Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Heat Treatment Processes

2.2. Microstructure Characterization

2.3. Mechanical Property Test

3. Results and Discussion

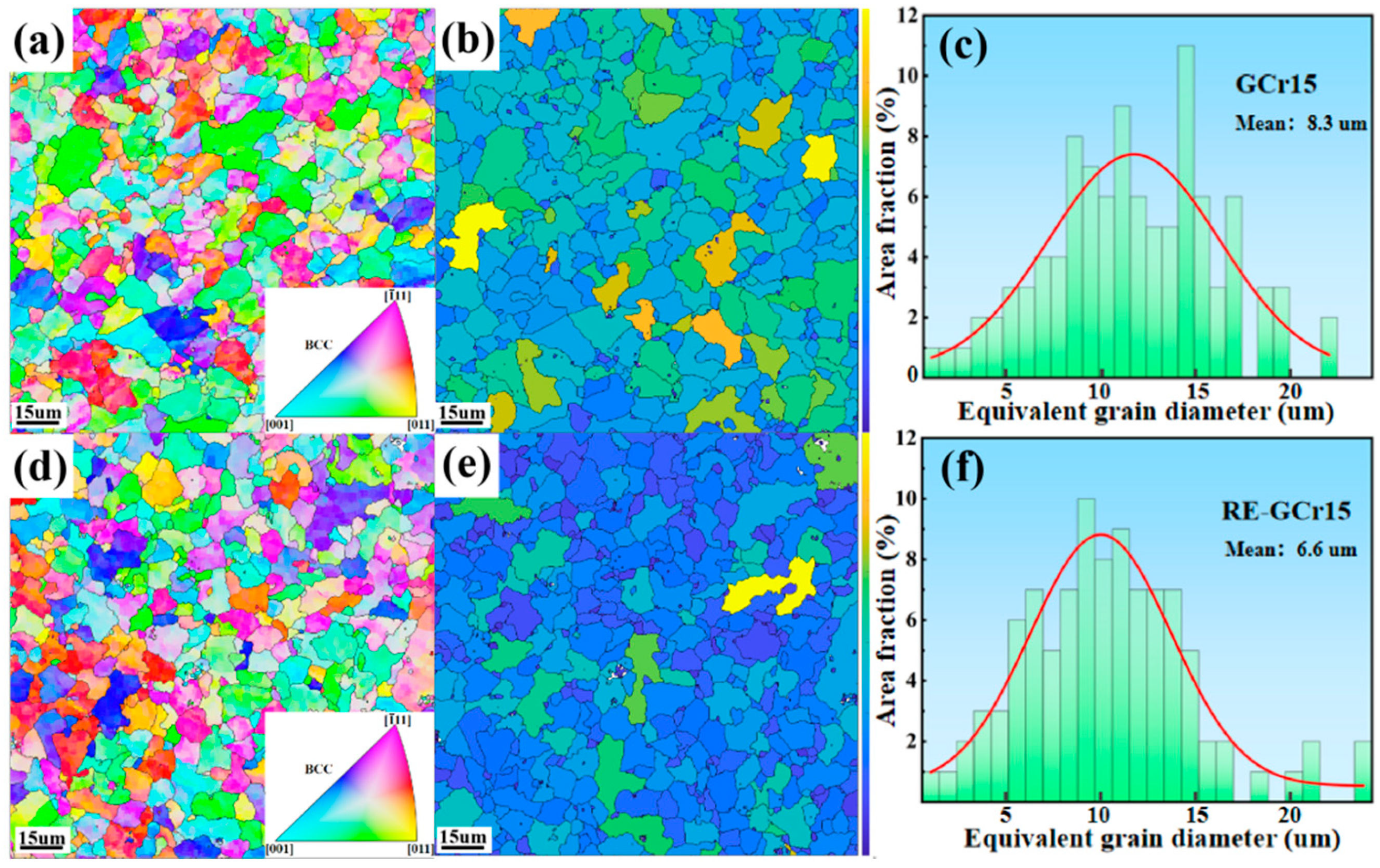

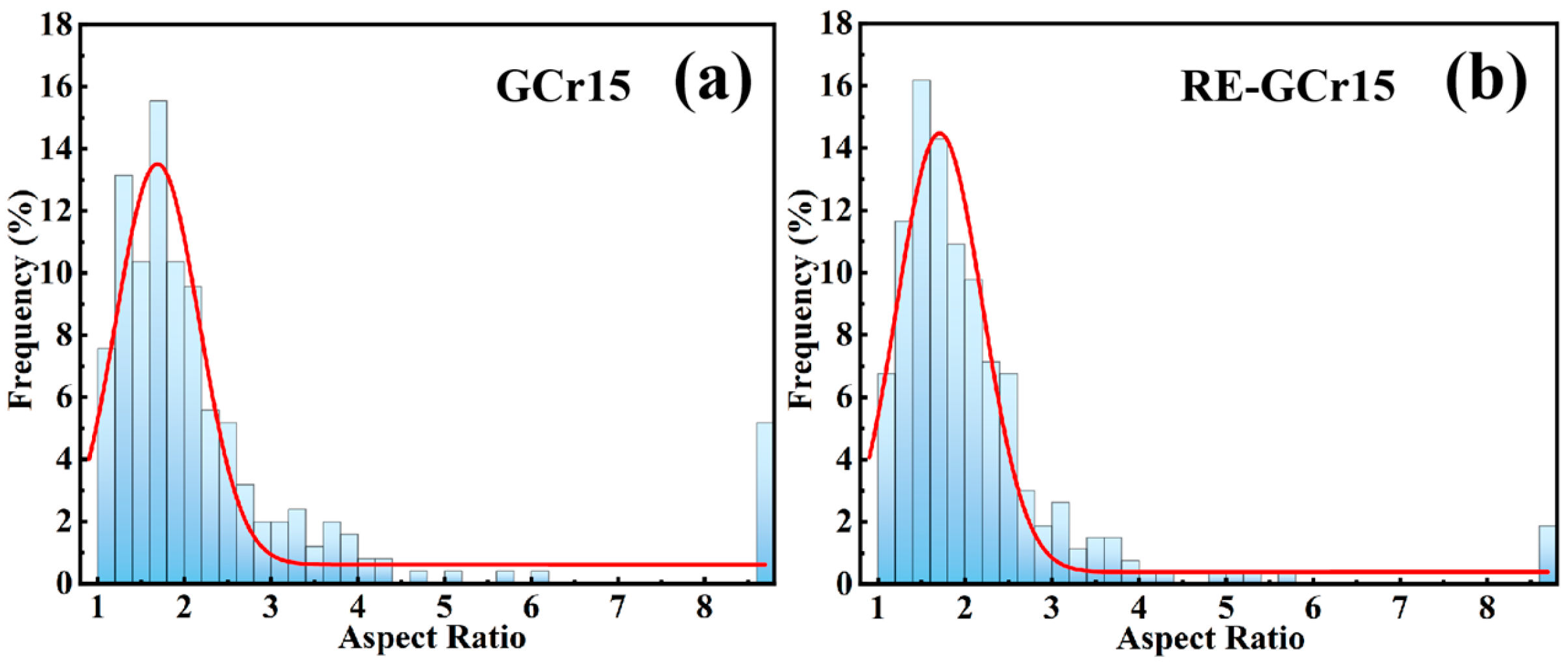

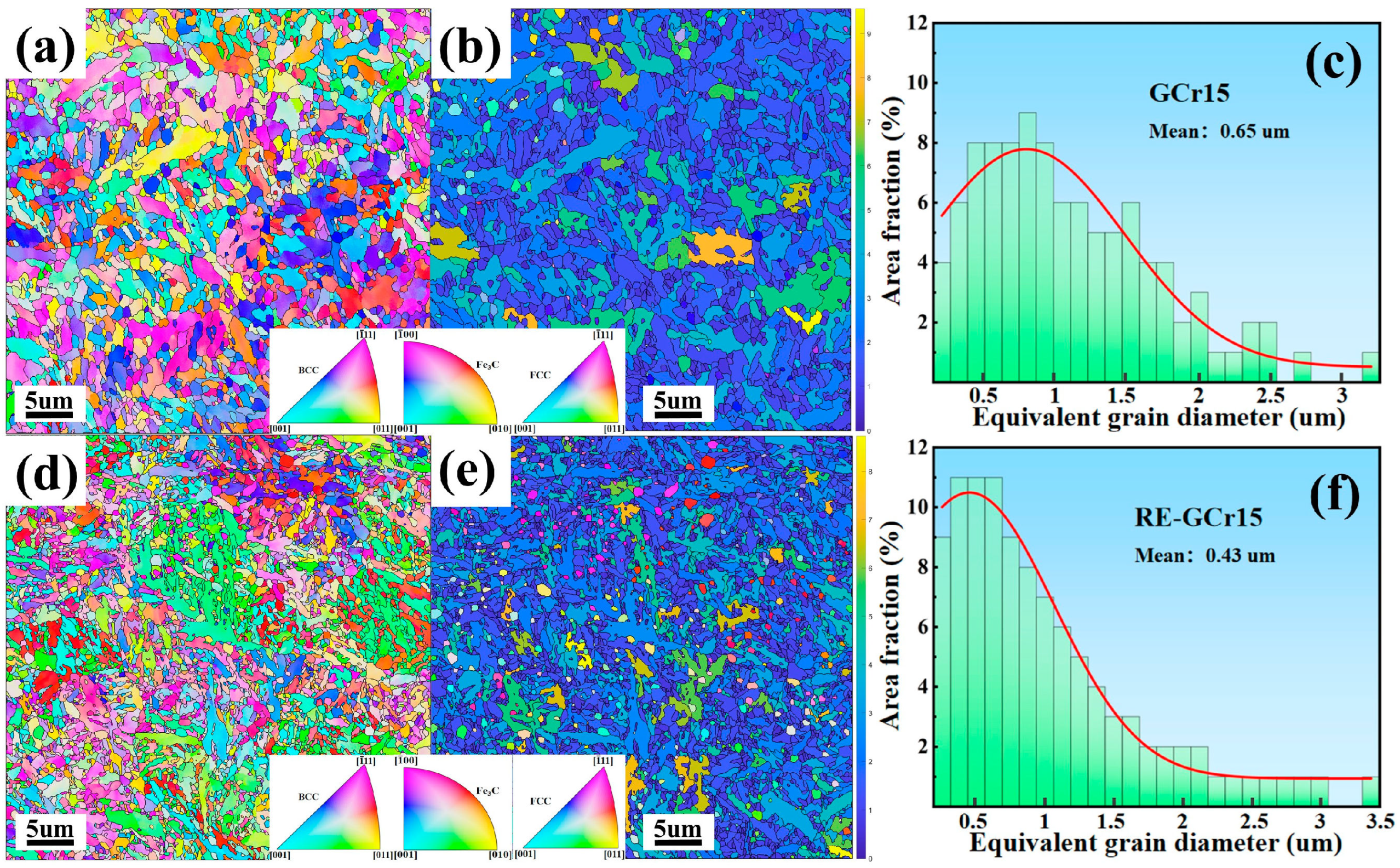

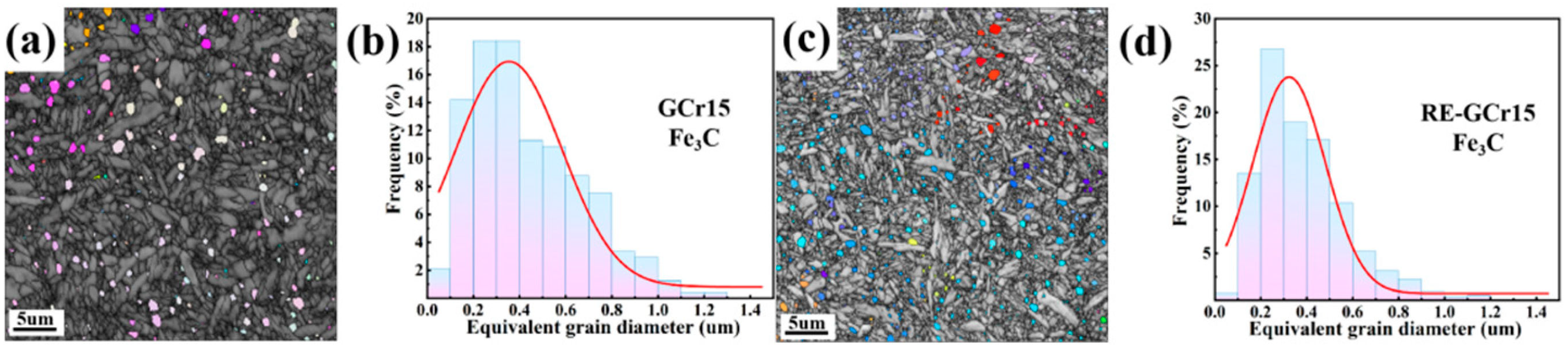

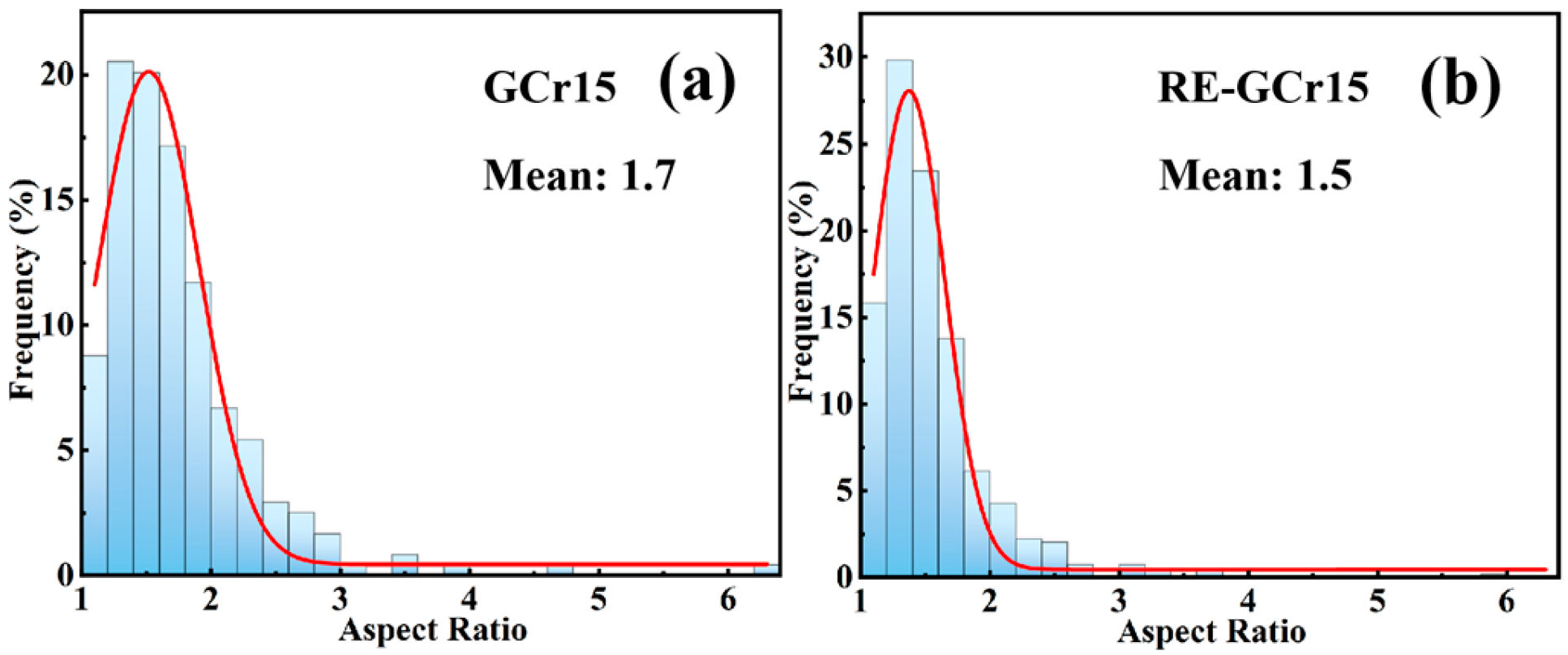

3.1. Phase Analysis and Microstructure

3.2. Mechanical Property

3.2.1. Effect of Rare Earth Y on the Hardness of GCr15 Bearing Steel under Different Heat Treatments

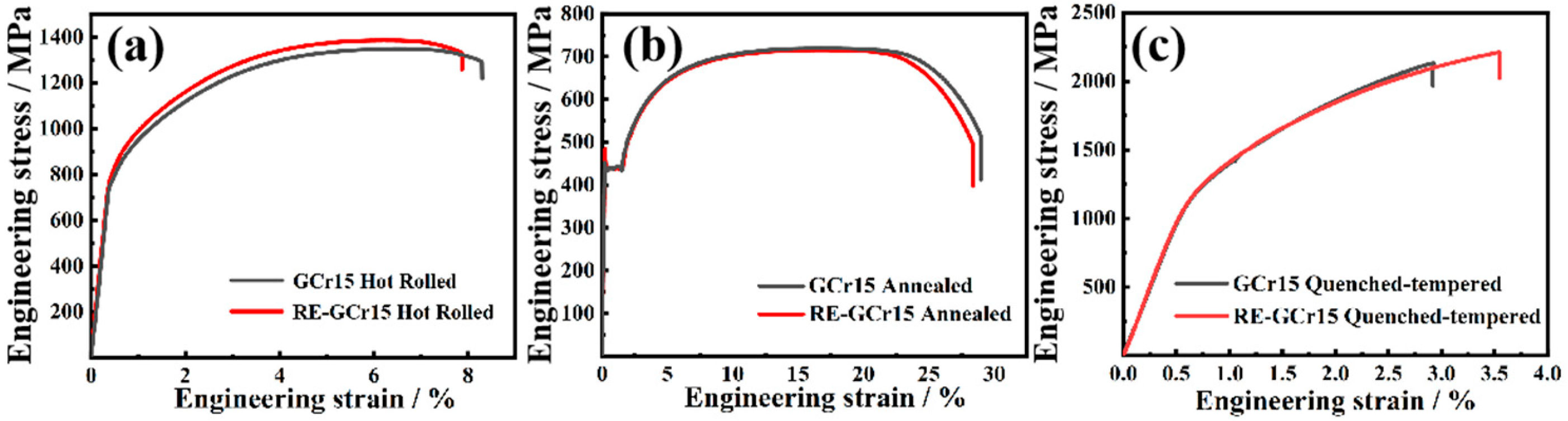

3.2.2. Effect of Rare Earth Y on the Tensile Properties of GCr15 Bearing Steel under Different Heat Treatments

3.2.3. Influence of Rare Earth Y on Impact Properties of GCr15 Bearing Steel under Different Heat Treatments

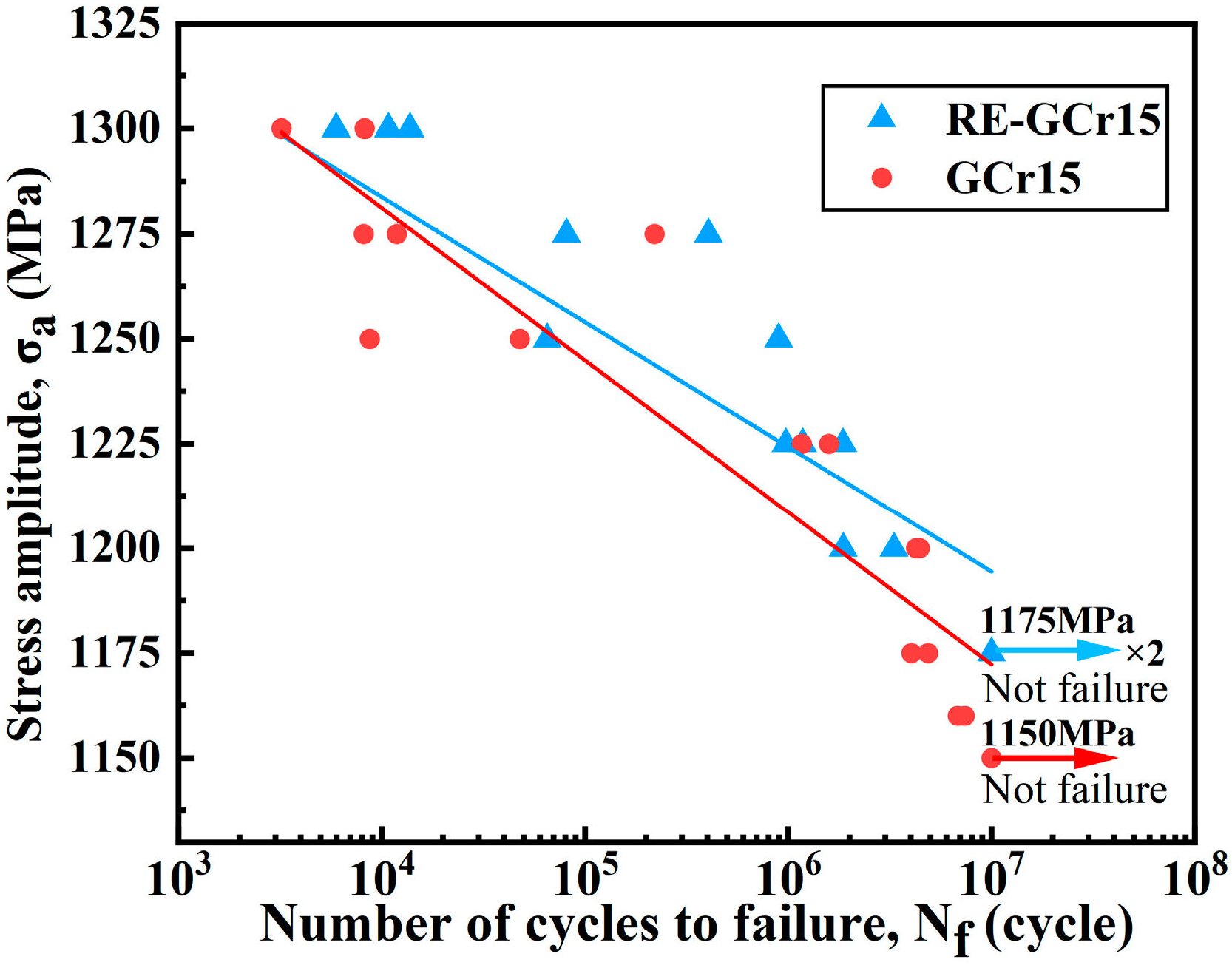

3.3. Effect of Rare Earth Y on Fatigue Properties of GCr15 Bearing Steel

3.3.1. Effect of Rare Earth Y on Fatigue Strength of GCr15 Bearing Steel

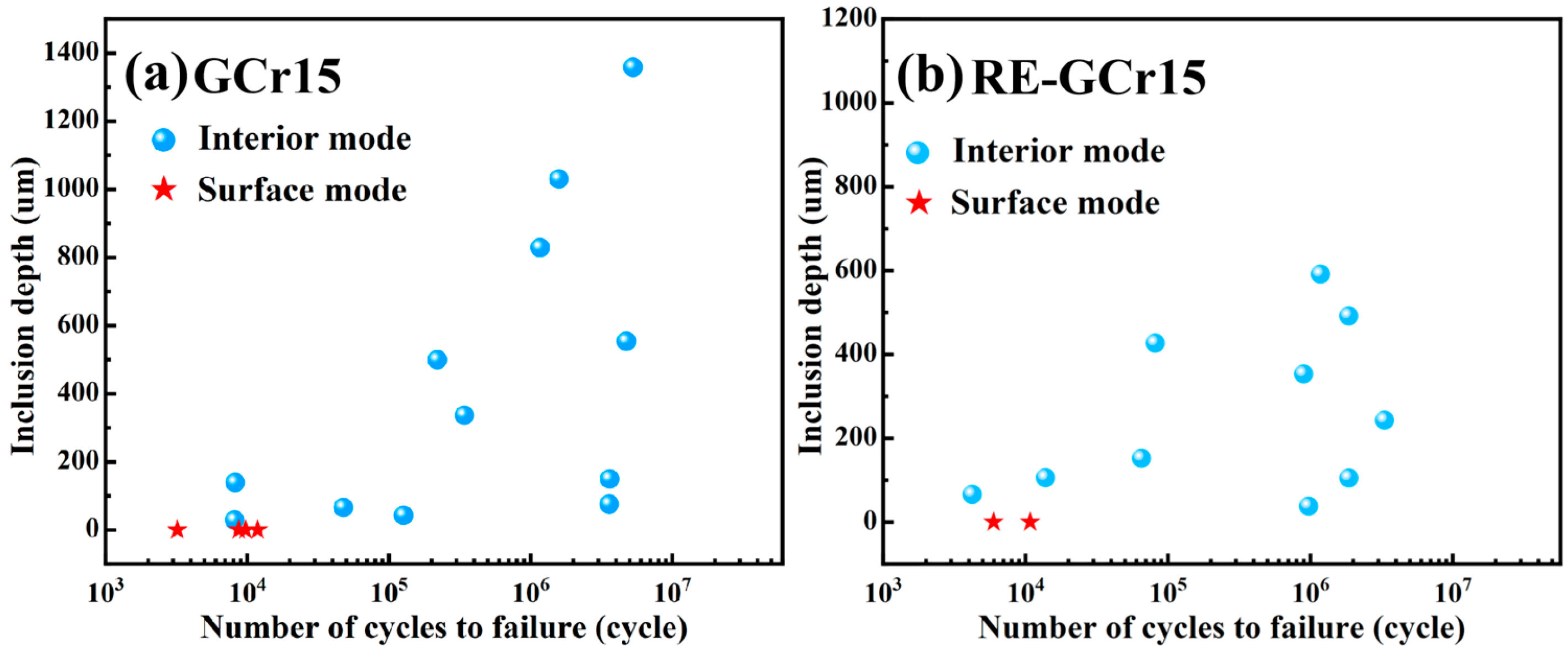

3.3.2. Effect of Rare Earth Y on Fatigue Cracking Mode

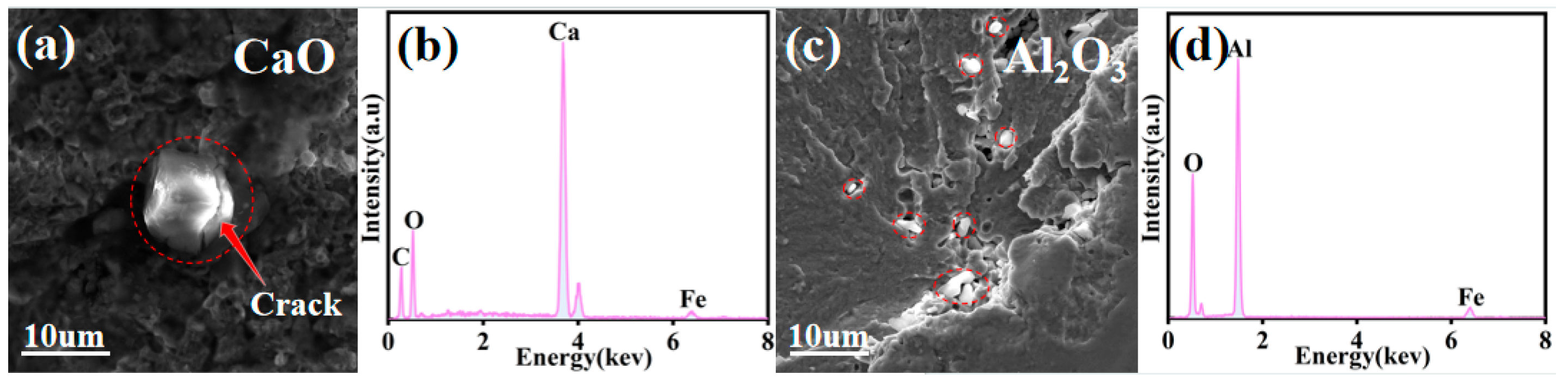

3.3.3. Effect of Inclusion Types on GCr15 Bearing Steel and RE-GCr15 Bearing Steel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.; Wang, Y.; Lin, J.; Xu, S.; Zhang, P. Research status of the influence of machining processes and surface modification technology on the surface integrity of bearing steel materials. Int. J. Adv. Manuf. Technol. 2023, 125, 2897–2923. [Google Scholar] [CrossRef]

- Cao, Y.; Sun, J.; Ma, F.; Chen, Y.; Cheng, X.; Gao, X.; Xie, K. Effect of the microstructure and residual stress on tribological behavior of induction hardened GCr15 steel. Tribol. Int. 2017, 115, 108–115. [Google Scholar] [CrossRef]

- Wu, H.; Han, D.; Du, Y.; Gao, X.; Du, L. Effect of initial spheroidizing microstructure after quenching and tempering on wear and contact fatigue properties of GCr15 bearing steel. Mater. Today Commun. 2022, 30, 103152. [Google Scholar] [CrossRef]

- An, D.; Wei, Y.; Kumar, A.; Ma, S.; Shao, M.; Zheng, H.; Wang, Y.; Xu, P. Dynamic analysis of full-ceramic bearing-rotor system under thermally induced loosening in aerospace applications. Eng. Fail. Anal. 2024, 159, 108080. [Google Scholar] [CrossRef]

- Rejith, R.; Kesavan, D.; Chakravarthy, P.; Murty, S.N. Bearings for aerospace applications. Tribol. Int. 2023, 181, 108312. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, P.; Wang, B.; Zhu, Y.; Xu, Z.; Zhang, Z. Fatigue cracking criterion of high-strength steels induced by inclusions under high-cycle fatigue. J. Mater. Sci. Technol 2023, 154, 114–128. [Google Scholar] [CrossRef]

- Liujian-Hua, C.M. Spheroidization and Ostwald Growth of Carbide in Isothermal Process of Hot—Deformed High Carbon Chromium Cast Steel. J. Iron. Steel Res. Int. 2003, 10, 36–39. [Google Scholar]

- Dyja, H.; Korczak, P. The thermal–mechanical and microstructural model for the FEM simulation of hot plate rolling. J. Mater. Process. Technol. 1999, 92, 463–467. [Google Scholar] [CrossRef]

- Han, H.; Zhao, X.; Zhao, X.; Wan, C.; Wang, W. Effect of proeutectoid carbide on heredity in microstructure-mechanical properties and fatigue life of GCr15 bearing steel. Metall. Res. Technol. 2017, 114, 208. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Zhu, F.; Huang, C.; Zhang, Z.; Xuan, W.; Wang, J.; Ren, Z. Effect of High Magnetic Field in Combination with High-Temperature Tempering on Microstructures and Mechanical Properties of GCr15 Bearing Steel. Metals 2022, 12, 1293. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Solano-Alvarez, W. Critical Assessment 13: Elimination of white etching matter in bearing steels. Mater Sci. Technol. 2015, 31, 1011–1015. [Google Scholar] [CrossRef]

- Chen, P.; Zhu, C.; Li, G.; Dong, Y.; Zhang, Z. Effect of Sulphur Concentration on Precipitation Behaviors of MnS-containing Inclusions in GCr15 Bearing Steels after LF Refining. ISIJ Int. 2017, 57, 1019–1028. [Google Scholar] [CrossRef]

- Huo, X.; Ning, Y.; Li, L.; Lv, Z.; Chen, S. Research and control of network carbide in GCr15 bearing steel. Mater. Res. Express 2020, 7, 016559. [Google Scholar] [CrossRef]

- Huo, X.; Tian, Z.; Li, L.; Liu, N. Effect of Cooling Rate on Microstructure and Transformation Temperature of GCr15 Bearing Steel. In Proceedings of the 2014 International Conference on Materials Science and Energy Engineering (CMSEE 2014), Sanya, China, 12–14 December 2014. [Google Scholar]

- Wang, Y.H.; Yang, Z.N.; Zhang, F.C.; Qin, Y.M.; Wang, X.B.; Lv, B. Microstructures and properties of a novel carburizing nanobainitic bearing steel. Mater. Sci. Eng. A 2020, 777, 139086. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.; Hua, L.; Mao, H.; Xie, L.; Song, X.; Dong, Z. Effect of high magnetic field on the microstructure evolution and mechanical properties of M50 bearing steel during tempering. Mater. Sci. Eng. A 2020, 771, 138623. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Wang, P.; Li, D.; Li, Y. Effect of a modified quenching on impact toughness of 52100 bearing steels. J. Mater. Sci. Technol. 2023, 160, 96–108. [Google Scholar] [CrossRef]

- Oezel, M.; Janitzky, T.; Beiss, P.; Broeckmann, C. Influence of steel cleanliness and heat treatment conditions on rolling contact fatigue of 100Cr6. Wear 2019, 430, 272–279. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, G.; Wang, J.; Yang, W. Evolution of nonmetallic inclusions in GCr15 bearing steels during continuous casting process. Steel Res. Int. 2022, 93, 2100445. [Google Scholar] [CrossRef]

- Zhang, P.; Li, G.; Zhang, J.; Huo, X.; Liu, Y. Effects of refining slag basicity and vacuum treatment on the cleanliness of bearing steel. Vacuum 2024, 222, 112984. [Google Scholar] [CrossRef]

- Feng, A.; Liu, B.; Wei, Y.; Xu, G.; Chen, C.; Pan, X. Microstructure, residual stress, and nanoindentation properties of GCr15-bearing steel by cryogenic treatment and laser-peening composite strengthening. Appl. Phys. A 2023, 129, 228. [Google Scholar] [CrossRef]

- Yue, X.; Hu, S.; Wang, X.; Liu, Y.; Yin, F.; Hua, L. Understanding the nanostructure evolution and the mechanical strengthening of the M50 bearing steel during ultrasonic shot peening. Mater. Sci. Eng. A 2022, 836, 142721. [Google Scholar] [CrossRef]

- Dong, Z.; Wang, F.; Qian, D.; Yin, F.; Wang, H.; Wang, X.; Hu, S.; Chi, J. Enhanced Wear Resistance of the Ultrastrong Ultrasonic Shot-Peened M50 Bearing Steel with Gradient Nanograins. Metals 2022, 12, 424. [Google Scholar] [CrossRef]

- Xue, X.; Xu, S.; Ma, X.; Han, J.; Zheng, W. Surface Microstructure Refinement and Mechanical Properties of GCr15 Steels Improved During Ultrasonic Surface Rolling Processing. Mater. Res. 2023, 26. [Google Scholar] [CrossRef]

- Zhang, L.; Thomas, B.G. State of the art in the control of inclusions during steel ingot casting. Metall. Mater. Trans. B 2006, 37, 733–761. [Google Scholar] [CrossRef]

- Bhadeshia, H. Steels for bearings. Prog. Mater Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Yang, C.; Luan, Y.; Li, D.; Li, Y. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel. J. Mater. Sci. Technol. 2019, 35, 1298–1308. [Google Scholar] [CrossRef]

- Li, Z.; Liu, P.; Yang, C.; Li, X.; Luan, Y.; Li, D. Effect of rare earth elements on microstructure and mechanical properties of bainite/martensite bearing steel. J. Mater. Res. Technol. 2023, 22, 1546–1557. [Google Scholar] [CrossRef]

- Hu, X.; Yang, L.; Wei, X.; Wang, H.; Fu, G. Molecular Dynamics Simulation on Nanoindentation of M50 Bearing Steel. Materials 2023, 16, 2386. [Google Scholar] [CrossRef]

- Dong, Z.; Qian, D.; Yin, F.; Wang, F. Enhanced Impact Toughness of Previously Cold Rolled High-Carbon Chromium Bearing Steel with Rare Earth Addition. J. Mater. Eng. Perform. 2021, 30, 8178–8187. [Google Scholar] [CrossRef]

- Bao, Y.-p.; Gao, S.; Wang, M. Effect of Rare Earth Ce on the Morphology and Distribution of Al2O3 Inclusions in High Strength IF Steel Containing Phosphorus during Continuous Casting and Rolling Process. ISIJ Int. 2021, 61, 657–666. [Google Scholar]

- Tie, Z.-P.; Jiang, X.-Y.; Tang, H.-Y.; Li, G.; Wang, Y.-H.; Zhang, J.-Q. Effect of Al content on modification behavior of non-metallic inclusions in high-strength steel treated with rare earth. J. Iron Steel Res. Int. 2024, 1–14. [Google Scholar] [CrossRef]

- Smirnov, L.; Rovnushkin, V.; Dobuzhskaya, A.; Yunin, G.; Polevoi, E.; Boikov, D.; Spirin, S. Influence of rare-earth modification on the formation of nonmetallic inclusions in high-carbon steel. Steel Transl. 2016, 46, 805–813. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Z.; Fan, J.; Cui, P.; Yu, P.; Jing, Q.; Ma, M.; Liaw, P.; Li, G. Effects of rare-earth element, Y, additions on the microstructure and mechanical properties of CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2018, 725, 437–446. [Google Scholar] [CrossRef]

- Torkamani, H.; Raygan, S.; Garcia Mateo, C.; Rassizadehghani, J.; Palizdar, Y.; San-Martin, D. Tensile Behavior of Normalized Low Carbon Nb-microalloyed Steel in the Presence of Rare Earth Elements. Mater. Sci. Eng. A 2019, 749, 56–64. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, S.; Song, S. Effect of minor rare earth cerium addition on the hot ductility of a reactor pressure vessel steel. Results Phys. 2019, 15, 102746. [Google Scholar] [CrossRef]

- Zhao, Q.; Luo, H.; Pan, Z.; Wang, X.; Cheng, H. Study on mechanical properties of rare earth elements modified high carbon chromium bearing steel. Mater. Today Commun. 2023, 34, 105329. [Google Scholar] [CrossRef]

- GB/T 18254-2016; High-Carbon Chromium Bearing Steel; Beijing, China, Promulgated on 29 August 2016 and implemented on 1 July 2017. China National Standards: Beijing, China, 2016.

- GB/T228.1-2021; Metallic Materials-Tensile Testing Part 1: Method of Test at Room Temperature. China National Standards: Beijing, China, 2021.

- GB/T229-2020; Metallic Materials-Charpy Pendulum Impact Test Method. China National Standards: Beijing, China, 2020.

- GB/T 3075-2021; Metallic Materials-Fatigue Testing-Axial Force-Controlled Method. China National Standards: Beijing, China, 2021.

- Zhao, Q.; Wang, X.; Pan, Z.; Wei, Y.; Cheng, H.; Ma, Y.; Luo, H.; Li, X. Effects of rare earth elements addition on mechanical properties and corrosion behavior of GCr15 bearing steel under different heat treatment conditions. Corros. Commun. 2023, 9, 65–76. [Google Scholar] [CrossRef]

- Gao, X.; Ren, H.; Wang, H.; Chen, M. Activity coefficient and solubility of yttrium in Fe-Y dilute solid solution. J. Rare Earths 2016, 34, 1168–1172. [Google Scholar] [CrossRef]

- Hamidzadeh, M.A.; Meratian, M.; Saatchi, A. Effect of cerium and lanthanum on the microstructure and mechanical properties of AISI D2 tool steel. Mater. Sci. Eng. A 2013, 571, 193–198. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Sang, C.; Wang, P.; Zhang, L.; Li, D. Effects of Rare Earth on the Microstructure and Mechanical Properties of a Pearlitic Steel Wire Rod. Steel Res. Int. 2023, 94, 2300063. [Google Scholar] [CrossRef]

- Wang, M.M.; Zhang, F.C.; Yang, Z.N. Effects of high-temperature deformation and cooling process on the microstructure and mechanical properties of an ultrahigh-strength pearlite steel. Mater. Des. 2017, 114, 102–110. [Google Scholar] [CrossRef]

- Torkamani, H.; Raygan, S.; Garcia Mateo, C.; Rassizadehghani, J.; Palizdar, Y.; San-Martin, D. Contributions of rare earth element (La, Ce) addition to the impact toughness of low carbon cast niobium microalloyed steels. Met. Mater. Int. 2018, 24, 773–788. [Google Scholar] [CrossRef]

- Cheng, X.; Xie, C. Effect of rare earth elements on the erosion resistance of nitrided 40Cr steel. Wear 2003, 254, 415–420. [Google Scholar] [CrossRef]

- Tang, L.; Yan, M. Effects of rare earths addition on the microstructure, wear and corrosion resistances of plasma nitrided 30CrMnSiA steel. Surf. Coat. Technol. 2012, 206, 2363–2370. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, J.; Chen, H.; Su, Y.; Kuo, C.; Su, Y.; Chen, S.; Lin, K.; Hsieh, P.; Hwang, W. Effects of Rare Earth Metals on Steel Microstructures. Materials 2016, 9, 417. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Xu, Y.; Chen, X.; Jiang, X. Effect of rare earth cerium and impurity tin on the hot ductility of a Cr-Mo low alloy steel. J. Rare Earths 2016, 34, 1062–1068. [Google Scholar] [CrossRef]

- Shi, R.; Wang, Z.; Qiao, L.; Pang, X. Microstructure evolution of in-situ nanoparticles and its comprehensive effect on high strength steel. J. Mater. Sci. Technol. 2019, 35, 1940–1950. [Google Scholar] [CrossRef]

- Jian, H.; Jiang, F.; Wei, L.; Zheng, X.; Wen, K. Crystallographic mechanism for crack propagation in the T7451 Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2010, 527, 5879–5882. [Google Scholar] [CrossRef]

- Wang, J.; Guo, W.; Sun, H.; Li, H.; Gou, H.; Zhang, J. Plastic deformation behaviors and hardening mechanism of M7C3 carbide. Mater. Sci. Eng. A 2016, 662, 88–94. [Google Scholar] [CrossRef]

- Lin, Q.; Ye, W.; Du, Y.; Yu, Z. Behaviour of rare earths in solid solution in steel. J. Mater. Sci. Technol. 1990, 6, 415–420. [Google Scholar]

- Zhou, L.; Tang, L.; Miao, D.; Sun, W.; Huang, H. Rare earth alloying and its effect on law of precipitation of V and Nb precipitated phase. Res. Iron Steel 2001, 4, 10–13. [Google Scholar]

- Ji, J.; Che, Y.; Liu, A.; Lu, X.; You, M. Research and theory in internal friction of alloying of rare earth in iron and steel. J. Rare Earths 1996, 14, 350–359. [Google Scholar]

- Zehong, J. A Study on Rare Earth Metal Microalloying of Alloy Steel. Spec. Steel 1997, 18, 5–8. [Google Scholar]

- Chu, R.; Fan, Y.; Li, Z.; Liu, J.; Yin, N.; Hao, N. Study on the control of rare earth metals and their behaviors in the industrial practical production of Q420q structural bridge steel plate. Metals 2018, 8, 240. [Google Scholar] [CrossRef]

- Shenhua, S.; Huajun, S.; Meng, W. Effect of rare earth cerium on brittleness of simulated welding heat-affected zones in a reactor pressure vessel steel. J. Rare Earths 2015, 33, 1204–1211. [Google Scholar]

- Yuan, Z.; Guo, A.; Liu, J.; Shen, D.; Jia, J.; Song, S. Antimony grain boundary segregation and its suppression by cerium in Fe-2% Mn-Sb structural steels. Acta Metall. Sin. 2003, 16, 175–182. [Google Scholar]

- Liu, G.; Zhang, G.; Li, R. Electronic theoretical study of the interaction between rare earth elements and impurities at grain boundaries in steel. J. Rare Earths 2003, 21, 372–374. [Google Scholar]

- Zhang, D.; Wu, C.; Yang, R. Interaction between cerium and phosphorus segregating in the grain boundaries in α-Fe studied by computer modelling and Auger electron spectroscopy. Mater. Sci. Eng. A 1991, 131, 93–97. [Google Scholar] [CrossRef]

- Ma, J.; Liu, F. Application of rare earth element in steel and its influence on steel properties. Res. Iron Steel 2009, 3, 54–56. [Google Scholar]

- Liu, X.; Yang, J.; Zhang, F.; Fu, X.; Li, H.; Yang, C. Experimental and DFT study on cerium inclusions in clean steels. J. Rare Earths 2021, 39, 477–486. [Google Scholar] [CrossRef]

- Chakraborty, J.; Bhattacharjee, D.; Manna, I. Development of ultrafine bainite+ martensite duplex microstructure in SAE 52100 bearing steel by prior cold deformation. Scr. Mater. 2009, 61, 604–607. [Google Scholar] [CrossRef]

| Steels | C | Si | Mn | Cr | Al | P | S | Y | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0RE | 0.95 | 0.28 | 0.36 | 1.56 | 0.055 | 0.006 | 0.001 | 0 | Bal. |

| RE | 0.95 | 0.27 | 0.36 | 1.55 | 0.050 | 0.006 | 0.001 | 0.013 | Bal. |

| Steels | Average Size of Carbide (um) | Volume Fraction of Carbide (%) | Volume Fraction of Retained Austensite (%) | Volume Fraction of Martensite (%) |

|---|---|---|---|---|

| GCr15 | 0.44 (0.41~0.47) | 5.2% | 1.3% | 93.5% |

| RE-GCr15 | 0.38 (0.37~0.40) | 6.3% | 3.4% | 90.3% |

| Heat Treatment Conditions | Yield Limit (MPa) | Tensile Limit (MPa) | ||

|---|---|---|---|---|

| GCr15 | RE-GCr15 | GCr15 | RE-GCr15 | |

| Hot rolled | 845 (842~851) | 900 (895~902) | 1349 (1347~1351) | 1387 (1385~1388) |

| Annealed | 431 (431~435) | 431 (430~435) | 721 (717~721) | 715 (713~716) |

| Quenched and tempered | 1320 (1319~1324) | 1335 (1328~1342) | 2134 (2129~2139) | 2217 (2213~2221) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Liu, L.; Yang, Q.; Zhou, W.; Luo, D.; Jiang, C.; Yin, B.; Lai, C. Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel. Metals 2024, 14, 372. https://doi.org/10.3390/met14040372

Xu W, Liu L, Yang Q, Zhou W, Luo D, Jiang C, Yin B, Lai C. Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel. Metals. 2024; 14(4):372. https://doi.org/10.3390/met14040372

Chicago/Turabian StyleXu, Wenwen, Luhua Liu, Qing Yang, Wei Zhou, Diqiang Luo, Cunchang Jiang, Binbing Yin, and Chaobin Lai. 2024. "Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel" Metals 14, no. 4: 372. https://doi.org/10.3390/met14040372

APA StyleXu, W., Liu, L., Yang, Q., Zhou, W., Luo, D., Jiang, C., Yin, B., & Lai, C. (2024). Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel. Metals, 14(4), 372. https://doi.org/10.3390/met14040372