Behavior of Two Dental Alloys as Ingot and Cast Crown in Artificial Saliva

Abstract

1. Introduction

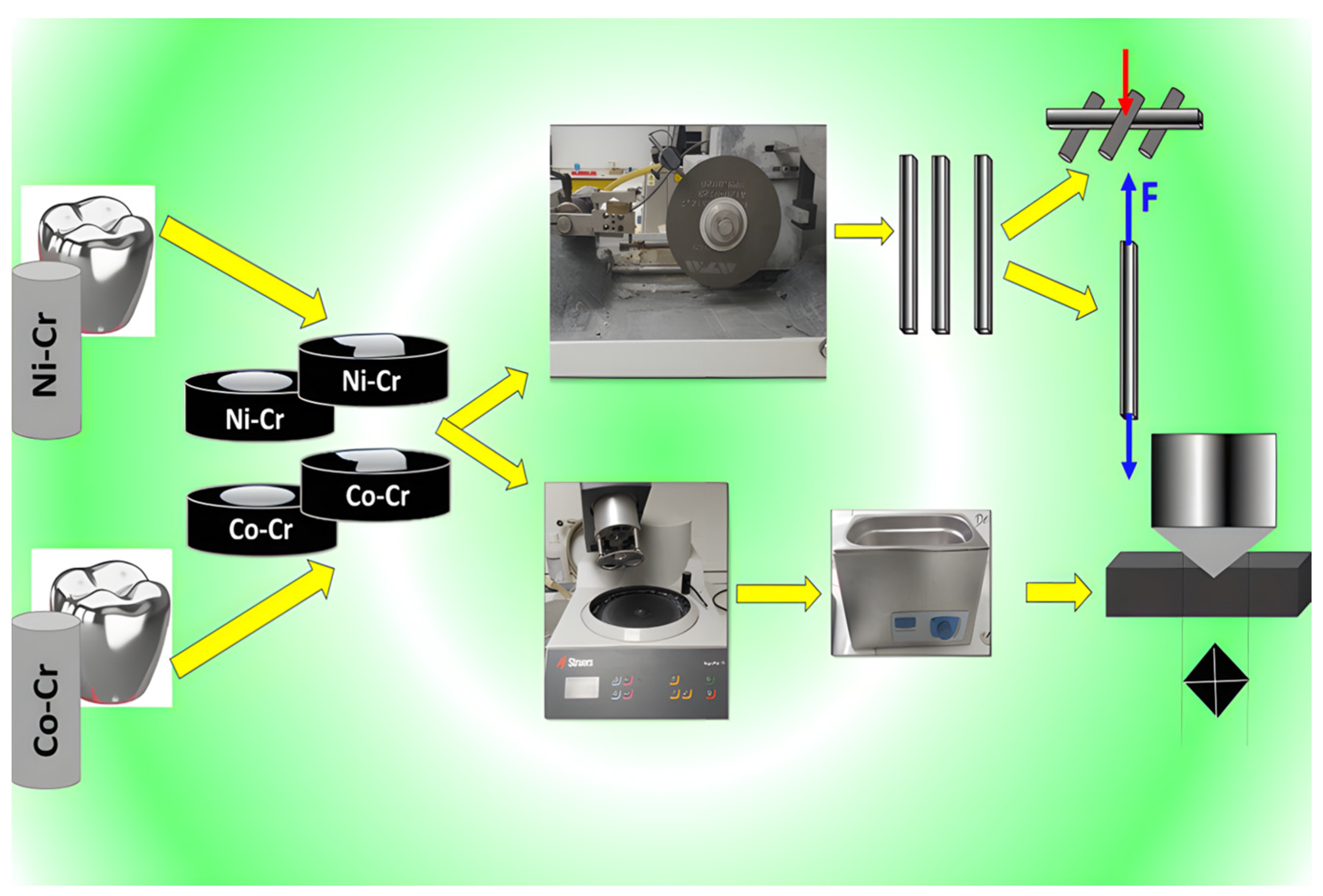

2. Materials and Methods

2.1. Selection and Samples Preparation

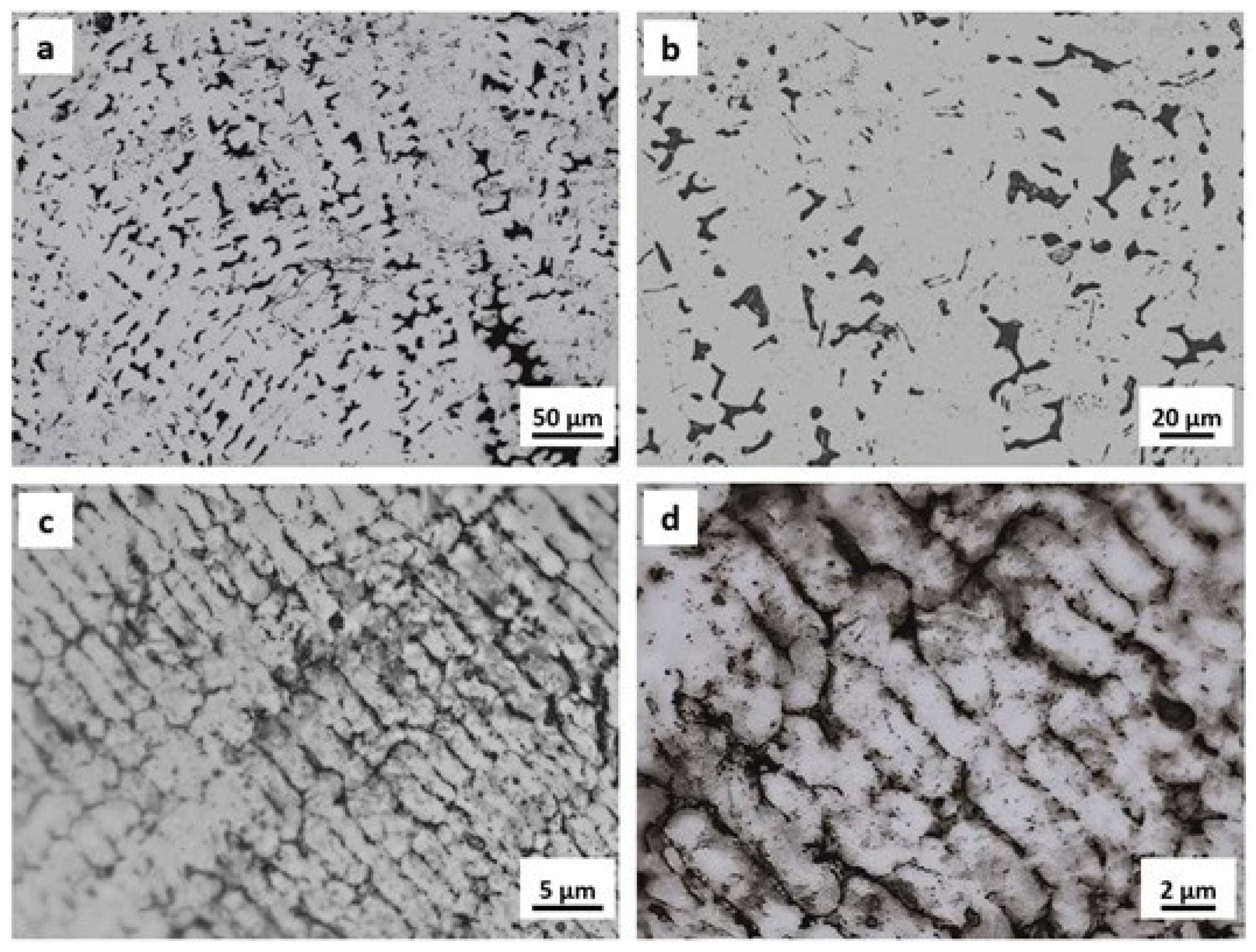

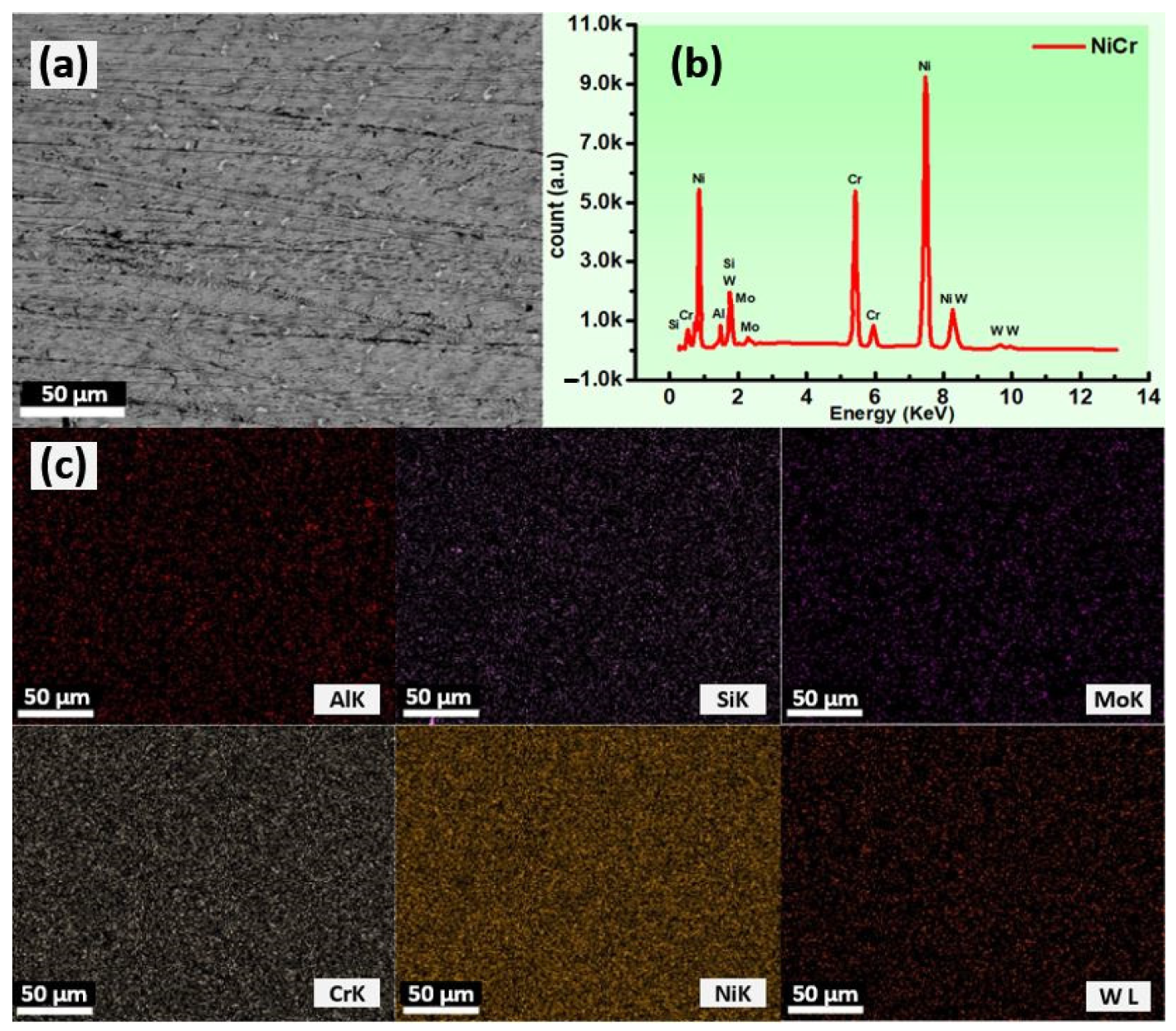

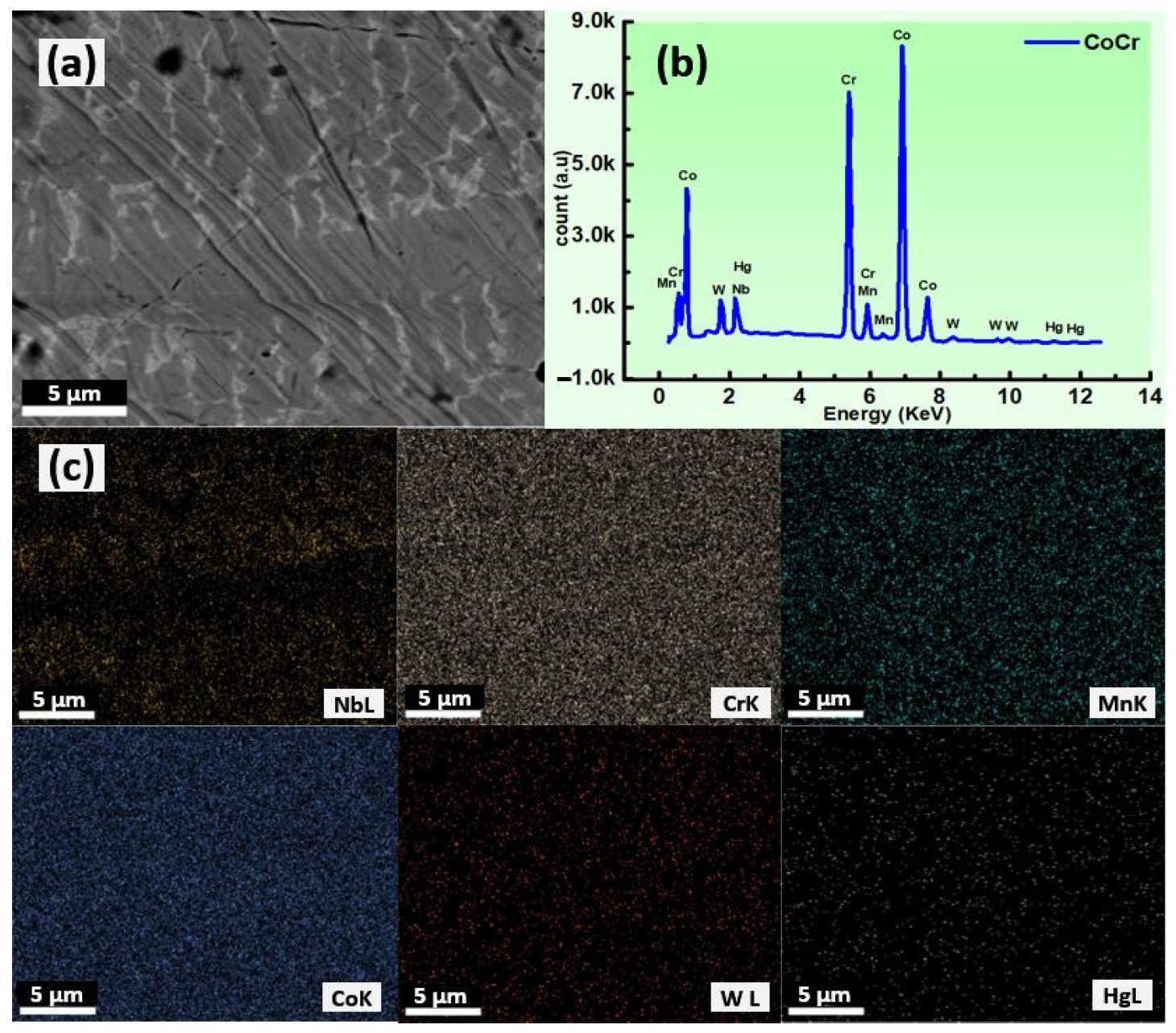

2.2. Microstructure

2.3. Electrochemical Tests

2.4. Microhardness

2.5. Tensile Test and 3-Point Bending Test

2.6. Statistical Analysis

3. Results

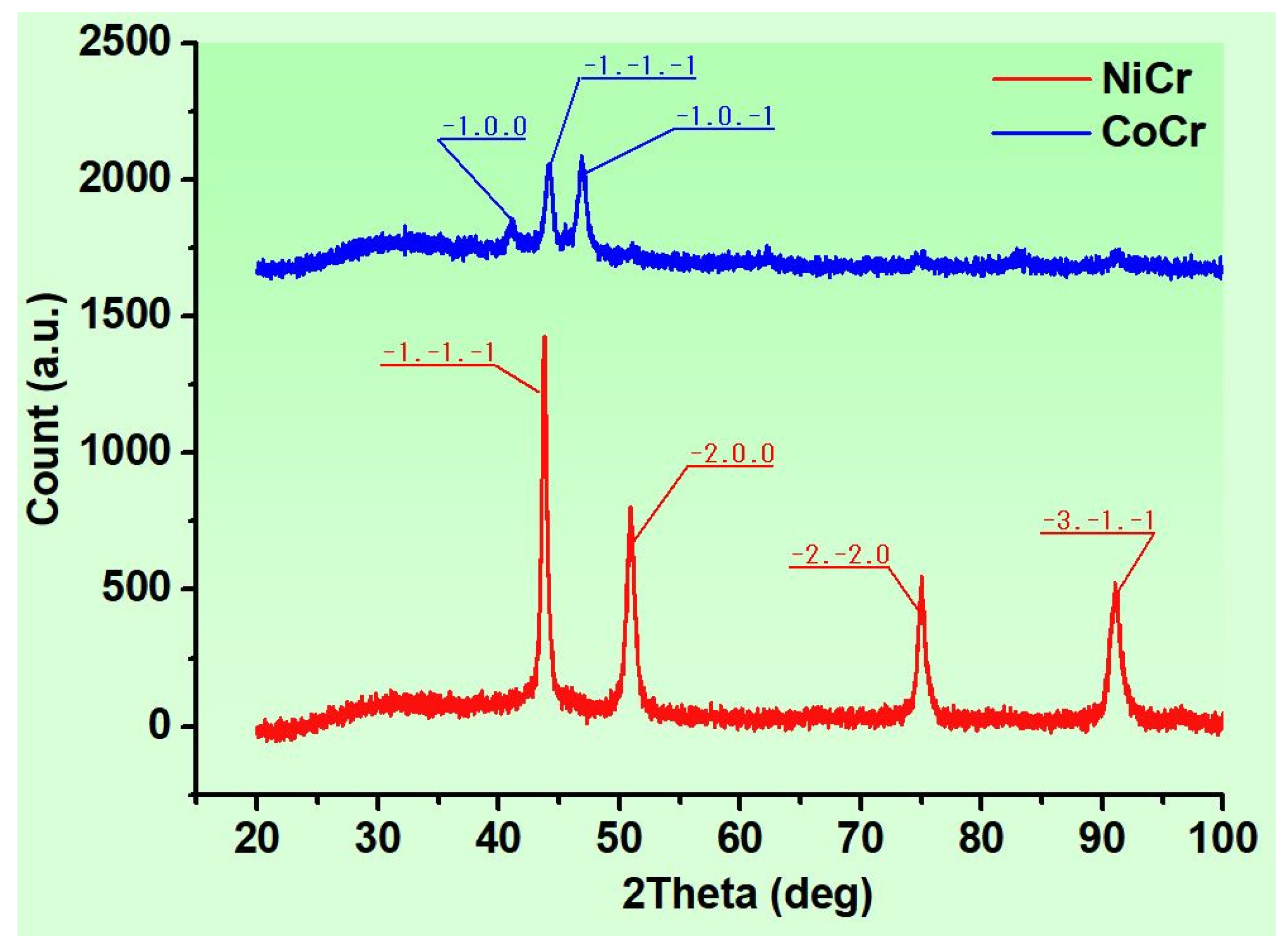

3.1. Microstructure Analysis

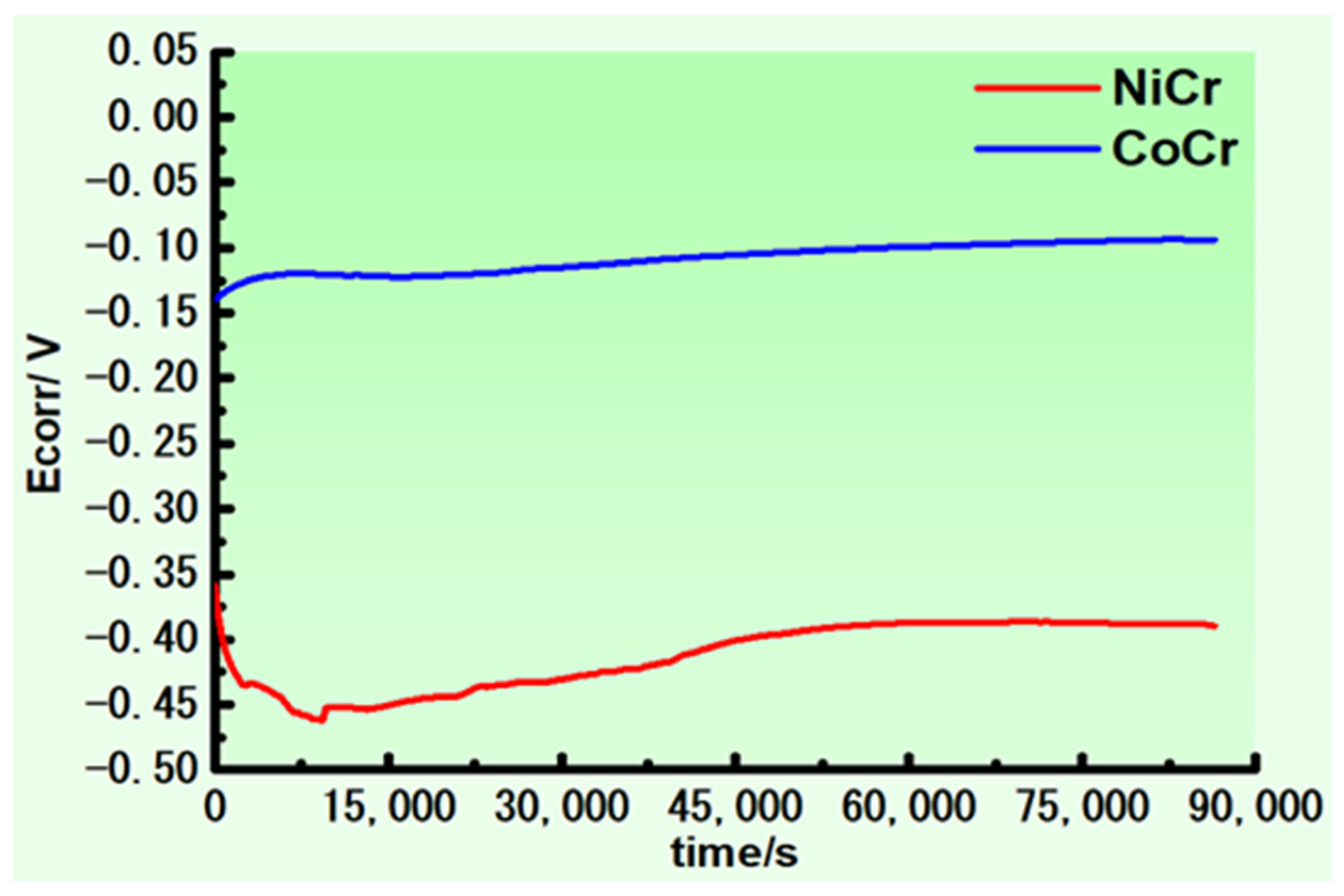

3.2. Corrosion Potential

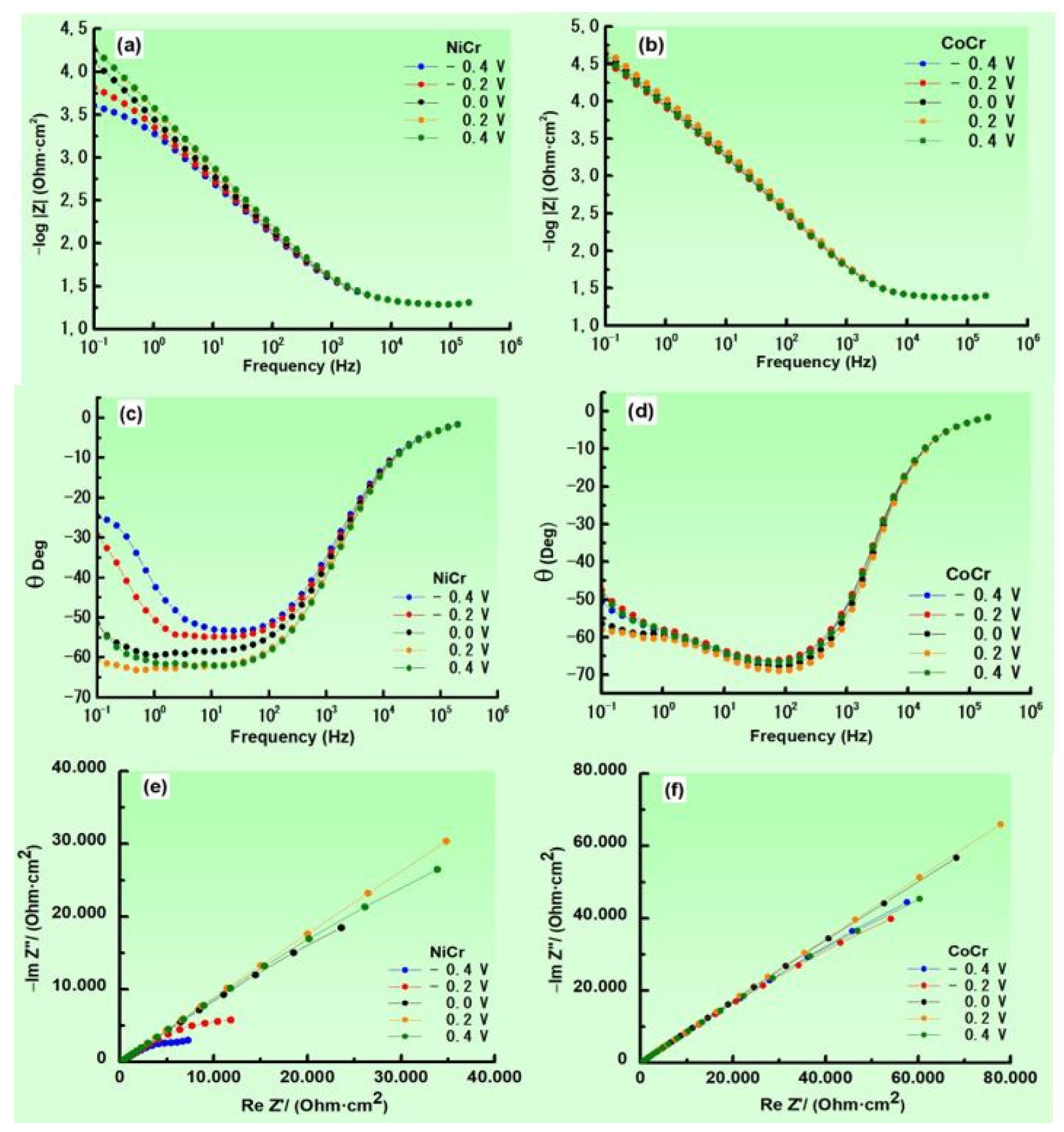

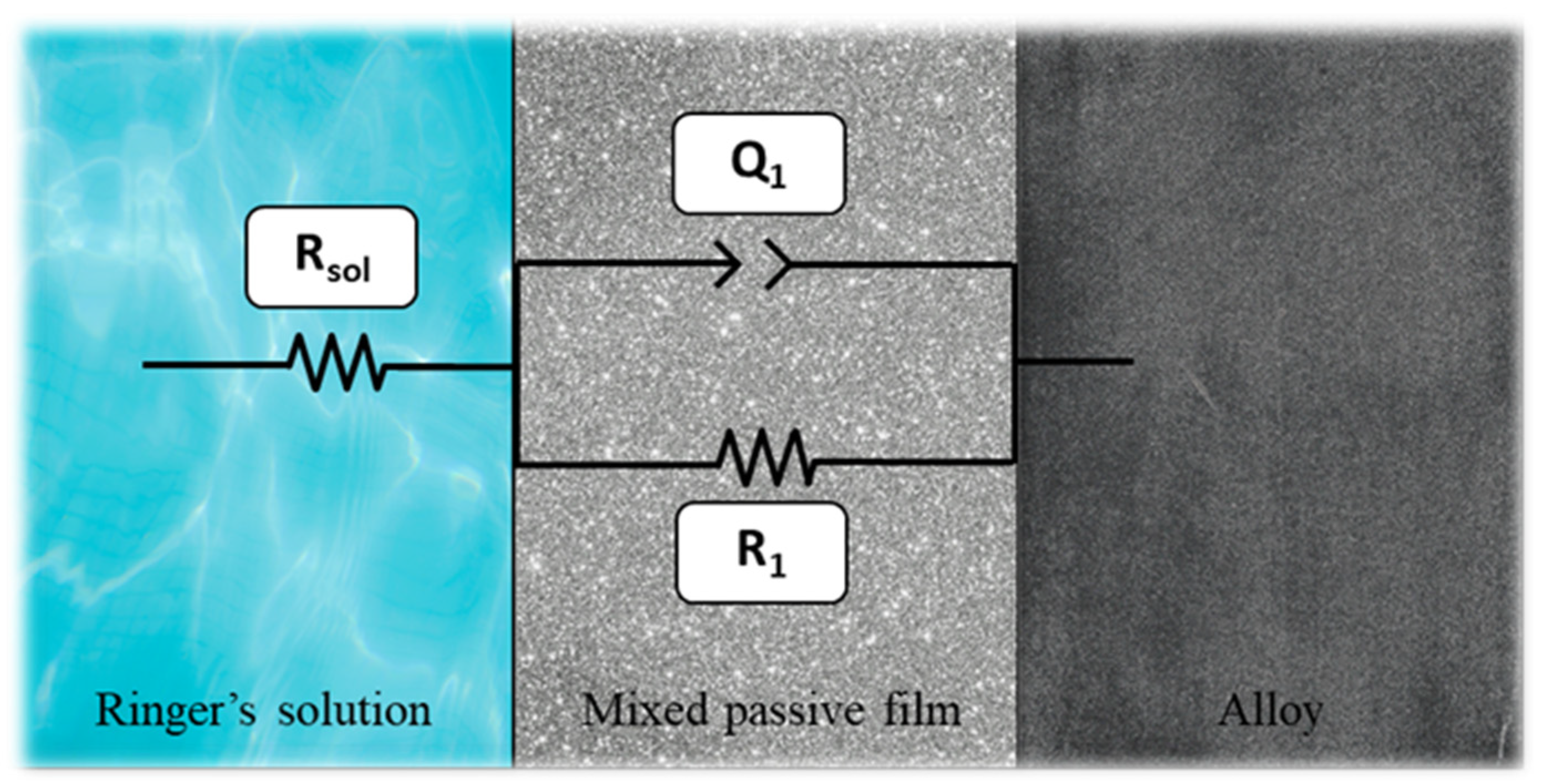

3.3. Electrochemical Impedance Spectroscopy (EIS)

3.4. Microhardness

3.5. Bending Test and Tensile Test

- E = Young’s modulus

- F = force applied to the specimen

- L = span between the supports

- d = diameter or width of the specimen

- y = deflection of the specimen at the center

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marin, E. History of dental biomaterials: Biocompatibility, durability and still open challenges. Herit. Sci. 2023, 11, 207. [Google Scholar] [CrossRef]

- Cempel, M.; Nikel, G. Nickel: A review of its sources and environmental toxicology. Pol. J. Environ. Stud. 2006, 15, 375–382. [Google Scholar]

- Baker, M. European Standards Developed in Support of the European Union Nickel Directive. In Metal Allergy: From Dermatitis to Implant and Device Failure; Chen, J.K., Thyssen, J.P., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 23–29. ISBN 978-3-319-58503-1. [Google Scholar]

- Schäfer, T.; Böhler, E.; Ruhdorfer, S.; Weigl, L.; Wessner, D.; Filipiak, B.; Wichmann, H.E.; Ring, J. Epidemiology of contact allergy in adults. Allergy Eur. J. Allergy Clin. Immunol. 2001, 56, 1192–1196. [Google Scholar] [CrossRef] [PubMed]

- Denkhaus, E.; Salnikow, K. Nickel essentiality, toxicity, and carcinogenicity. Crit. Rev. Oncol. Hematol. 2002, 42, 35–56. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Falcon, C.M.; Gil-Lopez, T.; Verdu-Vazquez, A.; Mirza-Rosca, J.C. Corrosion behavior in Ringer solution of several commercially used metal alloys. Anti-Corros. Methods Mater. 2021, 68, 324–330. [Google Scholar] [CrossRef]

- Yun, C.-S.; Hanawa, T.; Hong, M.-H.; Min, B.K.; Kwon, T.-Y. Biocompatibility of Ni–Cr alloys, with the same composition, prepared by two new digital manufacturing techniques. Mater. Lett. 2021, 305, 130761. [Google Scholar] [CrossRef]

- Waasdorp, M.; Krom, B.P.; Bikker, F.J.; van Zuijlen, P.P.M.; Niessen, F.B.; Gibbs, S. The bigger picture: Why oral mucosa heals better than skin. Biomolecules 2021, 11, 1165. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Falcon, C.M.; Gil-Lopez, T.; Verdu-Vazquez, A.; Mirza-Rosca, J.C. Electrochemical characterization of some cobalt base alloys in Ringer solution. Mater. Chem. Phys. 2021, 260, 124164. [Google Scholar] [CrossRef]

- Ashtiani, A.H.; Mardasi, N.; Fathi, A. Effect of multiple firings on the shear bond strength of presintered cobalt-chromium alloy and veneering ceramic. J. Prosthet. Dent. 2021, 126, 803.e1–803.e6. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, X.; Li, N.; Yan, J. Effects of post-treatment on metal-ceramic bond properties of selective laser melted Co-Cr dental alloy. Part 1: Annealing temperature. J. Prosthet. Dent. 2023, 129, 657.e1–657.e9. [Google Scholar] [CrossRef]

- Aldhohrah, T.; Yang, J.; Guo, J.; Zhang, H.; Wang, Y. Ion release and biocompatibility of Co-Cr alloy fabricated by selective laser melting from recycled Co-Cr powder: An in vitro study. J. Prosthet. Dent. 2023, 130, 393–401. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Dong, X.; Qu, Y.; Yan, J.; Li, N. Analysis of microstructure and fatigue of cast versus selective laser-melted dental Co-Cr alloy. J. Prosthet. Dent. 2022, 128, 218.e1–218.e7. [Google Scholar] [CrossRef] [PubMed]

- Şahin, M.; Ünalan, F.; Mutlu, İ. Corrosion, ion release, and surface hardness of Ti-6Al-4V and cobalt-chromium alloys produced by CAD-CAM milling and laser sintering. J. Prosthet. Dent. 2022, 128, 529.e1–529.e10. [Google Scholar] [CrossRef] [PubMed]

- Altuntas, M.C.; Guleryuz, A. Evaluation of the relationship between metallurgical properties and metal-ceramic bond characteristics of Co-Cr alloys manufactured by different techniques. Metals, 2023; 130, 937.e1–937.e10. [Google Scholar] [CrossRef]

- Chang, H.-S.; Peng, Y.-T.; Hung, W.-L.; Hsu, M.-L. Evaluation of marginal adaptation of Co Cr Mo metal crowns fabricated by traditional method and computer-aided technologies. J. Dent. Sci. 2019, 14, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Xing, X.; Hu, Q.; Liu, Y.; Wang, Y.; Cheng, H. Comparative analysis of the surface properties and corrosion resistance of Co-Cr dental alloys fabricated by different methods. J. Prosthet. Dent. 2022, 127, 497.e1–497.e11. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Falcon, C.M.; Gil-Lopez, T.; Verdu-Vazquez, A.; Mirza-Rosca, J.C. Analysis and Comparison of the Corrosive Behavior of Nickel-Based and Cobalt-Based Dental Alloys. Materials 2021, 14, 4949. [Google Scholar] [CrossRef] [PubMed]

- ASTM E3-11(2017); Standard Guide for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO/TS 21383:2021; Microbeam Analysis—Scanning Electron Microscopy—Qualification of The scanning Electron Microscope for Quantitative Measurements. ISO: Geneva, Switzerland, 2021.

- ISO 10271:2020; Dentistry—Corrosion Test Methods for Metallic Materials. ISO: Geneva, Switzerland, 2020.

- ISO 16773-1-4:2016; Electrochemical Impedance Spectroscopy (EIS) on Coated and Uncoated Metallic Specimens. ISO: Geneva, Switzerland, 2016.

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. ISO: Geneva, Switzerland, 2015.

- ISO 22674:2022; Dentistry—Metallic Materials for Fixed and Removable Restorations and Appliances. ISO: Geneva, Switzerland, 2022.

- ISO 7438:2020; Metallic Materials—Bend Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- ASTM E 1508-12a (2019); Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Fratila, A.; Jimenez-Marcos, C.; Mirza-Rosca, J.C.; Saceleanu, A. Mechanical properties and biocompatibility of various cobalt chromium dental alloys. Mater. Chem. Phys. 2023, 304, 127867. [Google Scholar] [CrossRef]

- Mercieca, S.; Caligari Conti, M.; Buhagiar, J.; Camilleri, J. Assessment of corrosion resistance of cast cobalt- and nickel-chromium dental alloys in acidic environments. J. Appl. Biomater. Funct. Mater. 2018, 16, 47–54. [Google Scholar] [CrossRef]

- Jiménez-Marcos, C.; Mirza-Rosca, J.C.; Fratila, A.; Saceleanu, A. Influence and Comparison of the Properties of Three Cobalt-Chromium Dental Alloys. Microsc. Microanal. 2023, 29, 156–160. [Google Scholar] [CrossRef]

- Socorro-Perdomo, P.P.; Florido-Suárez, N.R.; Voiculescu, I.; Mirza-Rosca, J.C. Comparative eis study of alxcocrfeni alloys in ringer’s solution for medical instruments. Metals 2021, 11, 928. [Google Scholar] [CrossRef]

- BOUKAMP, B. A Nonlinear Least Squares Fit procedure for analysis of immittance data of electrochemical systems. Solid State Ionics 1986, 20, 31–44. [Google Scholar] [CrossRef]

- Øilo, M.; Nesse, H.; Lundberg, O.J.; Gjerdet, N.R. Mechanical properties of cobalt-chromium 3-unit fixed dental prostheses fabricated by casting, milling, and additive manufacturing. J. Prosthet. Dent. 2018, 120, 156.e1–156.e7. [Google Scholar] [CrossRef] [PubMed]

- Cha, M.S.; Lee, S.W.; Huh, Y.H.; Cho, L.R.; Park, C.J. Correlation between microhardness and wear resistance of dental alloys against monolithic zirconia. J. Adv. Prosthodont. 2021, 13, 127–135. [Google Scholar] [CrossRef]

- Ekren, O.; Kocak, E.F.; Ucar, Y. Effect of internal design changes on the mechanical properties of laser-sintered cobalt-chromium specimens. J. Prosthet. Dent. 2023, 129, 508–512. [Google Scholar] [CrossRef]

- Chun, K.J.; Lee, J.Y. Comparative study of mechanical properties of dental restorative materials and dental hard tissues in compressive loads. J. Dent. Biomech. 2014, 5, 1758736014555246. [Google Scholar] [CrossRef]

| Sample | Ni | Co | Cr | W | Si | Al | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| Ni-Cr | 61.4 | - | 25.7 | - | 1.5 | <1.0 | 11 | - |

| Co-Cr | - | 59.5 | 31.5 | 3.0 | 2.0 | - | 5 | <1.0 |

| Elements | Ni-Cr | Co-Cr | ||

|---|---|---|---|---|

| wt.% | at.% | wt.% | at.% | |

| AlK | 2.72 | 5.67 | - | - |

| SiK | 3.50 | 7.00 | - | - |

| MoL | 1.06 | 0.62 | - | - |

| CrK | 21.11 | 22.83 | 30.44 | 34.53 |

| NiK | 64.36 | 61.66 | - | - |

| W L | 7.25 | 2.22 | 3.40 | 1.09 |

| NbL | - | - | 2.48 | 1.57 |

| MnK | - | - | 1.33 | 1.43 |

| CoK | - | - | 60.89 | 60.95 |

| HgL | - | - | 1.47 | 0.43 |

| Alloy | Ecorr, V vs. SCE | icorr | Rp | Βa | Βc | ipass | Ebd | ||

|---|---|---|---|---|---|---|---|---|---|

| Initial | After 3 h | After 24 h | µA/cm2 | KΩ/cm2 | mV/DIV | mV/DIV | µA/cm2 | mV | |

| Ni-Cr | −0.359 | −0.452 | −0.390 | 0.20 | 112 | 157 | 88 | 3.82 | 620 |

| Co-Cr | −0.139 | −0.121 | −0.094 | 0.24 | 98 | 164 | 84 | 4.14 | 600 |

| Potential (V) | Alloys | Max. Impedance (Ω) | Max. Phase Angle (°) |

|---|---|---|---|

| −0.400 | Ni-Cr | 7.24 × 103 | 53 |

| Co-Cr | 5.76 × 104 | 66 | |

| −0.200 | Ni-Cr | 1.18 × 104 | 55 |

| Co-Cr | 5.41 × 104 | 66 | |

| 0.000 | Ni-Cr | 2.36 × 104 | 60 |

| Co-Cr | 6.82 × 104 | 68 | |

| 0.200 | Ni-Cr | 3.48 × 104 | 63 |

| Co-Cr | 7.78 × 104 | 69 | |

| 0.400 | Ni-Cr | 3.38 × 104 | 62 |

| Co-Cr | 6.03 × 104 | 67 |

| Potential (V) | Samples | Parameters | |||

|---|---|---|---|---|---|

| Rsol (Ω·cm2) | Y01 (S·secn/cm2) | n1 | R1 (Ω·cm2) | ||

| −0.400 | Ni-Cr | 17.33 | 1.30 × 10−4 | 0.66 | 4.97·103 |

| Co-Cr | 21.00 | 2.78 × 10−5 | 0.75 | 6.75·104 | |

| −0.200 | Ni-Cr | 17.31 | 1.22 × 10−4 | 0.66 | 4.97·104 |

| Co-Cr | 21.00 | 2.88 × 10−5 | 0.75 | 5.83·104 | |

| 0.000 | Ni-Cr | 17.33 | 1.05 × 10−4 | 0.68 | 7.55·104 |

| Co-Cr | 20.91 | 2.47 × 10−5 | 0.76 | 8.92·104 | |

| 0.200 | Ni-Cr | 17.50 | 7.62 × 10−5 | 0.71 | 2.75·105 |

| Co-Cr | 20.90 | 2.15 × 10−5 | 0.77 | 1.02·105 | |

| 0.400 | Ni-Cr | 17.51 | 7.18 × 10−5 | 0.71 | 7.46·104 |

| Co-Cr | 20.97 | 2.68 × 10−5 | 0.76 | 6.48·104 | |

| Mean Parameter ± Standard Deviation | Ni-Cr | Co-Cr | ||

|---|---|---|---|---|

| IN | CC | IN | CC | |

| Vickers microhardness | 231.6 ± 11.2 | 182.2 ± 11.5 | 425.4 ± 16.2 | 326.6 ± 14.2 |

| Young´s modulus (GPa) | 201.5 ± 16.2 | 128.9 ± 22.9 | 282.2 ± 15.8 | 110.7 ± 12.9 |

| Tensile strength (MPa) | 720.3 ± 26.5 | 386.6 ± 12.4 | 1310.2 ± 28.8 | 623.3 ± 12.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porumb, A.; Brito-Garcia, S.; Mirza-Rosca, J.C.; Fratila, A. Behavior of Two Dental Alloys as Ingot and Cast Crown in Artificial Saliva. Metals 2024, 14, 398. https://doi.org/10.3390/met14040398

Porumb A, Brito-Garcia S, Mirza-Rosca JC, Fratila A. Behavior of Two Dental Alloys as Ingot and Cast Crown in Artificial Saliva. Metals. 2024; 14(4):398. https://doi.org/10.3390/met14040398

Chicago/Turabian StylePorumb, Anca, Santiago Brito-Garcia, Julia Claudia Mirza-Rosca, and Anca Fratila. 2024. "Behavior of Two Dental Alloys as Ingot and Cast Crown in Artificial Saliva" Metals 14, no. 4: 398. https://doi.org/10.3390/met14040398

APA StylePorumb, A., Brito-Garcia, S., Mirza-Rosca, J. C., & Fratila, A. (2024). Behavior of Two Dental Alloys as Ingot and Cast Crown in Artificial Saliva. Metals, 14(4), 398. https://doi.org/10.3390/met14040398