Metallurgical Defects and Roughness Investigation in the Laser Powder Bed Fusion Multi-Scanning Strategy of AlSi10Mg Parts

Abstract

:1. Introduction

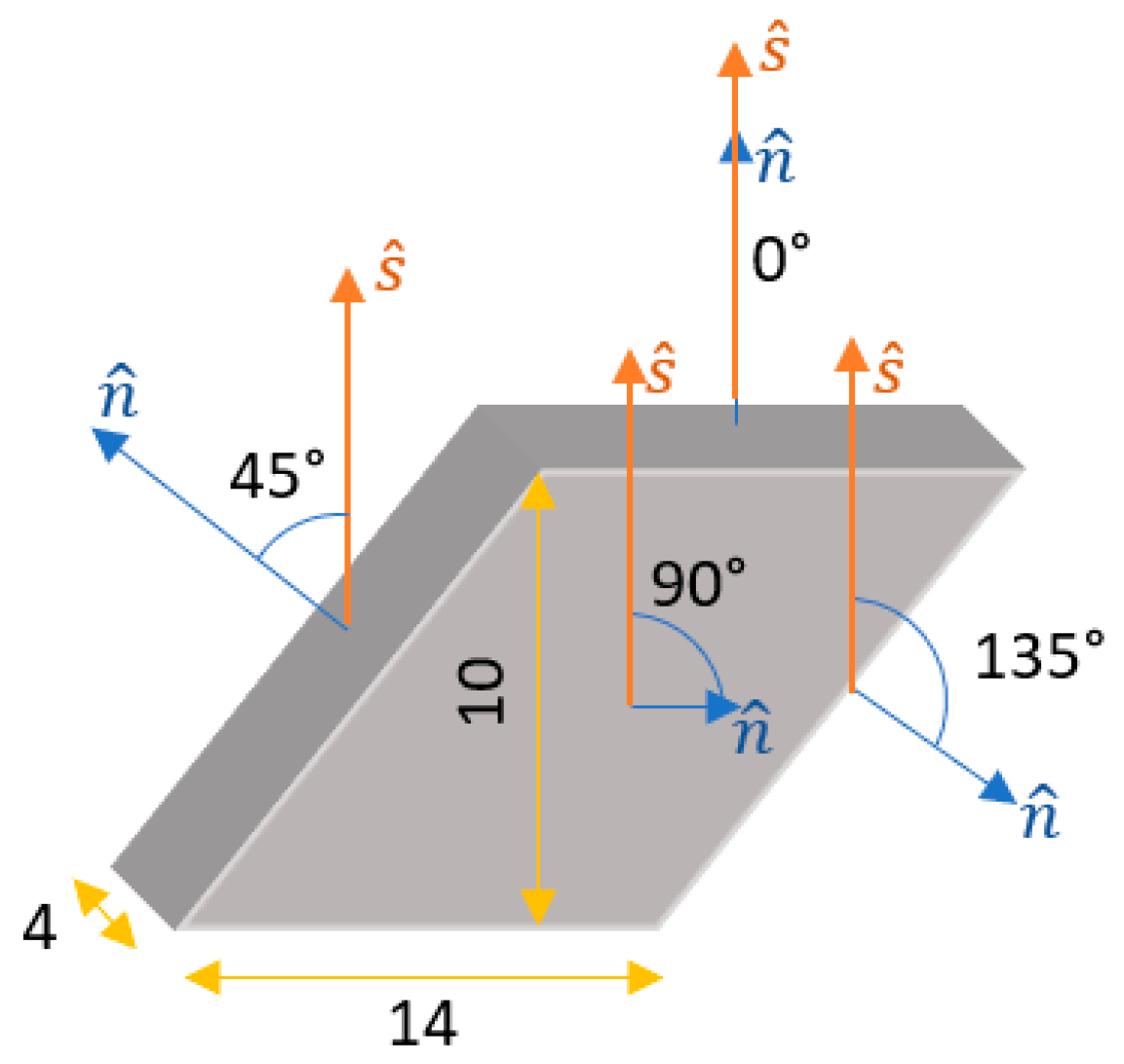

2. Materials and Methods

- The first scan (both for contour and hatching strategies) is used for the consolidation of the layer; it was performed using standard process parameters for the AlSi10Mg material suggested by EOS GmbH (machine and powders supplier, Krailling, Germany), i.e., 370 W laser power, 30 μm layer thickness, 1300 mm/s scan speed, 180 μm hatch distance, and 200 °C building platform temperature;

- A second scan was applied for each layer modifying the process parameters for contour and upskin strategies in order to treat, directly inside the fabrication process, the surfaces obtained through the first scan. This way, the proposed method is applied only to the external skin of the components maintaining the standard conditions for the core part to avoid microstructural and metallurgical changes inside the part.

3. Results and Discussion

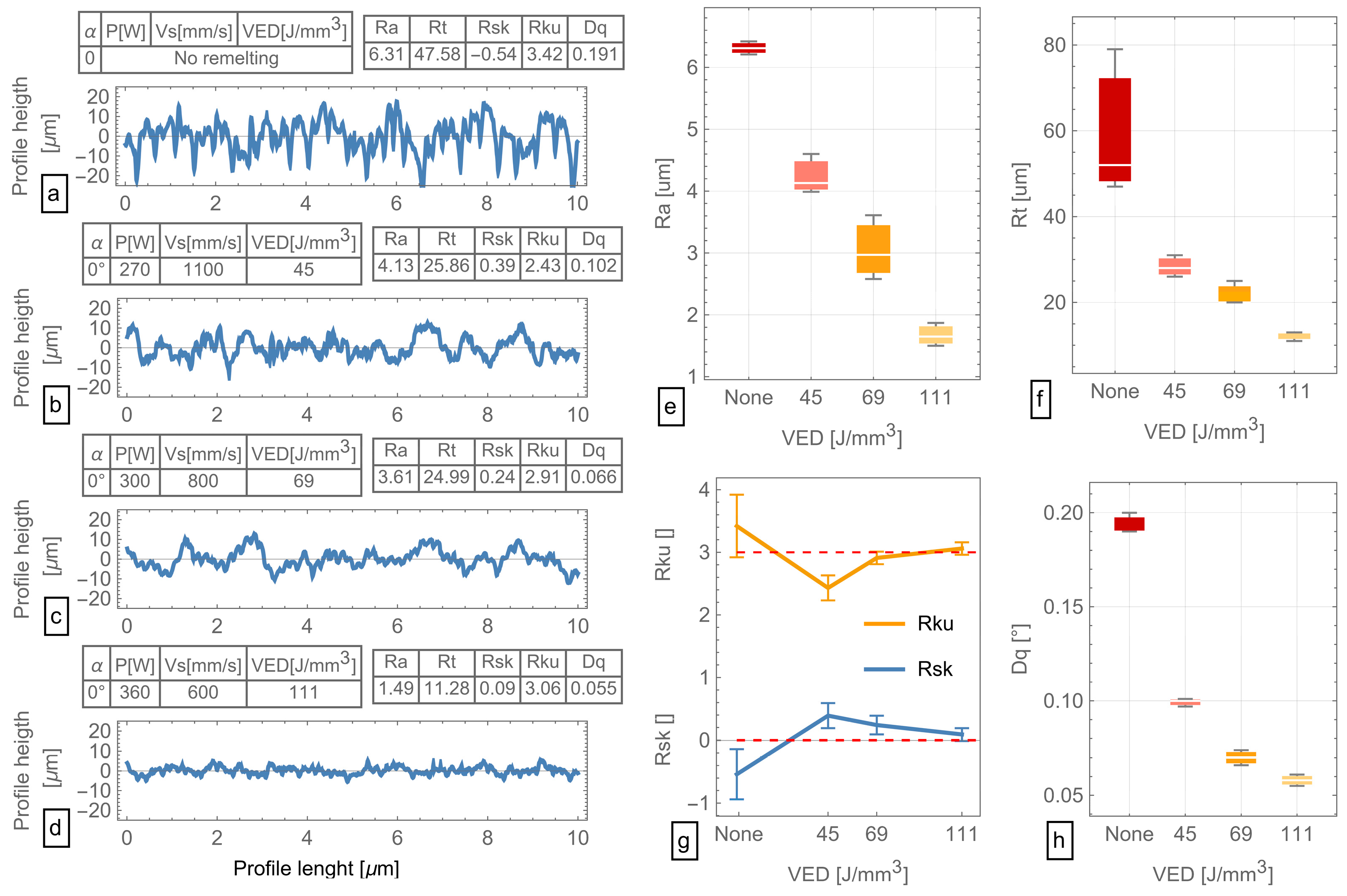

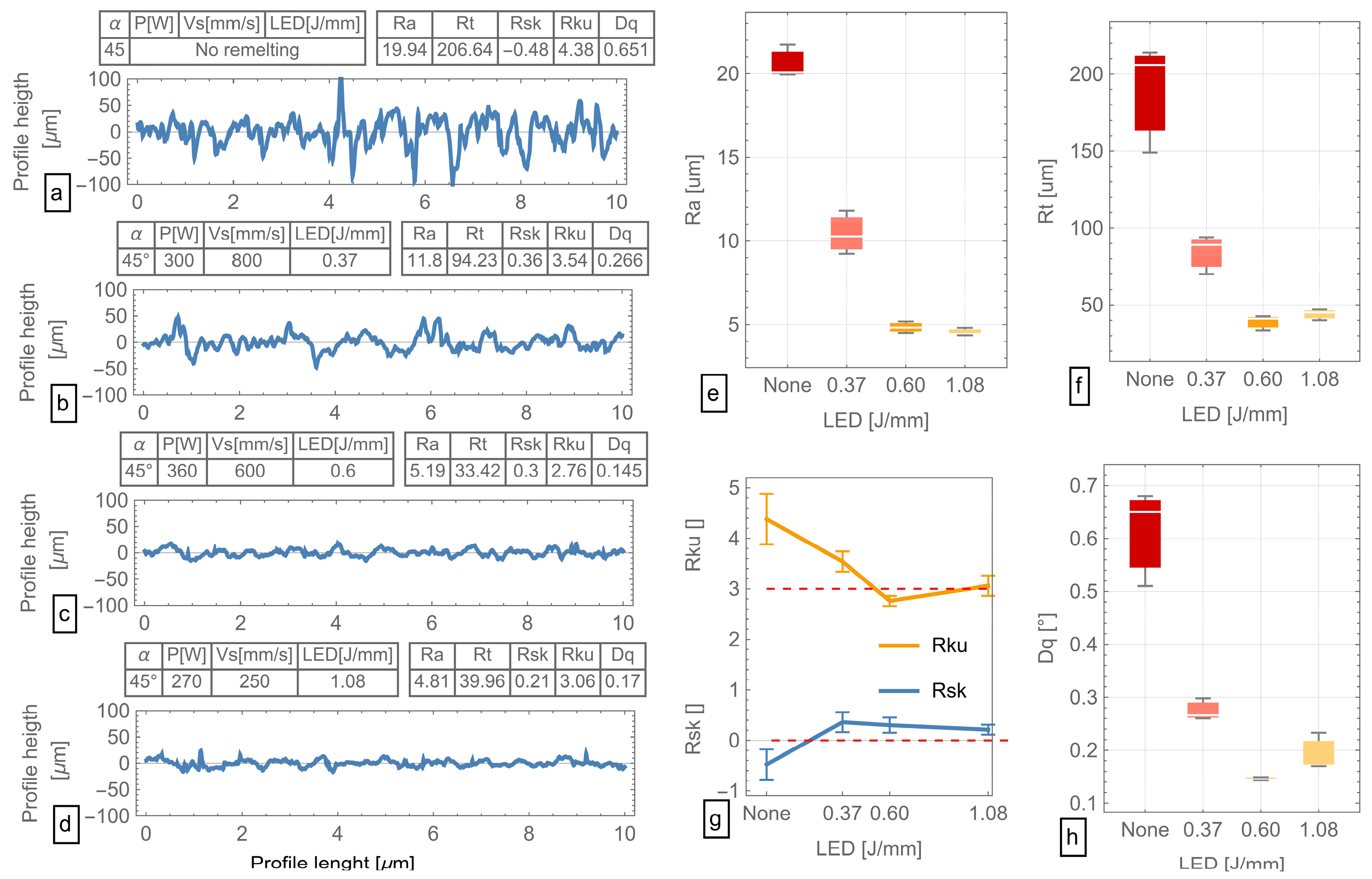

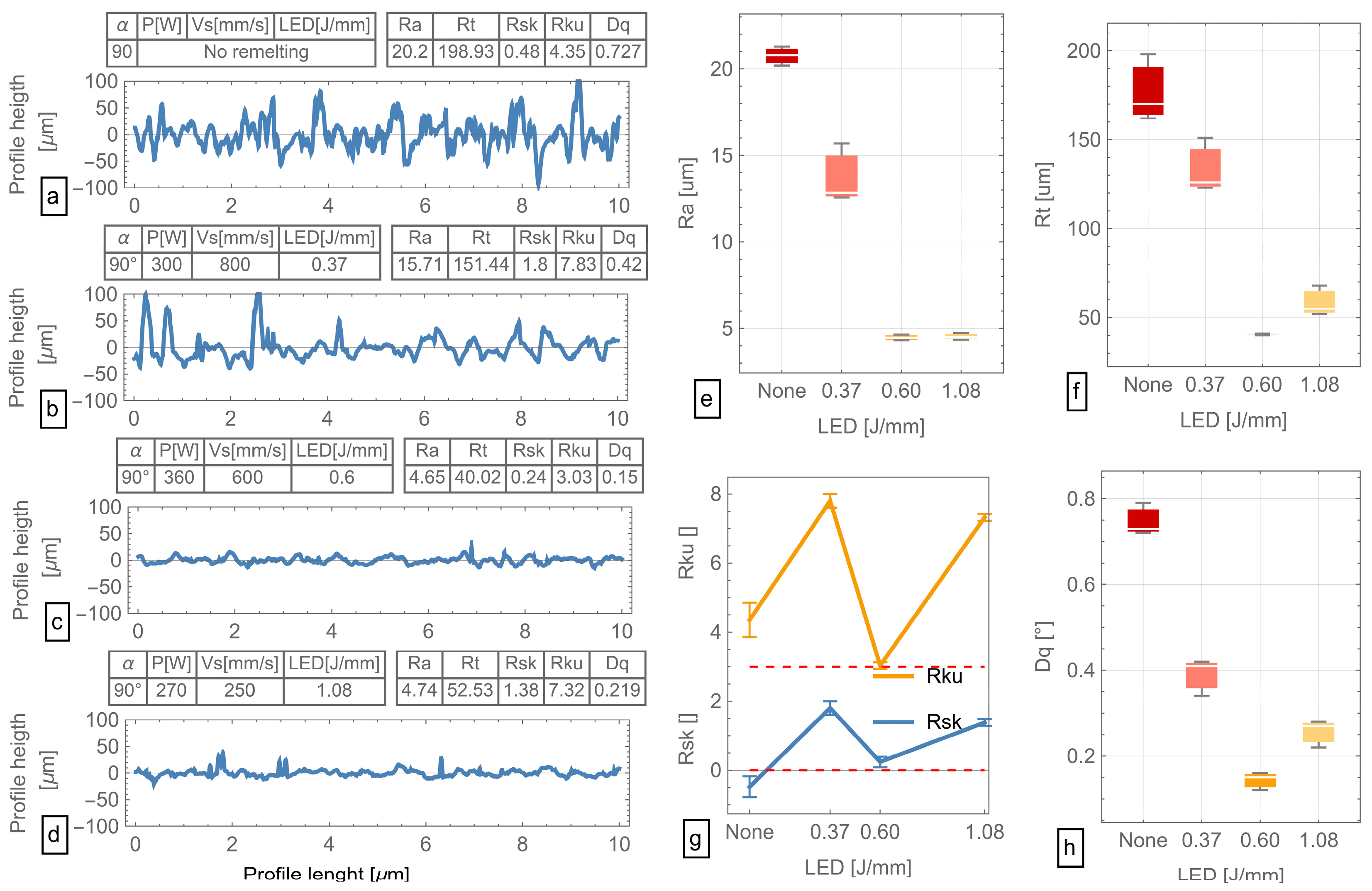

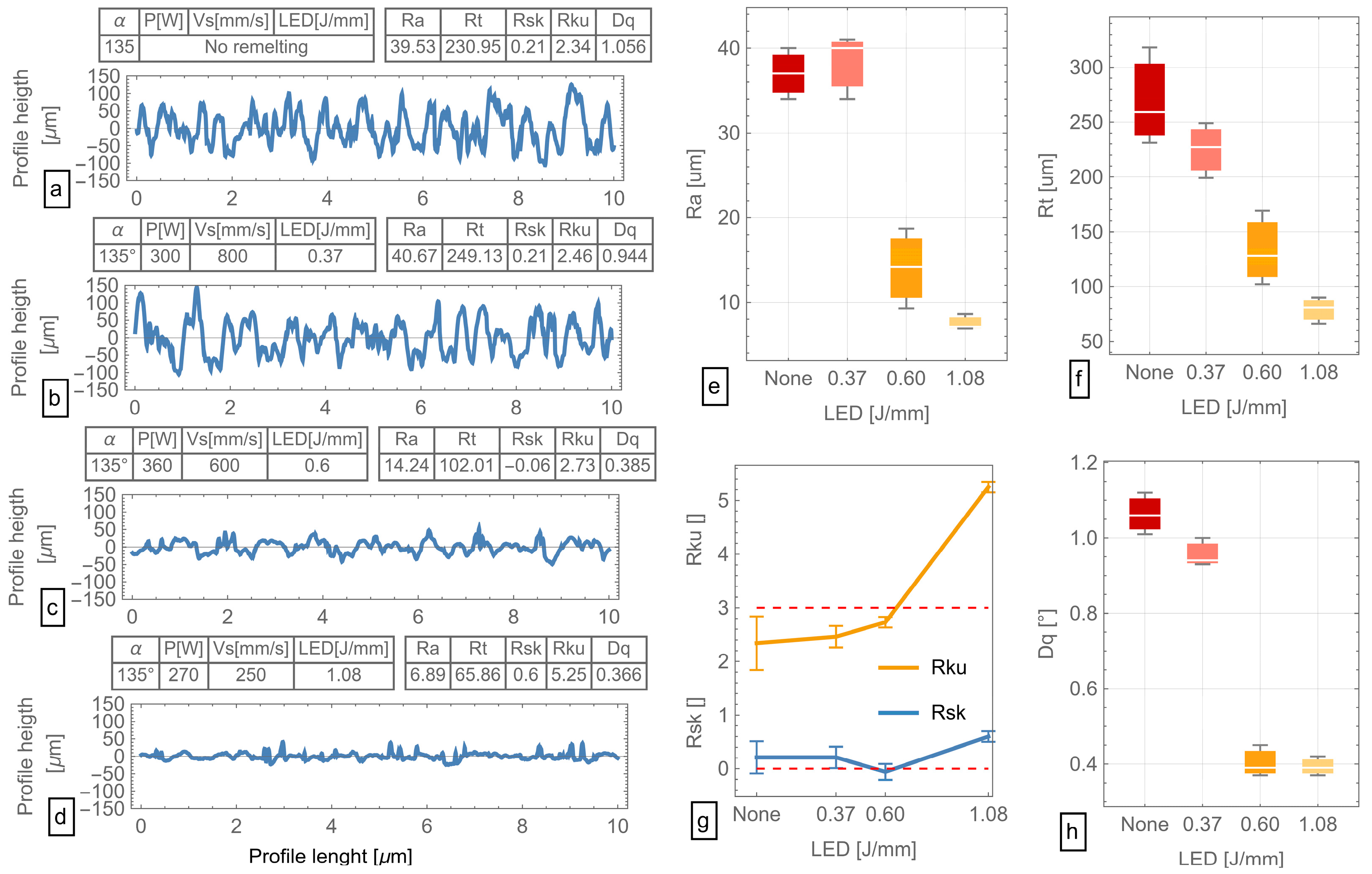

3.1. Roughness Evaluation

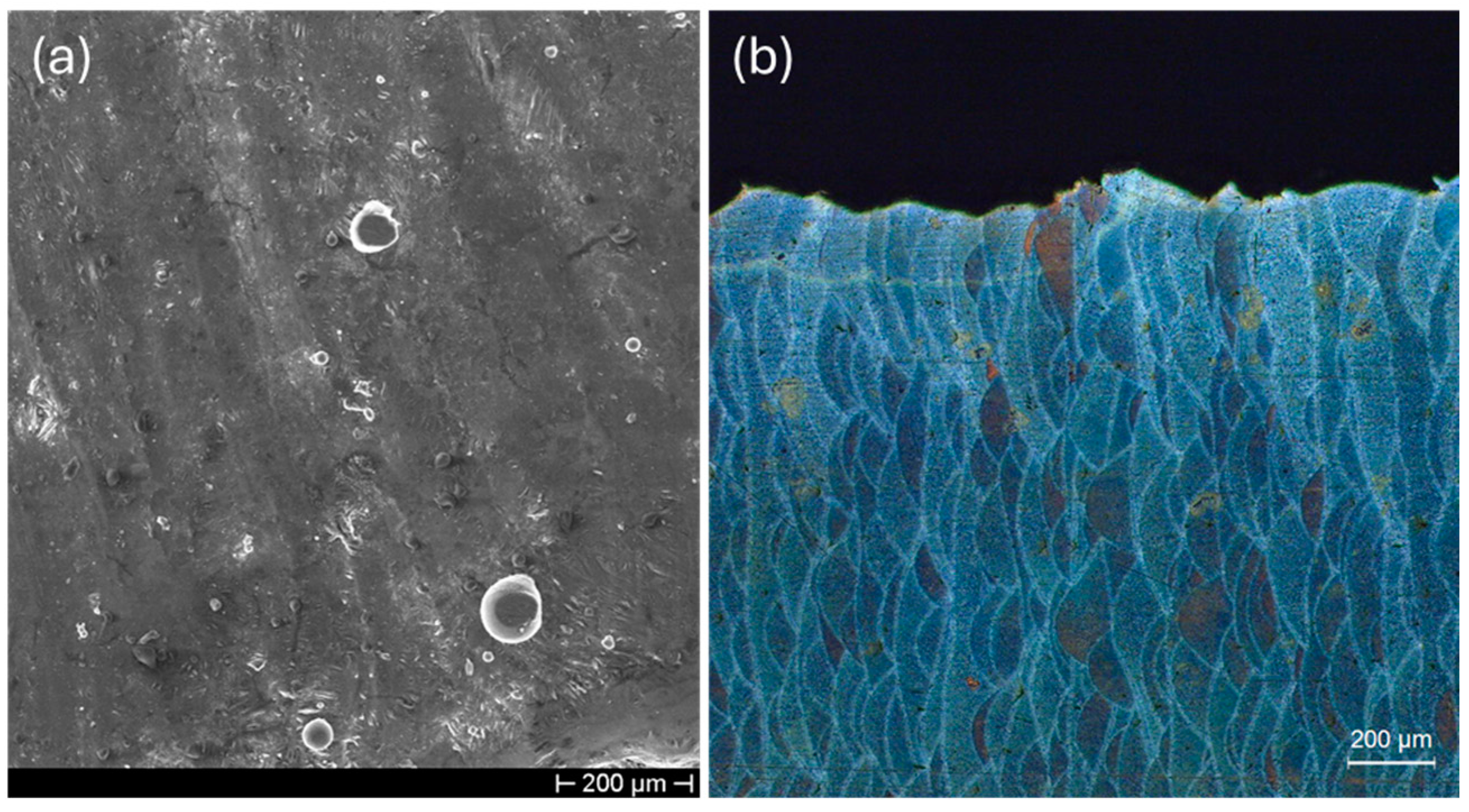

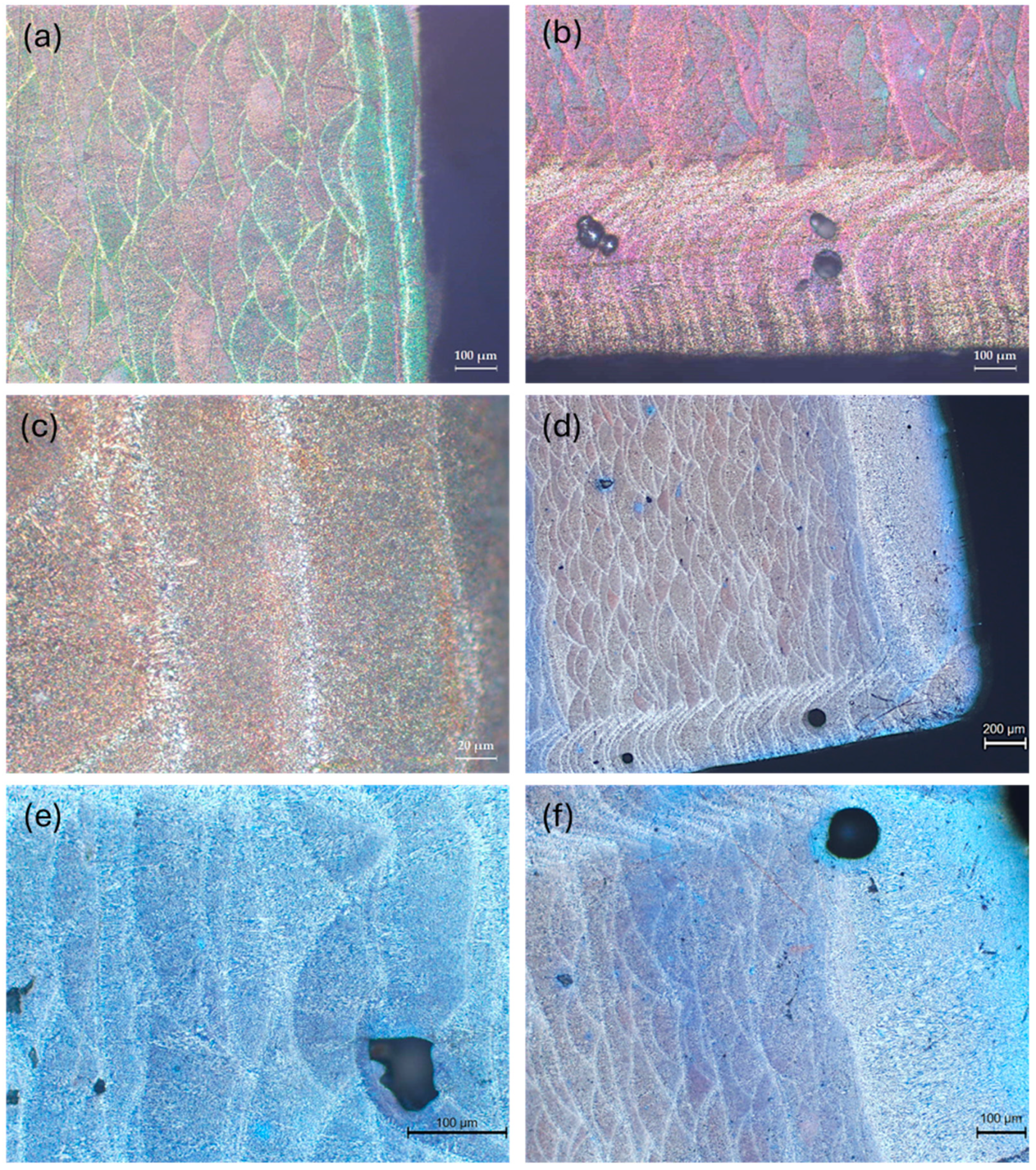

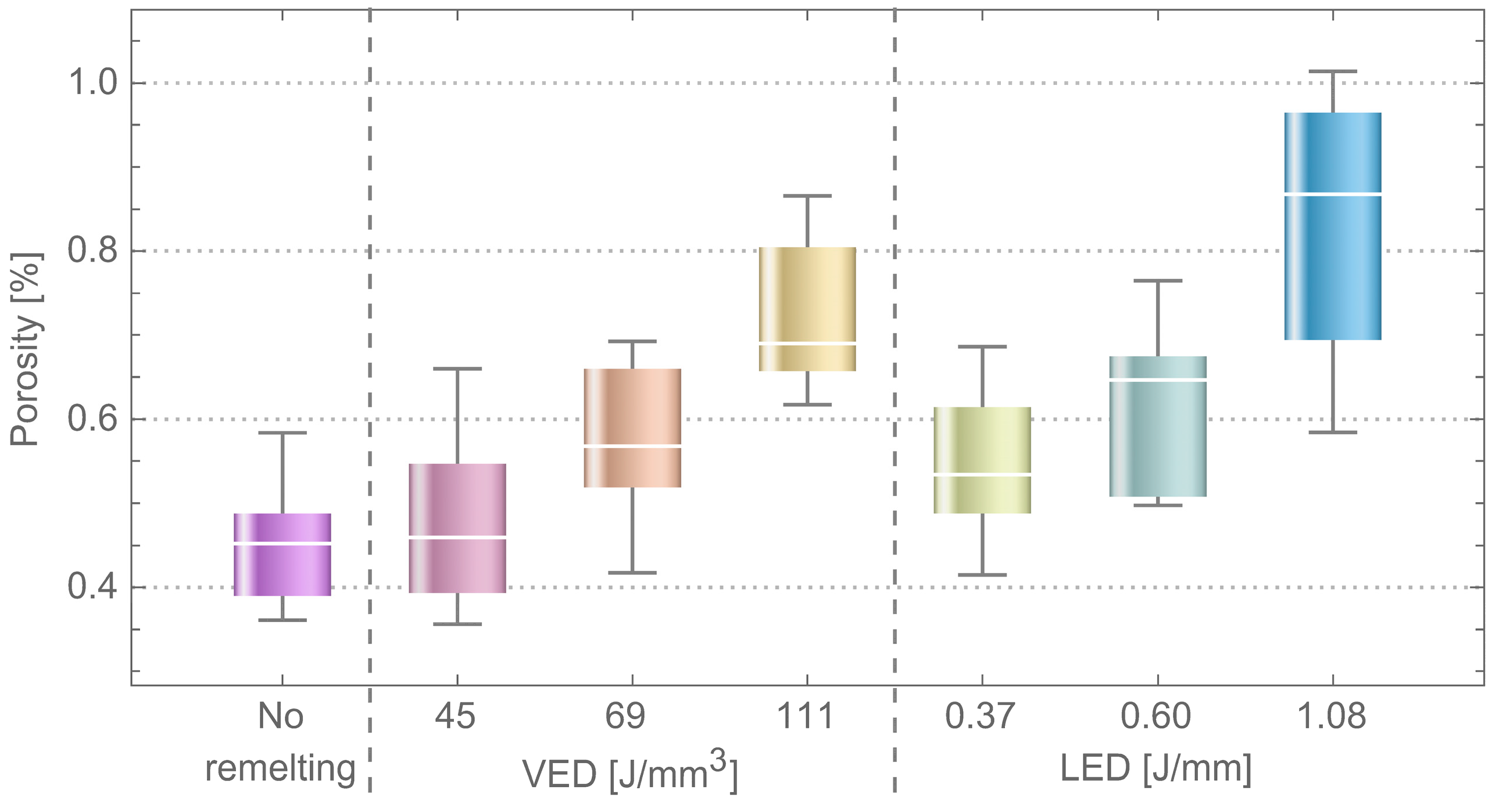

3.2. Microstructural and Defective Analyses

3.3. Productivity Evaluation

4. Conclusions

- ✓

- For the horizontal surfaces, the Ra was reduced by 76% with respect to the original surface, but VED values higher than 69 J/mm3 produce hydrodynamic instability with formation of gas defects in the subsurface area;

- ✓

- For surfaces characterized by a 45° local stratification angle, the proposed remelting strategy allowed to reduce the Ra from 20 µm to 5 µm; however, LED values greater than 0.60 J/mm cause a little increase of the Rt, which is a signal of excessive energy;

- ✓

- Similar outcomes are obtained on vertical surfaces, and the Ra starting at about 20 µm was modified down to 5 µm; also, in this case, it is advisable not to exceed 0.60 J/mm to avoid the generation of some superficial defects that determine an increase of the Rt as well as subsuperficial defects such as gas and microshrinkage pores produced by the Marangoni effect;

- ✓

- The downskin surfaces characterized by a slope of 135° present, in the standard condition, a very chaotic aspect due to the fact that each layer is only partially supported by the previous one.To reach a drastic reduction of the Ra, it is necessary to set a maximum LED value of 1.08 J/mm;

- ✓

- As expected, the additional scan causes the porosity to increase with the VED and LED values; however, the increase is within 1%, since the scan only processes the skin;

- ✓

- The production time to apply this multiscanning methodology calculated on some test bench geometries highlighted an increase of only some percentage points, confirming that the proposed methodology is affordable for industrial use.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kladovasilakis, N.; Charalampous, P.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Impact of metal additive manufacturing parameters on the powder bed fusion and direct energy deposition processes: A comprehensive review. Prog. Addit. Manuf. 2021, 6, 349–365. [Google Scholar] [CrossRef]

- Islam, S.A.; Hao, L.; Javaid, Z.; Xiong, W.; Li, Y.; Jamil, Y.; Chen, Q.; Han, G. Surface Roughness of Interior Fine Flow Channels in Selective Laser Melted Ti-6Al-4V Alloy Components. Micromachines 2024, 15, 348. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S. Additive Manufacturing Processes; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Kazantseva, N. Microstructure of L-PBF alloys. In Additive Manufacturing Materials and Technologies, Fundamentals of Laser Powder Bed Fusion of Metals; Yadroitsev, I., Yadroitsava, I., Plessis, A.D., MacDonald, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 215–243. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Bassani, P.; Tuissi, A. Continuous wave vs pulsed wave laser emission in selective laser melting of AlSi10Mg parts with industrial optimized process parameters: Microstructure and mechanical behaviour. Addit. Manuf. 2018, 24, 639. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109. [Google Scholar] [CrossRef]

- Lea, T.N.; Rauniyara, S.; Ha, N.V.; Choua, K. An Investigation into the Effects of Contouring Process Parameters on the Up-skin Surface Characteristics in Laser Powder-Bed Fusion Process. Manuf. Lett. 2023, 35, 707. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Effect of processing parameters on overhanging surface roughness during laser powder bed fusion of AlSi10Mg. J. Manuf. Process. 2021, 61, 440. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Tomus, D.; Davies, C.H.J. Surface roughness of Selective Laser Melted Ti-6Al-4V alloy components. Addit. Manuf. 2018, 21, 91. [Google Scholar] [CrossRef]

- Ren, Z.; Wei, D.; Wang, S.; Zhang, D.Z.; Mao, S. On the role of pre- and post-contour scanning in laser powder bed fusion: Thermal-fluid dynamics and laser reflections. Int. J. Mech. Sci. 2022, 226, 107389. [Google Scholar] [CrossRef]

- Gao, C.; Tang, H.; Zhang, S.; Ma, Z.; Bi, Y.; Rao, J.-H. Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion. Metals 2022, 12, 2053. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, C.; Zhao, J.; Dong, Y. Effects of Post-processing on the Surface Finish, Porosity, Residual Stresses, and Fatigue Performance of Additive Manufactured Metals: A Review. J. Mater. Eng. Perform. 2021, 30, 6407–6425. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue Life of Additively Manufactured Ti–6Al–4V in the Very High Cycle Fatigue Regime. Int. J. Fatigue 2017, 94, 236–245. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Phan, N. Significance of Hot Isostatic Pressing (HIP) on Multiaxial Deformation and Fatigue Behaviors Additive Manufactured Ti-6Al-4V Including Build Orientation and Surface Roughness Effects. Int. J. Fatigue 2018, 117, 352–370. [Google Scholar] [CrossRef]

- Wycisk, E.; Emmelmann, C.; Siddique, S.; Walther, F. High Cycle Fatigue (HCF) Performance of Ti-6Al-4V Alloy Processed by Selective Laser Melting. Adv. Mater. Res. 2013, 816–817, 134–139. [Google Scholar] [CrossRef]

- Nalli, F.; Bottini, L.; Boschetto, A.; Cortese, L.; Veniali, F. Effect of industrial heat treatment and barrel finishing on the mechanical performance of Ti6AL4V processed by selective laser melting. Appl. Sci. 2020, 10, 2280. [Google Scholar] [CrossRef]

- Didier, P.; Le Coz, G.; Robin, G.; Lohmuller, P.; Piotrowski, B.; Moufki, A.; Laheurte, P. Consideration of SLM additive manufacturing supports on the stability of flexible structures in finish milling. J. Manuf. Process. 2021, 62, 213. [Google Scholar] [CrossRef]

- Ali, U.; Fayazfar, H.; Ahmed, F.; Toyserkani, E. Internal Surface Roughness Enhancement of Parts Made by Laser Powder-Bed Fusion Additive Manufacturing. Vacuum 2020, 177, 109314. [Google Scholar] [CrossRef]

- An, L.; Wang, D.; Zhu, D. Electrochemical polishing with glycol-based electrolyte of the curved internal channels fabricated via laser powder bed fusion. J. Manuf. Process. 2024, 117, 375. [Google Scholar] [CrossRef]

- Guan, J.; Wang, Q. The effect of a remelting treatment scanning strategy on the surface morphology, defect reduction mechanism, and mechanical properties of a selective laser-melted Al-based alloy. J. Mater. Sci. 2022, 57, 9807–9817. [Google Scholar] [CrossRef]

- Bukhari, S.M.A.; Husnain, N.; Siddiqui, F.A.; Anwar, M.T.; Khosa, A.A.; Imran, M.; Qureshi, T.H.; Ahmad, R. Effect of laser surface remelting on Microstructure, mechanical properties and tribological properties of metals and alloys: A review. Opt. Laser Technol. 2023, 165, 109588. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Pilone, D. Effect of laser remelting on surface roughness and microstructure of AlSi10Mg selective laser melting manufactured parts. Int. J. Adv. Manuf. Technol. 2021, 113, 2739–2759. [Google Scholar] [CrossRef]

- Kang, N.; Verdy, C.; Coddet, P.; Xie, Y.; Fu, Y.; Liao, H.; Coddet, C. Effects of laser remelting process on the microstructure, roughness and microhardness of in-situ cold sprayed hypoeutectic Al-Si coating. Surf. Coat. Technol. 2017, 318, 355–359. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Ren, X. Size effect on fatigue performance of SLM-ed AlSi10Mg alloy: Role of defect size distribution. Int. J. Fatigue 2024, 182, 108163. [Google Scholar] [CrossRef]

- Qian, G.; Jian, Z.; Qian, Y.; Pan, X.; Ma, X.; Hong, Y. Very-high-cycle fatigue behavior of AlSi10Mg manufactured by selective laser melting: Effect of build orientation and mean stress. Int. J. Fatigue 2020, 138, 105696. [Google Scholar] [CrossRef]

- Shakil, S.I.; Hadadzadeh, A.; Amirkhiz, B.S.; Pirgazi, H.; Mohammadi, M.; Haghshenas, M. Additive manufactured versus cast AlSi10Mg alloy: Microstructure and micromechanics. Results Mater. 2021, 10, 100178. [Google Scholar] [CrossRef]

- Mertens, A.; Delahaye, J.; Dedry, O.; Vertruyen, B.; Tchuindjang, J.T.; Habraken, A.M. Microstructure and Properties of SLM AlSi10Mg: Understanding the Influence of the Local Thermal History. Procedia Manuf. 2020, 47, 1089–1095. [Google Scholar] [CrossRef]

- Yan, Q.; Song, B.; Shi, Y. Comparative study of performance comparison of AlSi10Mg alloy prepared by selective laser melting and casting. J. Mater. Sci. Technol. 2020, 41, 199–208. [Google Scholar] [CrossRef]

- Praneeth, J.; Venkatesh, S.; Krishna, L.S. Process parameters influence on mechanical properties of AlSi10Mg by SLM. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Wu, H.; Ren, Y.; Ren, J.; Liang, L.; Li, R.; Fang, Q.; Cai, A.; Shan, Q.; Tian, Y.; Baker, I. Selective laser melted AlSi10Mg alloy under melting mode transition: Microstructure evolution, nanomechanical behaviors and tensile properties. J. Alloys Compd. 2021, 873, 159823. [Google Scholar] [CrossRef]

- EOS GmbH—Electro Optical Systems. Material Data Sheet EOS AluminiumAlSi10Mg; EOS GmbH—Electro Optical Systems: Krailling/Munich, Germany, 2014. [Google Scholar]

- ISO 16610-22; Geometrical Product Specifications (GPS)—Filtration—Part 22: Linear Profile Filters: Spline Filters. Available online: https://www.iso.org/obp/ui/#iso:std:iso:16610:-22:ed-1:v1:en (accessed on 7 May 2024).

- ISO 4287:1997/Amd.1:2009; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters AMENDMENT 1: Peak Count Number. International Organization for Standardization. Available online: https://www.iso.org/obp/ui/#iso:std:iso:4287:ed-1:v1:amd:1:v1:en (accessed on 7 May 2024).

- Wang, D.; Yang, Y.; Liu, Y.; Bai, Y.; Tan, C. Study on Single-Track, Multi-track and Multi-layer Manufacturing. In Laser Powder Bed Fusion of Additive Manufacturing Technology, 1st ed.; Wang, D., Yang, Y., Liu, Y., Bai, Y., Tan, C., Eds.; Springer: Singapore, 2024; pp. 59–80. [Google Scholar]

- Limbasiya, N.; Jain, A.; Soni, H.; Wankhede, V.; Krolczyk, G.; Sahlot, P. A comprehensive review on the effect of process parameters and post-process treatments on microstructure and mechanical properties of selective laser melting of AlSi10Mg. J. Mater. Res. Technol. 2022, 21, 1141–1176. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Wu, J. Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt. Laser Technol. 2017, 96, 88–96. [Google Scholar] [CrossRef]

- Yue, D.; Zhang, X.; Li, D.; Li, Z.; Wang, Z.; Chen, B. Effect of remelting strategy on forming mechanism of selective laser melted AlSi10Mg. J. Mater. Res. Technol. 2024, 30, 4283–4293. [Google Scholar] [CrossRef]

- Pakkanen, J.; Calignano, F.; Trevisan, F.; Lorusso, M.; Ambrosio, E.P.; Manfredi, D.; Fino, P. Study of Internal Channel Surface Roughnesses Manufactured by Selective Laser Melting in Aluminum and Titanium Alloys. Metall. Mater. Trans. A 2016, 47, 3837–3844. [Google Scholar] [CrossRef]

- Poncelet, O.; Marteleur, M.; van der Rest, C.; Rigo, O.; Adrien, J.; Dancette, S.; Jacques, P.J.; Simar, A. Critical assessment of the impact of process parameters on vertical roughness and hardness of thin walls of AlSi10Mg processed by laser powder bed fusion. Addit. Manuf. 2021, 38, 101801. [Google Scholar] [CrossRef]

- Calignano, F. Design optimization of supports for overhanging structures in aluminum and titanium alloys by selective laser melting. Mater. Des. 2014, 64, 203–213. [Google Scholar] [CrossRef]

- Fu, J.; Li, H.; Song, X.; Fu, M.W. Multi-scale defects in powder-based additively manufactured metals and alloys. J. Mater. Sci. Technol. 2022, 122, 165–199. [Google Scholar] [CrossRef]

- Yang, G.; Xie, Y.; Zhao, S.; Qin, L.; Wang, X.; Wu, B. Quality Control: Internal Defects Formation Mechanism of Selective Laser Melting Based on Laser-powder-melt Pool Interaction: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100037. [Google Scholar] [CrossRef]

- Moylan, S.; Slotwinski, J.; Cooke, A.; Jurrens, K.; Donmez, M. An Additive Manufacturing Test Artifact. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 429–459. [Google Scholar] [CrossRef]

- Minetola, P.; Galati, M.; Calignano, F.; Iuliano, L.; Rizza, G.; Fontana, L. Comparison of dimensional tolerance grades for metal AM processes. Proc. CIRP 2020, 88, 399–404. [Google Scholar] [CrossRef]

| Pu [W] | Vu [mm/s] | Pc [W] | Vc [mm/s] | VED [J/mm3] | LED [J/mm] | |

|---|---|---|---|---|---|---|

| A | 270 | 1100 | 270 | 250 | 45.45 | 1.08 |

| B | 300 | 800 | 300 | 800 | 69.44 | 0.37 |

| C | 360 | 600 | 360 | 600 | 111.11 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boschetto, A.; Bottini, L.; Pilone, D. Metallurgical Defects and Roughness Investigation in the Laser Powder Bed Fusion Multi-Scanning Strategy of AlSi10Mg Parts. Metals 2024, 14, 711. https://doi.org/10.3390/met14060711

Boschetto A, Bottini L, Pilone D. Metallurgical Defects and Roughness Investigation in the Laser Powder Bed Fusion Multi-Scanning Strategy of AlSi10Mg Parts. Metals. 2024; 14(6):711. https://doi.org/10.3390/met14060711

Chicago/Turabian StyleBoschetto, Alberto, Luana Bottini, and Daniela Pilone. 2024. "Metallurgical Defects and Roughness Investigation in the Laser Powder Bed Fusion Multi-Scanning Strategy of AlSi10Mg Parts" Metals 14, no. 6: 711. https://doi.org/10.3390/met14060711