Experimental Study of Performance of Ti-6Al-4V Femoral Implants Using Selective Laser Melting (SLM) Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Apparatus and Experimental Methods

2.2.1. Orthogonal Test of Process Parameters

2.2.2. Densification Experiments Based on the Drainage Method

2.2.3. Micromorphological Analysis of Materials

2.2.4. Measurement of Surface Roughness

2.2.5. Micro-Vickers Hardness Determination

2.2.6. Tensile and Compression Tests

2.2.7. Friction Wear Test

3. Results and Discussion

3.1. Analysis of Orthogonal Test Results

3.2. Influence of Process Parameters on Molding Quality

3.2.1. Influence of Process Parameters on Densification

3.2.2. Influence of Process Parameters on Micromorphology

3.2.3. Influence of Process Parameters on Roughness

3.3. Analysis of the Results of the Experimental Study on the Evaluation of Properties of SLM-Molded TC4 Alloy

3.3.1. Microstructure Analysis of SLM-Molded TC4 Alloy

3.3.2. Testing and Analysis of Mechanical Properties of SLM-Molded TC4 Alloy

- Microhardness Analysis

- 2.

- Tensile Properties Analysis

- 3.

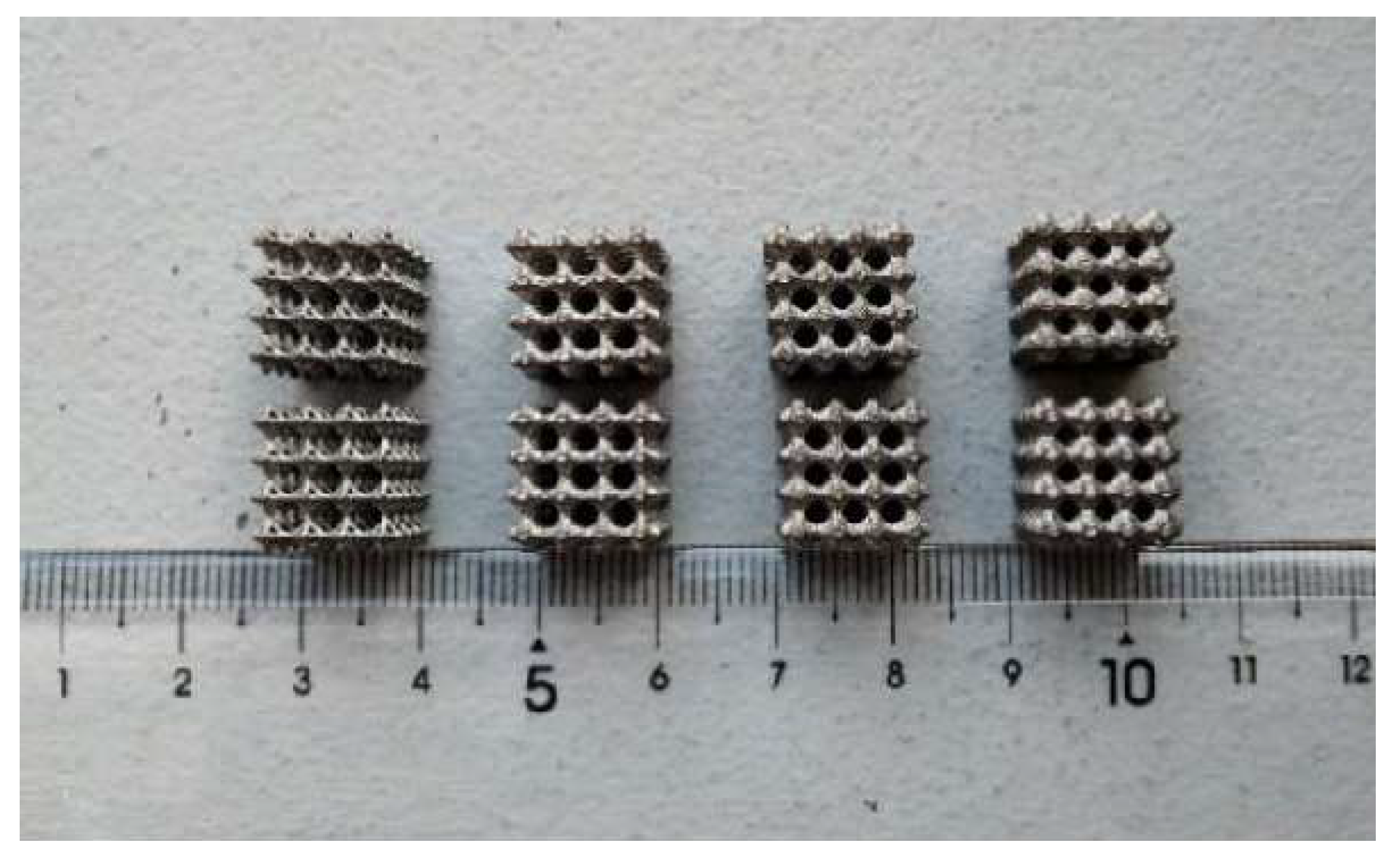

- Compression Performance Analysis

- 4.

- Friction and Wear Performance Analysis

4. Conclusions

- 1.

- The SLM process parameters were optimized through orthogonal tests, and for roughness, the optimized process parameter combinations were determined as follows: laser power of 300 W, scanning speed of 1250 mm/s, scanning spacing of 0.09 mm, and a powder layer thickness of 0.05 mm. When the density of the molded specimen is high, it has fewer internal pore defects, and, on the contrary, when the density is low, the internal pore defects are more obvious;

- 2.

- The microstructure of the cross-section of the molded specimen is mainly martensite, and there are oriented columnar crystals in the microstructure of the elongated cross-section; the microhardness of the side of the molded specimen averaged 369.13 HV, and the microhardness of the front side has an average value of 364.06 HV, and the sides and fronts of the molded specimen are harder than those of the casting specimen;

- 3.

- The average yield strength of the molded specimens was 1217.40 MPa, the tensile strength was 1315.32 MPa, and the elongation at break was 9.6%. It was found that the yield strength and tensile strength of the SLM-molded specimens were higher than that of the ASTM F136 and casting standards but the elongation at break was slightly lower than that of the ASTM F136 standard; the elastic modulus of the molded specimens was in the range of 0.7~12.7 GPa and the compressive strength between 8~338 MPa, which is in line with the range of human bone requirements [41]. For the materials used to make femoral implants, Ti-6Al-4V femoral implants made by SLM meet the requirements, but in practical orthopedics application, it is necessary to apply a coating that enables osseointegration to the alloy obtained by SLM;

- 4.

- Under the same experimental conditions, the friction coefficients of SLM-molded specimens are lower than those of casting specimens, and their wear resistance is higher than that of casting specimens. The friction and wear performance of the molded specimens on the side and the front side do not differ much, and there is basically no difference in the friction coefficient trends and sizes of the two, with the friction coefficient on the front side of the specimens being slightly higher.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shnaekel, A.; Morrison, J.C. High Rates of Aseptic Loosening in Modern Posterior-stabilized Femoral Components from a Single Manufacturer. Arthroplast. Today 2023, 22, 101132. [Google Scholar] [CrossRef]

- Apostu, D.; Lucaciu, O.; Berce, C.; Lucaciu, D.; Cosma, D. Current methods of preventing aseptic loosening and improving osseointegration of titanium implants in cementless total hip arthroplasty: A review. J. Int. Med. Res. 2018, 46, 2104–2119. [Google Scholar] [CrossRef] [PubMed]

- Munemoto, M.; Grammatopoulos, G.; Tanaka, Y.; Gibbons, M.; Athanasou, N.A. The pathology of failed McKee-Farrar implants: Correlation with modern metal-on-metal-implant failure, Journal of materials science. Mater. Med. 2017, 28, 66. [Google Scholar] [CrossRef] [PubMed]

- Levai, J.P.; Descamps, S.; Roch, G.; Boisgard, S. Early aseptic loosening of cemented cup in metal-on-metal total hip arthroplasties. Rev. Chir. Orthop. Reparatrice L’appareil Mot. 2006, 92, 575–580. [Google Scholar] [CrossRef] [PubMed]

- Doi, K.; Kobatake, R.; Makihara, Y.; Oki, Y.; Umehara, H.; Kubo, T.; Tsuga, K. Osseointegration Aspects of Implants at the Bone Reconstruction Site by a Novel Porous Titanium Scaffold. J. Oral Maxillofac. Res. 2021, 12, e4. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Xu, J.; Zou, L.; Luo, S.; Yao, R.; Zheng, B.; Liang, G.; Wu, D.; Li, Y. Long-lasting renewable antibacterial porous polymeric coatings enable titanium biomaterials to prevent and treat peri-implant infection. Nat. Commun. 2021, 12, 3303. [Google Scholar] [CrossRef]

- Gao, B.; Zhao, H.; Peng, L.; Sun, Z. A Review of Research Progress in Selective Laser Melting (SLM). Micromachines 2022, 14, 57. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Gao, H.; Wang, C.; Ji, P.; Huang, Y.; Wang, C. Assessment of Customized Alveolar Bone Augmentation Using Titanium Scaffolds vs Polyetheretherketone (PEEK) Scaffolds: A Comparative Study Based on 3D Printing Technology. ACS Biomater. Sci. Eng. 2022, 8, 2028–2039. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.-K.; Choi, Y.-J.; Choi, W.-C.; Song, I.-S.; Lee, U.-L. Reconstruction of maxillofacial bone defects using patient-specific long-lasting titanium implants. Sci. Rep. 2022, 12, 7538. [Google Scholar] [CrossRef]

- Elshaer, R.N.; Ibrahim, K.M. Performance, Study of Microstructure, Mechanical Properties, and Corrosion Behavior of As-Cast Ni-Ti and Ti-6Al-4V Alloys. J. Mater. Eng. Perform. 2022, 32, 7831–7845. [Google Scholar] [CrossRef]

- Sangali, M.; Cremasco, A.; Soyama, J.; Caram, R.; Contieri, R.J. Selective Laser Melting of Ti-6Al-4V Alloy: Correlation Between Processing Parameters, Microstructure and Corrosion Properties. Mater. Res. 2023, 26, e20230055. [Google Scholar] [CrossRef]

- Feng, X.; Qiu, J.; Ma, Y.; Lei, J.; Cui, Y.; Wu, X.; Yang, R. Influence of Processing Conditions on Microstructure and Mechanical Properties of Large Thin-Wall Centrifugal Ti–6Al–4V Casting. J. Mater. Sci. Technol. 2016, 32, 362–371. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Q.; Liu, X.; Geng, R.; Wang, B.; Jiang, Q.J.N. Improved Strength-Ductility of Ti-6Al-4V Casting Alloys with Trace Addition of TiC-TiB2 Nanoparticles. Nanomaterials 2020, 10, 2330. [Google Scholar] [CrossRef]

- Lee, H.-W.; Kong, B.-O.; Kim, S.E.; Joo, Y.; Yoon, S.; Lee, J.H. Microstructure and Mechanical Properties of Vacuum Centrifugal Casted Ti-6Al-4V Alloy by Casting and Heat Treatment. Korean J. Met. Mater. 2022, 60, 282–290. [Google Scholar] [CrossRef]

- Wen, F.; Zhao, J.-H.; Yuan, M.; Wang, J.; Zheng, D.; Zhang, J.; He, K.Z.; Shangguan, J.-J.; Guo, Y. Alloys, Influence of Ni interlayer on interfacial microstructure and mechanical properties of Ti-6Al-4V/AZ91D bimetals fabricated by a solid–liquid compound casting process. J. Magnes. Alloys 2021, 9, 1382–1395. [Google Scholar] [CrossRef]

- Banu, A.; Preda, L.; Marcu, M.; Dinca, L.L.; Maxim, M.E.; Dobri, G. Electrochemical Behavior of SLM Ti–6Al–4V Alloy After Long Time of Immersion in Lactic Acid Environment. Met. Mater. Trans. A 2022, 53, 2060–2070. [Google Scholar] [CrossRef]

- Cheng, Y.-J.; Hung, F.-Y.; Zhao, J.-R. Microstructural Characteristics and Material Failure Mechanism of SLM Ti-6Al-4V-Zn Alloy. Materials 2023, 16, 7341. [Google Scholar] [CrossRef] [PubMed]

- Metalnikov, P.; Ben-Hamu, G.; Eliezer, D. Corrosion behavior of AM-Ti-6Al-4V: A comparison between EBM and SLM. Prog. Addit. Manuf. 2022, 7, 509–520. [Google Scholar] [CrossRef]

- Naghavi, S.A.; Tamaddon, M.; Garcia-Souto, P.; Moazen, M.; Taylor, S.; Hua, J.; Liu, C. A novel hybrid design and modelling of a customised graded Ti-6Al-4V porous hip implant to reduce stress-shielding: An experimental and numerical analysis. Front. Bioeng. Biotechnol. 2023, 11, 1092361. [Google Scholar] [CrossRef]

- Mondal, P.; Das, A.; Mondal, A.; Chowdhury, A.R.; Karmakar, A. Fabrication of Ti-6Al-4V Porous Scaffolds Using Selective Laser Melting (SLM) and Mechanical Compression Test for Biomedical Applications. J. Inst. Eng. India Ser. D 2022, 103, 181–190. [Google Scholar] [CrossRef]

- Kutsukake, A.; Seki, A.; Yoshida, Y. Influence of Implantation Period on Bioactivity on the Surface of Ti-6Al-4V Implant Model Made by Selective Laser Melting. 2021. Available online: https://popups.uliege.be/esaform21/index.php?id=4350 (accessed on 5 March 2024).

- ASTM F136; Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401). ASTM International: West Conshohocken, PA, USA, 2021.

- GB/T 13810-2007; Wrought Titanium and Titanium Alloy for Surgical Implants. Standardization Administration of China: Beijing, China, 2007.

- Hao, Y.; Liu, Z.; Yao, C.; Liang, Y.; Li, Y. Topological design and high-performance additive manufacturing of porous femoral implants. J. Phys. Conf. Ser. 2023, 2566, 012086. [Google Scholar] [CrossRef]

- Bormann, T.; Müller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; De Wild, M. Microstructure of selective laser melted nickel-titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Greco, S.; Gutzeit, K.; Hotz, H.; Kirsch, B.; Aurich, J.C. Selective laser melting (SLM) of AISI 316L—Impact of laser power, layer thickness, and hatch spacing on roughness, density, and microhardness at constant input energy density. Int. J. Adv. Manuf. Technol. 2020, 108, 1551–1562. [Google Scholar] [CrossRef]

- Li, X.; Ni, X.; Xin, M.; Kong, B.; Wu, J. Wear Behavior of Reinforced Modified UHMWPE Material under Water Lubrication. China Plast. Ind. 2019, 47, 23–26+57. [Google Scholar]

- Stwora, A.; Skrabalak, G.; Maszybrocka, J. To enhance mechanical properties of parts produced from AlSi10Mg powder with use of SLS/SLM methods by densification of the product surface layer. Mechanik 2017, 90, 426–431. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Liang, S.-X.; Liu, Y.; Zhang, L.-C. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R Rep. 2021, 146, 100648. [Google Scholar] [CrossRef]

- Tardelli, J.D.C.; Firmino, A.C.D.; Ferreira, I.; dos Reis, A.C. Influence of the roughness of dental implants obtained by additive manufacturing on osteoblastic adhesion and proliferation: A systematic review. Heliyon 2022, 8, e12505. [Google Scholar] [CrossRef]

- Matos, G.R.M. Surgery, Surface Roughness of Dental Implant and Osseointegration. J. Maxillofac. Oral Surg. 2021, 20, 1–4. [Google Scholar] [CrossRef]

- Zhang, W. Investigation on Process and Performance of TC4 Alloy Fabricated by Selective Laser Melting. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Vasylyev, M.; Mordyuk, B.M.; Voloshko, S.M. Wire-Feeding Based Additive Manufacturing of the Ti–6Al–4V Alloy. Part II. Mechanical Properties. 2023. Available online: https://ufm.imp.kiev.ua/en/abstract/v24/i01/005.html (accessed on 10 March 2024).

- Eskandari, H.; Lashgari, H.R.; Zangeneh, S.; Kong, C.; Ye, L.; Eizadjou, M.; Wang, H. Microstructural characterization and mechanical properties of SLM-printed Ti–6Al–4V alloy: Effect of build orientation. J. Mater. Res. 2022, 37, 2645–2660. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the Texture Formation of Selective Laser Melted Ti-6Al-4V. Met. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Jiang, J. Organization and Properties of Medical Ti-6Al-4V Alloy by Selective Zone Laser Melting and Forming; Chongqing University: Chongqing, China, 2016. [Google Scholar]

- ASTME8/E8M-15a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Wang, D.; Yang, Y.Q.; Sun, X.B.; Chen, Y. Study on energy input and its influences on single-track, multi-track, and multi-layer in SLM. Int. J. Adv. Manuf. Technol. 2012, 58, 1189–1199. [Google Scholar]

- Yang, T.; Zheng, J.; Yao, Z.; Ma, L.; Zhang, Y. Finite element analysis of the biomechanical properties of the walking femur. Guangdong Med. J. 2016, 37, 512–515. [Google Scholar] [CrossRef]

- ISO 13314; Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals. International Organization for Standardization: Geneva, Switzerland, 2011.

- Gong, M.; Tan, L.; Yang, K. Bone tissue engineering scaffold materials and their mechanical properties. Mater. Rep. 2007, 10, 43–46+54. [Google Scholar]

| Ingredients | Ti | Al | V | Fe | C | O | N | H |

|---|---|---|---|---|---|---|---|---|

| ASTM F136 | Residual | 5.5–6.5 | 3.5–4.5 | ≤0.25 | ≤0.08 | ≤0.13 | ≤0.05 | ≤0.012 |

| GB/T 13810 | Residual | 5.5–6.75 | 3.5–4.5 | 0.3 | 0.08 | 0.02 | 0.05 | 0.015 |

| TC4 | Residual | 6.1 | 3.95 | 0.1 | 0.004 | 0.01 | 0.01 | 0.001 |

| D3 | D10 | D50 | D70 | D90 | D95 | D97 |

|---|---|---|---|---|---|---|

| 8.942 μm | 18.214 μm | 35.106 μm | 43.330 μm | 58.394 μm | 65.242 μm | 73.408 μm |

| Number | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Laser power P/(W) | 300 | 320 | 340 | 360 |

| Scanning speed v/(mm/s) | 1050 | 1250 | 1450 | 1650 |

| Scan spacing d/(mm) | 0.08 | 0.09 | 0.10 | 0.11 |

| Thickness of powder printing layer h/(mm) | 0.04 | 0.05 | 0.06 | 0.07 |

| Factors (Process Parameters) | Laser Power P | Scanning Speed v | Scan Spacing d | Thickness of Powder Layer h |

|---|---|---|---|---|

| Level index and K1 | 35.911 | 38.532 | 41.6 | 40.585 |

| Level index and K2 | 37.331 | 36.045 | 36.431 | 36.142 |

| Level index and K3 | 40.807 | 39.328 | 37.988 | 37.502 |

| Level index and K4 | 40.937 | 41.081 | 38.967 | 40.757 |

| Horizontal k1 | 8.978 | 9.633 | 10.400 | 10.146 |

| Horizontal k2 | 9.333 | 9.011 | 9.108 | 9.036 |

| Horizontal k3 | 10.202 | 9.832 | 9.497 | 9.376 |

| Horizontal k4 | 10.234 | 10.270 | 9.742 | 10.189 |

| Average index R | 1.256 | 1.259 | 1.292 | 1.153 |

| Factors (Process Parameters) | Laser Power P | Scanning Speed v | Scan Spacing d | Thickness of Powder Layer h |

|---|---|---|---|---|

| Level index and K1 | 42.422 | 43.578 | 44.745 | 44.677 |

| Level index and K2 | 44.501 | 42.426 | 42.028 | 43.356 |

| Level index and K3 | 45.59 | 44.506 | 45.433 | 45.365 |

| Level index and K4 | 46.867 | 48.87 | 47.174 | 45.982 |

| Horizontal k1 | 10.606 | 10.895 | 11.186 | 11.169 |

| Horizontal k2 | 11.125 | 10.607 | 10.507 | 10.839 |

| Horizontal k3 | 11.398 | 11.127 | 11.358 | 11.341 |

| Horizontal k4 | 11.717 | 12.218 | 11.794 | 11.496 |

| Average index R | 1.111 | 1.611 | 1.287 | 0.657 |

| Type | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| ASTM F136 | 795 | 860 | 10.0 |

| Casting | 847 | 976 | 5.1 |

| SLM molding | 1217.40 | 1315.32 | 9.6 |

| Volume Fraction | 10% | 20% | 30% | 40% |

|---|---|---|---|---|

| Modulus of elasticity (GPa) | 0.75 | 1.51 | 7.99 | 12.63 |

| Compressive strength (MPa) | 8 | 48 | 219 | 338 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, H.; Liu, Z.; Liang, Y.; Hao, Y. Experimental Study of Performance of Ti-6Al-4V Femoral Implants Using Selective Laser Melting (SLM) Methodology. Metals 2024, 14, 492. https://doi.org/10.3390/met14050492

Zhang W, Liu H, Liu Z, Liang Y, Hao Y. Experimental Study of Performance of Ti-6Al-4V Femoral Implants Using Selective Laser Melting (SLM) Methodology. Metals. 2024; 14(5):492. https://doi.org/10.3390/met14050492

Chicago/Turabian StyleZhang, Wenjie, Hongxi Liu, Zhiqiang Liu, Yuyao Liang, and Yi Hao. 2024. "Experimental Study of Performance of Ti-6Al-4V Femoral Implants Using Selective Laser Melting (SLM) Methodology" Metals 14, no. 5: 492. https://doi.org/10.3390/met14050492

APA StyleZhang, W., Liu, H., Liu, Z., Liang, Y., & Hao, Y. (2024). Experimental Study of Performance of Ti-6Al-4V Femoral Implants Using Selective Laser Melting (SLM) Methodology. Metals, 14(5), 492. https://doi.org/10.3390/met14050492