Effect of Deformation Degree on Microstructure and Properties of Ni-Based Alloy Forgings

Abstract

1. Introduction

2. Experimental Material and Methods

3. Results and Discussion

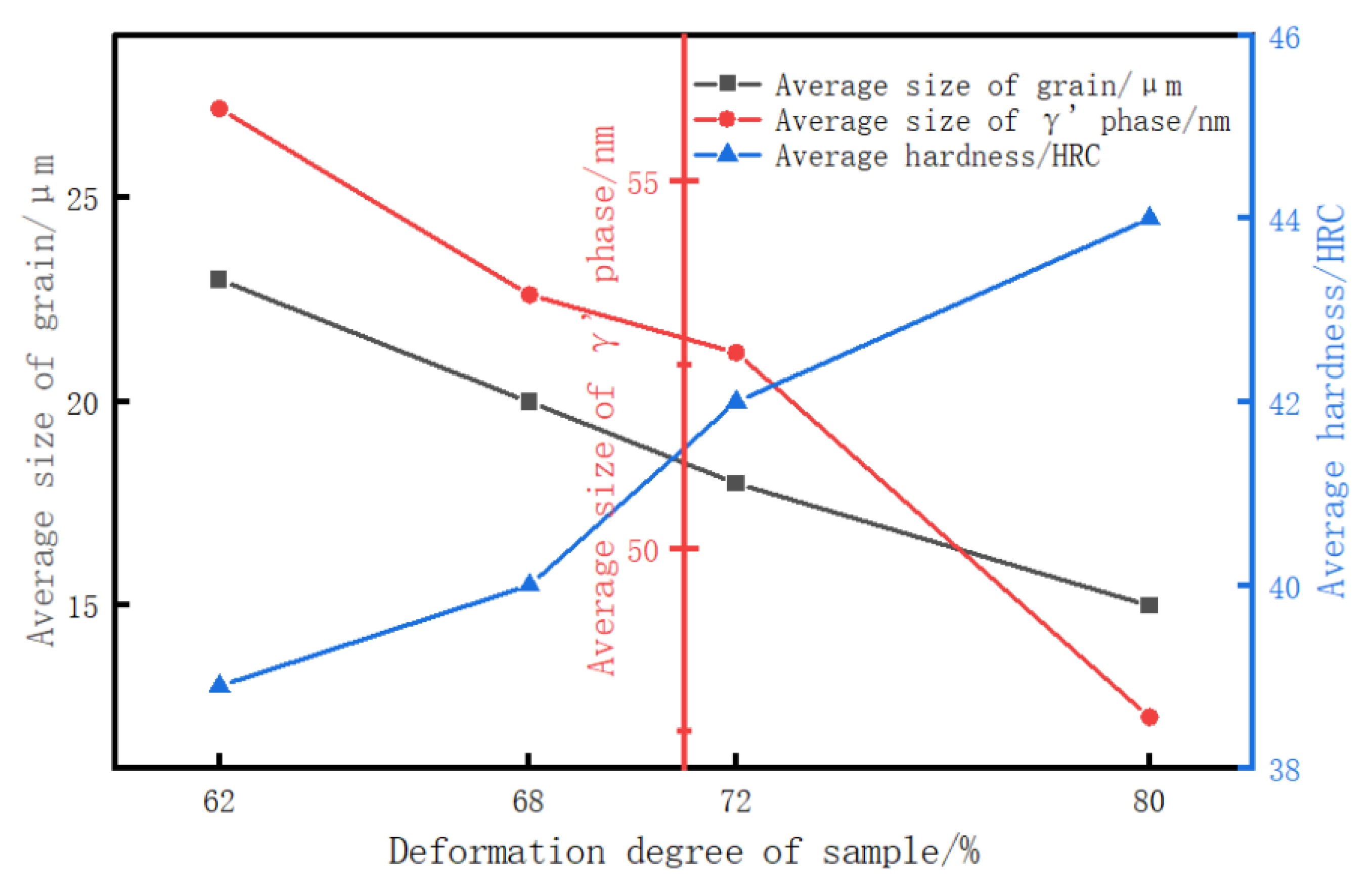

3.1. Effect of Deformation Degree on Microstructure of Ni-Based Alloy

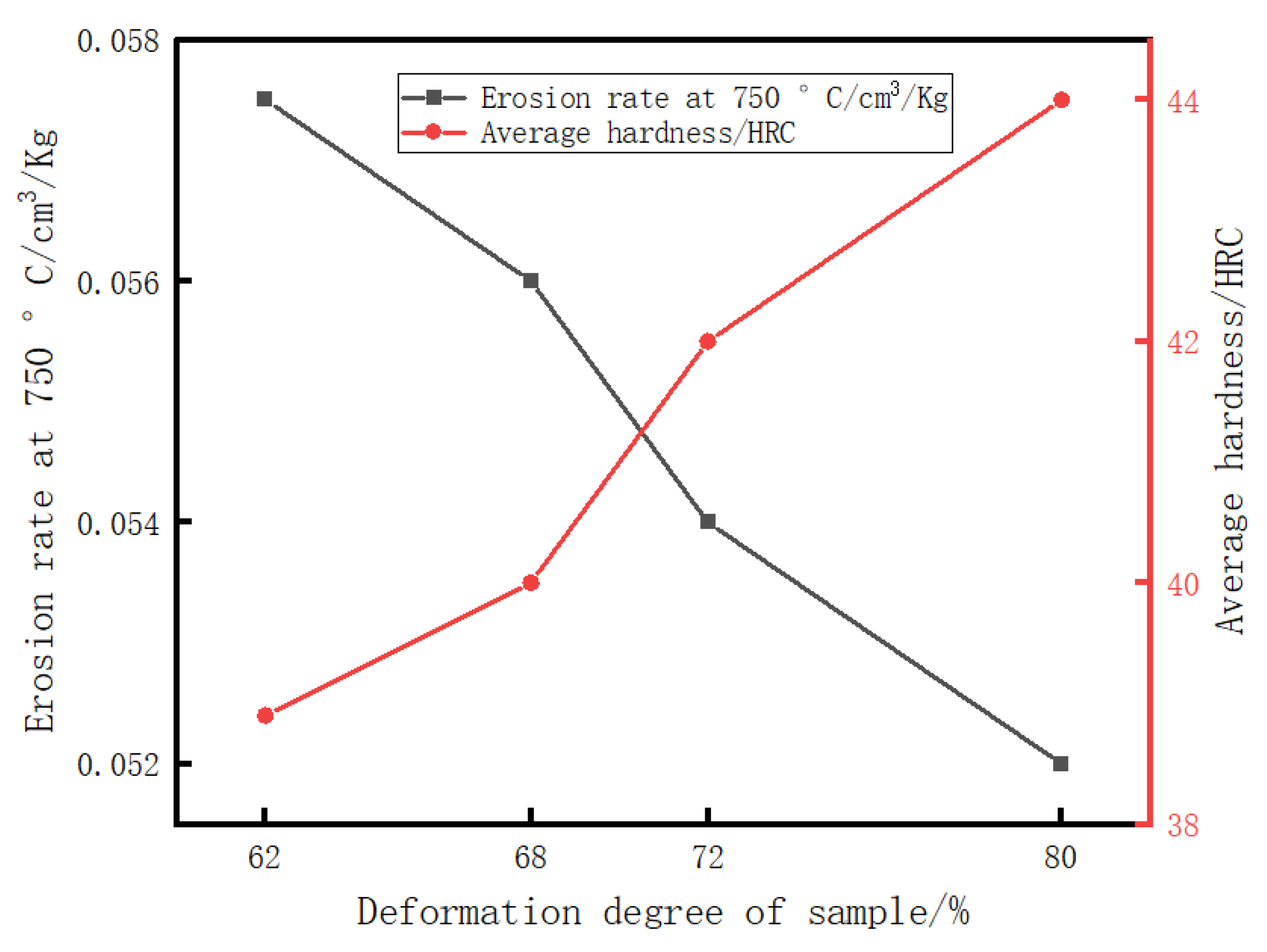

3.2. Effect of Deformation Degree on Properties of Ni-Based Alloy

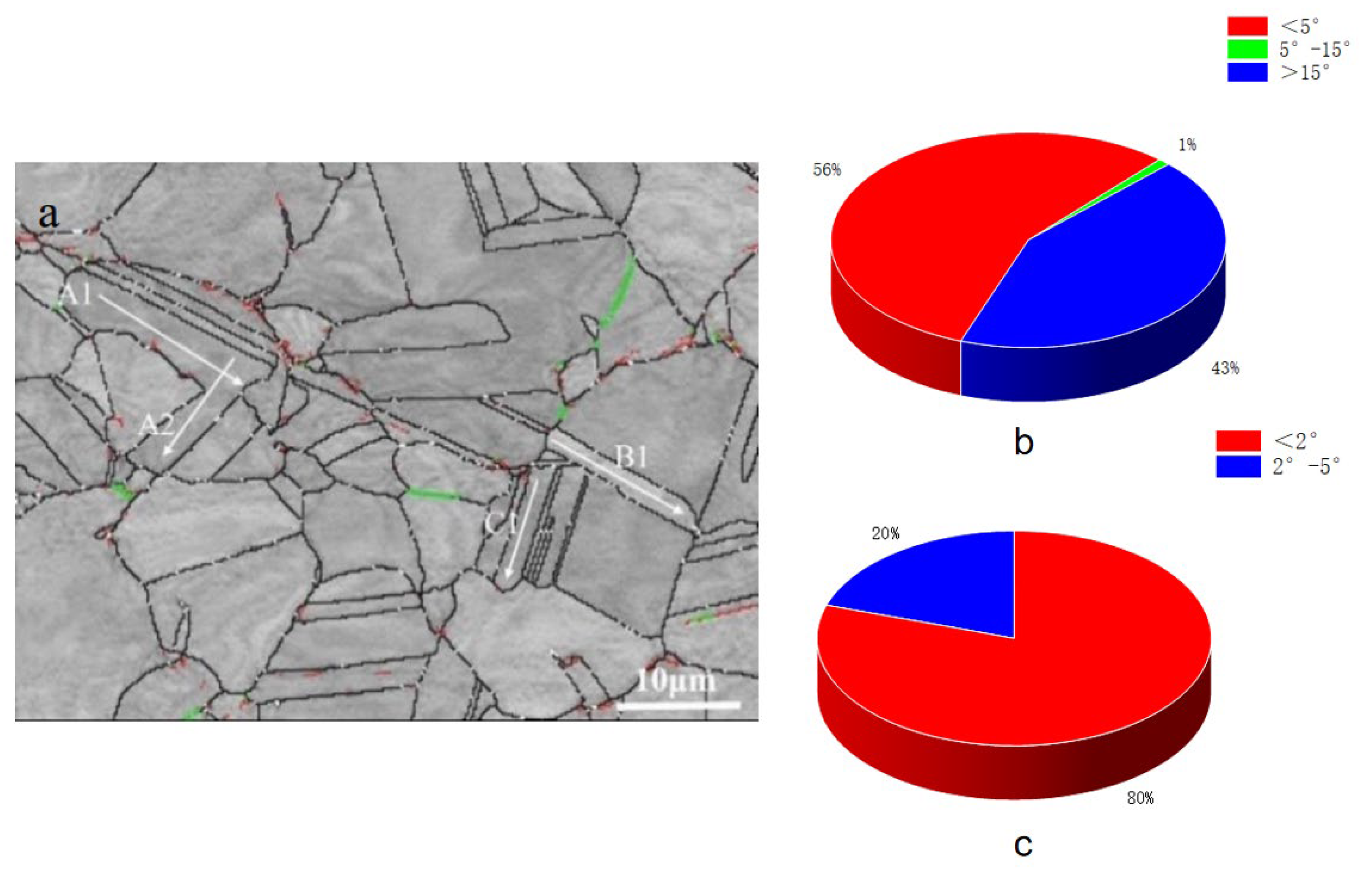

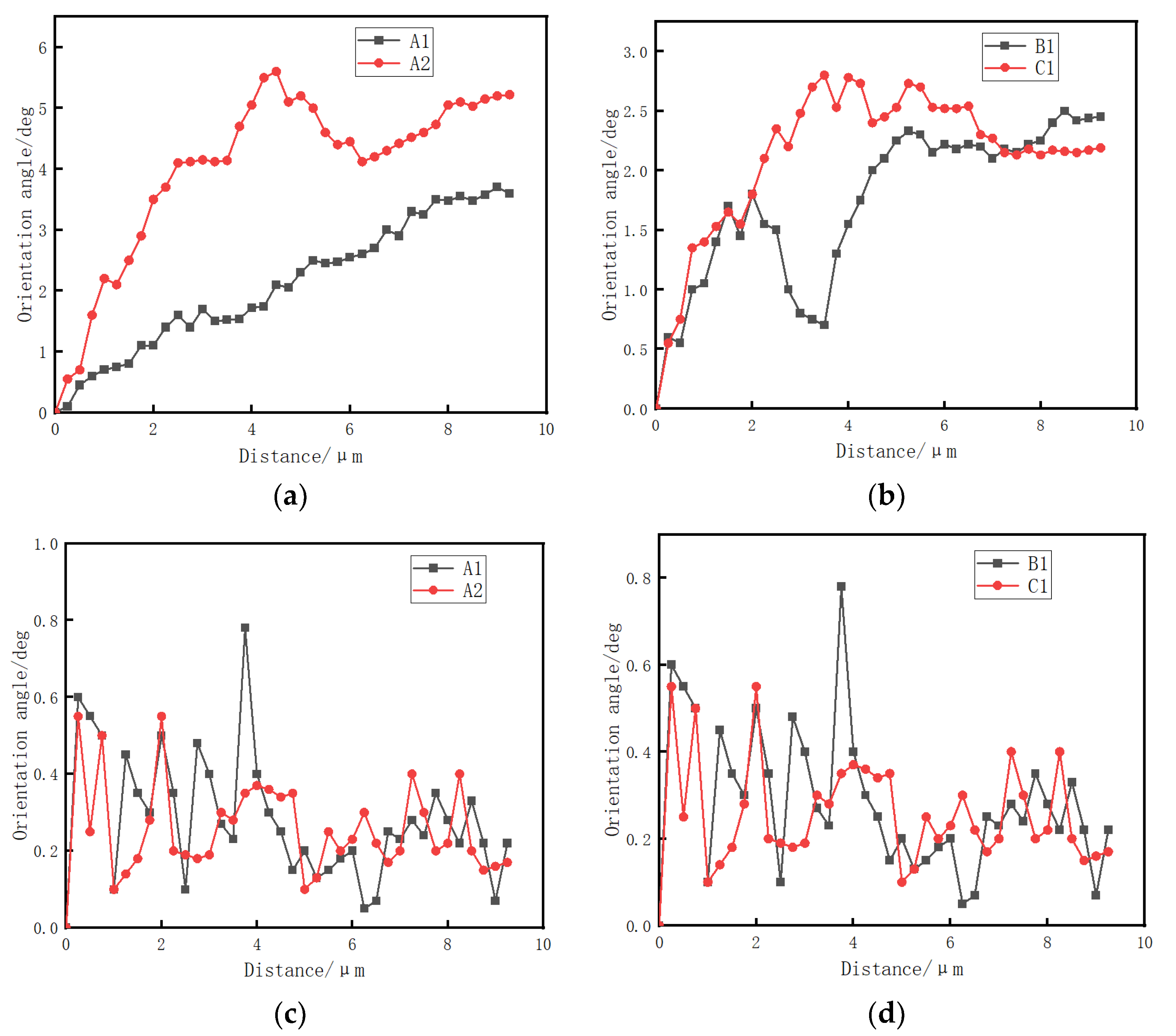

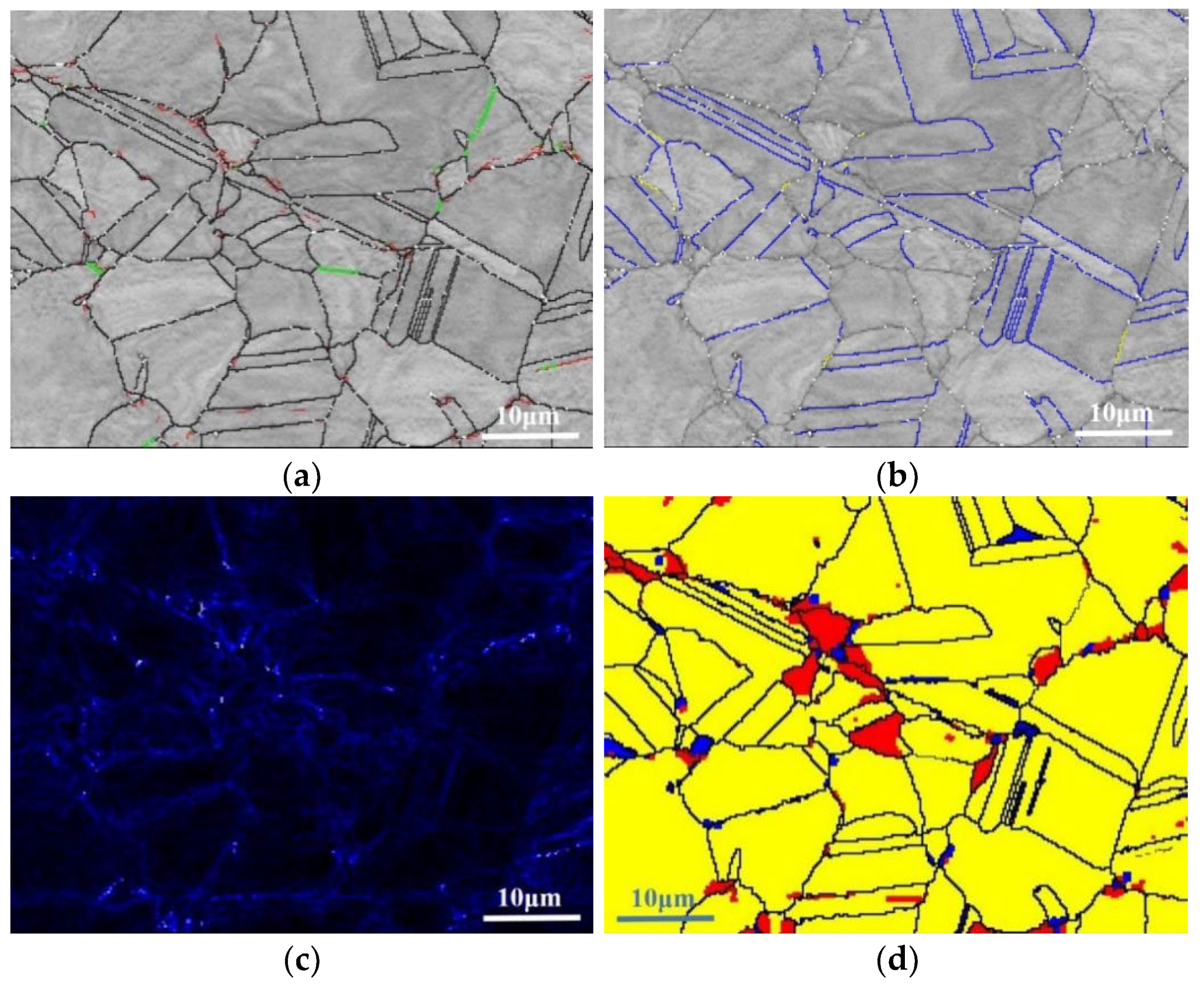

3.3. The Nucleation Mechanism of Recrystallized Grains in the Alloy and the Evolution of Substructure Inside the Grains

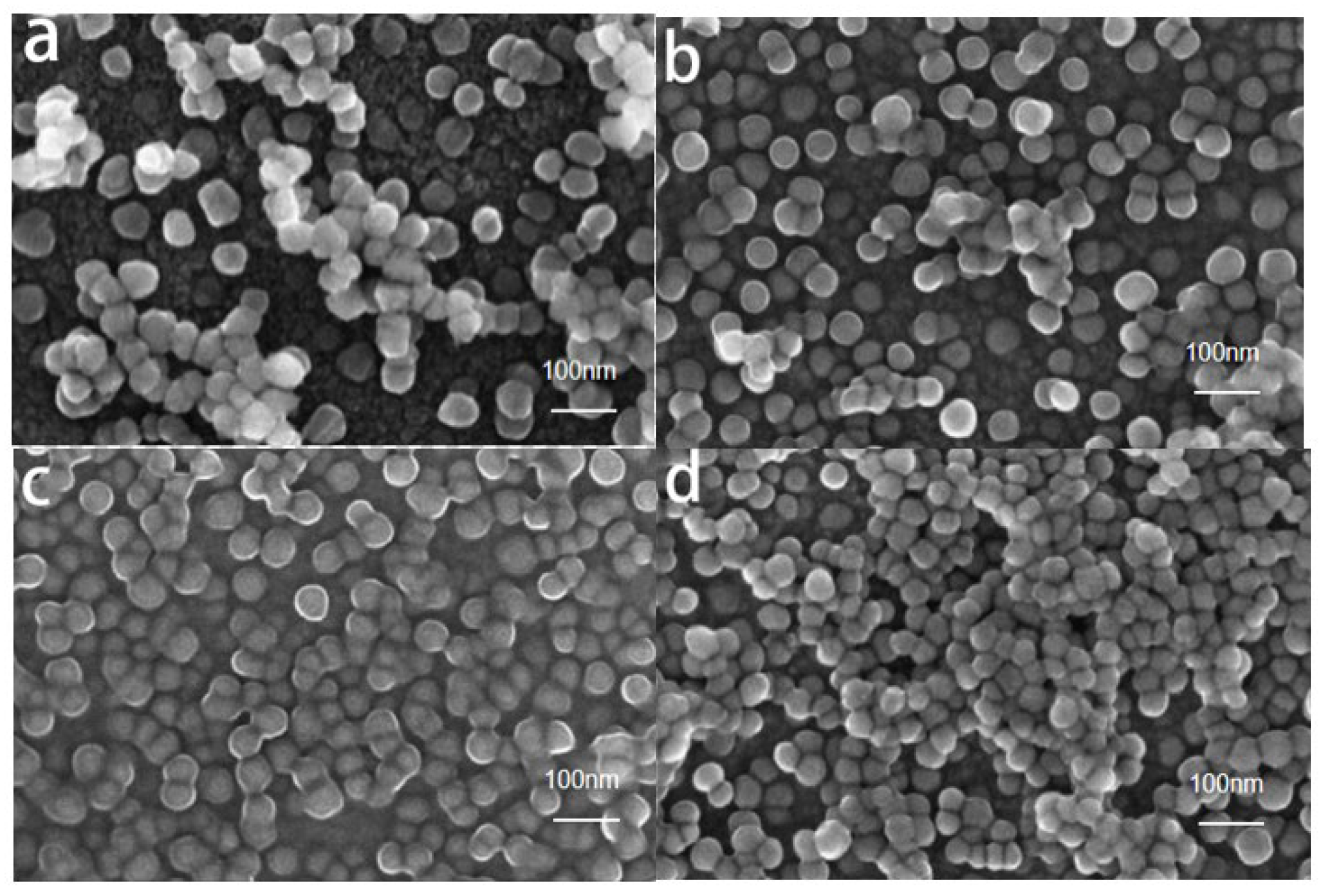

3.4. γ′ Phase Evolution in Nickel-Based Superalloys

4. Conclusions

- (1)

- The grain size of nickel-based superalloys and the particle size of the “phase” steadily shrunk as the degree of deformation increased, and the hardness gradually rose. At 80% deformation, the hardness was 14.3% greater than it was at 62% distortion.

- (2)

- Chiseling and a limited amount of cutting were the major characteristics of high-temperature erosion at 750 °C, which was mostly dependent on the impact deformation mechanism. The sample with an 80% deformation degree had a lower high-temperature erosion rate, which was decreased by 10.3% when compared to the sample with a 62% deformation degree. Furthermore, the harder the alloy was, the faster it corroded at high temperatures.

- (3)

- The method of grain recrystallization used in Ni-based alloy forgings is known as discontinuous dynamic recrystallization, and it is characterized by a high dislocation density at the recrystallized grain boundaries. As a result, the sample’s microstructure frequently had numerous substructures and twin borders. This structure effectively refined the grains and increased the grain boundary area, which increased the alloy’s functionality even more.

- (4)

- As the degree of deformation increased during the hot working of the Ni-based alloy, the particle size and dislocation spacing of the phase decreased. According to studies, the ‘phase’s critical shear stress value is high, and its particle size ranges from 40 to 100 nm, which has a favorable strengthening impact on the alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qian, Y.-H.; Li, H.-K. Superalloy; Metallurgical Industry Press: Beijing, China, 2022; pp. 1–99. [Google Scholar]

- Wang, H.-Y.; An, Y.-Q.; Li, C.-Y. Research Progress of Ni-based Superalloys. Mater. Rep. 2011, 25, 482–486. [Google Scholar]

- Qu, J.-L.; Yi, C.-S.; Chen, J.-W. Research progress of precipitated phase in GH4720Li superalloy. J. Mater. Eng. 2020, 48, 73–83. [Google Scholar]

- Du, J.; Zhao, G.; Deng, Q.; Lv, X.; Zhang, B. Development of Wrought Superalloy in China. J. Aeronaut. Mater. 2016, 36, 27–39. [Google Scholar]

- Ma, J.; Li, W.; Zhang, X.; Kou, H.; Shao, J.; Geng, P.; Deng, Y.; Fang, D. Tensile properties and temperature-dependent yield strength prediction of GH4033 wrought superalloy. Mater. Sci. Eng. A 2016, 676, 165–172. [Google Scholar] [CrossRef]

- Guo, J.-T. Materials Science and Engineering for Superalloys; Science Press: Beijing, China, 2010. [Google Scholar]

- Shi, C.-X.; Zhong, Z.-Y. Development and innovation of superalloy in China. Acta Metall. Sin. 2010, 46, 1281–1288. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.-A.; Wang, W.; Li, D.-S.; Ma, J.-Y. Influence of rare earth Y on microstructure and high temperature oxidation behavior of Ni-Fe-Co-Cu alloy. Chin. J. Rare Met. 2020, 44, 9–15. [Google Scholar]

- Velikanova, N.-P.; Protasova, N.-A.; Velikanov, P.-G.; Kiselev, A.S.; Salih, S.I.S. Influence of operating time on the strength reliability of the gas generator turbine disk of the aircraft drive for the GPA. J. Phys. Conf. Ser. 2021, 1891, 012044. [Google Scholar] [CrossRef]

- Li, C.-M.; Tan, Y.-B.; Zhao, F. Modification of Flow Stress Curve and Processing Maps of Inconel 718 Superalloy. Chin. J. Rare Met. 2020, 44, 585–596. [Google Scholar]

- Liu, W.-C.; Xiao, F.-R.; Yao, M.; Chen, Z.-L.; Jiang, Z.-Q.; Wang, S.-G. Relationship between the lattice constant of γ phase and the content of ö phase, γ″ and γ′ phases in inconel 718. Scr. Mater. 1997, 37, 59–64. [Google Scholar] [CrossRef]

- Yoo, B.; Im, H.-J.; Seol, J.-B.; Choi, P.-P. On the microstructural evolution and partitioning behavior of L12-structured γ′-based Co-Ti-W alloys upon Cr and Al alloying. Intermetallics 2019, 104, 97–102. [Google Scholar] [CrossRef]

- Su, X.; Lv, X.-D. Thermal deformation behavior of as-cast and as-forged GH4738 alloy. Heat Treat. Met. 2021, 46, 46–52. [Google Scholar]

- Li, H.-Y.; Dong, J.-X.; Li, L.-H. Evolution of microstructure and hot deformation behavior of GH4738 alloy during homogenization. Trans. Mater. Heat Treat. 2017, 38, 61–69. [Google Scholar]

- Goodfellow, A.-J.; Galindo-Nava, E.-I.; Christofidou, K.-A.; Jones, N.G.; Boyer, C.D.; Martin, T.L.; Bagot, P.A.J.; Hardy, M.C.; Stone, H.J. The effect of phase chemistry on the extent of strengthening mechanisms in model Ni-Cr-Al-Ti-Mo based superalloys. Acta Mater. 2018, 153, 290–302. [Google Scholar] [CrossRef]

- Dai, C.-W.; Ding, W.-F.; Xu, J.-H.; Fu, Y.-C.; Yu, T.-Y. Influence of Grain Wear on Material Removal Behavior during Grinding Nickel-based Superalloy with a Single Diamond Grain. Int. J. Mach. Tools Manuf. 2017, 113, 49–58. [Google Scholar] [CrossRef]

- Li, W.; Yang, G.; Lei, T.; Yin, S.-B.; Wang, L. Hot Deformation Behavior of GH738 for A-USC Turbine Blades. J. Iron Steel Res. 2015, 22, 1043–1048. [Google Scholar]

- Liu, H.; Cai, X.-Y. Effects of Hot Working Parameters on Dynamic Recrystallization Behaviors of GH738 Alloy. J. Iron Steel Res. 2014, 26, 46–50. [Google Scholar]

- Jiang, H.; Li, Y.-J.; Liu, Q.-Y.; Dong, J.-X. Effect of Final Forging Temperature on Hot Deformation Behavior of GH4738 Superalloy. Rare Met. Mater. Eng. 2021, 50, 2552–2556. [Google Scholar]

- Wang, L.-Y.; Wang, J.-G.; Liu, D.; Wang, H.-P.; Xu, W.-S.; Zhao, X.-D.; Tong, J.; Qin, W.-D. Characterization and verification on hot working process windows for GH4738 alloy. Forg. Stamp. Technol. 2021, 46, 207–215. [Google Scholar]

- Wang, W.-W.; Yi, Y.-P.; Li, P.-C.; Huang, S.-Q. Simulation on Forging Process for Superalloy Waspaloy Turbine Disc Using Composite Sheathed Technology. Hot Work. Technol. 2011, 40, 22–25. [Google Scholar]

- Kvackaj, T.; Zrnik, J.; Vrchovinsky, V. Influence of plastic deformation on creep behaviour of NiMoCr alloy. High Temp. Mater. Process. 2003, 22, 57–62. [Google Scholar] [CrossRef]

- Wang, H.-P.; Liu, D.; Shi, Y.-Z.; Wang, J.; Yang, Y.; Wang, L.; Qin, W. Matrix-Diffusion-Controlled Coarsening of the γ′ Phase in Waspaloy. Met. Mater. Int. 2019, 25, 1410–1419. [Google Scholar] [CrossRef]

- Yao, Z.-H.; Dong, J.-X.; Zhang, M.-C.; Hong, C.-M. Influence of solution and stabilization heat treatment on carbide and gamma prime for super alloy GH738. Trans. Mater. Heat Treat. 2013, 34, 43–49. [Google Scholar]

- Jackson, M.P.; Reed, R.C. Heat treatment of UDIMET 720Li: The effect of microstructure on properties. Mater. Sci. Eng. A 1999, 259, 85–97. [Google Scholar] [CrossRef]

- Decker, R. The evolution of wrought age-hardenable superalloys. JOM 2006, 58, 32–36. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.M.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef]

- Drapier, J.; Coutsouradis, D.; Habraken, L. Measurements of stacking-fault energies in CoNi and CoNi-Cr alloys. Acta Metall. 1967, 15, 673–675. [Google Scholar] [CrossRef]

- Wan, Z.-P. Study on High Temperature Deformation Behavior and Microstructure and Properties Control of GH4720LI Nickel-Based Alloy. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Xiang, S.; Ju, Q.; Liu, G.-Q. Dynamic recrystallization mechanism of 15Cr-25Ni-Fe base superalloy. J. Jiangsu Univ. 2010, 31, 665–669. [Google Scholar]

- Shi, C.-Y.; Zhang, M.-C.; Guo, J. Recrystallization Mechanism of Typical Ni-based Superalloys. Rare Met. Mater. Eng. 2023, 52, 63–73. [Google Scholar]

- Chen, X.-F.; Yao, Z.-H.; Dong, J.-X.; Shen, H.-W.; Wang, Y. The effect of stress on primary MC carbides degeneration of Waspaloy during long term thermal exposure. J. Alloys Compd. 2018, 735, 928–937. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Chen, Z.-S. Effect of Hot Working Process on Microstructure and Properties of GH4738 Superalloy. Master’s Thesis, Inner Mongolia University of Technology, Hohhot, China, 2021. [Google Scholar]

- Chen, Z.-Q.; Tai, Q.-A.; Zhao, X.-D.; Wang, J.-Y.; Li, C.-Y. Precipitation and dissolution on carbide for superalloy GH738. J. Iron Steel Res. 2013, 25, 37–45. [Google Scholar]

- Liu, X.-B.; Wang, T.; Chen, S.; Wei, K.; Fu, S.-H.; Li, Z.; Wan, Z.-P. Effect of Al and Ti elements on γ′ phase dissolution law of GH4738 alloy during heat treatment. Hot Work. Technol. 2022, 51, 93–96. [Google Scholar]

- Chen, Z.S.; Dong, R.F.; Li, J.N.; Deng, X.T.; Zhang, W.; Ren, X.L. Reasons for the stable existence of gamma’ phase and strengthening mechanism of GH4720Li nickel-based superalloy. Mater. Res. Experss 2021, 8, 056508. [Google Scholar]

- Li, J.-N. Effect of Hot Working Technology on Microstructure and Properties of GH4720Li Superalloy and Research on Its Mechanism. Master’s Thesis, Inner Mongolia University of Technology, Hohhot, China, 2020. [Google Scholar]

- Zhang, W.; Li, J.-N.; Dong, R.-F.; Chen, Z.-S.; Li, J.; Zhou, X.; Wang, Q.-Z.; Qu, J.-L. Effect of heat treatment process parameters on the microstructure and properties of GH4720Li superalloy. Mater. Res. Experss 2023, 10, 016514. [Google Scholar]

| Element | C | Cr | Co | Mo | Al | Ti | Fe | Ni |

|---|---|---|---|---|---|---|---|---|

| Mass % | 0.035 | 19.41 | 13.22 | 4.30 | 1.35 | 2.98 | 1.00 | bal |

| Scheme | Deformation Temperature (°C) | Billet Size (mm) | Finished Size (mm) | Deformation Degree (%) |

|---|---|---|---|---|

| 1 | 1140 | ɸ45 × 110 | ɸ69 × 42 | 62 |

| 2 | ɸ76 × 35 | 68 | ||

| 3 | ɸ82 × 30 | 72 | ||

| 4 | ɸ92 × 23 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, R.; Li, J.; Chen, Z.; Zhang, W.; Zhou, X. Effect of Deformation Degree on Microstructure and Properties of Ni-Based Alloy Forgings. Metals 2024, 14, 340. https://doi.org/10.3390/met14030340

Dong R, Li J, Chen Z, Zhang W, Zhou X. Effect of Deformation Degree on Microstructure and Properties of Ni-Based Alloy Forgings. Metals. 2024; 14(3):340. https://doi.org/10.3390/met14030340

Chicago/Turabian StyleDong, Ruifeng, Jian Li, Zishuai Chen, Wei Zhang, and Xing Zhou. 2024. "Effect of Deformation Degree on Microstructure and Properties of Ni-Based Alloy Forgings" Metals 14, no. 3: 340. https://doi.org/10.3390/met14030340

APA StyleDong, R., Li, J., Chen, Z., Zhang, W., & Zhou, X. (2024). Effect of Deformation Degree on Microstructure and Properties of Ni-Based Alloy Forgings. Metals, 14(3), 340. https://doi.org/10.3390/met14030340