Low-Temperature Impact Fracture Behavior of Medium Manganese Steel with Bcc-fcc Duplex Microstructures

Abstract

1. Introduction

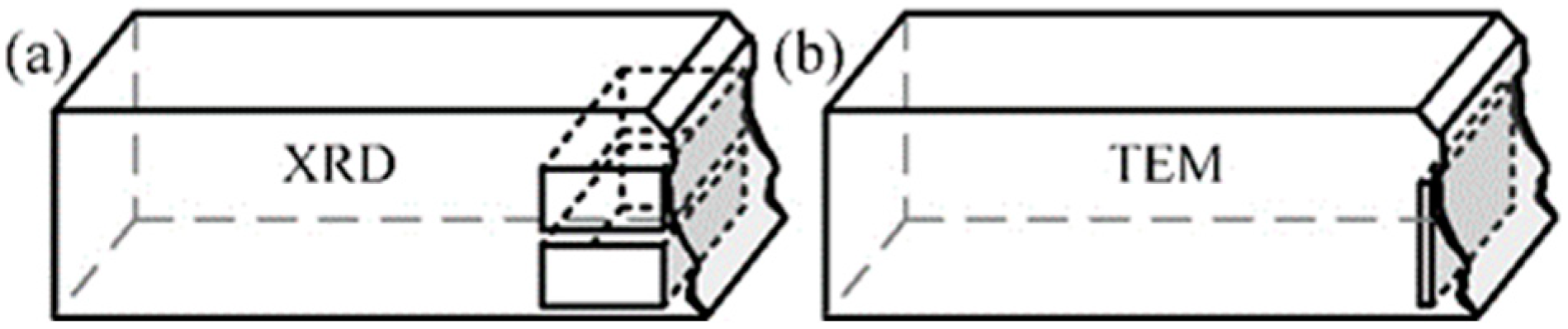

2. Experimental Methods

2.1. Materials and Heat Treatment

2.2. Charpy Impact Test

2.3. Microstructure Characterization

3. Results

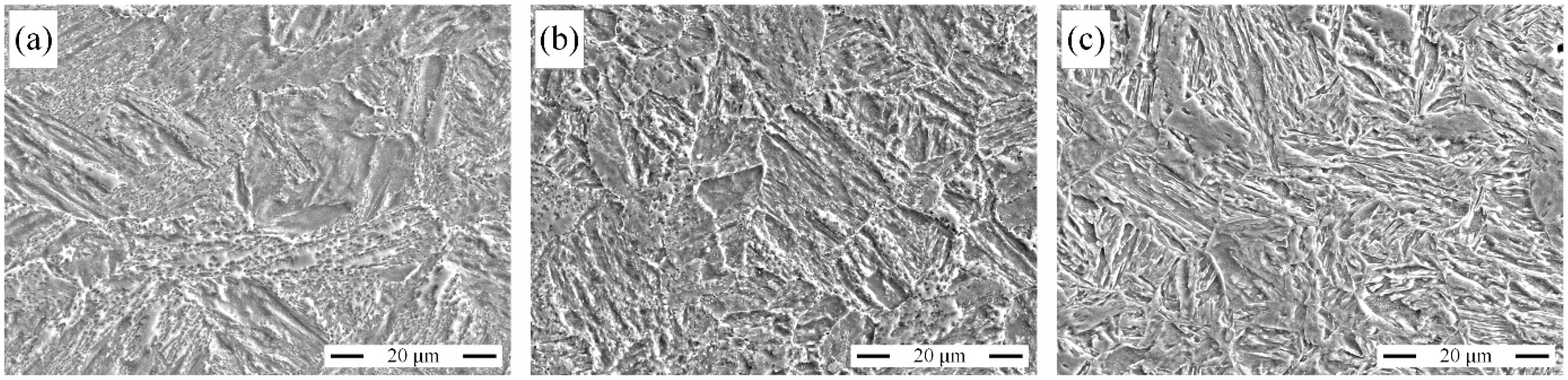

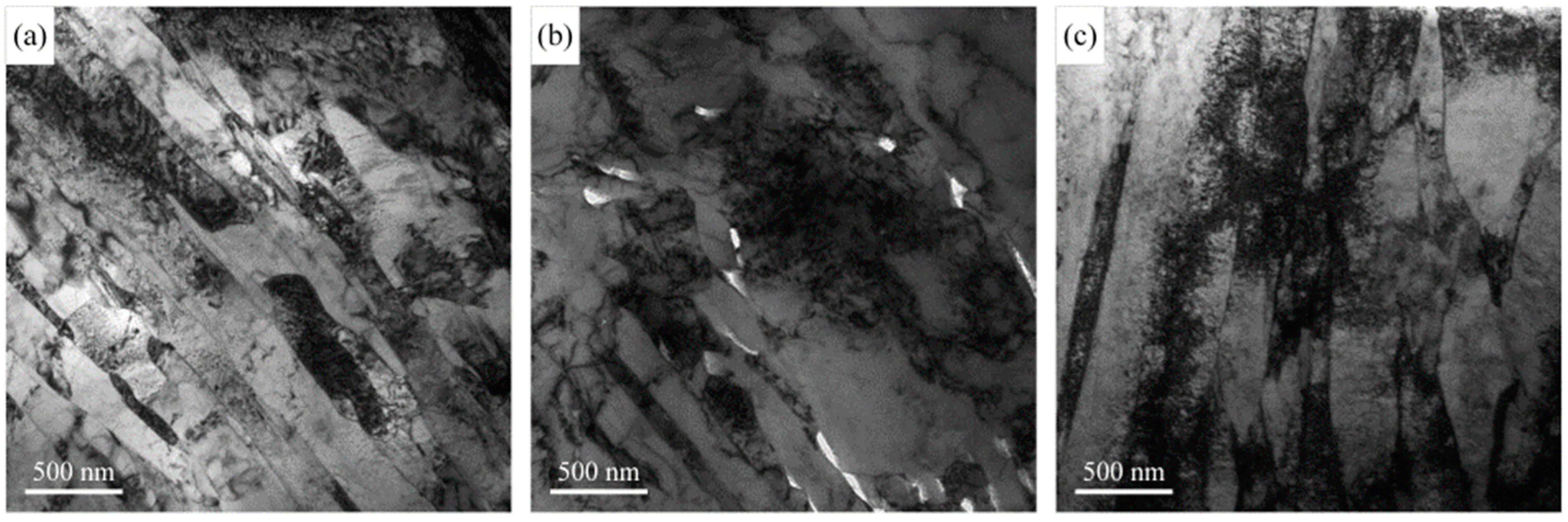

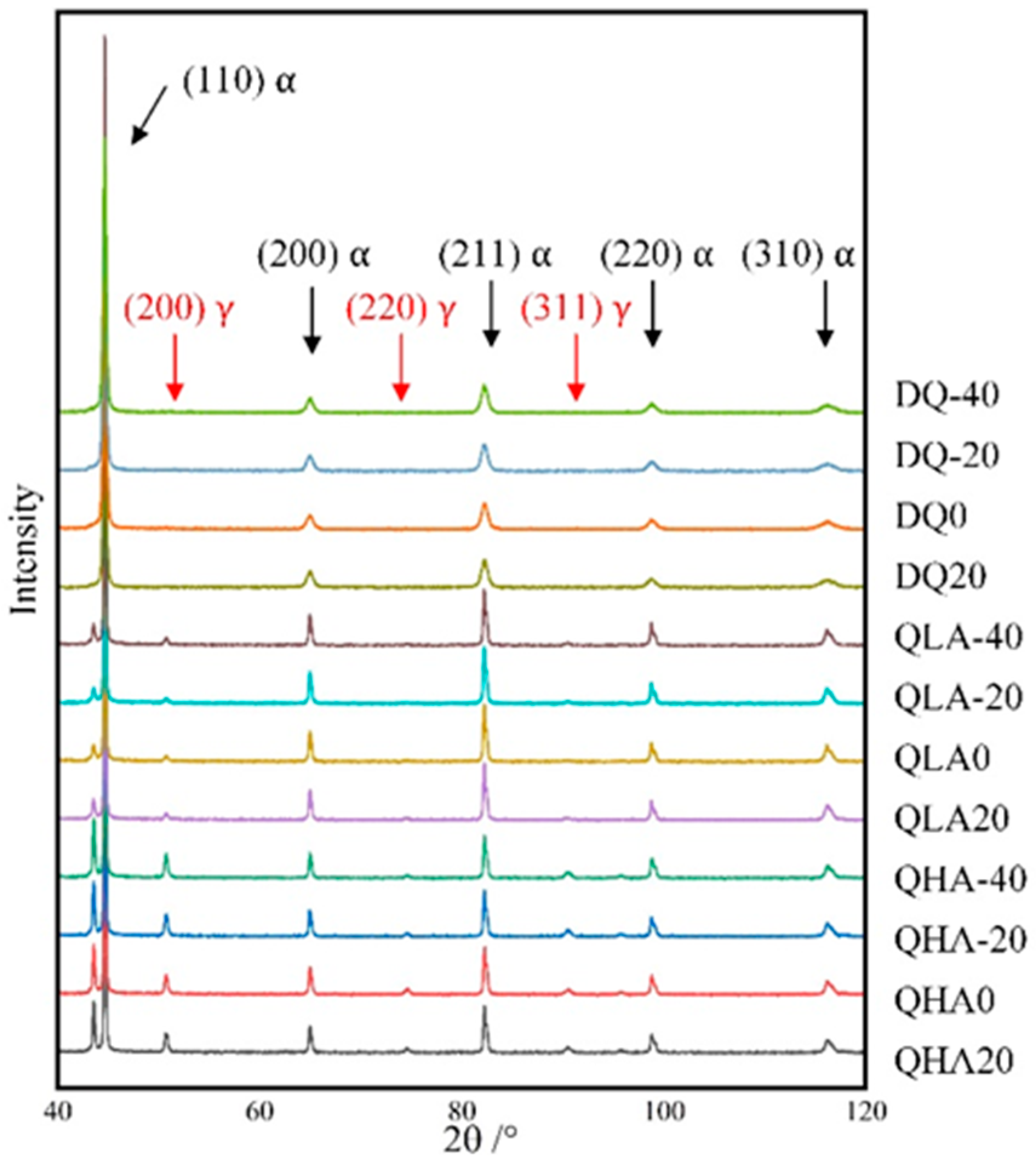

3.1. Microstructure Characterization

3.2. Charpy Impact Behavior Tested at Different Temperatures

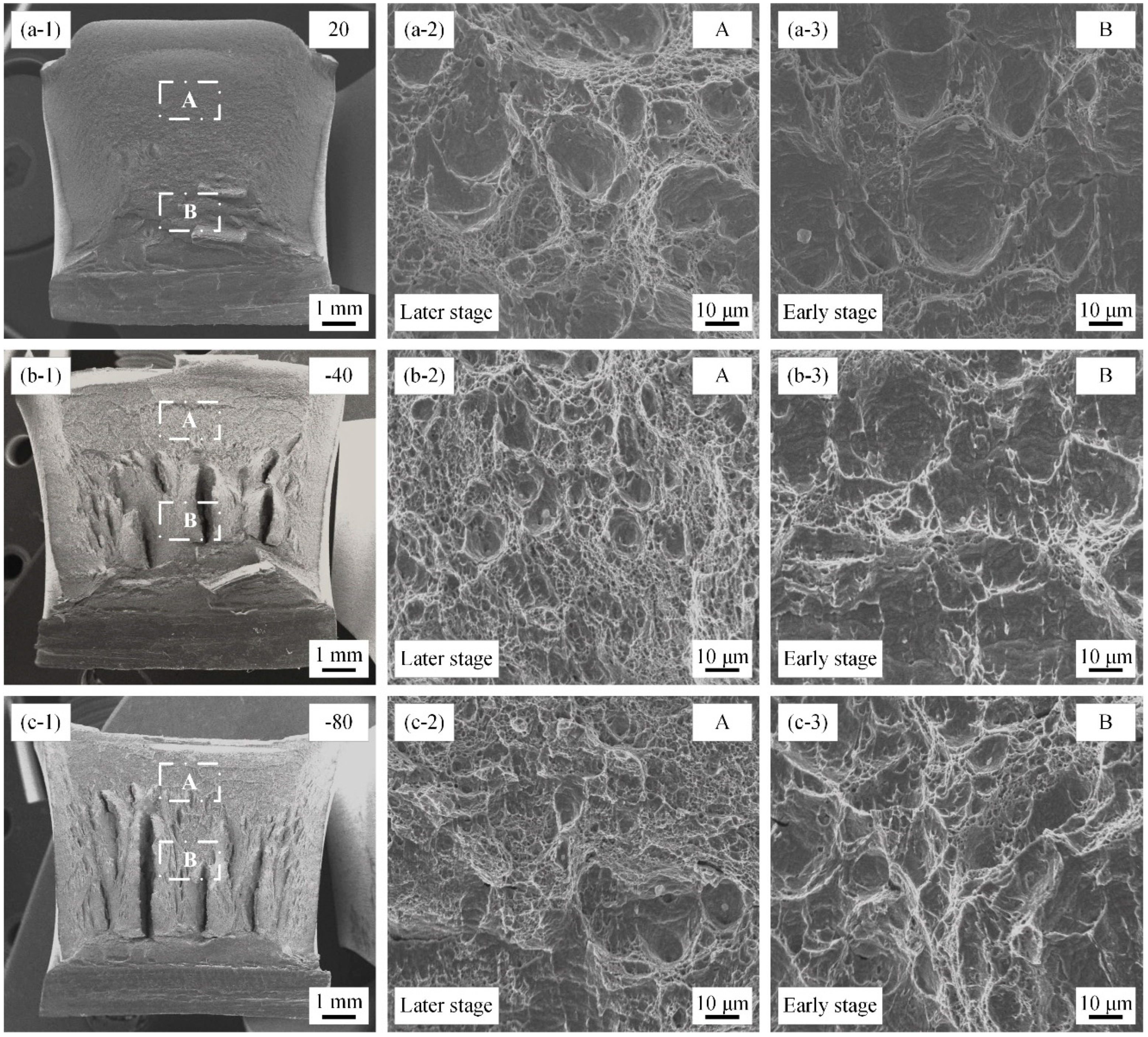

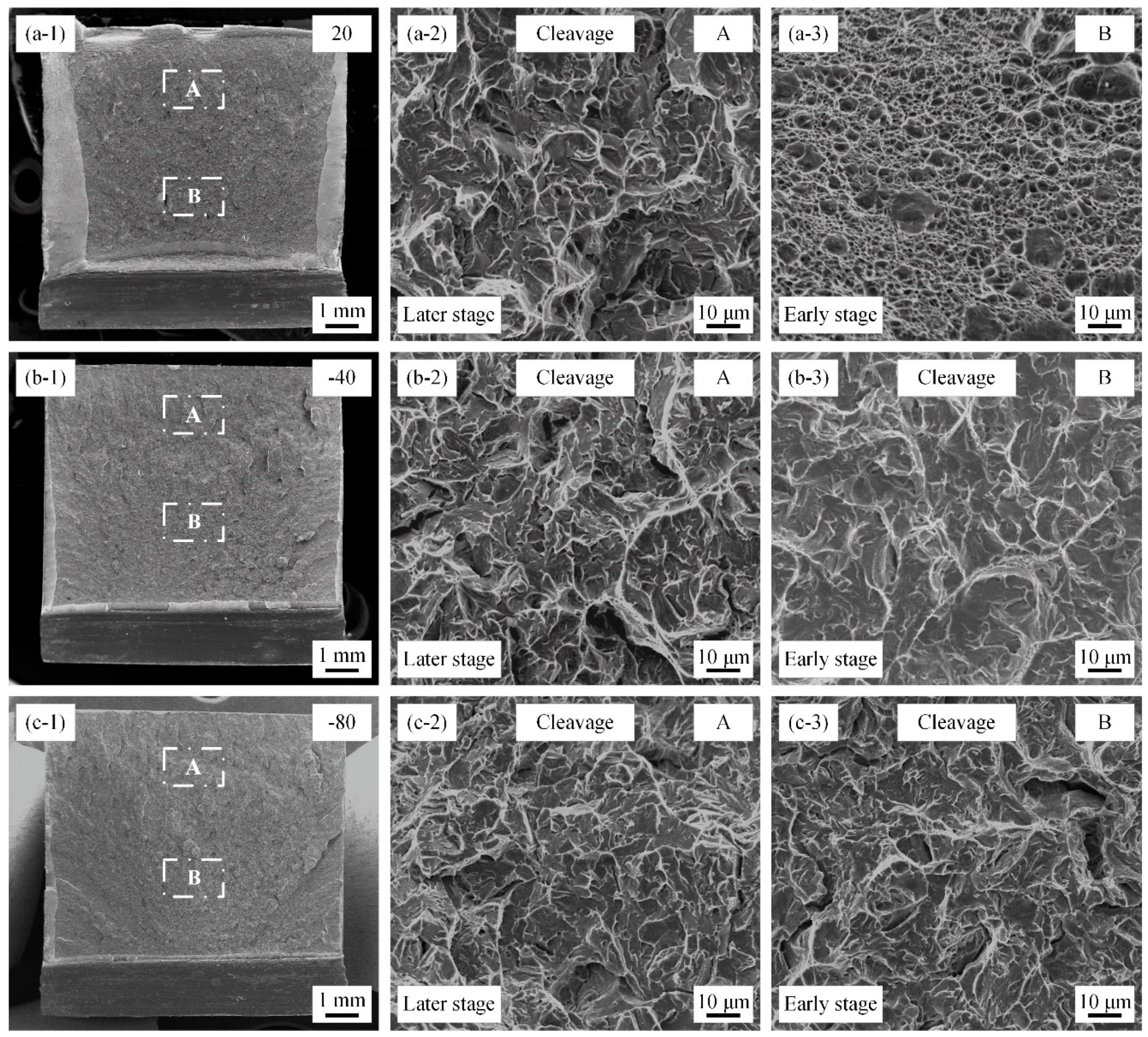

3.3. Fractography Observation

4. Discussion

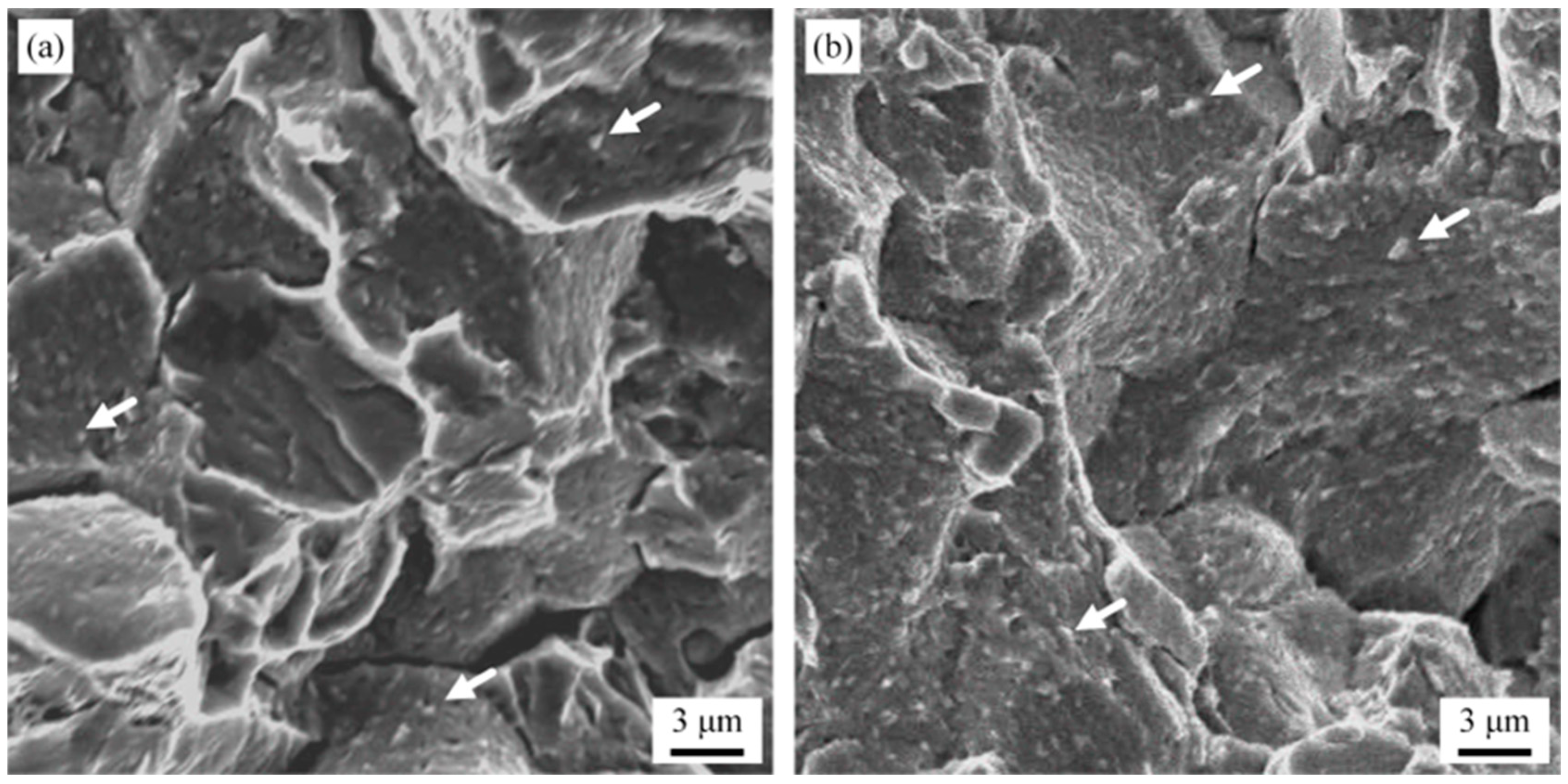

4.1. Low-Temperature Impact Fracture Behavior in Steel of Martensite with RA

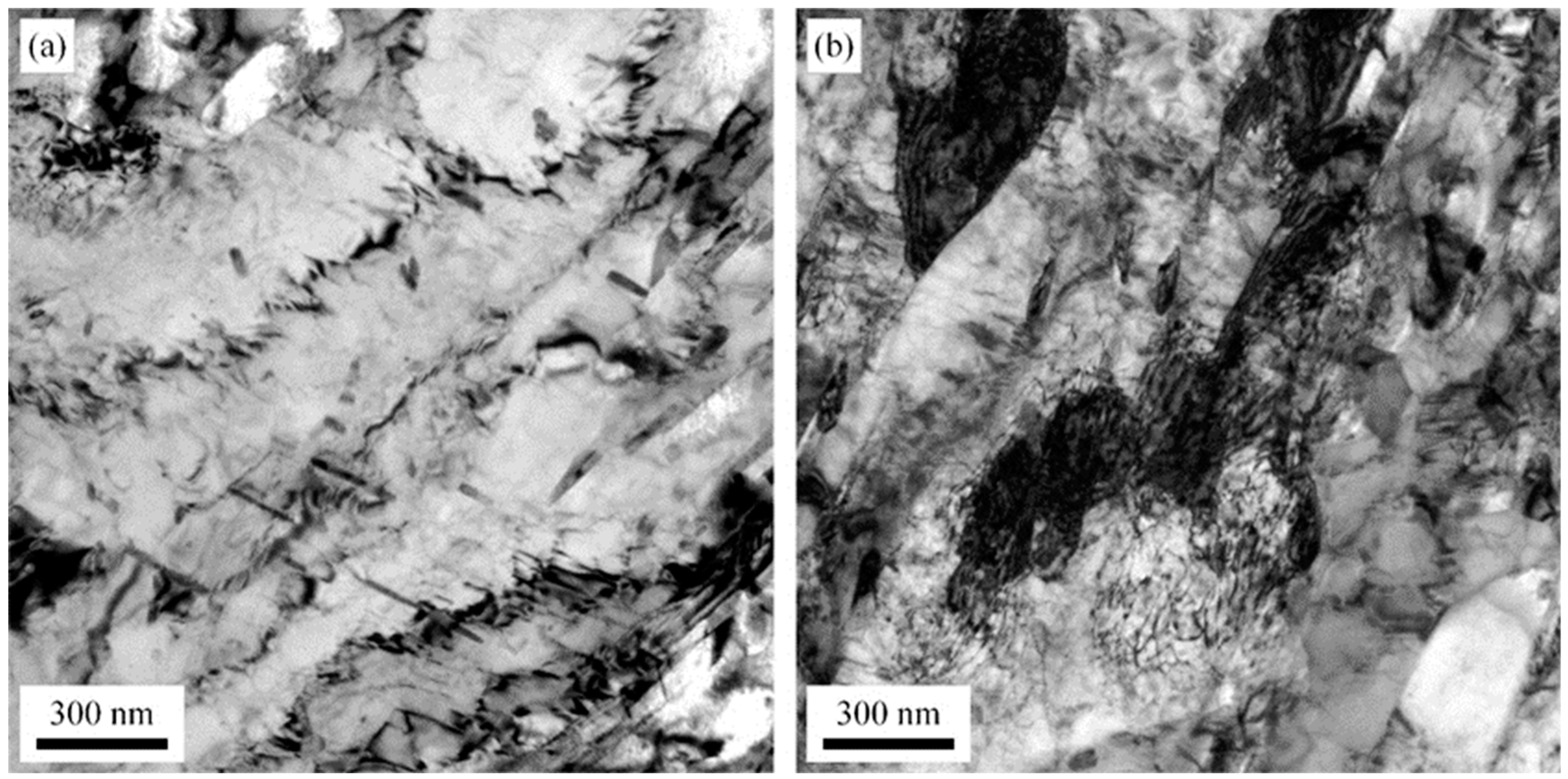

4.2. Effect of Dislocation Density of Martensite on Impact Fracture Behavior

5. Conclusions

- (1)

- The impact energy of QHA decreases slowly with temperature through the joint action of the bcc and fcc microstructures. The fracture morphology of QHA is entirely composed of dimples because of the low dislocation density of the martensite and the large volume fraction of RA with high stability.

- (2)

- The impact energy of QLA decreases faster than that of QLA with temperature, and QLA is fractured in intergranular mode, while the tested temperature decreases below −40 °C because of the low stability of RA and carbides precipitated at the prior austenite grain boundaries.

- (3)

- The impact energy of DQ tested at different temperatures is low and fractured in the elastic stage when the tested temperature is below −40 °C. DQ−40 and DQ−80 are fractured in cleavage mode instead of intergranular because of the high dislocation density in quenched martensite.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dadfarnia, M.; Novak, P.; Ahn, D.C.; Liu, J.B.; Sofronis, P.; Johnson, D.D.; Robertson, I.M. Recent Advances in the Study of Structural Materials Compatibility with Hydrogen. Adv. Mater. 2010, 22, 1128–1135. [Google Scholar] [CrossRef]

- Zhao, J.X.; Wang, H.; Koenigsmann, K.; Ran, X.Z.; Zhang, P.; Zhang, S.Y.; Li, Y.; Liu, H.; Liu, H.; Ren, L.; et al. Warm Deformation at the (α + γ) Dual-Phase Region to Fabricate 2 GPa Ultrafine-Grained TRIP Steels. Metals 2023, 13, 1997. [Google Scholar] [CrossRef]

- Yang, J.L.; Huang, F.; Guo, Z.H.; Rong, Y.H.; Chen, N.L. Effect of retained austenite on the hydrogen embrittlement of a medium carbon quenching and partitioning steel with refined microstructure. Mater. Sci. Eng. A 2016, 665, 76–85. [Google Scholar] [CrossRef]

- Chen, L.; Ma, Z.X.; Shi, R.J.; Su, Y.J.; Qiao, L.J.; Wang, L.L. Comprehensive effect of hydrostatic compressive stress in retained austenite on mechanical properties and hydrogen embrittlement of martensitic steels. Int. J. Hydrogen Energy 2020, 45, 22102–22112. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Hui, W.J.; Zhao, X.L.; Wang, C.Y.; Cao, W.Q.; Dong, H. Effect of reverted austenite fraction on hydrogen embrittlement of TRIP-aided medium Mn steel (0.1C-5Mn). Eng. Fail. Anal. 2019, 97, 605–616. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, B.; Zhao, M.M.; Du, Y.; Misra, R.D.K.; Du, L.X. Investigation of austenite decomposition behavior and relationship to mechanical properties in continuously cooled medium-Mn steel. Mater. Sci. Eng. A 2022, 831, 142208. [Google Scholar] [CrossRef]

- Cho, L.; Kong, Y.R.; Speer, J.G.; Findley, K.O. Review: Hydrogen Embrittlement of Medium Mn Steels. Metals 2021, 11, 358. [Google Scholar] [CrossRef]

- Scott, C.P. Recent Developments in Medium and High Manganese Steels. Metals 2022, 12, 743. [Google Scholar] [CrossRef]

- Sun, B.H.; Lu, W.J.; Gault, B.; Ding, R.; Makineni, S.K.; Wan, D.; Wu, C.H.; Chen, H.; Ponge, D.; Raabe, D. Chemical heterogeneity enhances hydrogen resistance in high-strength steels. Nat. Mater. 2021, 20, eaay1430. [Google Scholar] [CrossRef]

- Saha, D.C.; Biro, E.; Gerlich, A.P.; Zhou, Y. Influences of blocky retained austenite on the heat-affected zone softening of dual-phase steels. Mater. Lett. 2020, 264, 127368. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Ying, Z.Y. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar] [CrossRef]

- Lan, L.Y.; Yu, M.; Qiu, C.L. On the local mechanical properties of isothermally transformed bainite in low carbon steel. Mater. Sci. Eng. A 2019, 742, 442–450. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Deng, X.T.; Wang, Z.D. Achieving High Plasticity and High Toughness of Low-Carbon Low-Alloy Steel through Intercritical Heat Treatment. Metals 2023, 13, 1737. [Google Scholar] [CrossRef]

- Dulucheanu, C.; Severin, T.L.; Cerlinca, D.A.; Irimescu, L. Structures and Mechanical Properties of Some Dual-Phase Steels with Low Manganese Content. Metals 2022, 12, 189. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, Y.B.; Hu, Z.P.; Gu, X.L.; Peng, F.; Tan, X.D.; Chen, S.Q.; Han, D.H.; Misra, R.D.K.; Wang, G.D. Austenite stability and its effect on the toughness of a high strength ultra-low carbon medium manganese steel plate. Mater. Sci. Eng. A 2016, 675, 153–163. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, Y.B.; Hu, Z.P.; Chen, S.Q.; Han, D.T.; Misra, R.D.K.; Wang, G.Z. High strength-toughness combination of a low-carbon medium-manganese steel plate with laminated microstructure and retained austenite. Mater. Sci. Eng. A 2017, 707, 270–279. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.N.; Liu, Z.Y.; Wang, G.D. The role of retained austenite on the mechanical properties of a low carbon 3Mn-1.5Ni steel. Metall. Mater. Trans. A 2017, 48, 5849–5859. [Google Scholar] [CrossRef]

- Qi, X.Y.; Du, L.X.; Hu, J.; Misra, R.D.K. Effect of austenite stability on toughness, ductility and work-hardening of medium-Mn steel. Mater. Sci. Tech. A 2019, 35, 2134–2142. [Google Scholar] [CrossRef]

- Liao, Z.H.; Dong, Y.; Du, Y.; Wang, X.N.; Qi, M.; Wu, H.Y.; Gao, X.H.; Gao, L.X. Effects of different intercritical annealing processes on microstructure and cryogenic toughness of newly designed medium-Mn and low-Ni steel. J. Mater. Res. Technol. 2023, 23, 1471–1486. [Google Scholar] [CrossRef]

- Duesbery, M.S.; Vitek, V. Plastic anisotropy in b.c.c. transition metals. Acta Mater. 1988, 46, 1481–1492. [Google Scholar] [CrossRef]

- Vitek, V. Core structure of screw dislocations in body-centred cubicmetals: Relation to symmetry and interatomic bonding. Philos. Mag. 2004, 84, 415–428. [Google Scholar] [CrossRef]

- Mrovec, M.; Gröger, R.; Bailey, A.G.; Nguyen-Manh, D.; Elsässer, C.; Vitek, V. Bond-order potential forsimulations of extended defects in tungsten. Phys. Rev. B 2007, 75, 104119. [Google Scholar] [CrossRef]

- Du, Y.; Gao, X.H.; Lan, L.Y.; Qi, X.Y.; Wu, H.Y.; Du, L.X.; Misra, R.D.K. Hydrogen embrittlement behavior of high strength low carbon medium manganese steel under different heat treatments. Int. J. Hydrogen Energy 2019, 44, 32292–32306. [Google Scholar] [CrossRef]

- Du, Y.; Gao, X.H.; Du, Z.W.; Lan, L.Y.; Misra, R.D.K.; Wu, H.Y.; Du, L.X. Hydrogen diffusivity in different microstructural components in martensite matrix with retained austenite. Int. J. Hydrogen Energy 2021, 46, 8269–8284. [Google Scholar] [CrossRef]

- Fan, Y.H.; Zhang, B.; Yi, H.L.; Hao, G.S.; Sun, Y.Y.; Wang, J.Q.; Han, E.H.; Ke, W. The role of reversed austenite in hydrogen embrittlement fracture of S41500 martensitic stainless steel. Acta. Mater. 2017, 139, 188–195. [Google Scholar] [CrossRef]

- Lee, Y.K.; Han, J. Current opinion in medium manganese steel. Mater. Sci. Technol. 2015, 31, 843–856. [Google Scholar] [CrossRef]

- Takebayashi, S.; Kunieda, T.; Yoshinaga, N.; Ushioda, K.; Ogata, S. Comparison of the dislocation density in martensitic steels evaluated by some x-ray diffraction methods. ISIJ Int. 2010, 50, 875–882. [Google Scholar] [CrossRef]

- Yin, F.; Hanamura, T.; Umezawa, O.; Nagai, K. Phosphorus-induced dislocation structure variation in the warm-rolled ultrafine-grained low-carbon steels. Mater. Sci. Eng. A 2003, 354, 31–39. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals the dislocation model of strain anisotropy in practice. J. Appl. Crystal. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Kryzhanivskyy, Y.; Poberezhny, L.; Maruschak, P.; Lyakh, M.; Slobodyan, V.; Zapukhliak, V. Influence of test temperature on impact toughness of X70 pipe steel welds. Procedia Struct. Integr. 2019, 16, 237–244. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, M.; Xu, T.T.; Bao, W.; Li, Z.H. Study on impact toughness of TMCP and quenched and tempered high strength steels. Case Stud. 2024, 20, e02795. [Google Scholar] [CrossRef]

- Kokawa, H.; Shimada, M.; Sato, Y.S. Grain-boundary structure and precipitation in sensitized austenitic stainless steel. JOM 2000, 52, 34–37. [Google Scholar] [CrossRef]

- Tomotaka, H.; Kota, S.; Kaoru, S.; Kazuhiro, K. Beneficial role of the grain boundary precipitates for intergranular creep fracture of 25Cr–20Ni–Nb–N steel. Mater. Sci. Eng. A 2023, 882, 145487. [Google Scholar]

- Zabil’skii, V.V. Temper embrittlement of structural alloy steels (review). Met. Sci. Heat Treat. 1987, 29, 32–42. [Google Scholar] [CrossRef]

- Capus, J.M. Temper Embrittlement in Steel; Newhouse, D.L., Ed.; ASTM International: West Conshohocken, PA, USA, 1968. [Google Scholar]

- Michot, G. Mechanical analysis of the interaction between a semi-infinite Griffith crack and its coplanar plastic zone. Eur. J. Mech. A-Solid 2023, 100, 104982. [Google Scholar] [CrossRef]

- Zhang, J.D.; Sheng, Y.; Yang, H.D.; Wu, J.B.; Jiang, X.Y. Influence of Dislocation Pile-Up on Main Crack Propagation in Nanocrystals in the Hydrogen Environment. Acta. Mech. Solida. Sin. 2023, 36, 851–859. [Google Scholar] [CrossRef]

- Zhu, J.; Barber, G.; Sun, X.C. Effects of Isothermal Temperature on Dislocation Density in Bainite Transformation of 4140 Steel. Materials 2022, 15, 6066. [Google Scholar] [CrossRef]

- Jiang, C.P.; Ma, H.C.; Chen, Y.N.; Wang, N.; Zhao, Q.Y.; Wu, G.; Zhu, L.X.; Luo, J.H.; Zhao, Y.Q. Crack propagation behavior of dual-phase steel at low temperature. Int. J. Fatigue 2022, 155, 106633. [Google Scholar] [CrossRef]

| −80 °C | −40 °C | 0 °C | 20 °C | |

|---|---|---|---|---|

| QHA | 29.3 | 30.1 | 32.1 | 32.4 |

| QLA | 2.6 | 2.4 | 4.3 | 12.3 |

| DQ | 0 | 0 | 0 | 1.9 |

| −80 °C | −40 °C | 0 °C | 20 °C | |

|---|---|---|---|---|

| QHA | 1.83 | 1.79 | 1.69 | 1.70 |

| QLA | 2.25 | 2.23 | 2.15 | 1.92 |

| DQ | 18.56 | 18.02 | 17.32 | 17.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Gao, X.; Wang, X.; Wu, H.; Sun, C.; Sun, G.; Du, L. Low-Temperature Impact Fracture Behavior of Medium Manganese Steel with Bcc-fcc Duplex Microstructures. Metals 2024, 14, 293. https://doi.org/10.3390/met14030293

Du Y, Gao X, Wang X, Wu H, Sun C, Sun G, Du L. Low-Temperature Impact Fracture Behavior of Medium Manganese Steel with Bcc-fcc Duplex Microstructures. Metals. 2024; 14(3):293. https://doi.org/10.3390/met14030293

Chicago/Turabian StyleDu, Yu, Xiuhua Gao, Xiaonan Wang, Hongyan Wu, Chao Sun, Guosheng Sun, and Linxiu Du. 2024. "Low-Temperature Impact Fracture Behavior of Medium Manganese Steel with Bcc-fcc Duplex Microstructures" Metals 14, no. 3: 293. https://doi.org/10.3390/met14030293

APA StyleDu, Y., Gao, X., Wang, X., Wu, H., Sun, C., Sun, G., & Du, L. (2024). Low-Temperature Impact Fracture Behavior of Medium Manganese Steel with Bcc-fcc Duplex Microstructures. Metals, 14(3), 293. https://doi.org/10.3390/met14030293