Effect of Coiling Temperature on Microstructure and Properties of Ferritic-Bainitic Dual-Phase Steels

Abstract

:1. Introduction

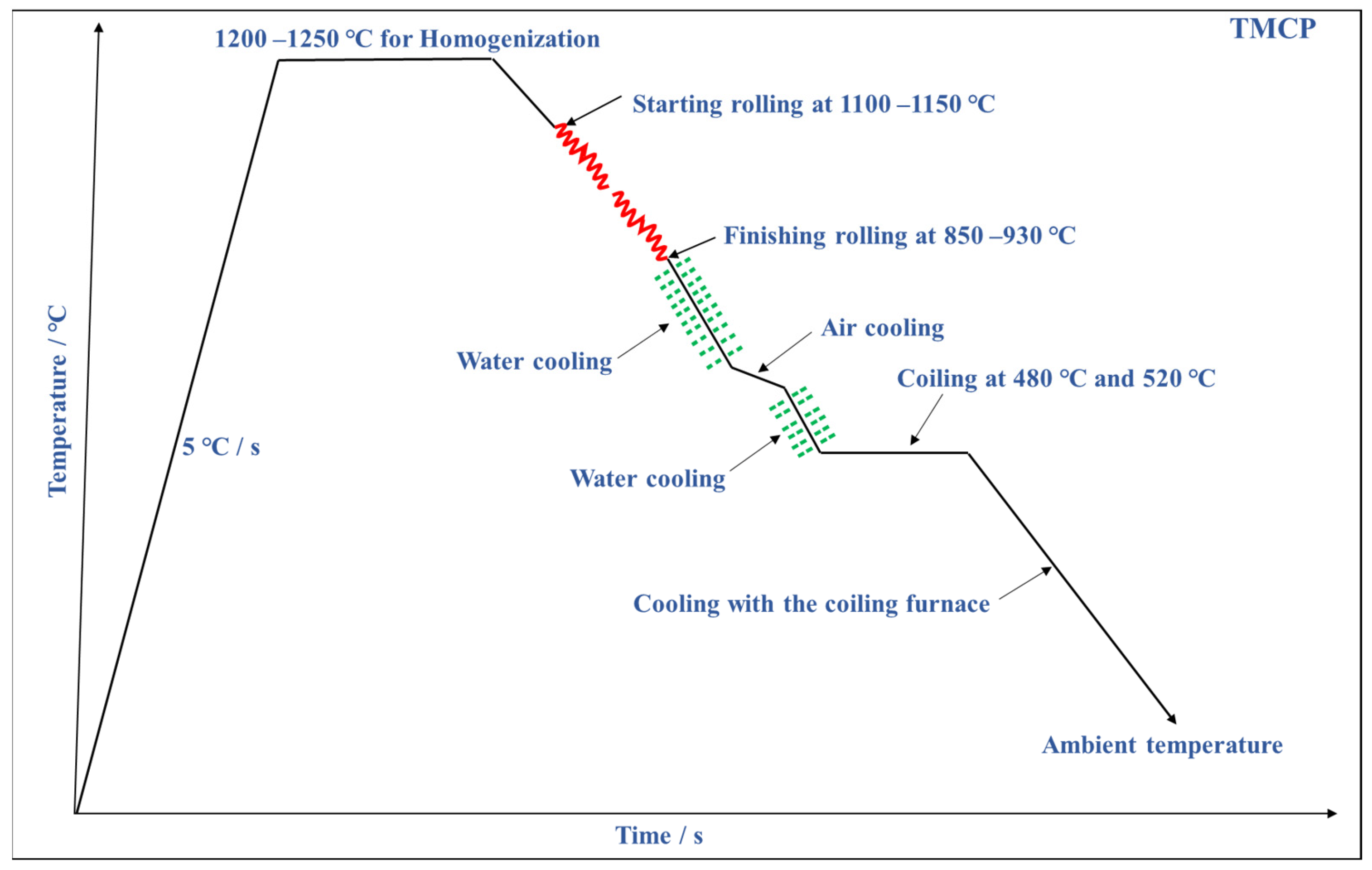

2. Materials and Methods

3. Results and Discussion

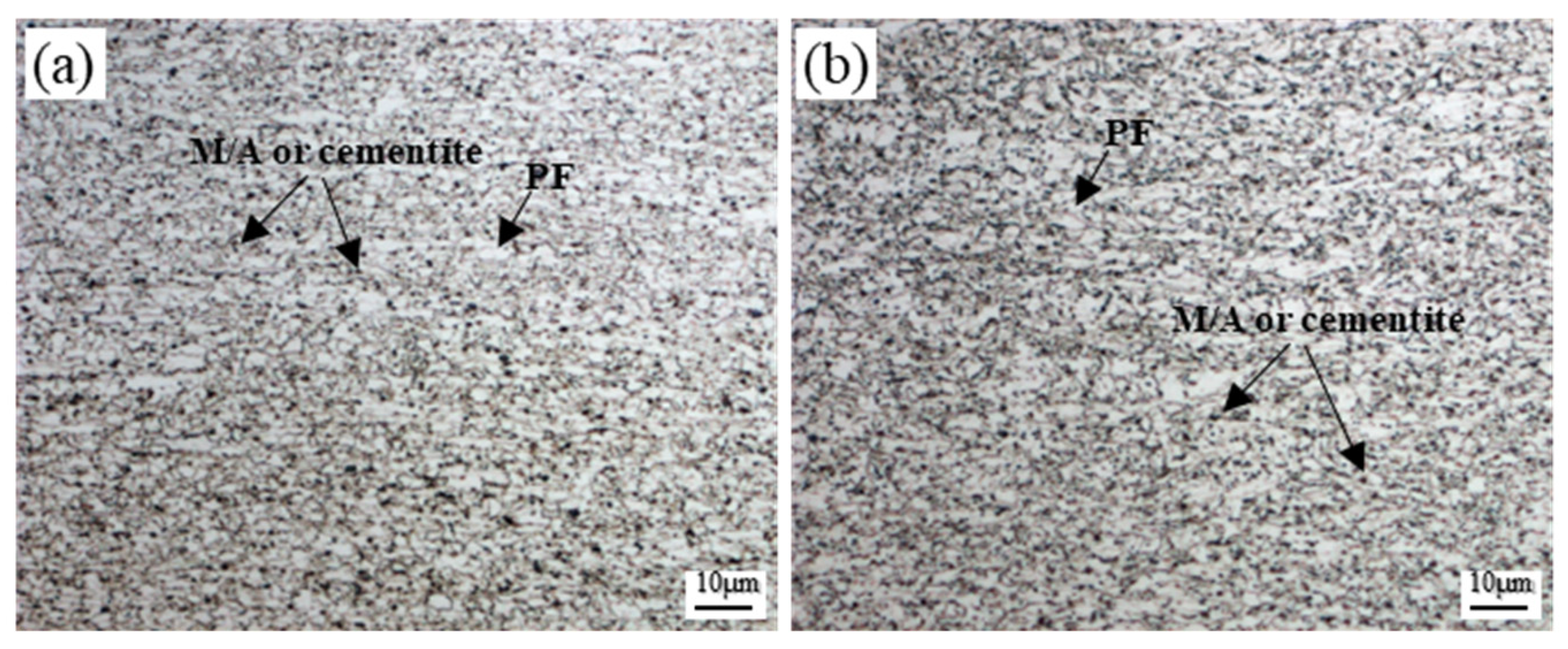

3.1. Tensile Properties, Hole Expansion Ratio, and Optical Microstructure Analysis

3.2. SEM Characterization

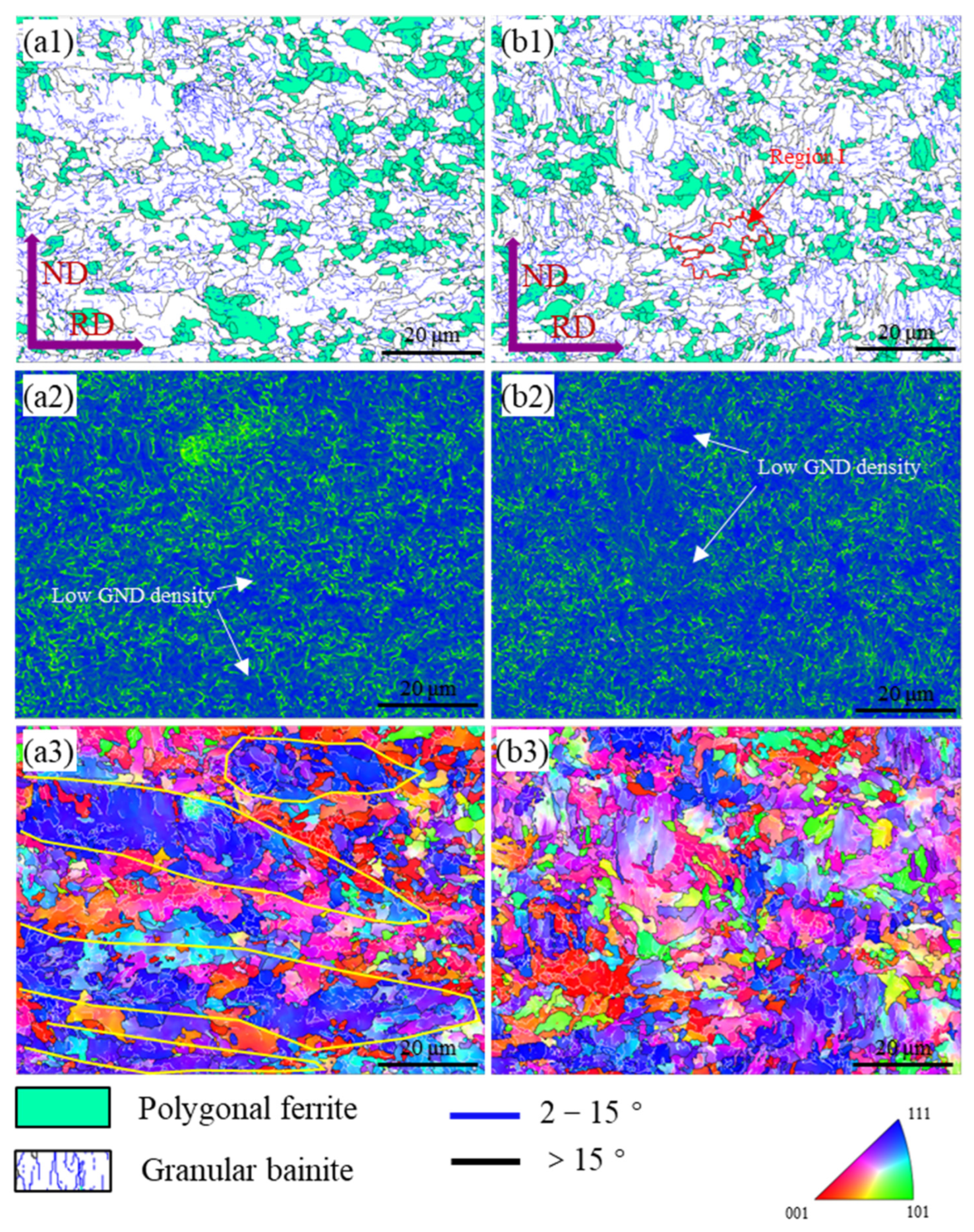

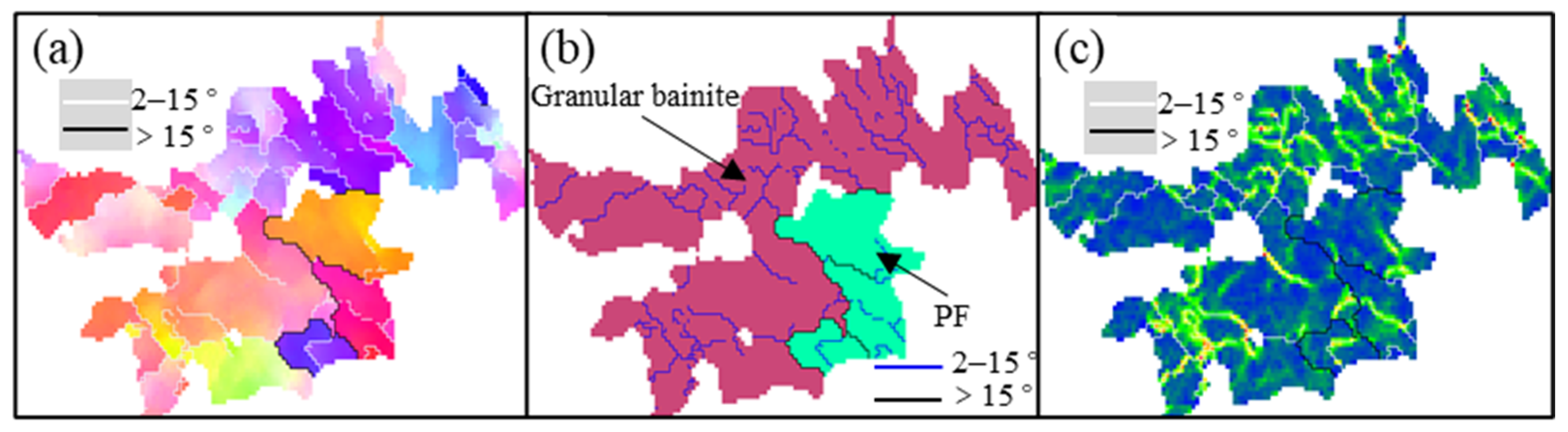

3.3. EBSD Characterization

3.4. Discussions

3.4.1. Effect of Coiling Temperature on Microstructure

3.4.2. Effect of Coiling Temperature on the Strength-Plasticity and Hole Expansion Ratio

4. Conclusions

- (1)

- Excellent strong plasticity and a high hole expansion ratio were obtained for the test steel at the coiling temperature of 520 °C. The PF and granular bainite at the coiling temperature of 520 °C were uniformly distributed with contents of 23.7 and 76.3%, respectively. The retained austenite content at the coiling temperature of 520 °C was higher.

- (2)

- The microstructure formed at low-temperature coiling is dominated by granular bainite, while high-temperature coiling is conducive to forming PF. The grain sizes at 480 °C and 520 °C coiling temperatures are very close. The lower GND density at higher coiling temperatures is attributed to the favorable dislocation movement and redistribution during high-temperature coiling.

- (3)

- The higher total elongation and hole expansion ratios of the test steels at higher coiling temperatures are attributed to the increased ferrite content, enhanced TRIP effect, and uniform distribution of the microstructure. The presence of polygonal ferrite or aggregates of granular bainite in the vascular organization of the test steels at low-temperature coiling resulted in an uneven distribution of soft and hard phases in the matrix. The strong texture parallel to the rolling direction, with a large difference in plasticity in different directions, leads to non-uniform deformation, which causes crack nucleation and propagation in the hole expansion process, thus reducing the hole expansion performance. Therefore, the use of reasonable coiling temperature to control the polygonal ferrite content and microstructure uniformity can effectively improve the forming properties of ferrite-bainite dual-phase steels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prasad, K.; Venkatesh, B.; Krishnaswamy, H.; Banerjee, D.K.; Chakkingal, U. On the interplay of friction and stress relaxation to improve stretch-flangeability of dual phase (DP600) steel. CIRP J. Manuf. Sci. Technol. 2021, 32, 154–169. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.; Jeong, B.; Jeong, K.; Lee, S.; Kim, H.; Lee, J.; Kim, S.; Han, H.N. New approach to hole-expansion ratio in complex phase and martensitic steels: Understanding the role of punching damage. J. Mater. Res. Technol. 2023, 26, 837–849. [Google Scholar] [CrossRef]

- Wu, Y.; Uusitalo, J.; DeArdo, A. Investigation of the critical factors controlling sheared edge stretching of ultra-high strength dual-phase steels. Mat. Sci. Eng. A 2021, 828, 142070. [Google Scholar] [CrossRef]

- Costa, F.S.; Oliveira, F.C.; Barbosa, R. Enhancement of the stretch-flangeability of a cold-rolled dual phase steel intercritically annealed. J. Mater. Res. Technol. 2024, 29, 691–702. [Google Scholar] [CrossRef]

- Qian, L.; Ji, W.; Sun, C.; Fang, G.; Lian, J. Prediction of edge fracture during hole-flanging of advanced high-strength steel considering blanking pre-damage. Eng. Fract. Mech. 2021, 248, 107721. [Google Scholar] [CrossRef]

- Park, S.; Jung, J.; Cho, W.; Jeong, B.; Na, H.; Kim, S.; Lee, M.; Han, N. Predictive dual-scale finite element simulation for hole expansion failure of ferrite-bainite steel. Int. J. Plast. 2021, 136, 102900. [Google Scholar] [CrossRef]

- Matsuno, T.; Sato, R.; Okamoto, R.; Mizumura, M.; Suehiro, M. Synergy effect of shear angle and anisotropic material ductility on hole-expansion ratio of high-strength steels. J. Mater. Process. Technol. 2016, 230, 167–176. [Google Scholar] [CrossRef]

- Park, S.; Jung, J.; Kim, K.; Kim, H.; Kim, S.; Oh, K.; Lee, M.; Han, H. Practical microstructure-informed dual-scale simulation for predicting hole expansion failure of hyper-burring steel. Int. J. Mech. Sci. 2019, 156, 297–311. [Google Scholar] [CrossRef]

- Choi, S.; Kim, E.; Kim, S. The micromechanical deformation behaviors of hot-rolled 590FB steel during hole-expansion test. Int. J. Plast. 2014, 58, 184–200. [Google Scholar] [CrossRef]

- Sugimoto, K.; Nakano, K.; Song, S.; Kashima, T.; Huang, H.; Xu, G. Retained austenite characteristics and stretch-flangeability of high-strength low-alloy TRIP type bainitic sheet steels. ISIJ Int. 2002, 42, 450–455. [Google Scholar] [CrossRef]

- Kamibayashi, K.; Tanabe, Y.; Takemoto, Y.; Shimizu, I.; Senuma, T. Influence of Ti and Nb on the strength-ductility-hole expansion ratio balance of hot-rolled low-carbon high-strength steel sheets. ISIJ Int. 2012, 52, 151–157. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Zhou, X.; Wang, G. Improvement of hole-expansion property for medium carbon steels by ultra fast cooling after hot strip rolling. J. Iron Steel Res. Int. 2013, 20, 25–32. [Google Scholar] [CrossRef]

- Fang, X.; Fan, Z.; Ralph, B.; Evans, P.; Underhill, R. Effects of tempering temperature on tensile and hole expansion properties of a C-Mn steel. J. Mater. Process. Technol. 2003, 132, 215–218. [Google Scholar] [CrossRef]

- Yoon, J.; Yu, H.; Lee, H.; Jung, J.; Kim, H. Effect of grain size on stretch-flangeability of twinning-induced plasticity steels. Mat. Sci. Eng. A 2018, 735, 295–301. [Google Scholar] [CrossRef]

- Schmidova, E.; Klejch, F.; Sunilkumar, M. Development of anisotropy and strain hardening in damaged stamped parts made of IF steel. Eng. Fail. Anal. 2023, 145, 107015. [Google Scholar] [CrossRef]

- Bakshi, S.; Javed, N.; Sasidhar, K.; Dhande, T.; Sharma, V.; Mukherjee, M. Effect of microstructure and crystallographic texture on mechanical anisotropy of Ti-Nb microalloyed hot rolled 800 MPa HSLA steel. Mater. Charact. 2018, 136, 346–357. [Google Scholar] [CrossRef]

- Lepera, F. Improved etching technique for the determination of percent martensite in high-strength dual-phase steels. Metallography 1979, 12, 263–268. [Google Scholar] [CrossRef]

- Yang, J.; Kim, D.; Lee, S.; Kim, Y.; Kim, W.; Sohn, S. Effects of granular bainite and polygonal ferrite on yield point phenomenon in API X65 line-pipe steels. Mat. Sci. Eng. A 2022, 840, 143006. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.Y.; Lee, S.G.K.; Jung, H.G.; Hwang, B. Effect of strain aging on tensile behavior and properties of API X60, X70, and X80 pipeline steels. Met. Mater. Int. 2018, 24, 1221–1231. [Google Scholar] [CrossRef]

- Kim, W.D.; Kim, W.K.; Bae, J.; Choi, W.; Kin, H.S.; Lee, S. Yield-strength prediction of flattened steel pipes by competing Bauschinger effect and strain hardening during pipe-forming. Sci. Rep. 2019, 9, 14002. [Google Scholar] [CrossRef]

- Kim, W.D.; Sohn, S.S.; Kim, W.K.; Kim, K.S.; Lee, S. Study of Bauschinger effect of acicular ferrite and polygonal ferrite through ex-situ interrupted bending tests in API X80 linepipe steels. Sci. Rep. 2018, 8, 15598. [Google Scholar] [CrossRef]

- Lee, S.G.; Li, L.; Lee, D.H.; Sohn, S.S.; Kim, W.G.; Um, K.K.; Kim, K.; Lee, S. Effects of Ni and Mn addition on critical crack tip opening displacement (CTOD) of weld-simulated heat-affected zones of three high-strength low-alloy (HSLA) steels. Mat. Sci. Eng. A 2017, 697, 55–65. [Google Scholar] [CrossRef]

- Lee, S.G.; Sohn, S.S.; Kim, B.; Kim, W.G.; Um, K.K.; Lee, S. Effects of martensite-austenite constituent on crack initiation and propagation in inter-critical heat-affected zone of high-strength low-alloy (HSLA) steel. Mat. Sci. Eng. A 2018, 715, 332–339. [Google Scholar] [CrossRef]

- Luo, X.; Xu, G.; Chen, X.; Wang, Z. Effect of undercooled austenite ausforming on the role of the M-A constituents in the CGHAZ toughness of the HSLA steels with bainite structure. Mat. Sci. Eng. A 2022, 833, 142571. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Sun, X.; Yong, Q.; Yang, J.; Li, Y.; Zhao, P. Development of Ti–V–Mo Complex Microalloyed Hot-Rolled 900-MPa-Grade High-Strength Steel. Acta Metall. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 641–648. [Google Scholar] [CrossRef]

- Kim, Y.W.; Song, S.W.; Seo, S.J.; Hong, S.; Lee, C.S. Development of Ti and Mo micro-alloyed hot-rolled high strength sheet steel by controlling thermomechanical controlled processing schedule. Mater. Sci. Eng. A 2013, 565, 430–438. [Google Scholar] [CrossRef]

- Xu, X.; Xu, B.Y.; Chen, P.; Liu, R.D.; Wang, G.D.; Yi, H.L. Effect of austenite stability on the hole expansion behavior of 8-TRIP steels. Mater. Today Commun. 2020, 24, 101034. [Google Scholar] [CrossRef]

- Verdeja, J.I.; Asensio, J.; Pero-Sanz, J.A. Texture, formability, lamellar tearing and HIC susceptibility of ferritic and low-carbon HSLA steels. Mater. Today Commun. 2003, 50, 81–86. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Nb + Ti + Mo | Fe |

|---|---|---|---|---|---|---|

| 0.06–0.08 | 0.5–0.7 | 1.40–1.80 | 0.005–0.015 | 0.003–0.008 | 0.15–0.40 | Bal. |

| CT/°C | Direction | Yield Strength/MPa | Tensile Strength/MPa | Total Elongation/% | Hole Expansion Ratio/% |

|---|---|---|---|---|---|

| 480 | 0° | 739 ± 11 | 815 ± 15 | 16.5 ± 0.8 | 44.2 ± 3.1 |

| 45° | 731 ± 9 | 794 ± 12 | 19.0 ± 0.6 | ||

| 90° | 773 ± 11 | 845 ± 13 | 15.5 ± 0.8 | ||

| 520 | 0° | 745 ± 9 | 807 ± 14 | 14.5 ± 0.5 | 58.8 ± 2.8 |

| 45° | 684 ± 6 | 772 ± 10 | 20.0 ± 0.9 | ||

| 90° | 723 ± 10 | 821 ± 15 | 18.0 ± 0.8 |

| CT/°C | Phase Ratio | Average Grain Size | Misorientation Angle/° | |||

|---|---|---|---|---|---|---|

| PF/% | Granular Bainite/% | PF/μm | Granular Bainite/μm | 2–15° | >15° | |

| 480 | 19.2 | 81.8 | 1.42 | 4.70 | 47.4 | 52.6 |

| 520 | 23.7 | 76.3 | 1.35 | 4.66 | 48.8 | 51.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhou, F.; Liu, J.; Liu, L.; Wang, C.; Zhao, Z. Effect of Coiling Temperature on Microstructure and Properties of Ferritic-Bainitic Dual-Phase Steels. Metals 2024, 14, 365. https://doi.org/10.3390/met14030365

Li Z, Zhou F, Liu J, Liu L, Wang C, Zhao Z. Effect of Coiling Temperature on Microstructure and Properties of Ferritic-Bainitic Dual-Phase Steels. Metals. 2024; 14(3):365. https://doi.org/10.3390/met14030365

Chicago/Turabian StyleLi, Zhengrong, Feng Zhou, Jinhai Liu, Lei Liu, Chuangwei Wang, and Zhengzhi Zhao. 2024. "Effect of Coiling Temperature on Microstructure and Properties of Ferritic-Bainitic Dual-Phase Steels" Metals 14, no. 3: 365. https://doi.org/10.3390/met14030365

APA StyleLi, Z., Zhou, F., Liu, J., Liu, L., Wang, C., & Zhao, Z. (2024). Effect of Coiling Temperature on Microstructure and Properties of Ferritic-Bainitic Dual-Phase Steels. Metals, 14(3), 365. https://doi.org/10.3390/met14030365