1. Introduction

The present text is the second part of an editorial written for a Special Issue entitled Advances in Metal Casting Technology. The first part, which was published in November 2022, contains an overview of the global metal casting industry and highlights specific aspects that have led to changes in markets and products, such as e-mobility, the associated advent of Gigacasting technology, or the increasing pressure on the casting industry to justify and minimize the environmental impact of its processes []. This second part assumes a different perspective by examining the technological developments within the industry that can either be seen as general trends or as responses to the preceding challenges; in other words, this text discusses technologies both new and revived. In doing so, it cannot possibly be complete, but it may provide readers with points of attack for further study. The final chapter is dedicated to the contributions to the Special Issue, contextualizing them with respect to the fields of technology that were previously discussed in detail. As in Part I, based on the author’s primary field of activity, there may be a bias toward the high-pressure die casting (HPDC) of aluminum alloys, which I hope the reader will accept.

2. Technologies New and Revived

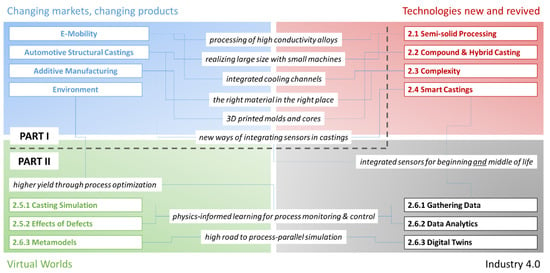

It is a platitude that science and technology do not necessarily evolve along straight paths. Instead, cycles may occur which can sometimes, but not always, be explained by technology-centered models, such as the famed Gartner hype cycle [,,], or more generally by economy-level observations, such as Kondratiev waves and all their relatives []. In other cases, new ideas, new market needs, or the expiration of limiting patents may support the reemergence of technologies. The casting industry has experienced its share of such effects, and in as far as they concern changing markets and boundary conditions, these have already been discussed in the preceding Part I of this text. The delimitation between both these parts is illustrated in Figure 1, which has also been included in a similar form in Part I [].

2.1. Semi-Solid Processing

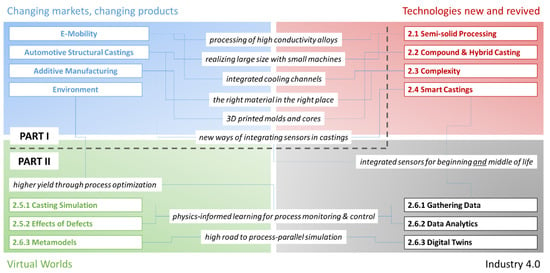

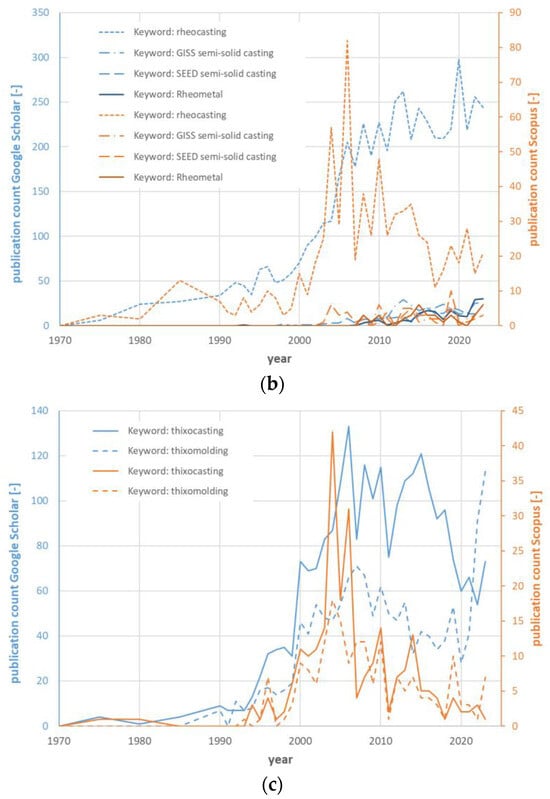

Semi-solid metal processing is not a new topic [,], but it certainly is one that has met with renewed interest in recent years. This is underlined from an industrial perspective by Jorstadt et al., assuming an industrial perspective [], but also is demonstrated by academic activity in the field. A rough measure in this respect is the number of publications, as derived from sources such as Google Scholar or Scopus, on semi-solid casting, of which Figure 2 provides an overview. The respective diagrams show that the number of publications reached a peak in the mid-2000s according to Scopus data, while Google Scholar suggests a constant rise, except for the special case of thixocasting, which peaked in the 2000s and 2010s before declining toward a low in 2022. The data for rheocasting match this pattern, though in the most recent years since 2018, Scopus data, too, indicate a rise that is not apparent in the data for semi-solid casting in general. Meanwhile, thixocasting exhibits a decline in both data sets. However, while thixo processes will not be discussed in detail here, they are certainly not obsolete; on the contrary, they are an established production process in certain areas, such as the processing of magnesium alloys [,,], as a recent overview of activities in China reveals []. The focus here, however, is primarily on thixomolding rather than thixocasting—the former process transfers the principles of plastic injection molding to the processing of metals, using materials in granulated form, as well as extruders for partial melting and plastification []. In 2019, more than 170 machines of this type were installed in China, with the vast majority of them in a locking force range of 650 tons and above. The main markets are components for electronic systems such as housings for laptops, etc., where wall thicknesses down to a minimum of 0.35–0.4 mm are reportedly achieved [].

Figure 1.

An overview of topics covered in the present text. The graphic shows the areas of interest discussed in the previously published first part of this editorial (PART I in the diagram, see []) as well as those focused on in this second part. While Part I concentrated on boundary conditions, Part II is technology oriented.

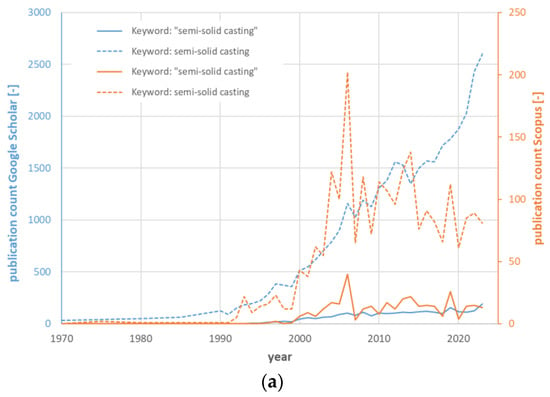

Figure 2.

Publication numbers sourced from Google Scholar and Scopus on semi-solid casting technologies: (a) semi-solid casting in general, (b) rheocasting and (c) thixocasting process family examples. Note that keywords had to be adapted slightly for scanning different databases.

In contrast to thixocasting and molding, rheocasting methods approach the required semi-solid state of the melt from the liquid rather than from the solid state. In practice, this eliminates the need for specially prepared and, thus, costly precursor materials []. Instead, in most cases, the melt is conditioned directly at the machine on a “per shot” basis. Thus, a distinctive feature of rheocasting, setting it apart from thixocasting, is the “slurry on demand” principle. This means that in contrast to thixocasting, not only the use of conventionally produced casting alloys but also the remelting of defective parts, runners, etc. and the direct re-use of the material in the same process are possible. Needless to say, this has a significant impact on both the economic and ecological viability of the process. Furthermore, in terms of boundary conditions such as tool design (gate cross sections, etc.) and process parameters, rheocasting is effectively closer to conventional HPDC than to classical thixocasting. In both cases, even though semi-solid processes proceed with slower filling velocity [], the fact that less heat must be extracted from the already partly solidified melt results in cycle times that are comparable to conventional HPDC processes. Further, the general advantages of rheocasting over HPDC include the following:

- Lower solidification shrinkage due to fraction solid:

- ○

- Reduction in residual stresses and distortion

- ○

- Improvements in dimensional accuracy, allowing tighter tolerancing and/or the abandoning of mechanical or other secondary alignment processes

- ○

- Reduction in shrinkage-induced porosity

- Laminar flow during mold filling:

- ○

- Reduction in gas entrapment

- ○

- Reduction in entrainment and oxide film defect levels

- ○

- Access to T6 treatment in conjunction with intensification pressure decrease

- Improved feeding efficiency due to globulitic solidification:

- ○

- Lower intensification pressure requirements

- ○

- Reduction in porosity levels

- ○

- Reduction in entrapped gas pressure

- ○

- Access to T6 treatment in conjunction with reduced gas entrapment

- ○

- Access to cost-efficient lost core techniques not suitable for HPDC

- ○

- Reduction in locking force needs, facilitating large projected area castings from limited scale machines

- Lower thermal energy levels of the melt and heat transfer coefficient (HTC) values:

- ○

- Increased lifetime of molds due to reductions in thermomechanical loads and the attenuation of thermal shock

In the past, several different rheocasting methods have been proposed, with Midson and Jackson reporting up to 18 different variants already evaluated by the mid-2000s [,]. Recent overviews have been provided, e.g., by Bakhtiyarov and Siginer as well as Jarfors, focusing on aluminum alloys [,]. On a wider scale, Kapranos also reviewed thixocasting and -molding []. Li et al., in their overview, name a total of 16 additional rheocasting process variants developed by Chinese researchers alone []. In essence, all these approaches must tackle the problems around (a) providing initial nuclei for crystallization, (b) avoiding dendritic growth in favor of the globulitic growth of these nuclei—typically by means of the agitation of the melt—and (c) controlling the amount of solid vs. liquid fraction. With respect to rheocasting, from today’s perspective, the following are among the most important processes, in alphabetical order:

- Gas-Induced Semi-Solid (GISS): A porous graphite mixer is lowered into the melt just prior to casting. Through it, inert gas is fed into the melt, causing cooling and agitation and potentially providing seeds for crystallization [].

- New Rheocasting (NRC): A separate metal volume in a cylindrical container is first cooled from the outside using air to reach the desired temperature, then heated to maintain the temperature until it is transferred into the shot chamber [,,].

- Rapid Slurry Formation (RSF, also known as RheoMetalTM): A separate piece of metal, the so-called enthalpy equilibration material (EEM), is cast and fixed to a stirring rod. While stirring, the EEM dissolves into the melt, providing cooling and seeds as the stirring itself accounts for breaking of dendrites [,].

- Swirled Enthalpy Equilibration Device (SEED): A single-shot volume of metal is filled into a container and swirled to achieve thermal equilibrium with the latter. Initial conditions such as the temperature, heat capacity and volume of the container and melt define the equilibrium reached and, thus, the final temperature and fraction solid. The claim is that no temperature control is needed; furthermore, fraction solid can be increased by the drainage of liquid phase from the container []. The drawback is that the latter procedure will influence the alloy composition.

- Semi-Solid Rheocasting (SSRTM): As in the GISS process, a graphite cylinder is lowered into the single shot melt volume, but in this case, no gas is introduced. Instead, the cylinder is used for stirring and cooling, thus initiating crystallization primarily via temperature control as in NRC, but with cooling from the inside rather than the outside. Prior to casting, the melt is left to rest for a defined amount of time to control the level of further solidification. The process was developed by the Italian HPDC equipment manufacturer, IDRA, the Gigacasting pioneers [].

For HPDC foundries, introducing rheocasting is facilitated by the fact that investment costs are limited to slurry preparation and handling equipment, while the HPDC machines themselves can serve both processes. Comptech, a provider of RSF/RheoMetalTM processing equipment, describes the process as follows on their website: “It is not a new casting process, it is a melt preparation HPDC process” []. Jarfors provides an analysis of the market penetration of the major rheocasting processes, GISS, RSF/RheoMetalTM and SEED, in terms of their use in manufacturing commercial products []. Typical applications in which rheocasting excels include complex, thin-walled structures combining such geometrical features with requirements for high thermal or electrical conductivity—radio filters for 4G and 5G antennae systems fall in this category, as do radiator housings, heat sinks or cooling units for electronics, including, e.g., automotive power electronics housings. As Li et al. point out, the advantage of rheocasting in these applications may become manifest in the combination of geometrical capabilities and low defect levels, as base material conductivity does not differ substantially from HPDC alloys and products []. Figure 3 depicts an example of a radio filter cast according to the RSF/RheoMetalTM process. The low wall thickness is a hallmark of this process, which operates at 30–40% fraction solid, with shear thinning effective specifically between 30–35%. Such conditions result in favorable Reynolds numbers, and the time period available for filling the die is extended by a factor of six. Furthermore, flow lengths reach a maximum at shear rates of 100 mm/s, supported by reduced heat transfer from melt to die. In an experimental die, flow lengths of up to 2.2 m at 3 mm thickness were successfully demonstrated [].

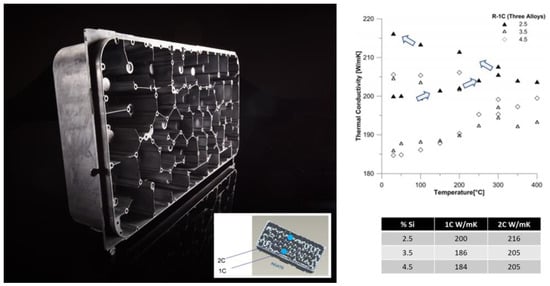

Figure 3.

Radio filter produced by means of the RSF/RheoMetalTM process. A unique feature of this product is the weight reduction of 1.6 kg facilitated by wall thicknesses as low as 0.4 mm at 40 mm height (aspect ratio 100). High conductivity low Si alloys were used, and thermal transport properties further increased by up to 20% depending on the alloy composition by means of heat treatments, as depicted in the top right diagram by means of arrows denoting the course of the latter (images provided by Comptech AB, Skillingaryd, Sweden).

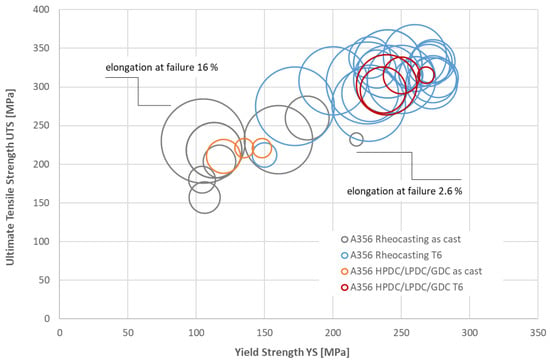

Apart from castability and conductivity, the effects of reduced shrinkage and laminar flow during mold filling on porosity and other defects provide advantages in terms of as-cast properties while also facilitating heat treatment. The latter opens up additional potential for adjusting and enhancing mechanical properties. Figure 4 below provides an overview of the ultimate tensile strength (UTS), yield strength (YS) and elongation at failure (EaF) of rheocast in contrast to high and low pressure as well as gravity die cast aluminum alloys. Apparent from this diagram is the advantage in ductility that rheocast alloys exhibit at comparable strength, represented by the size of the circles. Relative to low pressure and gravity die casting, rheocasting achieves such properties at a significantly reduced cycle time.

Figure 4.

Overview of rheocast and high-pressure die-cast aluminum and magnesium alloys in as-cast and T6 states in terms of yield strength, ultimate tensile strength and elongation at failure. The latter is represented by the size of the spheres. Data are sourced from [,,,,,,,,,,,,].

A major aspect of semi-solid processes is their apparent applicability to alloys typically not considered for casting. Atkinson summarized efforts in this direction in 2012, highlighting the use of the process class, among others, for wrought aluminum alloys and creep-resistant magnesium alloys, but also higher-melting-temperature materials such as copper, cast iron, stellites or steels []. While the applications of such uncommon alloys remain limited, there is doubtlessly an interest in the processing of wrought aluminum alloys, the motivation being the exceptional strength of many of these alloys in the wrought and age-hardened state. Table 1 summarizes some such studies, providing additional information on the material properties achieved. More detailed reviews on the topic were published by Curle in 2010 [] and Li et al. in 2020 [].

Table 1.

Overview of published research on semi-solid casting of wrought aluminum alloys. Alloys, semi-solid casting process, achieved mechanical properties and references are given.

Special cases among such wrought alloys are those that are not primarily selected for structural properties but rather for functional properties like thermal or electrical conductivity. Here, a link to e-mobility applications, as discussed in Part I of this work, is apparent, e.g., in rotor casting []. Classical rotor aluminum Al99.7 is almost pure and characterized by limited castability; nevertheless, it is employed in HPDC to produce electrical engine components []. Alternatives include low alloyed materials such as AlMn1.6, as, e.g., offered by Rheinfelden, which do pose similar castability problems but add strength, increasing yield strength from Al99.7’s 20–40 MPa to 90–120 MPa []. Increasing interest in such materials is also exemplified by recent patent applications, e.g., from Tesla [,]. The aspect of strength is introduced here due to the fact that there is a tendency in the automotive industry to increase electrical traction motor speed to allow for more compact designs, a trend which will raise the centrifugal forces acting on the rotors [,]. Beyond this, requirements regarding conductivity resemble those for radio filters and other electronic components as described above (see Figure 3). The link to rheocasting is established by its proven capability to handle materials with inferior castability. Candidate, low alloyed material systems like some of those summarized in Table 1 could profit from this.

2.2. Compound and Hybrid Casting

The use of the term hybrid when referring to hybrid materials and structures is not self-explanatory, as its detailed discussion by Ley et al. clearly shows. A general notion may be derived from the translation of a hybrid object as being “of mixed ancestry”. where, however, ancestry may refer to material or process, or both, and where the delimitation in terms of materials may be broader or narrower []. In the following, compound casting is understood to imply the joining, by casting, of materials originating from the same material class, i.e., metals. Hybrid casting, in contrast, implies a bond created during casting between materials of different classes, i.e., metals and polymers or metals and ceramics. As the topic is casting, it is assumed that it is always the metal which is in liquid or at least semi-solid state when the formation of the link between both materials is initiated. Furthermore, processes which are aimed at providing semi-finished materials rather than finished products, such as continuous casting or strip casting, are considered here only in as far as they provide insight into interface formation.

Having said this, what is the motivation behind devoting a section of this text to compound and hybrid casting technologies? In the preceding Part I of this Editorial, Gigacasting [,] was presented as one approach toward the realization of large structural castings for automotive applications []. There are, however, alternatives to this technique which may succeed in eliminating some of the drawbacks of the former approach. Compound and hybrid casting both imply integrating separate components with a casting, using the primary forming process for joining, too—this can be used to limit flow lengths in large structural castings, or to optimize material usage by following the dictum of employing “the (technically and economically) right material in the right place”, which is essentially, in its technical sense, a lightweight design paradigm. Furthermore, replacing part of the casting’s volume with sheet metal or extruded components effectively reduces the projected area and, thus, the locking forces required to produce the respective part. As a consequence, in HPDC, smaller machines can be used to produce parts with dimensions that were otherwise only achievable through Gigacasting. Compound casting can, thus, open up a parallel road to Gigacasting that is also suitable for brownfield scenarios, making it advantageous for established OEMs as opposed to newcomers such as Tesla or emerging Chinese enterprises like HiPhi, NIO or Wecan, which are often building up production facilities from scratch, leaving them a wider choice of options from an economic perspective, with Gigacasting quite naturally among them [,,,]. It is, thus, no coincidence that in view of such competitors, several established European manufacturers are actively investigating both Gigacasting and alternative paths. For example, when this text was written, Volkswagen was still evaluating the greenfield option of setting up an entirely new plant including Gigacasting facilities in Wolfsburg versus brownfield strategies based on design solutions allowing for the production of large castings using available HPDC machines in the locking force range below 5000 tons. In addition, Volvo recently acquired two Bühler Carat 840 HPDC machines exceeding 8000 tons locking force for their Torslanda plant [,,,,].

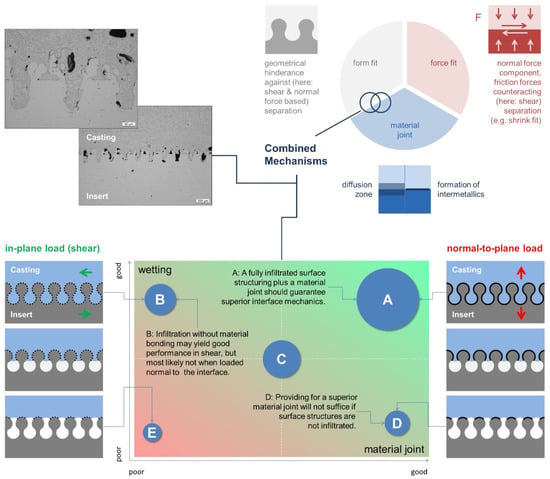

This, then, is the starting situation which defines the perspective guiding the following observations, and a recent publication by Blala et al. shows that the technique is actively being discussed for automotive applications []. However, beyond the automotive structural and Gigacasting challenge, there are other applications that warrant compound or hybrid casting approaches, some of them requiring heat or current transfer across an inter-material interface rather than mechanical strength. Examples from e-mobility were discussed in Part I of this Editorial, including aluminum cooling channels for e-motor housings or copper conductor bars for hybrid e-motor rotors, both produced via HPDC []. Irrespective of the application background, a main concern in both compound and hybrid casting remains the establishment of a stable and reproducible bond between castings and inserts. In principle, there are three paths toward achieving this aim (see Figure 5): material joints; form fit on micro-, meso- or macroscopic scale; and force fit. Needless to say, combinations of these approaches are also possible. For the transfer of forces, all three solutions can be tuned to satisfy a wide range of technological requirements. In contrast, if the aim is thermal or electrical conduction across the interface, a material joint is typically required.

Figure 5.

An overview of principles controlling strength in compound casting. The image in the top left corner shows metallographic sections of infiltrated surface structures created via laser pulses to facilitate a micro-scale form fit. E in the image marks the worst case, poor wetting and bonding, while C denotes the middle position. More interesting are the extreme cases described in the image.

Material joints imply close contact and some physical or chemical interaction between the materials in question. Among metals, the formation of intermetallics as well as solid solutions and diffusion zones extending into either or both partners are possible. Form fit is based on some geometrical hinderance like, e.g., interlocking, which acts against the separation of the partners. It can occur on different length scales, ranging from macro- to meso- to the microscopic range. Force fit relies on normal forces acting on the contact surface between the two components. In conjunction with friction coefficients, cohesion under shear loads is achieved. To realize this effect, solidification and cooling must be controlled. Typically, when casting around an insert, solidification will start from this cooler foreign body, causing the melt to shrink away from rather than onto it.

There are several motivations for realizing compound casting, some of which have already been mentioned:

- Lightweight design I: Combining different materials based on their structural materials properties without a need for fasteners, etc.

- Lightweight design II: As an alternative to the current practice in the automotive industry of producing large structural castings, in which local wall thickness is not necessarily defined by loads, but by processing requirements.

- Design freedom I: Realizing preferably local structural reinforcements to reduce weight and/or required design space.

- Design freedom II: Facilitating local complexity by the integration of, e.g., additively manufactured structures to reduce mold complexity or realize geometries that are otherwise not feasible, e.g., for complex, optimized water jacket solutions [].

- Smart products: Integrating functional devices like sensors, actuators or RFID systems (see Section 2.4 for an overview).

- Production efficiency: Dispensing with joining and assembly operations.

- Transfer of heat: Providing large-area thermal contact superior, e.g., to adhesive bonding.

- Conduction of electricity: Providing electrical connections, like, e.g., in hybrid rotor castings with Al short-circuit rings and Cu conductor bars.

Naturally, parts produced by compound casting processes inherit properties both from their constituents and processing history. The market penetration of this technology is not substantial, despite its theoretical potential. In research, the Al–steel system is clearly dominating the scene [,,]. The application background is structural, in this case. For similar reasons, Al–Al [,,,,,,,], Mg–Al [,] and even Mg–steel [] have been studied, with the foremost likely taking second place in terms of the number of publications. In contrast, Cu–Al [,] and in some cases also Al–Al [] are scrutinized with respect to thermal or electrical conductivity. Several other dissimilar metal systems, such as Al–Ti or Ni–Cu, have yet to be evaluated in detail, though individual publications exist []. Liu et al. [] attempted the compound casting of aluminum alloy A356 onto SiCp/AA8009 composite. Further extensive studies on Al–Al compound casting focusing, e.g., on optimum surface pretreatment include those by Schwankl et al. or Rübner et al. at Friedrich-Alexander Universität Erlangen. These studies examined sand blasting combined with electroless zinc coating and ultimately suggested the zincate treatment as the method of choice for the HPDC process [,,]. Researchers at Oak Ridge National Laboratory and Rice University successfully demonstrated the centrifugal casting of aluminum alloy A356 into a complex lattice structure produced by the laser powder-bed fusion of austenitic stainless steel AISI 316L []. Bührig-Polaczek and associated researchers have studied Al–steel combinations produced by HPDC as a means of stiffening steel sheet metal structures, providing the necessary transfer of forces primarily via macroscopic force fit solutions according to the so-called Variostruct approach []. Similar macroscopic solutions have been applied by Schittenhelm et al. for reinforcing steel inserts embedded in aluminum HPDC components [], the geometry of which was optimized using the so-called multi-phase topology optimization (MPTO) technique [,]. The drawback of such form fit approaches is the local introduction of structural weaknesses, a side effect which motivates studies addressing either material joints or micro-scale form fit, or combinations of both.

Since the 1950s, several studies addressed interface formation and characteristics between unmodified solid steel and liquid Al, hinting at Fe2Al5 (η phase) as the dominant phase, often taking a tongue-like shape extending into the steel part []. In between the η phase and the Al matrix, thin layers of Fe4Al13 or FeAl3 (θ phase) are observed. Both intermetallics are exceedingly brittle and undermine the properties of steel–Al hybrid parts, which is why many studies center on suppressing their emergence. Constraining the interlayer thickness to roughly below 10 µm is considered sufficient to suppress negative side effects [,]. Beyond this, certain alloying additions to Al, in particular, Si, can help minimize the amount of these undesirable intermetallic phases []. This has been demonstrated by Bobzin et al., showing that in the combination of (Al-coated) DC04 steel with a Si-rich AlSi9Mn melt, the interface is dominated by less critical β-AlFeSi phases []. Further approaches based on surface modification include zinc coatings []. Similarly, both zinc and nickel coatings reportedly work well for the compound casting of copper inserts with aluminum [,]. Bobzin et al. investigated the combinations of coatings with surface structuring, using a cold spray process to create approx. 100 µm thick Cu layers on steel substrates into which notches were introduced via cold rolling []. Senge et al. created additional undercuts by means of a secondary rolling process. The shear strength of such joints reached 45 MPa perpendicular to the notches [], but directionality and difficulties in processing (a) shaped parts and (b) local variations in surface structuring remain as unresolved issues hampering widespread commercial introduction. Laser micro-structuring [] offers unique possibilities both for achieving micro- or nanoscale form fit and for influencing wetting behavior, as well as material joint formation through compositional adjustment—the effects of which, thanks to the tool-free process, can also be varied locally over the part surface. These potentials have yet to be evaluated in detail in a compound casting context: In laser texturing, high-energy laser pulses are used to locally melt and vaporize the metal surfaces in a patterned manner for generating a three-dimensional (3D) surface structure. The geometry, dimensions and orientation of the surface structure can be controlled by adjusting the process parameters. Laser texturing can profoundly influence the solid/liquid wetting behavior, as demonstrated by Bizi-Bandoki et al. [] and Cunha et al. [], though not in view of compound casting. In an unsuccessful patent application, Lao Bin and Bührig-Polaczek describe metallic compounds consisting of a metal sheet and a die cast part in which, for optimum joint formation, metal sheets are structured in a regular fashion prior to the casting process, e.g., via laser treatment []. A critical aspect to consider is the possibility of the incomplete infiltration of surface structures caused by insufficient venting or wetting, or the combination of both, leading to air entrapment in the critical interface area. If flexible structuring processes are employed, the knowledge of local melt flow directions and patterns can be exploited to adapt the structural features accordingly. Typically, laser structuring is performed via ultra-short, pulsed laser (femto- or picosecond pulsed lasers) [,]. The respective systems have high investment costs at relatively low productivity. Furthermore, the treatment of complex geometries is hampered by complex beam guidance based on conventional optics and mirrors. In contrast, nanosecond pulsed lasers, especially in the near IR region, are commercially available in a broad power range and can be equipped with glass fiber systems for beam guidance. Nevertheless, a broad introduction in compound casting is still pending. For HPDC, the suitability of the process has been demonstrated by Nolte et al. in an Al–Al compound casting context, with lap shear strength values of up to 138 MPa recorded for optimized structures [,]. Further experiments based on LPDC have shown, though, that successful infiltration in HPDC is linked to intensification pressure and/or melt velocity—without both, as in LPDC, small-scale structures successfully tested in HPDC tend not to be infiltrated and may, thus, promote separation rather than the joining of materials [].

Al–Al compound casting is pursued both in view of structural as well as thermal and electrical applications. The main obstacle in this latter case is not necessarily the formation of intermetallics but rather the formation of an oxide layer covering the Al inserts, which proves exceedingly hard to remove and, if removed, forms anew almost instantaneously. A reasonably successful approach to overcome this difficulty is electroless zinc deposition preceded by extensive surface pretreatments including degreasing, acid pickling, etc. This so-called zincate treatment has been described and evaluated in terms of its mechanical properties by Schwankl et al., reaching lap shear strengths of 40 ± 0.7 MPa for an AlMg3, 54.4 ± 2.0 MPa for an AlMg4.5Mn0.7 and 61.8 ± 7.4 MPa for an AlCu4MgSi insert, all in combination with an AlSi10Mg casting alloy []. While falling short of what is achievable via the aforementioned laser surface treatment, these values still exceed the typical properties of structural adhesive joints, which generally reach approximately 20–30 MPa in lap shear tests []. In addition, they are subject to considerable scatter. However, the advantage of the zincate treatment as an immersion process is its applicability to complex structures which may not be accessible by laser, as well as its superior productivity. A recent alternative relies on a cold spray process to break the oxide layer by means of the kinetic energy of the powder particles. This technology has been successfully demonstrated for use in the copper, brass and zinc alloy coating of EN AW-5754, EN AW-6061 and EN AW-7075 inserts and the HPDC of AlSi10MnMg. An evaluation of strength is still ongoing, However, latest results suggest that specifically CuZn14, CuZn37 and ZnMg2.7 as coating materials on EN AW-6061 substrates can ascertain property levels exceeding structural adhesives in lap shear testing, while heat treatments at temperatures slightly above the liquidus temperature of the interface can further improve its mechanical characteristics. Some issues remain to be solved, though, such as the formation of porosity in the transient liquid-phase region at the interface between insert and cast materials []. In the case of copper coating, interface formation is likely to show similarities to observations on Al–Cu compound casting as discussed below, though it may still prove possible to fully eliminate certain phases via diffusion processes in the course of heat treatment.

For the Al–Cu system, a major difference is that here, the focus is entirely on thermal and/or electrical conductivity, which is why material joints are of even greater importance. As in the case of Al–steel, difficulties are caused by the large variety of intermetallics in the Al–Cu system, many of which are characterized by lower thermal conductivity than either of the partners to be joined. Pintore et al. investigated interface formation between pure Al and pure Cu using a sophisticated setup which first allowed the casting and solidification of copper, followed by the casting of aluminum onto the copper substrate at temperatures of the latter of 500 and 900 °C. Interface layer thickness was found to depend heavily on the thermal conditions present during its formation. For the higher substrate temperature, starting from the substrate, a phase sequence of Al4Cu9 (<0.7 µm), Al3Cu4 (12.3–13.7 µm), AlCu (4.7–10.2 µm) and Al2Cu (340–1100 µm) followed by the Al–Al2Cu eutectic (1600–2200 µm) and a transition zone between eutectic and pure Al (2000–3100 µm) was identified. For the lower substrate temperature, no Al4Cu9 phase was detected, and the individual layer thickness was reduced to 9.3–12.1 µm for Al3Cu4, 2.7–5.5 µm for AlCu, 20–200 µm for Al2Cu, 900–1300 µm for the eutectic and 450–3200 µm for the transition phase []. Further experiments at substrate temperatures of 300, 400, 500 and 700 °C were performed by the same authors with no bond obtained at 300° and significant interface defects at 400 °C. Above that, previous experiments were confirmed in terms of the layer thickness increasing with temperature []. Liu et al. performed similar experiments, varying interface cooling conditions through the adaptation of the liquid aluminum to copper insert volume ratio. At cooling rates between 0.8 and 1.83 K/s in sand casting, they found hypereutectic microstructures dominating the remelting zone during fast cooling and hypoeutectic ones prevailing during slow cooling. Interface mechanics, however, are dominated by intermetallics situated in between these phases and the copper substrate; their effects are least detrimental at lowest thickness []. Higher cooling rates have been realized by Liu et al. via a squeeze casting process and varied via melt temperature levels of 680, 700, 720 and 740 °C. Cu samples were mechanically polished, degreased, acid pickled, deoxidized and activated prior to Zn coating by thermal spraying to inhibit renewed oxide formation. Interface compositional analysis showed Al4Cu9, Al2Cu and eutectic layers at the lower three temperatures, plus an additional Al solid solution layer at 740 °C. The thickness grew from approximately 70 µm altogether at 680 °C to 90 µm at 700 °C, 140 µm at 720 °C and 200 µm at 740 °C. In contrast, increasing the applied pressure reduced the thickness from 105 µm at 30 MPa to 95 and 80 µm at 70 and 110 MPa, respectively. In the first experimental series, pressure was maintained at 70 MPa, while in the second, temperature remained unchanged at 700 °C [].

None of the intermetallic phases are considered beneficial in terms of thermal and electrical conductivity. Pintore et al. measured the specific electrical resistance of Al–Cu interface layers, confirming the expected rise in resistance with increasing interface thickness []. Liu et al. confirmed these findings for higher cooling rates, measuring an increase in resistance by almost 70% for a melt temperature of 740 °C compared to 680 °C, with corresponding interface thicknesses of 200 vs. 70 µm. Applied pressure showed no influence on resistance []. Thus, a reduction in the thickness of this layer is usually the target to improve electrical and, thus, thermal conductivity. Alternative approaches support the formation of alternative phases, e.g., via coating. Klose et al. performed extensive studies on Zn and brass-type Zn alloy coatings of copper inserts for HPDC, achieving material joints and a satisfactory overall thermal conductivity of compound cast samples matching that of the casting alloy despite the interface’s thermal contact resistance. Coating materials, too, were characterized in terms of their individual thermal conductivity. Here, ZnAl31Cu4 showed highest levels at approx. 120 W/mK at room temperature, rising to roughly 135 W/mK at 200 °C. Interface thickness was once more shown to depend strongly on the thermal history of the sample: the lower the thermal load, the thinner the interface area. This effect was demonstrated through the investigation of specimens subjected to water quenching and air cooling after casting [].

An exemplary overview of recent publications on compound casting, also outlining the relevant application scenario and/or the objective of the specific study, is provided in Table 2 below.

Table 2.

Exemplary overview of recent publications on compound casting. Note that most studies attempt to achieve a material joint.

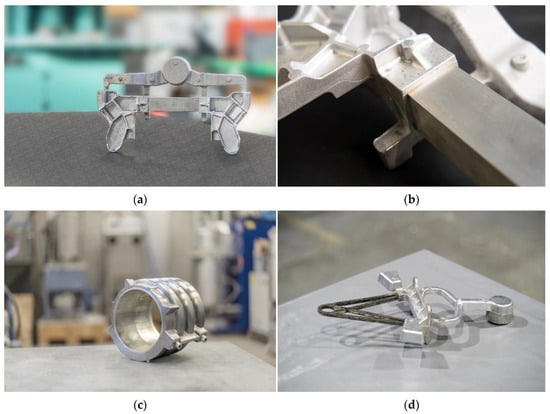

Figure 6 depicts examples of compound and hybrid casting produced either via LPDC or HPDC. Besides different materials combinations, the images illustrate the concepts of joining by casting (a, b), the realization of thermally optimized components (c) and lightweight design solutions (d).

Figure 6.

Sample images of parts produced by compound (a–c) and hybrid casting (d); (a,b) AlSi7Mg0.3 LPDC subsize front axle carrier frame demonstrator with integrated EN AW-6060 extrusion, general (a) and detail view (b); (c) AlSi9Cu3 HPDC e-motor housing demonstrator with integrated aluminum tubes as cooling channels, cast by ae group AG, Gerstungen, Germany; (d) aerospace secondary structure hybrid bracket combining a CFRP and an aluminum HPDC component [] (all images by Fraunhofer IFAM).

The literature on combining metals and polymers via metal casting through a hybrid casting approach is scarce in comparison to that on compound casting and shall be treated accordingly here [,,,,]. The main problem arises from the fact that the thermal stability of polymers is typically far below the typical metal-casting temperatures, which means that the respective polymer may be subject to thermal degradation or even decomposition. Schmid et al. have addressed this issue by means of placing a protective layer based on the high-temperature thermoplastic polyether ether ketone (PEEK) between a carbon fiber reinforced polymer (CFRP), also having a thermoplastic PEEK matrix, and the liquid metal. PEEK has a melting temperature of 343 °C and can effectively shield the CFRP, preventing its decomposition under HPDC conditions, as thermal energy input is limited in this process due to the typical, very fast cooling rates. In addition, the PEEK interlayer provides electrical decoupling between CFRP and aluminum under service conditions and thus alleviates the risk of galvanic corrosion. Samples were cast using an Al alloy. In lap shear tests performed on such compounds, strength levels of 13–16 MPa were obtained following a T5 heat treatment and artificial ageing []. These findings were employed in manufacturing the demonstrator component shown in Figure 6d []. Further optimization of processing conditions allowed for an increase in the shear strength values to 22 MPa, which matches those known from typical structural adhesive joints [].

A major prerequisite for designing and specifically dimensioning compound and hybrid casting components is the availability of methods for predicting interface strength and simulating interface performance under service conditions. Major contributions in this respect have been made by Bitsche, who investigated combinations of Al and steel and discussed the influence of solidification conditions, the emergence of residual stress fields based on deviations in thermal history, and the thermomechanical properties of cast materials and inserts []. In a more recent study, Struss et al. extended these investigations by suggesting and validating a cohesive zone model capable of describing the interface characteristics of cast hybrid joints, while simultaneously outlining the experimental procedures required for the parameterization of this model []. Further to the modelling of casted compound or hybrid joints, evaluating the quality of such components is an object of study. Non-destructive testing (NDT) solutions are required in order to monitor quality in series production. Initial approaches in this respect have been proposed and evaluated by Leinenbach et al. using coupon-type samples of both compound and hybrid casting types for the validation of X-ray computed tomography (CT) []. A potential drawback of CT methods is that delamination-like defects between the insert and casting may be difficult to discern in CT due to their limited extension perpendicular to the fault plane. This is of even greater relevance in view of potential future components of larger size, as CT resolution typically goes down as the volume covered increases. A solution to this problem may be local CT scans focusing specifically on critical areas within the casting. Methods of this kind have been developed for large components, generally based on dedicated robotic rather than conventional CT systems [,,]. Alternatives may be NDT techniques which are specifically suited to detect material discontinuities, such as ultrasonic testing or thermal methods. In order to optimize the use of either of these options, further research efforts must identify the most critical areas based on process simulation. To date, the prediction of local interface properties based, e.g., on casting or combined casting and FEM simulation approaches is—specifically for material joints—a problem that is not yet solved in its entirety. An interesting step toward solving this issue was recently published by Glück Nardi et al., which involved simulating the interface evolution of a liquid Al–solid Cu system. Their model incorporates heat transfer across the interface as well as diffusion, solution and intermetallic phase formation. Its validity has been proven against experimental findings gathered from a continuous casting process []. Further progress in this respect would also support the design and dimensioning of compound and hybrid casting components, specifically with respect to the layout of interface geometries, sizes and locations in conjunction with the casting system and the processing conditions.

2.3. Achieving Complexity

2.3.1. Complexity: What It Is and How to Get There

Castings can be of complex shapes by nature; however, there are certain technologies which specifically support increasingly intricate shapes; some of these shall be discussed below. But to start, what is complexity? Beyond the general notion of complexity as including internal cavities, high surface-to-volume ratios and the like, a taxonomy of this characteristic is needed. In fact, such a taxonomy has been suggested specifically in view of cast parts by Joshi and Ravi. In their study, they suggest a multi-parametric equation capable of quantifying the relative complexity of a given part based on CAD data. Their aim is to provide designers with a tool allowing them to better estimate costs—this illustrates that naturally, complexity has a price. The parameters they suggest include the number of cored features, the volume and surface area of the cast part, core volume, section thickness and draw distance. Values of these parameters are determined based on forty benchmark cases, i.e., casting designs, representing various levels of complexity, as perceived subjectively. The results are then fed into a regression analysis, from which weighting coefficients for each of the parameters are derived, allowing the determination of a single measure of complexity for any new design. As a result, the highest importance is given to the number of cores and core volume, partly due to the fact that complexity is linked to cost, and the evaluation also allows for an estimation of relative production cost based on the determination of the overall complexity factor for a given part geometry []. Their solution is in line with more general studies attempting to classify CAD models irrespective of the underlying manufacturing process [,]. At Youngstown State University, Almaghariz proceeded with a similar study to determine when AM techniques are recommendable for the production of sand molds from an economic perspective. A main point in this regard is that for AM, as opposed to conventional manufacturing techniques, the cost driver is not complexity but rather the volume of the bounding box of the printed part. Effectively, this means that AM becomes more competitive the more complex the part is, and the further development of AM productivity will shift the break-even point to lower and lower levels of complexity [,]. Martof et al. followed up on this phenomenon in 2018, arriving at similar conclusions []. Their measure of complexity is clearly inspired by the AM process itself, as it derives the information from layer-based criteria such as the number of contours or concave features, or contour length divided by the enclosed area per layer, as well as combinations of these. The results obtained for selected geometries are compared to data obtained following the approaches by Almaghariz et al. [,], who, in turn, built on Joshi and Ravi [], for several product categories, within each of which complexity was increased stepwise. Contrasting both methods showed that they generally agree in terms of tendencies, with either reacting more sensitively depending on the part family under scrutiny. The advantage of Martof et al.’s suggestion in terms of predicting costs, however, is that it is entirely geometry based and does not require information about the manufacturing technique. Martof et al. close their study by comparing the costs of AM and the conventional model, mold and core production as function of complexity and production volume, highlighting the fact that the combination of both together determines whether AM processes are viable in a specific case [].

Thus far, having successfully defined and measured complexity in a casting context, though with a clear focus on sand casting, the following question remains: how can complexity actually be achieved or increased? In practice, there are several approaches which may differ based on the casting process. Here, the question is specifically focused on the type of molds and models employed in the casting process. While permanent molds may e.g., afford sliders to realize undercuts, as shown before, sand casting as well as investment casting can rely on the geometrical flexibility of AM processes in this and many other aspects. Table 3 provides an overview of techniques that aim to increase the complexity of castings, sorted by casting process. Since some of these have already been discussed, such as compound casting solutions, where complexity is introduced through an insert, the main focus of the present section will be on cores in general, as well as AM of lost and permanent molds.

Table 3.

Selected examples of approaches toward increasing complexity in different casting processes. Note that besides direct paths, indirect solutions like the improvement of flow paths or thermal management may also contribute to facilitating increased part complexity.

2.3.2. New Core Technologies

Realizing complexity in terms of internal cavities is the domain either of the integration of hollow structures or inserts by means of compound casting (see Section 2.2), or of lost cores. Similarly, cores may be employed to realize undercuts. Technologies for core production as well as core materials are closely linked to cast materials and casting processes and too diverse to cover in full here; thus, a focus is set on lost cores for HPDC, as well as new developments in decoring represented by the concept of collapsible cores [], while the additive manufacturing of cores is discussed further below in Section 2.3.3 (note that general links to studies in this field may also be found among the entries in Table 3 above).

Lost cores for HPDC are not readily available on the market. None of the conventionally manufactured sand or salt cores can withstand the combined thermal and mechanical boundary conditions associated with this process, which have been scrutinized in great detail by Kohlstädt using computational fluid dynamics (CFD) methods [,,], as well as by Fuchs et al. []. The latter considered a simple reference mold yielding a hollow section of rectangular shape, with the inner cavity of the casting realized by a pressed and sintered salt core mainly consisting of sodium chloride and having a bending strength of 6.5 MPa at relevant temperature levels of 175 °C. Their experimental program foresaw variation in in-gate velocities ranging from 15 to 35 m/s with the in-gate extending over almost the full length of the casting. The failure of cores was observed at all velocities exceeding 15 m/s. In addition, inhomogeneous filling of the cavity surrounding the core contributed to failure. Parallel simulation covering fluid–structure interactions confirmed that core strength levels were surpassed under these conditions. On the positive side, the chosen simulation approach—which can obviously be transferred to other types of cores, too—was successfully confirmed as being able to predict core failure. Hence, the study underlined the limited viability of pressed and sintered salt cores for HPDC, suggesting the improvement of bending strength levels and optimized in-gate design as mandatory prerequisites for applying lost cores under typical HPDC conditions [].

Kohlstädt and Kohlstädt et al. provided detailed studies on the factors affecting core failure in HPDC. Their findings, based on experimentally validated computational continuum mechanics simulations using the OpenFOAM framework and toolbox, indicate that the initial impact of the melt is a critical phase during the casting process, which is not adequately covered in standard commercial casting simulation software. To capture this effect, Kohlstädt et al. relied on more complex models incorporating fluid–structure interactions, though not covering the plastic deformation of cores. The workaround suggested for addressing the latter issue is to evaluate core deformation at 95% filling rather than after its completion. Thus, their study can be applied to virtually evaluate core viability for a given core material and casting system. The downside, which they frankly acknowledge, is the fact that in the triangle constituting the accuracy, stability and efficiency of the simulation approach, it is impossible to achieve an optimum for all of these aspects at the same time [,,].

The apparent scarcity of suitable cores for HPDC has motivated several research activities. General evaluations of various core-making technologies for HPDC with a focus on salt-based solutions have recently been published by both Jelínek and Adámková, as well as Kallien [,]. A primary approach is increasing the strength of these materials in comparison to conventional, pressed salt cores. To this end, HPDC equipment manufacturer Bühler investigated the HPDC of salt cores, proving the general feasibility of this technique but failing to achieve significant market penetration [,]. However, the insight that salt cores produced from the melt rather than based on pressing can sustain the harsh HPDC process conditions has since fueled further research. A broad overview of the HPDC production of salt cores, updating and extending the aforementioned earlier studies by Bühler, was recently provided by Becker in his PhD thesis []. Further work on salt cores originating from a molten state was, e.g., performed by Findeisen et al., directed toward the gravity and low-pressure die casting of salt and salt mixtures [].

An alternative is the strengthening of conventionally produced salt cores using reinforcing materials and structures, essentially following a composite materials approach. Gong et al. combined casting and reinforcement when studying the influence of glass fiber reinforcement of KNO3-type salts on microstructure and mechanical characteristics when varying fiber lengths from 12.5 to 74 µm and stepping up content levels from 10 to 30 wt.%. Grain refinement, fiber pull-out and crack deflection were identified as primary mechanisms leading to a maximum bending strength of 41.32 MPa. Compared to non-reinforced materials, bending strength and impact toughness were increased by 55.9 and 315.1%, respectively []. In an earlier publication, Gong et al. reported results regarding Na2SO4–NaCl materials containing bauxite powders. This study is of particular interest, as it relies on extrusion-based additive manufacturing for shape generation, suggesting a path to highly complex core geometries. Mechanical properties are further enhanced via a liquid phase sintering step at 630 °C, resulting in up to 24.43 MPa of bending strength []. An further extension of these investigations was recently published by Gong et al. in which strength levels of 59.08 MPa are reported for codundum powder reinforced salt cores with an matrix composed of Na2SO4 and NaCl []. Similar studies by Tu et al. extended the scope of this research by focusing on bauxite, glass fiber and sericite powders as strengthening additions at varied content levels. Depending on the type of reinforcement, bending strengths in the range of 35.08 to 40.88 MPa were achieved at an optimum powder fraction of 20 wt.%. While the added particles reduced shrinkage and had a positive effect on the hygroscopic properties of the materials, a decrease in the water solubility rate by roughly 20% as consequence of adding 20 wt.% of filler content may be seen as a drawback of the approach [].

Beyond salt cores, sand cores, too, remain in focus for use in HPDC. Their general feasibility also for larger parts with considerable flow lengths was demonstrated by Koya et al., who considered a hollow casting for application as a motorcycle rear swing arm. Their studies confirmed aspects of the previously cited work by Kohlstädt et al. [,,], showing that the impulsive pressure waves that were theoretically predicted and later experimentally confirmed contribute significantly to the loads acting on the core, but they can be alleviated via the adaptation of flow paths and filling conditions, thus opening up a process window for the use of sand cores in large component HPDC []. Currently, several suppliers of molding materials, such as Hüttenes-Albertus or Foseco, are taking up this approach and are actively working on or have already presented sand cores suitable for HPDC. While these typically remain limited to geometries of lower complexity, they are still likely to find their niche in select applications [,,].

Having said this, there may be ways of circumnavigating the strength issue altogether: The lowered mechanical and thermal loads exerted by rheocasting on molds and cores may facilitate the use of more conventional core-making techniques while still yielding results that are economically competitive with HPDC components. With this in mind, Michels et al. evaluated several core materials and production techniques in view of their suitability, if not for HPDC, then at least for rheocasting. Prior to the advent of commercial sand core solutions for HPDC, they managed to show that surface-conditioned sand, as well as salt and even zinc cores, reach the required quality levels in rheocasting []. In a sense, their data indirectly confirms the aforementioned dominant effect of fluid impact on core failure identified by Kohlstädt et al. [,,]. Considering the current, renewed interest in rheocasting discussed in Section 2.1, as well as the growing need of the automotive industry for housings incorporating water jacket cooling solutions fueled by the e-mobility transition (see []), this observation could open up an additional market for a growing rheocasting industry.

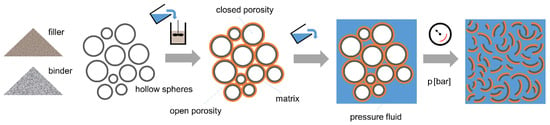

As far as the required strength of cores is concerned, casting processes like gravity sand and die casting, as well as investment casting, are less demanding than HPDC. This opens up alternative paths toward the realization of lost cores that diverge from the current state of the art. An entirely new approach in this respect is so-called collapsible cores, which are not dissolved for removal but destroyed by means of hydrostatic pressure. As such, the concept is based on so-called syntactic foams, i.e., materials with significant levels of engineered porosity introduced via hollow filler particles such as metal hollow spheres, glass or ceramic microspheres and cenospheres [,]. Materials of this type are well established based on polymeric matrices, e.g., as buoyancy devices in submarine and deep-sea exploration techniques [,], but they have also been produced with metallic matrices []. When used as cores, inorganic matrix materials are selected to which glass microspheres are added. Processing conditions are chosen to guarantee a certain level of open and, thus, interconnected matrix porosity. Via this porosity, it is possible to exert sufficient pressure on the hollow filler particles to make them collapse. The core can then simply be washed out as slurry in a batch process utilizing cold isostatic pressing (CIP) to build up the required levels of pressure []. The fundamental principle of this approach is illustrated in Figure 7 below.

Figure 7.

The fundamental principle behind the concept of collapsible cores. Hollow microspheres are embedded in an open-porous matrix. Decoring is achieved via cold isostatic pressing. Fluid entering the open porosity of the matrix in which the microspheres are embedded exerts pressure on the latter, making them collapse. The integrity of the core is lost, and its remainders can easily be washed out [,].

Detailed studies of this type of material have allowed for the identification of suitable hollow sphere and matrix types, indicating that the main challenge is maintaining the fine balance between providing sufficient strength for the casting process and limiting this property for the ease of decoring. This is best achieved at hollow particle volume fractions as high as 65%, combined with a filler consisting of magnesium oxide, monoammoniumphosphate and amorphous silicic acid, all mixed with silica sol in a ratio of 45:55 [].

2.3.3. Printing of Cores, Molds and Patterns, Permanent and Lost

Additive manufacturing (AM) was discussed as a challenge the casting industry is confronted with in Part 1 of the present text (see Section 3.2.3 in []). However, it does also offer major benefits when employed not for the production of parts otherwise cast but of molds, patterns, cores and inserts, both lost and permanent. Thus, metal AM offers its generic benefits to casting if it is not seen as competing part production technology, as was the perspective in Part I of this Editorial [], but rather in the context of permanent mold design and manufacturing. Links to the relevant AM processes are generally shorter than one might think, as related techniques such as build-up welding have been used for the repair and remanufacturing of molds for a considerable time. Of potentially even greater immediate benefit for the casting industry is, thus, the direct printing of sand molds and cores by means of binder jetting, a powder bed process in which the particles that form the powder are joined via a binding agent, printed layer by layer via an inkjet printhead into the powder bed [].

Since the initial development of AM processes for metals, progress has been made in productivity, part size, accuracy and flexibility. The latter aspect nowadays even extends to producing multi-material structures. Still, the dominant process for metal AM remains the so-called laser beam melting (LBM) or laser powder bed fusion (LPBF) process, which relies on a powder bed built up layer by layer on a building platform and the fusion of powder particles via one or several lasers []. While powder bed technologies like this do not lend themselves easily to multi-material processing []—though some approaches have been realized and even commercialized, e.g., by companies like Aerosint via selective powder deposition [,]—methodologies that fall into the directed energy deposition category do [,]. These techniques transport the building material directly to the spot where the consolidation of the part occurs. A metal-based example of this kind is the LENS process, which is closely related to powder-based laser cladding processes []. In this case, the building material is transferred to the focal point of a laser as a powder by means of a carrier gas, where it is fused to the already existing structure. In short, the process allows for building up features on top of an existing, even non-planar, substrate, and it supports facile switching from one type of powder to another. With such characteristics, AM processes are optimally suited for complex die inserts. Their main benefit is the realization of complex, thermally optimized structures by means of facilitating the following:

- Conformal cooling, with cooling channels of complex geometry directly adjacent to the die surface, and/or

- Heat spreading, by combining materials providing strength with others supporting controlled transport of thermal energy.

Anand et al. recently dedicated an extensive review to this topic, which specifically stresses the benefits of conformal cooling for energy consumption, which is achieved directly by improving thermal management, as well as indirectly via superior process control. As a result, fewer scraps need to be remelted []. In both the conformal cooling and the heat spreading scenarios, laser-based AM processes profit from an extensive development history, which, over time, has covered most materials that are relevant for the manufacturing of permanent molds and dies. These include common tool steels, which can be processed by LPBF [], binder jetting [] and powder- and wire-based directed energy deposition (DED) processes [,], as well as highly conductive materials like copper [,,] or even tungsten, which combines strength with attractive thermal properties []. If the highest productivity is sought, combinations of wire-based AM (WBAM) techniques with intermediate subtractive machining may also be considered. Machining is required due to the limited resolution of this process compared to the common powder-based techniques. Intricate internal cavities are, thus, difficult to produce, as they lack access for surface machining. However, multi-material structures have successfully been produced by means of such processes []. In cases where even higher productivity is required, wire arc additive Manufacturing (WAAM) may be considered as an alternative to laser-based technologies []. Achieving the required surface finish may require a hybrid manufacturing approach, combining additive with subtractive manufacturing both in the case of powder- and wire-based processes []. While all these technologies are available, their application in series production remains limited. Among the reasons are the cost of additively manufactured die inserts and also the technical concerns related to die life and to the danger of leakage. As a consequence, toolmakers still tend to acquire additively manufactured die inserts from external suppliers specializing in the respective processes and acting as contract manufacturers for a variety of industries, or for several foundries.

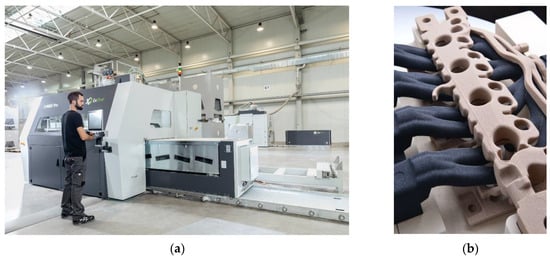

Much better established on an industrial scale is the printing of lost patterns, cores and molds. A recent review encompassing the full range of the topic was published by Shah et al. []. Specifically, the printing of sand cores and molds-often referred to as 3D sand printing (3DSP) - has already developed into a standard process. While there are solutions based on selective laser sintering (SLS) using binder-coated sand [,], binder jetting clearly dominates the field []. The massive advantage of this technique is that it combines the fundamental characteristics of the well-recognized sand-casting process with the productivity of a fast AM process. In essence, for sand casting, this unleashes all the geometrical freedom of the AM process but, for the final parts, saves the often-horrendous material costs associated with direct metal printing processes. As an added benefit, the possible part sizes surpass the typical limitations of common metal AM systems by far []. This new flexibility can be used to optimize the part itself but also to adapt the casting system, e.g., in terms of flow conditions yielding low-defect and, thus, high-performance parts. The latter approach was demonstrated by Sama et al. [,], who went even further by using AM processes for the integration of sensors in sand molds in order to facilitate the direct monitoring of melt flow, mold filling, core shift or ventilation during production [,,]. Recent reviews on sand printing technology and use were provided by Upadhyay et al. and Sivarupan et al., who both stress the advantages of the process and highlight the evolution of the field [,], while Thiel et al. dedicated their slightly earlier study to the materials employed in this process []. An important aspect, which clearly illustrates the difference between sand printing and direct metal additive manufacturing processes, is the performance data documented in their studies: In sand printing, build rates reach more than 100 L per hour instead of cubic centimeters as in the case of powder-based metal AM, while the dimensions of the largest systems’ build envelopes are measured in meters [,]. Major equipment providers like ExOne or Voxeljet offer systems with maximum build volumes of up 1.9 and 8 cubic meters, respectively. Figure 8 provides an idea of the sizes of such system, as well as an example of a complex core package printed using two types of binders.

Figure 8.

(a) S-Max Pro sand printer as offered by ExOne, offering a build box of 1800 × 1000 × 700 mm (build volume 1260 L) and a build rate of up to 145 L/h, (b) examples of a printed core package for an internal combustion engine block consisting of furan-bonded components in black and hot hardened phenol-bonded components in beige (pictures kindly provided by ExOne (North Huntingdon, PA, USA); Copyright: ExOne).

However, despite such achievements, development needs remain with respect to new binder systems that are less hazardous and environmentally critical than, e.g., common furan resins [,]. Realizing such alternative binder systems would mirror developments in conventional sand casting, where aluminum foundries have, in many cases, already adopted inorganic binder systems [] and new solutions are becoming available that are also suited for iron and steel [,]. The challenge has in fact been taken up already by the respective industries, with the result that printable inorganic binders are available commercially for the casting of light alloys [,], while others suitable for the casting of higher melting materials are either under development [] or are currently being evaluated on a semi-commercial basis. The chemistry of such inorganic binders is typically based on alkali–silicates or waterglass. A disadvantage of this system is the need for additional curing at elevated temperatures, which is not required for the common organic systems, and a certain sensitivity to moisture, which calls for adequate packaging and storage measures.

Interestingly, in a recent study conducted in the USA, Lynch et al. find obstacles against broad introduction of 3DSP similar to those highlighted above for permanent die inserts when investigating the manufacturing ecosystem, with a special focus on small- and medium-sized foundries. They conclude that, among others, limited knowledge of the process on both the casting supplier and customer sides combined with considerable capital costs favor business models featuring specialized suppliers of cores and molds acting as hubs serving multiple foundries []. Beyond 3D sand printing, further AM techniques have gained importance in the production of lost cores. A very special example is the extrusion-based AM of Na2SO4–NaCl salt cores, as proposed by Gong et al. Depending on the composition, which may include bauxite powders as reinforcing additive, their materials achieved room-temperature bending strength levels of up to 24.43 MPa, exceeding the salt cores evaluated by Fuchs et al. in HPDC by one third [] and, thus, possibly paving the way for the introduction of 3D-printed lost cores to this demanding process [].

It is only a small step from the printing of lost cores or molds to the printing of lost models or patterns as used, e.g., in investment or lost foam casting. Investment casting has, thus, absorbed additive manufacturing technology basically in two different forms: the indirect method, which implies printing a master pattern used to create typically soft (e.g., silicone) molds for the actual patterns used in casting; and the direct method, producing the latter via AM [,]. The indirect approach will be disregarded here, as it is not necessarily a means to achieve increased complexity. For the direct approach, when using wax as printing material, a process very similar to conventional investment casting can be adopted. In contrast, producing patterns from either thermoplastic or thermoset polymers like epoxy, PLA or ABS calls for burning out rather than melting. An intermediate solution is the use of wax-like thermoplastic polymers typically processed as filaments using the FDM process. These combine the required strength with suitable melting characteristics for conventional removal techniques. Their advantages are, thus, rooted in the side effects of burning or thermally decomposing the patterns, among which are shell cracking, incomplete pattern removal or the accumulation of residual ash within the shell. Countermeasures against this deficiency of the process include limiting the amount of material used for the pattern. While the pattern’s outer shell must necessarily be closed and of sufficient surface quality, internally, an intricate lattice rather than fully dense structures may provide the necessary strength by constituting a kind of 3D sandwich structure in which the skin takes the role of the face sheets. Needless to say, investment casting can also profit from rapid tooling approaches when it comes to the manufacturing of wax injection molding dies. In this respect, advantages match those already discussed above in a permanent mold casting context, as dies are typically made of metals—a fact which further distinguishes this method from the aforementioned indirect approach of producing a master pattern. Besides, as in sand casting, the direct production of molds—i.e., shells—using ceramic AM techniques is available and, according to Cheah et al., offers the largest lead time reductions in all additively supported processes []. The AM of ceramic materials in general has recently been summarized by Zocca et al. as well as Lakhdar et al.—in both cases, their use in investment casting is considered among the relevant application scenarios [,]. Table 4 below provides an overview of AM processes and materials for applications specific to investment casting, thus excluding the production of permanent dies for wax injection molding, and indicates the content of associated studies in the field.

Table 4.

Overview of AM processes used in rapid investment casting (RIC), as well as associated materials and specific application in the investment casting context.

Wang et al. recently summarized the various technologies used in rapid investment casting (RIC) and highlighted its benefits for the investment casting industry. As does 3DSP for sand casting, these techniques facilitate the production of highly complex, structurally optimized components. The drawback is, once more, productivity, such that the technique can mainly be employed for individual part to limited-scale series production, while conventional mold-based processes prevail for a larger series of components characterized by lower complexity limits []. However, according to Cheah et al., what seems to be a limitation in effect opens up a new opportunity for investment casting, which is not accessible to the conventional processing route due to its extended lead times (typically between 13 and 21 weeks according to this source, which can be reduced down to an optimum of 2.5 weeks by AM-based techniques) and the cost of tooling [].

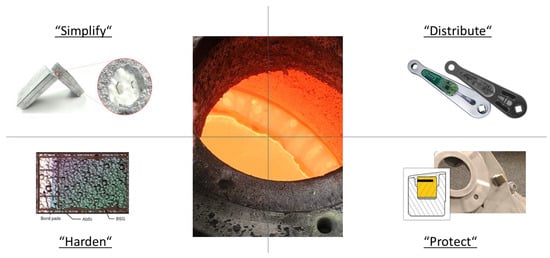

2.4. Smart Castings

Endowing components of all kinds with some level of intelligence is an ongoing trend []. The purposes are manifold and include the monitoring and control of production or logistic processes [], as well as the constant supervision of the components’ state—the Structural Health Monitoring (SHM) case []—and the gathering of usage data [] to optimize next generation product design [] or facilitate predictive maintenance [,], to name but a few application scenarios. The motivation behind these can naturally be transferred to any kind of component, irrespective of the manufacturing process. However, while there are a wide range of publications about smart structures based on fiber-reinforced composites—partly based on their mechanical behavior, which may heighten the need for monitoring and is, thus, linked to the SHM topic in the aerospace sector [,,]—there are far fewer studies focusing on smart castings. The reason is not necessarily a lack of interest in the field but rather the difficulties linked to the comparatively high process temperatures in metal casting, which afford specific protective measures. Lehmhus et al. recently suggested a classification of such approaches distinguishing between the four generalized principles illustrated in Figure 9 below [].

Figure 9.

How to enable sensors and electronic systems to survive integration in metal castings—general principles: Top left, simplify—example of a rip wire sensor []; top right, distribute—integrate just those components that need to be integrated []; bottom left, harden—use materials that can withstand the process loads []; bottom right, protect—shield the integrated system against thermal and/or mechanical loads [].

Table 5 below offers an overview of the published literature, sorting studies by their main approach according to Figure 9, casting process, material and type of sensor. This listing is far from complete and should mainly provide a rough idea of the methods that are actually in use today. What is apparent from this collection is that in most cases, a combination of the enabling measures, namely simplify, distribute, harden and protect, is employed.

Table 5.

Selected examples of published research on functional system integration in metal casting.

Of all the examples in Table 5, not surprisingly, most refer to the processing of aluminum alloys. This is partly due to the ease of processing associated with lower melt temperatures but also due to the emerging application scenarios in the area of automotive and unmanned aerial vehicles (UAV) for passenger transport. In both cases, the structural monitoring of safety-relevant components is the primary motivation—for the automotive industry, this aspect is gaining importance due to the advent of autonomous driving techniques, as well as new mobility concepts like car sharing. Both these trends imply that the car users are less aware of the state of the car they are occupying, as they are either not actively involved in driving or do not perceive themselves as being responsible for the car in the same way as they would if they owned it. As a consequence, the task of supervising condition and, thus, safety must be transferred to the vehicle—and for this purpose, it must be endowed with the necessary senses.

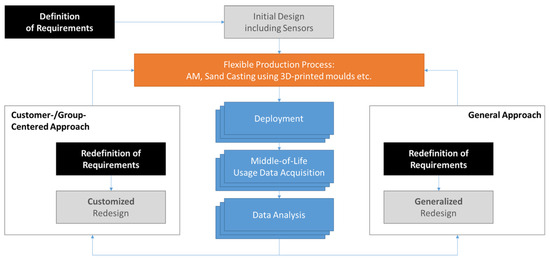

Beyond the direct impact of structural health monitoring and related techniques on safety, additive manufacturing has opened up a new perspective on sensor integration, which can be applied to metal casting primarily via the 3D printing of lost molds. Lehmhus et al. have suggested a framework in which component-integrated sensors provide feedback on in-service loads to the manufacturer and, thus, allow product optimization. In an AM context, irrespectively of whether it relies on direct part manufacturing or the indirect, casting-related approach, such knowledge could be used to facilitate design improvements not only from product generation to product generation, but from individual part to individual part []. The principle is illustrated in Figure 10. Needless to say, knowledge about the state of a component and/or the loads it has seen can also help form decisions about its suitability for potential reuse once the overall system has reached the end of its service life.

Figure 10.

Schematic diagram describing a concept for constant product evolution relying on monitoring of in-service loads and conditions in combination with a highly flexible manufacturing process like indirect AM, i.e., the printing of sand molds.

Further investigations on the overarching topic of sensor integration in metal casting are available from Lehmhus et al., providing an overview of additional application scenarios as well as a more detailed description of selected technological approaches, including combined thick and thin film techniques for sensor deposition via screen printing [,].

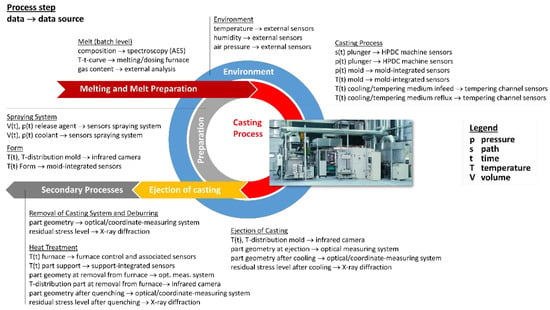

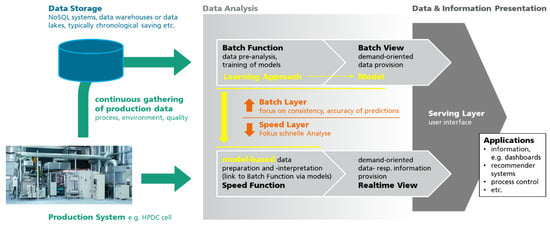

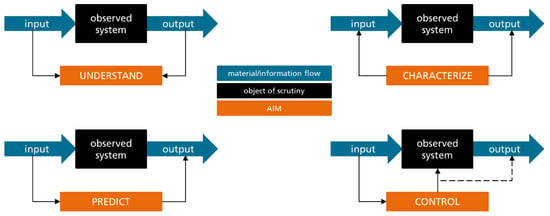

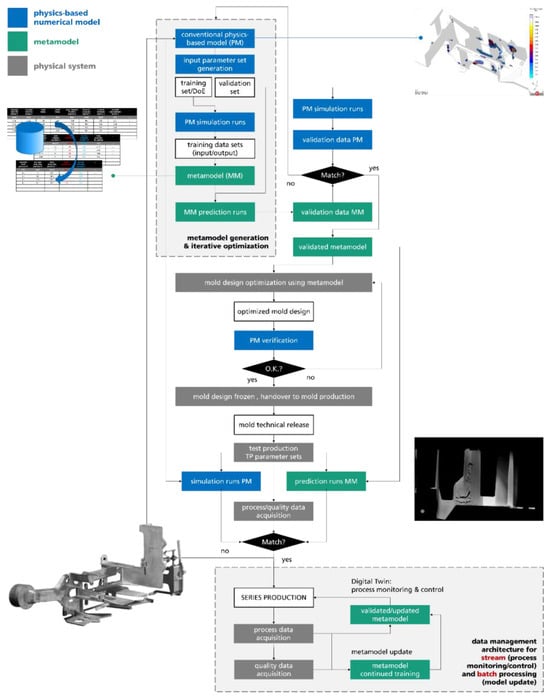

2.5. Virtual Worlds: Modelling, Simulation and Optimization

2.5.1. Casting Simulation: State of the Art