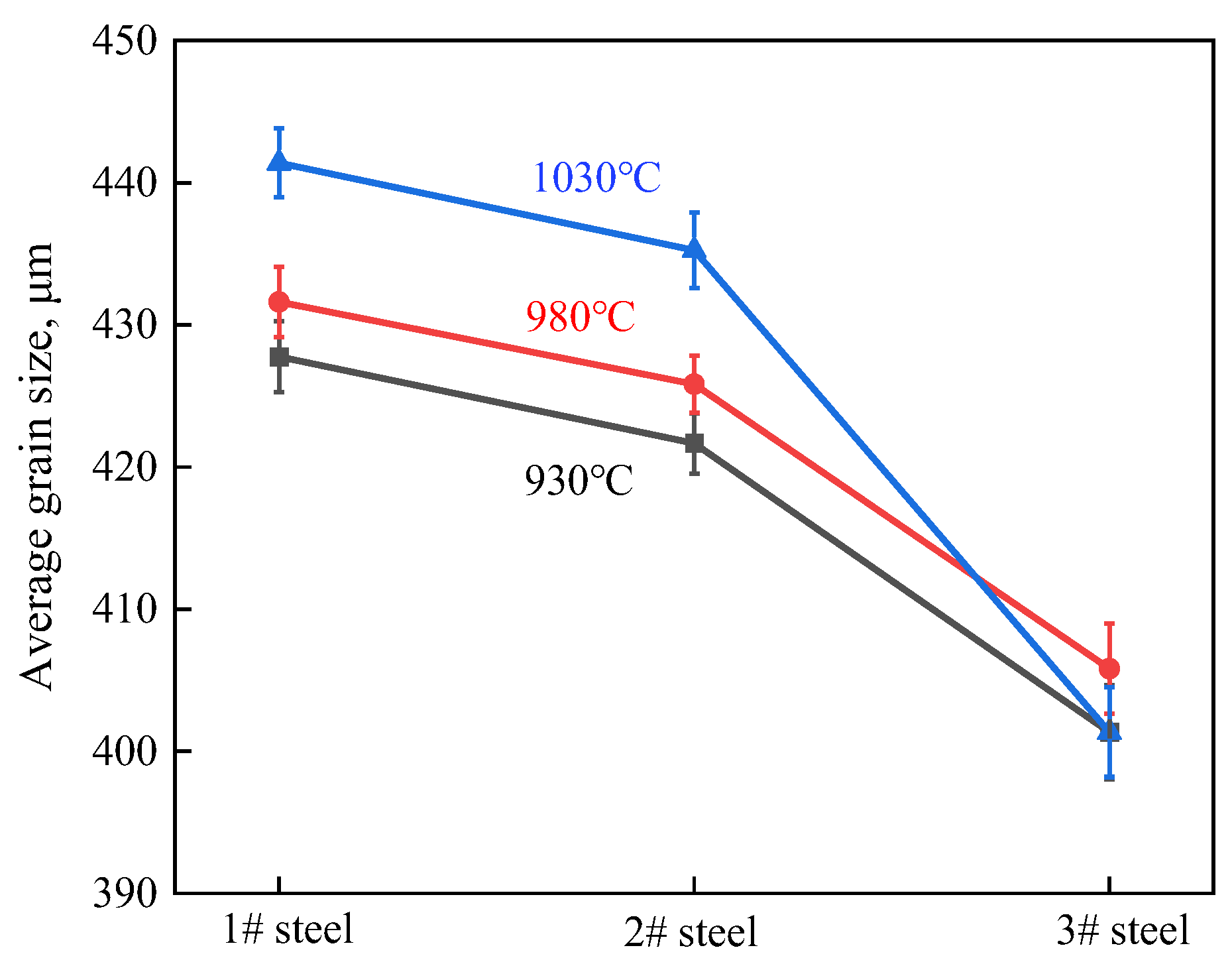

3.1. Microstructure

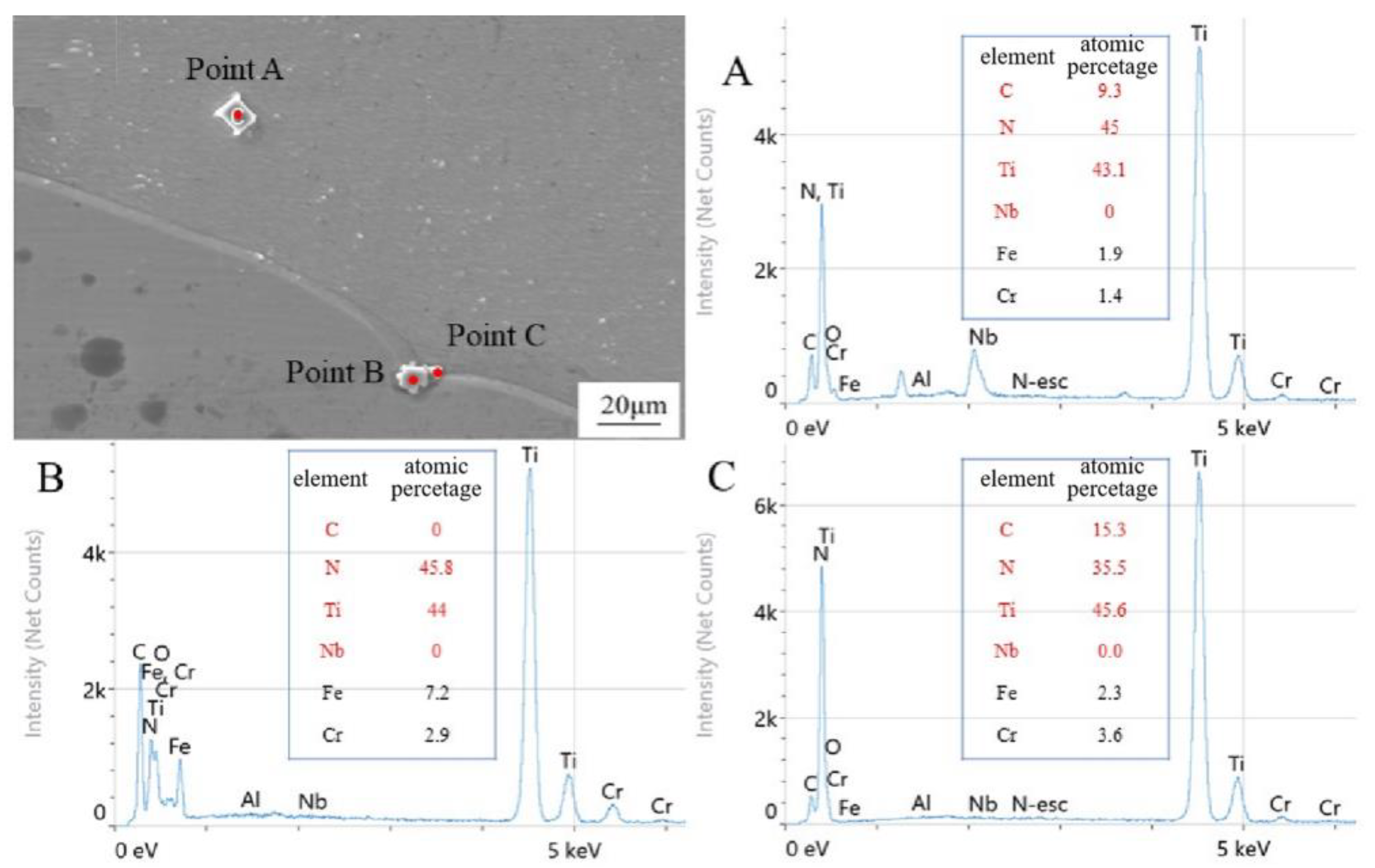

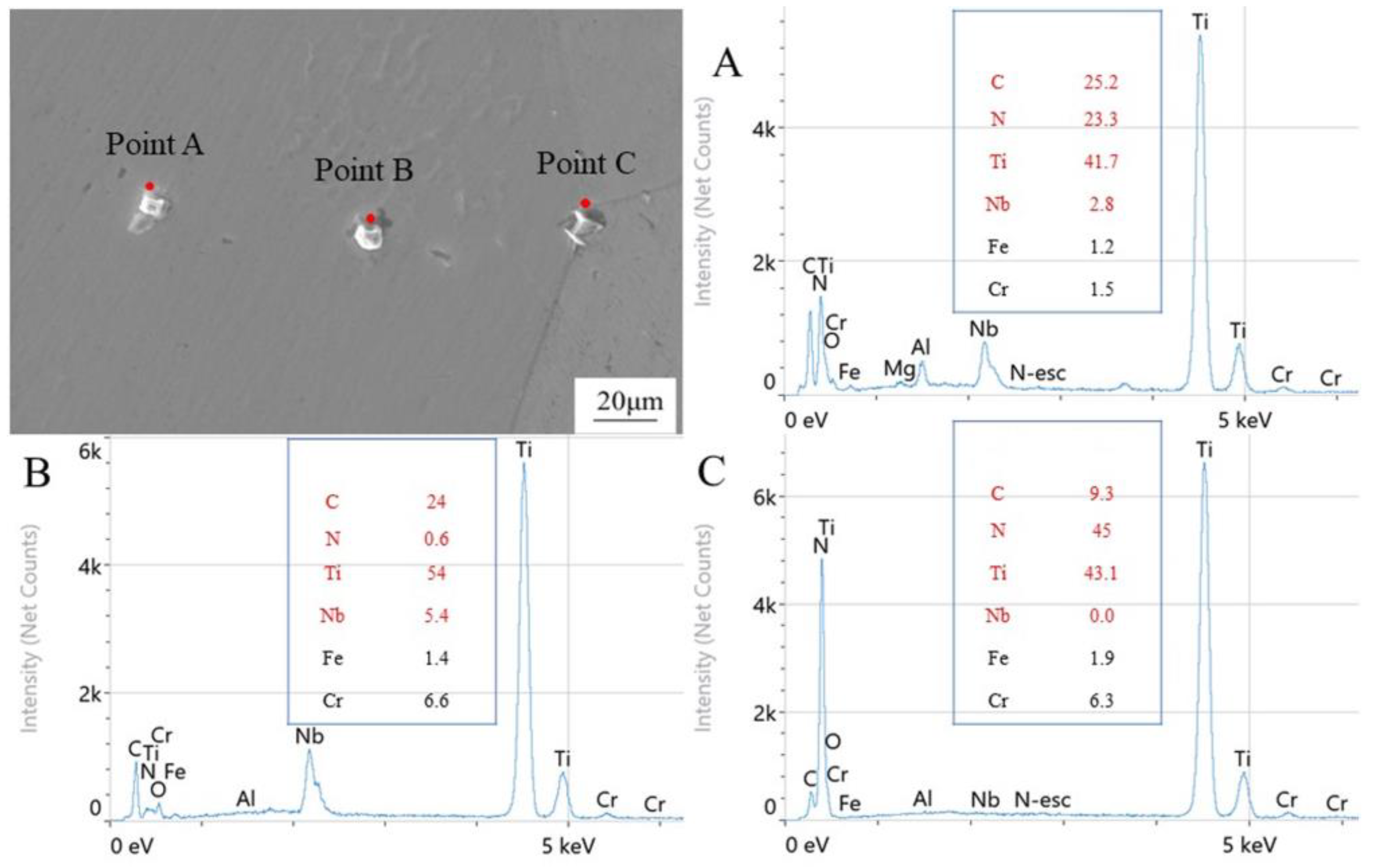

3.2. Analysis of Precipitate Phase

3.3. Mechanical Properties

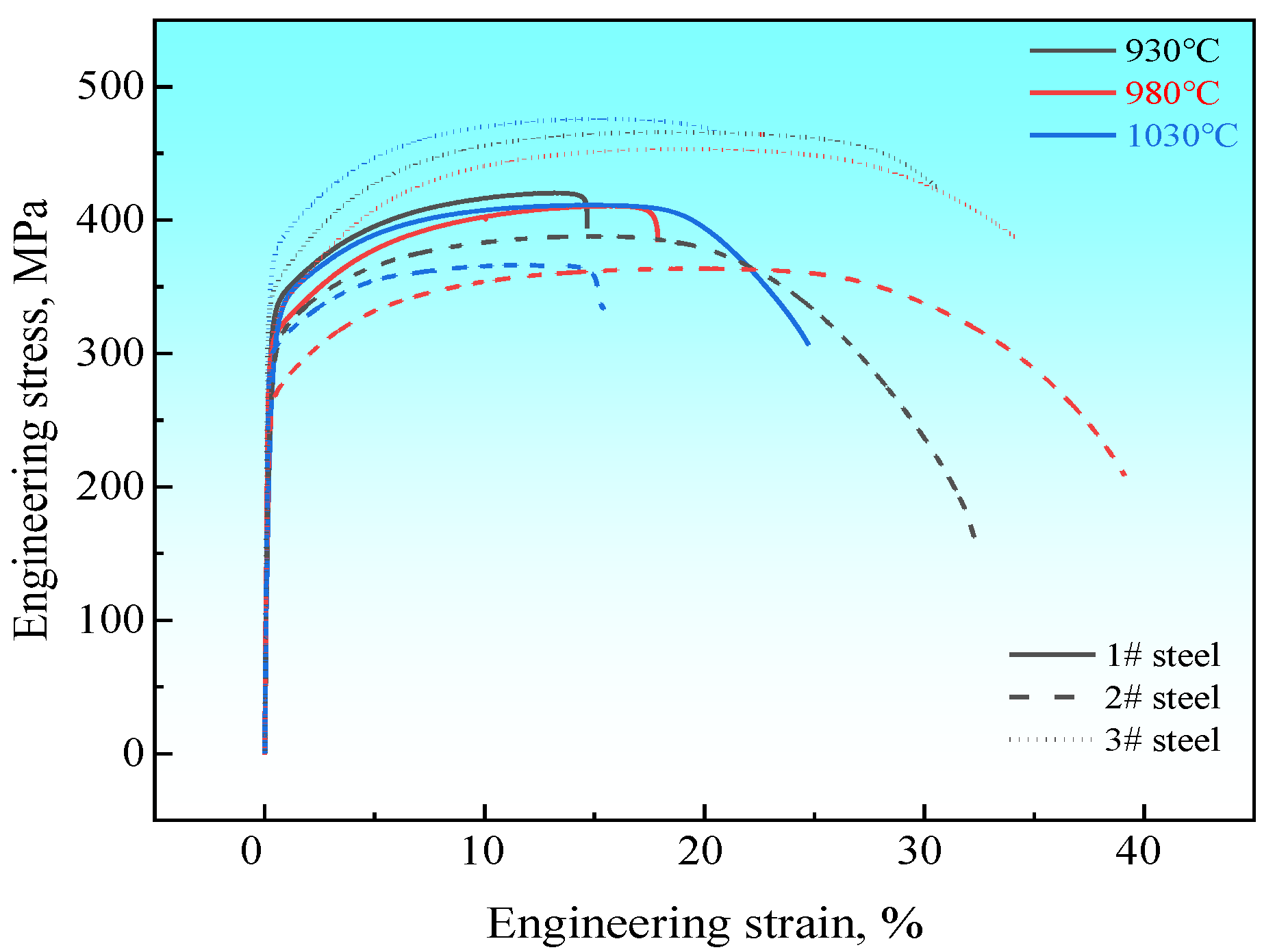

3.3.1. Tensile Properties

3.3.2. Hardness

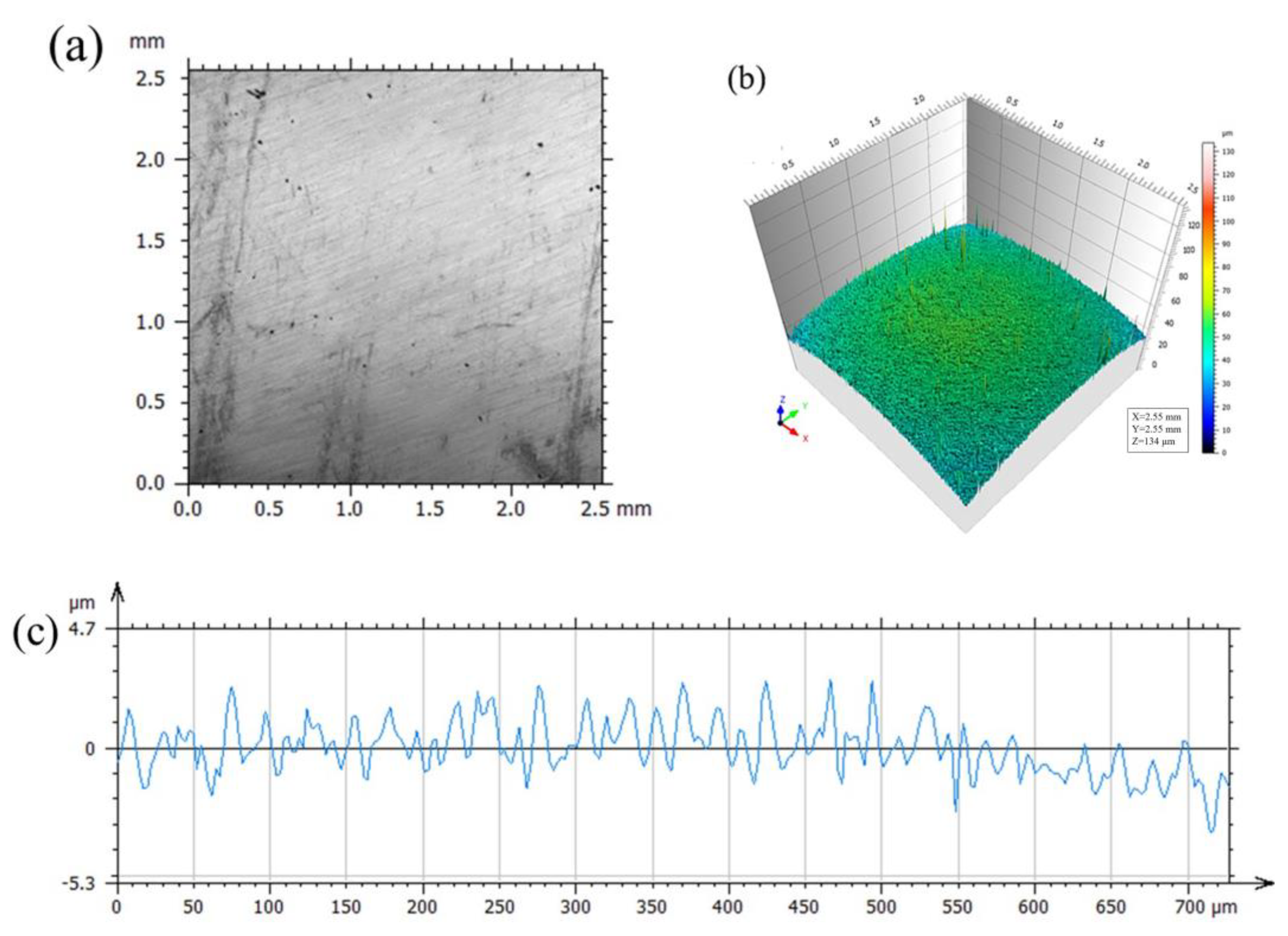

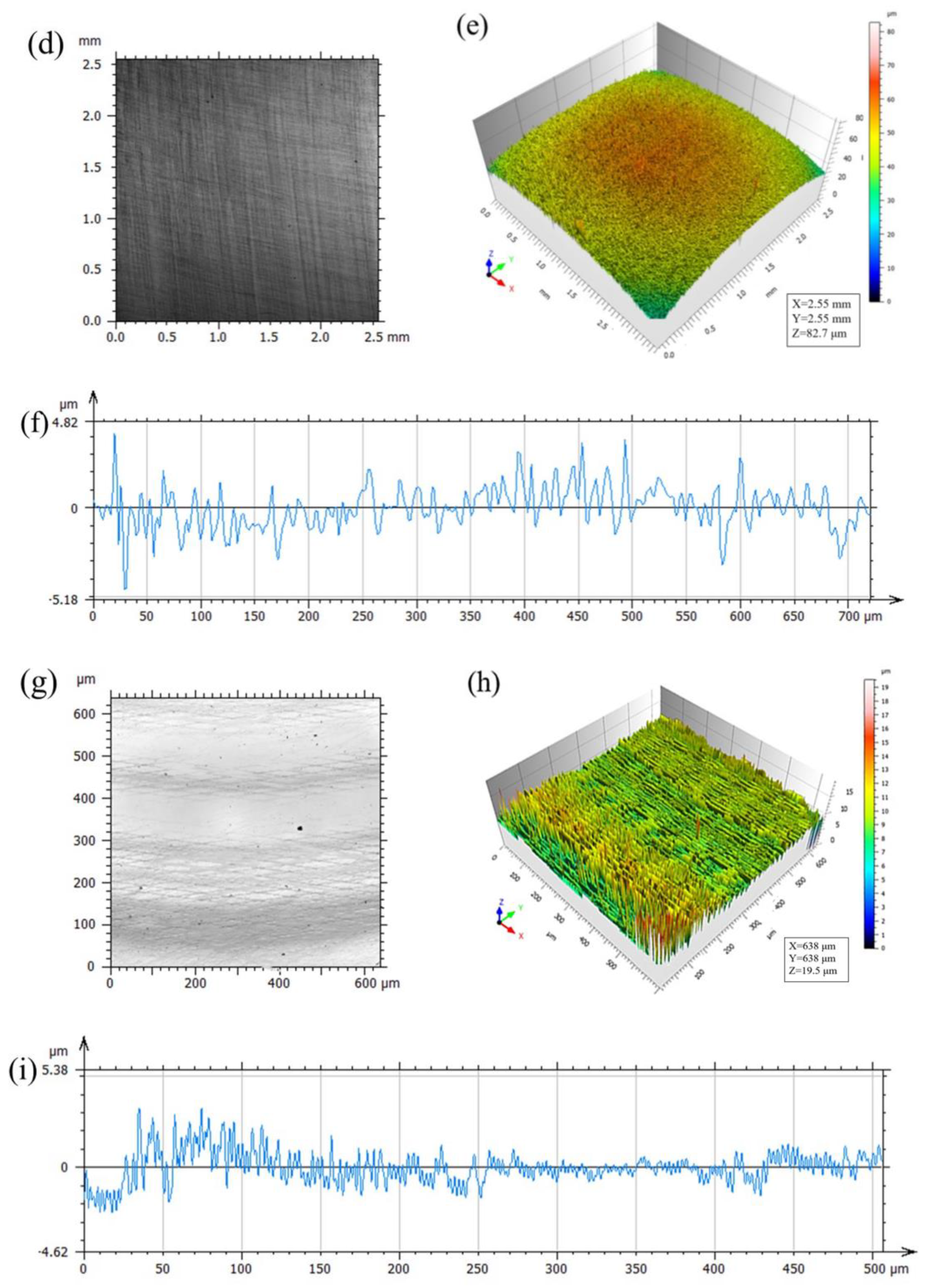

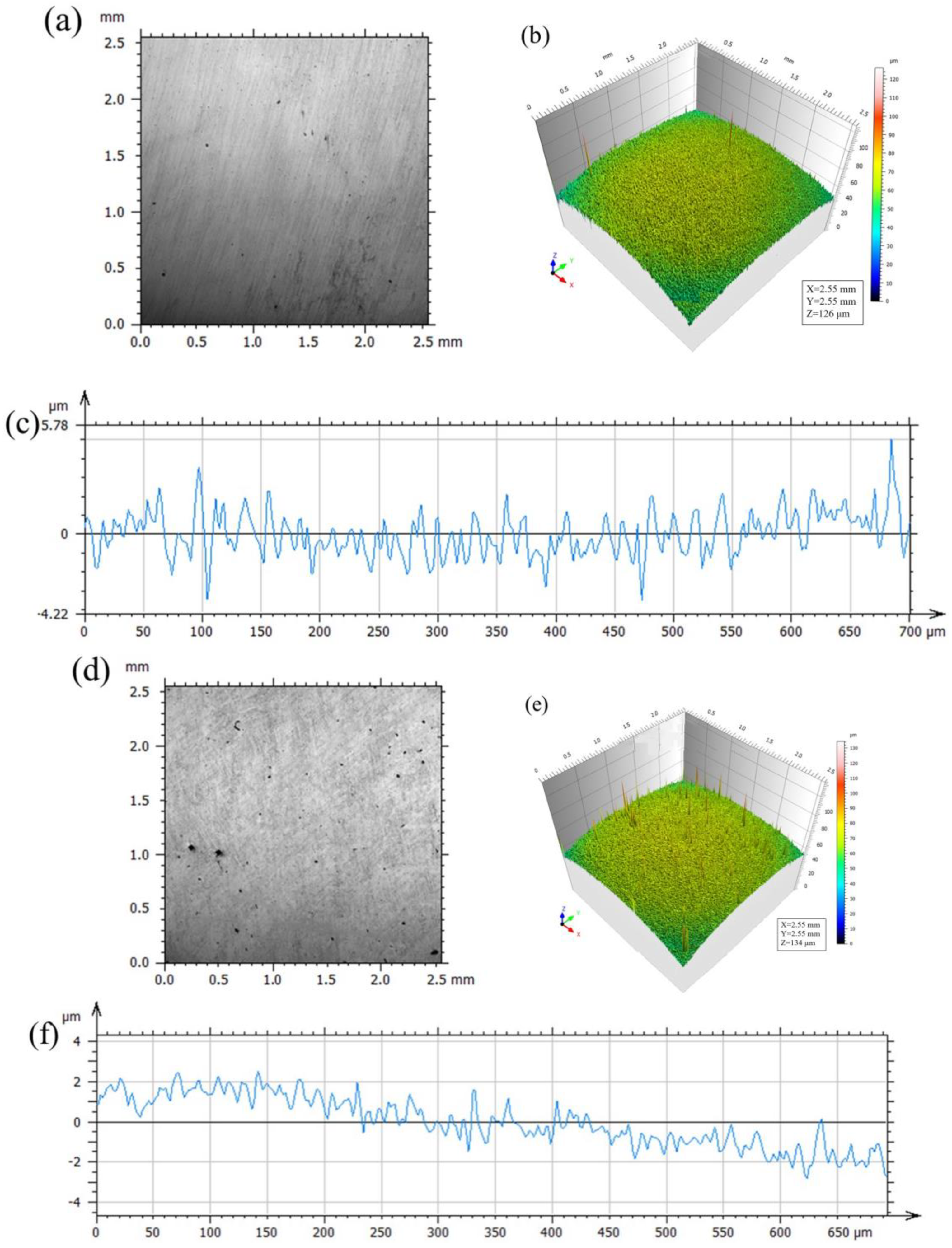

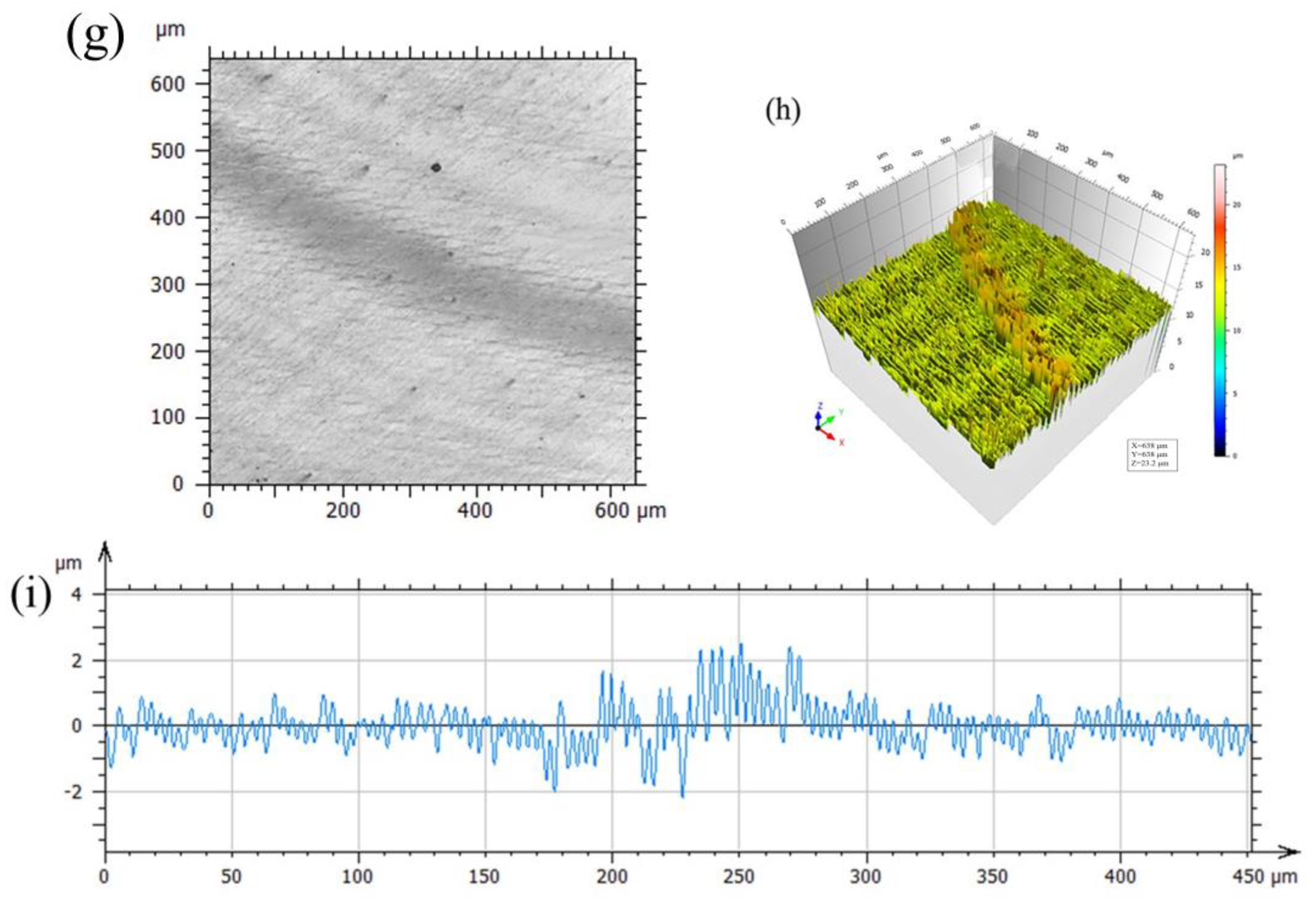

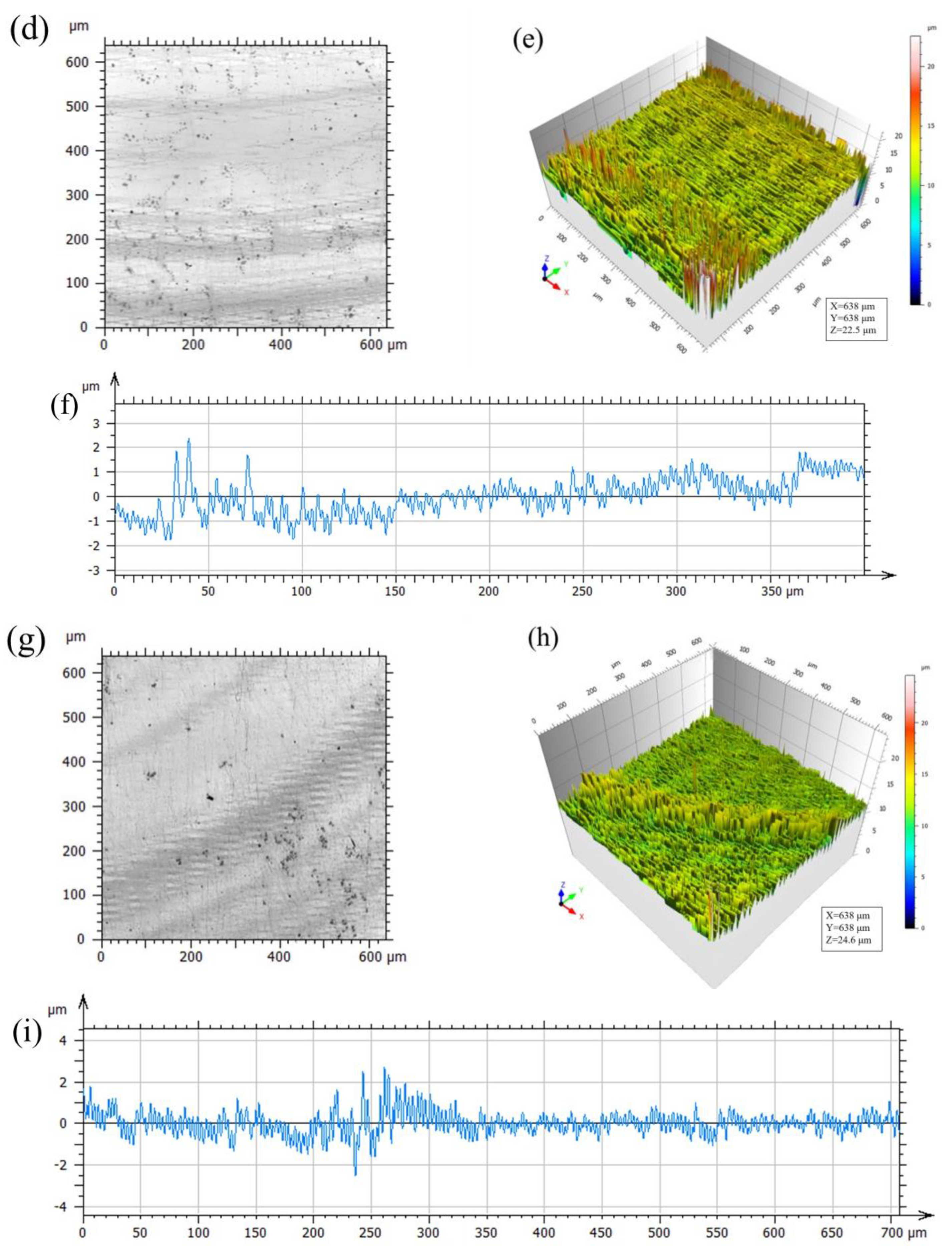

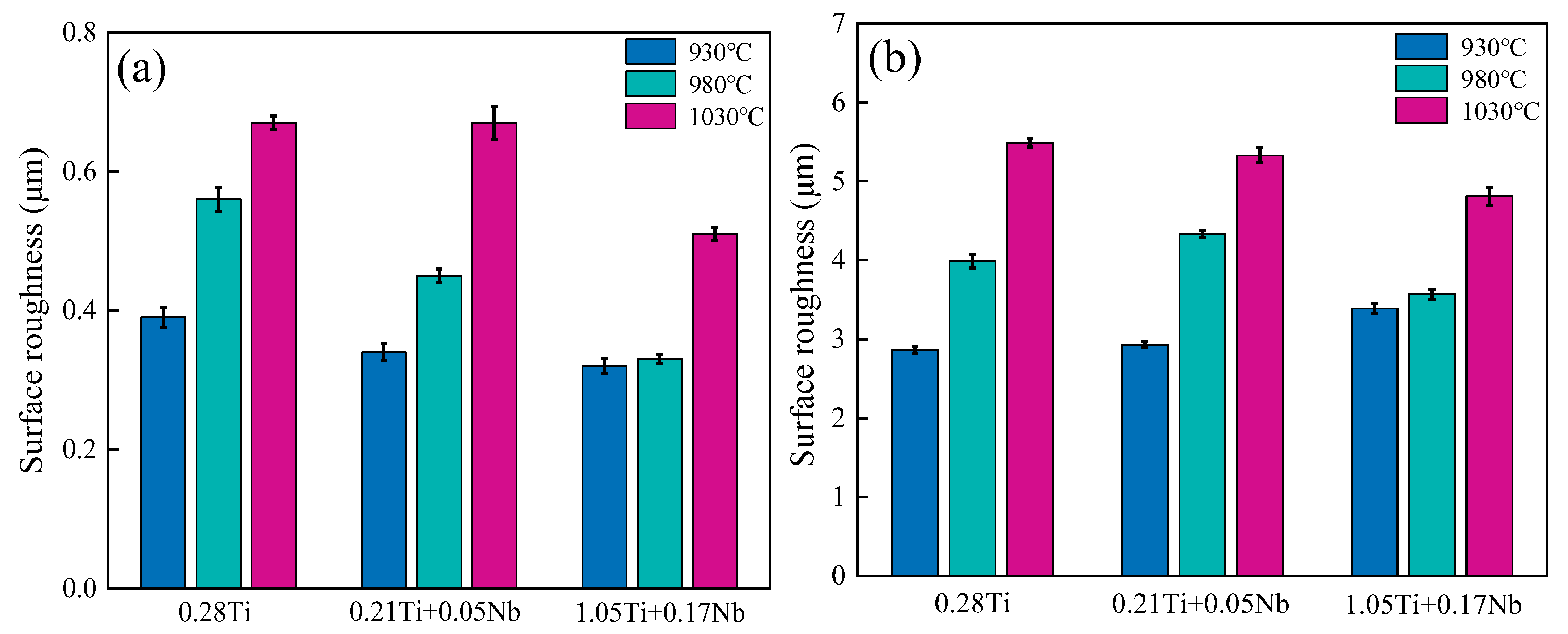

3.3.3. Surface Roughness

4. Analysis and Discussion

4.1. Effect of Hot-Rolling Temperature on Microstructure

4.2. Impact of Hot-Rolling Temperature on Mechanical Characteristics

4.2.1. Effect of Hot-Rolling Temperature on Tensile Properties and Hardness

4.2.2. Influence of Hot-Rolling Temperature on Surface Roughness

5. Conclusions

- As the hot-rolling temperature increased, the average grain size enlarged. When the temperature reached 980 °C, the grain size was appropriately moderate, exhibiting the best degree of uniformity and overall performance. The relationship between the hardness and increasing the hot-rolling temperature aligned with the trend in the strength, initially exhibiting a decrease followed by a slight increase. Implementing medium-temperature annealing (980 °C) in hot-rolled steel is an effective approach to achieve excellent comprehensive mechanical properties.

- The primary precipitate phases in steel were Ti(C,N) and TiN. In the low-Nb steel 2#, the primary precipitated phases were (Nb,Ti)(C,N) and Ti(C,N). The formation of (Nb,Ti)(C,N) occurred during the annealing process, consuming a portion of the stored deformation energy and delaying the onset temperature of recrystallization. Additionally, the pinning effect of (Nb,Ti)(C,N) at the grain boundaries contributed to suppressing grain coarsening during annealing. The primary precipitates in the high-Nb steel 3# were (Nb,Ti)(C,N). The tested steel achieved excellent performance through the strengthening mechanisms of precipitate hardening from the Nb-Ti carbonitride phases and grain refinement.

- At an annealing temperature of 930 °C, the wrinkle resistance performance of all three types of steel was outstanding. Among them, at the same temperature, steel 3# exhibited the smallest Ra value. An increase in the Ti content in the steel was beneficial for promoting recrystallization but was detrimental to grain refinement. The addition of Nb enhanced the refinement of the grain structure, resulting in improved surface smoothness and better resistance to wrinkling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, L.J.; Chen, J.C.; Huang, H.C.; Zhang, Z.L.; Xiong, H.B.; Wang, J.A. Effect of recrystallization grain orientation distribution on the ridging phenomenon in FSS sheet. J. Iron Steel Res. Int. 2016, 28, 49–54. [Google Scholar]

- Dong, Z.G.; Chen, H.T.; Lang, Y.P.; Xiang, J.Z. Effect of Ti and Nb on high temperature mechanical property of FSS used for hot end of automotive exhaust system. Iron Steel 2013, 48, 64–68+74. [Google Scholar]

- Zhang, C.; Gao, F.; Liu, Z.Y.; Wang, G.D. Effects of hot finish rolling temperature on texture evolution and formability in an ultra purified 21%Cr FSS. Iron Steel 2011, 46, 55–59. [Google Scholar]

- Sheng, J.; Wei, J.F.; Meng, Y.H.; Li, Z.N.; Man, K.; Chen, W.Q.; Ma, G.C.; Zheng, Y.H..; Zhan, F.Q.; La, P.Q.; et al. Thermodynamical analysis of TiN precipitation in 21Cr ultra pure ferrite stainless steel. J. Lanzhou Univ. Technol. 2021, 49, 1–9. [Google Scholar]

- Sheng, J.; Man, K.; Ma, G.C.; Meng, Y.H.; Li, Y.F.; Gao, Y.; Yang, P.H.; Wei, J.F.; La, P.Q. Effect of annealing temperature on properties and second phase characteristics of 443 stainless steel hot rolled sheets. Ferroelectrics 2024. [Google Scholar]

- Zhao, X.J.; Zhao, K.; Liu, C.B.; Yang, Z.N.; Zhang, F.C. Effect of ausforming on the bainitic transformation and microstructure in medium carbon V-N micro-alloyed steel. J. Mater. Res. Technol. 2023, 23, 637–647. [Google Scholar] [CrossRef]

- Sun, L.C.; Zhang, S.S.; Song, R.B.; Ren, S.H.; Zhang, Y.C.; Sun, X.M.; Dai, G.W.; Hao, Y.Y.; Huo, W.F.; Zhao, S.; et al. Effect of V, Nb, and Ti microalloying on low-temperature impact fracture behavior of non-quenched and tempered forged steel. Mater. Sci. Eng. A 2023, 879, 145229. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.Y.; Ma, H.C.; Cheng, X.Q.; Li, X.G. Comparative study on mechanical and corrosion fatigue properties of high-strength bridge steels produced by TMCP and intercritical quenching and tempering process. Mater. Sci. Eng. A 2022, 853, 143771. [Google Scholar] [CrossRef]

- Sheng, J.; Du, M.C.; Li, Y.F.; Ma, G.C.; Chen, W.Q.; Zheng, Y.H.; Zhan, F.Q.; Ren, J.Q.; Raab, G.I.; La, P.Q. Deformation mechanism of bimodal structured 2205 duplex stainless steel in two yield stages. J. Wuhan Univ. Technol. 2023, 38, 184–191. [Google Scholar] [CrossRef]

- GB/T 6394-2002; Method for Determination of Average Grain Size of Metals. Standardization Administration of the People’s Republic of China: Beijing, China, 2002.

- GB/T 228.2-2010; Method for Tensile Testing of Metallic Materials at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- GB/T 230.1-2018; Rockwell Hardness Test Method-Part 1: Test Methods. Standardization Administration of the People’s Republic of China: Beijing, China, 2018.

- Wang, B.S.; Wang, W.W.; Zhang, H.L.; Zhang, X.B.; Feng, G.H. Continuous gradient temperature rolling process of 10Ni5CrMoV heavy plate. Iron Steel 2024, 59, 94–101. [Google Scholar] [CrossRef]

- Xu, S.K.; Sun, X.Y.; Chen, L.; Li, J.H.; Zhang, M.Y. Effect of annealing on microstructure and mechanical properties of cold-rolled 430 FSS. Chin. J. Process. Eng. 2024, 2–10+1. [Google Scholar]

- Zhu, S.X.; Wang, Q.J.; Liu, J.R.; Chen, Z.Y. Macrosegregation of Zr and Mo in TC19 titanium alloy ingot. Acta Metall. Sin. 2024, 60, 869–880. [Google Scholar] [CrossRef]

- Qing, G.Q.; Li, Y.; Jiang, Z.H.; Du, P.F.; Liu, H.; Hu, H. The Study on the influence of TiN to ferrite stainless steel microstructure. In Proceedings of the 11th China Iron & Steel Annual Conference S02 Steel Making & Continuous Casting, Beijing, China, 21 November 2017. [Google Scholar]

- Hou, D.Y.; Zhang, J.; Xin, W.B.; Zhao, Z.B.; Peng, J.; Tong, Y. Effect of Mo on precipitation behavior of composite carbonitrides in Nb-V-N microalloyed steel. Iron Steel 2024, 59, 104–116. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xu, X.D.; Liu, W.H.; Zhao, Y.; Chen, L.Q. Effect of cold rolling reduction ratio on microstructure and properties of 439L FSS. J. Mater. Met. 2024, 23, 173–180+204. [Google Scholar] [CrossRef]

- Gao, F.; Liu, Z.Y.; Yu, F.X. Precipitation behavior of ultra-pure FSS during hot deformation. J. Northeast. Univ. (Nat. Sci.) 2016, 37, 44–48. [Google Scholar] [CrossRef]

- GB/T 1031-2009; Parameters and Values of Surface Roughness. Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Zheng, W.X. Titanium-Stabilized Fe-17%Cr Ultra-Pure FSS TiN Formation Mechanism. Master’s thesis, Hefei University of Technology, Hefei, China, 2018. [Google Scholar]

- Liu, H.T.; Wang, M.; Gao, F.; Liu, Z.Y. Dynamic recovery behavior in hot deformation of ultra-purified Cr17 FSS. J. Northeastern Univ. (Nat. Sci.) 2012, 33, 1734–1736+1753. [Google Scholar]

- Lei, L.L.; Shang, B.G.; Zheng, K.K.; Wang, X.Y.; Tan, X.; Li, J.; Jiang, Y.M.; Sun, Y.T. Understanding the pitting mechanism of super FSS in bromide solutions: The role of Ti/Nb-Mo precipitates with a core-shell structure. Corros. Sci. 2022, 199, 110176. [Google Scholar] [CrossRef]

- Tang, W.S.; Yang, Y.Q.; Li, S.L.; Du, B.; Li, H.J. Numerical and experimental investigation on friction stir welding of Ti- and Nb-modified 12% Cr FSS. J. Manuf. Process. 2020, 59, 223–237. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Wang, D.Y.; Li, X.L.; Qu, T.P.; Hou, D.; Hu, S.Y.; Zhang, Z.X.; Wang, H.H. Mechanism for TiN refinement and resultant heterogeneous nucleation of δ-Fe in magnesium-rare earth-treated ultrapure FSS. Mater. Charact. 2023, 205, 113250. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Wang, D.Y.; Tian, J.; Qu, T.P.; Zhang, Z.X.; Wang, Y.P.; Li, X.L.; Hou, D. TiN refinement and resultant grain refinement in magnesium-treated ultra-pure FSS. Mater. Charact. 2024, 208, 113659. [Google Scholar] [CrossRef]

- Hou, Y.Y.; Cheng, G.G. Formation mechanism and nucleation effect of Ti2O3-TiN complex nucleus at solidification front of 18Cr FSS. Metall. Mater. Trans. B 2019, 50, 1351–1364. [Google Scholar] [CrossRef]

- Cao, Y.B.; Xiao, F.R.; Qiao, G.Y.; Liao, B. Quantitative research on dissolving of Nb in high Nb microalloyed steels during reheating. J. Iron Steel Res. Int. 2014, 21, 596–599. [Google Scholar] [CrossRef]

- Merkushkin, E.; Berezovskaya, V.; Serzhanin, M.; Kirillova, A. Effect of tin alloying on corrosion and mechanical properties of ferritic and metastable austenitic steels. Mater. Today 2019, 19, 2252–2254. [Google Scholar] [CrossRef]

- Chao, H.C. Recent studies into the mechanism of ridging in FSSs. Metall. Trans. 1973, 4, 1183. [Google Scholar] [CrossRef]

- Wright, R.N. Anisotropic plastic flow in FSSs and the “roping” phenomenon. Metall. Trans. 1972, 3, 83. [Google Scholar] [CrossRef]

- Duan, H.J.; Zhang, Y.; Ren, Y.; Zhang, L.F. Distribution of TiN inclusions in Ti-stabilized ultra-pure ferrite stainless steel slab. J. Iron Steel Res. Int. 2019, 26, 962–972. [Google Scholar] [CrossRef]

- Viana, C.S.D.; Candido, F.S.; Pinto, A.L.; Houtte, P.V.; Kestens, L. An EBSD analysis of the origins of ridging in AISI 430 steel sheets. Mater. Sci. Forum 2005, 525, 173–178. [Google Scholar]

| Steel | Cr | C | N | Ti | Nb | Si | Mn | P | S | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1# | 20.67 | 0.008 | 0.008 | 0.28 | — | 0.28 | 0.16 | 0.013 | 0.0006 | 0.12 | 0.37 | Bal. |

| 2# | 20.74 | 0.009 | 0.009 | 0.21 | 0.05 | 0.30 | 0.17 | 0.015 | 0.0007 | 0.11 | 0.39 | Bal. |

| 3# | 21.19 | 0.008 | 0.008 | 1.05 | 0.17 | 0.39 | 0.2 | 0.013 | 0.0009 | 0.12 | 0.43 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Sheng, J.; Ma, Z.; Gao, Y.; Tuo, L.; Duan, H.; Man, K. The Influence of the Hot-Rolling Temperature on the Microstructure and Mechanical Properties of Ti-Nb Microalloyed 21%Cr Ferritic Stainless Steel. Metals 2024, 14, 1099. https://doi.org/10.3390/met14101099

Meng Y, Sheng J, Ma Z, Gao Y, Tuo L, Duan H, Man K. The Influence of the Hot-Rolling Temperature on the Microstructure and Mechanical Properties of Ti-Nb Microalloyed 21%Cr Ferritic Stainless Steel. Metals. 2024; 14(10):1099. https://doi.org/10.3390/met14101099

Chicago/Turabian StyleMeng, Yahui, Jie Sheng, Zongwen Ma, Yang Gao, Lixu Tuo, Hongyan Duan, and Kun Man. 2024. "The Influence of the Hot-Rolling Temperature on the Microstructure and Mechanical Properties of Ti-Nb Microalloyed 21%Cr Ferritic Stainless Steel" Metals 14, no. 10: 1099. https://doi.org/10.3390/met14101099

APA StyleMeng, Y., Sheng, J., Ma, Z., Gao, Y., Tuo, L., Duan, H., & Man, K. (2024). The Influence of the Hot-Rolling Temperature on the Microstructure and Mechanical Properties of Ti-Nb Microalloyed 21%Cr Ferritic Stainless Steel. Metals, 14(10), 1099. https://doi.org/10.3390/met14101099