Magnetostructural Transformation and Magnetocaloric Properties of (Ni37.5Co12.5Mn35Ti15)100−xBx (x = 0.0 and 0.4) Melt-Spun Ribbons

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tegus, O.; Brück, E.; Buschow, K.H.J.; de Boer, F.R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef]

- Gschneidner, V.K.; Pecharsky, K.A., Jr. Magnetocaloric Materials. Annu. Rev. Mater. Sci. 2000, 30, 387–429. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A., Jr.; Pecharsky, A.O.; Tishin, A.M. Thermodynamics of the magnetocaloric effect. Phys. Rev. B 2001, 64, 144406. [Google Scholar] [CrossRef]

- Shen, B.G.; Sun, J.R.; Hu, F.X.; Zhang, H.W.; Cheng, Z.H. Recent Progress in Exploring Magnetocaloric Materials. Adv. Mater. 2009, 21, 4545–4564. [Google Scholar] [CrossRef]

- Kitanovski, A. Energy Applications of Magnetocaloric Materials. Adv. Energy Mater. 2020, 10, 1903741. [Google Scholar] [CrossRef]

- Law, J.Y.; Moreno-Ramírez, L.M.; Díaz-García, Á.; Franco, V. Current perspective in magnetocaloric materials research. J. Appl. Phys. 2023, 133, 040903. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Sánchez-Valdés, C.F.; Llamazares, J.L.S.; Esling, C.; Zhao, X.; Zuo, L. Giant magnetocaloric effect in melt-spun Ni-Mn-Ga ribbons with magneto-multistructural transformation. Appl. Phys. Lett. 2014, 104, 044101. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Yang, J.; Yang, B.; Zhao, X.; Zuo, L. Large room temperature adiabatic temperature variation in a Ni40Co8Mn42Sn10 polycrystalline alloy. Intermetallics 2018, 100, 57–62. [Google Scholar] [CrossRef]

- Li, Z.; Dong, S.; Li, Z.; Yang, B.; Liu, F.; Sánchez-Valdés, C.; Llamazares, J.S.; Zhang, Y.; Esling, C.; Zhao, X.; et al. Giant low-field magnetocaloric effect in Si alloyed Ni-Co-Mn-In alloys. Scr. Mater. 2018, 159, 113–118. [Google Scholar] [CrossRef]

- Zhang, G.; Li, D.; Liu, C.; Li, Z.; Yang, B.; Yan, H.; Zhao, X.; Zuo, L. Giant low-field actuated caloric effects in a textured Ni43Mn47Sn10 alloy. Scr. Mater. 2021, 201, 113947. [Google Scholar] [CrossRef]

- Guan, Z.; Bai, J.; Zhang, Y.; Gu, J.; Morley, N.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L. Ni-Co-Mn-Ti-B high performance multiferroic phase transformation material: Simultaneous modulation of mechanical properties and successive caloric effects by B doping. Mater. Today Phys. 2023, 36, 101183. [Google Scholar] [CrossRef]

- Sun, S.; Bai, J.; Gu, J.; Guo, K.; Morley, N.; Gao, Q.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L. Extraordinary mechanical properties and room-temperature magnetocaloric effects in spark plasma sintered all-d-metal Ni-Co-Mn-Ti alloy. J. Alloys Compd. 2024, 976, 173406. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Liu, E.K.; Chen, J.H.; Li, Y.; Liu, G.D.; Luo, H.Z.; Xi, X.K.; Zhang, H.W.; Wang, W.H.; Wu, G.H. Realization of multifunctional shape-memory ferromagnets in all-d-metal Heusler phases. Appl. Phys. Lett. 2015, 107, 022406. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Liu, E.K.; Li, Y.; Han, X.L.; Du, Z.W.; Luo, H.Z.; Liu, G.D.; Xi, X.K.; Zhang, H.W.; Wang, W.H.; et al. Magnetostructural martensitic transformations with large volume changes and magneto-strains in all-d-metal Heusler alloys. Appl. Phys. Lett. 2016, 109, 071904. [Google Scholar] [CrossRef]

- Bez, H.N.; Pathak, A.K.; Biswas, A.; Zarkevich, N.; Balema, V.; Mudryk, Y.; Johnson, D.D.; Pecharsky, V.K. Giant enhancement of the magnetocaloric response in Ni–Co–Mn–Ti by rapid solidification. Acta Mater. 2019, 173, 225–230. [Google Scholar] [CrossRef]

- Li, Y.; Qin, L.; Zhang, H.; Li, L. Tailored martensitic transformation and enhanced magnetocaloric effect in all-d-metal Ni35Co15Mn33Fe2Ti15 alloy ribbons. Chin. Phys. B 2022, 31, 087103. [Google Scholar] [CrossRef]

- Zhang, F.; Westra, K.; Shen, Q.; Batashev, I.; Kiecana, A.; van Dijk, N.; Brück, E. The second-order magnetic phase transition and magnetocaloric effect in all-d-metal NiCoMnTi-based Heusler alloys. J. Alloy Compd. 2022, 906, 164337. [Google Scholar] [CrossRef]

- Samanta, S.; Chatterjee, S.; Sinha, J.; Mandal, K. Giant reversibility of magnetoresponsive properties in all- d -metal Ni-Co-Mn(Cu)-Ti Heusler alloys: Role of phase-fraction-assisted magnetostructural transition. Phys. Rev. Mater. 2023, 7, 084406. [Google Scholar] [CrossRef]

- Li, Y.; Ye, X.; Lou, L.; Wang, L.; Qin, L. Ferromagnetic Martensitic Transition and Magnetocaloric Effect in Ni35Co15−xVxMn35Ti15 (x = 1, 2, 3) All-d-Metal Heusler Alloy Ribbons. J. Supercond. Nov. Magn. 2023, 36, 1–6. [Google Scholar] [CrossRef]

- Khan, A.N.; Moreno-Ramírez, L.M.; Díaz-García, Á.; Law, J.Y.; Franco, V. All-d-metal Ni(Co)-Mn(X)-Ti (x = Fe or Cr) Heusler alloys: Enhanced magnetocaloric effect for moderate magnetic fields. J. Alloy Compd. 2023, 931, 167559. [Google Scholar] [CrossRef]

- Zhang, F.; Batashev, I.; van Dijk, N.; Brück, E. Reduced Hysteresis and Enhanced Giant Magnetocaloric Effect in B-Doped all-d-Metal Ni-Co-Mn-Ti-Based Heusler Materials. Phys. Rev. Appl. 2022, 17, 054032. [Google Scholar] [CrossRef]

- Luo, H.; Meng, F.; Jiang, Q.; Liu, H.; Liu, E.; Wu, G.; Wang, Y. Effect of boron on the martensitic transformation and magnetic properties of Ni50Mn36.5Sb13.5-xBx alloys. Scr. Mater. 2010, 63, 569–572. [Google Scholar] [CrossRef]

- Pandey, S.; Quetz, A.; Rodionov, I.D.; Aryal, A.; Blinov, M.I.; Titov, I.S.; Prudnikov, V.N.; Granovsky, A.B.; Dubenko, I.; Stadler, S.; et al. Magnetic, transport, and magnetocaloric properties of boron doped Ni-Mn-In alloys. J. Appl. Phys. 2015, 117, 183905. [Google Scholar] [CrossRef]

- Meng, F.; Hao, H.; Liu, X.; Luo, H. Effect of B doping on phase transition and magnetic properties of Mn50Ni40In10-xBx: Experimental and theoretical investigation. J. Phys. Chem. Solids 2018, 123, 19–24. [Google Scholar] [CrossRef]

- Cicek, M.; Saritas, S.; Yildirim, O.; Emre, B. Effect of the low constituent boron on martensitic transformation, magnetic, and magnetocaloric properties of Ni50Mn35In15 Heusler alloys. J. Alloy Compd. 2020, 845, 155493. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.; Wang, W.; Liu, E.; Li, L. Ferromagnetic martensitic transformation and large magnetocaloric effect in Ni35Co15−xFexMn35Ti15 (x = 2, 4, 6, 8) alloys. J. Appl. Phys. 2020, 127, 233907. [Google Scholar] [CrossRef]

- López-Cruz, M.; Zamora, J.; Sánchez-Valdés, C.F.; Llamazares, J.L.S. On the synthesis, structural transformation and magnetocaloric behavior of Ni37.5Co12.5Mn35Ti15 melt-spun ribbons. AIP Adv. 2021, 11, 015010. [Google Scholar] [CrossRef]

- Bez, H.N.; Yibole, H.; Pathak, A.; Mudryk, Y.; Pecharsky, V. Best practices in evaluation of the magnetocaloric effect from bulk magnetization measurements. J. Magn. Magn. Mater. 2018, 458, 301–309. [Google Scholar] [CrossRef]

- Da, S.; Zheng, Z.; Huang, P.; Qiu, Z.; Zeng, D. Effect of B doping on magnetic and mechanical properties of all-d-metal Heusler alloys. Phys. B Condens. Matter 2023, 670, 415396. [Google Scholar] [CrossRef]

- Gorria, P.; Llamazares, J.L.S.; Álvarez, P.; Pérez, M.J.; Marcos, J.S.; Blanco, J.A. Relative cooling power enhancement in magneto-caloric nanostructured Pr2Fe17. J. Phys. D Appl. Phys. 2008, 41, 192003. [Google Scholar] [CrossRef]

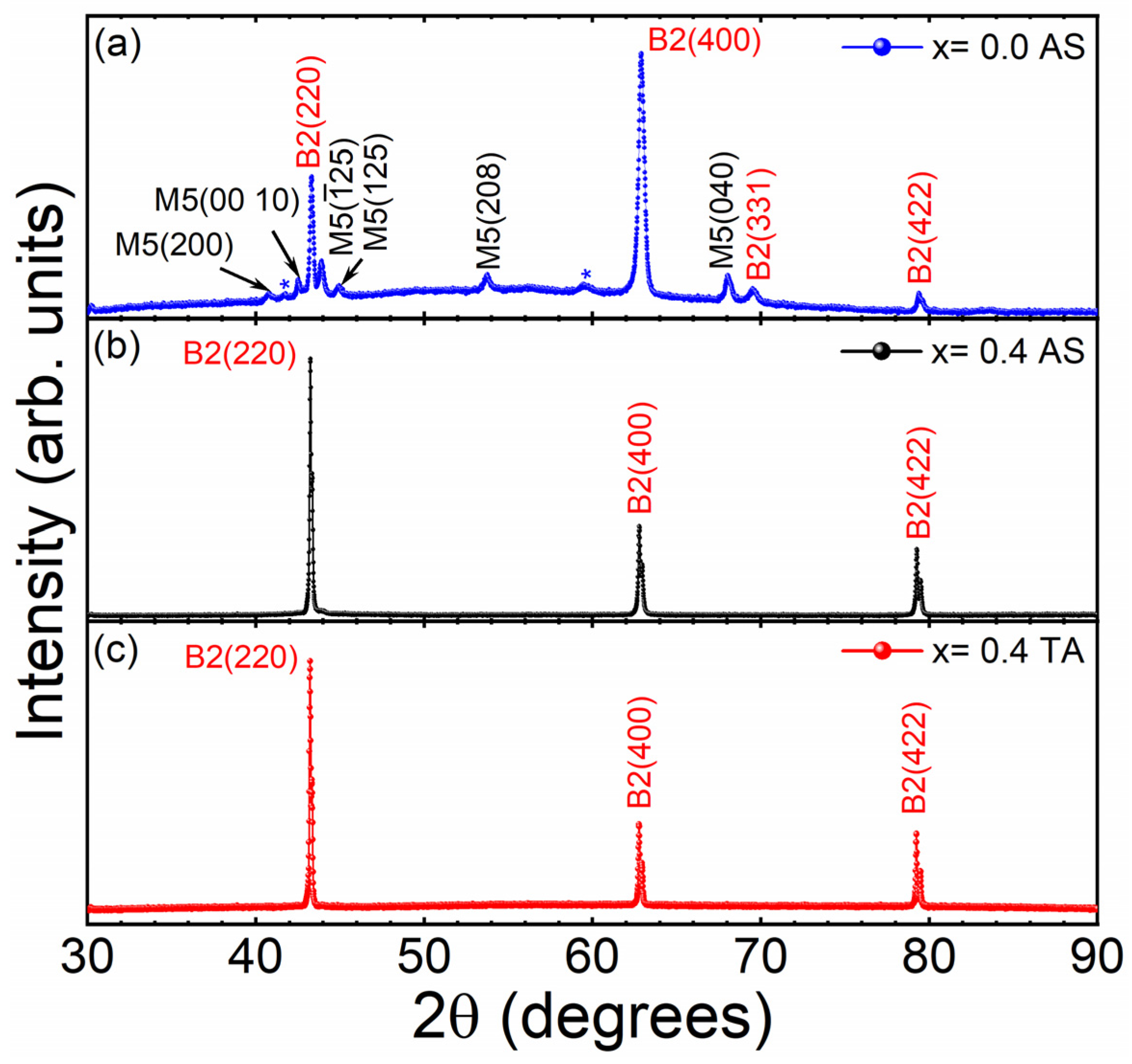

| Sample | Structure | Cell Parameters (Å) | Angles (°) | Cell Volume (Å)3 | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| x = 0.0 AS | Monoclinic | 4.428 | 5.508 | 21.30 | α = γ = 90 β = 94.1386 | 518.251 |

| Cubic | 5.901 | 5.901 | 5.901 | α = β = γ = 90° | 205.542 | |

| x = 0.4 AS | Cubic | 5.915 | 5.914 | 5.914 | α = β = γ = 90° | 206.935 |

| x = 0.4 TA | Cubic | 5.699 | 5.699 | 5.699 | α = β = γ = 90° | 185.112 |

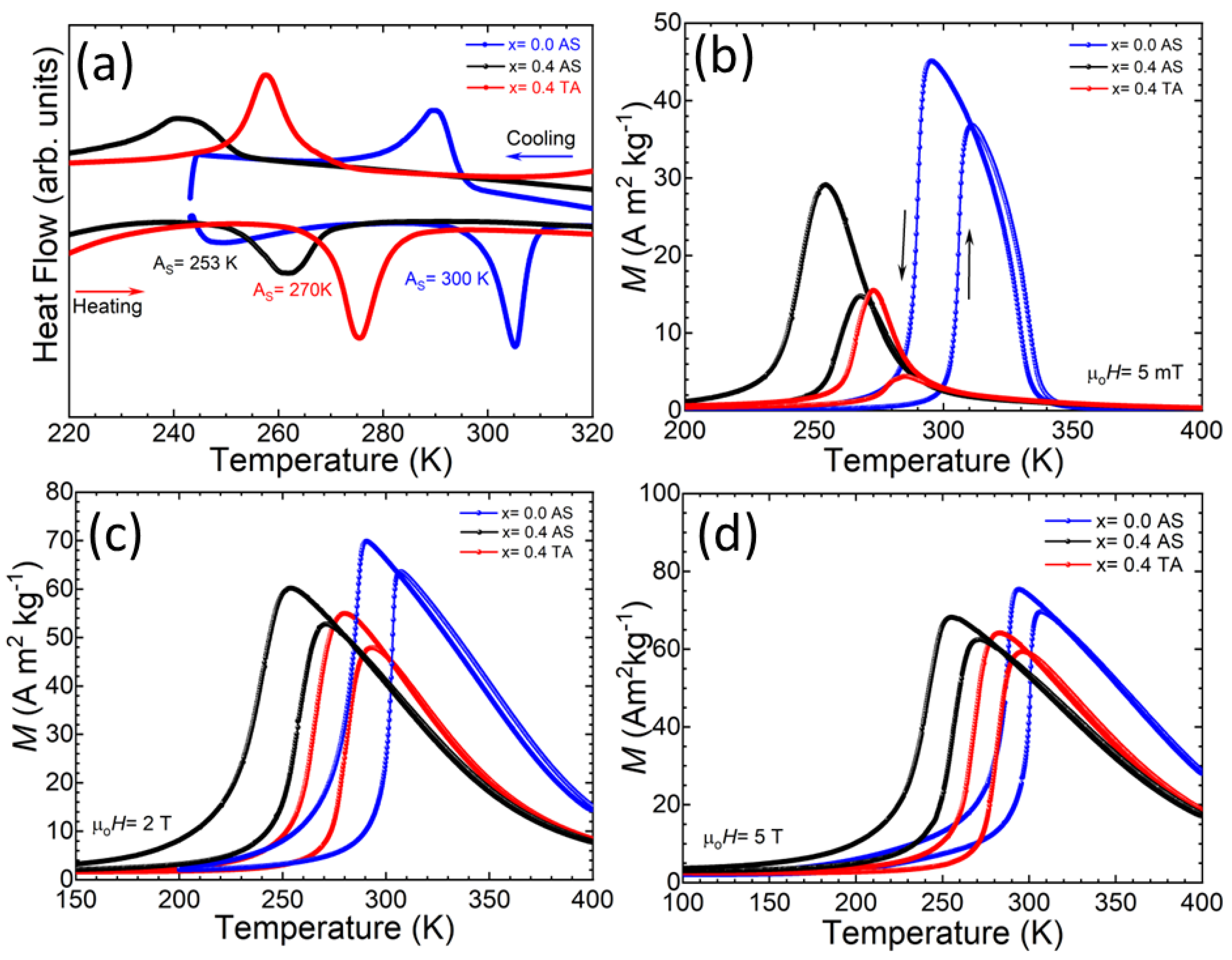

| DSC | ||||||

|---|---|---|---|---|---|---|

| Sample | AS (K) | Af (K) | MS (K) | Mf (K) | ΔThyst (K) | TCA (K) |

| x = 0.0 AS | 300 | 309 | 295 | 281 | 14 | ✕ |

| x = 0.4 AS | 253 | 270 | 253 | 233 | 17 | ✕ |

| x = 0.4 TA | 270 | 282 | 265 | 251 | 17 | ✕ |

| M(T)5 mT | ||||||

| x = 0.0 AS | 303 | 309 | 292 | 286 | 17 | 333 |

| x = 0.4 AS | 253 | 268 | 254 | 235 | 14 | 276 |

| x = 0.4 TA | 272 | 283 | 272 | 260 | 11 | 290 |

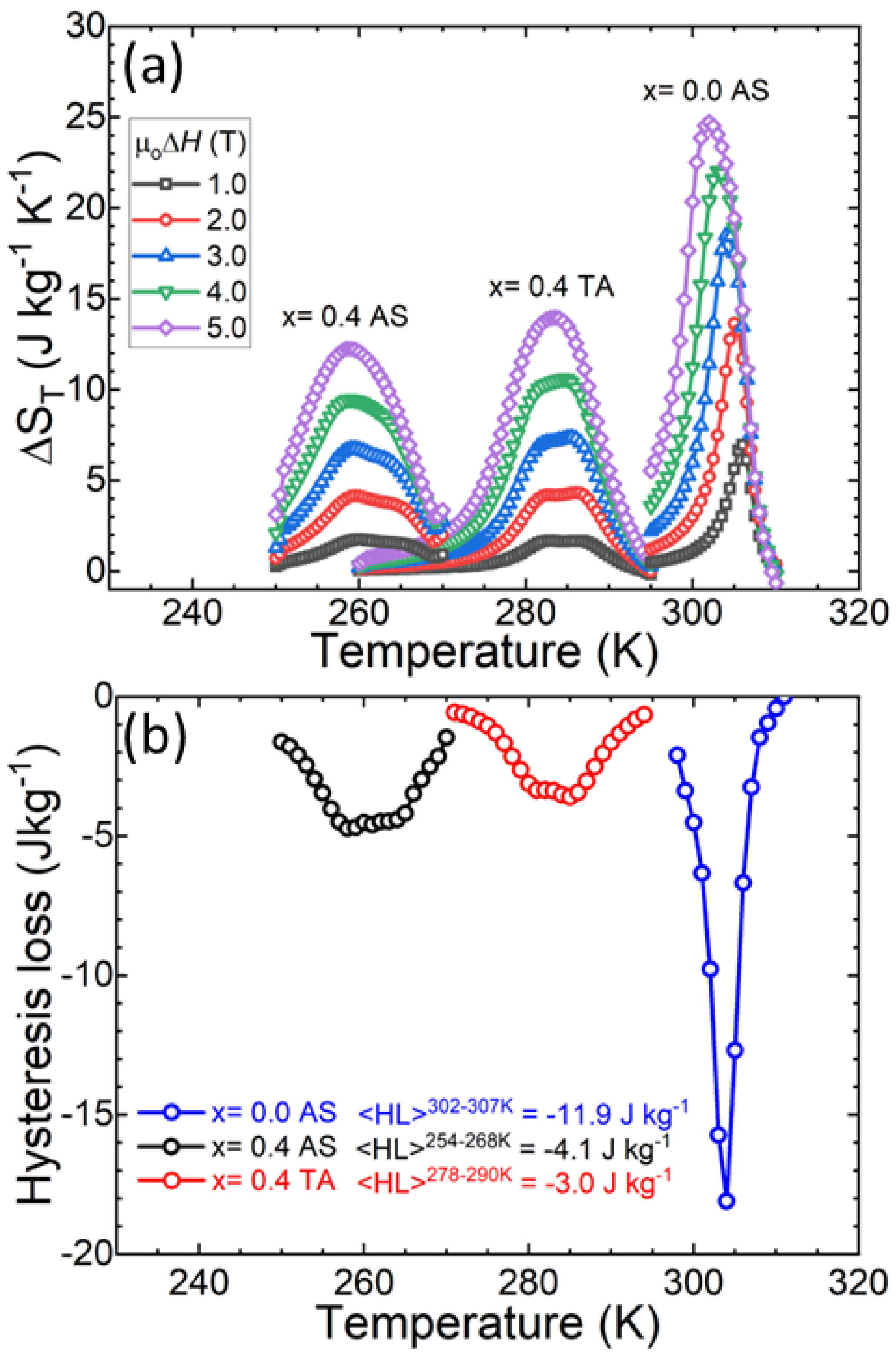

| x = 0.0 AS | x = 0.4 AS | x = 0.4 TA | ||||

|---|---|---|---|---|---|---|

| μoΔH = 2 T | μoΔH = 5 T | μoΔH = 2 T | μoΔH = 5 T | μoΔH = 2 T | μoΔH = 5 T | |

| |ΔST|max (J kg−1 K−1) | 13.6 | 24.7 | 4.1 | 12.2 | 4.2 | 14.0 |

| <HL> (J kg−1) | −12 | ✕ | −4.1 | ✕ | −3.0 | ✕ |

| RC-1 (J kg−1) | 58 | 195 | 59 | 183 | 49 | 176 |

| RC-2 (J kg−1) | 47 | 163 | 48 | 150 | 43 | 144 |

| Thot (K) | 307 | 306 | 268 | 266 | 290 | 289 |

| Tcold (K) | 303 | 298 | 254 | 252 | 278 | 276 |

| δTFWHM (K) | 4 | 8 | 14 | 15 | 12 | 13 |

| RC-3 (J kg−1) | 29 | 105 | 31 | 97 | 29 | 92 |

| δTRC−3 (K) | 4.5 | 6 | 13 | 12 | 8 | 10 |

| ThotRC−3 (K) | 307 | 305 | 267 | 265 | 288 | 288 |

| TcoldRC−3 (K) | 303 | 299 | 255 | 253 | 280 | 278 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Cruz, M.; Varga, R.; Sánchez Llamazares, J.L. Magnetostructural Transformation and Magnetocaloric Properties of (Ni37.5Co12.5Mn35Ti15)100−xBx (x = 0.0 and 0.4) Melt-Spun Ribbons. Metals 2024, 14, 216. https://doi.org/10.3390/met14020216

López-Cruz M, Varga R, Sánchez Llamazares JL. Magnetostructural Transformation and Magnetocaloric Properties of (Ni37.5Co12.5Mn35Ti15)100−xBx (x = 0.0 and 0.4) Melt-Spun Ribbons. Metals. 2024; 14(2):216. https://doi.org/10.3390/met14020216

Chicago/Turabian StyleLópez-Cruz, Mauricio, Rastislav Varga, and José Luis Sánchez Llamazares. 2024. "Magnetostructural Transformation and Magnetocaloric Properties of (Ni37.5Co12.5Mn35Ti15)100−xBx (x = 0.0 and 0.4) Melt-Spun Ribbons" Metals 14, no. 2: 216. https://doi.org/10.3390/met14020216