Abstract

This study aims to enhance the amorphous formation ability and magnetic properties that are crucial for the production of high-quality nanocrystalline alloys. The structural, thermal, and magnetic characteristics of the alloy ribbons were analyzed through a systematic adjustment of Nb content, and, including Nb, significantly improved the amorphous formation ability and thermal stability of the alloy, which is vital for nanocrystalline production. By varying the Nb content within Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5), we explored finer adjustments to achieve homogeneous amorphousness during the melt spinning process. Careful control over the Nb content facilitated the production of amorphous ribbons with consistent homogeneity, which was critical for the subsequent fabrication of nanocrystalline structures through heat treatment. As a result, the amorphous ribbon of Fe85.5Si2B8P4Cu1Nb0.5 showed a low coercivity of 7 A/m. The heat treatment showed a remarkably high saturation magnetic flux density of 1.94 T. Additionally, the grain size (D) decreased as the Nb content increased, with D values ranging from 25.09 nm to 24.29 nm, as calculated by the Scherrer formula. Mössbauer spectroscopy confirmed the formation of nanocrystalline and residual amorphous phases. The hyperfine magnetic field values (Beff) decreased from 25.7 T to 24.7 T in the amorphous samples and reached 33.0 T in the nanocrystalline phases. This study highlights Nb’s positive impact on thermal stability and amorphous formation capacity in Fe-Si-B-P-Cu alloys, culminating in the successful fabrication of nanocrystalline ribbons with superior structural and magnetic properties.

1. Introduction

Electric motors and wind turbine generators are crucial in the effort towards sustainable energy. These machines use permanent and soft magnets, but the current soft magnets made from silicon steel have some drawbacks. They suffer from high core (iron) loss, which reduces efficiency in energy conversion [1,2]. Amorphous and nanocrystalline alloys are being developed in response to the strong demand for waste reduction and energy savings in the continuous development of electrical devices [3,4,5,6]. Transformers and motors with improved energy efficiency are needed to reduce electricity consumption and physical dimensions [7,8]. This requires the development of a new material with excellent soft magnetic properties that can withstand severe operating conditions such as high temperature and frequency [9,10,11]. The study of annealed nanocrystalline materials demonstrates that annealing conditions have an influence on the distribution of iron microenvironments in Fe-Si nanocrystalline and amorphous matrices, thereby affecting magnetic anisotropy and permeability [12,13,14,15,16,17]. Various nanocrystalline soft magnetic alloys have been developed for specific issues in recent years. Notable examples include FINEMET (Hitachi Metals Ltd., Tokyo, Japan) (Yoshizawa et al., 1988) Fe-Si-B-Nb-Cu [3], NANOPERM (MH&W International Corp., Mahwah, NJ, USA) (Suzuki et al., 1990) Fe-Cu-(Zr, Hf, Nb) [4], HITPERM (Hitperm (Carnegie Mellon University, Pittsburgh, PA, USA) (Willard et al., 1998) Fe-Co-B-Cu-(Zr, Hf, Nb) [5], and NANOMET Fe-Si-B-P-Cu [13]. These alloys offer distinct advantages; for example, FINEMET exhibits low core loss but also a low saturation magnetic flux density (BS) from 1.2 to 1.4 T [3]. To improve the magnetic properties of FINEMET, refractory elements like Zr and Hf have been used to replace Si and B in creating NANOPERM, which has resulted in moderate iron loss and a higher BS. Further enhancements in BS were achieved in NANOPERM by partially substituting Fe with Co, although this also led to an increased core loss [14,18]. While HITPERM offers a high Curie temperature, it has high material costs due to the significant addition of Co [5]. In contrast, NANOMET, a notable advancement in this field, addresses these limitations by offering both low iron loss and a high BS of 1.83 T, attributed to its unique composition. [13,19,20]. Despite their improved mechanical properties, glass-forming ability, and thermal stability, amorphous alloys still have limitations in their soft magnetic properties being significantly degraded under high frequencies due to their metastable state and the absence of magnetic domain walls [21,22]. Optimization for specific applications is possible by reducing residual stress and magneto-crystalline anisotropy through heat treatment, which promotes fine ferromagnetic nanocrystalline formation [12,18].

The NANOMET alloy (Fe-Si-B-P-Cu), developed over 15 years ago, demonstrates great potential due to its exceptional features. It has a high BS of at least 1.83 T, low coercivity (HC), and low iron loss (W) [13,19]. For Fe-based amorphous alloys, mainly used in soft magnetic applications, the first crystalline phase precipitated at the lowest temperature is most likely α-Fe, contributing primarily to high magnetization [8]. Therefore, an appropriate heat treatment temperature is usually within the range between the end of the first crystallization and the beginning of the second crystallization, which effectively controls the volume fraction, precipitate size, and distribution of α-Fe [23]. The NANOMET alloy exhibits magnetic properties primarily due to the presence of α-Fe atoms contributing to its magnetization. Additionally, Si contributes to a DO3-ordered structure that supports magnetic properties, while B prevents the formation of hard magnetic Fe-B compounds. Metalloid elements like P stabilize the amorphous phase, and Cu aids in nucleating Fe nanocrystals, which reduces grain size and increases Fe-based nanograin density, enhancing soft magnetic properties [19,24,25,26]. Recent studies have demonstrated that substituting specific elements in Fe-based alloys can modify their magnetic and structural characteristics. For example, substituting Co in Fe-B-Sn alloys has shown minimal impact on Fe’s local magnetic interactions but significant alterations in those of Sn, attributed to Co’s higher magnetic moment, as revealed by Mössbauer spectroscopy [27]. These findings suggest that elemental substitution provides a viable approach to fine-tuning the local magnetic properties of Fe-based alloys [28].

To address these limitations, we proposed using the Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy system with a high saturation magnetic flux density (Bs) by ensuring at least 80 at.% Fe content [29]. Si is incorporated to facilitate the glass formation [30], B is added to prevent the Fe-B compound formation at higher concentrations [31], and P serves to stabilize the amorphous phase [32], while Cu promotes the phase separation during crystallization, enabling a controlled heat treatment [32]. Finally, approximately 1 at.% of Cu effectively separates the first and second crystallization temperatures (Tx), which correspond to the primary nucleation of α-Fe and the precipitation of the Fe-B compound, respectively [19]. This separation offers a wider and safer temperature interval, ΔT (= Tx2 − Tx1) for the annealing process, which minimizes the possibility of Fe-B formation, which is detrimental to soft magnetic properties. Furthermore, it has been reported that the addition of both Cu and P results in a stable coercivity even after annealing at high temperatures (Ta) [19,32]. Nb is included to enhance the glass-forming ability (GFA) by suppressing the formation of α-Fe and Fe3B phases.

In this study, we synthesized a series of alloys with varying Nb content to enhance the GFA of NANOMET. The addition of Nb effectively suppresses the formation of α-Fe and Fe3B phases in NANOMET-based alloys, improving the GFA. The addition of Nb has been shown to significantly enhance the GFA of metallic glasses. It has been demonstrated that Nb not only improves the structural stability of the alloys but also promotes uniform amorphousness, thereby facilitating better control over the crystallization process [33,34]. Moreover, it resulted in an increase in crystallization temperatures (Tx) and temperature interval between the first and second crystallization temperatures ΔT (=Tx2 − Tx1), leading to improved thermal characteristics of the alloys. After the survey of the different alloys, an annealing treatment was carried out to optimize the magnetic properties further. The effects of annealing on the microstructure and magnetic characteristics were examined using Mössbauer spectroscopy and X-ray diffraction (XRD) to analyze the structural and magnetic transformations induced by the heat treatment.

2. Materials and Methods

The Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy ingots were meticulously prepared through a two-step process to ensure high purity and homogeneity. The raw materials, consisting of Fe (99.95%), Si (99.999%), B (99.5%), Cu (99.99%), Nb (99.95%), and pre-melted Fe3P (99.9%), were carefully melted using induction heating. This method was chosen to avoid complications often encountered during the melting of phosphorus, as it has a relatively low boiling point and high reactivity. By using pre-melted Fe3P, we aimed to prevent any phosphorus volatilization, which could otherwise lead to compositional inaccuracies. The alloys were further processed using arc melting after meticulous induction melting to ensure compositional uniformity. The arc-melting step was performed under a high-purity argon (Ar) atmosphere, minimizing the risk of oxidation. Each alloy ingot underwent a total of four remelting cycles—two via induction and two via arc melting. This repeated remelting, conducted with the utmost care, ensured maximum compositional homogeneity across the entire ingot, reducing any potential for inhomogeneities or segregations within the alloy structure. Once the alloy ingots were prepared, we focused on optimizing the rapid solidification process (RSP) with precision to enhance the material’s ability to form an amorphous structure. Several trial experiments were conducted to determine the ideal conditions for the RSP process, as this directly influences the ability to form amorphous formation. Ultimately, the optimal conditions were found to be a wheel rotation speed of 4000 RPM (which translates to 51.3 m/s), a gap of 1.0 mm between the rotating copper wheel and the quartz tube, and a hole diameter of 0.84 mm in the quartz tube. These specific parameters were selected with great care to maximize cooling rates and improve the amorphous nature of the resulting ribbons. The thermal properties of the produced ribbons were then analyzed using differential scanning calorimetry (DSC). The measurements were carried out under an argon gas flow, and the samples were heated at a controlled rate of 0.34 °C/s. This allowed us to assess the amorphous ribbons’ thermal stability and crystallization behavior. The as-spun ribbons were subjected to annealing treatments to produce nanocrystalline ribbons from the amorphous precursors. These heat treatments were carried out at various temperatures, ranging from 380 °C to 480 °C, for a duration of 10 min. By controlling the annealing temperature and time, we aimed to induce controlled crystallization and thus improve the magnetic properties of the ribbons. The structural properties of both the as-spun and annealed ribbons were investigated using X-ray diffraction (XRD, D8 Advance, Bruker, Billerica, MA, USA), with Cu-Kα radiation as the source. Our study conducted XRD measurements on both as-spun and annealed ribbons using a Bruker D8 Advance diffractometer with Cu-Kα radiation (wavelength: 1.54060 Å) as the source. The operating conditions were set at an accelerating voltage of 40 kV and a current of 40 mA. The scanning rate was maintained at 2.4°/min, with a 2Q range from 20° to 105°, allowing us to examine the phase composition and crystalline structure before and after annealing. Additionally, a helium gas pycnometer was employed to measure the density of the samples, ensuring accurate measurements of the material’s physical properties. Magnetic properties, including saturation magnetic flux density (BS) and coercivity (HC), were measured at room temperature (298 K) using a vibrating sample magnetometer (VSM, 7410-S, Lake Shore, Westerville, OH, USA). These measurements were taken under an in-plane magnetic field, varying from −10,000 to 10,000 Oe, to assess the ribbons’ amorphous and nanocrystalline states. Additionally, the coercivity (HC) of the samples was further analyzed using a direct current (DC) B-H loop tracer (REMAGRAPH C-500, MAGNET-PHYSIK, Cologne, Germany), under a maximum applied field of 800 A/m, also at room temperature (298 K). This provided a more detailed understanding of the magnetic performance, especially with regard to the influence of heat treatment on coercivity. Finally, Mössbauer spectroscopy measurements were conducted at the Korea Atomic Energy Research Institute (KAERI). The Mössbauer spectra were recorded at room temperature (298 K) using a WissEl (GmbH, Mömbris, Germany) spectrometer in the constant acceleration mode in transmission geometry with moving source. A 57Co/Rh source (Ritverc GmbH, Berlin, Germany) with activity of 50 mCi was also at room temperature. The detector counts were stored in 1024 memory channels. The triangular waveform and the 1024 channels generated two mirror-image Mössbauer spectra, each with 512 channels. To measure the clear absorption spectrum, the two spectra were folded into a single 512-channel Mössbauer spectrum [15]. Consequently, a transmission spectrum was obtained with 1024 velocity channels folded into 512 channels to improve measurement efficiency by combining forward and backward spectra. Calibration was performed using general α-Fe foils (25 µm) or α-57Fe foils (4 µm). Although 4 µm foil is optimal for minimizing self-absorption effects and determining metrology linewidth broadening, 25 µm foil is also a widely accepted standard and was sufficient for accurate velocity scale calibration in this study. Calibration spectra using both α-Fe foils (25 µm) and α-57Fe foils (4 µm) were recorded and compared until achieving the same gamma-ray counts. Reference [15] provides data comparing folded and unfolded spectra, demonstrating that the differences are not significant. The velocity range was set to ±12 mm/s. For an optimal comparison of results, all measured spectra were recorded over the same period of time. The thickness of all measured samples was 17 mg Fe/cm2. The Mössbauer spectra were analyzed using the MossWinn 4.0 code, which processes both crystalline components and amorphous phases simultaneously, as shown in [25,35]. The Mössbauer spectra were analyzed using the MossWinn 4.0 code, which processes both crystalline components and amorphous phases simultaneously, allowing for the determination of a magnetic hyperfine field (Beff), hyperfine magnetic field (Hhf), isomer shift (δ), quadrupole splitting (Δ), and relative area (A). This approach is consistent with common practices in Mössbauer spectroscopy, as discussed in the work of Kuzmann, [15,35]. The Mössbauer spectra were fitted using the least-squares method with the MossWinn 4.0 software [15,25,35]. The error values for Beff (±0.1 T) and A (±0.2%) represented the uncertainties associated with the least-squares fitting process of the Mössbauer spectra. These errors arose due to experimental conditions, data quality, and the statistical nature of the fitting procedure. The error for A was updated to reflect its correct dimension as a percentage (%), consistent with how A was represented as a relative area fraction. The corresponding errors in determining Beff and A were ±0.1 T and ±0.2, respectively. The residuals between the experimental data and the fitted data were shown below each Mössbauer spectrum, providing a visual representation of the fitting accuracy and alignment. This information has been included to demonstrate the quality of the spectral fits.

3. Results and Discussion

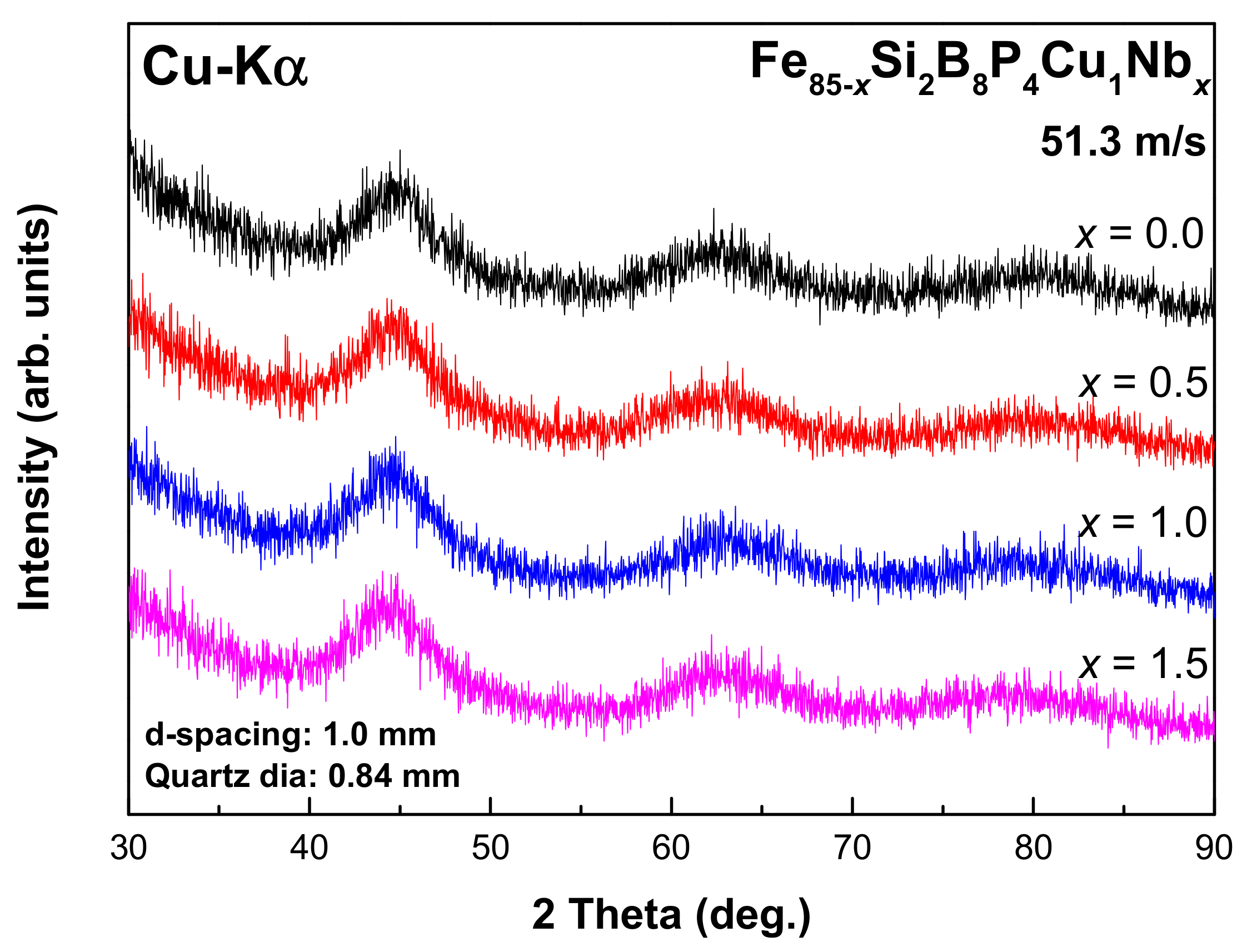

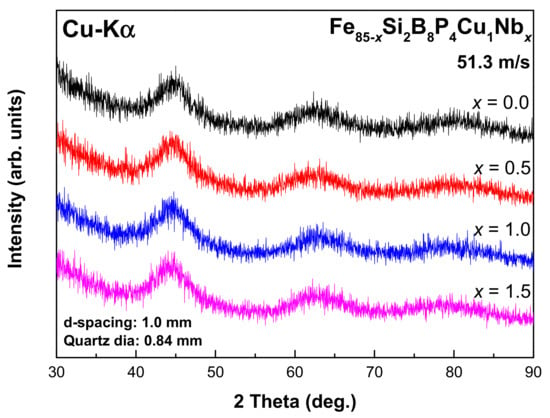

In this paper, we investigated Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloys to investigate further effects of Nb addition. Figure 1 shows the X-ray diffraction pattern of Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5), an amorphous ribbon scanned through melt spinning. It can be seen that the patterns are all amorphous alloys with wide peaks. This characteristic broadening confirms that the alloys lack long-range crystalline order, indicating an amorphous structure. This observation aligns with typical XRD patterns of amorphous metals, as described in the literature [36]. Based on previous experimental research experience, the conditions in the manufacturing process of amorphous ribbons were fine-tuned. The results obtained RSP optimization conditions so that the distance between the wheel and the quartz tube was 1.0 mm and the size of the quartz tube hole was 0.84 mm.

Figure 1.

XRD patterns of as-spun Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy ribbons.

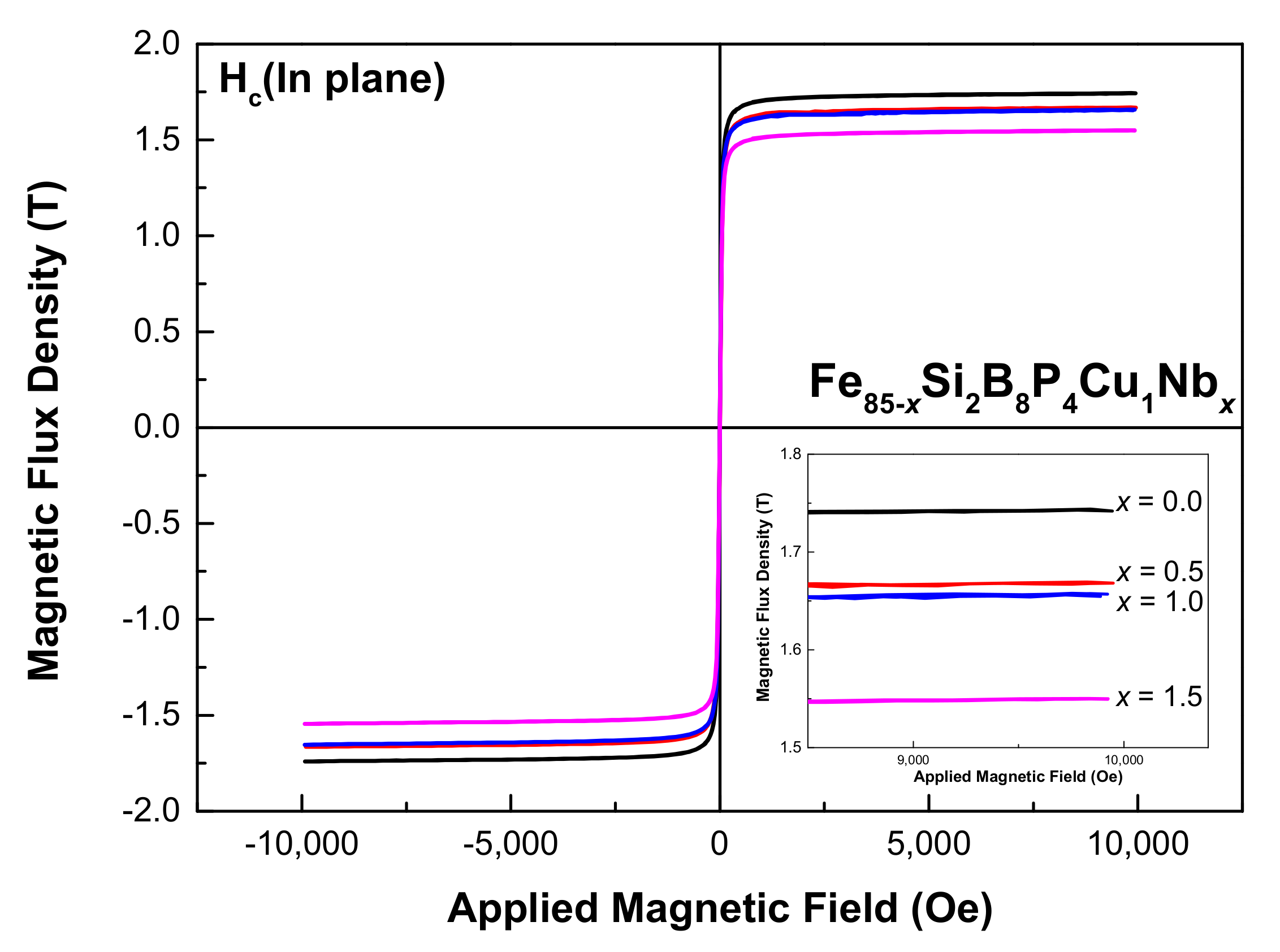

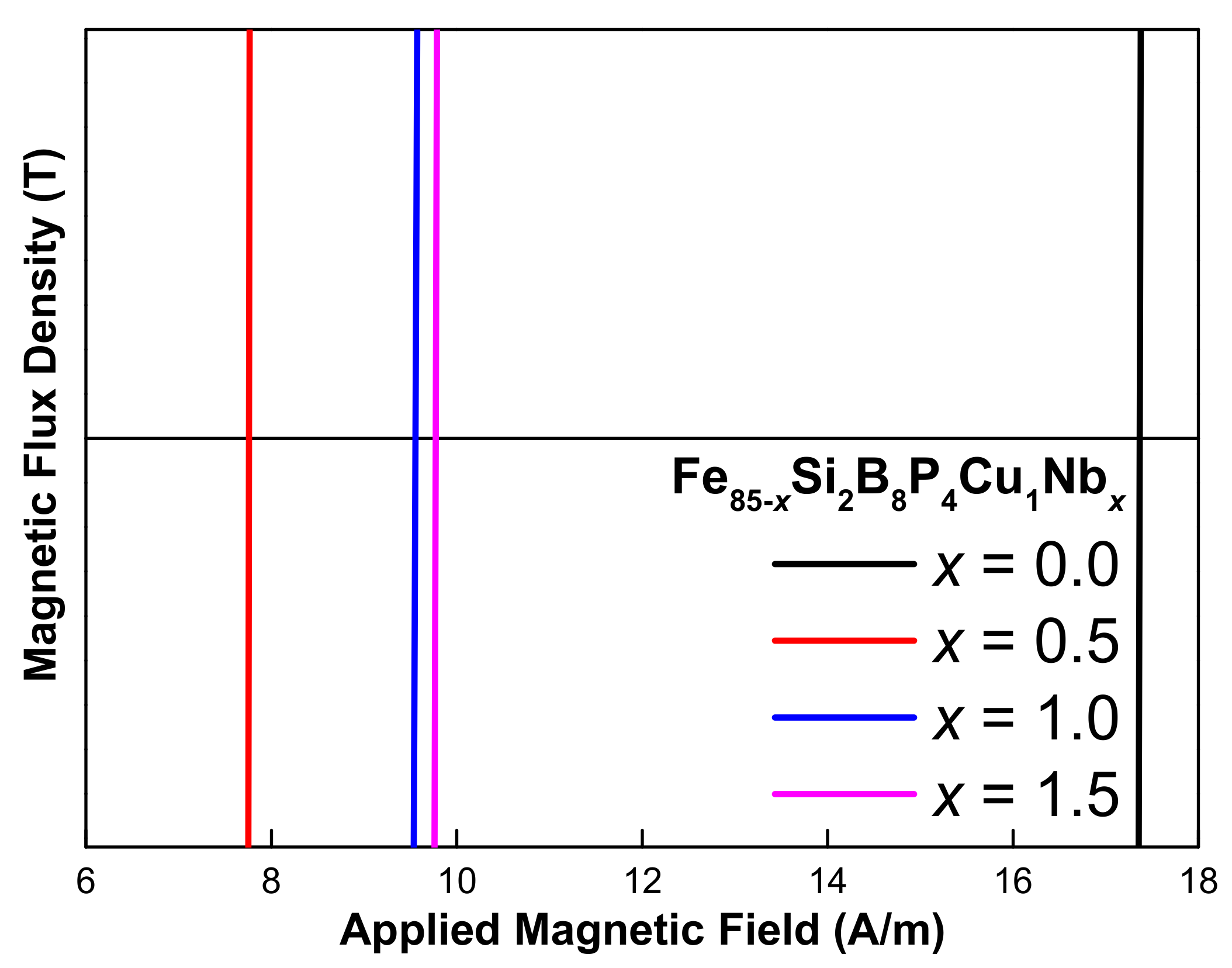

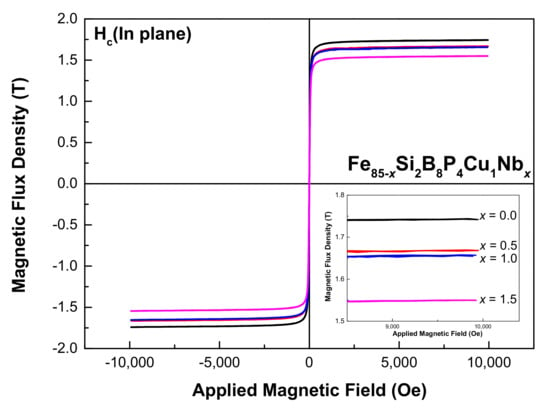

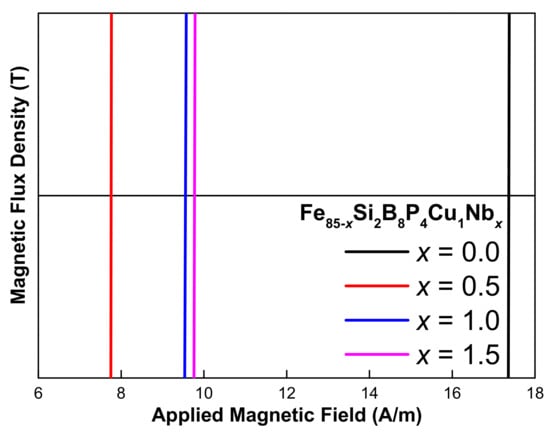

Figure 2 shows that Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) amorphous ribbons are rectangular hysteresis B-H loops. Figure 3 shows excellent soft magnetic properties because the coercivity (HC) measured using the DC B-H tracer is very low. Fe85.0Si2B8P4Cu1 (x = 0.0) shows the highest BS value, but Fe84.5Si2B8P4Cu1Nb0.5 (x = 0.5) shows the highest Bs value among samples to which Nb was added. In this study, we focused on the Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy system, particularly examining the effects of Nb addition on magnetic and thermal properties. Among the amorphous alloys, Fe84.5Si2B8P4Cu1Nb0.5 (x = 0.5) exhibits the lowest coercivity of 7.5 A/m and the highest saturated magnetic flux density of 1.67 T. However, it can be seen that all compositions to which Nb is added show a reduced magnetic flux compared with Fe85.0Si2B8P4Cu1 (x = 0.0). Lower HC and higher BS values are essential to produce a good soft magnetic material. Adding Nb reduces the magnetic flux density, so heat treatment is required to enhance the magnetic properties and compensate for the lower saturated magnetic flux density. Through an effective heat treatment process, we would like to make nanocrystal ribbons with numerous characteristics.

Figure 2.

Hysteresis loops of as-spun Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy ribbons. Insert shows the saturation magnetization part measured by VSM.

Figure 3.

Enlarged B-H loop near coercivity (HC), measured by the DC B-H tracer.

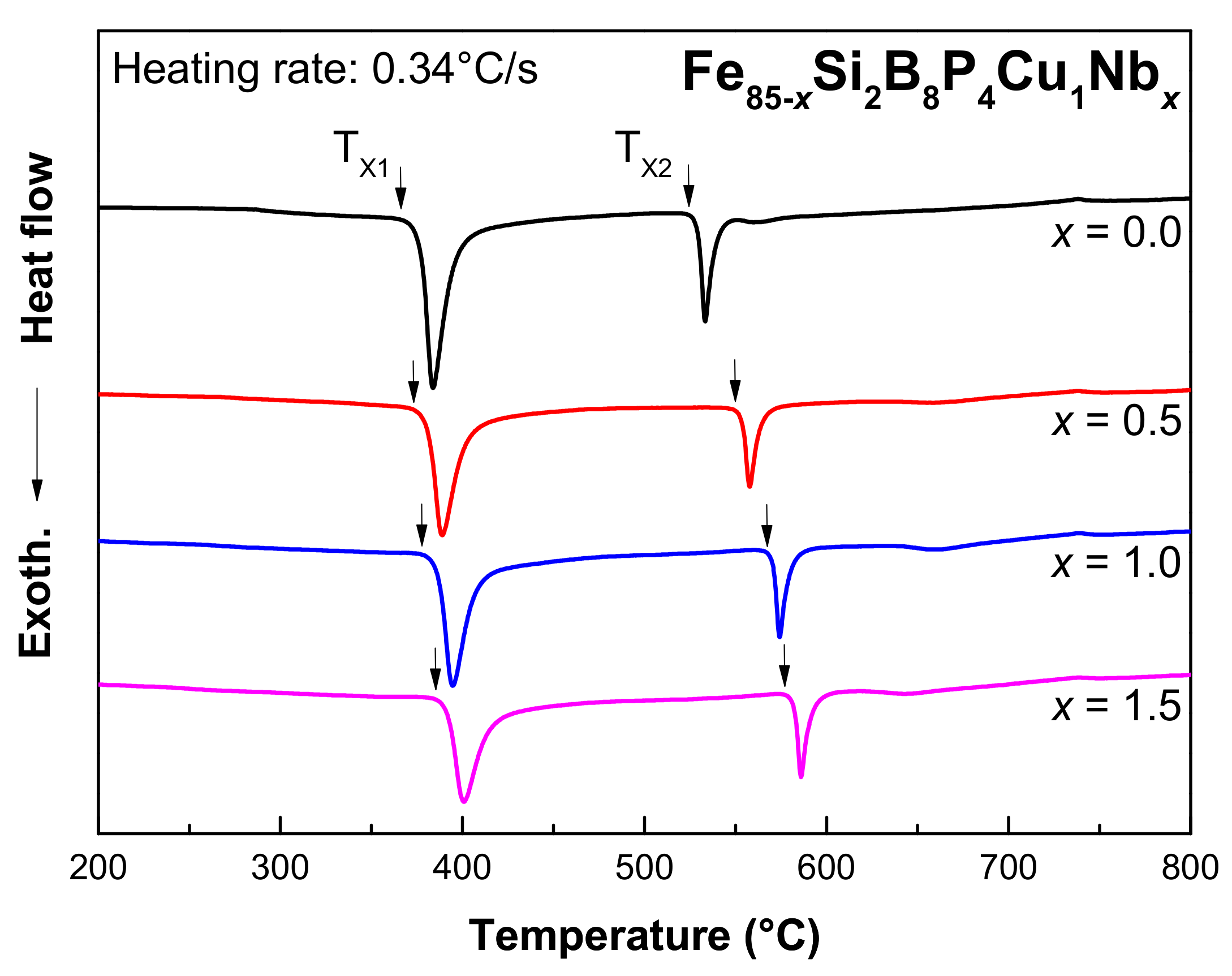

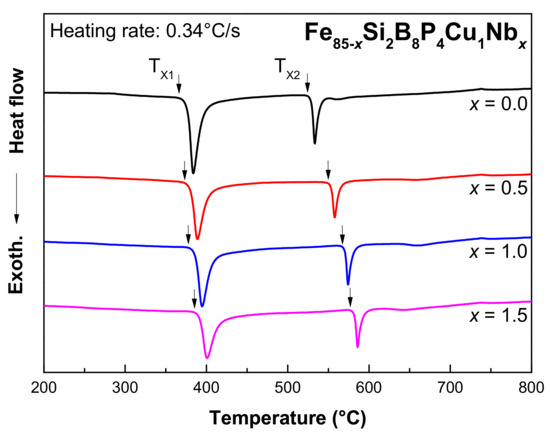

Thermal properties were evaluated, and optimal heat treatment conditions were determined by analyzing the differential scanning calorimeter (DSC) pattern of Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) amorphous ribbons, as shown in Figure 4. All compositions show two exothermic peaks, suggesting crystallization in at least two phases. The first crystallization temperature (Tx1) of the DSC curve corresponds to the formation of the α-Fe phase, and the second crystallization temperature (Tx2) corresponds to the formation of the Fe3B phase [37,38]. When the α-Fe phase is formed, excellent BS is obtained. On the other hand, when the Fe3B phase is formed, attraction increases rapidly, and soft magnetic properties are lost. As shown in the results, the increase in the amount of Nb increases both Tx1 and ΔT (= Tx2 − Tx1) (the interval between the two crystallization temperatures). Specifically, when checking the values in Table 1, it can be seen that Tx1 increases from 374 °C to 391 °C and ΔT increases from 153 °C to 191 °C as the Nb content increases. It can be seen that the highest content of Nb represents the highest value. This means that the addition of Nb improves the thermal stability of the alloy. This improvement in thermal stability is very important for material applications in various fields. In addition, it is important to form an α-Fe phase optimized for excellent softness while controlling the Fe3B phase. Accordingly, the addition of Nb can form a nanocrystal microstructure, mainly composed of the α-Fe phase, in the heat treatment process of the ribbon. To determine the appropriate heat treatment conditions, this paper utilized the Tx1 results obtained in Table 1 to generate the α-Fe phase of each composition. The heat treatment was conducted at 380 °C to 480 °C at 20 °C intervals, and the heat treatment time was conducted for 10 min.

Figure 4.

DSC curves of as-spun Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloy ribbons.

Table 1.

Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) thermal and magnetic properties of amorphous ribbons.

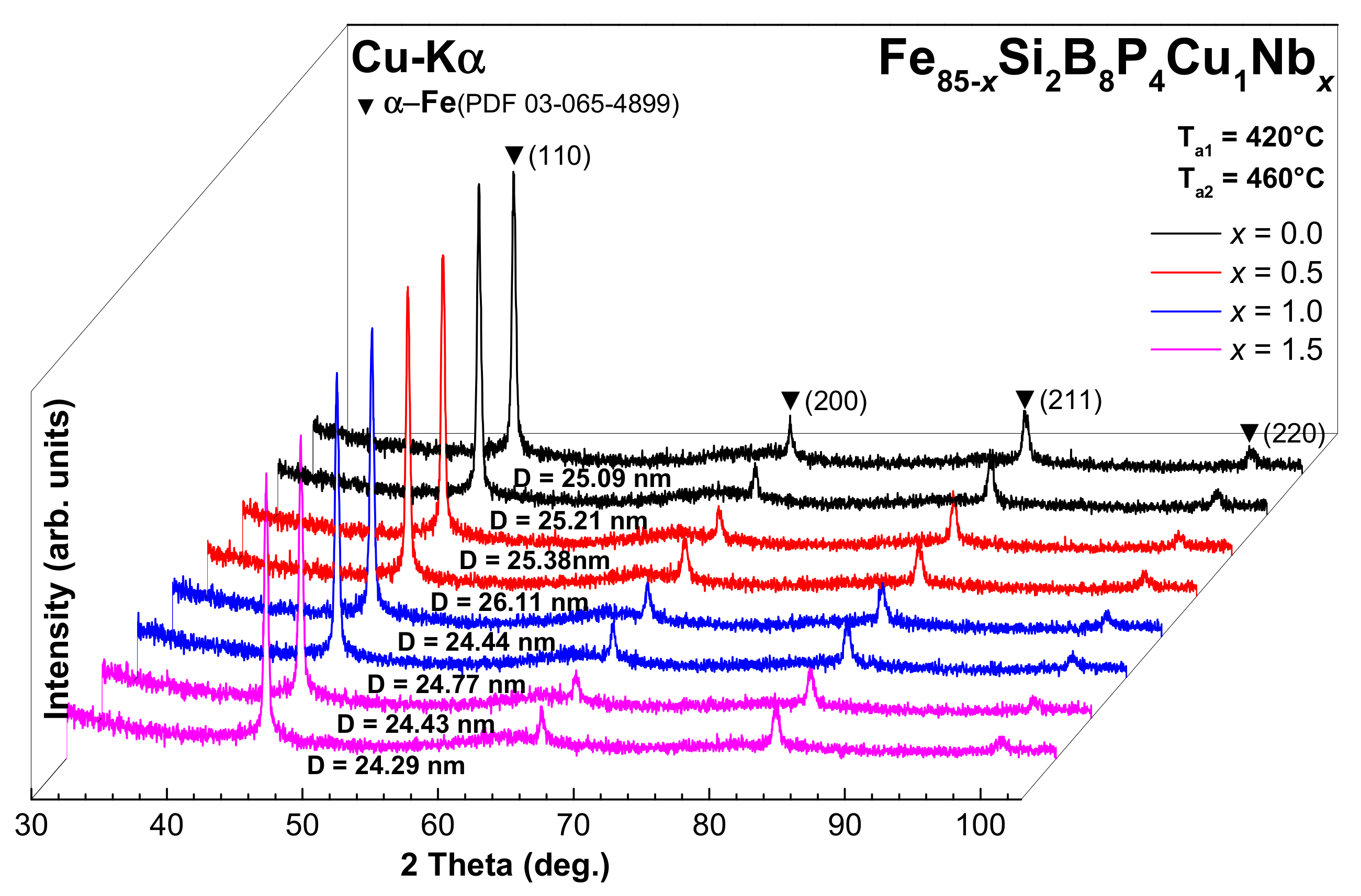

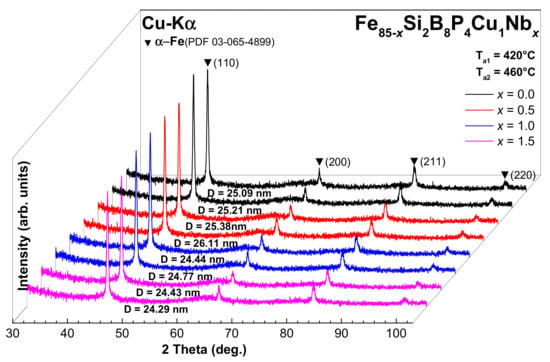

Figure 5 presents the X-ray diffraction pattern of the ribbon heat-treated at 420 °C and 460 °C for 10 min, revealing the presence of the α-Fe phase. Sharp peaks corresponding to α-Fe nanocrystals indicate successful crystallization. The relationship between the broadening of the peak and the grain size (D) can be explained by the Scherrer formula: D = Kλ/(β cosθ), where D is the average grain size, λ is the X-ray wavelength, β is the peak full-width half maximum (FWHM), θ is the diffraction angle, and K is a constant related to the crystallite shape, which is normally taken as 0.9 respectively. The Cu-Kα wavelength of 0.15418 nm is used for λ. In the XRD pattern analysis shown in Figure 5, the particle size quantification method using the Scherrer formula is based only on the peak around 45°.

Figure 5.

XRD patterns of the Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) ribbons annealed at 420 °C and 460 °C for 10 min and the grain size calculated by the Scherrer formula.

XRD experiments on ribbons heat-treated between 380 °C and 480 °C consistently show the formation of the α-Fe phase. The temperatures of 420 °C and 460 °C were chosen for comparison based on their high saturated magnetic flux density values, as determined by nanocrystal magnetic property analysis. The grain size (D) calculated using the Scherrer formula in Figure 5 shows that D decreases from 25.09 nm to at least 24.29 nm as the Nb addition increases. Scherrer equation-based calculations provide an indirect but valuable tool for assessing nanocrystalline structures. This result suggests that Nb, due to its role in suppressing the crystallization kinetics, contributes to the formation of nanometer-sized magnetic α-Fe phases with smaller grain sizes, as supported by broadening analysis of the XRD patterns [39,40]. Notably, at 420 °C, Fe85.0Si2B8P4Cu1 (x = 0.0) exhibits optimal magnetism, while all compositions, including Nb, reach their highest saturated magnetic flux density value at 460 °C.

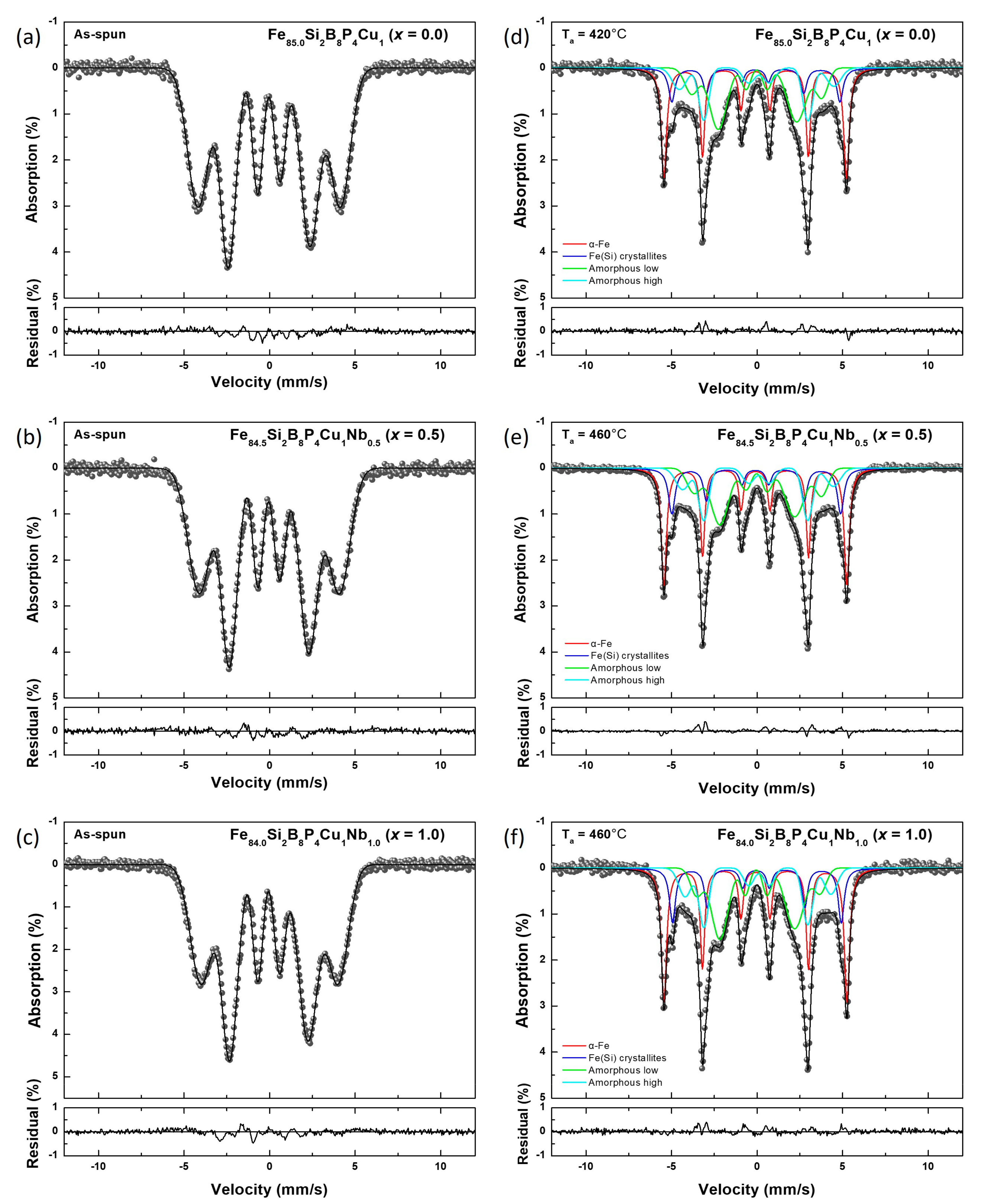

Mössbauer spectroscopy can be used to analyze variations in the magnetic hyperfine field (B-value) at the 57Fe nucleus in Fe-Si-B-P-Cu-Nb alloys, which are determined by the magnetic and electronic configurations in the local microenvironment. This allows for the investigation of how these configurations, arising from the arrangement of magnetic and nonmagnetic atoms, influence local magnetic interactions in both amorphous and nanocrystalline structures. Amorphous materials lack long-range atomic order, whereas nanocrystalline materials consist of nanosized grains that exhibit long-range atomic order within individual grains. In polycrystalline materials, the different random orientations of these grains may result in an irregular overall arrangement. Amorphous and nanocrystalline materials have irregular atomic arrangements or nanosized grains. The amorphous structure can be inferred from the Mössbauer spectra exhibiting broadened absorption lines without well-defined sextet splitting, indicative of the absence of long-range magnetic ordering [25,41,42]. The magnetic and crystallographic structural changes before and after Nb substitution can be compared to investigate the effect of Nb substitution on the alloy structure. Mössbauer spectroscopy provides critical insights into the local magnetic and electronic environments of Fe atoms and can complement other techniques, such as XRD, for investigating the structural characteristics of materials containing both amorphous and nanocrystalline phases [15]. The annealing of Nb-substituted ribbon samples reveals the formation of nanocrystalline and residual amorphous phases. Furthermore, it is important to use other analytical techniques, such as XRD, in conjunction with Mössbauer spectroscopy to accurately identify the mixed structure of crystalline grains and amorphous phases.

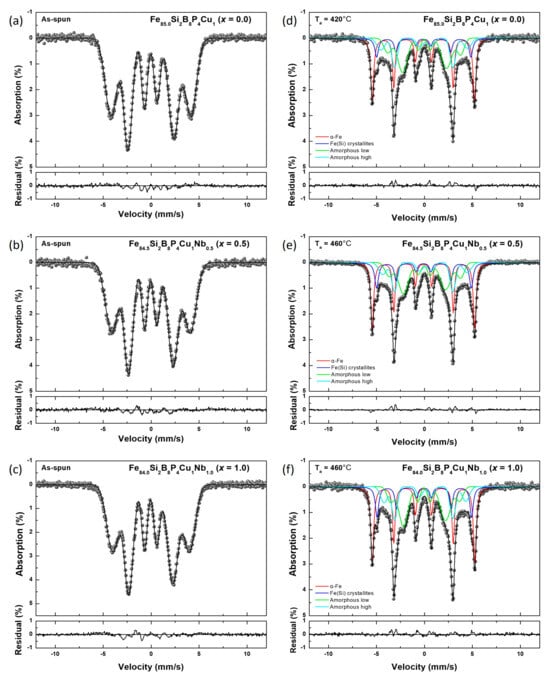

Figure 6a–c show the Mössbauer spectra of as-spun Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0). The spectra exhibit broad absorption lines with overlapping sextet components, which are commonly observed in amorphous alloys due to their complex magnetic microenvironments. The residuals between the experimental data and the fitted data are displayed below each spectrum. The Mössbauer parameters—magnetic hyperfine field (Beff), hyperfine magnetic field (Hhf), isomer shift (δ), quadrupole splitting (Δ), and relative area (A)—are presented in Table 2 and Table 3. The spectrum characteristics presented in Table 2 of this study are consistent with those reported in the literature for as-quenched FINEMET alloys [27], with an average isomer shift of approximately 0.02–0.04 mm/s and a hyperfine field ranging from 24.7 to 25.7 T. This agreement highlights the alignment of our findings with prior studies on comparable amorphous alloy systems. Furthermore, the values observed in Table 2 (25.3–25.7 T) are comparable to the reference data, which report a range of 26.6–28.7 T [20]. These results suggest similar magnetic behavior in the amorphous phases. Additionally, the observed δ value (~0.04 mm/s) suggests a highly uniform environment around Fe atoms, reflecting the ideal structural characteristics of amorphous materials. As summarized in Table 3, the magnetic field values for alpha-Fe in this study (33.0 T) are slightly lower than the range of 33.3 to 36.7 T reported in the reference [20]. Regarding the relative amount (A) of phases, the reference describes a diverse distribution of nanocrystalline phases, such as alpha-Fe and Fe-Si crystallites [20], while this study demonstrates a more balanced phase distribution, indicative of a controlled crystallization process. For isomer shift (IS) and quadrupole splitting (QS), the reference reports an isomer shift of approximately -0.11 mm/s for alpha-Fe, which is in good agreement with the values obtained in this study [20]. This consistency reinforces the similarities in hyperfine interactions and microstructural environments between the two datasets.

Figure 6.

Mösbauer spectroscopy spectra of amorphous and nanocrystalline ribbons of Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0): (a–c) as-spun state; (d–f) annealed at 420 °C or 460 °C.

Table 2.

Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0) Mössbauer parameters of amorphous ribbons.

Table 3.

Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0) Mössbauer parameters of nanocrystalline ribbon.

As shown in Figure 6a–c, the Beff value decreases from 25.7 to 24.7 T as Nb is substituted in the Fe85-xSi2B8P4Cu1Nbx amorphous samples. The addition of Nb results in an increase in the near-neighbor distance and a decrease in the topological order in the system, leading to an overall reduction in the Beff value [43]. The Mössbauer spectra of the ribbon samples through heat treatment were evaluated using a model comprising two components representing the amorphous rest (amorphous components with higher and lower magnetic hyperfine fields) and two components representing the crystalline phases (α-Fe and Fe(Si) crystallites) [25,35]. Figure 6d–f show the Mössbauer spectra of the nanocrystalline ribbons obtained by heat treatment of the amorphous precursors of Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0) at 420 °C or 460 °C for 10 min. The spectra of the nanocrystalline ribbons were analyzed with α-Fe, Fe(Si) crystalline, and amorphous components with higher hyperfine fields and low states corresponding to residual amorphous phases. In the spectrum of Figure 6d, the appearance of a peak corresponding to 33.0 T of bcc Fe (α-Fe) characterizes the microstructure with nanograins within the remaining amorphous phase [44]. The Fe(Si) crystalline (<10 at.% Si) phase tends to form a bcc Fe structure during crystallization, where the central Fe atom has 6–8 nearest-neighbor Fe atoms with Si atoms occupying the residual sites [45]. Si atoms tend to occupy the closer regions of Fe atoms in the bcc Fe structure, which diversifies the nanocrystals and increases the crystallinity of the alloy ribbons. The amorphous spectrum of the nanocrystalline ribbons consists of two components: the amorphous component with higher hyperfine field state with a high internal magnetic field and the amorphous component with a lower hyperfine field state with a low internal magnetic field [20]. Additionally, as with Nb substitution, the Beff value of both the amorphous component with the lower hyperfine field (23.6 to 22.4 T) and the amorphous component with the higher hyperfine field (28.0 to 26.4 T) states decrease. Based on these Mössbauer analysis results, we have confirmed that a portion of the amorphous phase crystallizes into the nanocrystalline phase through heat treatment. These data are crucial for understanding the magnetic properties of the amorphous and nanocrystalline ribbons and their relationship to the heat treatment process. The XRD and Mössbauer spectroscopy analyses confirm the formation of α-Fe phases in our samples, correlating with improved magnetic properties post heat treatment.

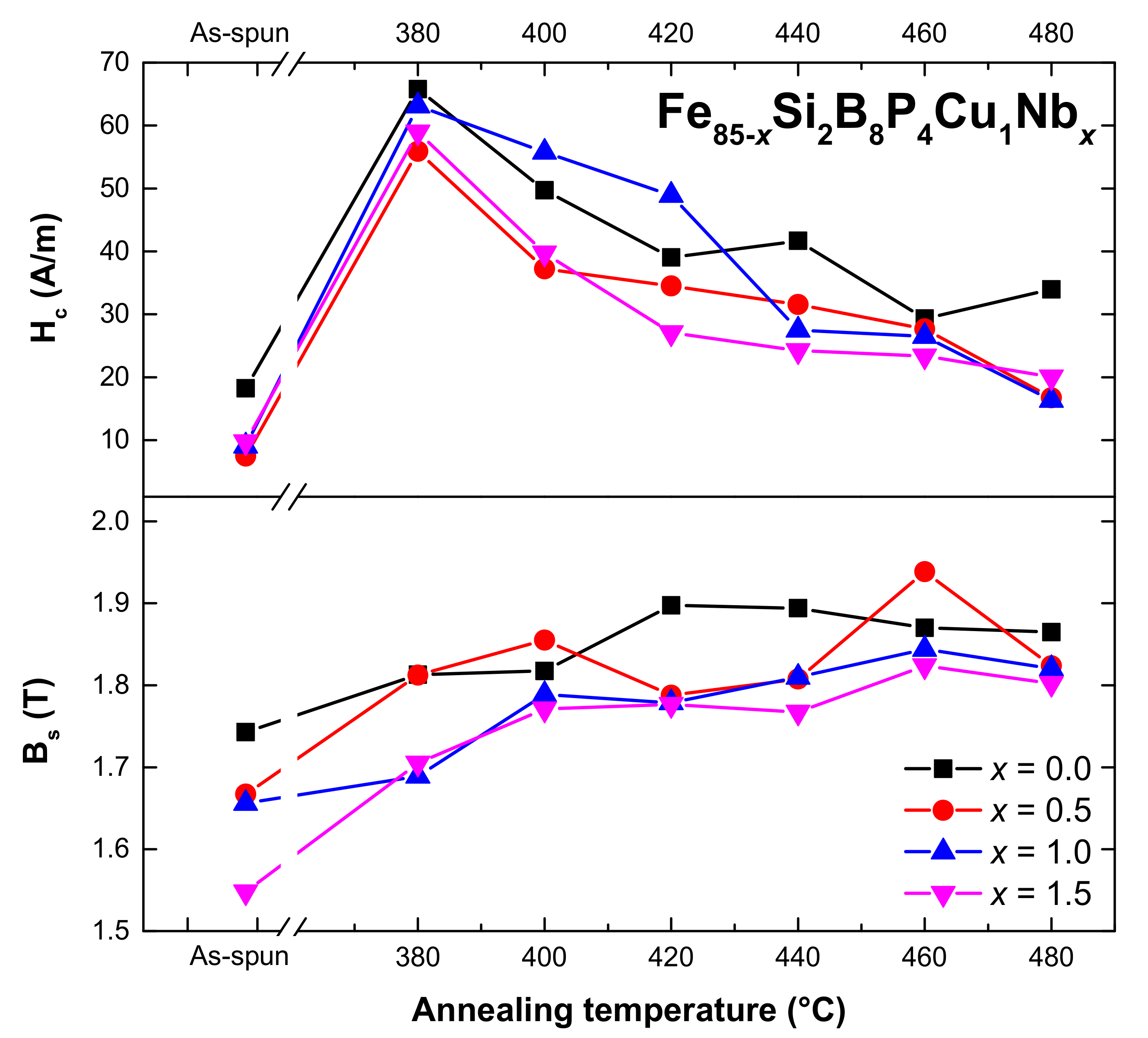

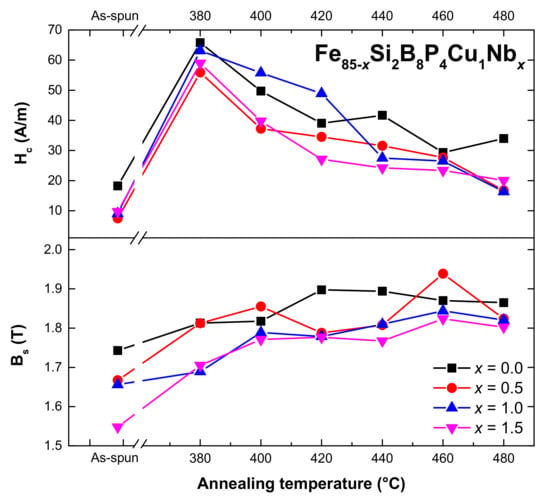

Figure 7 shows the tendency of coercivity (HC) and saturated magnetic flux density (BS) of amorphous and nanocrystalline ribbons by composition. In all the composition results, BS tend to increase as the heat treatment temperature increases, attributed to the formation of the α-Fe phase. Among the nanocrystalline alloys, our Nb-doped samples demonstrate a maximum saturation magnetization of 1.94 T, surpassing typical values reported for other well-known alloys. For instance, the FINEMET alloys are known for a lower BS from 1.2 to 1.4 T [3], and NANOMET alloys exhibit a BS of around 1.83 T [19]. This improvement in BS in our Nb-doped samples highlights the enhancements introduced by Nb addition. In all cases, the coercivity (HC) is higher than the amorphous ribbons, with a notable increase, particularly at 380 °C. All of the coercivity results show higher values than amorphous, and it can be seen that the coercivity value increases sharply, especially at 380 °C. This seems to be due to the structural characteristics that are insufficient to form an α-Fe phase by heat treatment at a temperature closer to or lower than the crystallization temperature due to the formation of a non-uniform phase.

Figure 7.

Trends of BS and HC on the annealing temperature of the composition Fe85-xSi2B8P4Cu1Nbx (x = 0. 0, 0.5, 1.0, 1.5) after annealing at 380 °C to 480 °C for 10 min.

From the values in Table 4, we can see the saturated magnetic flux density and magnetic force values of Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) nanocrystal ribbons heat-treated at 420 °C and 460 °C for 10 min. As the amount of Nb added increases, the magnetic force decreases due to the control of the crystal grains. In conclusion, comparing the results of samples without Nb to those with Nb, it is evident that Nb addition partially inhibits the increase in HC upon annealing. In addition, the composition shows a high saturated magnetic flux density (BS) of 1.94 T with low coercivity, indicating well-balanced magnetic properties. This can be attributed to the inhibitory effect of Nb on the crystallization kinetics and also the stabilizing effect of the amorphous matrix [39]. This improvement, along with the observed stabilization effects of Nb, demonstrates both similarities and distinctions in thermal stability and magnetic behavior relative to other Fe-based alloys.

Table 4.

Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) magnetic properties of nanocrystalline ribbons.

4. Conclusions

The Fe85-xSi2B8P4Cu1Nbx (x = 0.0, 0.5, 1.0, and 1.5) alloys were synthesized using a refined amorphous ribbon fabrication process that leveraged extensive experimental experience to produce high-quality material. This enhanced process led to the successful fabrication of nanocrystalline ribbons with a fully amorphous initial structure. This study explored the effects of varying Nb content on these alloys’ structural, thermal, and magnetic properties, revealing key insights into the relationship between composition and performance. One of the significant findings from this work is the increase in thermal stability as indicated by ΔT, with the addition of 1.5 at.% Nb in Fe83.5Si2B8P4Cu1Nb1.5, ΔT rose to 191 °C. This substantial improvement in the alloy’s ability to resist crystallization underscores Nb’s role as a stabilizing element in amorphous alloys. Additionally, the grain size (D), calculated using the Scherrer formula, was found to decrease with increasing Nb content, ranging from 25.09 nm to 24.29 nm. This reduction in grain size contributed to the enhancement of the alloy’s soft magnetic properties. Regarding magnetic properties, the introduction of Nb also proved beneficial to the alloy, with 0.5 at.% Nb, Fe83.5Si2B8P4Cu1Nb1.5 exhibited an exceptionally low coercivity (HC) of 7.5 A/m. This low coercivity is critical in developing soft magnetic materials, as it allows for minimal energy loss during magnetization and demagnetization cycles. Moreover, this composition achieved low coercivity and exhibited a high saturation magnetic flux density (BS) of 1.94 T, demonstrating a favorable balance between magnetic softness and flux density. A comparative analysis with the Nb-free alloy further highlights the advantages of Nb addition. In contrast, the Nb-free alloy showed a higher coercivity of 18.2 A/m, emphasizing the advantages of Nb addition in improving magnetic properties. Mössbauer spectroscopy further confirmed the presence of nanocrystalline and residual amorphous phases, with hyperfine magnetic field (Beff) values decreasing from 25.7 T to 24.7 T in the amorphous phase and reaching 33.0 T in the nanocrystalline phase. This result underscores Mössbauer spectroscopy’s role in identifying and characterizing the microstructural changes induced by varying Nb content. The combination of low HC and high BS in Fe84.5Si2B8P4Cu1Nb0.5 positions it as an ideal candidate for applications requiring high magnetic performance with minimal energy loss. The heat treatment process was another critical factor in optimizing the properties of these alloys. Specifically, heat treating Fe84.5Si2B8P4Cu1Nb0.5 at 460 °C for 10 min facilitated the formation of a nanocrystalline structure, which played a pivotal role in enhancing thermal and magnetic characteristics. The alloy achieved a BS value of 1.94 T and a HC value of 27.7 A/m, a highly desirable balance in soft magnetic materials for use in electronic devices, transformers, and electromagnetic components. These findings underscore the importance of precise control over heat treatment conditions and composition adjustments to achieve superior material performance.

Author Contributions

Conceptualization, H.C.-Y.; methodology, H.L., H.C., and Y.R.U.; validation, H.C.-Y., and H.L.; formal analysis, H.L., H.C., and Y.R.U.; investigation, H.L., H.C., and Y.R.U.; resources, H.C.-Y., and H.L.; data curation, H.L.; writing—original draft preparation, H.L.; writing—review and editing, H.L., and H.C.; visualization, H.L.; supervision, H.C.-Y.; project administration, H.C.-Y.; funding acquisition, H.C.-Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Technology Innovation Program (00424202, Development of manufacturing technology for 1.3T (Remanence) class anisotropic magnetic powders and anisotropic bonded magnet without heavy rare earths for DC servo motors) and (20011368, Development of Thin Film Technology on Soft Magnetic Steel Sheet and Application Technology on Hybrid Permanent Magnet for High-Performance Traction Motor) funded By the Ministry of Trade, Industry & Energy (MOTIE, Korea) and also supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No.2021R1A2C2008220), equally. This work was supported by the Korea government (MSIT) (1711078081).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kittel, C. Introduction to Solid State Physics; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2005; ISBN 0471680575. [Google Scholar]

- Enomoto, Y.; Deguchi, K.; Imagawa, T. Development of an Ultimate-High-Efficiency Motor by Utilizing High-Bs Nanocrystalline Alloy. IEEJ J. Ind. Appl. 2020, 9, 102–108. [Google Scholar] [CrossRef]

- Yoshizawa, Y.a.; Oguma, S.; Yamauchi, K. New Fe-based Soft Magnetic Alloys Composed of Ultrafine Grain Structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Suzuki, K.; Kataoka, N.; Inoue, A.; Makino, A.; Masumoto, T. High Saturation Magnetization and Soft Magnetic Properties of Bcc Fe–Zr–B Alloys with Ultrafine Grain Structure. Mater. Trans. JIM 1990, 31, 743–746. [Google Scholar] [CrossRef]

- Willard, M.A.; Laughlin, D.E.; McHenry, M.E.; Thoma, D.; Sickafus, K.; Cross, J.O.; Harris, V.G. Structure and Magnetic Properties of (Fe 0.5 Co 0.5) 88 Zr 7 B 4 Cu 1 Nanocrystalline Alloys. J. Appl. Phys. 1998, 84, 6773–6777. [Google Scholar] [CrossRef]

- Makino, A. Nanocrystalline Soft Magnetic Fe-Si-BP-Cu Alloys with High $ B $ of 1.8–1.9 T Contributable to Energy Saving. IEEE Trans. Magn. 2012, 48, 1331–1335. [Google Scholar] [CrossRef]

- Kubota, T.; Makino, A.; Inoue, A. Low Core Loss of Fe85Si2B8P4Cu1 Nanocrystalline Alloys with High Bs and B800. J. Alloys Compd. 2011, 509, S416–S419. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, S.; Yim, H.; Kang, K.H.; Yoon, C.S. High Saturation Magnetic Flux Density of Novel Nanocrystalline Core Annealed under Magnetic Field. J. Alloys Compd. 2020, 826, 154136. [Google Scholar] [CrossRef]

- Jia, P.; Wang, E.; Han, K. The Effects of a High Magnetic Field on the Annealing of [(Fe0. 5Co0. 5) 0.75 B0. 2Si0. 05] 96Nb4 Bulk Metallic Glass. Materials 2016, 9, 899. [Google Scholar] [CrossRef]

- Willard, M.A.; Daniil, M.; Kniping, K.E. Nanocrystalline Soft Magnetic Materials at High Temperatures: A Perspective. Scr. Mater. 2012, 67, 554–559. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Flohrer, S.; Schäfer, R.; Polak, C.; Herzer, G. Interplay of Uniform and Random Anisotropy in Nanocrystalline Soft Magnetic Alloys. Acta Mater. 2005, 53, 2937–2942. [Google Scholar] [CrossRef]

- Makino, A.; Men, H.; Yubuta, K.; Kubota, T. Soft Magnetic FeSiBPCu Heteroamorphous Alloys with High Fe Content. J. Appl. Phys. 2009, 105, 013922. [Google Scholar] [CrossRef]

- Oshtrakh, M.I.; Klencsár, Z.; Semionkin, V.A.; Kuzmann, E.; Homonnay, Z.; Varga, L.K. Annealed FINEMET Ribbons: Structure and Magnetic Anisotropy as Revealed by the High Velocity Resolution Mössbauer Spectroscopy. Mater. Chem. Phys. 2016, 180, 66–74. [Google Scholar] [CrossRef]

- Kuzmann, E.; Stichleutner, S.; Machala, L.; Pechoušek, J.; Vondrášek, R.; Smrčka, D.; Kouřil, L.; Homonnay, Z.; Oshtrakh, M.I.; Mozzolai, A. Change in Magnetic Anisotropy at the Surface and in the Bulk of FINEMET Induced by Swift Heavy Ion Irradiation. Nanomaterials 2022, 12, 1962. [Google Scholar] [CrossRef]

- Kuzmann, E.; Stichleutner, S.; Sápi, A.; Klencsár, Z.; Oshtrakh, M.I.; Semionkin, V.A.; Kubuki, S.; Homonnay, Z.; Varga, L.K. Mössbauer Study of FINEMET with Different Permeability. Hyperfine Interact. 2013, 219, 63–67. [Google Scholar] [CrossRef]

- Herzer, G. Grain Size Dependence of Coercivity and Permeability in Nanocrystalline Ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Makino, A.; Men, H.; Kubota, T.; Yubuta, K.; Inoue, A. FeSiBPCu Nanocrystalline Soft Magnetic Alloys with High Bs of 1.9 Tesla Produced by Crystallizing Hetero-Amorphous Phase. Mater. Trans. 2009, 50, 204–209. [Google Scholar] [CrossRef]

- Kong, F.; Wang, A.; Fan, X.; Men, H.; Shen, B.; Xie, G.; Makino, A.; Inoue, A. High B s Fe84− x Si4B8P4Cu x (X= 0–1.5) Nanocrystalline Alloys with Excellent Magnetic Softness. J. Appl. Phys. 2011, 109, 07A303. [Google Scholar] [CrossRef]

- Sitek, J.; Holková, D.; Dekan, J.; Novák, P.; Sojak, S.; Dobrovodský, J. Influence of Cu Ion Implantation on Nanocrystalline Alloy of NANOMET. AIP Conf. Proc. 2019, 2131, 020042. [Google Scholar]

- Luborsky, F.; Becker, J.; McCary, R. Magnetic Annealing of Amorphous Alloys. IEEE Trans. Magn. 1975, 11, 1644–1649. [Google Scholar] [CrossRef]

- Kronmüller, H.; Fähnle, M.; Domann, M.; Grimm, H.; Grimm, R.; Gröger, B. Magnetic Properties of Amorphous Ferromagnetic Alloys. J. Magn. Magn. Mater. 1979, 13, 53–70. [Google Scholar] [CrossRef]

- Kulik, T. The Influence of Copper, Niobium and Tantalum Additions on the Crystallization of Fe Si B-Based Glasses. Mater. Sci. Eng. A 1992, 159, 95–101. [Google Scholar] [CrossRef]

- Hono, K.; Hiraga, K.; Wang, Q.; Inoue, A.; Sakurai, T. The Microstructure Evolution of a Fe73. 5Si13. 5B9Nb3Cu1 Nanocrystalline Soft Magnetic Material. Acta Metall. Et Mater. 1992, 40, 2137–2147. [Google Scholar] [CrossRef]

- Hosseini-Nasb, F.; Beitollahi, A.; Moravvej-Farshi, M.K. Effect of Crystallization on Soft Magnetic Properties of Nanocrystalline Fe80B10Si8Nb1Cu1 Alloy. J. Magn. Magn. Mater. 2015, 373, 255–258. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Illeková, E.; Coïsson, M.; Celegato, F.; Vinai, F.; Tiberto, P.; Moya, J.A.; Cremaschi, V.J. High Performance of Low Cost Soft Magnetic Materials. Bull. Mater. Sci. 2011, 34, 1407–1413. [Google Scholar] [CrossRef]

- Kuzmann, E.; Stichleutner, S.; Sápi, A.; Varga, L.K.; Havancsák, K.; Skuratov, V.; Homonnay, Z.; Vértes, A. Mössbauer Study of FINEMET Type Nanocrystalline Ribbons Irradiated with Swift Heavy Ions. In Proceedings of the ICAME 2011: Proceedings of the 31st International Conference on the Applications of the Mössbauer Effect (ICAME 2011), Tokyo, Japan, 25–30 September 2011; Springer: Berlin/Heidelberg, Germany, 2013; pp. 509–515. [Google Scholar]

- Grey, D.G.; Cesnek, M.; Bujdoš, M.; Miglierini, M.B. Effect of Cobalt on the Microstructure of Fe-B-Sn Amorphous Metallic Alloys. Metals 2024, 14, 712. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Chu, D.; Xie, S.; Sun, H.; Ferry, M.; Li, S. Composition Dependence of the Microstructure and Soft Magnetic Properties of Fe-Based Amorphous/Nanocrystalline Alloys: A Review Study. J. Non Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Meng, Y.; Pang, S.; Chang, C.; Luan, J.; Inoue, A.; Zhang, T. Effects of Si on the Microstructure, Soft Magnetic Properties and Bendability of Rapidly-Annealed Nanocrystalline Fe–Si–B–P–Cu Alloy Ribbons. J. Alloys Compd. 2023, 940, 168799. [Google Scholar] [CrossRef]

- Yao, B.; Si, L.; Tan, H.; Zhang, Y.; Li, Y. Effects of High Boron Content on Crystallization, Forming Ability and Magnetic Properties of Amorphous Fe91− XZr5BxNb4 Alloy. J. Non Cryst. Solids 2003, 332, 43–52. [Google Scholar] [CrossRef]

- Kong, F.; Men, H.; Liu, T.; Shen, B. Effect of P to B Concentration Ratio on Soft Magnetic Properties in FeSiBPCu Nanocrystalline Alloys. J. Appl. Phys. 2012, 111, 07A311. [Google Scholar] [CrossRef]

- Panahi, S.L.; Ramasamy, P.; Masdeu, F.; Stoica, M.; Torrens-Serra, J.; Bruna, P. Evaluation of the Effect of Minor Additions in the Crystallization Path of [(Fe0. 5Co0. 5) 0.75 B0. 2Si0. 05] 100-XMx Metallic Glasses by Means of Mössbauer Spectroscopy. Metals 2021, 11, 1293. [Google Scholar] [CrossRef]

- Sitek, J.; Holková, D.; Dekan, J.; Novák, P. Change of Magnetic Properties of Nanocrystalline Alloys under Influence of External Factors. AIP Conf. Proc. 2016, 1781, 020003. [Google Scholar]

- Klencsár, Z.; Kuzmann, E.; Vértes, A. User-Friendly Software for Mössbauer Spectrum Analysis. J. Radioanal. Nucl. Chem. 1996, 210, 105–118. [Google Scholar] [CrossRef]

- Carter, C.B. Ceramic Materials: Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Li, Z.; Wang, A.; Chang, C.; Wang, Y.; Dong, B.; Zhou, S. Synthesis of FeSiBPNbCu Nanocrystalline Soft-Magnetic Alloys with High Saturation Magnetization. J. Alloys Compd. 2014, 611, 197–201. [Google Scholar] [CrossRef]

- Dou, Z.X.; Li, Y.L.; Lv, K.; Wang, T.; Li, F.S.; Hui, X.D. Improving the Glass Formation Ability and Magnetic Properties by Nb in Fe-Si-BP-Cu-Nb Nanocrystalline Alloys. Mater. Sci. Eng. B 2021, 264, 114942. [Google Scholar] [CrossRef]

- Mattern, N.; Danzig, A.; Müller, M. Effect of Cu and Nb on Crystallization and Magnetic Properties of Amorphous Fe77. 5Si15. 5B7 Alloys. Mater. Sci. Eng. A 1995, 194, 77–85. [Google Scholar] [CrossRef]

- Uhm, Y.R.; Rhee, C.K.; Lee, H.M.; Kim, C.S. Magnetic Properties and Dispersion Stability of Carbon Encapsulated Fe Nano Particles. J. Korean Phys. Soc. 2010, 57, 1609–1613. [Google Scholar]

- Eibschütz, M.; Lines, M.E. Observation of Linewidth Asymmetry in the Mössbauer Zeeman Spectrum of Amorphous Yttrium Iron Garnet. Phys. Rev. B 1982, 26, 2288. [Google Scholar] [CrossRef]

- Raj, P. Correlations among Hyperfine Parameters in Amorphous Metal Systems: Mössbauer Linewidth Asymmetries and Fluctuation Hyperfine Correlation Functions. Hyperfine Interact. 1990, 52, 373–378. [Google Scholar] [CrossRef]

- Gupta, A.; Kane, S.N.; Bhagat, N.; Kulik, T. Effect of Cu, Nb and Ta Addition on the Structural and Magnetic Properties of Amorphous Fe–Si–B Alloys. J. Magn. Magn. Mater. 2003, 254, 492–494. [Google Scholar] [CrossRef]

- Xia, G.T.; Wang, Y.G.; Dai, J.; Dai, Y.D. Effects of Cu Cluster Evolution on Soft Magnetic Properties of Fe83B10C6Cu1 Metallic Glass in Two-Step Annealing. J. Alloys Compd. 2017, 690, 281–286. [Google Scholar] [CrossRef]

- Stearns, M.B. Internal Magnetic Fields, Isomer Shifts, and Relative Abundances of the Various Fe Sites in FeSi Alloys. Phys. Rev. 1963, 129, 1136. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).