1. Introduction

Since the early days of replacing load-bearing parts of the human body with different kinds of implants, metals have been one of the most preferred materials [

1]. Some metals are biofriendly, have good strength and corrosion resistance, and have many other qualities which make them suitable and one of the best choices for the replacement of body parts with load-bearing applications [

2]. However, since the strength and stiffness of metal alloys that are usually applied for bone implants (such as medical-grade steel and titanium alloys) are far higher than the corresponding mechanical properties of human or animal bone, the long-term use of metal implants can generate some unwanted drawbacks. One major drawback is a phenomenon called stress shielding, which occurs when implants have higher elastic modulus and tensile strength than the bones to which they are connected. Since the implants bear most of the load, reduction in bone density (osteopenia) occurs. With titanium, this is very much the case, as its mechanical properties are very different from bone properties. This is why a lot of research has focused on mimicking the mechanical properties of cancellous bone with titanium (Ti6Al4V) through creating lattice structure designs. Generally, there are three classes of lattice structures used in biomedical engineering: strut-based structures, triply periodic minimal-surface (TPMS) skeletal structures [

3], and TPMS sheet structures [

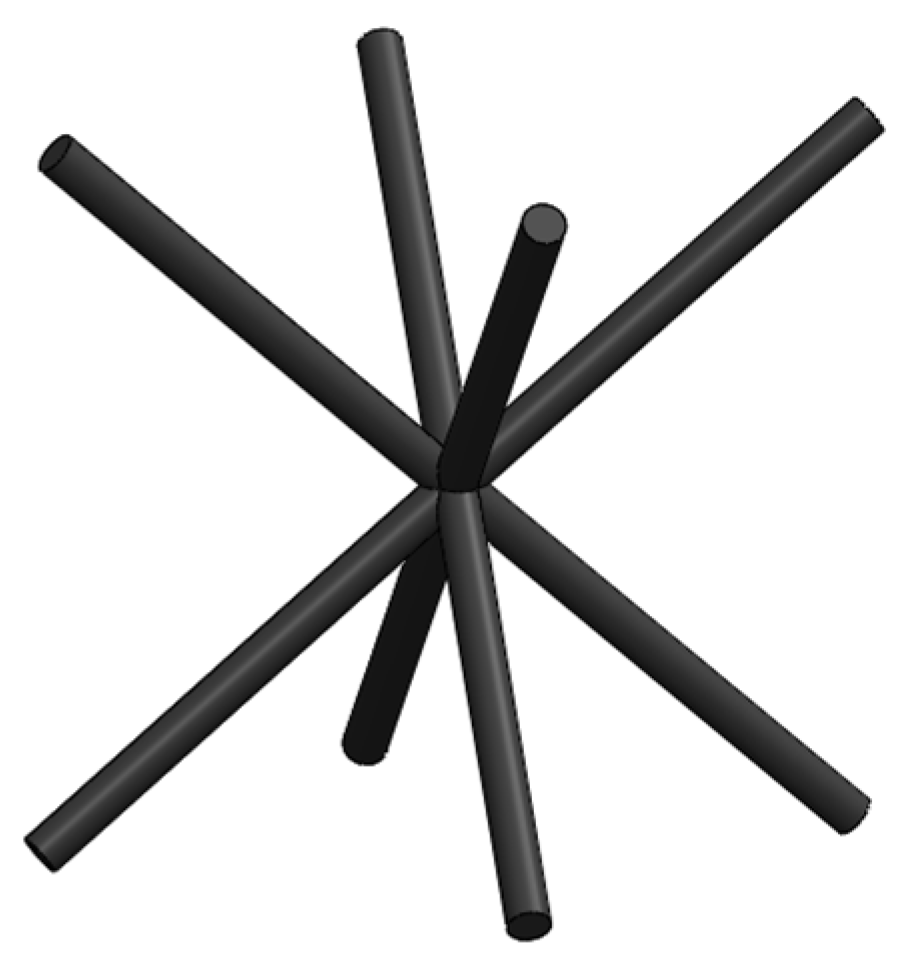

4]. Strut-based structures are made from struts combined in different ways, generating multiple strut-based topologies. Some of the most well-known ones are based on centered cubic (BCC) topology (

Figure 1). TPMS skeletal and TPMS sheet structures have mathematically defined architectures. Distefano et al. [

4] and Maconachie et al. [

5] gave a good and easily understandable classification of lattice structures used in biomedical engineering. In addition, Milovanović et al. [

6] also provided a comprehensive overview of different lattice structure designs.

Obviously, there are some lattice structure designs which are more custom and do not fall into the categories defined in previously mentioned articles. This paper will attempt to evaluate if (and how) the outer-strut orientation of a custom-made strut-based lattice scaffold (Ti6Al4V material) influences the mechanical properties of the scaffold. For this purpose, two strut orientations of the same scaffold design have been used, made with DLMS 3D printing technology. This scaffold is a custom-made scaffold first presented in paper [

7], made specifically for the case of real-life rabbit surgical applications. As such, it can be classified in the group of scaffolds with strut-based structure, but it does not fall under any specific topology of this group (presented in the studies by Distefano et al. [

4] and Maconachie et al. [

5]).

Since modern medicine and bioengineering have seen more and more focus being put on creating tissues and bones tailored to specific patients [

8,

9], some technologies, such as additive manufacturing, have come up as the best choice for this purpose. In addition, through additive manufacturing, implants can be customized to excellently resemble natural tissue [

10,

11]. Looking at the reviews on the topic of biomedical implants focusing on biomedical scaffolds, review articles [

4,

5,

12] give a good starting point into the research. The study of Maconachie et al. [

5] focused on the scaffolds made with SLM 3D printing technology. One of the conclusions, demonstrated through regression analysis, showed a positive correlation between relative density and the strength of the scaffold. On the other hand, Distefano et al. [

4] focused on the review of titanium scaffolds and their mechanical and surface roughness properties. The authors concluded that it was hard to determine which pore size of the scaffolds should be employed, as the reported data from the literature ranged from 100 to 1000 µm; however, the relative density of the scaffolds (at least for the Gibson–Ashby model [

13]) should be under 30%. Tyagi and Manjaiah [

12] presented an overview of titanium-based lattice structures. The authors talked about the geometrical errors which could be expected and discussed the variations in lattice parameters and the effects those variations could have. Other research has focused on the topic of the mechanical properties and functionality of scaffolds depending on their design [

6,

14,

15,

16]. Scaffold geometry and porosity are depicted as the scaffold characteristics which most affect mechanical properties. However, material composition, surface modification, and manufacturing processes can also have a great impact on scaffold properties.

Different additive manufacturing technologies have been utilized for producing lattice structures. Several studies have experimented with the Selective Laser Melting (SLM) technique for producing Ti6Al4V scaffold materials [

16,

17,

18,

19]. Hudak et al. [

16] experimented with scaffolds different from each other in terms of pore size and structure topology. The lowest weight and highest porosity were achieved with a trabecular structure and 600 µm pore size, but the scaffolds with 200 µm pore size and a cubic structure achieved the best mechanical properties. Dhiman et al. [

17] fabricated Ti6Al4V scaffold materials with SLM technology and analyzed it through finite element (FE) analysis. The authors noted that the failure of the scaffold structures was a result of micro-porosities formed during the fabrication process. The microporosities were attributed to improper melting along a plane inclined at a 45° angle, which was also reported in other studies (dealing with other additive manufacturing techniques) [

20,

21]. Loginov et al. [

18] found that compressive offset stress (σ

0.2) decreased 12 times across the porosity range of 50% to 80% (ranging from 138 to 11 MPa). Mondal et al. [

19] produced different scaffold designs with approximately 65% porosity. The scaffolds’ modulus of elasticity closely matched the ones of the human bone.

The importance of surface roughness in additive manufactured parts is greatly documented in scientific papers [

22]. Dong et al. [

23] investigated how electrochemical polishing and chemical etching methods, used as post-process treatments, improve the surface finish of lattice structures made from Ti6Al4V manufactured with direct metal laser sintering (DMLS). The findings of this paper suggest that the removal rate at the edges is more important. In addition, it was determined that the more material removed with post-processing processes, the better the surface finish. Dzogbewu [

24] focused on the production of lattice structures using rhombic and diagonal nodes. The structures were produced with laser powder-bed fusion manufacturing technology. The average elastic modulus values for rhombic and diagonal lattice structures were 5.3 GPa and 5.1 GPa, respectively. Yan et al. [

25] extensively explored the microstructural characteristics and mechanical attributes of AlSi10Mg periodic cellular lattice structures. These lattice structures were produced through direct metal laser sintering (DMLS) and varied in both volume fraction (ranging from 5% to 20%) and unit cell size (ranging from 3 mm to 7 mm). Alkentar and Mankovits [

26] studied the deviations between the designed lattice structure and the 3D-printed ones. The DMLS technique was used for manufacturing Ti6Al4V lattice structures. It was determined that the accuracy of the printing process becomes lower as the complexity of the shapes of the unit cells increases. Crupi et al. [

27] used Titanium Ti64 in their study, produced with DMLS technology. The authors concluded that DMLS technology offers high design flexibility depending on the application. Mechanical properties of the lattice structures increase with the increase in strut diameter, strut aspect ratio, and relative density, but decrease with the increase in unit cell size.

As can be seen, a lot of research has already been completed on conventional lattice structures made from different materials and different manufacturing techniques. However, there still exists the need to further the research already undertaken, as well as to investigate some designs which do not fall into conventionally established categories of lattice structures [

4,

5,

6]. One such structure, called anatomically shaped lattice scaffold (ASLS) hereinafter, will be investigated in terms of its mechanical properties. The investigated ASLS was made from Ti6Al4V material and was manufactured with DMLS technology. As the ASLS was meant for bearing quasi-uniaxial compression in rabbits’ legs, compression testing was conducted. The real load for such cases cannot be considered as an ideal uniaxial compression, but the dominant portion of the load can be considered almost uniaxial (that is why the designation of quasi-uniaxial will be used in the study). This research represents a logical extension of the prior work undertaken by the authors of [

28] which predominantly centered on the quasi-elastic characteristics of the ASLS model manufactured via Electron Beam Melting (EBM) technology. However, it is relevant to note that the earlier study extensively explored the quasi-elastic attributes of the ASLS model. In the present study, the primary focus will be directed towards assessing the influence of varying strut orientations within the ASLS model on its mechanical properties, thereby enhancing our understanding of this lattice structure.

3. Results and Discussion

Microscopic analysis of the ASLS models (

Figure 8) revealed distinct characteristics in their structure. ASLS×90° exhibited struts composed of numerous small particles of titanium joined through DMLS technology, while ASLS×60° presented a relatively smoother surface on the struts. Further, measurements of the outer-strut diameters revealed that ASLS×90° had a manufactured outer-strut diameter of 0.37 (±0.03) mm, with the majority of outer struts being under the modeled 0.4 mm outer-strut diameter. ASLS×60° had a manufactured outer-strut diameter of 0.42 (±0.01) mm, with the majority of outer struts being over the modeled 0.4 mm.

The characteristic stages of deformation under the quasi-uniaxial compression load (force–stroke diagram F(x)) which were noticed during the same measurements where similar ASLSs (ASLS×60°) manufactured with EBM technology were subjected to the same compression force [

28] were also noticed here for both strut orientations (

Figure 9). As all stages of the ASLS force–stroke (force–displacement) diagram have already been explained in detail in the authors’ previous paper [

28], only a brief overview will be presented here. The first zone exhibited quasi-elastic deformation, and in the second zone, the rupture of scaffold struts occurred.

In the scaffold setting-up stage (first zone), the scaffold did not bear any load, it only implied the setting up in the seating mechanism of the custom tool. In the first compression stage, an almost linear relationship between the compression stroke and the reactive force of the scaffold was evident. The second stage of compression was characterized by an almost constant reactive force of the scaffold (“force plateau”), and this stage can be named as “elastic creeping” [

28]. In this stage of compression, the reactive force of ASLS×90° increased from 34 N to 44 N, and from 36 N to 49 N for ASLS×60°. These increases represented modest 2.4% and 2% changes, respectively, when considering the maximum achieved forces for the ASLS models, which were 400 N and 624 N, respectively. During decompression (i.e., the decrease in compressive force), the scaffold returns to its original height and during this return it is noticeable that the height returns, again with a slight decrease in force. The “force plateau” also exists during decompression, with a very similar shape as during compression. This indicates that the deformation is mostly reversible, even in the second stage. For this reason, it seems as if the structure of the ASLS is elastically creeping. After the second stage of compression, the third stage of compression began, which exhibited a quasi-linear relationship between the reactive force and the deformation of the scaffold. In addition, the same “elastic creeping” phenomenon (as explained in [

28]) was also evident here. A series of compression and decompressions cycles of the ASLS models were completed, and each increase in compression force caused a further increase in permanent deformation of the ASLS (

Figure 10 and

Figure 11). Following the initial exposure of the ASLS to the upper load limit characteristic of each of the three compression phases, a noticeable increase in scaffold stiffness was observed compared to its pre-loaded state. Subsequent loading and relaxation cycles within each phase exhibited quasi-elastic behavior, with deformations displaying nearly full reversibility. This property proves to be highly advantageous, especially in scenarios where the stiffness (rigidity) of the ASLS must be tailored to accommodate the specific load generated by a patient during the recovery process [

28]. Such adjustments facilitate the controlled deformation of the bone graft inside the scaffold, thereby optimizing the rate of the ossification process.

As for the direct comparison of the mechanical properties of the ASLSs made by DMLS with different orientations, here are some observations. ASLS×90° achieved a maximal reactive force of 400 N, while ASLS×60° surpassed this with a maximal reactive force of 624 N. Just for reference, the ASLS model investigated in our previous work [

28] made with EBM technology achieved a maximal reactive force of 1300 N. In the first stage of compression for ASLS×90°, the reactive force increased from 2 N to 34.7 N, representing 8.2% of the maximal force. The third stage of compression for this model, where a quasi-linear relationship between the reactive force and the scaffold deformation was observed, spanned from 44.3 N to 400 N, constituting approximately 89.4% of the maximal reactive force. On the other hand, for ASLS×60°, the first stage of compression ranged from 0.8 N to 36.5 N, constituting 5.7% of the maximal force. The third stage of compression extended from 49.1 N to 624 N, accounting for about 92% of the maximal reactive force. In the third stage of compression for ASLS×90°, the stroke ranged from 0.3 mm to 0.79 mm, equivalent to 73.8% of the total stroke. For ASLS×60°, the third stage of compression ranged from 0.3 mm to 0.92 mm, accounting for 69.82% of the total stroke. A comparison of the percentages of reactive forces and strokes in each compression stage for both ASLS models, with respect to the maximum reactive force and total stroke, revealed remarkable similarities.

Figure 12 illustrates that the compression stages for the ASLS models are highly comparable, and no significant differences can be observed.

Another interesting analysis that can be made from these data concerns the energy dissipation during cycling loading (compression–decompression), presented in

Figure 13 and

Figure 14. It is possible to calculate the work needed to compress the ASLS structure and dissipated energy after each decompression cycle (after hardening the ASLS structure).

The return leg of the work diagram indicates the return to the level of work that is irrecoverably invested in the elastic and plastic deformation of the ASLS structure after decompression, and the part is converted to heat. The level of work performed at which the breaking point of the diagram is located represents the amount of dissipated energy.

Figure 15 indicates that ASLS×90° tends to dissipate more energy while it deforms compared to ASLS×60°.

However, due to the different orientation of the struts in the ASLS structures, the cross-sectional area of the scaffolds varied, potentially influencing the comparison of stress between the two ASLS models. Given the challenge in calculating the exact stress of the ASLS models, an approximation was employed. The approximative normal stress within the ASLS structure was determined as the ratio of the reactive force to the average cross-sectional area, as expressed in Equations (1) and (2):

where

In this way, the calculated approximated maximal stress (ultimate compression strength) of ASLS×90° was determined to be 263.17 N/mm

2, whereas for ASLS×60°, it was 172.85 N/mm

2.

where

is the force which causes the fracturing of the first strut of ASLS×90°;

is the force which causes the fracturing of the first strut of ASLS×60°;

is the ultimate compression strength of the ASLS×90° structure;

is the ultimate compression strength of the ASLS×60° structure.

This finding is as expected, as ASLS×60° exhibited a 42% higher volume compared to ASLS×90° (if the volume of ASLS×90° is used as a reference). Because of the higher volume of ASLS×60°, the force was distributed on the larger cross-sectional area, which produced a smaller stress value. This implies that, with a smaller volume and, consequently, reduced material usage, one can achieve a superior ultimate compression strength for ASLSs, just by using optimal outer-strut orientation for the specific load case. When it comes to the stiffness of the ASLS structure (K

ASLS), which is defined as the ratio of the force and the corresponding deflection (deformation) of the structure, ASLS×60° demonstrated a superior stiffness compared to ASLS×90° in the third stage of deformation (see

Figure 16a,b).

where

As previously mentioned, the TrapeziumX UTM software (version 1.4.0) employed for testing did not provide a stress–strain curve due to the anisotropic nature of the ASLS cross sections. Instead, the software generated a force–stroke (i.e., force–displacement) diagram. To address this limitation, an approximation of the stress–strain diagram was undertaken. For each recorded force point, stress was calculated by dividing the force by the average cross-sectional area of the ASLS models. Strain (ε) was then determined by dividing the stroke at each recorded point by the initial length of the ASLS model (10 mm). This methodology allowed the generation of an approximated stress–strain diagram. Subsequently, using data points from the third stage of compression where quasi-linear elastic behavior was evident, a linear trendline was fitted to determine the elasticity coefficient (Ec) of the ASLS structure, which can be interpreted as a kind of modulus of elasticity of ASLS, but as an object, and not as a modulus of elasticity of the ASLS strut material. This term, elasticity coefficient (Ec), is introduced only for the purpose of comparing the performance of the material–geometry pair, which act together to resist the external load. By analyzing the third stage of deformation, the calculated ratio of the normal stress (approximately calculated according to expressions 1 and 2) and strain (i.e., relative deformation) of scaffold ASLS×90° (as an object) was 4866 N/mm

2 (

Figure 17a), and for ASLS×60° it was 3325 N/mm

2 (

Figure 17b). This underscores the significance of optimal strut orientation in ASLSs for achieving targeted rigidity (compressibility) of the structure in the required direction. Importantly, this result highlights that, even with the utilization of less material in manufacturing, the careful selection of strut orientation can lead to stiffer structures. Just for reference, when observing the elasticity coefficient of the same ASLS×60° model manufactured with EBM technology [

28], when a force of around 500 N was applied (which is comparable to the force presented here for models made from DMLS), the elasticity coefficient was 9738 N/mm

2.

To delve deeper into the comparison of the two ASLS models, a focused examination of the first compression stage was undertaken. This stage was chosen due to the minimal plastic deformation that occurred during this stage, allowing for a more accurate assessment of the stiffness and the elasticity coefficient of the ASLS structures. The isolated exploration of this stage also enabled the use of finite element analysis (FEA), as the plastic deformation in the ASLS models during this stage was nearly nonexistent. This approach ensured more reliable and accurate results from the FEA, an advantage that would be compromised if, for instance, the third stage of compression was utilized, given the presence of permanent small plastic deformation in these structures with increased load.

Figure 18a,b present force–displacement diagrams of the first stage of compression for both ASLS models.

Figure 19a,b display approximated stress–strain diagrams, for the same stage of compression, for both ASLS models.

Analyzing the measurement results, it is possible to notice the following:

- 1.

The value of the elasticity coefficient of the ASLS structure (as an object, and not a material) is much lower (from 20 to 40 times lower) than the modulus of elasticity of the test specimen produced by the same process (DMLS) from the same material (Ti64 powder). This can be explained by the fact that in the case of the test specimen (

Figure 20a), the neck of the specimen is 5 mm in diameter, i.e., the area of the specimen cross section (19.635 mm

2) is much greater (156 times) than the area of an ASLS strut (~0.126 mm

2) (

Figure 20b). A vast number of Ti-alloy powder particles in every cross-sectional layer and between the layers are joined. This causes the inner structure of the test specimen (D = 5 mm), which is made of Ti-alloy powder from DMLS, to appear much more homogenous than the inner structure of the ASLS struts (D ≅ 0.4 mm), that is, it appears very similar to the specimen made of the same Ti alloy, but conventionally, due to being cut from the rolled plate of the same Ti alloy.

That is why the modulus of elasticity of both test specimens, one made of Ti64 powder sintered by the DMLS process, and another, made conventionally, is almost the same (104 GPA—110 Gpa). This similarity in homogeneity of the material is even more apparent if the specimen made from Ti-alloy powder is being additionally shot-peened and aged afterwards. In the case of the ASLS, we found, however, the strut diameter was only ~0.4 mm, which is at the limit of the minimum wall thickness of parts that can be fabricated by DMLS, as claimed in the EOSINT material data sheet (min. wall thickness approx. 0.3–0.4 mm). In

Figure 8, looking at the outside of the strut, it is possible to see that such a slender structure is formed from a series of separately formed macro-particles (fused or sintered and from particles of Ti-alloy powder) sintered with each other in the direction of the axis of the strut (

Figure 20b). Tests, as well as comparative analyses using the finite element method (which are not shown here in the paper), show that the structures of slender struts with such a small cross section are not characterized by that level of homogeneity of material. Consequently, the isotropy of mechanical properties (inherent to the specimen of D = 5 mm) ultimately reflects the fact that such struts do not have anywhere near as high an elasticity coefficient as a test specimen with a diameter of 5 mm, although both the test specimen and the strut are made from the same Ti64 powder using the same DMLS process.

- 2.

The value of the elasticity coefficient (Ec) of the ASLS lattice structure depends to a significant extent on two angles: (1) the angle at which the struts cross (α), and the angle (γ) that is between the load direction and the axis of the struts in the outer layer of the ASLS (

Figure 4). Additionally, one can observe that the mutual ratio of the elasticity coefficient of the ASLS×90° and ASLS×60° structures differs depending on which stage of quasi-reversible deformation the elasticity coefficient is being sampled in. In the stage of quasi-reversible deformation, which is characterized by a higher degree of deformation (compression) of the scaffold (150 ≤ F ≤ 400), the ratio of the elasticity coefficient of these structures is smaller (Equations (7) and (8)):

Bearing in mind the presented results, in the future, a special challenge would be to explore the dependency of the elasticity coefficient of the macro-lattice structure of a bone scaffold (e.g., a kind of generic shape of ASLS for the recovery of the missing pieces of so-called long bones) on the angle at which the struts in a scaffold’s outer layer cross, the angle that forms the direction of force action (the direction of the mechanical axis of the long bone), and the struts in a scaffold’s outer layer.