The Evolution of Cube Texture in Directionally Solidified Fe-3.0 wt. % Si Alloy Assisted by a High Static Magnetic Field

Abstract

:1. Introduction

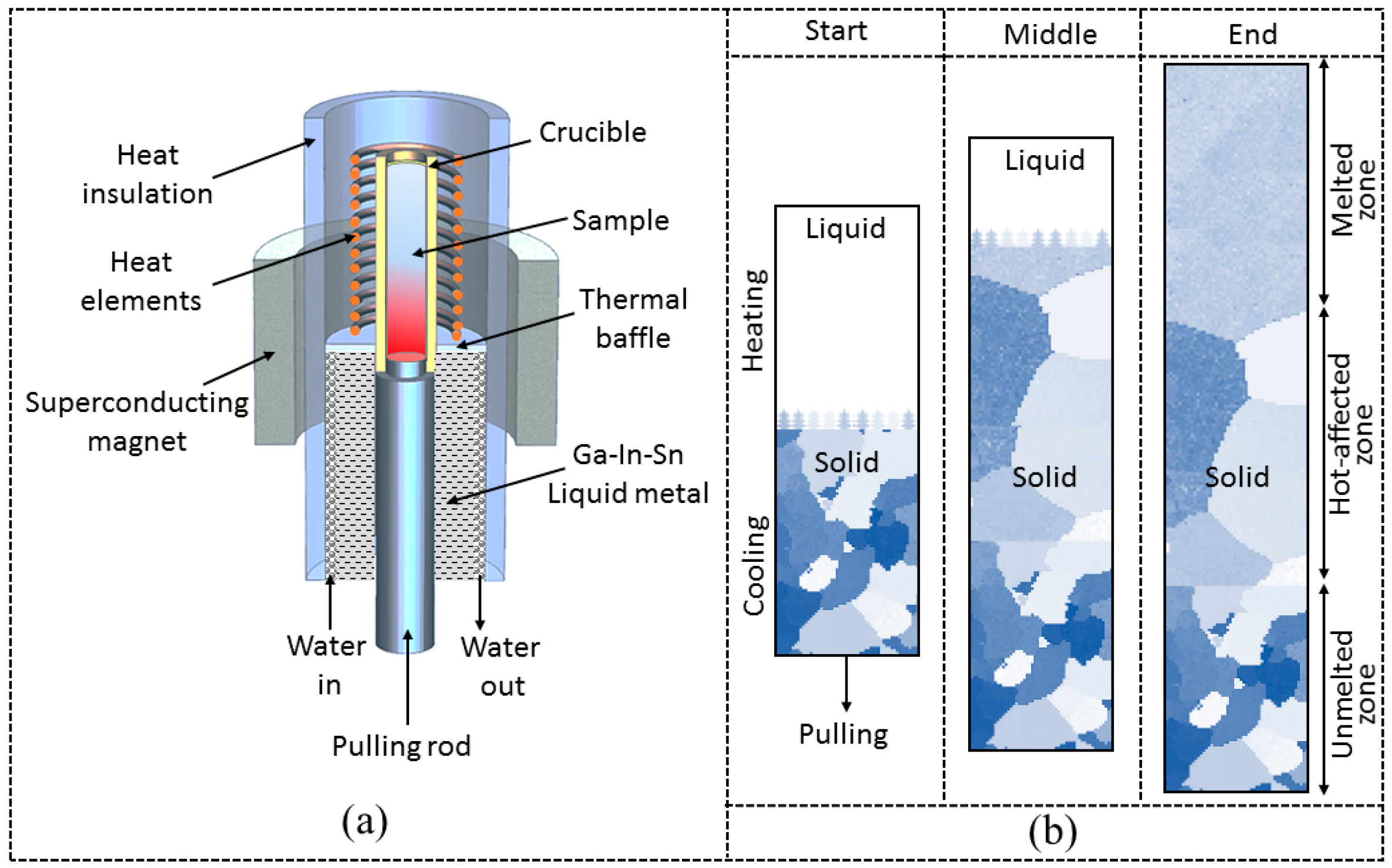

2. Experimental Procedure

3. Results and Discussion

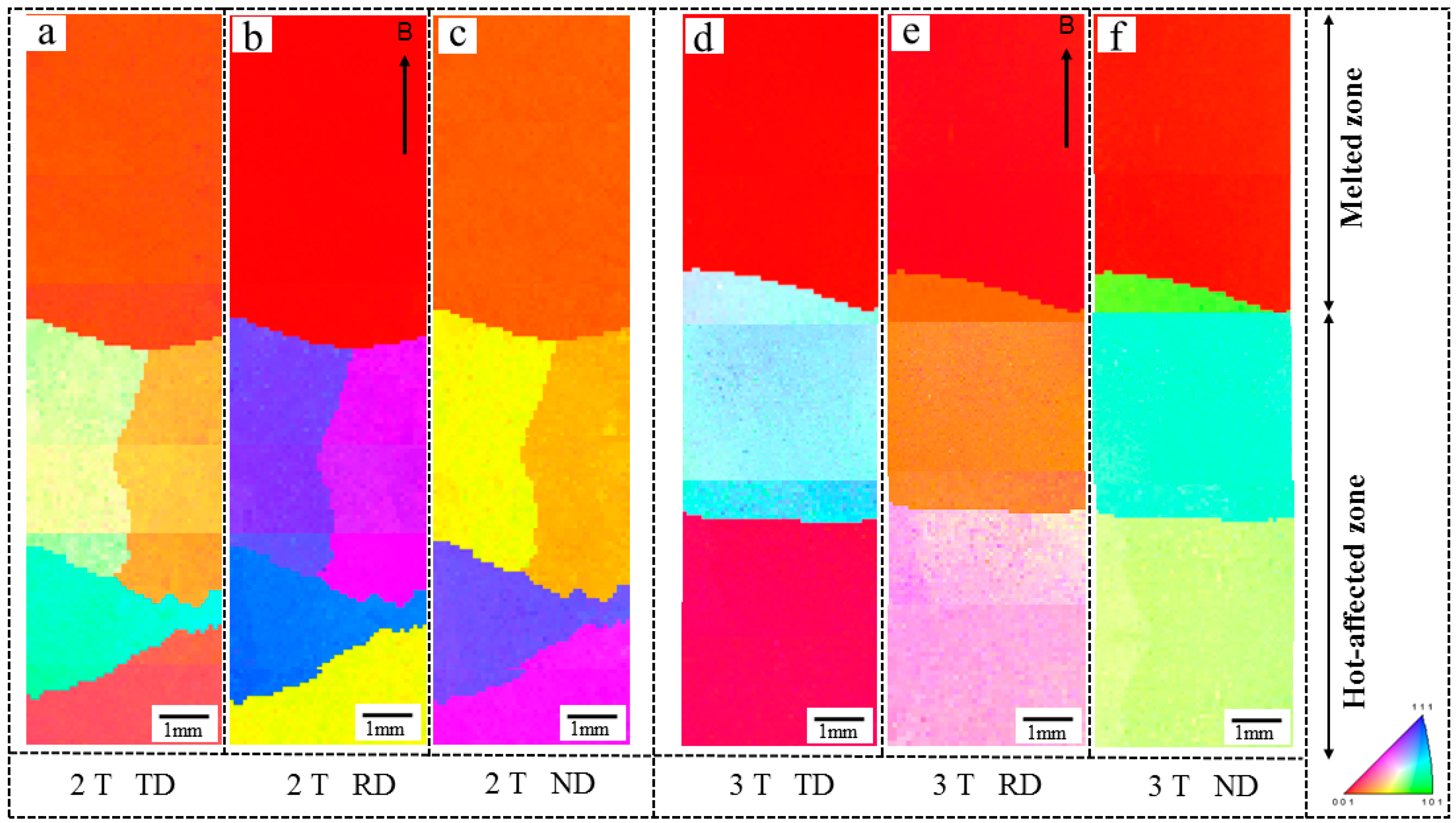

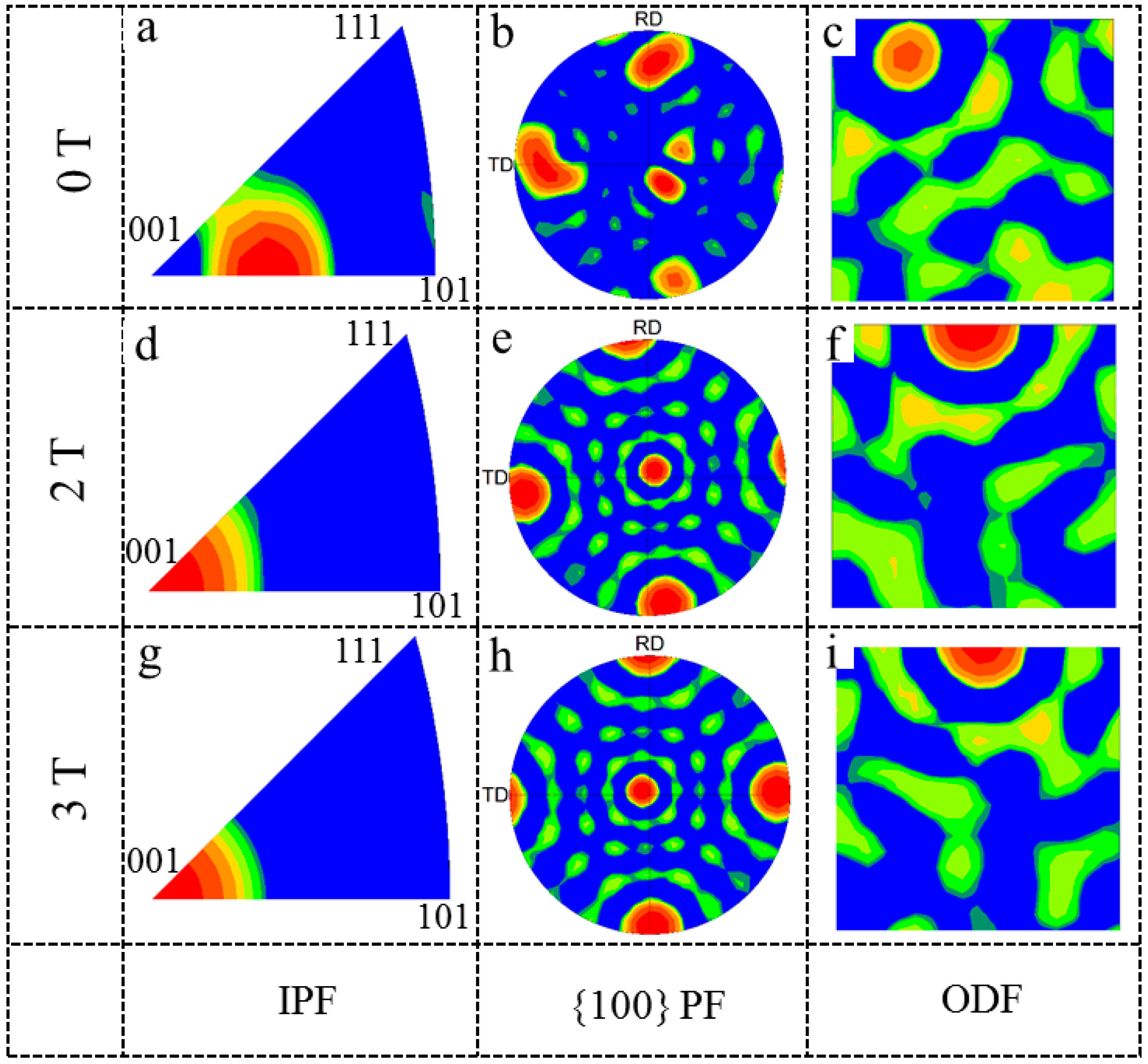

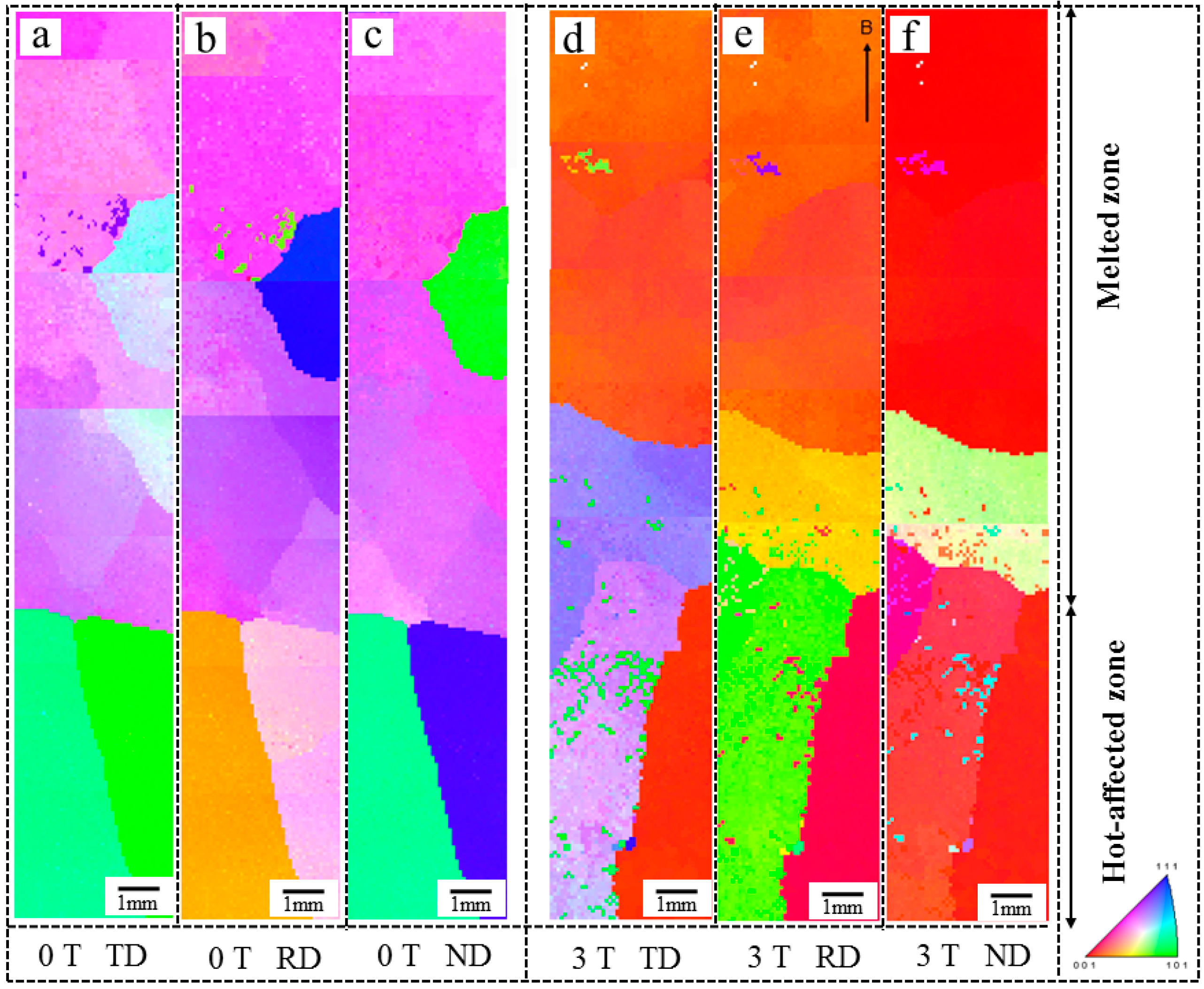

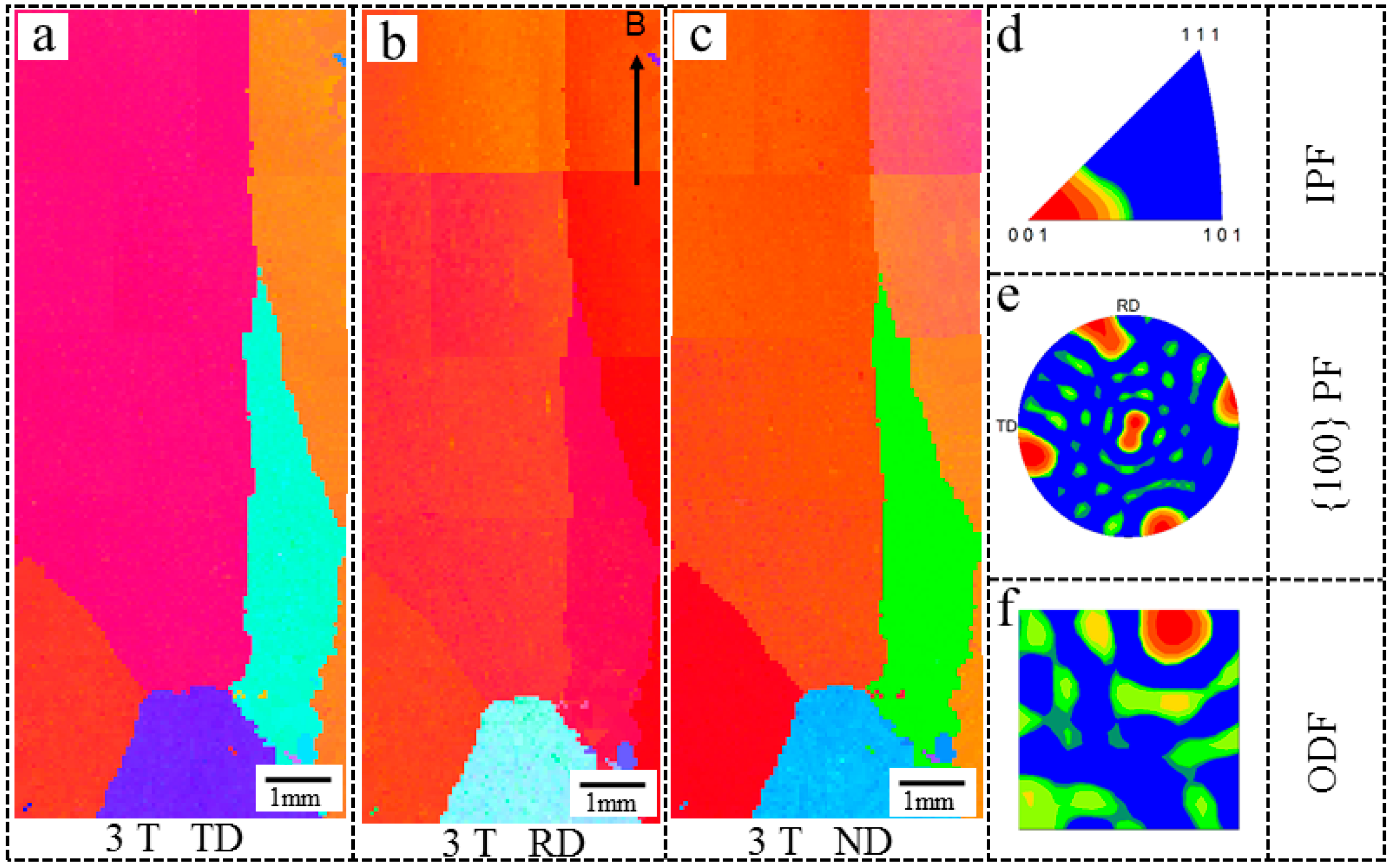

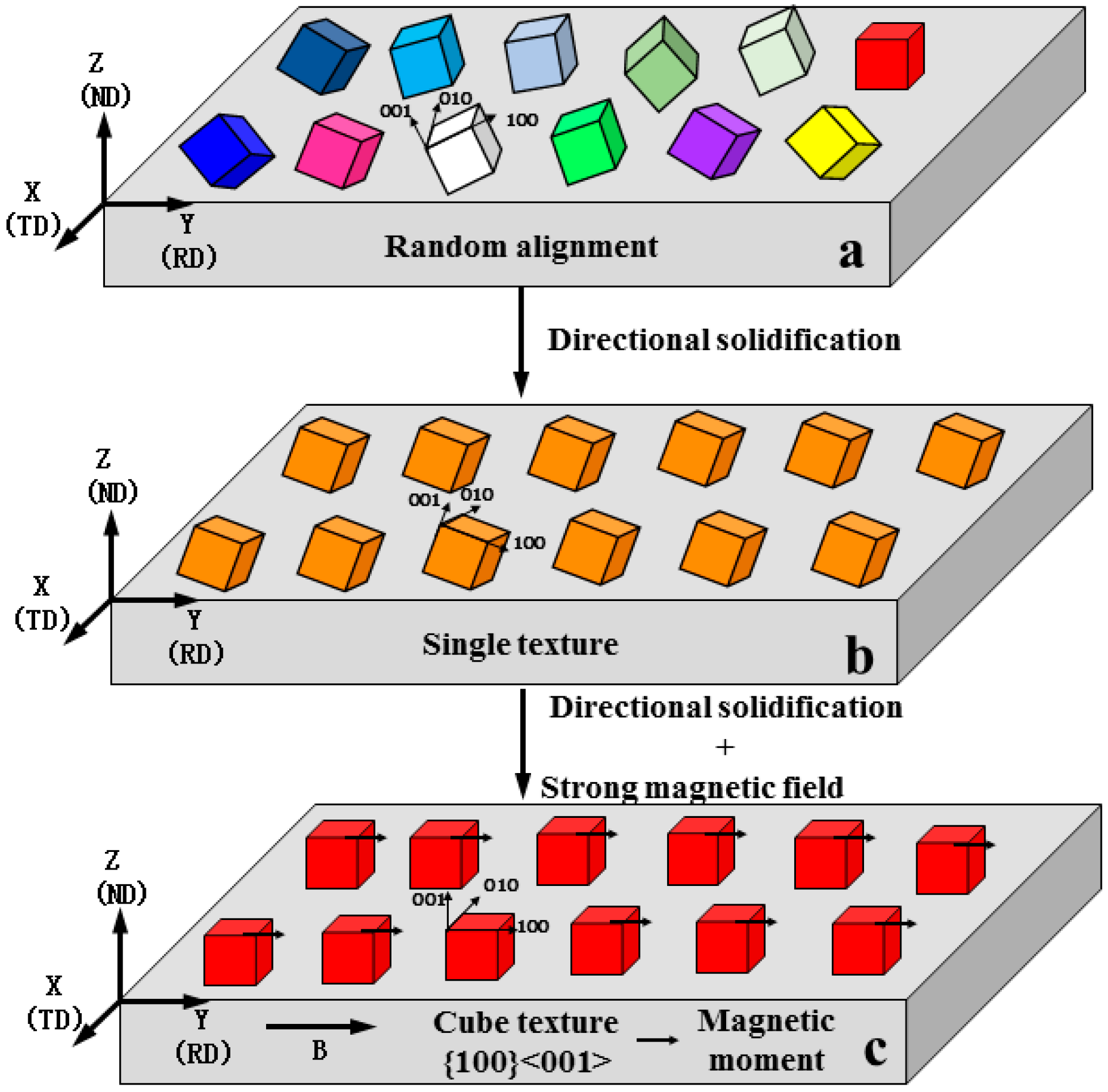

3.1. The Effect of MFD and Growth Speed on the Orientation Selection of α-Fe Crystals

3.2. Effect of an Axial HSMF on Magnetic Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Takada, Y.; Abe, M.; Masuda, S.; Inagaki, J. Commercial scale production of Fe-6.5 wt.% Si sheet and its magnetic properties. J. Appl. Phys. 1998, 64, 5367–5369. [Google Scholar] [CrossRef]

- Ouyang, G.; Chen, X.; Liang, Y.X.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt.% Si high silicon steel-A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Lu, X.; Yuan, G.; Wang, Y.; Fang, F.; Zhang, X.; Wang, G. Texture and microstructure evolution during different rolling methods in strip-cast grain-oriented 6.5% Si steel. J. Magn. Magn. Mater. 2020, 499, 166256. [Google Scholar] [CrossRef]

- Xu, Y.B.; Zhang, Y.X.; Wang, Y.; Li, C.G.; Cao, G.M.; Liu, Z.Y.; Wang, G.D. Evolution of cube texture in strip-cast non-oriented silicon steels. Scr. Mater. 2014, 87, 17–20. [Google Scholar] [CrossRef]

- Jiao, H.T.; Xu, Y.B.; Zhao, L.Z.; Misra, R.D.K.; Tang, Y.C.; Liu, D.J.; Hu, Y.; Zhao, M.J.; Shen, M.X. Texture evolution in twin-roll strip cast non-oriented electrical steel with strong Cube and Goss texture. Acta Mater. 2020, 199, 311–325. [Google Scholar] [CrossRef]

- Cheng, L.; Yang, P.; Fang, Y.P.; Mao, W.M. Preparation of non-oriented silicon steel with high magnetic induction using columnar grains. J. Magn. Magn. Mater. 2012, 324, 4068–4072. [Google Scholar] [CrossRef]

- Zhou, M.C.; Zhang, X.F. Regulating the recrystallized grain to induce strong cube texture in oriented silicon steel. J. Mater. Sci. Technol. 2022, 96, 126–139. [Google Scholar] [CrossRef]

- Zou, X.; Liu, Q.; Qiu, S. A Study on the Formation of Fiber Texture in the Subsurface Layer of Hot-Rolled Plate of 3.2% Si Grain Oriented Steel. Metals 2023, 13, 1597. [Google Scholar] [CrossRef]

- Mehdi, M.; He, Y.L.; Hilinski, E.J.; Kestens, L.A.I.; Edrisy, A. The evolution of cube ({001}<100>) texture in non-oriented electrical steel. Acta Mater. 2020, 185, 540–554. [Google Scholar]

- Sonboli, A.; Mohammad, M.R.; Edris, H.; Szpunar, J.A. Effect of deformation route and intermediate annealing on magnetic anisotropy and magnetic properties of a 1 wt.% Si non-oriented electrical steel. J. Magn. Magn. Mater. 2015, 385, 331–338. [Google Scholar] [CrossRef]

- Zhang, L.W.; Yang, P.; Mao, W.M. Opposite relationship between orientation selection and texture memory in the deformed electrical steel sheets during α→γ→α transformation. J. Mater. Sci. Technol. 2017, 33, 1522–1530. [Google Scholar] [CrossRef]

- Rango, P.D.; Lees, M.; Lejay, P.; Sulpice, A.; Tournier, R.; Ingold, M.; Germi, P.; Pernet, M. Texturing of magnetic materials at high temperature by solidification in a magnetic field. Nature 1991, 349, 770–772. [Google Scholar] [CrossRef]

- Zheng, T.X.; Zhong, Y.B.; Lei, Z.S.; Ren, W.L.; Ren, Z.M.; Wang, H.; Wang, Q.L.; Debray, F.; Beaugnon, E.; Fautrelle, Y. Effects of high static magnetic field on crystal orientation and magnetic property of Bi-5 wt.% Zn alloys. Mater. Lett. 2015, 140, 68–70. [Google Scholar] [CrossRef]

- Guo, X.Y.; Liu, T.; Zhang, B.Z.; Dong, M.; Yang, H.Z.; Yuan, S.; Wang, Q. Microstructure, residual stress and magnetic properties of Tb0.27Dy0.73Fe1.95 alloy heat treated in high magnetic field. J. Magn. Magn. Mater. 2023, 588, 171472. [Google Scholar] [CrossRef]

- Dong, M.; Liu, T.; Guo, X.Y.; Dong, S.L.; Wang, T.; Wang, Q. Crystal orientation induced by high magnetic fields during peritectic reaction of alloys. Mater. Charact. 2022, 183, 111608. [Google Scholar] [CrossRef]

- Tang, P.; Tian, Y.; Liu, S.; Lv, Y.; Xie, Y.; Yan, J.; Liu, T.; Wang, Q. Microstructure development in eutectic Al-Fe alloy during directional solidification under high magnetic fields at different growth velocities. J. Mater. Sci. 2021, 56, 16134–16144. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, T.; Tong, Y.; Dong, M.; Li, J.; Wang, J.; Wang, Q. Microstructure evolution of peritectic Al-18 at% Ni alloy directionally solidified in high magnetic fields. J. Mater. Sci. Technol. 2021, 76, 51–59. [Google Scholar] [CrossRef]

- Liu, C.M.; Zhong, Y.B.; Shen, Z.; Zheng, T.X.; Dong, L.C.; Ren, W.L.; Lei, Z.S.; Ren, Z.M. Effect of an axial high static magnetic field on the crystal orientation and magnetic property of Fe-4.5 wt.% Si alloy during bulk solidification. Mater. Lett. 2019, 247, 189–192. [Google Scholar] [CrossRef]

- Hou, Y.; Shuai, S.S.; Dong, Y.H.; Xuan, W.D.; Wang, J.; Zhang, Z.Q.; Ren, X.F.; Ren, Z.M. Effect of thermoelectric magnetic convection on shrinkage porosity at the final stage of solidification of GCr18Mo steel under axial static magnetic field. Metall. Mater. Trans. B 2019, 50, 881–889. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Chen, G.; Bei, H.B.; Li, F.; Ye, F.; Chen, G.L.; Liu, C.T. Directional recrystallization and microstructures of an Fe–6.5 wt.% Si alloy. J. Mater. Res. 2009, 24, 2654–2660. [Google Scholar] [CrossRef]

- Tournier, R.F.; Beaugnon, E. Texturing by cooling a metallic melt in a magnetic field. Sci. Technol. Adv. Mat. 2009, 10, 014501. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.D.; Zhang, Z.H.; Jiang, Y.B.; Xie, J.X. Improvement of magnetic properties of an Fe–6.5 wt.% Si alloy by directional solidification. Mater. Lett. 2011, 65, 1416–1419. [Google Scholar] [CrossRef]

- Liu, C.M.; Zhong, Y.B.; Shen, Z.; Zheng, T.X.; Dong, L.C.; Ren, W.L.; Lei, Z.S.; Ren, Z.M. Magnetic field–dependent microstructure evolution and magnetic property of Fe–6.5 Si–0.05 B alloy during solidification. J. Mater Res. 2019, 34, 4076–4084. [Google Scholar] [CrossRef]

- Du, D.-F.; Fautrelle, Y.; Ren, Z.M.; Moreau, R.; Li, X. Effect of a high magnetic field on the growth of ternary Al-Cu-Ag alloys during directional solidification. Acta Mater. 2016, 121, 240–256. [Google Scholar] [CrossRef]

- Li, X.; Fautrelle, Y.; Ren, Z.M.; Gagnoud, A.; Zhang, Y.D.; Esling, C. Morphological instability of interface, cell and dendrite during directional solidification under strong magnetic field. J. Cryst. Growth 2011, 318, 23–27. [Google Scholar] [CrossRef]

- Liu, H.; Xuan, W.D.; Xie, X.L.; Li, C.J.; Wang, J.; Yu, J.B.; Li, X.; Zhong, Y.B.; Ren, Z.M. Columnar-to-equiaxed transition and equiaxed grain alignment in directionally solidified Ni3Al alloy under an axial magnetic field. Metall. Mater. Trans. A 2017, 48, 4193–4203. [Google Scholar] [CrossRef]

- Akiyama, J.; Asano, H.; Iwai, K. Analysis of uniaxial alignment behavior of nonmagnetic materials under static magnetic field with sample rotation. Mater. Trans. 2008, 49, 787–791. [Google Scholar] [CrossRef]

- Sun, Z.H.I.; Guo, M.; Vleugels, J.; Van, O.; Blanpain, B. Strong static magnetic field processing of metallic materials. Curr. Opin. Solid. St. M. 2012, 16, 254–267. [Google Scholar] [CrossRef]

- Ren, W.L.; Zhang, T.; Ren, Z.M.; Zhao, A.K.; Zhong, Y.B.; Guo, J.T. A dramatic increase in dendrite number for directionally solidified superalloy DZ417G with a strong static magnetic field. Mater. Lett. 2009, 63, 382–385. [Google Scholar] [CrossRef]

- Myung, N.V.; Park, D.Y.; Yoo, B.Y.; Sumodjo, P.T.A. Development of electroplated magnetic materials for MEMS. J. Magn. Magn. Mater. 2003, 265, 189–198. [Google Scholar] [CrossRef]

- Wang, S.; Liang, Y.F.; Ye, F.; Geng, G.H.; Lin, J.P. Microstructure, mechanical and magnetic properties of melt extracted Fe-6.5 wt.% Si microwires. J. Mater. Process. Technol. 2017, 249, 325–330. [Google Scholar] [CrossRef]

- Stojakovic, D.; Doherty, R.D.; Kalidindi, S.R.; Landgraf, F.J.G. Thermomechanical processing for recovery of desired <001> fiber texture in electric motor steels. Metall. Mater. Trans. A 2018, 39, 1738–1746. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Chen, Z.; Li, H.; Lin, W.; Feng, M.; Zheng, T.; Zhou, B.; Zhong, Y. The Evolution of Cube Texture in Directionally Solidified Fe-3.0 wt. % Si Alloy Assisted by a High Static Magnetic Field. Metals 2024, 14, 1264. https://doi.org/10.3390/met14111264

Liu C, Chen Z, Li H, Lin W, Feng M, Zheng T, Zhou B, Zhong Y. The Evolution of Cube Texture in Directionally Solidified Fe-3.0 wt. % Si Alloy Assisted by a High Static Magnetic Field. Metals. 2024; 14(11):1264. https://doi.org/10.3390/met14111264

Chicago/Turabian StyleLiu, Chunmei, Zijian Chen, Hongyu Li, Wenhao Lin, Meilong Feng, Tianxiang Zheng, Bangfei Zhou, and Yunbo Zhong. 2024. "The Evolution of Cube Texture in Directionally Solidified Fe-3.0 wt. % Si Alloy Assisted by a High Static Magnetic Field" Metals 14, no. 11: 1264. https://doi.org/10.3390/met14111264

APA StyleLiu, C., Chen, Z., Li, H., Lin, W., Feng, M., Zheng, T., Zhou, B., & Zhong, Y. (2024). The Evolution of Cube Texture in Directionally Solidified Fe-3.0 wt. % Si Alloy Assisted by a High Static Magnetic Field. Metals, 14(11), 1264. https://doi.org/10.3390/met14111264