Solidification Mechanism of Microstructure of Al-Si-Cu-Ni Alloy Manufactured by Laser Powder Bed Fusion and Mechanical Properties Effect

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

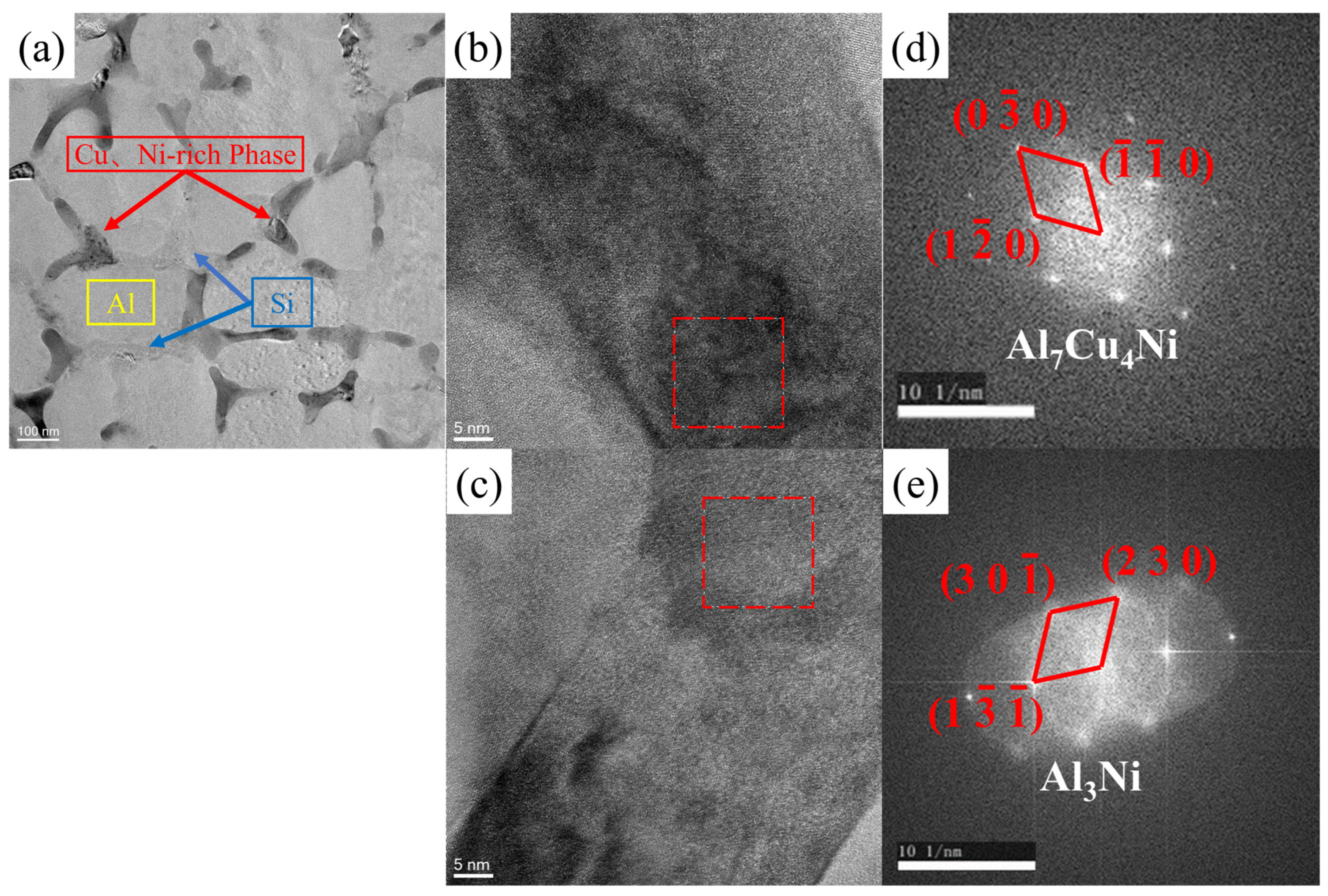

3.1. Phases of Powder and Samples

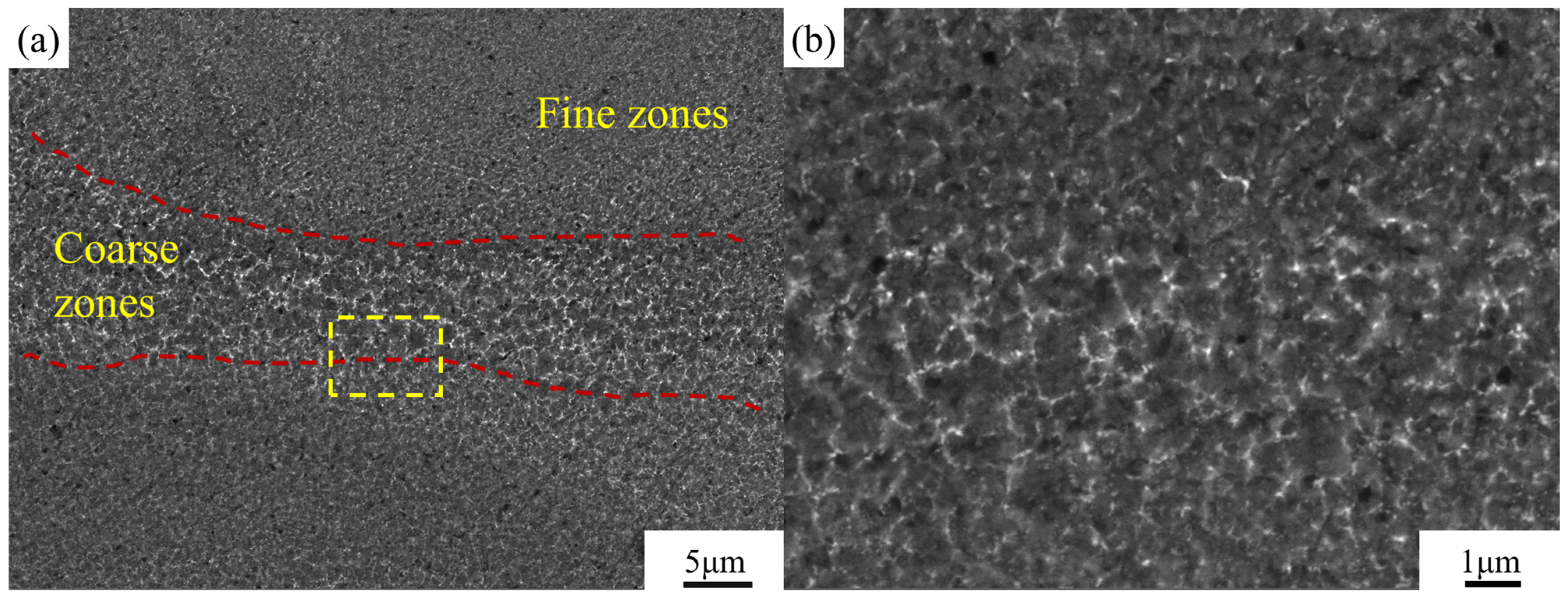

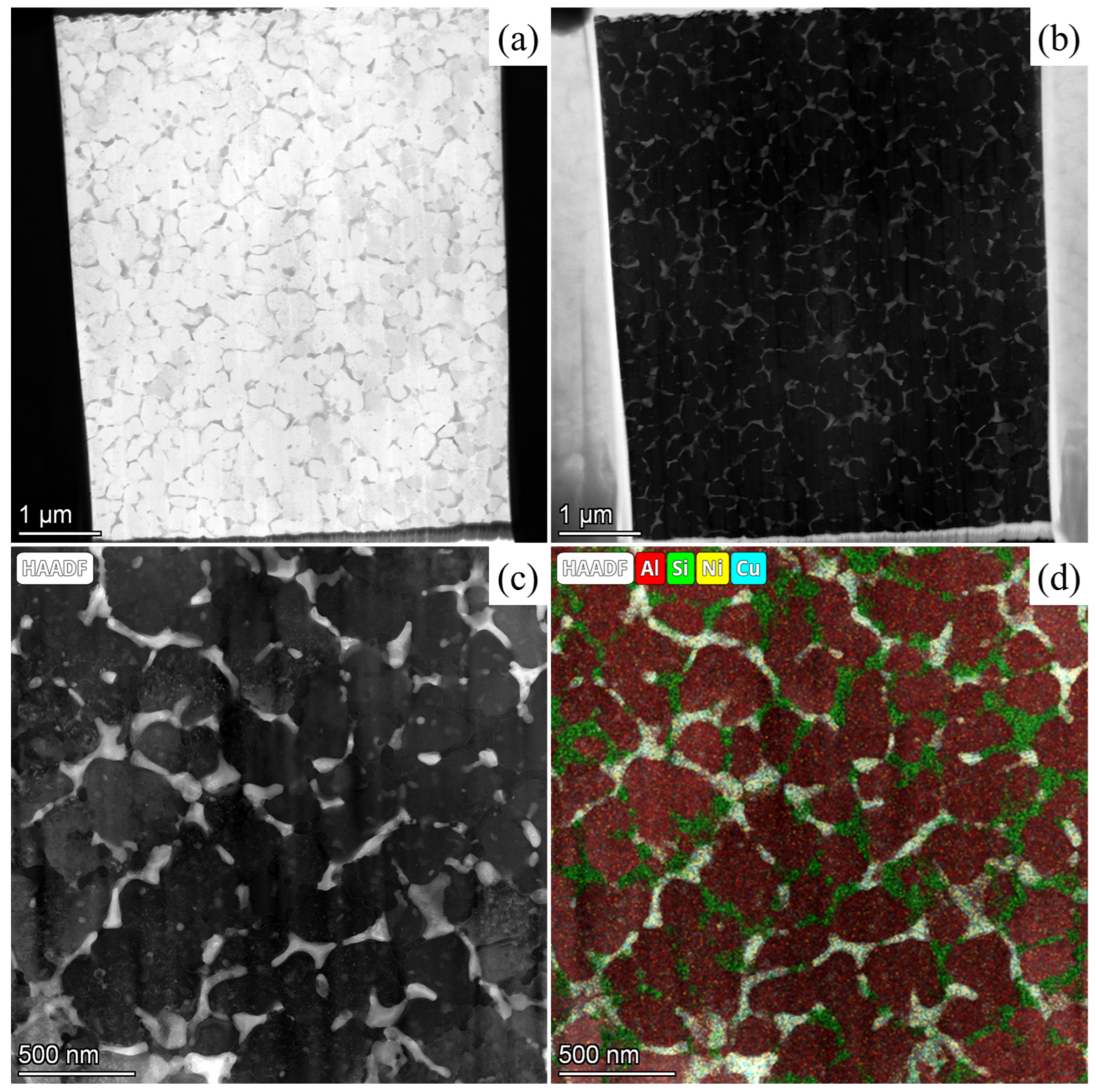

3.2. Microstructure of PBF-LB/M Al-Si-Cu-Ni Alloys

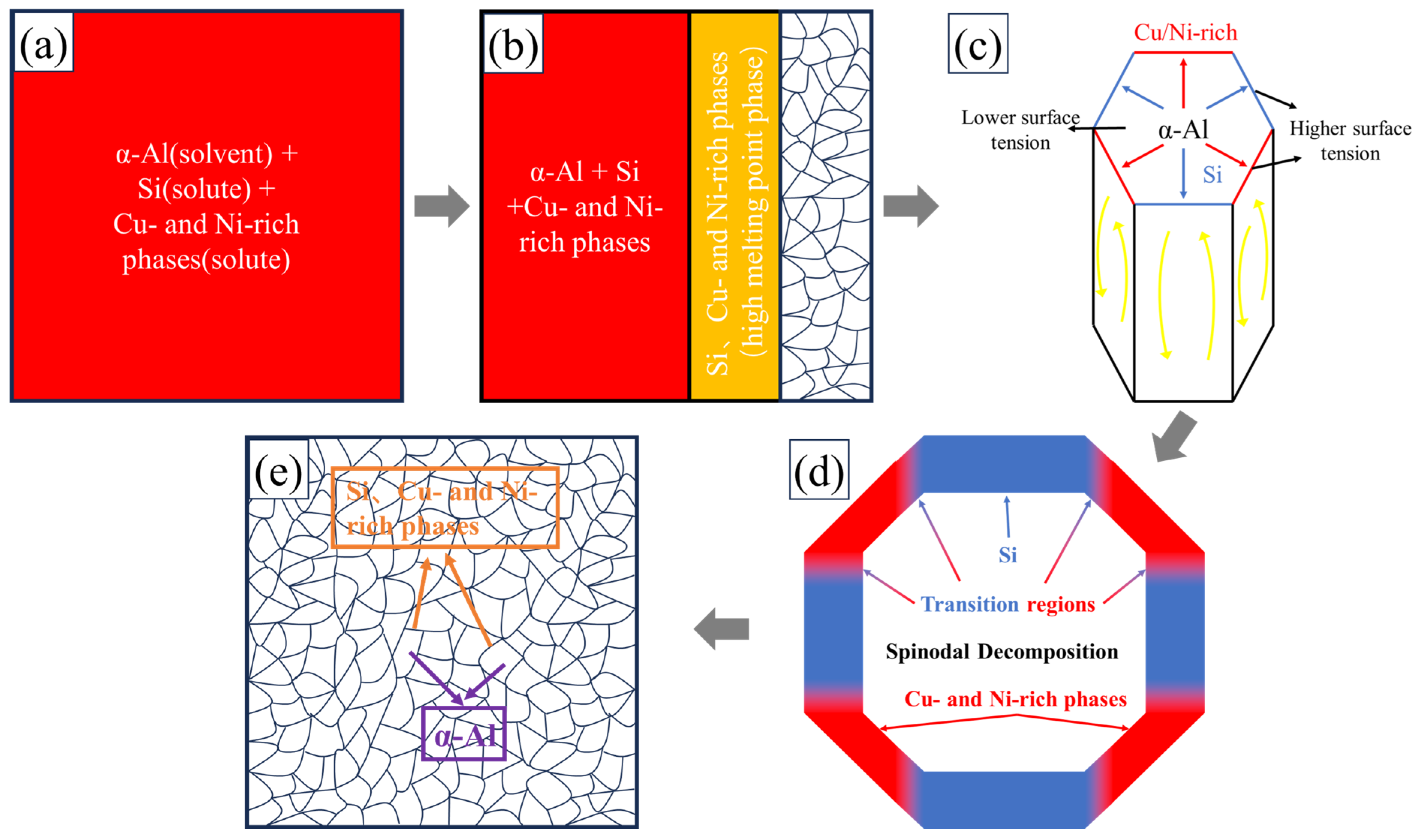

3.3. Solidification Mechanism of PBF-LB/M Al-Si-Cu-Ni Alloys

3.4. Mechanical Properties of PBF-LB/M Al-Si-Cu-Ni Alloys

3.4.1. Bending Property

3.4.2. Tensile Property

4. Conclusions

- (1)

- The PBF-LB/M Al-Si-Cu-Ni alloy comprises α-Al, Si, and small amounts of Al7Cu4Ni, Al3Ni, and Al2Cu phases. The complementary interlacing between the Si and the Cu- and Ni-rich phases together constitutes a cellular heterogeneous microstructure, which can significantly improve the mechanical properties of the alloy. The bending strength, fracture displacement, ultimate tensile strength, and yield strength of the alloy are 766 ± 30 MPa, 0.84 ± 0.03 mm, 437 ± 6 MPa, and 344 ± 4 MPa, but the fracture elongation is relatively low, at only ~1.51 ± 0.07%.

- (2)

- During the solidification process of the PBF-LB/M Al-Si-Cu-Ni alloy, α-Al solidifies initially, occupying the core of the cellular structure. The high-melting-point Si and Cu-and Ni-rich phases are deposited along the boundary of the cellular structure under the influence of surface tension and undergo spinodal decomposition. Influenced by the lattice spacing, they interconnect and cross-distribute among each other, collectively forming the cellular heterogeneous microstructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mei, J.; Han, Y.; Sun, J.; Jiang, M.; Zu, G.; Song, X.; Zhu, W.; Ran, X. Improving the comprehensive mechanical property of the AlSi10Mg alloy via parameter adaptation of selective laser melting and heat treatment. J. Alloys Compd. 2024, 981, 173623. [Google Scholar] [CrossRef]

- Kang, N.; El Mansori, M. A new insight on induced-tribological behaviour of hypereutectic Al-Si alloys manufactured by selective laser melting. Tribol. Int. 2020, 149, 105751. [Google Scholar] [CrossRef]

- Goudar, D.M.; Raju, K.; Srivastava, V.C.; Rudrakshi, G.B. Effect of copper and iron on the wear properties of spray formed Al–28Si alloy. Mater. Des. 2013, 51, 383–390. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Huang, A.; Wu, X.; Zhang, K. Improving fatigue performances of selective laser melted Al-7Si-0.6Mg alloy via defects control. Int. J. Fatigue 2019, 129, 105215. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.; Han, Y.; Zu, G.; Zhu, W.; Zhao, Y.; Chen, H.; Ran, X. Achieving Superior Strength and Ductility of AlSi10Mg Alloy Fabricated by Selective Laser Melting with Large Laser Power and High Scanning Speed. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1665–1672. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Park, T.-H.; Baek, M.-S.; Hyer, H.; Sohn, Y.; Lee, K.-A. Effect of direct aging on the microstructure and tensile properties of AlSi10Mg alloy manufactured by selective laser melting process. Mater. Charact. 2021, 176, 111113. [Google Scholar] [CrossRef]

- Belov, N.A.; Eskin, D.G.; Avxentieva, N.N. Constituent phase diagrams of the Al–Cu–Fe–Mg–Ni–Si system and their application to the analysis of aluminium piston alloys. Acta Mater. 2005, 53, 4709–4722. [Google Scholar] [CrossRef]

- Chuang, H.-C.; Lui, T.-S.; Chen, L.-H. Characteristics and Effects of Particle Morphology and Tensile Ductility Resulting from FSP of Al-Si-Cu-Ni Casting and Forging Piston. Mater. Trans. 2013, 54, 1373–1380. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Timelli, G.; Bonollo, F. Characterization of the solidification path and microstructure of secondary Al-7Si-3Cu-0.3Mg alloy with Zr, V and Ni additions. Mater. Charact. 2017, 128, 100–108. [Google Scholar] [CrossRef]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, A.V.; Ryabov, D.K.; Korolev, V.A.; Daubarayte, D.K. Novel heat-resistant Al-Si-Ni-Fe alloy manufactured by selective laser melting. Mater. Lett. 2019, 236, 676–679. [Google Scholar] [CrossRef]

- Thapliyal, S.; Shukla, S.; Zhou, L.; Hyer, H.; Agrawal, P.; Agrawal, P.; Komarasamy, M.; Sohn, Y.; Mishra, R.S. Design of heterogeneous structured Al alloys with wide processing window for laser-powder bed fusion additive manufacturing. Addit. Manuf. 2021, 42, 102002. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiao, W.; Ge, S.; Zhao, W.; Hanada, S.; Ma, C. Effects of Cu content and Cu/Mg ratio on the microstructure and mechanical properties of Al–Si–Cu–Mg alloys. J. Alloys Compd. 2015, 649, 291–296. [Google Scholar] [CrossRef]

- Rometsch, P.; Jia, Q.; Yang, K.; Wu, X. Aluminum alloys for selective laser melting—Towards improved performance. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 301–325. [Google Scholar]

- Medrano-Prieto, H.M.; Garay-Reyes, C.G.; Gómez-Esparza, C.D.; Estrada-Guel, I.; Aguilar-Santillan, J.; Maldonado-Orozco, M.C.; Martínez-Sánchez, R. Effect of Nickel addition and solution treatment time on microstructure and hardness of Al-Si-Cu aged alloys. Mater. Charact. 2016, 120, 168–174. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, P.; Yan, B. Effect of Different Heat Treatments on the Evolution of Novel Al-Si-Cu-Ni-Fe-Re Alloy Fabricated by Selective Laser Melting. Metals 2022, 12, 1827. [Google Scholar] [CrossRef]

- Dai, H.; Song, Y.; Chen, H.; Miao, J. Directed Energy Deposition-Arc Repair Al6.5Cu2Ni0.3Ti0.5Zr0.25V Alloy: Microstructure Evolution and Strengthening Mechanism. Adv. Eng. Mater. 2024, 26, 2301772. [Google Scholar] [CrossRef]

- Wang, H.; He, L.; Zhang, Q.; Yuan, Y. Influence of Ni Contents on Microstructure and Mechanical Performance of AlSi10Mg Alloy by Selective Laser Melting. Materials 2023, 16, 4679. [Google Scholar] [CrossRef] [PubMed]

- Jandaghi, M.R.; Aversa, A.; Manfredi, D.; Calignano, F.; Lavagna, L.; Pavese, M. In situ alloying of AlSi10Mg-5 wt% Ni through laser powder bed fusion and subsequent heat treatment. J. Alloys Compd. 2022, 904, 164081. [Google Scholar] [CrossRef]

- Ming, X.; Song, D.; Yu, A.; Tan, H.; Zhang, Q.; Zhang, Z.; Chen, J.; Lin, X. Effect of heat treatment on microstructure, mechanical and thermal properties of selective laser melted AlSi7Mg alloy. J. Alloys Compd. 2023, 945, 169278. [Google Scholar] [CrossRef]

- Xue, Y.; Shao, Q.; Mu, J.; Ji, X.; Wang, X. Microstructure and compression performance of novel AlSi10Mg composite auxetic structures fabricated by additive manufacturing. Mater. Sci. Eng. A 2024, 897, 146330. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Bayat, M.; Tan, Q.; Yin, Y.; Fan, Z.; Liu, S.; Hattel, J.H.; Dargusch, M.; Zhang, M.-X. Achieving high ductility in a selectively laser melted commercial pure-titanium via in-situ grain refinement. Scr. Mater. 2021, 191, 155–160. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Niendorf, T.; Eckert, J.; Scudino, S. A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties. Compos. Part B Eng. 2018, 147, 162–168. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.; Yang, Y.; Bai, Y. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 2016, 100, 291–299. [Google Scholar] [CrossRef]

- Qian, B.; Saeidi, K.; Kvetková, L.; Lofaj, F.; Xiao, C.; Shen, Z. Defects-tolerant Co-Cr-Mo dental alloys prepared by selective laser melting. Dent. Mater. 2015, 31, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, N. The effects of turbulence on molten pool transport during melting and solidification processes in continuous conduction mode laser welding of copper–nickel dissimilar couple. Appl. Therm. Eng. 2009, 29, 3618–3631. [Google Scholar] [CrossRef]

- Asta, M.; Beckermann, C.; Karma, A.; Kurz, W.; Napolitano, R.; Plapp, M.; Purdy, G.; Rappaz, M.; Trivedi, R. Solidification microstructures and solid-state parallels: Recent developments, future directions. Acta Mater. 2009, 57, 941–971. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Cahn, J.W. Free Energy of a Nonuniform System. II. Thermodynamic Basis. J. Chem. Phys. 1959, 30, 1121–1124. [Google Scholar] [CrossRef]

- Division, C.; Ridge, O.; Sciences, P. Spinadal decompsotion Fe-Cr alloys: Experimental study at the atomic level and comparison with computer models-development of morphology—I introduction and methodology. Acta Metall. Mater. 1995, 43, 3385–3401. [Google Scholar]

- Caron, P.; Khan, T.; Veyssière, P. On precipitate shearing by superlattice stacking faults in superalloys. Philos. Mag. A 1988, 57, 859–875. [Google Scholar] [CrossRef]

- Cahn, J.W. On spinodal decomposition in cubic crystals. Acta Metall. 1962, 10, 179–183. [Google Scholar] [CrossRef]

- Smith, D.W.; Elliott, C.M. Spinodal decompsotion Fe-Cr alloys: Experimental study at the atomic level and comparison with computer models-development of morphology—III. Development of metholody. Acta Metall. Mater. 1995, 43, 3415–3426. [Google Scholar]

- Tsai, M.-H.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Li, N.; Li, Z.; Wei, Y. The Influence of Metastable Cellular Structure on Deformation Behavior in Laser Additively Manufactured 316L Stainless Steel. Nanomaterials 2021, 11, 2859. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Li, Q.; Du, A.; Fan, Y.; Zhao, X.; Yu, Y.; Ma, R.; Cao, X. Effects of Cu content on the wettability of SiC with Al-Ti-Si-xCu alloy and bending strength of resulting SiC matrix composite. Ceram. Int. 2018, 44, 5327–5335. [Google Scholar] [CrossRef]

- Chen, G.; Yang, W.; Xin, L.; Wang, P.; Liu, S.; Qiao, J.; Hu, F.; Zhang, Q.; Wu, G. Mechanical properties of Al matrix composite reinforced with diamond particles with W coatings prepared by the magnetron sputtering method. J. Alloys Compd. 2018, 735, 777–786. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Peng, C.; Cai, Z.; Zhou, Z.; Li, X.; Cao, X. Microstructural evolution and mechanical performance of in-situ TiB2/AlSi10Mg composite manufactured by selective laser melting. J. Alloys Compd. 2021, 853, 157287. [Google Scholar] [CrossRef]

- Yin, C.; Lu, Z.; Wei, X.; Yan, B.; Yan, P. High Bending Strength Hypereutectic Al-22Si-0.2Fe-0.1Cu-Re Alloy Fabricated by Selective Laser Melting. Metals 2021, 11, 528. [Google Scholar] [CrossRef]

- Kekana, N.; Shongwe, M.B.; Mpofu, K.; Muvunzi, R. A review on factors influencing mechanical properties of AlSi12 alloy processed by selective laser melting. Int. J. Adv. Manuf. Technol. 2022, 121, 4313–4323. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. (1980–2015) 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Aksoy, S.; Kabakcı, F.; Acarer, M.; Düzcükoğlu, H.; Ünüvar, E.; Fındık, F. Effect of Mg addition on microstructure and mechanical properties of AlSi12 alloy produced by high-pressure casting method. Ind. Lubr. Tribol. 2022, 75, 27–35. [Google Scholar] [CrossRef]

- Zhao, Z.; Bai, P.; Misra, R.D.K.; Dong, M.; Guan, R.; Li, Y.; Zhang, J.; Tan, L.; Gao, J.; Ding, T.; et al. AlSi10Mg alloy nanocomposites reinforced with aluminum-coated graphene: Selective laser melting, interfacial microstructure and property analysis. J. Alloys Compd. 2019, 792, 203–214. [Google Scholar] [CrossRef]

- Roth, C.C.; Tancogne-Dejean, T.; Mohr, D. Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling. Addit. Manuf. 2021, 43, 101998. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Hwang, W.J.; Bang, G.B.; Choa, S.-H. Effect of a Stress Relief Heat Treatment of AlSi7Mg and AlSi10Mg Alloys on Mechanical and Electrical Properties According to Silicon Precipitation. Met. Mater. Int. 2022, 29, 1311–1322. [Google Scholar] [CrossRef]

- Croteau, J.R.; Griffiths, S.; Rossell, M.D.; Leinenbach, C.; Kenel, C.; Jansen, V.; Seidman, D.N.; Dunand, D.C.; Vo, N.Q. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater. 2018, 153, 35–44. [Google Scholar] [CrossRef]

| Element | Al | Si | Cu | Ni | Fe | Re |

|---|---|---|---|---|---|---|

| Element Weight (wt%) | Bal. | 12.0 | 3.8 | 2.0 | 0.2 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Yan, P.; Yan, B. Solidification Mechanism of Microstructure of Al-Si-Cu-Ni Alloy Manufactured by Laser Powder Bed Fusion and Mechanical Properties Effect. Metals 2024, 14, 586. https://doi.org/10.3390/met14050586

Shi Z, Yan P, Yan B. Solidification Mechanism of Microstructure of Al-Si-Cu-Ni Alloy Manufactured by Laser Powder Bed Fusion and Mechanical Properties Effect. Metals. 2024; 14(5):586. https://doi.org/10.3390/met14050586

Chicago/Turabian StyleShi, Zhichao, Pengfei Yan, and Biao Yan. 2024. "Solidification Mechanism of Microstructure of Al-Si-Cu-Ni Alloy Manufactured by Laser Powder Bed Fusion and Mechanical Properties Effect" Metals 14, no. 5: 586. https://doi.org/10.3390/met14050586

APA StyleShi, Z., Yan, P., & Yan, B. (2024). Solidification Mechanism of Microstructure of Al-Si-Cu-Ni Alloy Manufactured by Laser Powder Bed Fusion and Mechanical Properties Effect. Metals, 14(5), 586. https://doi.org/10.3390/met14050586