Heterogeneous Microstructure and Tensile Properties of an Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

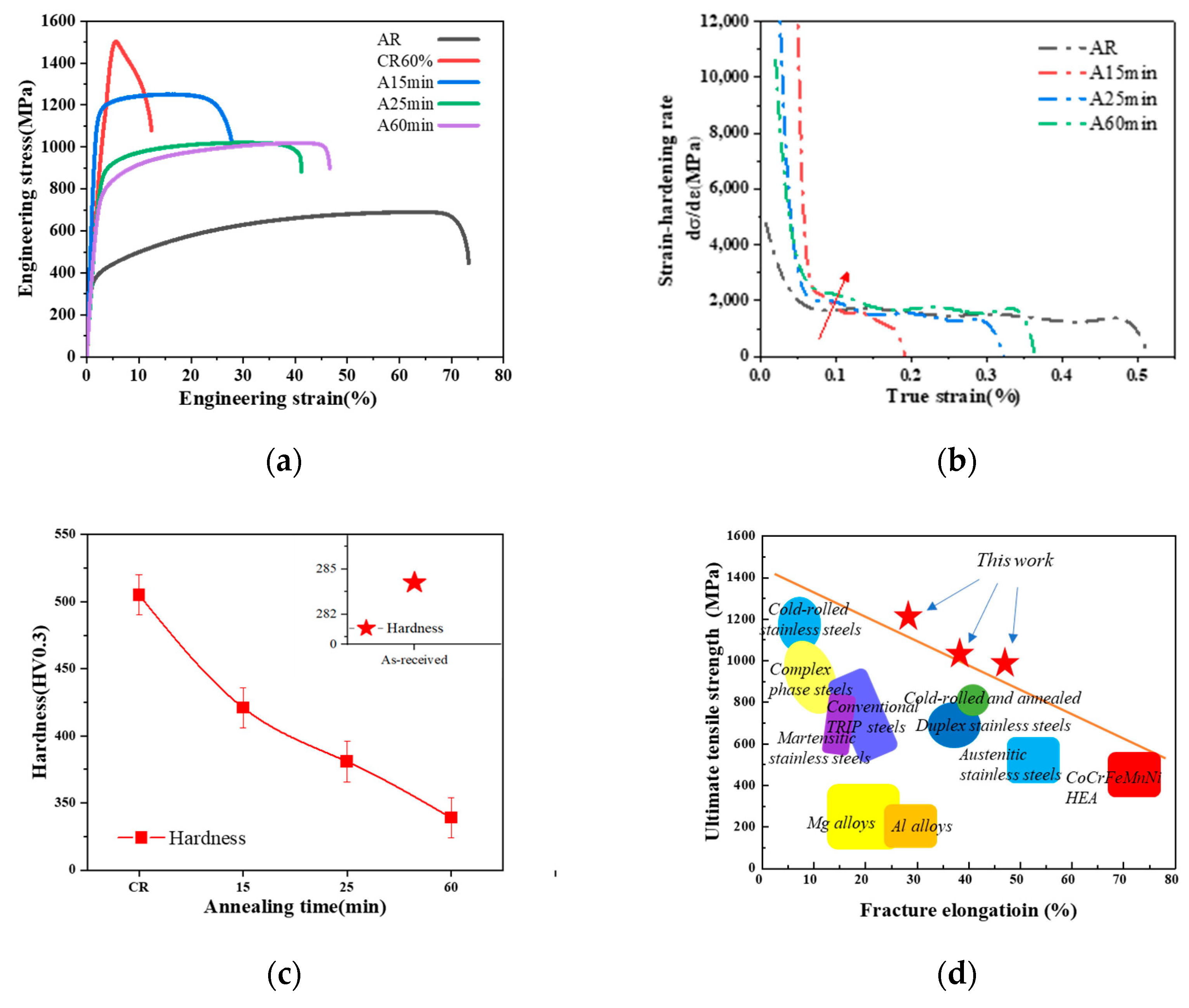

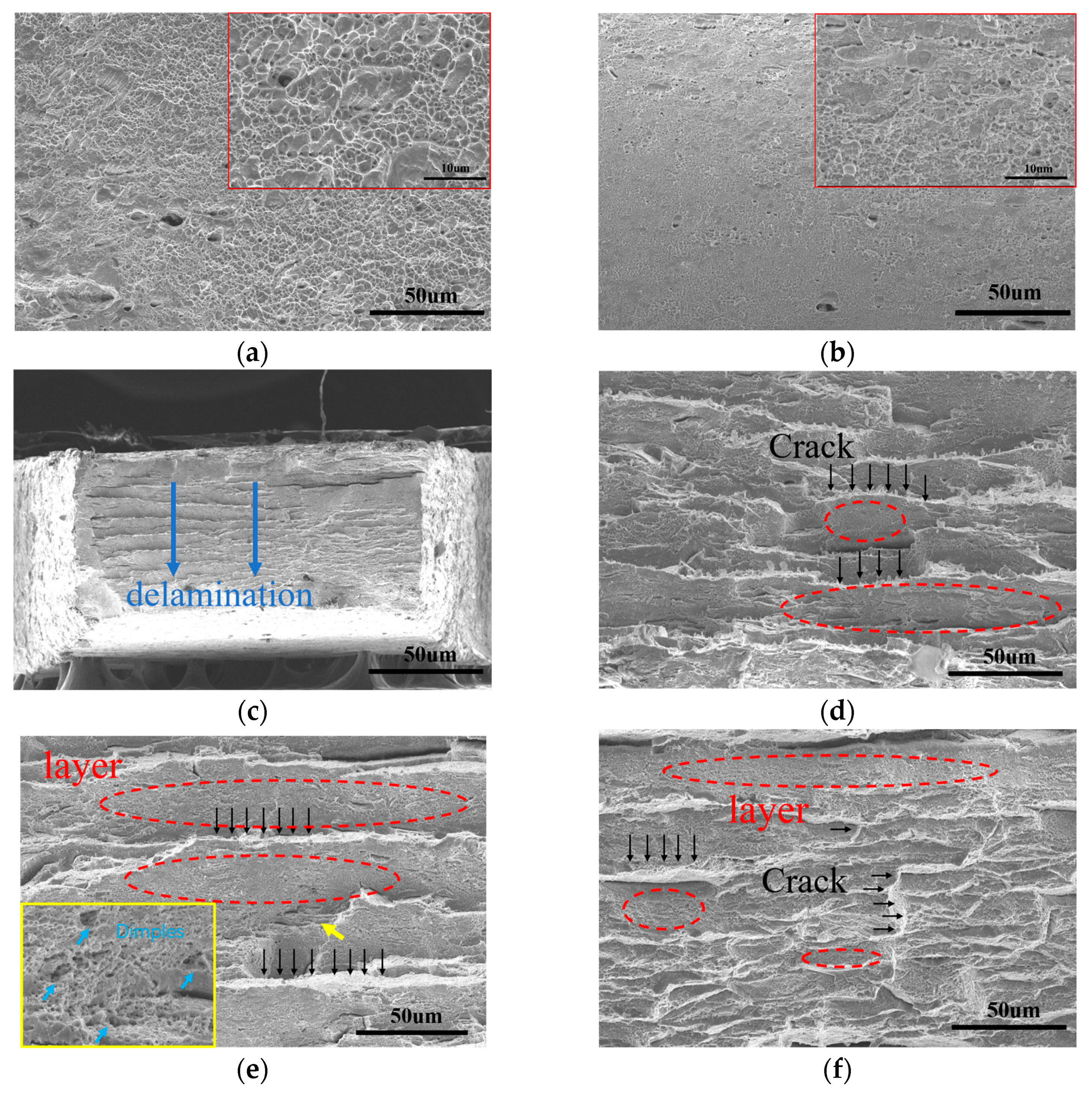

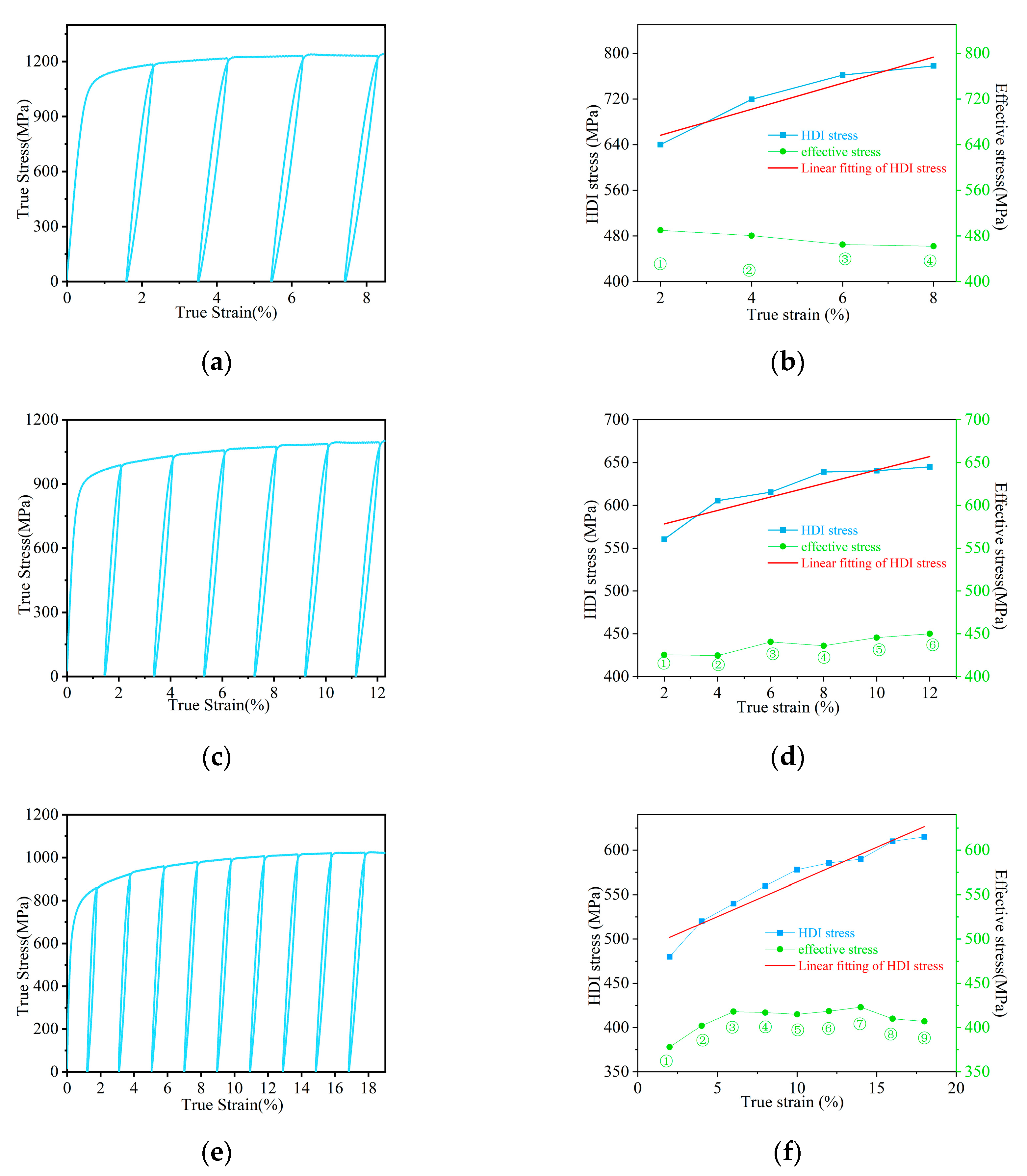

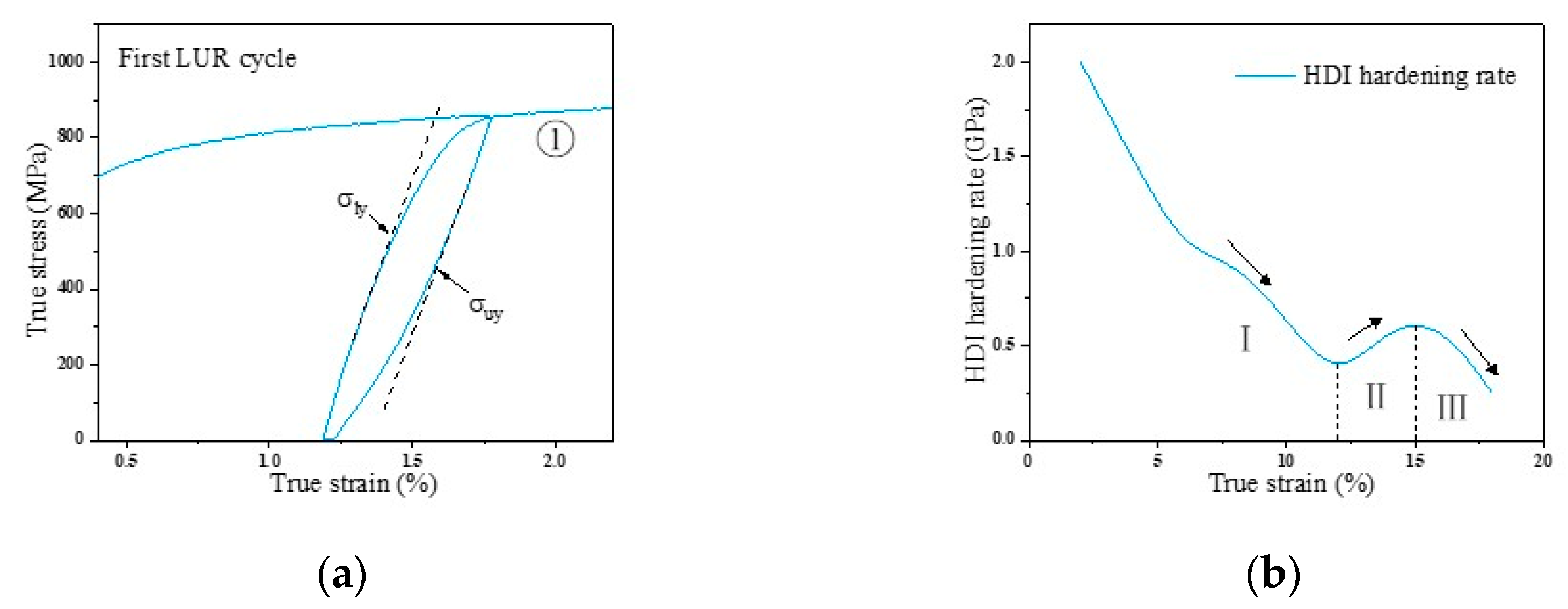

3.1. Mechanical Properties

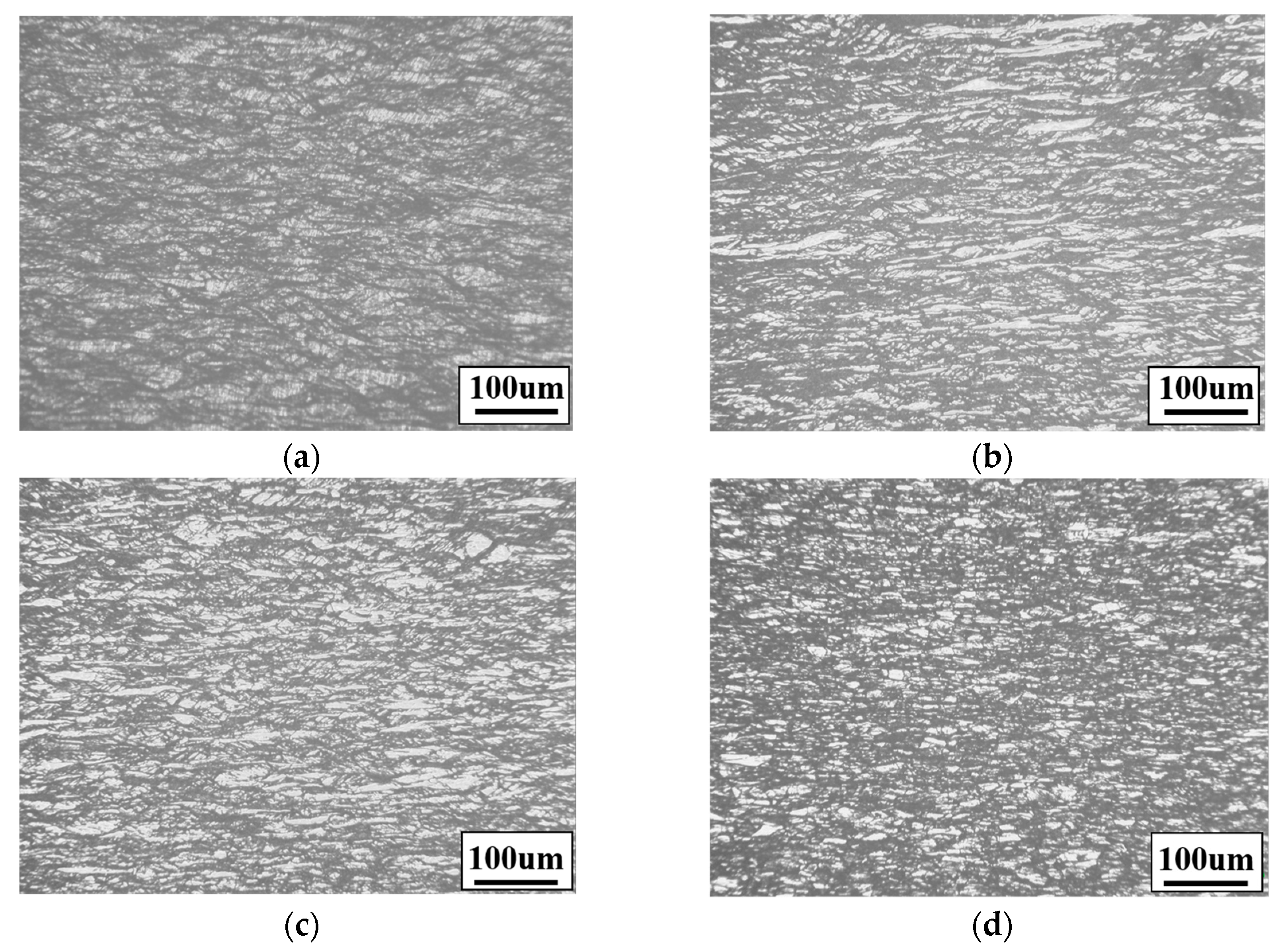

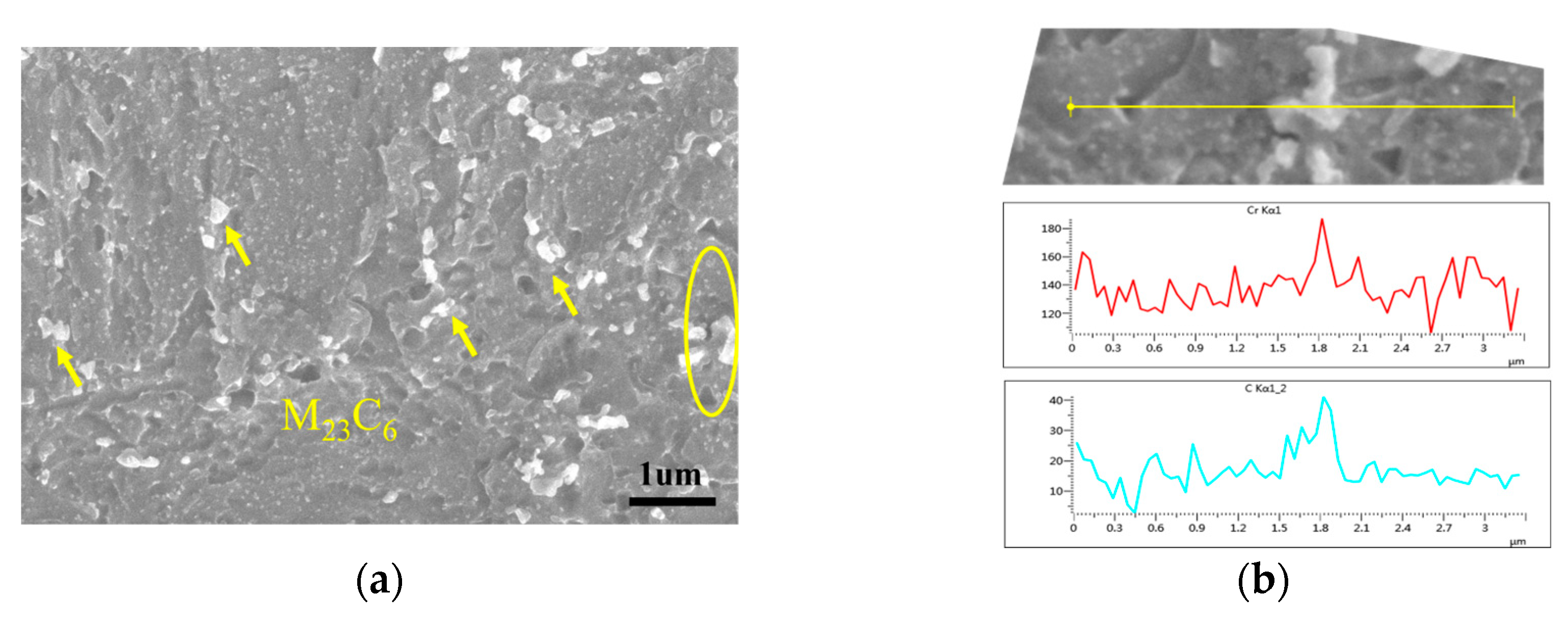

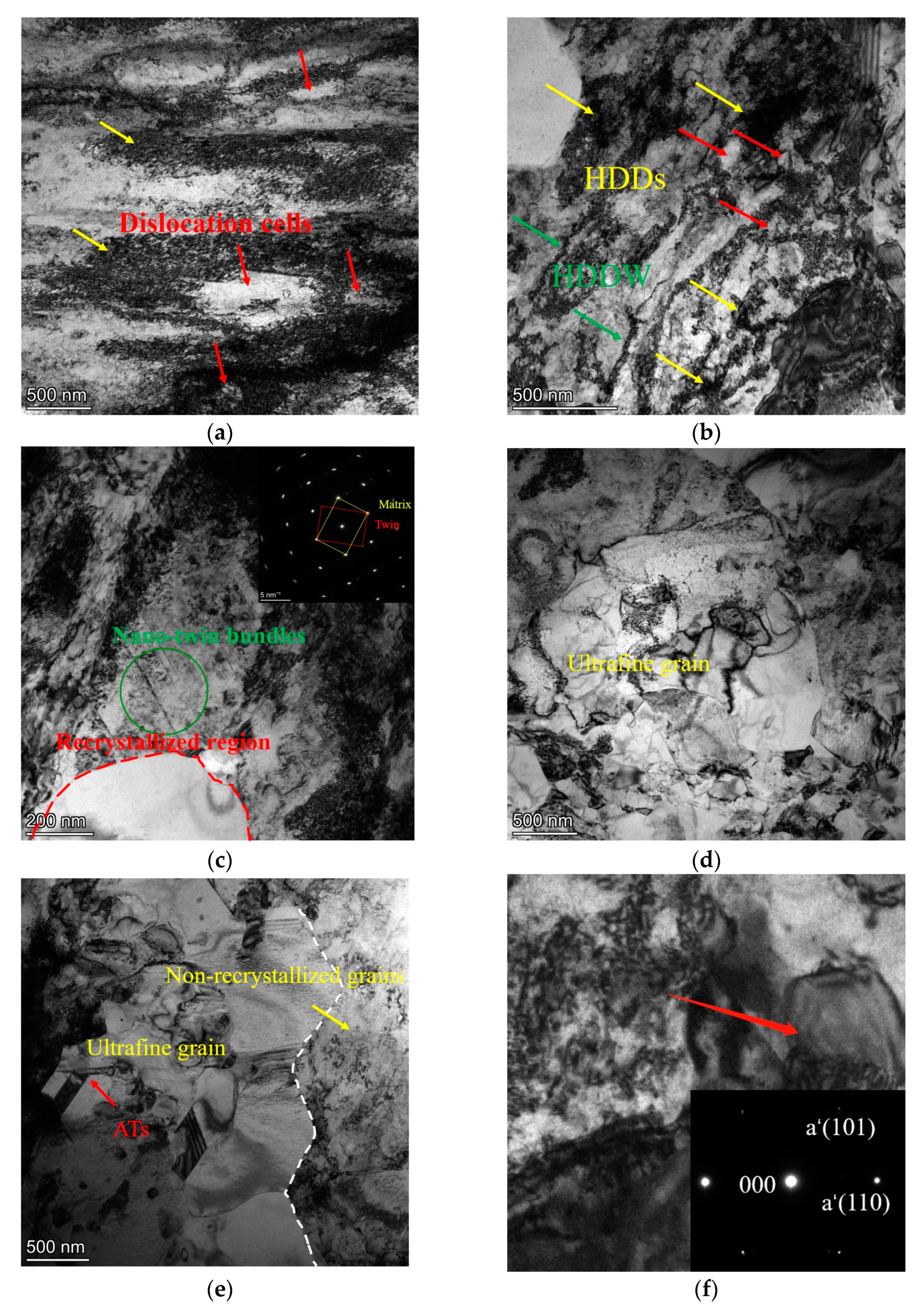

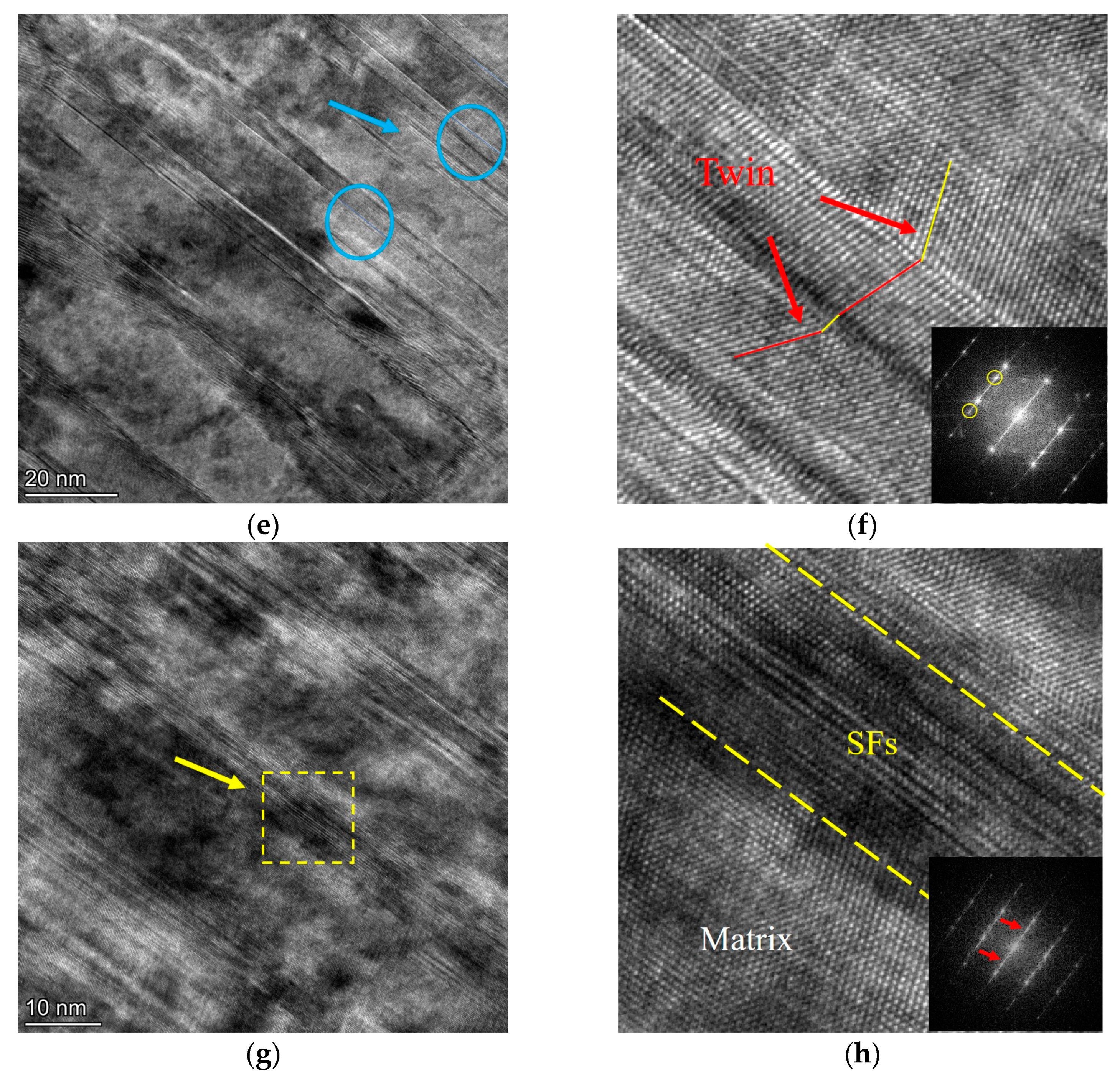

3.2. Microstructure

4. Discussion

4.1. The Evolution of Microstructure

4.2. Strengthening Mechanisms

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, R.; Northwood, D.O.; Liu, C. On nitrogen diffusion during solution treatment in a high nitrogen austenitic stainless steel. J. Mater. Res. Technol. 2020, 9, 2331–2337. [Google Scholar] [CrossRef]

- Kostina, M.V.; Bannykh, O.A.; Blinov, V.M. Special Features of Steels Alloyed with Nitrogen. Met. Sci. Heat Treat. 2000, 42, 459–462. [Google Scholar] [CrossRef]

- Zhufeng, H.; Yanxin, G.; Lifang, S.; Hai-Le, Y.; Xianjun, G.; Shuang, J.; Yongfeng, S.; Wen, Y.; Xiaoli, Z.; Zhiming, L.; et al. Inter-stitial-driven local chemical order enables ultrastrong face-centered cubic multicomponent alloys. Acta Mater. 2023, 243, 118495. [Google Scholar]

- Makhmutov, T.; Razumov, N.; Kim, A.; Ganin, S.; Shamshurin, A.; Popovich, A.; Popovich, V. Microstructure and mechanical properties of high-nitrogen 16Cr-2Ni-Mn-Mo-xN stainless steel obtained by powder metallurgy techniques. Nano Mater. Sci. 2020, 30, 768–772. [Google Scholar] [CrossRef]

- Mohammed, R.; Reddy, G.M.; Rao, K.S. Welding of nickel free high nitrogen stainless steel: Microstructure and mechanical properties. Def. Technol. 2017, 13, 59–71. [Google Scholar] [CrossRef]

- Zhang, Z.; Vajpai, S.K.; Orlov, D.; Ameyama, K. Improvement of mechanical properties in SUS304L steel through the control of bimodal microstructure characteristics. Mater. Sci. Eng. A 2014, 598, 106–113. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Liu, J.W.; Gao, Y. Achieving high strength and high ductility in 304 stainless steel through bi-modal microstruc-ture prepared by post-ECAP annealing. Mater. Sci. Eng. A 2017, 680, 426–432. [Google Scholar] [CrossRef]

- Wu, X.L.; Jiang, P.; Chen, L.; Zhang, J.F.; Yuan, F.P.; Zhu, Y.T. Synergetic Strengthening by Gradient Structure. Mater. Res. Lett. 2014, 2, 185–191. [Google Scholar] [CrossRef]

- Moering, J.; Ma, X.; Malkin, J.; Yang, M.; Zhu, Y.; Mathaudhu, S. Synergetic strengthening far beyond rule of mixtures in gradi-ent structured aluminum rod. Scr. Mater. 2016, 122, 106–109. [Google Scholar] [CrossRef]

- Wang, H.; Tao, N.; Lu, K. Architectured surface layer with a gradient nanotwinned structure in a Fe–Mn austenitic steel. Scr. Mater. 2013, 68, 22–27. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Vecchio, K. Non-equiatomic FeNiCoAl-based high entropy alloys with multiscale heterogeneous lamella structure for strength and ductility. Mater. Sci. Eng. A 2019, 743, 361–371. [Google Scholar] [CrossRef]

- Li, J.; Fang, C.; Liu, Y.; Huang, Z.; Wang, S.; Mao, Q.; Li, Y. Deformation mechanisms of 304L stainless steel with heterogeneous lamella structure. Mater. Sci. Eng. A 2018, 742, 409–413. [Google Scholar] [CrossRef]

- Sekiguchi, T.; Ono, K.; Fujiwara, H.; Ameyama, K. New Microstructure Design for Commercially Pure Titanium with Out-standing Mechanical Properties by Mechanical Milling and Hot Roll Sintering. Mater. Trans. 2010, 51, 39–45. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y. Geometrically necessary dislocation and size-dependent plasticity. Scr. Mater. 2003, 48, 113–118. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Ma, E.; Zhu, T. Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 2017, 20, 323–331. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density–induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef]

- Shukla, S.; Choudhuri, D.; Wang, T.; Liu, K.; Wheeler, R.; Williams, S.; Gwalani, B.; Mishra, R.S. Hierarchical features infused heterogeneous grain structure for extraordinary strength-ductility synergy. Mater. Res. Lett. 2018, 6, 676–682. [Google Scholar] [CrossRef]

- Yan, F.; Liu, G.; Tao, N.; Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 2012, 60, 1059–1071. [Google Scholar] [CrossRef]

- Niu, G.; Zurob, H.S.; Misra, R.D.K.; Wu, H.; Zou, Y. Strength-ductility synergy in a 1.4 GPa austenitic steel with a heterogene-ous lamellar microstructure. J. Mater. Sci. Technol. 2022, 106, 133–138. [Google Scholar] [CrossRef]

- Etienne, A.; Radiguet, B.; Genevois, C.; Le Breton, J.-M.; Valiev, R.; Pareige, P. Thermal stability of ultrafine-grained austenitic stainless steels. Mater. Sci. Eng. A 2010, 527, 5805–5810. [Google Scholar] [CrossRef]

- Naghizadeh, M.; Mirzadeh, H. Microstructural Evolutions During Reversion Annealing of Cold-Rolled AISI 316 Austenitic Stainless Steel. Met. Mater. Trans. A 2018, 49, 2248–2256. [Google Scholar] [CrossRef]

- Baghbadorani, H.S.; Kermanpur, A.; Najafizadeh, A.; Behjati, P.; Rezaee, A.; Moallemi, M. An investigation on micro-structure and mechanical propertiesof a Nb-microalloyed nano/ultrafine grained 201 austenitic stainless steel. Mater. Sci. Eng. A 2015, 636, 593–599. [Google Scholar] [CrossRef]

- Liu, L.; Yu, Q.; Wang, Z.; Ell, J.; Huang, M.X.; Ritchie, R.O. Making ultrastrong steel tough by grain-boundary delamination. Science 2020, 368, 1347–1352. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Gall, K.; Chumlyakov, Y.; Maier, H. Deformation of single crystal Hadfield steel by twinning and slip. Acta Mater. 2000, 48, 1345–1359. [Google Scholar] [CrossRef]

- Bracke, L.; Verbeken, K.; Kestens, L.; Penning, J. Microstructure and texture evolution during cold rolling and annealing of a high Mn TWIP steel. Acta Mater. 2009, 57, 1512–1524. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Yu, F.; Xu, D.; Wang, M.; Li, L.; Lu, Y. Achieving a strength-ductility combination in VCoNi medium-entropy alloy via N alloy-ing. J. Alloys Compd. 2023, 963, 10. [Google Scholar] [CrossRef]

- Deng, Y.H.; Cao, J.C.; Qian, H. Research on Dynamic Recrystallization Behavior of 23Cr-2.2Ni-6.3Mn-0.26N Low Nickel TypeDuplex Stainless Steel. Acta Metall. Sin. 2018, 55, 445–456. [Google Scholar]

- Li, Z.; Chen, L.; Fu, P.; Su, H.; Dai, P.; Tang, Q. The effect of Si addition on the heterogeneous grain structure and mechanical properties of CrCoNi medium entropy alloy. Mater. Sci. Eng. A 2022, 852, 143655. [Google Scholar] [CrossRef]

- Zheng, X.; Xie, W.; Zeng, L.; Wei, H.; Zhang, X.; Wang, H. Achieving high strength and ductility in a heterogeneous-grain-structured CrCoNi alloy processed by cryorolling and subsequent short-annealing. Mater. Sci. Eng. A 2021, 821, 141610. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, J.; Jiang, L.; Yang, C.; Jiang, M. Effect of Tensile Deformation on Microstructure and Corrosion Resistance of High Nitrogen Austenitic Stainless Steels. Acta Metall. Sin. 2022, 58, 193–205. [Google Scholar]

- Zhou, Z.; Wang, S.; Li, J.; Li, Y.; Wu, X.; Zhu, Y. Hardening after annealing in nanostructured 316L stainless steel. Nano Mater. Sci. 2019, 2, 80–82. [Google Scholar] [CrossRef]

- An, Z.; Mao, S.; Liu, Y.; Yang, L.; Vayyala, A.; Wei, X.; Liu, C.; Shi, C.; Jin, H.; Liu, C.; et al. Inherent and multiple strain hardening imparting synergistic ultrahigh strength and ductility in a low stacking faulted heterogeneous high-entropy alloy. Acta Mater. 2023, 243, 118516. [Google Scholar] [CrossRef]

- Yang, M.; Pan, Y.; Yuan, F.; Zhu, Y.; Wu, X. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Qin, S.; Yang, M.; Wang, J.; Jiang, P.; Yuan, F.; Wu, X. Dual heterogeneous structured medium-entropy alloys showing a superior strength-ductility synergy at cryogenic temperature. J. Mater. Res. Technol. 2022, 17, 3262–3276. [Google Scholar] [CrossRef]

- Yang, G.; Kim, J.-K. Hierarchical precipitates, sequential deformation-induced phase transformation, and enhanced back stress strengthening of the micro-alloyed high entropy alloy. Acta Mater. 2022, 233, 117974. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Feaugas, X. On the origin of the tensile flow stress in the stainless steel AISI 316L at 300 K: Back stress and effective stress. Acta Mater. 1999, 47, 3617–3632. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| QN1803 | 0.07 | 0.35 | 5.40 | 0.03 | 0.0005 | 18.2 | 3.20 | 1.05 | 0.12 | 0.225 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Wang, H.; Li, Z.; Tian, J.; Huang, J.; Dai, P. Heterogeneous Microstructure and Tensile Properties of an Austenitic Stainless Steel. Metals 2024, 14, 285. https://doi.org/10.3390/met14030285

Chen Q, Wang H, Li Z, Tian J, Huang J, Dai P. Heterogeneous Microstructure and Tensile Properties of an Austenitic Stainless Steel. Metals. 2024; 14(3):285. https://doi.org/10.3390/met14030285

Chicago/Turabian StyleChen, Qingxin, Haichao Wang, Zhanjiang Li, Jun Tian, Jianeng Huang, and Pinqiang Dai. 2024. "Heterogeneous Microstructure and Tensile Properties of an Austenitic Stainless Steel" Metals 14, no. 3: 285. https://doi.org/10.3390/met14030285

APA StyleChen, Q., Wang, H., Li, Z., Tian, J., Huang, J., & Dai, P. (2024). Heterogeneous Microstructure and Tensile Properties of an Austenitic Stainless Steel. Metals, 14(3), 285. https://doi.org/10.3390/met14030285