Comparative Analysis of Mechanical Properties and Microstructure of 7B52 Aluminum Alloy Laser-MIG Hybrid Welding and MIG Welding Joints

Abstract

:1. Introduction

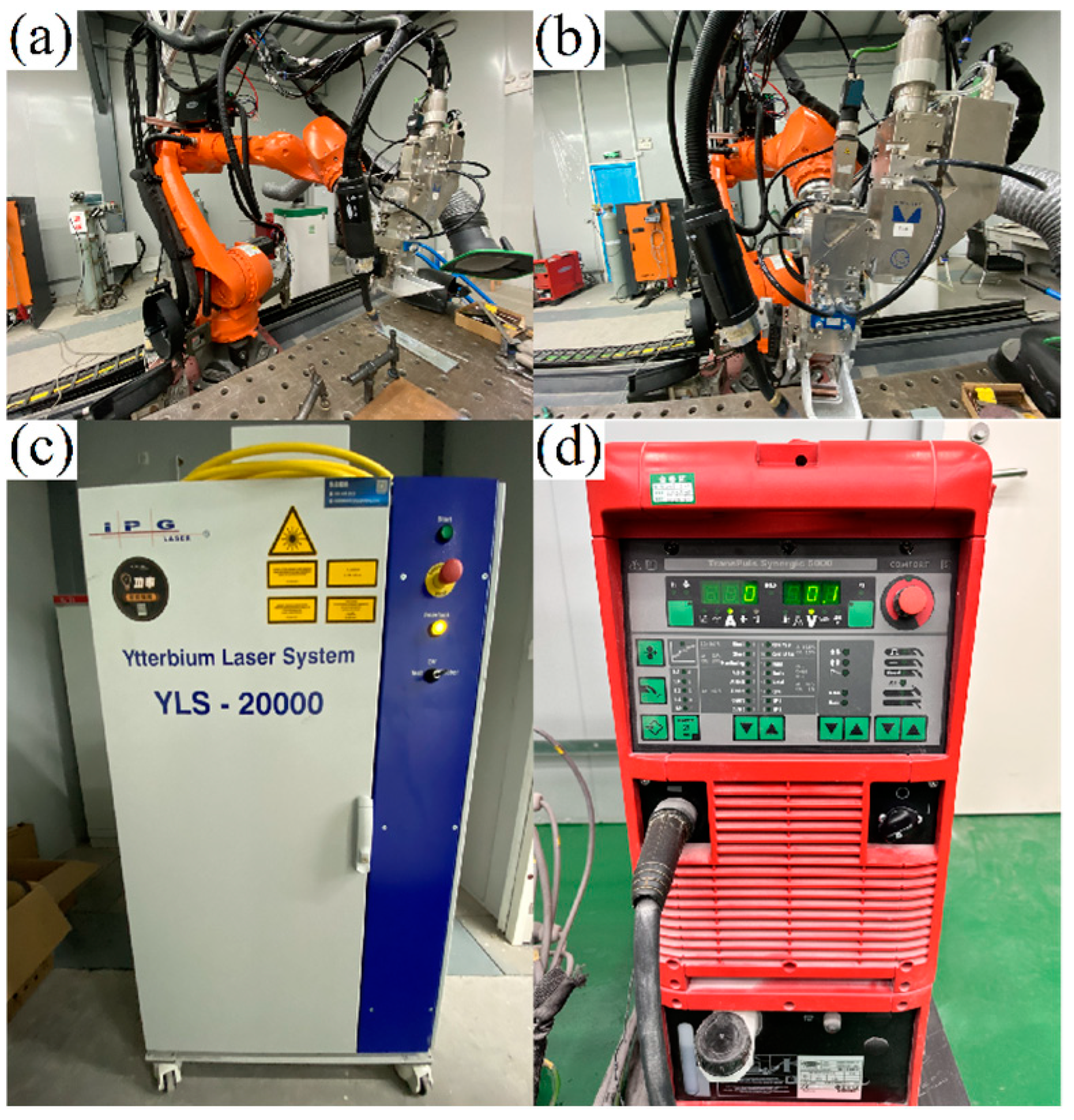

2. Materials and Experiments

2.1. Materials

2.2. Microstructure Observation

2.3. Microhardness Test

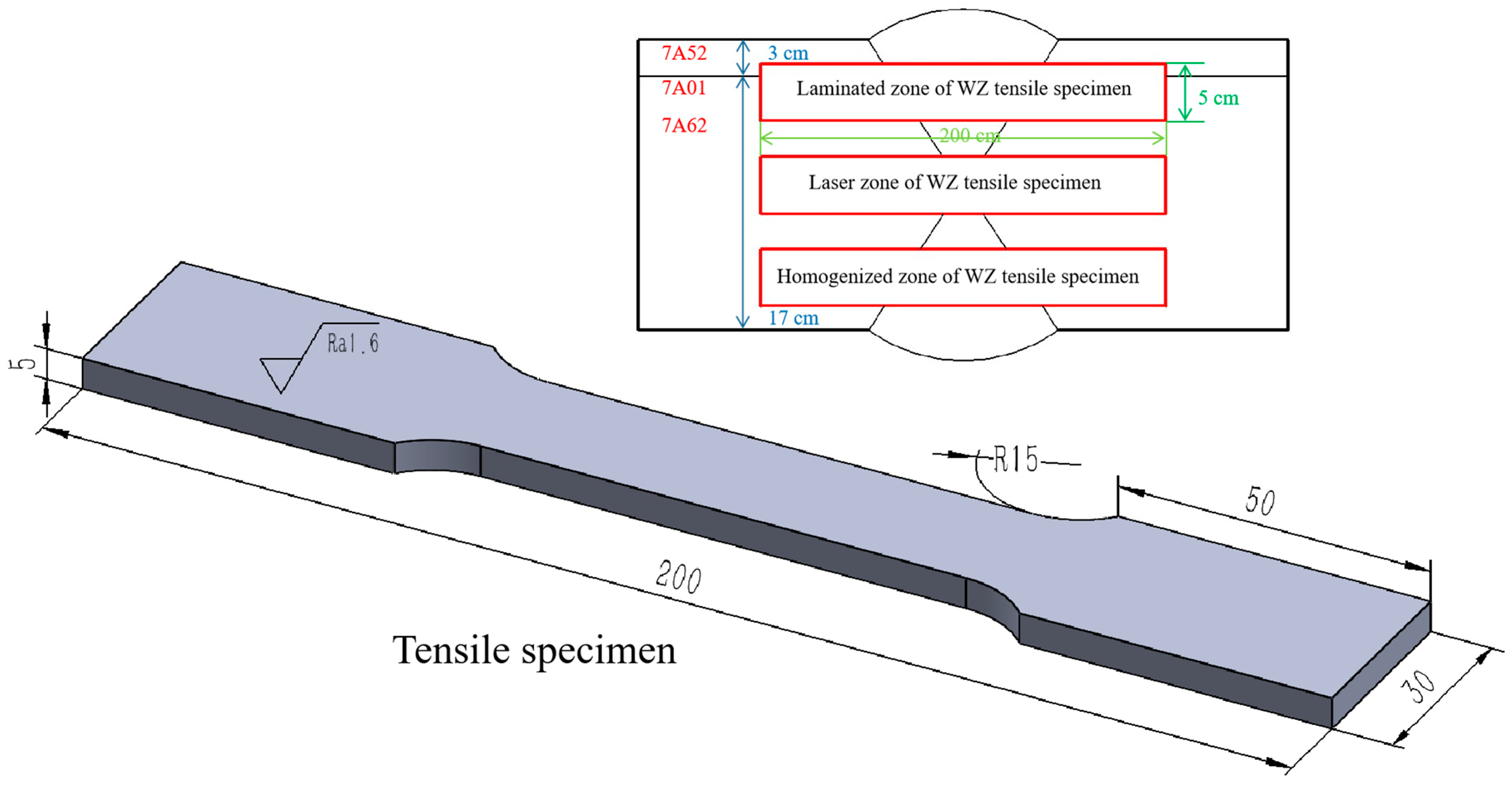

2.4. Tensile Strength Test

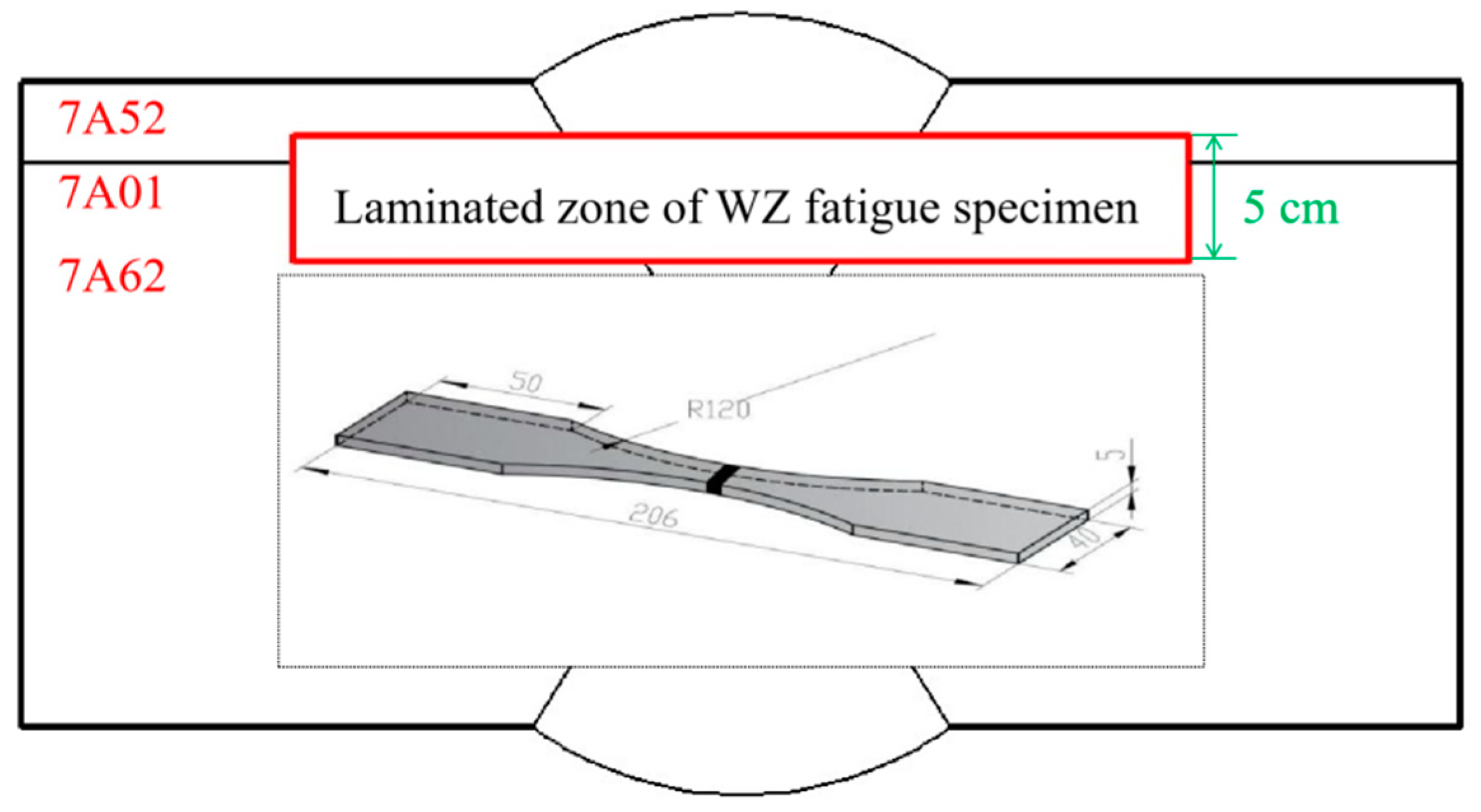

2.5. High-Cycle Fatigue Test

2.6. Fracture Surfaces

3. Results

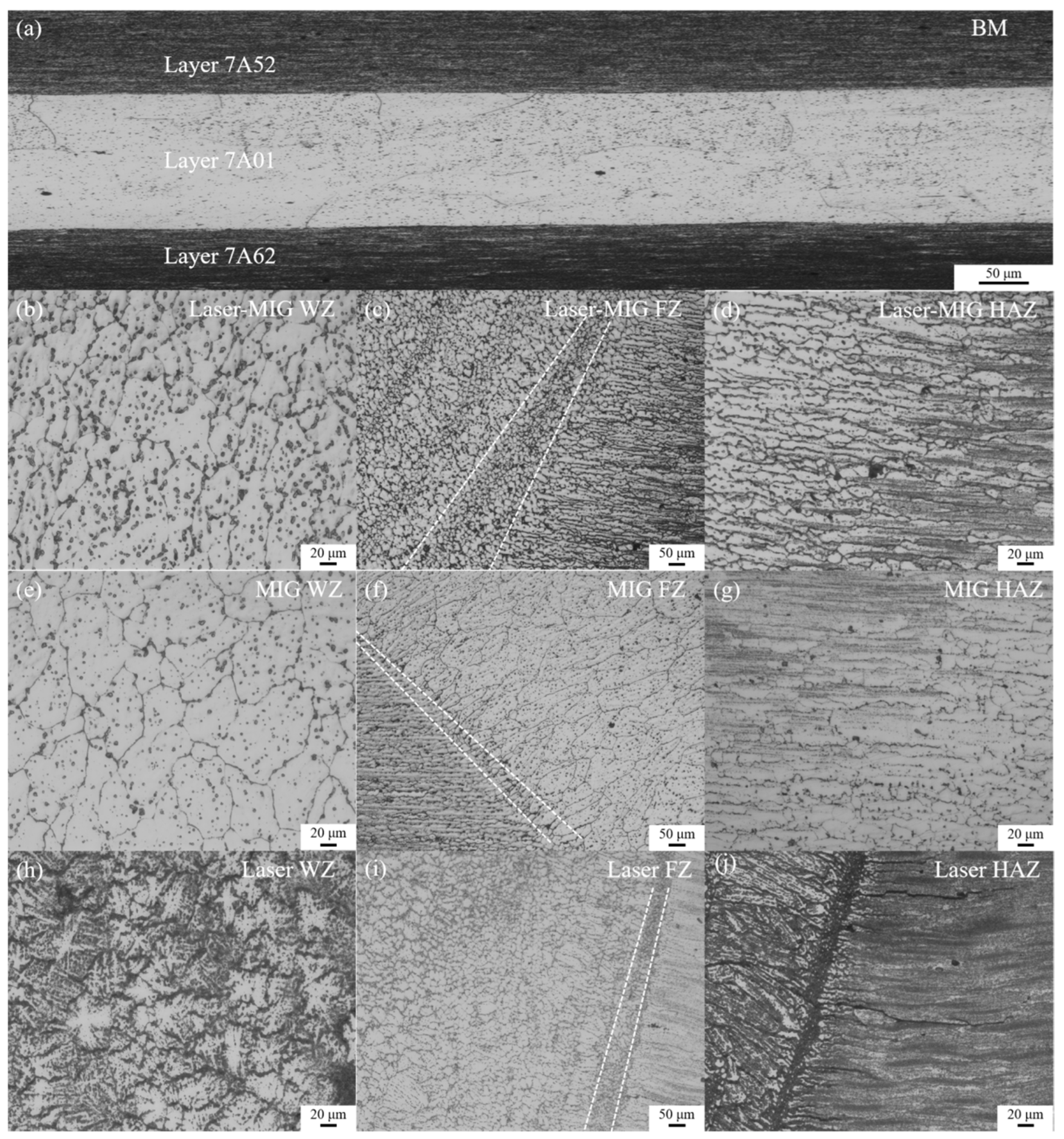

3.1. Microstructure Analysis

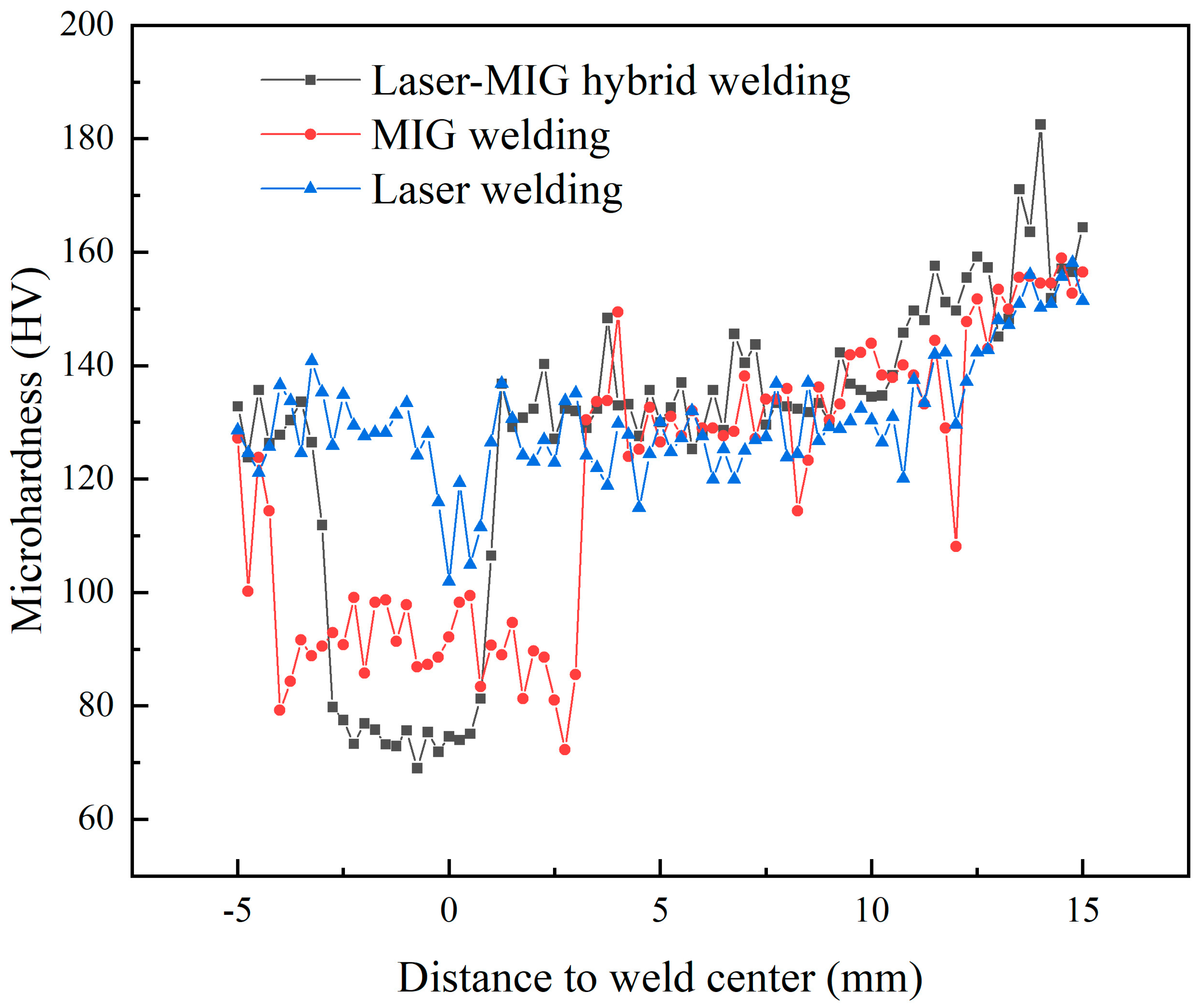

3.2. Microhardness Analysis

3.3. Tensile Properties Analysis

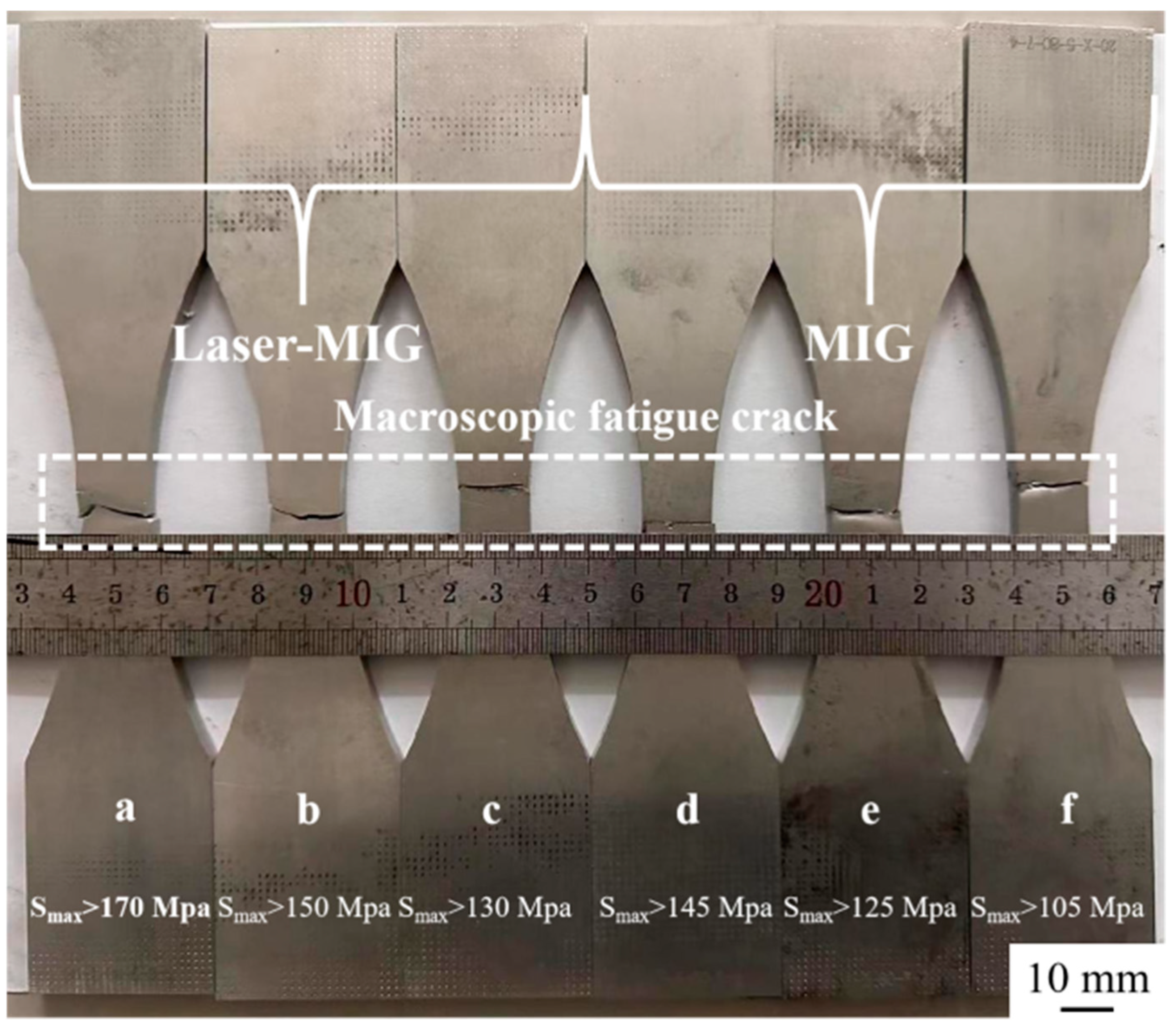

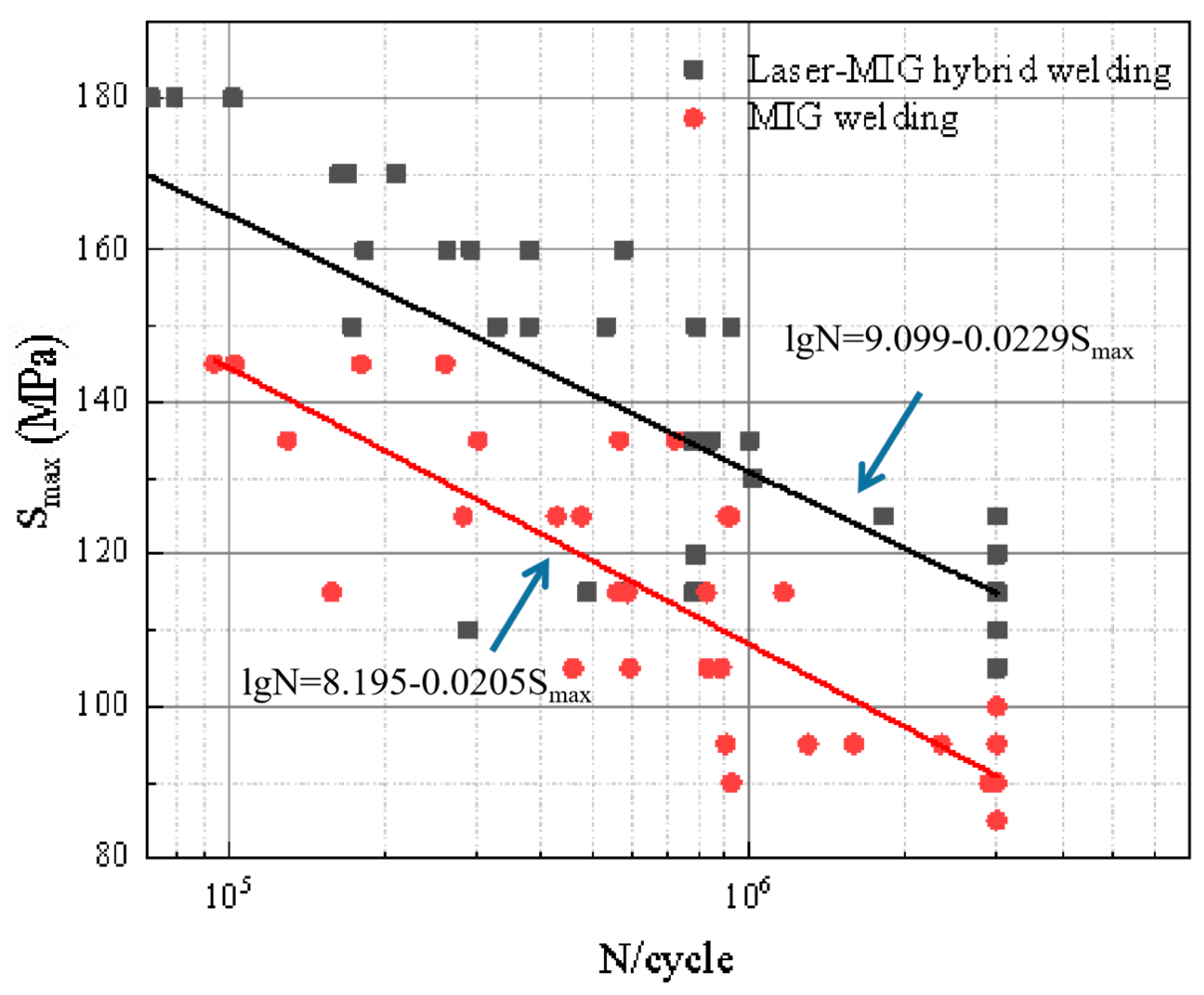

3.4. Fatigue Performance Analysis

3.5. Fatigue Fracture Analysis

4. Conclusions

- (1)

- The average grain sizes of laser-MIG hybrid welding, MIG welding, and laser zone WZ were 18.38 μm, 24.16 μm, and 15.96 μm, respectively. MIG welding had the highest heat input and the largest grain size. The hardness of the laser zone is better than that of the laser-MIG hybrid WZ and that of the MIG WZ.

- (2)

- The heat input of a single laser is lower than that of the arc and laser-arc, and the width of the HAZ of the laser zone is smaller than that of the laser-MIG hybrid welding zone and MIG welding zone. The microhardness of the laser weld zone is higher than that of the laser-MIG hybrid welding zone and MIG welding zone.

- (3)

- Compared with laser-MIG hybrid welding, MIG welding produces more pores, which affects its tensile strength. Therefore, the tensile strength of each laser-MIG hybrid welding joint zone is higher than that of MIG welding. The cracks in the laser zone propagate along the grain boundary, so the tensile strength of the laser zone is the lowest.

- (4)

- The fatigue performance of the laser-MIG hybrid welded head laminated zone is better than MIG welding under the same conditions, and the defects in the welded joint are the leading cause of fatigue fracture.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Parameter Summary | |

| Parameter | Physical meaning |

| R | stress ratio |

| Nf | cycle |

| Smax | loading stress |

| ΔK | stress intensity factor range |

| KIC | stress intensity factor critical value |

| a | crack half length |

| C | material-related coefficients |

| n | the number of specimens |

| σ−1 | fatigue limit of the smooth specimen |

| σ−1K | net section size and processing method of the same notched specimen fatigue limit |

| Kf | influential stress concentration factor |

| Kt | theoretical stress concentration factor |

| q | fatigue notch sensitivity |

| Abbreviation | Full Name |

| BM | base mental |

| WZ | weld zone |

| HAZ | heat-affected zone |

| FZ | fusion zone |

| MIG | melt inert gas |

References

- Zhou, G.X.; Lang, Y.J.; Hao, J.; Liu, W.; Wang, S.; Qiao, L.; Chen, M. Interface analysis of 7B52 Al alloy laminated hybrid fabricated by hot roll bonding. Trans. Nonferrous Met. Soc. China 2016, 26, 1269–1275. [Google Scholar] [CrossRef]

- Chao, C.; Chen, F.; Zhang, H. Surface Nanocrystallization of 7A52 Aluminum Alloy Welded Joint by Aging and Ultrasonic Impact Compound Treatment. Rare Met. Mater. Eng. 2018, 47, 2637–2641. [Google Scholar] [CrossRef]

- Zeng, H.; Wang, Z.; Chen, D.; Ding, H.; Yang, W.; Ma, L.; Lu, Y. Effect of Sc on the Wettability of ER5356 Welding Wires and the Porosity of Deposited Metal. ACS Omega 2024, 9, 14255–14261. [Google Scholar] [CrossRef]

- Zhu, G.C.; Huang, S.H.; Li, X.W.; Li, Z.H.; Tong, Y.Z.; Zhang, Y.G.; Xiong, B.Q. Macro-micro dynamic behaviors and fracture modes of roll bonded 7A52/7A01/7B52 aluminum laminates in high velocity deformation. Prog. Nat. Sci. Mater. Int. 2018, 4, 510–519. [Google Scholar] [CrossRef]

- Liu, X.; Jia, R.; Cheng, W.; Zhang, H.; Tian, J.; Zhai, X. Influence of the second phase on relative fracture behavior of friction stir welded 7A52 aluminum alloy. Mater. Today Commun. 2022, 33, 104215. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, S.; Shen, Z.; Cao, H.; Zhong, X.; Withers, P.J. Fine equiaxed zone induced softening and failure behavior of 7050 aluminum alloy hybrid laser welds. Mater. Sci. Eng. A 2021, 821, 141597. [Google Scholar] [CrossRef]

- Li, X.C.; Fu, Z.Q.; Ji, B.H.; Sun, G.Y. Fatigue performance of deck-rib double-side welded joints considering asymmetric stress cycling. J. Constr. Steel Res. 2024, 221, 108913. [Google Scholar] [CrossRef]

- Madavi, K.; Jogi, B.; Lohar, G. Investigational study and microstructural comparison of MIG welding process for with and without activated flux. Mater. Today Proc. 2022, 51, 212–216. [Google Scholar] [CrossRef]

- Cai, C.; He, S.; Chen, H.; Zhang, W. The influences of Ar-He shielding gas mixture on welding characteristics of fiber laser-MIG hybrid welding of aluminum alloy. Opt. Laser Technol. 2019, 113, 37–45. [Google Scholar] [CrossRef]

- Ghosal, S.; Chaki, S. Estimation and optimization of depth of penetration in hybrid CO2 LASER-MIG welding using ANN-optimization hybrid model. Int. J. Adv. Manuf. Technol. 2010, 47, 1149–1157. [Google Scholar] [CrossRef]

- Jia, Y.; Wen, T.; Huang, N.; Zhang, J.; Xiao, J.; Chen, S.; Huang, W. Research on aluminum alloy welding process based on high frequency and low power pulsed Laser-MIG hybrid welding. Opt. Laser Technol. 2022, 150, 107899. [Google Scholar] [CrossRef]

- Aqeel, M.; Gautam, J.P.; Shariff, S.M. Influence of heat input on bead profile and microstructure characteristics in laser and laser-hybrid welding of Inconel 617 alloy. Weld. Int. 2022, 36, 256–270. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yang, C.; Gao, M. Study of porosity suppression in oscillating laser-MIG hybrid welding of AA6082 aluminum alloy. J. Mech. Work. Technol. 2021, 292, 117053. [Google Scholar] [CrossRef]

- Yang, X.; Chen, H.; Li, M.V.; Bu, H.; Zhu, Z.; Cai, C. Porosity suppressing and grain refining of narrow-gap rotating laser-MIG hybrid welding of 5A06 aluminum alloy. J. Manuf. Process 2021, 68, 1100–1113. [Google Scholar] [CrossRef]

- Chen, X.; Yu, G.; He, X.; Li, S.; Miao, H. Effect of droplet impact on molten pool dynamics in hybrid laser-MIG welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 96, 209–222. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, X.P.; Chang, L.Y.; Wu, S.C. Fatigue Lifetime of Laser-MIG Hybrid Welded Joint of 7075-T6 Aluminum Alloy by in-situ Observation. Rare Met. Mater. Eng. 2017, 46, 2411–2416. [Google Scholar]

- Duan, C.; Yang, S.; Liu, H.; Gu, J.; Xiong, Q.; Wang, Y. Formation and fatigue property of MIG welded high-speed train 6005A-T6 aluminum alloy. Mater. Res. Express 2019, 6, 056532. [Google Scholar] [CrossRef]

- Hao, H.; Ye, D.; Chen, C. Strain ratio effects on low-cycle fatigue behavior and deformation microstructure of 2124-T851 aluminum alloy. Mater. Sci. Eng. A 2014, 605, 151–159. [Google Scholar] [CrossRef]

- Cisko, A.; Jordon, J.; Avery, D.; McClelland, Z.; Liu, T.; Rushing, T.; Brewer, L.; Allison, P.; Garcia, L. Characterization of fatigue behavior of Al-Li alloy 2099. Mater. Charact. 2019, 151, 496–505. [Google Scholar] [CrossRef]

- Ma, Y.L.; Huang, Y.C.; Zhang, X.Y. Precipitation thermodynamics and kinetics of the second phase of Al–Zn–Mg–Cu–Sc–Zr–Ti aluminum alloy. J. Mater. Res. Technol. 2021, 10, 445–452. [Google Scholar] [CrossRef]

- Lin, Y.; Zheng, Z.Q. Microstructural evolution of 2099 AlLi alloy during friction stir welding process. Mater. Charact. 2017, 123, 307–314. [Google Scholar] [CrossRef]

- Odeshi, A.; Adesola, A.; Badmos, A. Failure of AA 6061 and 2099 aluminum alloys under dynamic shock loading. Eng. Fail. Anal. 2013, 35, 302–314. [Google Scholar] [CrossRef]

- Yuen, B.K.C.; Taheri, F. Proposed Modification to the Zheng and Hirt Fatigue Model. J. Mater. Eng. Perform. 2004, 13, 226–231. [Google Scholar] [CrossRef]

- Zheng, X.L.; Manfred, A.H. Fatigue crack propagation in steels. Eng. Fract. Mech. 1983, 18, 965–973. [Google Scholar]

- Liu, Y.; Pan, Q.; Liu, B.; Yu, Q.; Li, G.; Pan, D. Effect of aging treatments on fatigue properties of 6005A aluminum alloy containing Sc. Int. J. Fatigue 2022, 163, 107103. [Google Scholar] [CrossRef]

- Najafi, S.; Eivani, A.; Samaee, M.; Jafarian, H.; Zhou, J. A comprehensive investigation of the strengthening effects of dislocations, texture and low and high angle grain boundaries in ultrafine grained AA6063 aluminum alloy. Mater. Charact. 2018, 136, 60–68. [Google Scholar] [CrossRef]

- Ding, X.; Liu, W.; Jiang, B.; Qiang, H.; Huang, H.; Xiao, M.; Chen, Y.; Song, Y. Effect of large pre-deformation on microstructure and mechanical properties of 7B52 laminated aluminum alloy. J. Alloys Compd. 2023, 967, 171749. [Google Scholar] [CrossRef]

- Nakrani, J.; Yan, W.; Shrivastava, A. Effect of notch location on fatigue crack growth behavior for inhomogeneous material domains in friction stir welded magnesium alloy. Int. J. Fatigue 2023, 177, 107956. [Google Scholar] [CrossRef]

- Li, X.-K.; Zhu, S.-P.; Liao, D.; Correia, J.A.; Berto, F.; Wang, Q. Probabilistic fatigue modelling of metallic materials under notch and size effect using the weakest link theory. Int. J. Fatigue 2022, 159, 106788. [Google Scholar] [CrossRef]

- Wang, Z.; Kong, X.; Xie, L.; Wu, N.; Zhen, C.; Gu, J. An enhanced stress field intensity approach for fatigue life assessment combining notch and size effect. Int. J. Fatigue 2024, 183, 108239. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, T.; Yang, B.; Xiao, S.; Yang, G. Fatigue crack evaluation of butt weld joints in full-scale aluminum alloy joints: Experimental and numerical study of traction structural stress. Int. J. Fatigue 2024, 187, 108478. [Google Scholar] [CrossRef]

- Jin, J.; Lu, W.; Fu, Z.; Zhu, Z.; Chen, W.; Gou, G. Corrosion fatigue crack growth in A7N01S−T5 aluminum alloy MIG welded joints. J. Mater. Res. Technol. 2023, 23, 2202–2218. [Google Scholar] [CrossRef]

- Pan, D.; Pan, Q.; Yu, Q.; Li, G.; Liu, B.; Deng, Y.; Liu, H. Microstructure and fatigue behavior of MIG-welded joints of 6005A aluminum alloy with trace amounts of scandium. Mater. Charact. 2022, 194, 112482. [Google Scholar] [CrossRef]

| Laser-MIG Hybrid | MIG | Remark | |

|---|---|---|---|

| Welding current/A | 270~280 | 250~270 | |

| Welding speed m/min | 13 (single laser) | 0.6~0.7 | Bottoming welding |

| 0.8 | 0.5~0.7 | Filling welding | |

| Laser power/kW | 10 | - | Bottoming welding |

| 1.5 | - | Filling welding | |

| Laser-arc distance/mm | 3 | - | |

| Defocus amount/mm | 0 | - | |

| Shielding gas flow rate L/min | 10~15 | 10~15 | |

| Heat input kJ/m | 310~510 | 330~550 |

| Elements | Mg | Zn | Mn | Ti | Cr | Al |

|---|---|---|---|---|---|---|

| Materials | ||||||

| ER5356 | 4.50~5.50 | <0.10 | 0.10 | 0.18 | 0.15 | Bal. |

| 7A52 | 2.00~2.80 | 4.00~4.80 | 0.25 | 0.07 | 0.17 | Bal. |

| 7A62 | 2.80~3.20 | 7.00~7.40 | 0.35 | 0.06 | 0.12 | Bal. |

| 7A01 | - | 0.90~1.30 | - | 0.05 | 0.25 | Bal. |

| Specimen Area | Tensile Strength MPa | Yield Strength MPa | Elongation % | Intercepted Area at Distance mm2 |

|---|---|---|---|---|

| Laser-MIG hybrid welding laminated zone | 289 298 296 | 131 142 149 | 9.5 7.5 8.0 | 4.99 × 19.78 4.7 × 19.86 4.98 × 19.88 |

| Laser-MIG hybrid welding homogenized zone | 315 320 332 | 186 142 120 | 7.5 5.5 8.0 | 4.98 × 19.78 5 × 19.86 4.99 × 19.89 |

| Laser zone | 263 270 271 | - - - | 1.5 1.5 1.0 | 5.44 × 19.82 4.95 × 19.82 5 × 19.86 |

| MIG welding laminated zone | 275 280 280 | 124 118 115 | 6.5 6.5 6.0 | 4.84 × 19.8 4.87 × 19.71 4.7 × 19.75 |

| MIG welding homogenized zone | 288 287 289 | 143 153 159 | 4.0 4.0 4.0 | 5.11 × 19.8 4.99 × 19.72 5.08 × 19.76 |

| High-Cycle Fatigue | Serial Number | Maximum Stress | Number of Fatigue Life | Logarithmic Life | The Median Value of Logarithmic Life | Median Fatigue Life | |

|---|---|---|---|---|---|---|---|

| Group method | Level 1 | 8-3 | 180 | 79,000 | 4.8976 | 4.9192 | 83,016 |

| 8-9 | 180 | 102,000 | 5.0086 | ||||

| 8-6 | 180 | 71,000 | 4.8513 | ||||

| Level 2 | 7-1 | 170 | 169,000 | 5.2279 | 5.2550 | 179,880 | |

| 7-2 | 170 | 16,400 | 5.2148 | ||||

| 3-7 | 170 | 210,000 | 5.3222 | ||||

| Level 3 | 3-4 | 160 | 263,000 | 5.4200 | 5.4976 | 314,481 | |

| 8-4 | 160 | 183,000 | 5.2625 | ||||

| 3-2 | 160 | 380,000 | 5.5798 | ||||

| 9-5 | 160 | 574,000 | 5.7589 | ||||

| 9-2 | 160 | 293,000 | 5.4669 | ||||

| Level 4 | 2-10 | 150 | 379,000 | 5.5786 | 5.6540 | 450,804 | |

| 8-8 | 150 | 173,000 | 5.2380 | ||||

| 8-7 | 150 | 531,000 | 5.7251 | ||||

| 7-4 | 150 | 328,000 | 5.5159 | ||||

| 7-7 | 150 | 928,000 | 5.9675 | ||||

| 2-2 | 150 | 792,000 | 5.8987 | ||||

| Level 5 | 6-3 | 135 | 1,004,000 | 6.0017 | 5.9397 | 870,361 | |

| 7-6 | 135 | 779,000 | 5.8915 | ||||

| 2-3 | 135 | 843,000 | 5.9258 | ||||

| Lifting and lowering method | 2-9 | 110 | 289,000 | Coefficient of variation: 0.0563 | |||

| 2-5 | 105 | 3,000,000 | |||||

| 2-4 | 110 | 3,000,000 | |||||

| 2-6 | 115 | 63,000 | |||||

| 2-8 | 110 | 3,000,000 | |||||

| 6-8 | 115 | 3,000,000 | |||||

| 6-6 | 120 | 3,000,000 | |||||

| 6-5 | 125 | 3,000,000 | |||||

| 6-7 | 130 | 1,020,000 | |||||

| 6-1 | 125 | 1,822,000 | |||||

| 8-2 | 120 | 790,000 | |||||

| 8-1 | 115 | 578,000 | |||||

| 2-1 | 110 | 3,000,000 | |||||

| 7-5 | 115 | 785,000 | |||||

| 3-1 | 110 | 3,000,000 | |||||

| 8-5 | 115 | 490,000 | |||||

| High-Cycle Fatigue | Serial Number | Maximum Stress | Number of Fatigue Life | Logarithmic Life | The Median Value of Logarithmic Life | Median Fatigue Life | |

|---|---|---|---|---|---|---|---|

| Group method | Leve 1 | 7-4 | 145 | 94,000 | 4.9731 | 5.1645 | 146,039 |

| 6-4 | 145 | 180,000 | 5.2553 | ||||

| 5-6 | 145 | 103,000 | 5.0128 | ||||

| 5-4 | 145 | 261,000 | 5.4166 | ||||

| Level 2 | 7-5 | 135 | 302,000 | 5.4800 | 5.5510 | 355,633 | |

| 7-6 | 135 | 130,000 | 5.1139 | ||||

| 1-1 | 135 | 564,000 | 5.7513 | ||||

| 2-1 | 135 | 722,400 | 5.8588 | ||||

| Level 3 | 5-3 | 125 | 283,000 | 5.4518 | 5.7370 | 545,731 | |

| 4-6 | 125 | 427,900 | 5.6313 | ||||

| 5-5 | 125 | 922,000 | 5.9647 | ||||

| 6-2 | 125 | 477,000 | 5.6785 | ||||

| 2-2 | 125 | 908,900 | 5.9585 | ||||

| Level 4 | 1-3 | 115 | 558,200 | 5.7468 | 5.7399 | 549,393 | |

| 6-1 | 115 | 158,000 | 5.1987 | ||||

| 6-5 | 115 | 829,000 | 5.9186 | ||||

| 7-3 | 115 | 1,169,000 | 6.0678 | ||||

| 2-3 | 115 | 585,600 | 5.7676 | ||||

| Level 5 | 1-6 | 105 | 884,700 | 5.9468 | 5.8253 | 668,862 | |

| 6-3 | 105 | 833,000 | 5.9206 | ||||

| 4-2 | 105 | 591,300 | 5.7718 | ||||

| 4-5 | 105 | 459,300 | 5.6621 | ||||

| Lifting and lowering method | 3-4 | 90 | 3,000,000 | Coefficient of variation: 0.0376 | |||

| 2-5 | 95 | 2,344,000 | |||||

| 3-6 | 90 | 3,000,000 | |||||

| 2-4 | 95 | 903,000 | |||||

| 2-6 | 90 | 2,889,400 | |||||

| 3-2 | 85 | 3,000,000 | |||||

| 4-1 | 90 | 927,200 | |||||

| 3-3 | 85 | 3,000,000 | |||||

| 5-1 | 90 | 3,000,000 | |||||

| 3-5 | 95 | 1,299,100 | |||||

| 7-1 | 90 | 3,000,000 | |||||

| 7-2 | 95 | 3,000,000 | |||||

| 1-4 | 100 | 3,000,000 | |||||

| 1-5 | 95 | 1,592,400 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Wang, D.; Cao, L.; Ma, L.; Zeng, H. Comparative Analysis of Mechanical Properties and Microstructure of 7B52 Aluminum Alloy Laser-MIG Hybrid Welding and MIG Welding Joints. Metals 2024, 14, 1110. https://doi.org/10.3390/met14101110

Lu Y, Wang D, Cao L, Ma L, Zeng H. Comparative Analysis of Mechanical Properties and Microstructure of 7B52 Aluminum Alloy Laser-MIG Hybrid Welding and MIG Welding Joints. Metals. 2024; 14(10):1110. https://doi.org/10.3390/met14101110

Chicago/Turabian StyleLu, Yu, Dafeng Wang, Lijun Cao, Liangchao Ma, and Haolin Zeng. 2024. "Comparative Analysis of Mechanical Properties and Microstructure of 7B52 Aluminum Alloy Laser-MIG Hybrid Welding and MIG Welding Joints" Metals 14, no. 10: 1110. https://doi.org/10.3390/met14101110