Study on the Bronze Weapons Excavated from Xichuan, China

Abstract

:1. Introduction

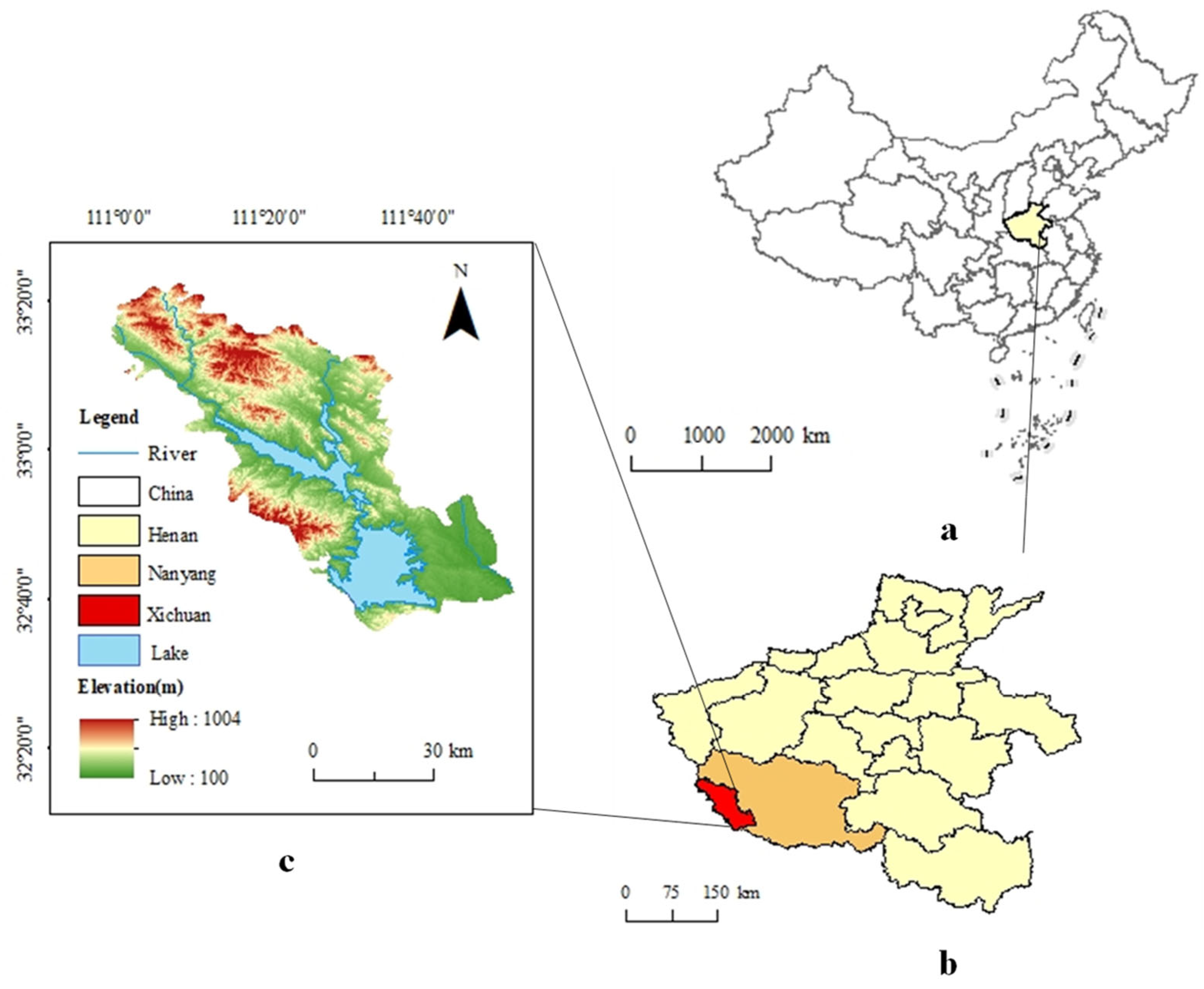

2. Materials and Methods

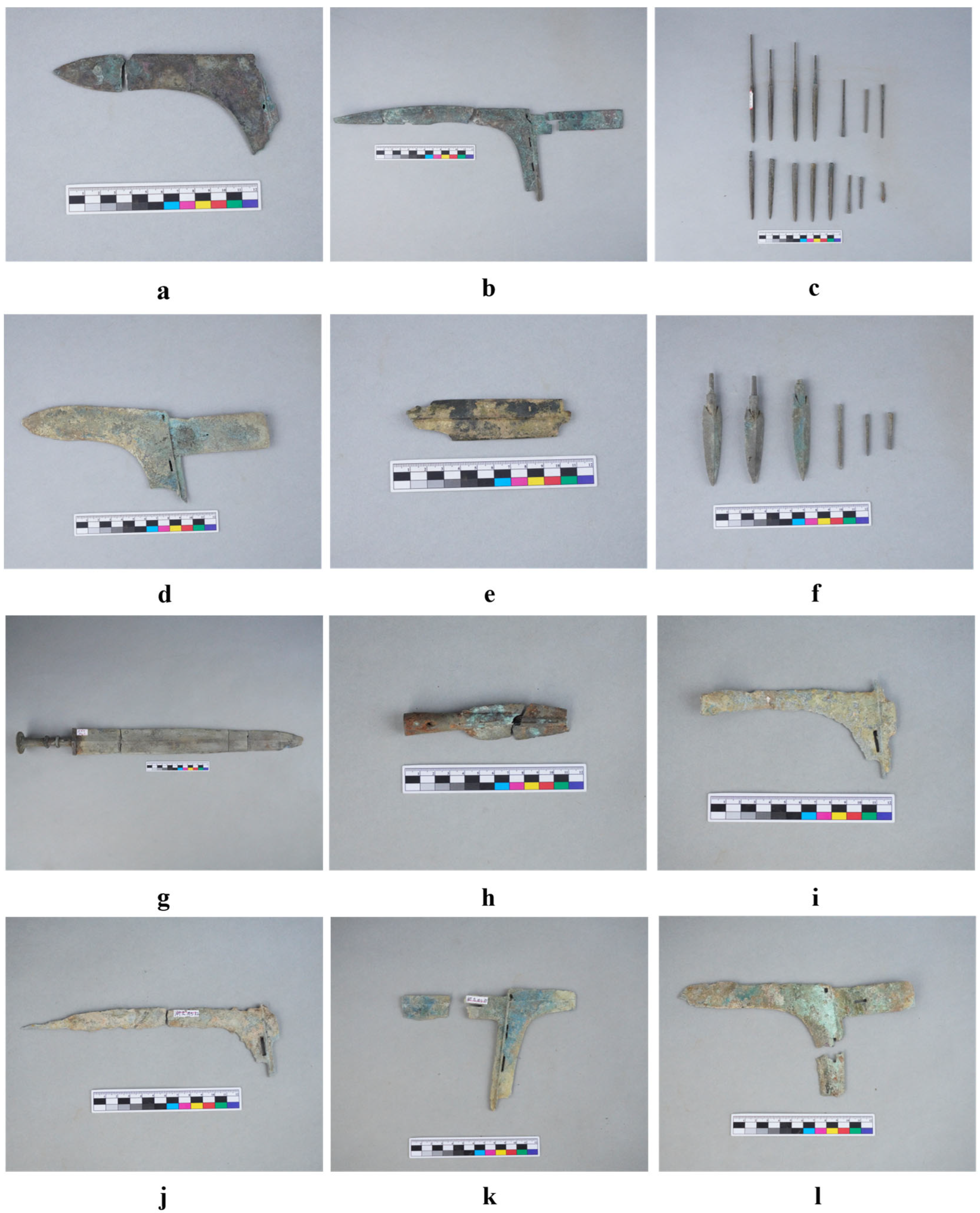

2.1. Materials

| No. | Bronze Vessel | Vessel No. | Sample No. | Size (cm) | Weight (kg) | |

|---|---|---|---|---|---|---|

| Length | Breadth | |||||

| 1 | Dagger-axe | M3:7 | XCJX1 | 13.7 | - | 0.08 |

| 2 | Dagger-axe | M3:30 | XCJX2 | 33.8 | 11.8 | 0.24 |

| 3 1 | Arrowhead | M3:32 | XCJX3 | 6.7 | - | 0.16 |

| 4 | Dagger-axe | M3:37 | XCJX4 | 21.2 | 7.9 | 0.20 |

| 5 | Spearhead | M3:58 | XCJX5 | 9.9 | - | 0.03 |

| 6 2 | Arrowhead | M3:59 | XCJX6 | 8.8 | - | 0.12 |

| 7 | Sword | M4:9 | XCJX7 | 54.3 | - | 0.84 |

| 8 | Spearhead | M4:19 | XCJX8 | 11.4 | - | 0.03 |

| 9 | Dagger-axe | M5:31 | XCJX9 | 13.0 | 6.7 | 0.04 |

| 10 | Dagger-axe | M5:32 | XCJX10 | 22.0 | 6.3 | 0.06 |

| 11 | Dagger-axe | M5:33 | XCJX11 | 10.6 | 11.0 | 0.08 |

| 12 | Dagger-axe | M11:10 | XCJX12 | 21.0 | 9.0 | 0.10 |

2.2. Experimental Instruments and Testing Methods

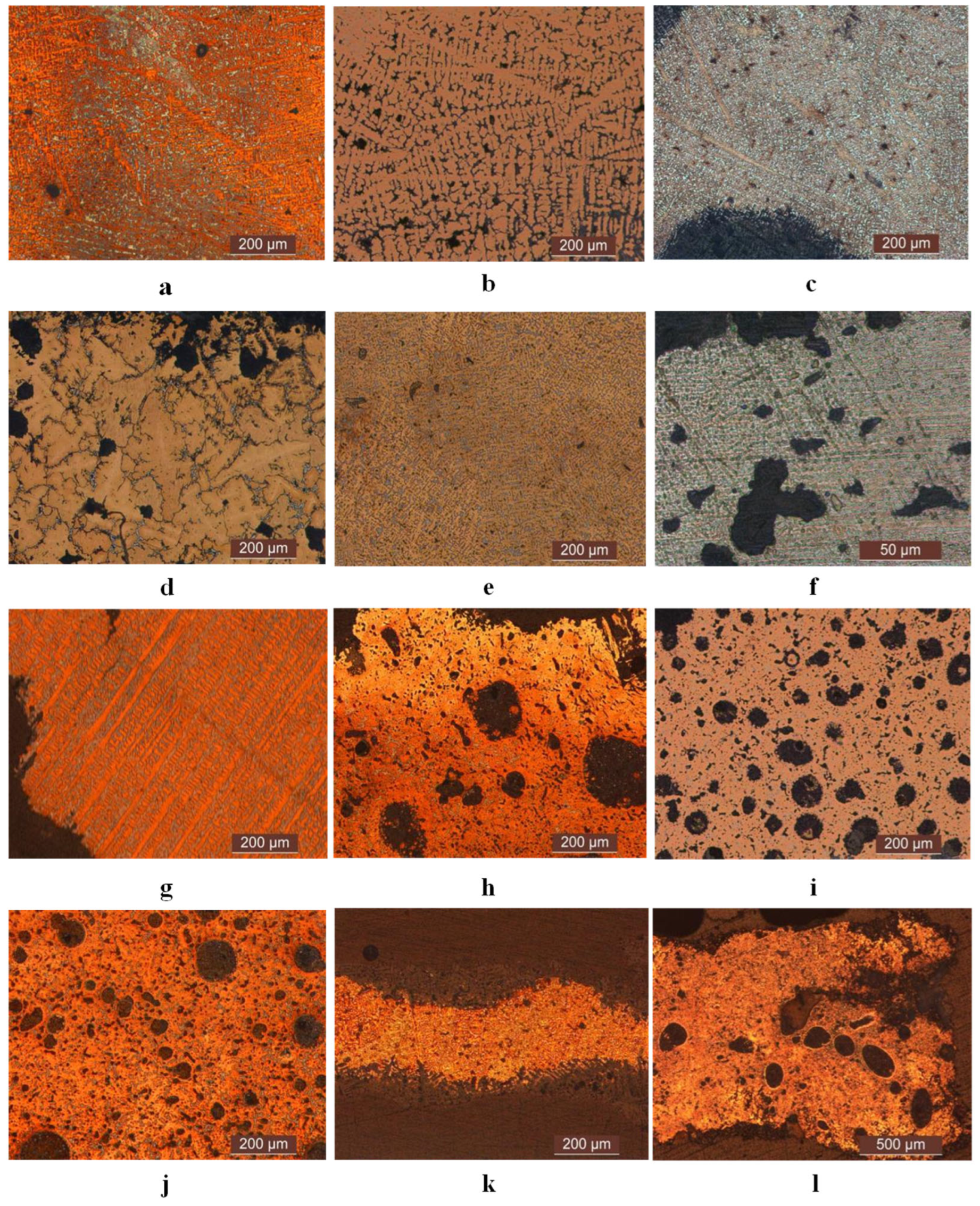

2.2.1. Metallographic Analysis

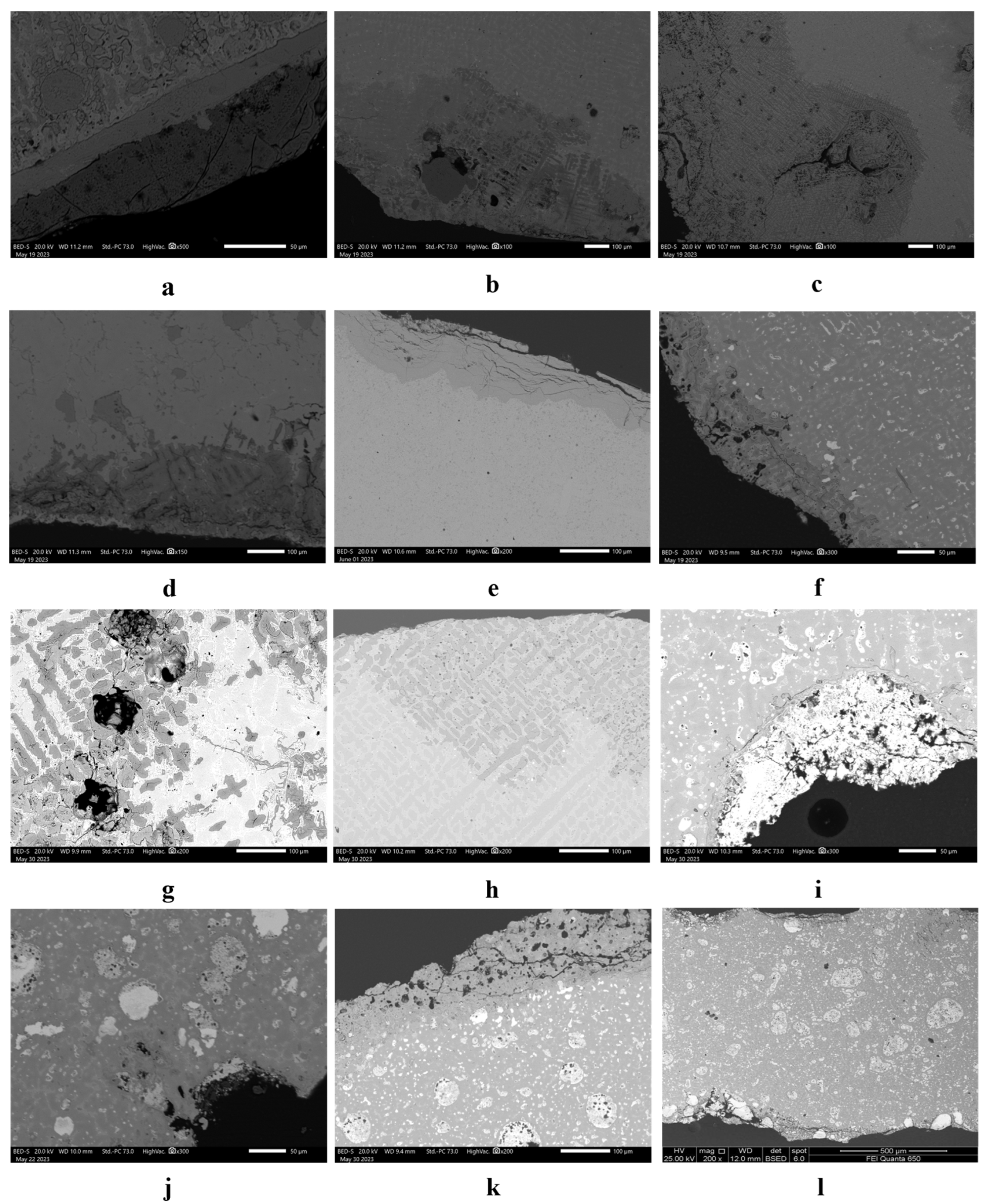

2.2.2. Scanning Electron Microscopy and Energy-Dispersive X-ray Spectroscopy (SEM-EDS) Analysis

3. Results and Discussion

3.1. Types and Uses of Bronze Weapons

3.2. Matrix Structure Analysis

4. Conclusions

- (1)

- The bronze weapons unearthed from the Guozhuang site date back to the mid-Warring States period. The period of the manufacture and use of bronze weapons is relatively close to the burial period of the tombs.

- (2)

- Severe corrosion was evident on the bronze weapons from the Xichuan site, primarily corroding the copper-rich α phase. The preservation conditions were suboptimal, highlighting the necessity for protective measures.

- (3)

- All the bronze weapons from the Guozhuang site were cast. Notably, the bronze dagger-axe (M3:37) underwent secondary heating after casting.

- (4)

- Among the 12 samples, half were tin–bronze and half were tin–lead bronze, with the tin content in the tin–bronze being mostly around 12%. The copper–tin and copper–tin–lead ratios demonstrated a certain scientific consistency.

- (5)

- The alloys of bronze weapons with similar shapes and functions exhibited relatively consistent compositions, some of which aligned with the alloy ratios mentioned in the Rites of Zhou–Kaogongji. This indicates a level of technological uniformity during that period and a recognition of bronze alloys.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.P.; Wang, P.; Yan, M.J.; Ma, B.; Cao, R.X. Source apportionment of soil heavy metals based on multivariate statistical analysis and the PMF model: A case study of the Nanyang Basin, China. Environ. Technol. Innov. 2024, 33, 103537. [Google Scholar] [CrossRef]

- Sun, K.; He, W.B.; Shen, Y.F.; Yan, T.S.; Liu, C.; Yang, Z.Z.; Han, J.M.; Xie, W.S. Ecological security evaluation and early warning in the water source area of the Middle Route of South-to-North Water Diversion Project. Sci. Total Environ. 2023, 868, 161561. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.S.; Zhao, T.Q.; Xiao, C.Y.; Guo, X.M.; Chen, F.H. Isotopic characteristics and source analysis of atmospheric ammonia during agricultural periods in the Xichuan area of the Danjiangkou Reservoir. J. Environ. Sci. 2024, 136, 460–469. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.P.; Chen, B.C. Asia, East: China, Bronze Age Civilizations. In Encyclopedia of Archaeology, 2nd ed.; Academic Press: Cambridge, MA, USA, 2024; pp. 1–18. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, A.C.; Jin, Z.Y.; Liu, L.; Li, Y.; Fan, Z.Y.; Wu, X.Y.; Yang, M.; Huang, F. Scientific analysis and research on the Warring States bronze mirrors unearthed from Changsha Chu cemetery, Hunan province, China. Archaeometry 2022, 64, 1187–1201. [Google Scholar] [CrossRef]

- Wood, J.R.; Liu, Y.A. Multivariate Approach to Investigate Metallurgical Technology: The Case of the Chinese Ritual Bronzes. J. Archaeol. Method. Theory 2023, 30, 707–756. [Google Scholar] [CrossRef]

- Luo, W.G.; Song, G.D.; Hu, Y.Q.; Chen, D. Tentative determination of a special bronze material by multiple technological test on a xuan-liu dagger-axe from the Xujialing Site, the Eastern Zhou period, Henan Province, China. J. Cult. Herit. 2020, 46, 304–312. [Google Scholar] [CrossRef]

- Wang, X.T.; Yang, Y.D.; Wang, T.Y.; Luo, W.G. Subdivision of culture and resources: Raw material transformation and cultural exchange reflected by bronze poleaxes from the Warring States sites in the Chengdu Plain. Archaeol. Anthropol. Sci. 2022, 14, 121. [Google Scholar] [CrossRef]

- Cantini, F.; Scherillo, A.; Fedrigo, A.; Galeotti, M.; Cagnini, A.; Porcinai, S.; Patera, A.; Morandini, F.; Grazzi, F. The Vittoria Alata from Brescia: A combined neutron techniques and SEM-EDS approach to the study of the alloy of a bronze Roman statue. J. Archaeol. Sci. Rep. 2023, 51, 104112. [Google Scholar] [CrossRef]

- Nerantzis, N.; Papadopoulos, S. Tools and jewels: An analytical study of copper-alloy artefacts from Early Bronze Age Thasos, north Aegean. J. Archaeol. Sci. Rep. 2023, 51, 104154. [Google Scholar] [CrossRef]

- Cantisani, E.; Salvioli, N.; Salvadori, B. Polychrome Bronze Sculpture: A Multi-Analytical Approach to Unveil the Renaissance Gilded Eagles in the Abbey of San Miniato al Monte, Florence. Heritage 2024, 7, 983–996. [Google Scholar] [CrossRef]

- Porcaro, M.; Barbaro, B.; Canovaro, C.; Artioli, G.; Lucarelli, C.; Lugli, F.; Depalmas, A.; Brunetti, A. A multi analytical characterization of a small bronze figurine from Gran Carro site (Bolsena Lake, Italy). J. Archaeol. Sci. Rep. 2023, 51, 104230. [Google Scholar] [CrossRef]

- Yu, Y.B.; Mei, J.J.; Chen, K.L.; Xiang, G.H.; Zhao, D.X.; Xiao, C.Y. Scientific study of bronze bells of the Western Zhou period recovered in Yichang, Hubei. J. Cult. Herit. 2022, 56, 85–95. [Google Scholar] [CrossRef]

- Ma, D.; Luo, W.G.; Qin, Y.; Chen, D.; Huang, F.H.; Wang, C.S. Study on the casting cores to identify the manufacturing place of Chinese bronze vessels excavated in the Qiaojiayuan tombs from Spring and Autumn period. Archaeol. Anthropol. Sci. 2020, 12, 203. [Google Scholar] [CrossRef]

- Wen, Y.D.; Shi, Y.; Li, W.C.; Ma, Y.R.; Yang, C.Y. Art and technique of Cuojinyin: Two belt hooks from luoyang of eastern zhou dynasty. J. Archaeol. Sci. Rep. 2023, 51, 104163. [Google Scholar] [CrossRef]

- Witasiak, D.; Garbacz-Klempka, A.; Papaj, M.; Papaj, P.; Maj, M.; Piękoś, M.; Kozana, J. Effect of Alloying Additives and Moulding Technology on Microstructure, Tightness, and Mechanical Properties of CuSn10 Bronze. Materials 2023, 16, 7593. [Google Scholar] [CrossRef]

- Manu, K.; Jezierski, J.; Ganesh, M.R.S.; Shankar, K.V.; Narayanan, S.A. Titanium in Cast Cu-Sn Alloys-A Review. Materials 2021, 14, 4587. [Google Scholar] [CrossRef]

- Ren, X.Y.; Zhang, G.W.; Xu, H.; Wang, Z.J.; Liu, Y.J.; Sun, F.E.; Kang, Y.Y.; Wang, M.J.; Lv, W.Z.; Yin, Z. Effects of B on the Structure and Properties of Lead-Tin Bronze Alloy and the Mechanism of Strengthening and Toughening. Materials 2021, 14, 7806. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Cui, J.F. Revisiting the addition of tin and lead in Chinese bronzes: A statistical perspective. Adv. Archaeomater. 2022, 3, 78–85. [Google Scholar] [CrossRef]

- Pollard, A.M.; Zhang, Y.; Liu, R.L. Bronze alloying recipes at Anyang during the Shang Dynasty. Archaeol. Anthropol. Sci. 2023, 15, 156. [Google Scholar] [CrossRef]

- Liu, R.L.; Pollard, A.M. Squeezing mind out of metal: Combining textual evidence with scientific data for metallurgy in early dynastic China. Archaeol. Anthropol. Sci. 2022, 14, 117. [Google Scholar] [CrossRef]

- Figueiredo, E.; Rodrigues, A.; Fonte, J.; Meunier, E.; Dias, F.; Lima, A.; Gonçalves, J.A.; Gonçalves-Seco, L.; Gonçalves, F.; Pereira, M.F.C.; et al. Tin and Bronze Production at the Outeiro de Baltar Hillfort (NW Iberia). Minerals 2022, 12, 758. [Google Scholar] [CrossRef]

- Panagopoulou, A.; Karydas, A.G.; Banou, E. Chemical analysis of bronze votives from the Minoan peak sanctuary at Ayios Yeoryios Sto Vouno, Kythera. J. Archaeol. Sci. Rep. 2024, 53, 104314. [Google Scholar] [CrossRef]

- Liu, L.; Zhong, Q.; Jiang, L.M.; Li, P.; Xiao, L.; Gong, Y.M.; Zhu, Z.Y.; Yang, J.C. Metallurgical and corrosion characterization of warring states period bronzes excavated from Pujiang, Chengdu, China. Herit. Sci. 2022, 10, 36. [Google Scholar] [CrossRef]

- Manti, P.; Watkinson, D. Corrosion phenomena and patina on archaeological low-tin wrought bronzes: New data. J. Cult. Herit. 2022, 55, 158–170. [Google Scholar] [CrossRef]

- Cohen, M.; Inberg, A.; Ashkenazi, D.; Cvikel, D. What You Clean Is What You Get: A Novel Chemical Cleaning Technique and the Interpretation of Corrosion Products Found in Late Roman Copper Alloy Coins Retrieved from the Sea. Heritage 2022, 5, 3628–3647. [Google Scholar] [CrossRef]

- Wang, X.Y.; Song, J.L.; Zhou, H.; Fan, Z.H.; Shi, J.R.; Chen, J.C.; Xiao, K. Mechanism of dendrite segregation on corrosion behaviour of antique cast low Sn bronze. Corros. Sci. 2023, 222, 111402. [Google Scholar] [CrossRef]

- Pagano, S.; Balassone, G.; Germinario, C.; Grifa, C.; Izzo, F.; Mercurio, M.; Munzi, P.; Pappalardo, L.; Spagnoli, E.; Verde, M.; et al. Archaeometric Characterisation and Assessment of Conservation State of Coins: The Case-Study of a Selection of Antoniniani from the Hoard of Cumae (Campania Region, Southern Italy). Heritage 2023, 6, 2038–2055. [Google Scholar] [CrossRef]

- Kwon, H. Corrosion Behaviors of Artificial Chloride Patina for Studying Bronze Sculpture Corrosion in Marine Environments. Coatings 2023, 13, 1630. [Google Scholar] [CrossRef]

- Muşkara, Ü.; Aras, O.; Işıklı, M. Chemical analyses of Urartian bronze objects from the Ayanis fortress. J. Archaeol. Sci. Rep. 2023, 49, 104018. [Google Scholar] [CrossRef]

- Garbacz-Klempka, A.; Piękoś, M.; Kozana, J.; Perek-Nowak, M.; Wardas-Lasoń, M.; Silska, P.; Stróżyk, M. Bronze Age Raw Material Hoard from Greater Poland: Archaeometallurgical Study Based on Material Research, Thermodynamic Analysis, and Experiments. Materials 2024, 17, 230. [Google Scholar] [CrossRef]

| No. | Sample No. | Vessel No. | Main Element Content (Wt%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Cl | Si | S | Nb | |||

| 1 | XCJX1 | M3:7 | 41.82 ± 0.39 | 46.88 ± 0.31 | 9.16 ± 0.22 | 0.85 ± 0.04 | 0.77 ± 0.05 | 0.53 ± 0.04 | - |

| 2 | XCJX2 | M3:30 | 86.87 ± 0.80 | 13.12 ± 0.26 | - | - | - | - | - |

| 3 | XCJX3 | M3:32 | 87.95 ± 0.87 | 12.04 ± 0.28 | - | - | - | - | - |

| 4 | XCJX4 | M3:37 | 86.13 ± 0.85 | 13.86 ± 0.28 | - | - | - | - | - |

| 5 | XCJX5 | M3:58 | 73.07 ± 0.54 | 26.93 ± 0.26 | - | - | - | - | - |

| 6 | XCJX6 | M3:59 | 77.13 ± 0.75 | 14.87 ± 0.27 | 6.90 ± 0.28 | - | - | - | 1.11 ± 0.15 |

| 7 5 | XCJX7 | M4:9 | 74.27 | 25.73 | - | - | - | - | - |

| 8 | XCJX8 | M4:19 | 86.80 ± 0.64 | 13.20 ± 0.27 | - | - | - | - | - |

| 9 | XCJX9 | M5:31 | 76.61 ± 0.73 | 13.74 ± 0.26 | 9.65 ± 0.29 | - | - | - | - |

| 10 | XCJX10 | M5:32 | 60.99 ± 0.55 | 10.05 ± 0.20 | 28.96 ± 0.37 | - | - | - | - |

| 11 | XCJX11 | M5:33 | 58.92 ± 0.60 | 11.92 ± 0.24 | 27.92 ± 0.41 | - | 1.25 ± 0.07 | - | - |

| 12 | XCJX12 | M11:10 | 75.05 ± 1.52 | 6.79 ± 0.58 | 17.94 ± 2.81 | - | 0.22 ± 0.16 | - | - |

| No. | Sample No. | Vessel No. | Results of Metallographic Structure Observation | Production Method |

|---|---|---|---|---|

| 1 | XCJX1 | M3:7 | α-solid-solution dendritic-segregation structure; numerous (α + δ) eutectic phases interconnected in a reticular pattern; and lead distributed unevenly in fine granular, large ellipsoidal, and irregular shapes. | Casting |

| 2 | XCJX2 | M3:30 | α-solid-solution dendritic-segregation structure; numerous (α + δ) eutectic phases interconnected in a reticular pattern with fine dendrites. | Casting |

| 3 | XCJX3 | M3:32 | α-solid-solution dendritic-segregation structure; a large number of (α + δ) eutectic phases distributed in an island-like pattern; and casting shrinkage cavities. | Casting |

| 4 | XCJX4 | M3:37 | α-solid-solution appeared in a granular form; (α + δ) eutectic phases were distributed along grain boundaries; and there was severe corrosion at the grain boundaries. | Subjected to heat after casting |

| 5 | XCJX5 | M3:58 | α-solid-solution dendritic-segregation structure; numerous (α + δ) eutectic phases interconnected in a reticular pattern. | Casting |

| 6 | XCJX6 | M3:59 | α-solid-solution dendritic-segregation structure; a large number of (α + δ) eutectic phases distributed in an island-like pattern; and lead was unevenly distributed in fine granular and large ellipsoidal shapes. | Casting |

| 7 | XCJX7 | M4:9 | α-solid-solution dendritic segregation structure; numerous (α + δ) eutectic phases interconnected in a reticular pattern. | Casting |

| 8 | XCJX8 | M4:19 | α-solid-solution dendritic-segregation structure; a large number of (α + δ) eutectic phases distributed in an island-like pattern. | Casting |

| 9 | XCJX9 | M5:31 | α-solid-solution dendritic-segregation structure; a large number of (α + δ) eutectic phases distributed in an island-like pattern; and lead was unevenly distributed in fine granular and large ellipsoidal shapes. | Casting |

| 10 | XCJX10 | M5:32 | The matrix was severely corroded and mineralized, with preferential corrosion of the α phase. Most of the α-phase grain boundaries were severely corroded, intertwining into a reticular pattern. Residual α-solid-solution phases and (α + δ) eutectic phases were distributed in an island-like pattern. | Casting |

| 11 | XCJX11 | M5:33 | α-solid-solution dendritic-segregation structure; numerous (α + δ) eutectic phases interconnected in a reticular pattern; and lead was unevenly distributed in fine granular and large ellipsoidal shapes. | Casting |

| 12 | XCJX12 | M11:10 | α-solid-solution dendritic-segregation structure; a large number of (α + δ) eutectic phases distributed in an island-like pattern; and lead was unevenly distributed in fine granular and large ellipsoidal shapes. | Casting |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Liu, X.; Chen, Z.; Zhang, S.; Niu, Q.; Zhao, X. Study on the Bronze Weapons Excavated from Xichuan, China. Metals 2024, 14, 395. https://doi.org/10.3390/met14040395

Zhao S, Liu X, Chen Z, Zhang S, Niu Q, Zhao X. Study on the Bronze Weapons Excavated from Xichuan, China. Metals. 2024; 14(4):395. https://doi.org/10.3390/met14040395

Chicago/Turabian StyleZhao, Shengwei, Xin Liu, Zhen Chen, Siyu Zhang, Qing Niu, and Xing Zhao. 2024. "Study on the Bronze Weapons Excavated from Xichuan, China" Metals 14, no. 4: 395. https://doi.org/10.3390/met14040395

APA StyleZhao, S., Liu, X., Chen, Z., Zhang, S., Niu, Q., & Zhao, X. (2024). Study on the Bronze Weapons Excavated from Xichuan, China. Metals, 14(4), 395. https://doi.org/10.3390/met14040395