Experimental and Numerical Characterization of Local Properties in Laser-Welded Joints in Thin Plates of High-Strength–Low-Alloy Steel and Their Dependence on the Welding Parameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Base Material

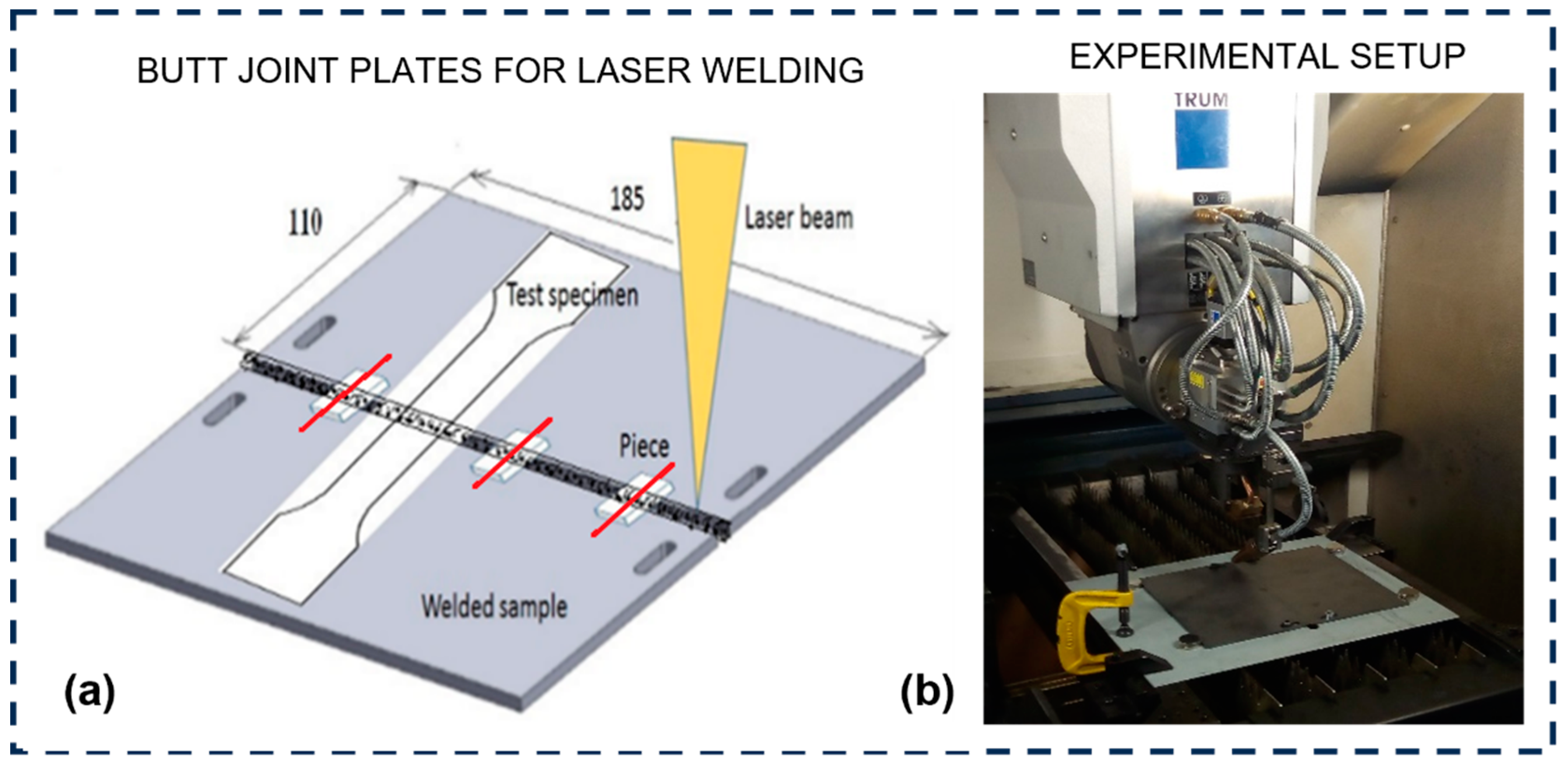

2.2. Laser Welding

2.3. Weld Bead Geometry, Microstructure, and Mechanical Properties

2.4. Numerical Simulation

3. Results and Discussion

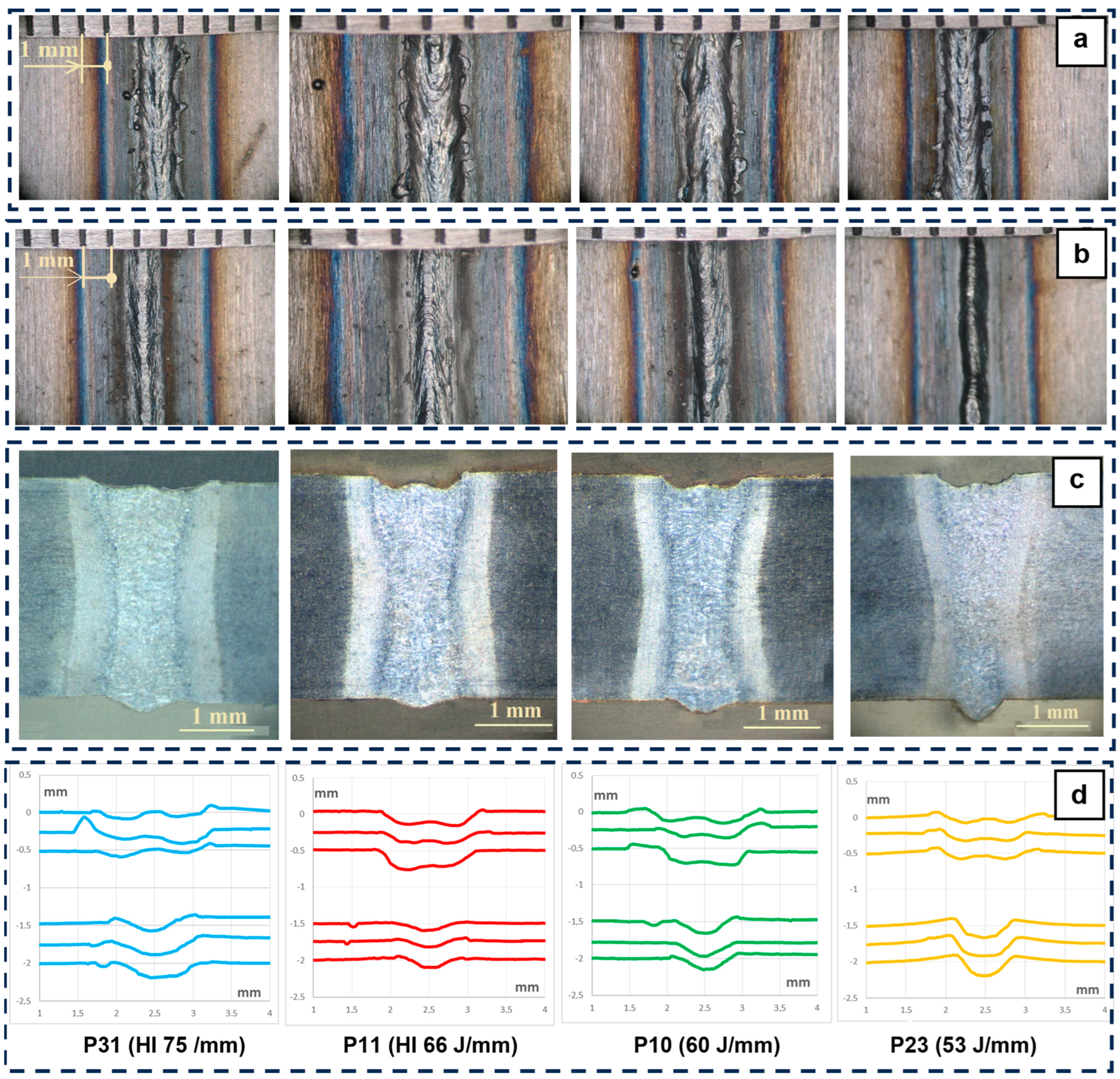

3.1. Weld Bead Geometry Assessment

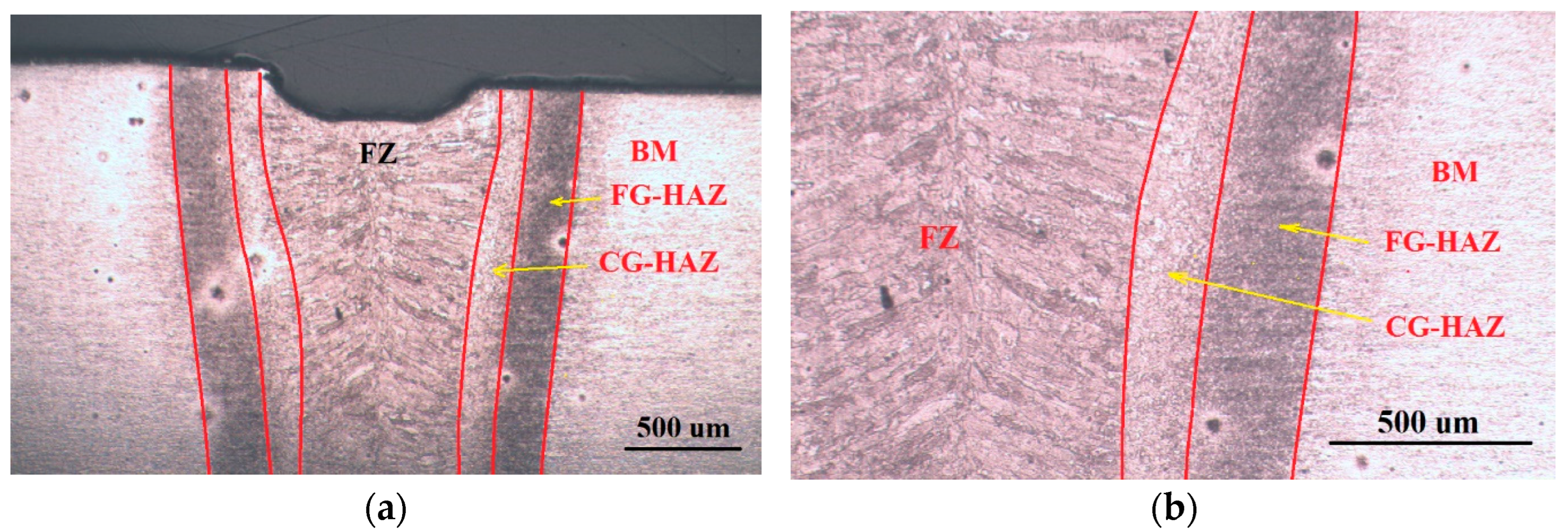

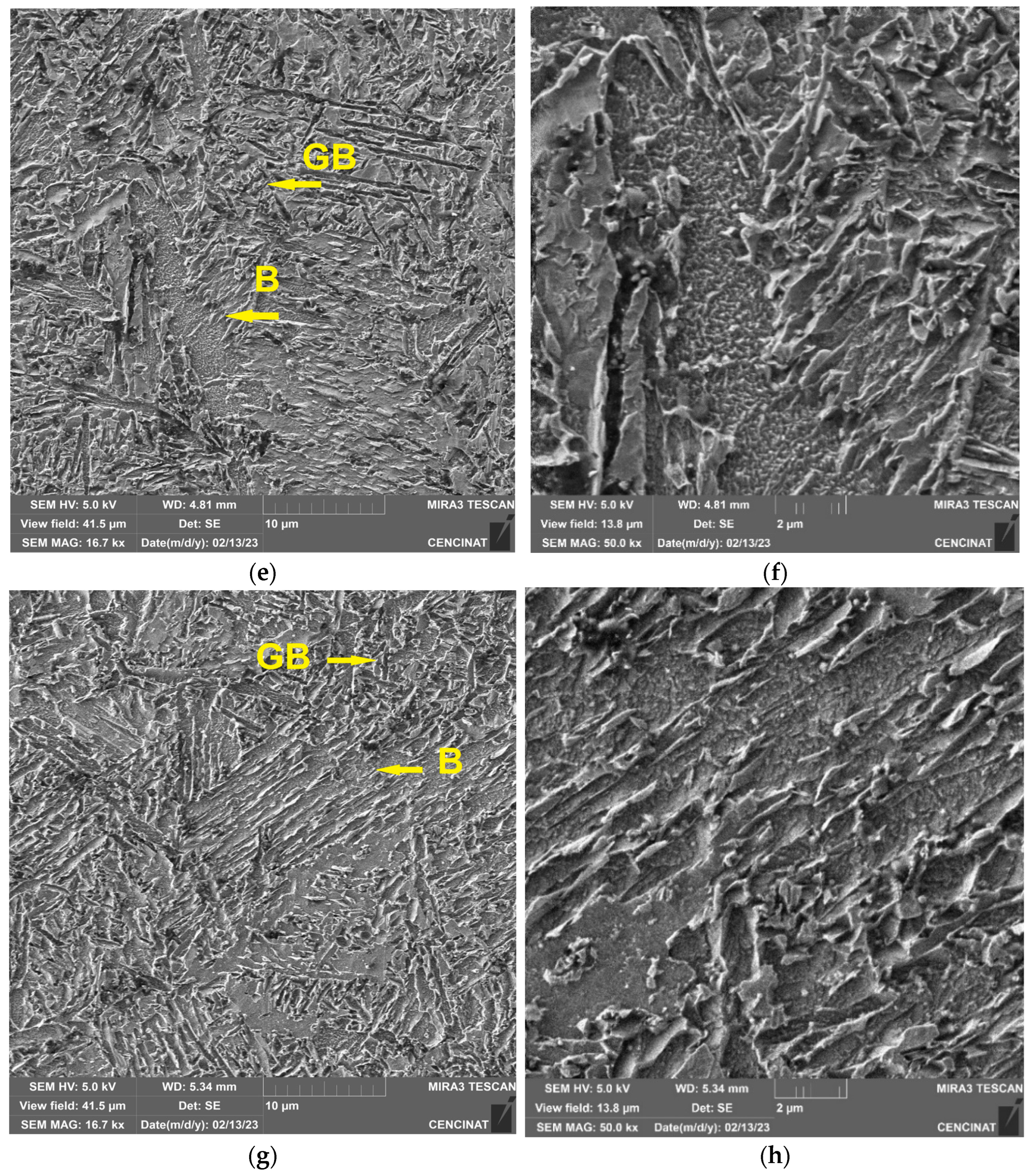

3.2. Microstructural Evolution of Welded Joints

3.3. Mechanical Properties

3.3.1. Microhardness

3.3.2. Tensile Response

3.4. Statistical Analysis of the Weld Bead Profile

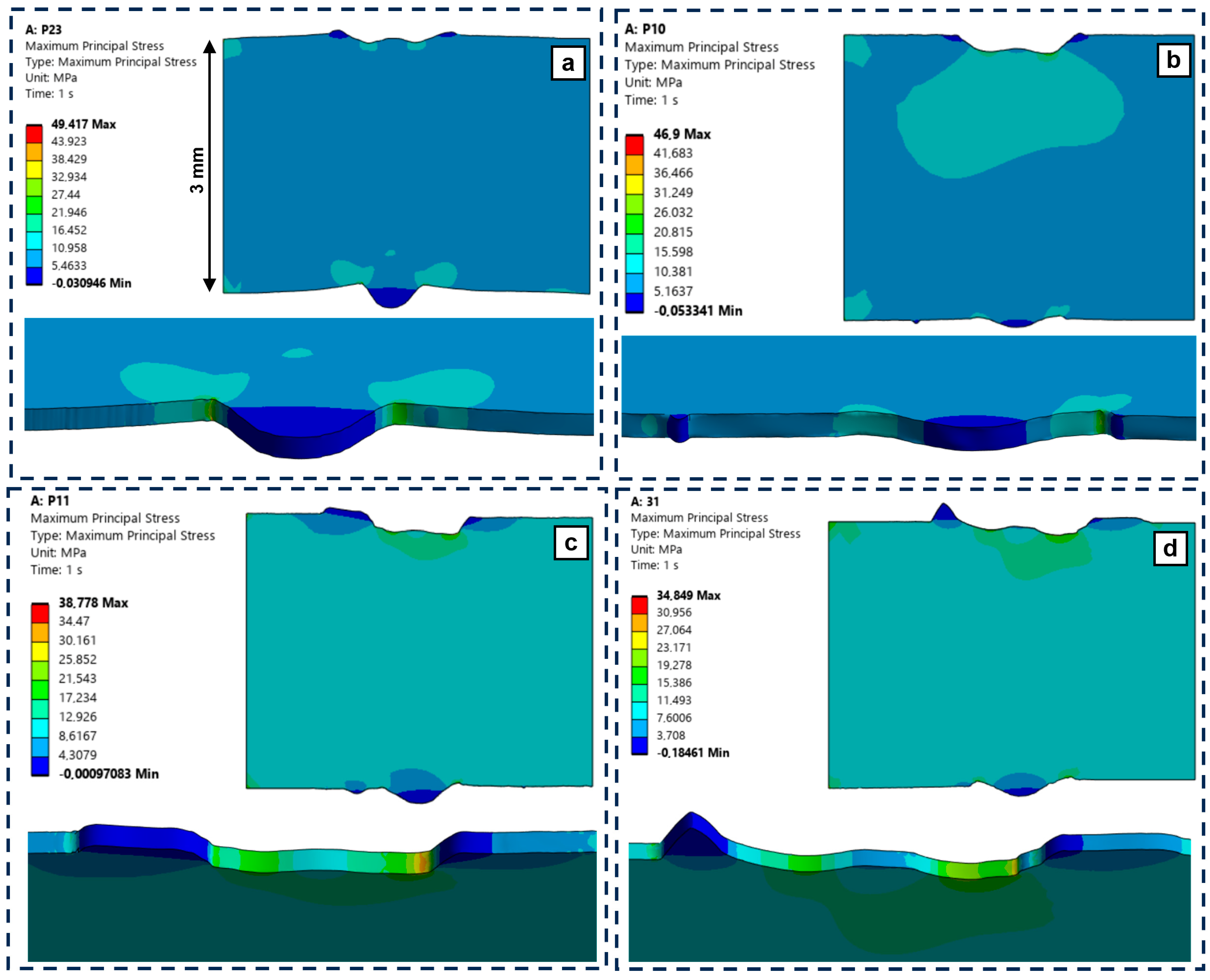

3.5. Stress Concentrating Effect Due to Weld Bead Profile

4. Conclusions

- The base metal microstructure, composed of elongated ferrite and bainite grains, evolved into different microstructures depending on their location in the weld joint and the heat input. For all heat inputs, the FG-HAZ evolved to small equiaxed ferrite and bainite grains, causing softening, and, in the CG-HAZ, to larger grains composed mainly of bainite and lath bainite, causing hardening. In the FZ evolved presenting large columnar grains that, as the heat input increased, blocks of lath-shaped bainite changed to granular bainite, hardening occurred, regardless of the amount of heat input.

- As the heat input increased in the welding joints, the weld bead width, hardness, and mechanical properties resulting from the tensile test also increased. Concerning the base metal, the mechanical properties of the welded joints showed the following behavior: hardness decreased in the FG-HAZ, while it increased in the CG-HAZ and FZ; the ultimate tensile strength was equaled and even slightly exceeded for low heat inputs; the yield strength and the elongation percentage were lower for all heat inputs.

- The factorial experimental design identified the main effects and interaction of laser power and welding speed on the imperfections and weld bead width. It was shown that there was an interaction on all three imperfections, while there was no interaction on weld bead width. ANOVA analysis revealed that underfill was affected by the interaction of the parameters, the excess weld by laser power, and α angle of the excess weld by the welding speed. The welding speed and the interaction turned out to be the most influential considering all the imperfections.

- The values of the stress concentration factor Kt determined by FEM in the real profiles of the weld beads showed relatively high values, the stress concentration was both in the upper profile and lower profile, and there was a slight tendency to increase the value of Kt as the heat input decreased.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, D.; Kim, R.; Choi, K.; Shin, D.; Lee, S. Effects of Beam Shape on the Microstructures and Mechanical Properties during Thin-Foil Laser Welding. Metals 2023, 13, 916. [Google Scholar] [CrossRef]

- Khan, M.S.; Soleimani, M.; Midawi, A.R.H.; Aderibigbe, I.; Zhou, Y.N.; Biro, E. A review on heat affected zone softening of dual-phase steels during laser welding. J. Manuf. Process. 2023, 102, 663–684. [Google Scholar] [CrossRef]

- Afkhami, S.; Javaheri, V.; Amraei, M.; Skriko, T.; Piili, H.; Zhao, X.L.; Björk, T. Thermomechanical simulation of the heat-affected zones in welded ultra-high strength steels: Microstructure and mechanical properties. Mater. Des. 2022, 213, 110336. [Google Scholar] [CrossRef]

- Yang, L.; Gao, S.; Huang, Y.; Sun, M.; Li, Y. Effect of microstructure on tensile and fatigue properties of laser-welded DP780 and DP980 high-strength steel joints. Mater. Sci. Eng. A 2019, 754, 535–555. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, J.; Li, Z.; Gao, S. Effect of heat input on microstructure and corrosion resistance of high-nitrogen austenitic stainless steel welded joints. J. Phys. Conf. Ser. 2023, 2478, 122075. [Google Scholar] [CrossRef]

- Čapek, J.; Kec, J.; Trojan, K.; Černý, I.; Ganev, N.; Kolařík, K.; Němeček, S. Heat-Resistant Pressure Vessel Steel, Verification on Vessel Model. Metals 2022, 12, 1517. [Google Scholar] [CrossRef]

- Churiaque, C.; Sánchez-Amaya, J.M.; Porr, M.; Gumenyuk, A.; Rethmeier, M. The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel. Metals 2021, 11, 600. [Google Scholar] [CrossRef]

- Ribeiro, H.V.; Reis Pereira Baptista, C.A.; Fernandes Lima, M.S.; Santos Torres, M.A.; Marcomini, J.B. Effect of laser welding heat input on fatigue crack growth and CTOD fracture toughness of HSLA steel joints. J. Mater. Res. Technol. 2021, 11, 801–810. [Google Scholar] [CrossRef]

- Vidal, J.G.; Barrionuevo, G.O.; Ramos-grez, J.A.; Vergara, J.; Mullo, J.L. Vibration-assisted laser welding: Frequency and amplitude vibration effect on the microhardness of A36 steel. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2139–2149. [Google Scholar] [CrossRef]

- Mullo, J.L.; Ramos-Grez, J.; Barrionuevo, G.O. Effect of Laser Heat Treatment on the Mechanical Performance and Microstructural Evolution of AISI 1045 Steel-2017-T4 Aluminum Alloy Joints during Rotary Friction Welding. J. Mater. Eng. Perform. 2021, 30, 2617–2631. [Google Scholar] [CrossRef]

- Ma, B.; Gao, X.; Huang, Y.; Gao, P.P.; Zhang, Y. A review of laser welding for aluminium and copper dissimilar metals. Opt. Laser Technol. 2023, 167, 109721. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, X.; Liu, Y.; Cui, H. A Comparative Study on Microstructural Characterization of Thick High Strength Low Alloy Steel Weld by Arc Welding and Laser Welding. Materials 2023, 16, 2212. [Google Scholar] [CrossRef] [PubMed]

- Cornacchia, G.; Cecchel, S. Study and characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 aluminum alloy welding of structural applications: Metal inert gas (MIG), cold metal transfer (CMT), and fiber laser-MIG hybrid comparison. Metals 2020, 10, 441. [Google Scholar] [CrossRef]

- Paul, S.; Singh, R.; Yan, W. Lasers Based Manufacturing; Springer New Delhi: New Delhi, India, 2015; ISBN 978-81-322-2351-1. [Google Scholar]

- He, H.; Forouzan, F.; Volpp, J.; Robertson, S.M.; Vuorinen, E. Microstructure and mechanical properties of laser-welded DP steels used in the automotive industry. Materials 2021, 14, 456. [Google Scholar] [CrossRef]

- Sowards, J.W.; Pfeif, E.A.; Connolly, M.J.; McColskey, J.D.; Miller, S.L.; Simonds, B.J.; Fekete, J.R. Low-cycle fatigue behavior of fiber-laser welded, corrosion-resistant, high-strength low alloy sheet steel. Mater. Des. 2017, 121, 393–405. [Google Scholar] [CrossRef]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F. Microstructure and mechanical behavior of Nd:YAG laser beam welded high strength low alloy steel joints. Optik 2020, 208, 164050. [Google Scholar] [CrossRef]

- Chen, L.; Nie, P.; Qu, Z.; Ojo, O.A.; Xia, L.; Li, Z.; Huang, J. Influence of heat input on the changes in the microstructure and fracture behavior of laser welded 800MPa grade high-strength low-alloy steel. J. Manuf. Process. 2020, 50, 132–141. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Zhou, Y. Fatigue properties of laser welded dual-phase steel joints. Procedia Eng. 2010, 2, 835–843. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Sailer, H.; Brezina, J.; Sahul, M.; Maruschak, P.; Prentkovskis, O. Properties evaluation of the welded joints made by disk laser. Materials 2021, 14, 2002. [Google Scholar] [CrossRef]

- Riofrío, P.G.; Antunes, F.; Ferreira, J.; Batista, A.C.; Capela, C. Fatigue performance of thin laser butt welds in HSLA steel. Metals 2021, 11, 1499. [Google Scholar] [CrossRef]

- Schork, B.; Kucharczyk, P.; Madia, M.; Zerbst, U.; Hensel, J.; Bernhard, J.; Tchuindjang, D.; Kaffenberger, M.; Oechsner, M. The effect of the local and global weld geometry as well as material defects on crack initiation and fatigue strength. Eng. Fract. Mech. 2018, 198, 103–122. [Google Scholar] [CrossRef]

- Guan, M.; Yu, H. Fatigue crack growth behaviors in hot-rolled low carbon steels: A comparison between ferrite–pearlite and ferrite–bainite microstructures. Mater. Sci. Eng. A 2013, 559, 875–881. [Google Scholar] [CrossRef]

- Li, S.; Kang, Y.; Kuang, S. Effects of microstructure on fatigue crack growth behavior in cold-rolled dual phase steels. Mater. Sci. Eng. A 2014, 612, 153–161. [Google Scholar] [CrossRef]

- Riofrío, P.G.; de Jesus, J.; Ferreira, J.A.M.; Capela, C. Influence of local properties on fatigue crack growth of laser butt welds in thin plates of high-strength low-alloy steel. Appl. Sci. 2021, 11, 7346. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, M.; Chen, X.; Wei, L.; Wang, S.; Jiang, Y.; Jiang, N.; Wang, Z.; Lei, Z.; Chen, Y. Investigation of Weld Root Defects in High-Power Full-Penetration Laser Welding of High-Strength Steel. Materials 2022, 15, 1095. [Google Scholar] [CrossRef]

- Riofrío, P.G.; Ferreira, J.A.M.; Capela, C.A. Imperfections and modelling of the weld bead profile of laser butt joints in hsla steel thin plate. Metals 2021, 11, 151. [Google Scholar] [CrossRef]

- Cui, S.; Pang, S.; Zhang, S.; Liao, Y.; Cai, H. Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint. Materials 2022, 15, 3627. [Google Scholar] [CrossRef]

- Ai, Y.; Jiang, P.; Shao, X.; Wang, C.; Li, P.; Mi, G.; Liu, Y.; Liu, W. An optimization method for defects reduction in fiber laser keyhole welding. Appl. Phys. A 2015, 122, 31. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, J.; Ananth, K.P.; Zhao, S.; Ji, X.; Bai, J. Stretchable, self-healing and biodegradable water-based heater produced by 3D printing. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105863. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Romoli, L.; Fiaschi, M.; Dini, G.; Sarri, F. Experimental design approach to the process parameter optimization for laser welding of martensitic stainless steels in a constrained overlap configuration. Opt. Laser Technol. 2011, 43, 158–172. [Google Scholar] [CrossRef]

- Rehman, A.; Lathkar, G.S.; Zubairuddin, M. Finite element analysis of laser welding of 304L butt joint. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Aberbache, H.; Mathieu, A.; Bolot, R.; Bleurvacq, L.; Corolleur, A.; Laurent, F. Experimental analysis and numerical simulation of Laser welding of thin austenitic stainless-steel sheets using two models: Bilinear isotropic strain hardening model and Johnson–Cook model. J. Adv. Join. Process. 2024, 9, 100198. [Google Scholar] [CrossRef]

- STRENX. “Strenx®700 MC”, SSAB. Available online: https://www.ssab.com/en/brands-and-products/strenx (accessed on 25 September 2024).

- Mičian, M.; Frátrik, M.; Brůna, M. Softening effect in the heat-affected zone of laser-welded joints of high-strength low-alloyed steels. Weld. World 2024, 68, 1497–1514. [Google Scholar] [CrossRef]

- Xie, W.; Tu, H.; Nian, K.; Zhang, X. Microstructure and mechanical properties of laser beam welded 10 mm-thick Q345 steel joints. Weld. Int. 2024, 38, 34–44. [Google Scholar] [CrossRef]

- Górka, J. Assessment of steel subjected to the thermomechanical control process with respect to weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef]

- Bayock, F.N.; Kah, P.; Mvola, B.; Layus, P. Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of dissimilar S700MC/S960QC high-strength steels. Metals 2019, 883, 10. [Google Scholar] [CrossRef]

- Chen, S.; Hu, J.; Shan, L.; Wang, C.; Zhao, X.; Xu, W. Characteristics of bainitic transformation and its effects on the mechanical properties in quenching and partitioning steels. Mater. Sci. Eng. A 2021, 803, 140706. [Google Scholar] [CrossRef]

- Lun, N.; Saha, D.C.; Macwan, A.; Pan, H.; Wang, L.; Goodwin, F.; Zhou, Y. Microstructure and mechanical properties of fibre laser welded medium manganese TRIP steel. Mater. Des. 2017, 131, 450–459. [Google Scholar] [CrossRef]

- Yakubtsov, I.A.; Poruks, P.; Boyd, J.D. Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater. Sci. Eng. A 2008, 480, 109–116. [Google Scholar] [CrossRef]

- Olasolo, M.; Uranga, P.; Rodriguez-Ibabe, J.M.; López, B. Effect of austenite microstructure and cooling rate on transformation characteristics in a low carbon Nb–V microalloyed steel. Mater. Sci. Eng. A 2011, 528, 2559–2569. [Google Scholar] [CrossRef]

- Sanati, S.; Nabavi, S.F.; Esmaili, R.; Farshidianfar, A.; Dalir, H. A Comprehensive Review of Laser Wobble Welding Processes in Metal Materials: Processing Parameters and Practical Applications. Lasers Manuf. Mater. Process. 2024, 11, 492–528. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Zhang, P.; Laleh, M.; Hughes, A.E.; Marceau, R.K.W.; Hilditch, T.; Tan, M.Y. Effect of microstructure on hydrogen embrittlement and hydrogen-induced cracking behaviour of a high-strength pipeline steel weldment. Corros. Sci. 2024, 227, 111764. [Google Scholar] [CrossRef]

- Rudzinskas, V.; Kapustynskyi, O. The Role of Welding Parameters in Hydrogen Embrittlement Mitigation: A Case Study in Steel. Res. Rev. Int. J. Multidiscip. 2024, 9, 203–212. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; Volume 106, ISBN 9781119113478. [Google Scholar]

- Behúlová, M.; Babalová, E. Heat source models for numerical simulation of laser welding processes—A short review. J. Phys. Conf. Ser. 2024, 2712, 012018. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.; Walczak, M.; La Fé-Perdomo, I. Numerical analysis of the effect of processing parameters on the microstructure of stainless steel 316L manufactured by laser-based powder bed fusion. Mater. Today Proc. 2021, 59, 93–100. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | V | Nb | Ni | Cu | Al | Mo | Ti | Co | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. | 0.07 | 1.69 | 0.01 | 0.012 | 0.006 | 0.03 | 0.02 | 0.046 | 0.04 | 0.011 | 0.044 | 0.016 | 0.117 | 0.016 | balanced |

| D.S.* | 0.12 | 2.1 | 0.21 | 0.020 | 0.01 | - | 0.20 | 0.09 | - | - | 0.015 | - | 0.15 | - | balanced |

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | |

|---|---|---|---|

| Exp. | 751 | 808 | 18.2 |

| D.S. | 700 | 750–950 | 12 |

| Sample Designation | Power (kW) | Welding Speed (m/min) | Heat Input (J/mm) |

|---|---|---|---|

| P23 | 1.75 | 2.0 | 53 |

| P10 | 2.00 | 2.0 | 60 |

| P11 | 1.75 | 1.6 | 66 |

| P31 | 2.00 | 1.6 | 75 |

| Sample Designation | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Heat Input (J/mm) |

|---|---|---|---|---|

| BM | 751 | 808 | 18.2 | -- |

| P23 | 738 | 820 | 14.4 | 53 |

| P10 | 737 | 815 | 15.0 | 60 |

| P11 | 727 | 797 | 14.8 | 66 |

| P31 | 723 | 787 | 14.1 | 75 |

| Sample | Welding Parameters P (kW); v (m/min); HI (J/mm) | Width (mm) | Underfill (µm) | Excess Weld (µm) | Angle (Degrees) |

|---|---|---|---|---|---|

| P 31 | 2.00; 1.60; 75 | 2.10 | −162 | 202 | 27 |

| P 11 | 1.75; 1.60; 66 | 1.98 | −204 | 102 | 26 |

| P 10 | 2.00; 2.00; 60 | 1.81 | −164 | 194 | 31 |

| P 23 | 1.75; 2.00; 53 | 1.72 | −77 | 180 | 52 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | Fo | p-Value | Test the Hypothesis |

|---|---|---|---|---|---|---|

| Power | 9.687 | 1 | 9.687 | 44.2 | 0.0002 | Rejected |

| Welding speed | 3.663 | 1 | 3.663 | 16.7 | 0.0035 | Rejected |

| Interaction | 5.645 | 1 | 5.645 | 25.7 | 0.0010 | Rejected |

| Error | 1.754 | 8 | 219 | |||

| Total | 20.749 | 11 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | Fo | p-Value | Test the Hypothesis |

|---|---|---|---|---|---|---|

| Power | 1416 | 1 | 1416 | 1.4 | 0.2687 | Not Rejected |

| Welding speed | 11,633 | 1 | 11,633 | 11.6 | 0.0093 | Rejected |

| Interaction | 12,470 | 1 | 12,470 | 12.4 | 0.0078 | Rejected |

| Error | 8020 | 8 | 1003 | |||

| Total | 33,540 | 11 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | Fo | p-Value | Test the Hypothesis |

|---|---|---|---|---|---|---|

| Power | 316 | 1 | 316 | 14.1 | 0.0056 | Rejected |

| Welding speed | 694 | 1 | 694 | 30.9 | 0.0005 | Rejected |

| Interaction | 362 | 1 | 362 | 16.1 | 0.0038 | Rejected |

| Error | 179 | 8 | 22 | |||

| Total | 1551 | 11 |

| Sample | Heat Input (J/mm) | Maximum Equivalent Stress (MPa) | Stress Concentration Factor-Kt | Maximum Stress Location |

|---|---|---|---|---|

| P23 | 53 | 32.44 | 3.24 | Lower profile, weld root |

| P10 | 60 | 29.78 | 2.98 | Lower profile, weld root |

| P11 | 66 | 31.77 | 3.18 | Upper profile, underfill |

| P31 | 75 | 27.53 | 2.75 | Upper profile, underfill |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riofrío, P.G.; Barrionuevo, G.O.; Olmedo, F.; Debut, A. Experimental and Numerical Characterization of Local Properties in Laser-Welded Joints in Thin Plates of High-Strength–Low-Alloy Steel and Their Dependence on the Welding Parameters. Metals 2024, 14, 1219. https://doi.org/10.3390/met14111219

Riofrío PG, Barrionuevo GO, Olmedo F, Debut A. Experimental and Numerical Characterization of Local Properties in Laser-Welded Joints in Thin Plates of High-Strength–Low-Alloy Steel and Their Dependence on the Welding Parameters. Metals. 2024; 14(11):1219. https://doi.org/10.3390/met14111219

Chicago/Turabian StyleRiofrío, Patricio G., Germán Omar Barrionuevo, Fernando Olmedo, and Alexis Debut. 2024. "Experimental and Numerical Characterization of Local Properties in Laser-Welded Joints in Thin Plates of High-Strength–Low-Alloy Steel and Their Dependence on the Welding Parameters" Metals 14, no. 11: 1219. https://doi.org/10.3390/met14111219

APA StyleRiofrío, P. G., Barrionuevo, G. O., Olmedo, F., & Debut, A. (2024). Experimental and Numerical Characterization of Local Properties in Laser-Welded Joints in Thin Plates of High-Strength–Low-Alloy Steel and Their Dependence on the Welding Parameters. Metals, 14(11), 1219. https://doi.org/10.3390/met14111219