Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials

Abstract

1. Introduction

2. Materials and Methods

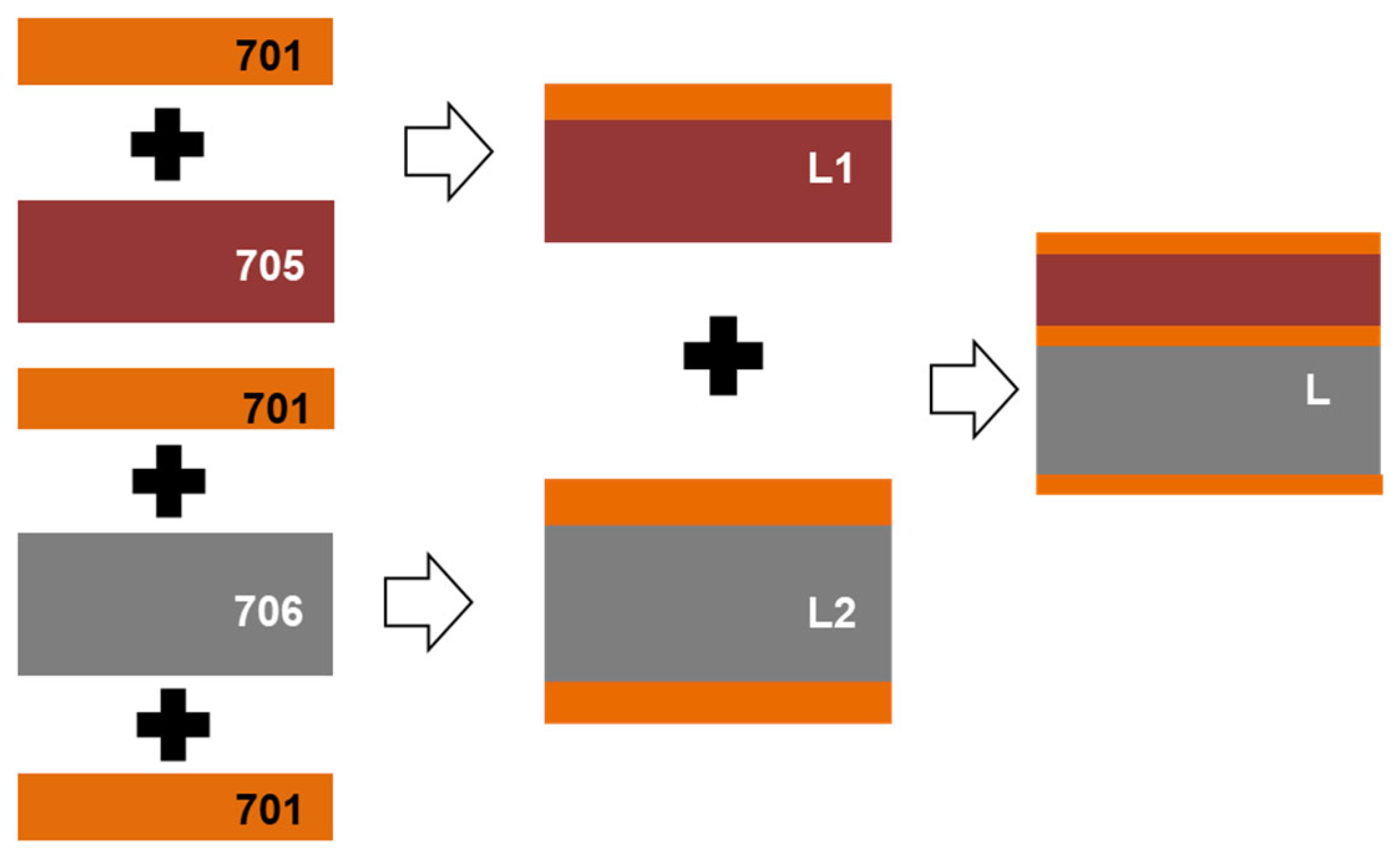

2.1. Materials

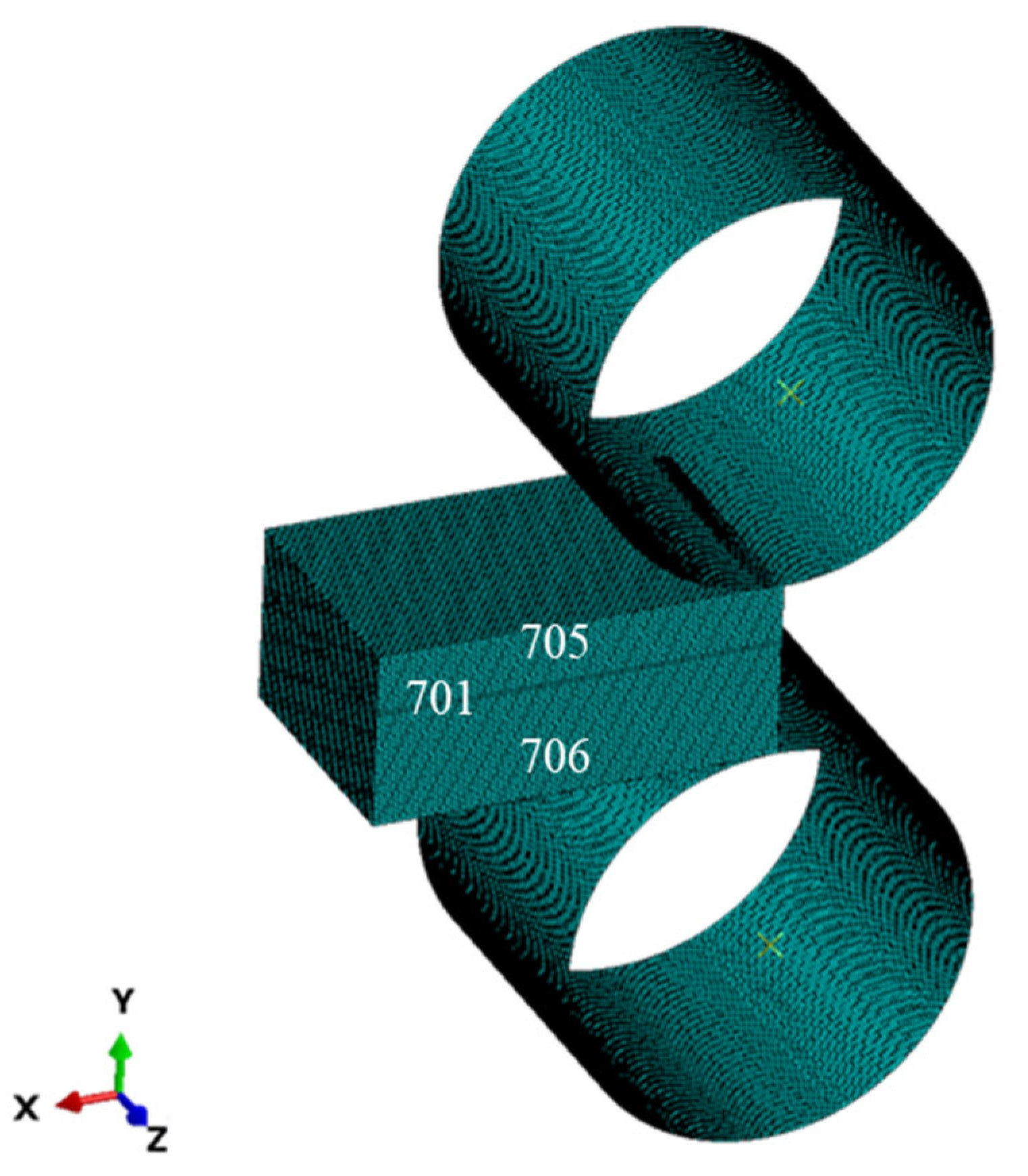

2.2. Finite Element Modeling

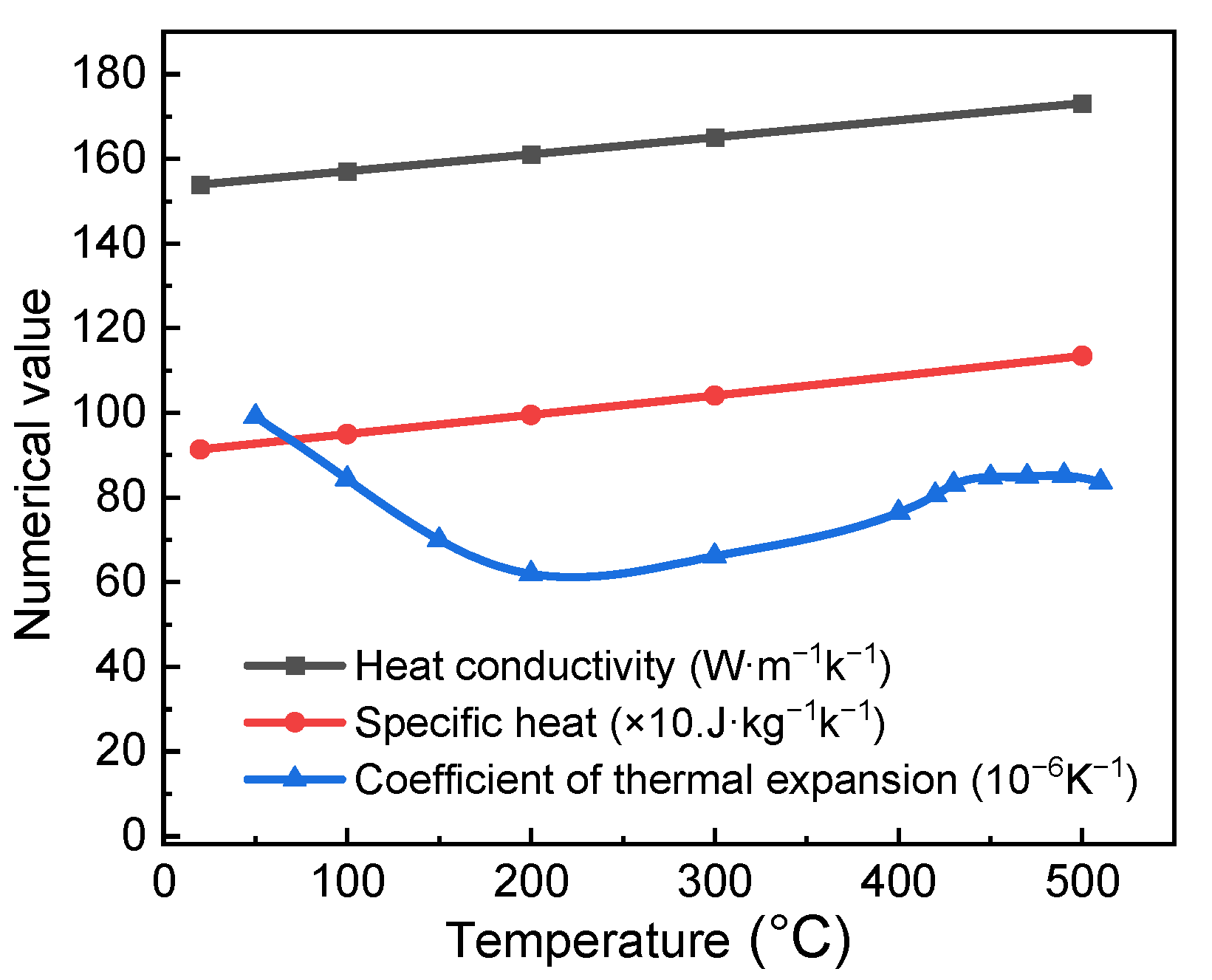

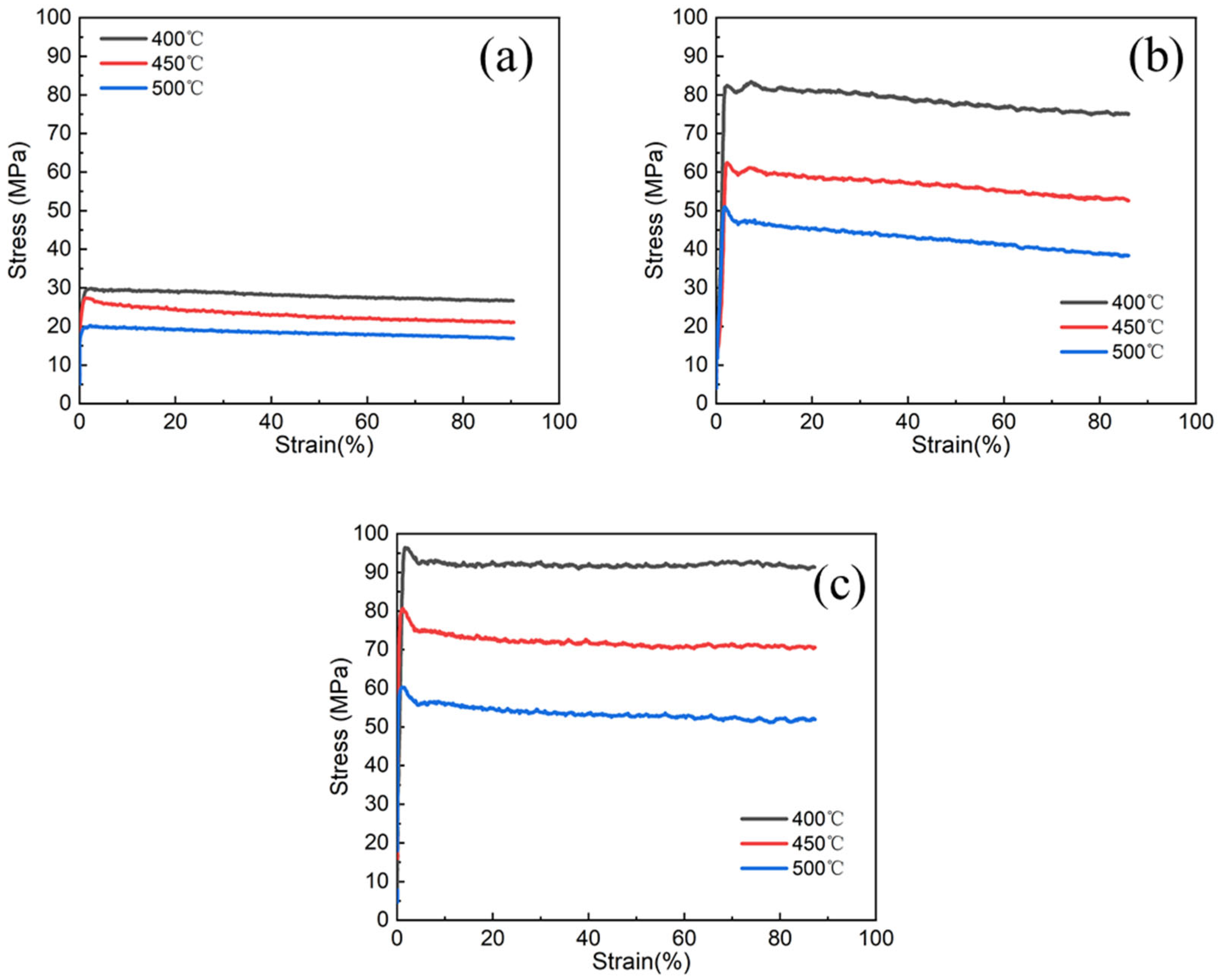

2.3. Determination of Material Parameters

2.4. Experimental Methods

3. Results and Discussion

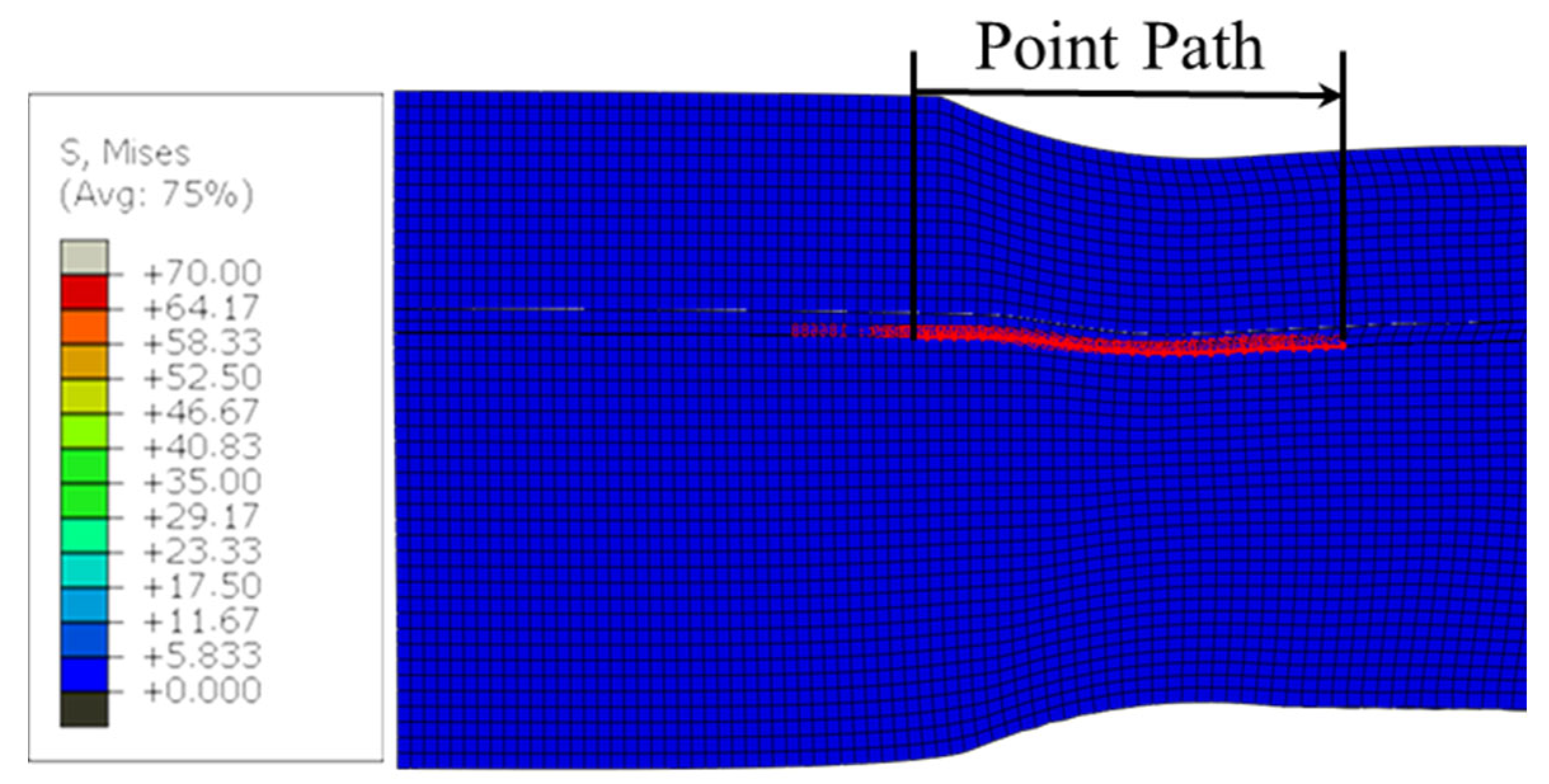

3.1. Simulation Design and Results

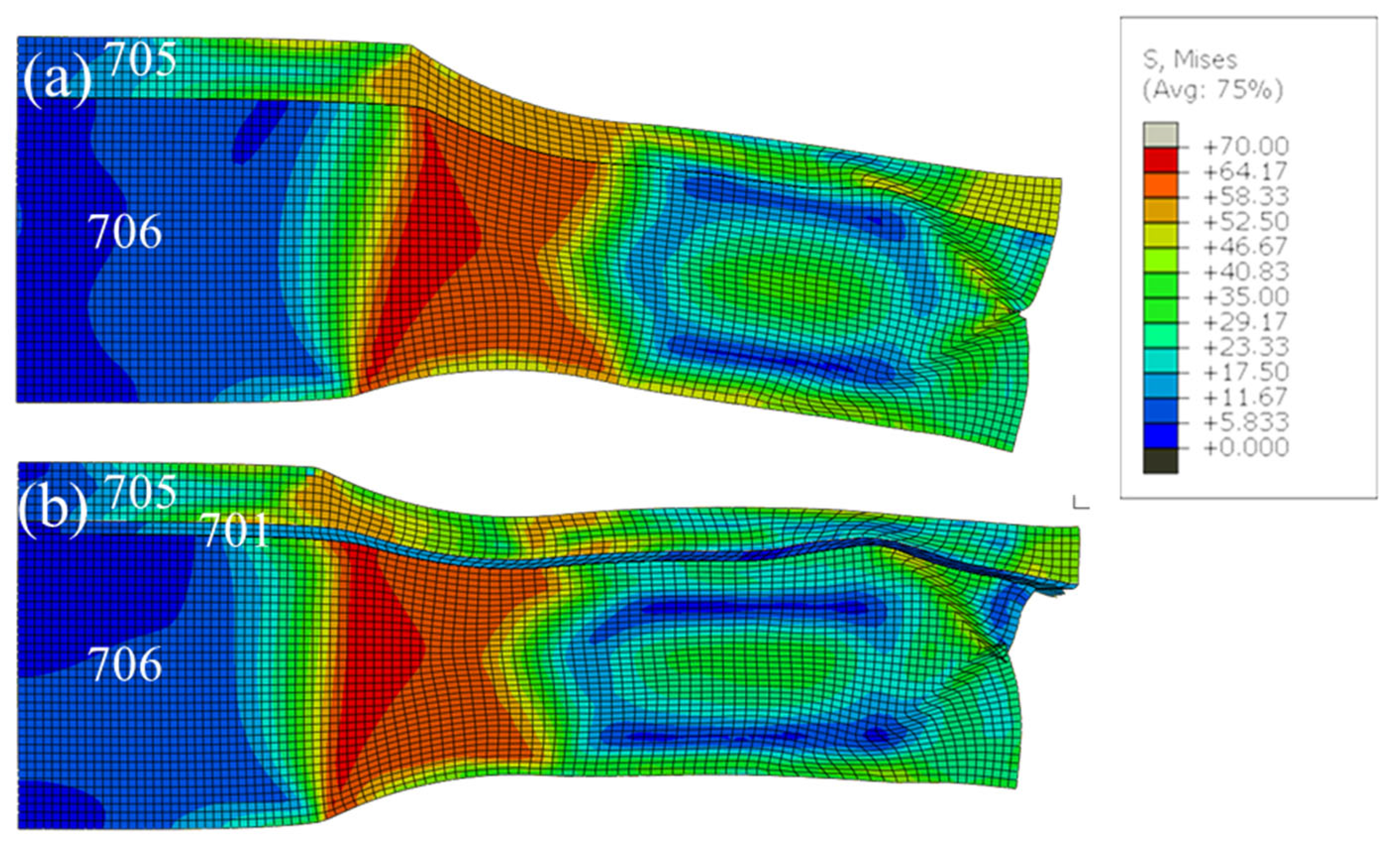

3.1.1. Simulation Results of 701 Interlayer Addition

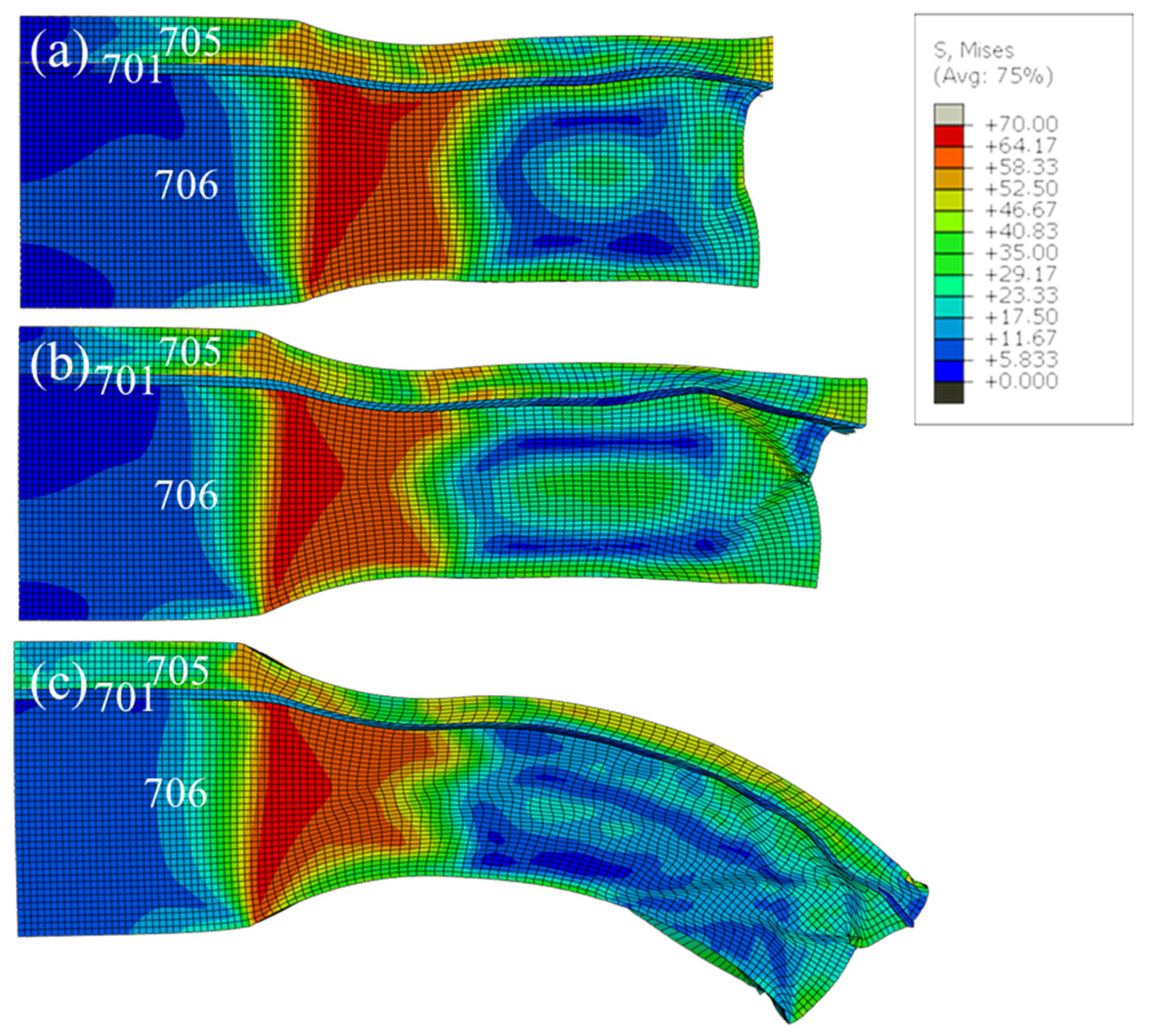

3.1.2. Simulation Results of Different Rolling Reduction Ratios

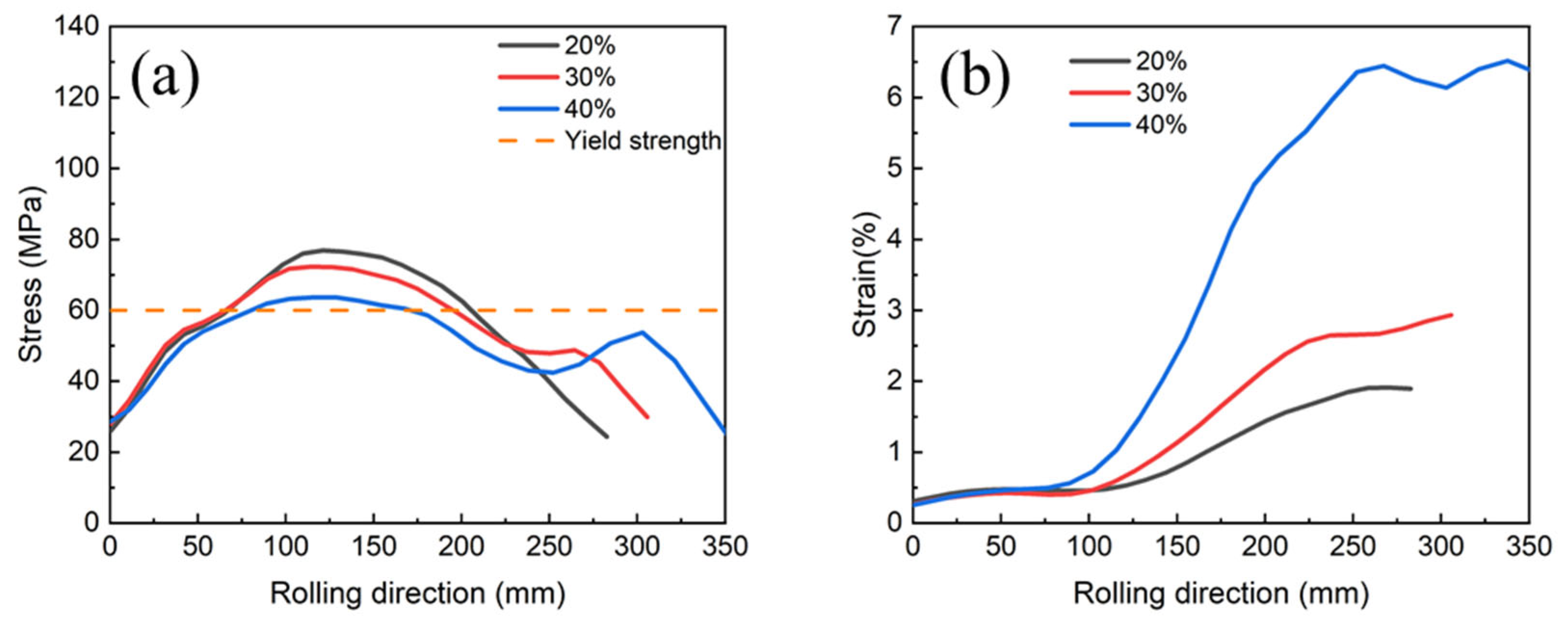

3.1.3. Simulation Results of Different Rolling Speeds

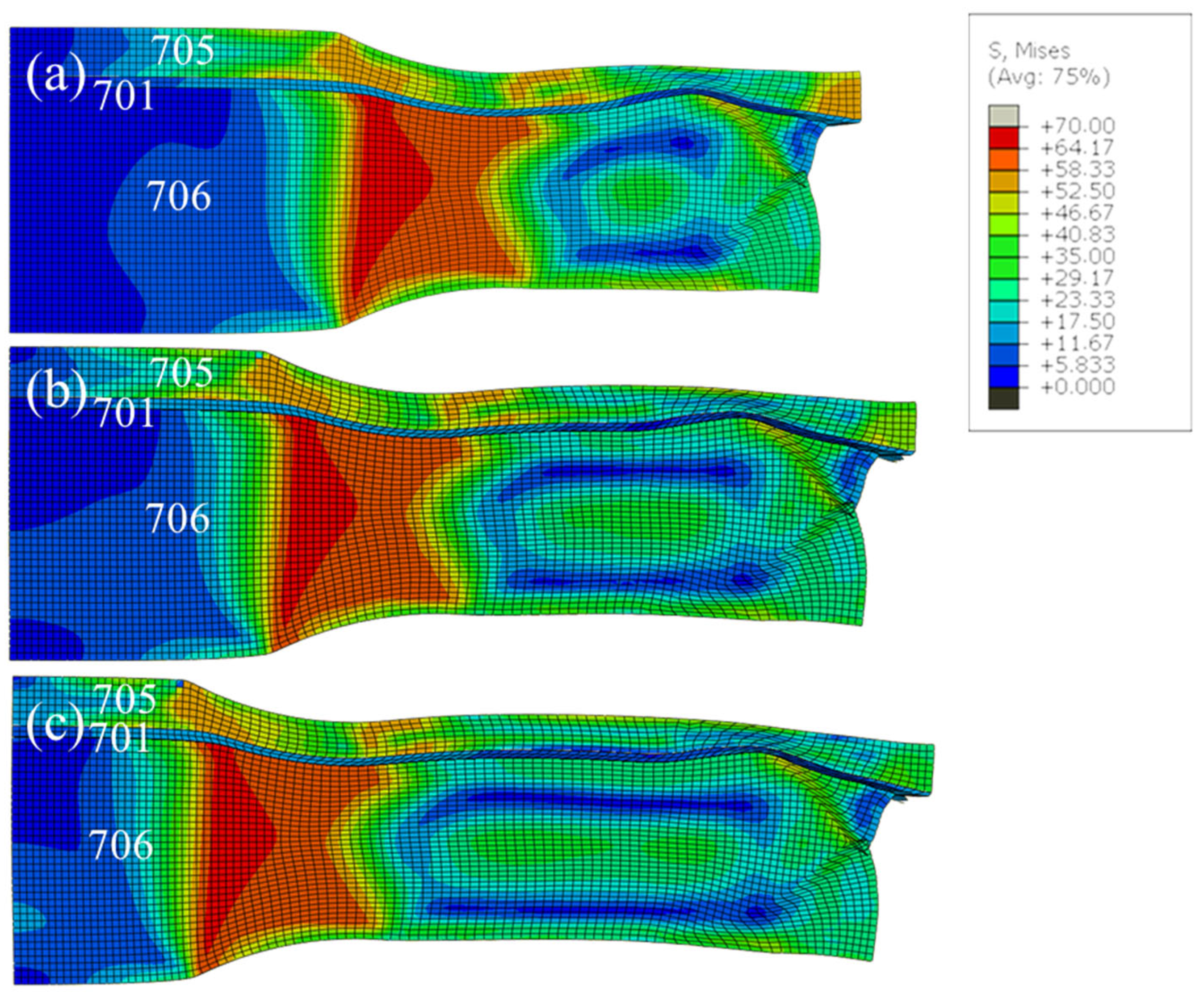

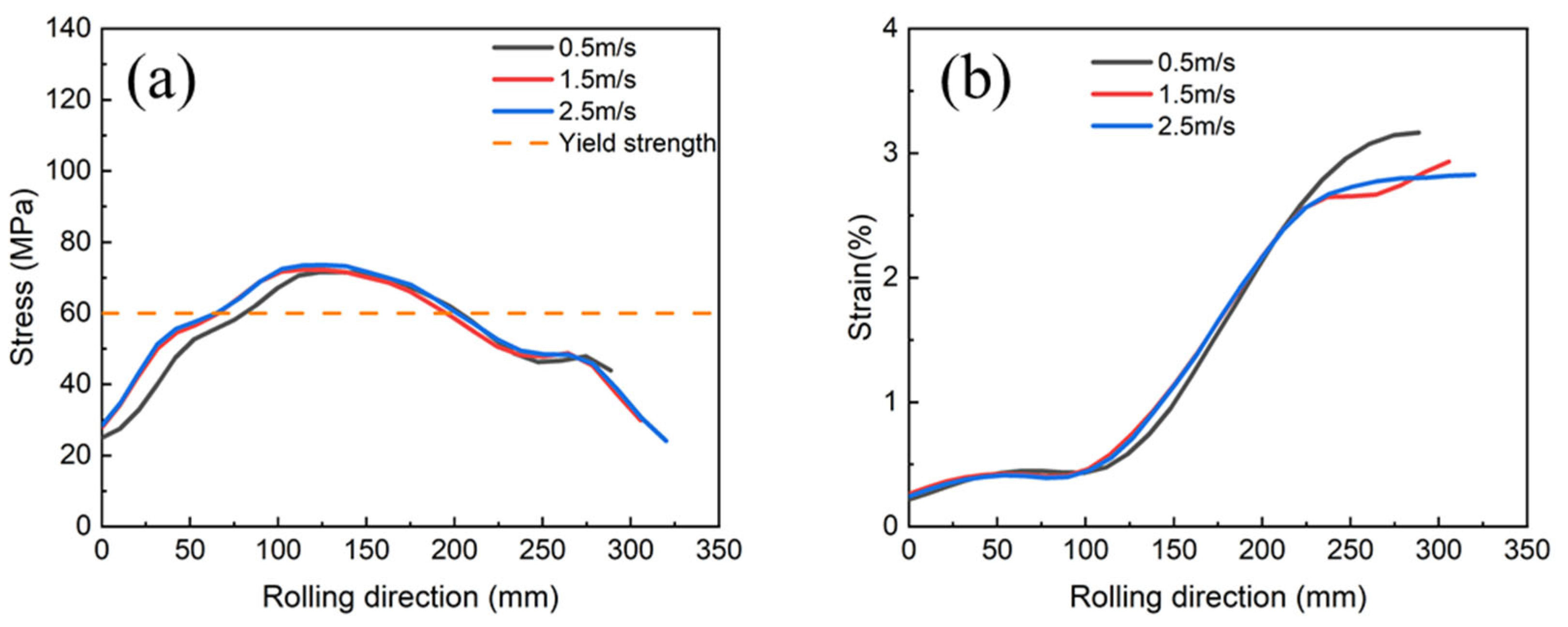

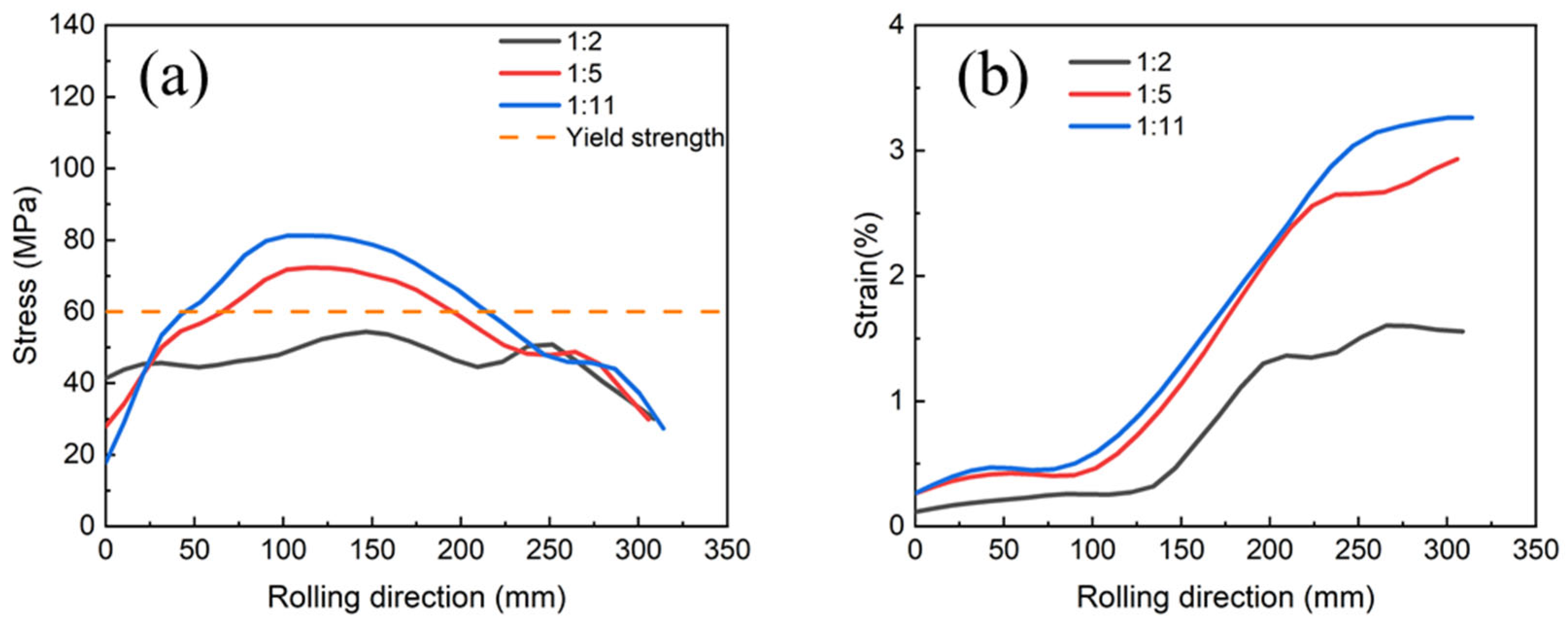

3.1.4. Simulation Results of Different Component Layer Thickness Ratios

3.2. Discussion of Simulation Results

3.2.1. The Effect of Intermediate Layer

3.2.2. The Effect of Rolling Reduction Ratios

3.2.3. The Effect of Hot Rolling Speeds

3.2.4. The Effect of Thickness Ratio of the Layers

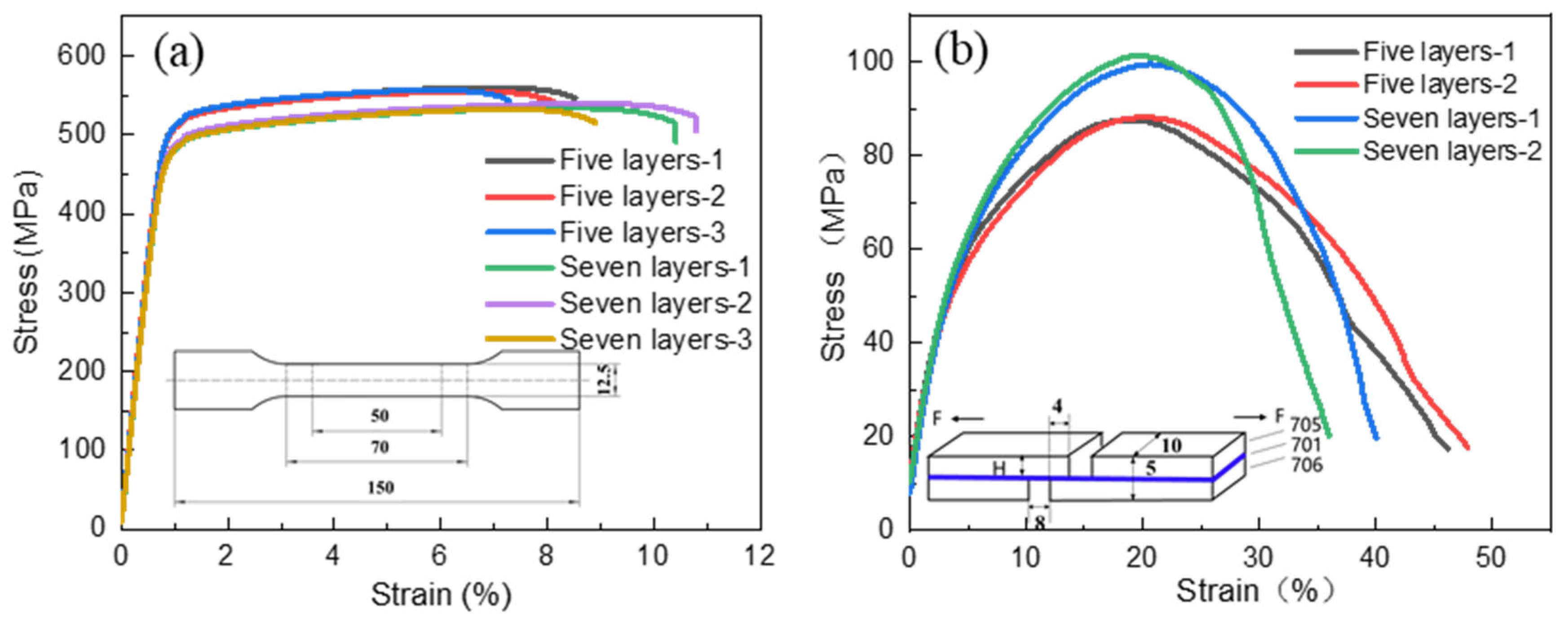

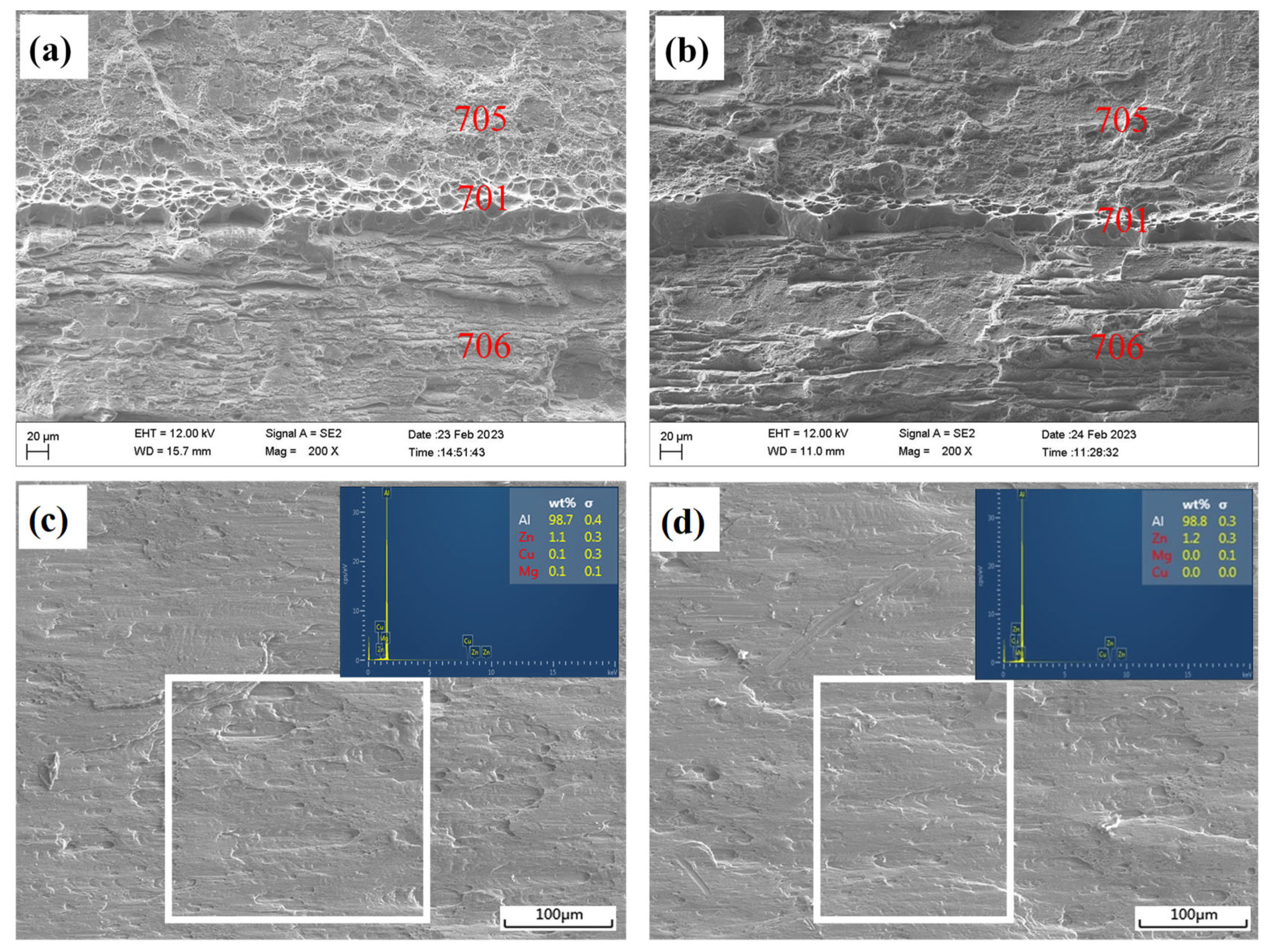

3.3. Experimental Verification

4. Conclusions

- (1)

- The addition of the 701 intermediate layer could effectively coordinate the deformation of the 705 layer and 706 layer and prevent the warping of the laminated material in the hot roll bonding process;

- (2)

- The recommended hot roll bonding process parameters were a pass reduction ratio of 20%~30%, hot rolling speed of 1.5~2.5 m/s and thickness ratio of 1:5 for the 705 layer and 706 layer;

- (3)

- The interface of the five-layer and seven-layer composites prepared by the hot roll bonding process was well bonded. The experimental results verified the rationality of the hot roll bonding process parameters obtained by the finite element simulation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Le, V.T.; San Ha, N.; Goo, N.S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: A review. Compos. Part B 2021, 226, 109301. [Google Scholar] [CrossRef]

- Xia, C.D.; Deng, S.H.; Ni, C.Y.; Ji, Y.Y.; Zheng, W.H.; Luo, J.Q.; Xu, W.; Li, W.D.; Pang, Y. Study on laminar structure and process on high strength brazed aluminum alloy for heat exchangers. Vacuum 2023, 215, 112303. [Google Scholar] [CrossRef]

- Costa, R.D.F.S.; Sales-Contini, R.C.M.; Silva, F.J.G.; Sebbe, N.; Jesus, A.M.P. A critical review on fiber metal laminates (fml): From manufacturing to sustainable processing. Metals 2023, 13, 638. [Google Scholar] [CrossRef]

- Catania, G.; Strozzi, M. Damping Oriented Design of Thin-Walled Mechanical Components by Means of Multi-Layer Coating Technology. Coatings 2018, 8, 73. [Google Scholar] [CrossRef]

- Yu, L.; Ma, Y.; Zhou, C.; Xu, H. Damping efficiency of the coating structure. Int. J. Solids Struct. 2005, 42, 3045–3058. [Google Scholar] [CrossRef]

- Chang, L.; Yuan, S.; Huang, X.; Cai, Z. Determination of Johnson-Cook damage model for 7xxx laminated aluminum alloy and simulation application. Mater. Today Commun. 2023, 34, 105224. [Google Scholar] [CrossRef]

- Liu, W.H.; Cao, P.; Zhao, C.B.; Song, Y.F.; Tang, C.P. Effect of temperature and strain rate on deformation mode and crack behavior of 7B52 laminated aluminum alloy under impact loading. Met. Mater. Int. 2021, 27, 4397–4407. [Google Scholar] [CrossRef]

- Gao, H.T.; Kong, C.R.; Yu, H.L. Lightweight metal laminated plates produced via (hot, cold and cryogenic) roll bonding: A review. Trans. Nonferrous Met. Soc. China 2023, 33, 337–356. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, X.; Liu, B.; He, J.; Feng, J.; Ji, P.; Fang, W.; Yin, F. The deformation characteristics, fracture behavior and strengthening-toughening mechanisms of laminated metal composites: A review. Metals 2020, 10, 4. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q.D. Accumulative roll-bonding of aluminum alloys and composites: An overview of properties and performance. J. Mater. Res. Technol. 2022, 19, 4381–4403. [Google Scholar] [CrossRef]

- Frolov, Y.; Haranich, Y.; Bobukh, O.; Remez, O.; Voswinkel, D.; Grydin, O. Deformation of expanded steel mesh inlay inside aluminum matrix during the roll bonding. J. Manuf. Process. 2020, 58, 857–867. [Google Scholar] [CrossRef]

- Habila, W.; Azzeddine, H.; Mehdi, B.; Tirsatine, K.; Baudin, T.; Helbert, A.L.; Brisset, F.; Gautrot, S.; Mathon, M.H.; Bradai, D. Investigation of microstructure and texture evolution of a Mg/Al laminated composite elaborated by accumulative roll bonding. Mater. Charact. 2019, 147, 242–252. [Google Scholar] [CrossRef]

- Naseri, M.; Reihanian, M.; Borhani, E. Bonding behavior during cold roll-cladding of tri-layered Al/brass/Al composite. J. Manuf. Process. 2016, 24, 125–137. [Google Scholar] [CrossRef]

- Fu, L.; Xiao, H.; Yu, C.; Chen, N.; Guo, Y.; Yang, B.; Ren, Z. Analysis on mechanism of steel plate pre-oxidation in improving bonding properties of cold-rolled 6061 Al/Q235 steel composite plate. J. Mater. Process. Technol. 2023, 316, 117960. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, W.Q.; Yun, Y.L.; Li, Z.X.; Wang, Z.H.; Huang, Q.X. A dynamic composite rolling model based on Lemaitre damage theory. Int. J. Mech. Sci. 2024, 269, 109067. [Google Scholar] [CrossRef]

- Qi, Z.C.; Yu, C.; Xiao, H. Microstructure and bonding properties of magnesium alloy AZ31/CP-Ti clad plates fabricated by rolling bonding. J. Manuf. Process. 2018, 32, 175–186. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, W.; Jiang, R.; Wu, Y.; Xiao, H. Preparation method and properties of Q235/5083 composite plate with 1060 interlayer by differential temperature rolling with induction heating. Metals 2023, 13, 1501. [Google Scholar] [CrossRef]

- Zhi, C.C.; Wu, Z.Y.; Ma, L.F.; Huang, Z.Q.; Zheng, Z.B.; Xv, H.; Jia, W.T.; Lei, J.Y. Effect of thickness ratio on interfacial structure and mechanical properties of Mg/Al composite plates in differential temperature asymmetrical rolling. J. Mater. Res. Technol. 2023, 24, 8332–8347. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Shokai, T.; Hong, J.G. Accumulative roll-bonding of 1100 aluminum. J. Jpn. Inst. Met. Mater. 1999, 63, 790–795. [Google Scholar] [CrossRef]

- Du, Q.L.; Li, C.; Cui, X.H.; Kong, C.; Yu, H.L. Fabrication of ultrafine-grained AA1060 sheets via accumulative roll bonding with subsequent cryorolling. Trans. Nonferrous Met. Soc. China 2021, 31, 3370–3379. [Google Scholar] [CrossRef]

- Wang, Z.J.; Ma, M.; Qiu, Z.X.; Zhang, J.X.; Liu, W.C. Microstructure, texture and mechanical properties of AA 1060 aluminum alloy processed by cryogenic accumulative roll bonding. Mater. Charact. 2018, 139, 269–278. [Google Scholar] [CrossRef]

- Su, L.H.; Lu, C.; Gazder, A.A.; Saleh, A.A.; Deng, G.Y.; Tieu, K.; Li, H.J. Shear texture gradient in AA6061 aluminum alloy processed by accumulative roll bonding with high roll roughness. J. Alloys Compd. 2014, 594, 12–22. [Google Scholar] [CrossRef]

- Wu, B.; Li, L.; Xia, C.D.; Guo, X.F.; Zhou, D.J. Effect of surface nitiding treatment in a steel plate on the interfacial bonding strength of the aluminum/steel clad sheets by the cold roll bonding process. Mater. Sci. Eng. A 2017, 682, 270–278. [Google Scholar] [CrossRef]

- Lukaschkin, N.D.; Borissow, A.P. Interface surface behaviour in the upsetting of sandwich metal sheets. J. Mater. Process. Technol. 1996, 61, 292–297. [Google Scholar] [CrossRef]

- Zhou, M.; Hu, R.; Li, J.G.; Zou, H.; Gao, Z.T.; Luo, X. Interfacial optimization by CPED coating for improving mechanical properties of Nbf/TiAl composite. Mater. Sci. Eng. A Struct. Mater. 2024, 892, 145967. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.; Höppel, H.W.; Göken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface affected zone for optimal strength and ductility in heterogeneous laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef]

- Sun, Z.B.; Liu, L.L.; Tong, J.H.; Han, Y.Q.; Chen, F.R. Numerical analysis of MIG welding of aluminum alloy based on improved heat source model. Trans. China Weld. Inst. 2023, 44, 111–116. [Google Scholar] [CrossRef]

- Huang, J.W.; Yin, Z.M.; Nie, B.; Chen, J.Q.; He, Z.B. Investigation of phases and thermal expansivity of 7A52 alloy in in-situ heating. Ordnance Mater. Sci. Eng. 2007, 30, 9–12. [Google Scholar] [CrossRef]

- Liu, L.X.; Chen, J.G. LC52 aluminum alloy forging process and performance. Forg. Stamp. Technol. 1999, 24, 13–14. [Google Scholar] [CrossRef]

- Liu, B.X.; An, Q.; Yin, F.X.; Wang, S.; Chen, C.X. Interface formation and bonding mechanisms of hot-rolled stainless steel clad plate. J. Mater. Sci. 2019, 54, 11357–11377. [Google Scholar] [CrossRef]

- Shan, S.J.; Liu, Y.X.; Zhang, J.L.; Fan, X.Y.; Jiao, K.X. Explosion welding research on large-size ultra-thick copper-steel composites: A review. J. Mater. Res. Technol. 2023, 24, 4130–4142. [Google Scholar] [CrossRef]

- Huang, M.; Xu, C.; Fan, G.H.; Maawad, E.; Gan, W.M.; Geng, L.; Lin, F.X.; Tang, G.Z.; Wu, H.; Du, Y.; et al. Role of layered structure in ductility improvement of layered Ti-Al metal composite. Acta Mater. 2018, 153, 235–249. [Google Scholar] [CrossRef]

- Wang, T.; Zha, M.; Gao, Y.P.; Wang, S.Q.; Jia, H.L.; Wang, C.; Wang, H.Y. Deformation mechanisms in a novel multiscale hetero-structured Mg alloy with high strength-ductility synergy. Int. J. Plast. 2023, 170, 103766. [Google Scholar] [CrossRef]

- Yin, Y.F.; Kou, W.J.; Zhao, Y.Q.; Zeng, W.D. Formation and deformation mechanism of the hierarchical diffusion layer in the laminated Ti/Ti-50Nb alloy. Mater. Sci. Eng. A 2023, 873, 144996. [Google Scholar] [CrossRef]

- Zhou, X.L.; Chen, C.Q. Molecular dynamic simulations of the mechanical properties of crystalline/crystalline and crystalline/amorphous nanolayered pillars. Comput. Mater. Sci. 2015, 101, 194–200. [Google Scholar] [CrossRef]

- Manesh, H.D.; Taheri, A.K. Study of mechanisms of cold roll welding of aluminium alloy to steel strip. Mater. Sci. Technol. 2004, 20, 1064–1068. [Google Scholar] [CrossRef]

- Ma, M.; Huo, P.; Liu, W.C.; Wang, G.J.; Wang, D.M. Microstructure and mechanical properties of Al/Ti/Al laminated composites prepared by roll bonding. Mater. Sci. Eng. A 2015, 636, 301–310. [Google Scholar] [CrossRef]

- Abbasi, M.; Toroghinejad, M.R. Effects of processing parameters on the bond strength of Cu/Cu roll-bonded strips. J. Mater. Process. Technol. 2010, 210, 560–563. [Google Scholar] [CrossRef]

- Khan, H.A.; Asim, K.; Akram, F.; Hameed, A.; Khan, A.; Mansoor, B. Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals 2021, 11, 1344. [Google Scholar] [CrossRef]

- Tsuji, N.; Toyoda, T.; Minamino, Y.; Koizumi, Y.; Yamane, T.; Komatsu, M.; Kiritani, M. Microstructural change of ultrafine-grained aluminum during high-speed plastic deformation. Mater. Sci. Eng. A 2003, 350, 108–116. [Google Scholar] [CrossRef]

- Hwang, Y.-M.; Chen, T.-H.; Hsu, H.-H. Analysis of asymmetrical clad sheet rolling by stream function method. Int. J. Mech. Sci. 1996, 38, 443–460. [Google Scholar] [CrossRef]

- Rezaii, A.; Shafiei, E.; Ostovan, F.; Daneshmanesh, H. Experimental & theoretical investigation of roll bonding process of multilayer strips by finite element method. J. Manuf. Process. 2020, 54, 54–69. [Google Scholar] [CrossRef]

| Element (wt.%) | Si | Fe | Cu | Mn | Mg | Zn | Ti | Zr | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 701 | 0.262 | 0.32 | 0.0085 | 0.055 | 0.002 | 1.05 | / | / | / | Bal. |

| 705 | 0.048 | 0.129 | 0.10 | 0.356 | 2.44 | 4.52 | 0.097 | 0.105 | 0.201 | Bal. |

| 706 | 0.042 | 0.119 | 0.105 | 0.304 | 2.970 | 7.230 | 0.094 | 0.071 | 0.196 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Xia, C.; Ni, C. Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials. Metals 2024, 14, 551. https://doi.org/10.3390/met14050551

Xu W, Xia C, Ni C. Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials. Metals. 2024; 14(5):551. https://doi.org/10.3390/met14050551

Chicago/Turabian StyleXu, Wei, Chengdong Xia, and Chengyuan Ni. 2024. "Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials" Metals 14, no. 5: 551. https://doi.org/10.3390/met14050551

APA StyleXu, W., Xia, C., & Ni, C. (2024). Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials. Metals, 14(5), 551. https://doi.org/10.3390/met14050551