Cracking Behavior of the ZhS6K Superalloy during Direct Laser Deposition with Induction Heating

Abstract

:1. Introduction

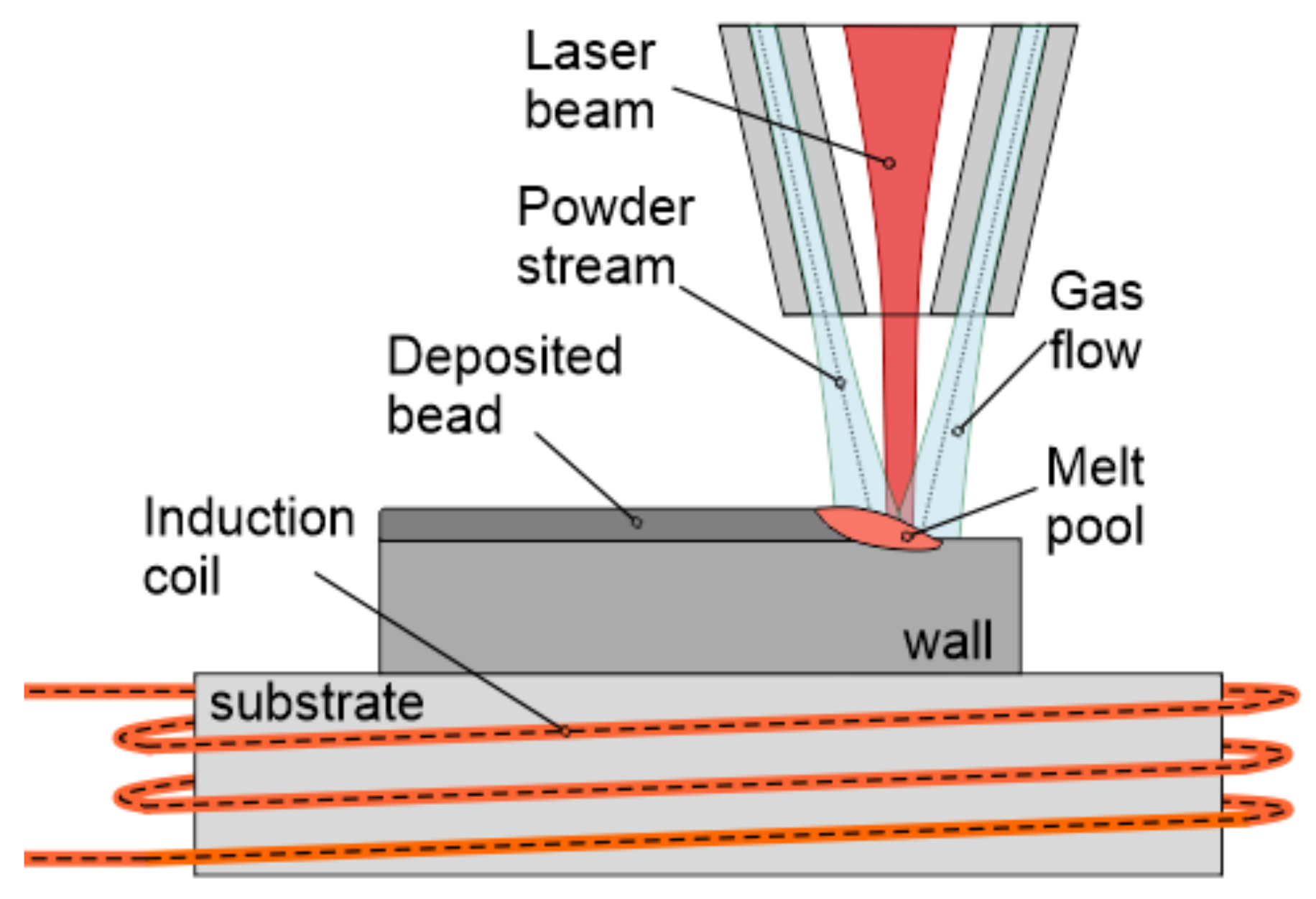

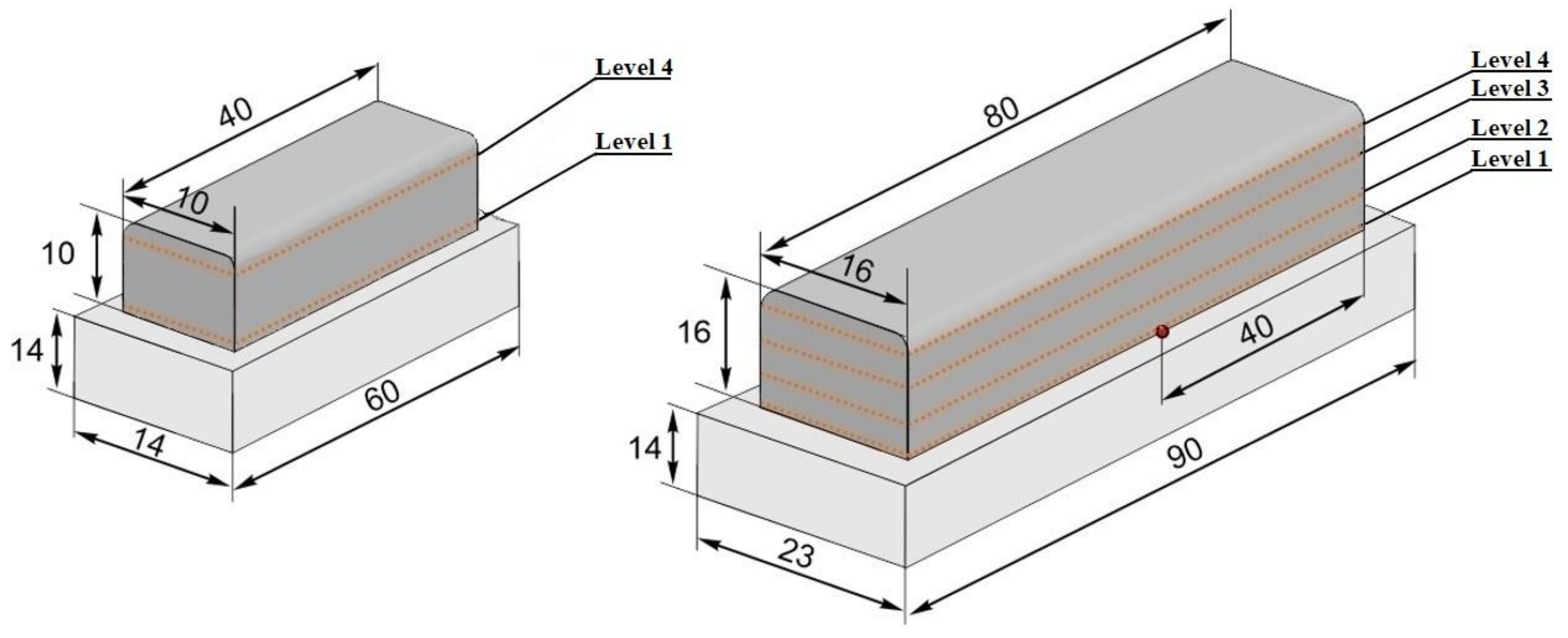

2. Materials and Methods

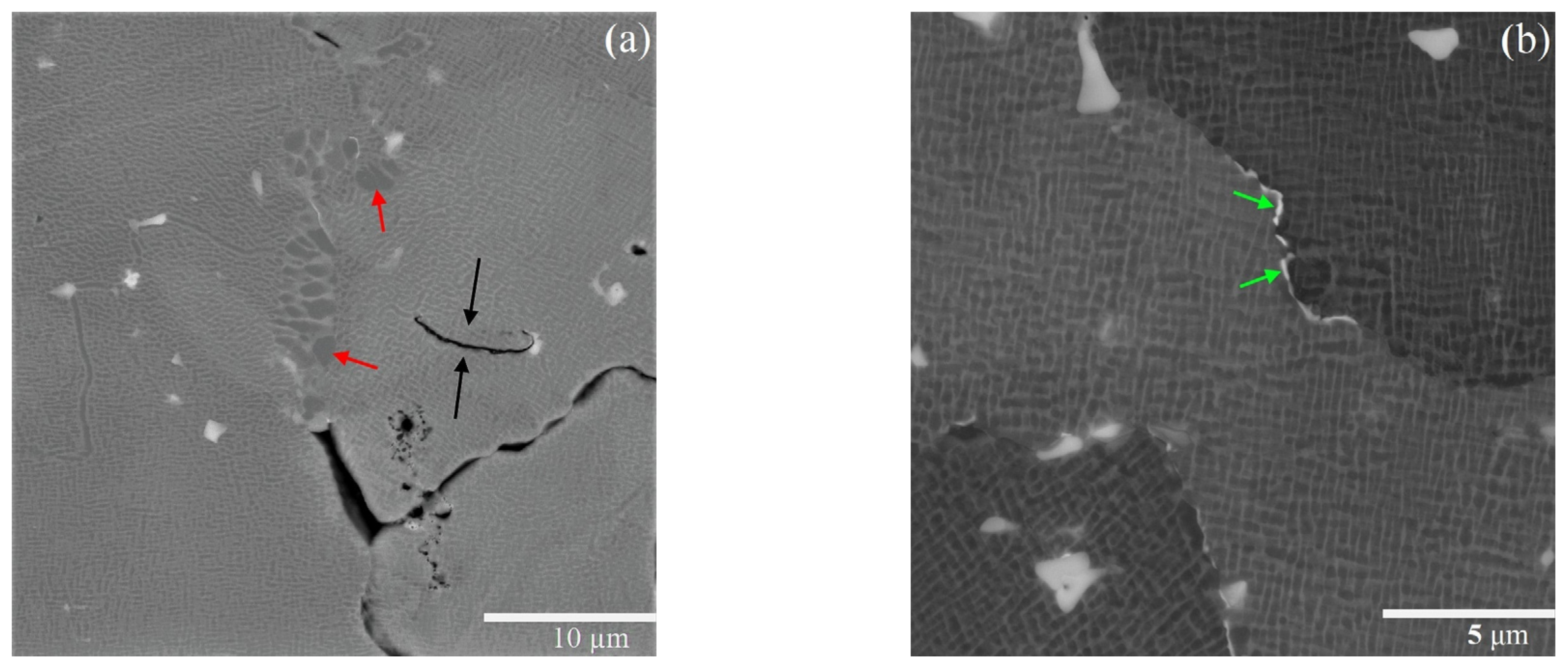

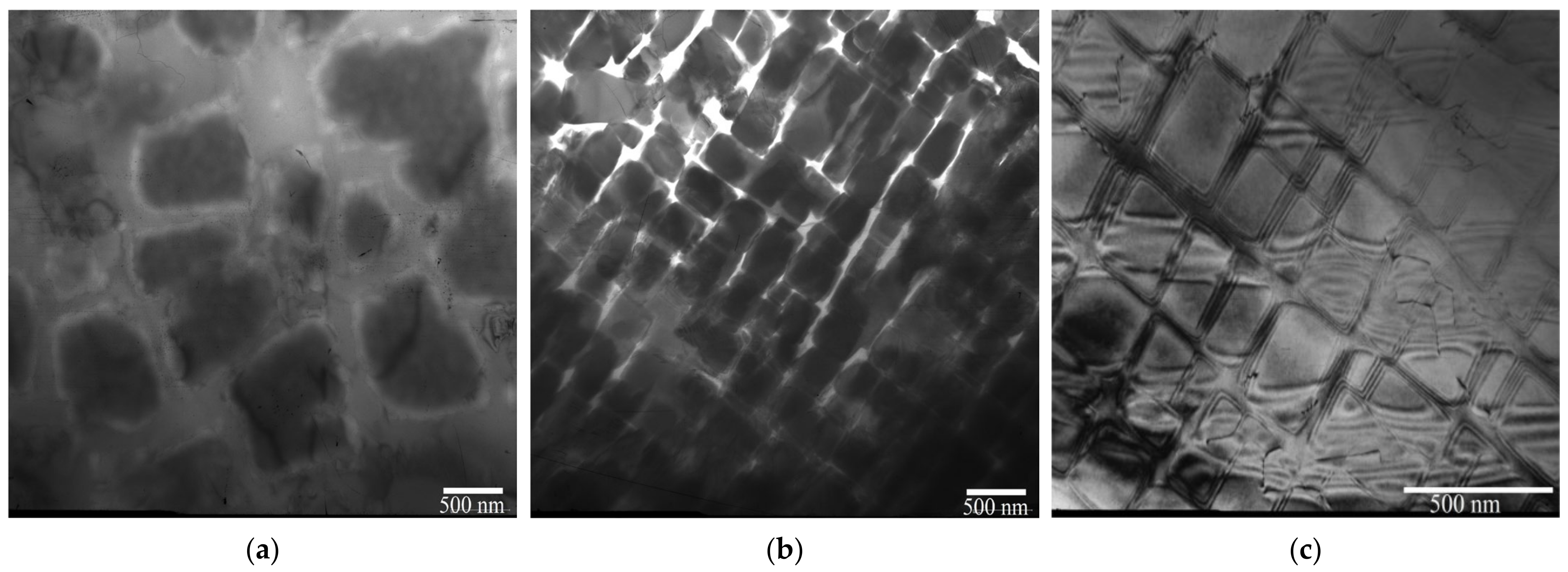

3. Results

4. Discussion

5. Conclusions

- (1)

- The “small” sample was relatively crack-free, while the “large” underwent extensive cracking. The cracking of the “large” sample was associated with the formation of the columnar structure, which provided the fast tracks for the propagation of solid-state cracks, while the “small” sample had an equiaxed structure. In addition, liquation cracks at the grain boundaries decorated by eutectic γ/γ’ agglomerates and/or carbides were observed in both samples.

- (2)

- Both the “small” and “large” samples exhibited a strong gradient in the γ’ phase particles’ sizes and fraction from the bottom to the top. In particular, the size of the γ’ particles decreased from 530 nm to 100 nm in the “large” specimen. The fraction of the γ’ phase increased from the bottom to the top; in the “large” specimen this variation was as large as from 0 to 65%. Such changes were associated with the complex thermal history of the samples, revealed both computationally and experimentally, and are likely the reason for the increase in the hardness of the samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/74514.html (accessed on 9 June 2023).

- Froes, F.; Boyer, R. Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128140635. [Google Scholar]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Ahmed, N. Direct metal fabrication in rapid prototyping: A review. J. Manuf. Process. 2019, 42, 167–191. [Google Scholar] [CrossRef]

- Feenstra, D.R.; Banerjee, R.; Fraser, H.L.; Huang, A.; Molotnikov, A.; Birbilis, N. Critical review of the state of the art in multi-material fabrication via directed energy deposition. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Negi, S.; Nambolan, A.A.; Kapil, S.; Joshi, P.S.; Manivannan, R.; Karunakaran, K.P.; Bhargava, P. Review on electron beam based additive manufacturing. Rapid Prototyp. J. 2020, 26, 485–498. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Arungalai Vendan, S. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Gushchina, M.O.; Klimova-Korsmik, O.G.; Turichin, G.A. Direct laser deposition of Cu-Mo functionally graded layers for dissimilar joining titanium alloys and steels. Mater. Lett. 2022, 307, 131042. [Google Scholar] [CrossRef]

- Makarenko, K.I.; Konev, S.D.; Dubinin, O.N.; Shishkovsky, I.V. Mechanical characteristics of laser-deposited sandwich structures and quasi-homogeneous alloys of Fe-Cu system. Mater. Des. 2022, 224, 111313. [Google Scholar] [CrossRef]

- Kuzminova, Y.O.; Dubinin, O.N.; Gushchina, M.O.; Simonov, A.P.; Konev, S.D.; Sarkeeva, A.A.; Zhilyaev, A.P.; Evlashin, S.A. The mechanical behavior of the Ti6Al4V/Ti/Ti6Al4V composite produced by directed energy deposition under impact loading. Materialia 2023, 27, 101684. [Google Scholar] [CrossRef]

- Reed, R.C.; Roger, C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780511541285. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.T.; Strayer, S.; Chang, K.C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Attallah, M.M.; Jennings, R.; Wang, X.; Carter, L.N. Additive manufacturing of Ni-based superalloys: The outstanding issues. MRS Bull. 2016, 41, 758–764. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Additive Manufacturing of Nickel-Base Superalloy René N5 through Scanning Laser Epitaxy (SLE)—Material Processing, Microstructures, and Microhardness Properties. Adv. Eng. Mater. 2017, 19, 1600690. [Google Scholar] [CrossRef]

- Moosavy, H.N.; Aboutalebi, M.R.; Seyedein, S.H.; Khodabakhshi, M.; Mapelli, C. New approach for assessing the weldability of precipitation-strengthened nickel-base superalloys. Int. J. Miner. Metall. Mater. 2013, 20, 1183–1191. [Google Scholar] [CrossRef]

- Kontis, P.; Chauvet, E.; Peng, Z.; He, J.; da Silva, A.K.; Raabe, D.; Tassin, C.; Blandin, J.J.; Abed, S.; Dendievel, R.; et al. Atomic-scale grain boundary engineering to overcome hot-cracking in additively-manufactured superalloys. Acta Mater. 2019, 177, 209–221. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron Beam Melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Wei, Q.; Xie, Y.; Teng, Q.; Shen, M.; Sun, S.; Cai, C. Crack Types, Mechanisms, and Suppression Methods during High-energy Beam Additive Manufacturing of Nickel-based Superalloys: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100055. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.G.; Németh, A.A.N.; McCartney, D.G.; Reed, R.C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Divya, V.D.; Muñoz-Moreno, R.; Messé, O.M.D.M.; Barnard, J.S.; Baker, S.; Illston, T.; Stone, H.J. Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater. Charact. 2016, 114, 62–74. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Z.; Yu, L.; Liu, Y. New alloy design approach to inhibiting hot cracking in laser additive manufactured nickel-based superalloys. Acta Mater. 2023, 247, 118736. [Google Scholar] [CrossRef]

- Murray, S.P.; Pusch, K.M.; Polonsky, A.T.; Torbet, C.J.; Seward, G.G.E.; Zhou, N.; Forsik, S.A.J.; Nandwana, P.; Kirka, M.M.; Dehoff, R.R.; et al. A defect-resistant Co–Ni superalloy for 3D printing. Nat. Commun. 2020, 11, 4975. [Google Scholar] [CrossRef] [PubMed]

- Park, J.U.; Jun, S.Y.; Lee, B.H.; Jang, J.H.; Lee, B.S.; Lee, H.J.; Lee, J.H.; Hong, H.U. Alloy design of Ni-based superalloy with high γ′ volume fraction suitable for additive manufacturing and its deformation behavior. Addit. Manuf. 2022, 52, 102680. [Google Scholar] [CrossRef]

- Ghoussoub, J.N.; Klupś, P.; Dick-Cleland, W.J.B.; Rankin, K.E.; Utada, S.; Bagot, P.A.J.; McCartney, D.G.; Tang, Y.T.; Reed, R.C. A new class of alumina-forming superalloy for 3D printing. Addit. Manuf. 2022, 52, 102608. [Google Scholar] [CrossRef]

- Seidel, A.; Finaske, T.; Straubel, A.; Wendrock, H.; Maiwald, T.; Riede, M.; Lopez, E.; Brueckner, F.; Leyens, C. Additive Manufacturing of Powdery Ni-Based Superalloys Mar-M-247 and CM 247 LC in Hybrid Laser Metal Deposition. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 3812–3830. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kirka, M.M.; Ferguson, J.; Paquit, V.C. Correlations of cracking with scan strategy and build geometry in electron beam powder bed additive manufacturing. Addit. Manuf. 2020, 32, 101031. [Google Scholar] [CrossRef]

- Dang, X.; Li, Y.; Chen, K.; Ramamurty, U.; Luo, S.; Liang, X.; He, W. Avoiding cracks in additively manufactured non-weldable directionally solidified Ni-based superalloys. Addit. Manuf. 2022, 59, 103095. [Google Scholar] [CrossRef]

- Lukina, E.A.; Bazaleeva, K.O.; Petrushin, N.V.; Treninkov, I.A.; Tsvetkova, E.V. Effect of the selective laser melting parameters on the structure–phase state of a ZhS6K-VI nickel superalloy. Russ. Metall. (Met.) 2017, 2017, 594–600. [Google Scholar] [CrossRef]

- Nie, J.; Chen, C.; Liu, L.; Wang, X.; Zhao, R.; Shuai, S.; Wang, J.; Ren, Z. Effect of substrate cooling on the epitaxial growth of Ni-based single-crystal superalloy fabricated by direct energy deposition. J. Mater. Sci. Technol. 2021, 62, 148–161. [Google Scholar] [CrossRef]

- Guan, W.; Chen, C.; Pan, X.; Zhao, R.; Xufei, L.; Tao, H.; Songzhe, X.; Xuan, W.; Panwisawas, C.; Lei, L.; et al. On the control of epitaxial growth and stray grains during laser-directed energy deposited Ni-based single crystal superalloy. Mater. Charact. 2024, 113969. [Google Scholar] [CrossRef]

- Meng, G.; Gong, Y.; Zhang, J.; Zhao, J. The microstructural evolution and mechanical response of laser direct energy deposition Inconel 718 alloy based on simulation and experimental methods. Eng. Fail. Anal. 2024, 161, 108334. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Xiao, Y.; Horstemeyer, M.F.; Cui, X.; Chen, L. Insight into the mechanisms of columnar to equiaxed grain transition during metallic additive manufacturing. Addit. Manuf. 2019, 26, 22–29. [Google Scholar] [CrossRef]

- Zhao, Y.; Aoyagi, K.; Yamanaka, K.; Chiba, A. A survey on basic influencing factors of solidified grain morphology during electron beam melting. Mater. Des. 2022, 221, 110927. [Google Scholar] [CrossRef]

- Shao, J.; Yu, G.; Li, S.; He, X.; Tian, C.; Dong, B. Crystal growth control of Ni-based alloys by modulation of the melt pool morphology in DED. J. Alloy. Compd. 2022, 898, 162976. [Google Scholar] [CrossRef]

- Li, H.; Fu, W.; Chen, T.; Huang, Y.; Ning, Z.; Sun, J.; Bai, H.; Dai, X.; Fan, H.; Ngan, A.H.W. Toward tunable microstructure and mechanical properties in additively manufactured CoCrFeMnNi high entropy alloy. J. Alloy. Compd. 2022, 924, 166513. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Wang, X.; Carter, L.N.; Pang, B.; Attallah, M.M.; Loretto, M.H. Microstructure and yield strength of SLM-fabricated CM247LC Ni-Superalloy. Acta Mater. 2017, 128, 87–95. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Laser power (W) | 1400 |

| Deposition speed (mm/s) | 25 |

| Powder flow rate (g/min) | 16.5 |

| Laser spot size (mm) | 2.5 |

| Width offset (mm) | 1.67 |

| Height offset (mm) | 0.8 |

| Pause time (s) | 0 |

| Temperature, °C | Density, kg/m3 | Heat Capacity, J/(kg·K) | Thermal Conductivity, W/m·K | |||

|---|---|---|---|---|---|---|

| INC718 | ZhS6K | INC718 | ZhS6K | INC718 | ZhS6K | |

| 25 | 8190 | 8200 | 0.435 | 0.38 | 8.9 | 8 |

| 100 | 8160 | 8200 | 0.455 | 0.4 | 10.8 | 9 |

| 200 | 8118 | 8200 | 0.479 | 0.42 | 12.9 | 11 |

| 300 | 8079 | 8200 | 0.497 | 0.445 | 15.2 | 12 |

| 400 | 8040 | 8200 | 0.515 | 0.47 | 17.4 | 14 |

| 500 | 8001 | 8200 | 0.527 | 0.485 | 18.7 | 15 |

| 600 | 7962 | 8200 | 0.558 | 0.515 | 20.8 | 17 |

| 700 | 7925 | 8200 | 0.568 | 0.56 | 21.9 | 19 |

| 800 | 7884 | 8200 | 0.68 | 0.61 | 26.9 | 22 |

| 900 | 7845 | 8200 | 0.64 | 0.66 | 25.8 | 24 |

| 1000 | 7806 | 0.62 | 26.7 | |||

| 1100 | 7767 | 0.64 | 28.3 | |||

| 1170 | 7727 | 0.65 | 29.3 | |||

| 1336 | 7400 | 0.72 | 29.6 | |||

| 1400 | 7340 | 0.72 | 29.6 | |||

| 1500 | 7250 | 0.72 | 29.6 | |||

| 1600 | 7160 | 0.72 | 29.6 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dmitrieva, A.; Semenyuk, A.; Klimova, M.; Udin, I.; Mukin, D.; Vildanov, A.; Zherebtsov, S.; Klimova-Korsmik, O.; Stepanov, N. Cracking Behavior of the ZhS6K Superalloy during Direct Laser Deposition with Induction Heating. Metals 2024, 14, 610. https://doi.org/10.3390/met14060610

Dmitrieva A, Semenyuk A, Klimova M, Udin I, Mukin D, Vildanov A, Zherebtsov S, Klimova-Korsmik O, Stepanov N. Cracking Behavior of the ZhS6K Superalloy during Direct Laser Deposition with Induction Heating. Metals. 2024; 14(6):610. https://doi.org/10.3390/met14060610

Chicago/Turabian StyleDmitrieva, Anastasiia, Anastasiya Semenyuk, Margarita Klimova, Ilya Udin, Dmitrii Mukin, Artur Vildanov, Sergey Zherebtsov, Olga Klimova-Korsmik, and Nikita Stepanov. 2024. "Cracking Behavior of the ZhS6K Superalloy during Direct Laser Deposition with Induction Heating" Metals 14, no. 6: 610. https://doi.org/10.3390/met14060610

APA StyleDmitrieva, A., Semenyuk, A., Klimova, M., Udin, I., Mukin, D., Vildanov, A., Zherebtsov, S., Klimova-Korsmik, O., & Stepanov, N. (2024). Cracking Behavior of the ZhS6K Superalloy during Direct Laser Deposition with Induction Heating. Metals, 14(6), 610. https://doi.org/10.3390/met14060610