Effect of Cr3C2 Addition on Microstructure and Mechanical Properties of WC-CoNiFe Cemented Carbides

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Preparation and Debinding Sintering

2.2. Material Characterization

3. Results and Discussions

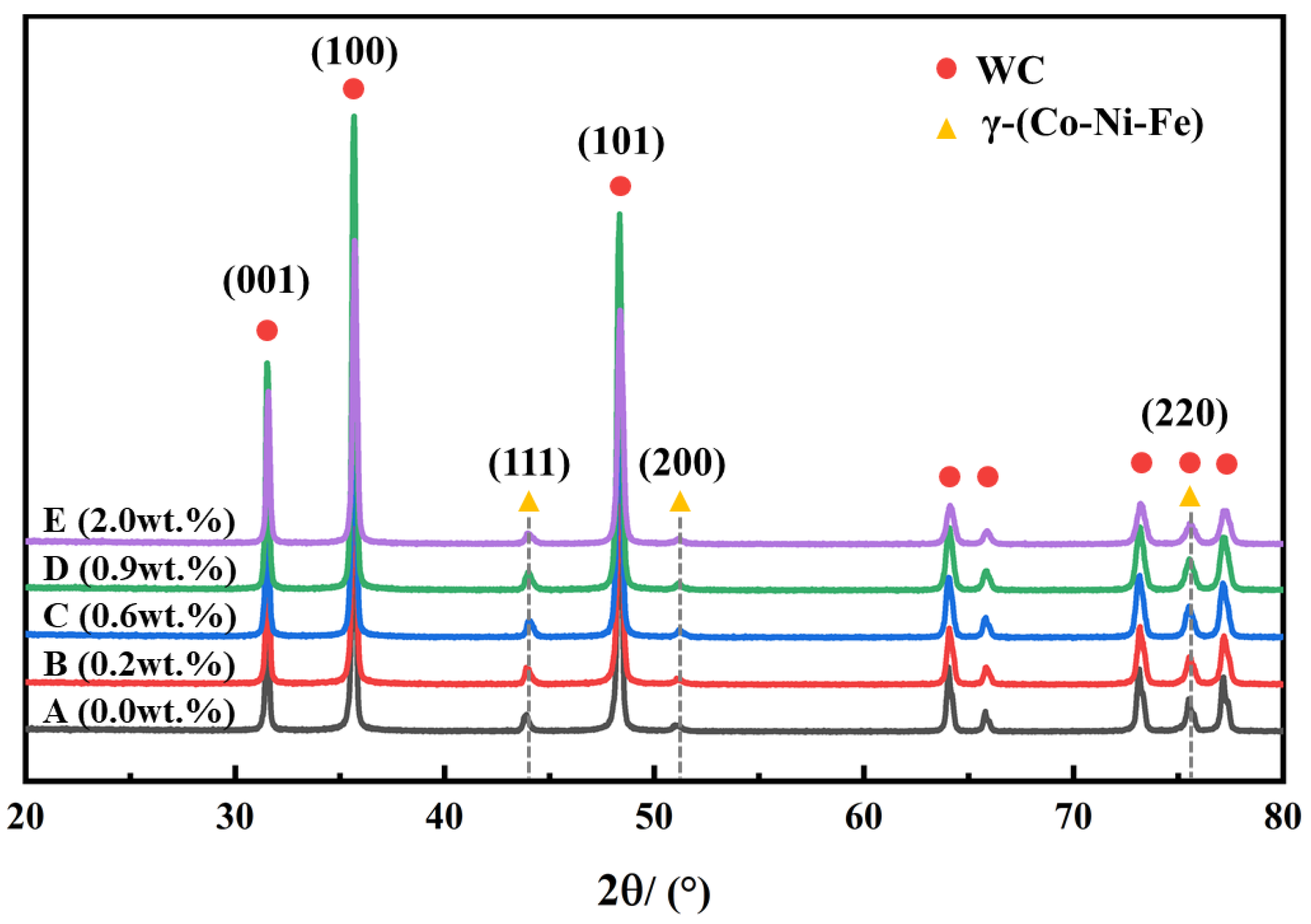

3.1. Effect of Different Cr3C2 Contents on the Phase Composition of the Alloy

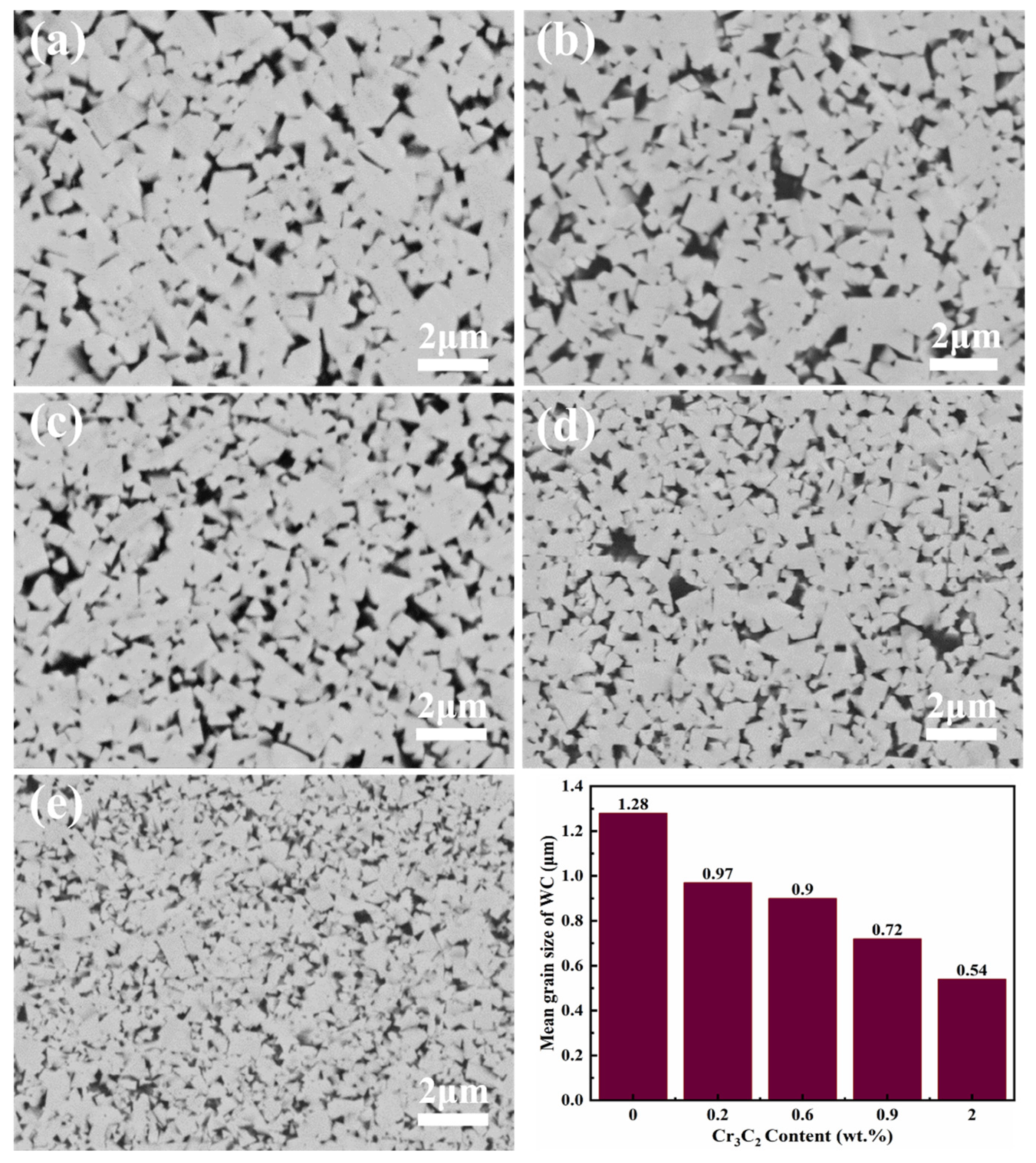

3.2. Effect of Cr3C2 Content on the Microstructure of the Alloy

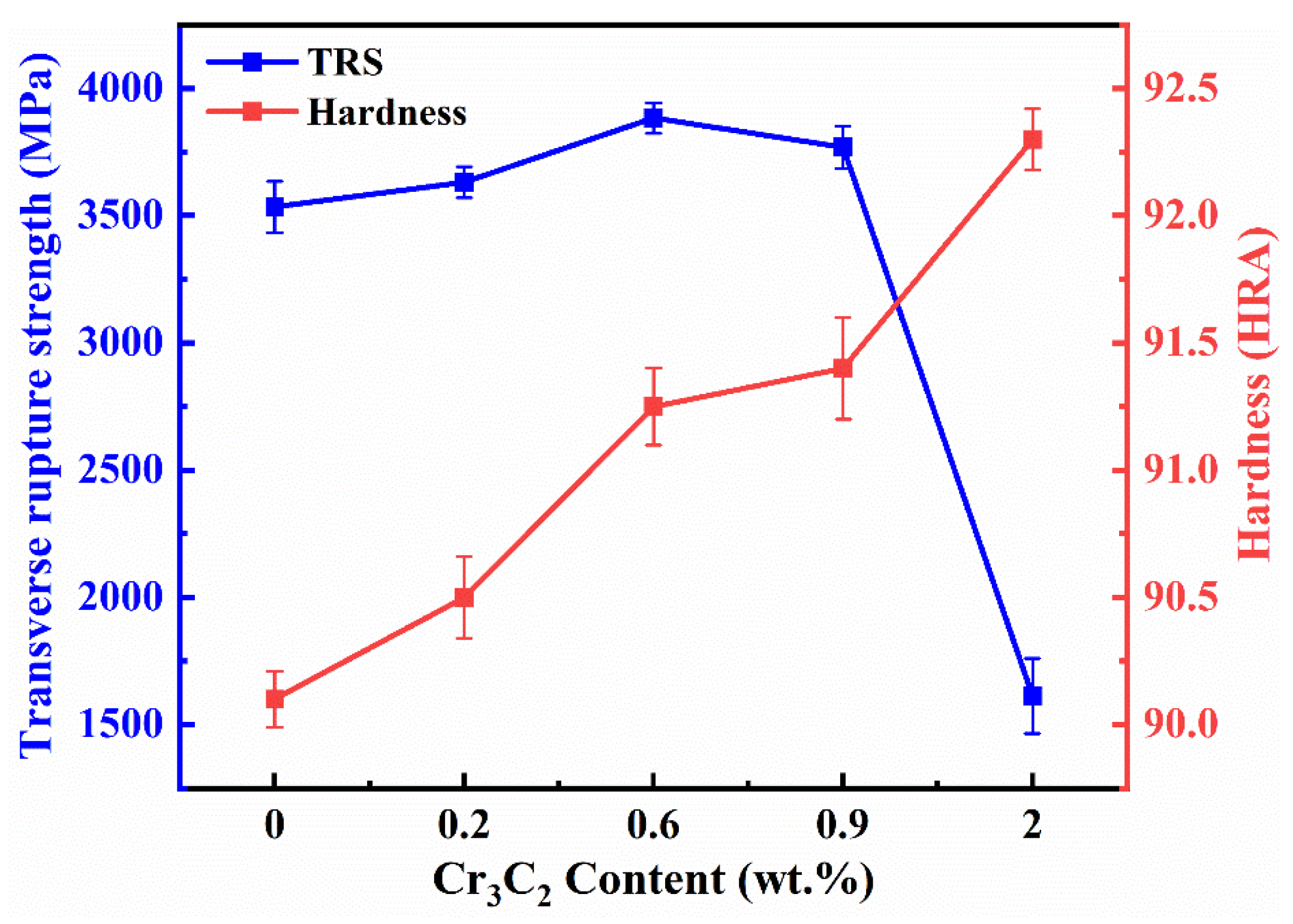

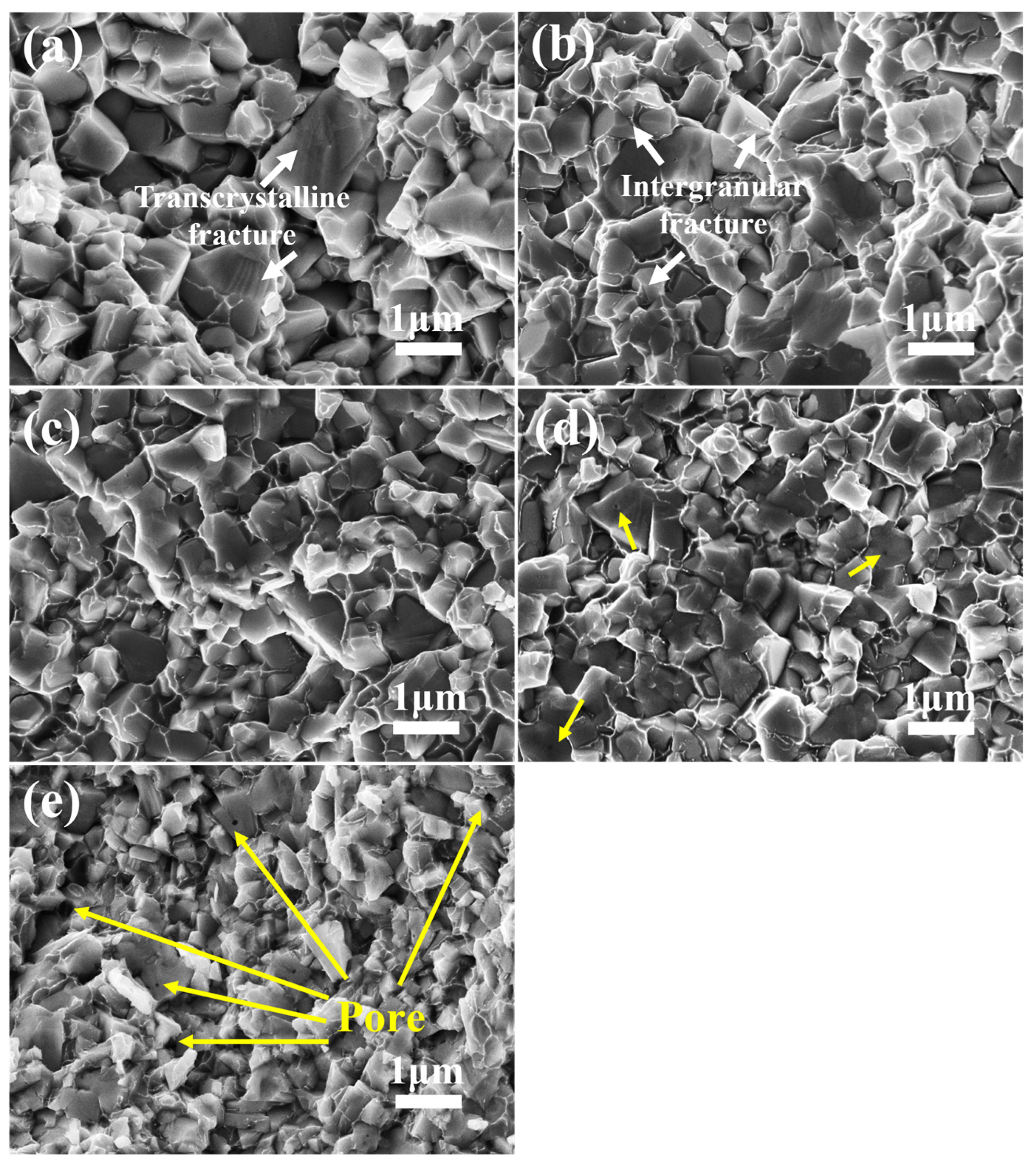

3.3. Effect of Cr3C2 Addition on the Mechanical Properties of the Alloy

| Materials Composition (wt.%) | Mean Grain Size of WC (μm) | Hardness | TRS (MPa) |

|---|---|---|---|

| WC−10Co [40] | 0.8 | 90.8 HRA | 3700 |

| WC−10Co−0.6Cr3C2 [40] | <0.8 | 91.8 HRA | 3975 |

| WC−10Co [35] | 0.46 | 91.8 HRA | 2818 |

| WC−12Co−0.2Cr3C2 [35] | 0.39 | 92.9 HRA | 3483 |

| WC−10Co [5] | 1.38 | 1605 HV1 | 1677 |

| WC−5Co4Ni1Fe [5] | 1.32 | 1506 HV1 | 1772 |

| WC−10Co7Ni2Fe1Cr−4.5C [41] | 1~2 | 1080 HV30 | 1800 |

| WC−10Co7Ni2Fe1Cr−4.9C [41] | 1~2 | 950 HV30 | 3450 |

| WC−5Co4Ni1Fe [This work] | 1.28 | 90.1 HRA | 3533.86 |

| (WC−5Co4Ni1Fe)−0.6Cr3C2 [This work] | 0.9 | 91.25 HRA | 3883.2 |

4. Conclusions

- (1)

- Cr3C2 effectively inhibits the grain growth of WC−CoNiFe. The undoped sample has coarse and uneven grains with a tendency for abnormal growth; with the increase in the amount of refiner, the degree of WC grain refinement in the alloy increases.

- (2)

- As the Cr3C2 content increases, the coercivity of the alloy increases, and the cobalt magnetism decreases, further indicating that Cr3C2 has a significant refinery effect on WC grain growth. The inhibition mechanism is closely related to the W and C content in the binder.

- (3)

- With the increase in Cr3C2 content and the refinement of grains, the hardness of the alloy continuously increases, while the transverse rupture strength first increases and then decreases. The decrease in transverse rupture strength is due to Cr3C2 reducing the fluidity of the binder, preventing pores from being fully filled, which subsequently leads to a decrease in the alloy’s crack propagation resistance. Additionally, the WC−CoNiFe presented in this study exhibits mechanical properties comparable to the traditional WC−Co cemented carbide cutting tools and may offer lower raw material costs and better engineering application potential.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Z.; Ren, X.; Liu, M.; Xu, C.; Zhang, X.; Guo, S.; Chen, H. Effect of Cu on the Microstructures and Properties of WC-6Co Cemented Carbides Fabricated by SPS. Int. J. Refract. Met. Hard Mater. 2017, 62, 155–160. [Google Scholar] [CrossRef]

- García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Watts, J.; Hilmas, G. Crack Deflection in Tungsten Carbide Based Laminates. Int. J. Refract. Met. Hard Mater. 2006, 24, 222–228. [Google Scholar] [CrossRef]

- Ding, Q.; Zheng, Y.; Ke, Z.; Zhang, G.; Wu, H.; Xu, X.; Lu, X.; Zhu, X. Effects of Fine WC Particle Size on the Microstructure and Mechanical Properties of WC-8Co Cemented Carbides with Dual-Scale and Dual-Morphology WC Grains. Int. J. Refract. Met. Hard Mater. 2020, 87, 105166. [Google Scholar] [CrossRef]

- Qian, C.; Li, K.; Guo, X.; Liu, B.; Long, Z.; Liu, Y. Effect of WC Grain Size on Mechanical Properties and Microstructures of Cemented Carbide with Medium Entropy Alloy Co-Ni-Fe Binder. J. Cent. South Univ. 2020, 27, 1146–1157. [Google Scholar] [CrossRef]

- Farag, S.; Konyashin, I.; Ries, B. The Influence of Grain Growth Inhibitors on the Microstructure and Properties of Submicron, Ultrafine and Nano-Structured Hardmetals—A Review. Int. J. Refract. Met. Hard Mater. 2018, 77, 12–30. [Google Scholar] [CrossRef]

- Wittmann, B.; Schubert, W.-D.; Lux, B. WC Grain Growth and Grain Growth Inhibition in Nickel and Iron Binder Hardmetals. Int. J. Refract. Met. Hard Mater. 2002, 20, 51–60. [Google Scholar] [CrossRef]

- Mannesson, K.; Jeppsson, J.; Borgenstam, A.; Ågren, J. Carbide Grain Growth in Cemented Carbides. Acta Mater. 2011, 59, 1912–1923. [Google Scholar] [CrossRef]

- Sommer, M.; Schubert, W.-D.; Zobetz, E.; Warbichler, P. On the Formation of Very Large WC Crystals during Sintering of Ultrafine WC–Co Alloys. Int. J. Refract. Met. Hard Mater. 2002, 20, 41–50. [Google Scholar] [CrossRef]

- Fu, J.; Song, X.Y.; Wei, C.B.; Liu, X.M.; Wang, H.B.; Gao, Y.; Wang, Y. Effect of Combined Addition of Grain Growth Inhibitors on the Cemented Carbides Prepared by WC-Co Composite Powder. Rare Met. Mater. Eng. 2014, 43, 1928–1934. [Google Scholar]

- Johansson, S.A.E.; Wahnström, G. First-Principles Study of an Interfacial Phase Diagram in the V-Doped WC-Co System. Phys. Rev. B 2012, 86, 035403. [Google Scholar] [CrossRef]

- Yin, C.; Ruan, J.; Du, Y.; Long, J.; Peng, Y.; Li, K. Effects of Cr3C2, VC, and TaC on Microstructure, WC Morphology and Mechanical Properties of Ultrafine WC–10 Wt. % Co Cemented Carbides. Metals 2020, 10, 1211. [Google Scholar] [CrossRef]

- Reiberg, M.; Hitzler, L.; Apfelbacher, L.; Schanz, J.; Kolb, D.; Riegel, H.; Werner, E. Additive Manufacturing of CrFeNiTi Multi-Principal Element Alloys. Materials 2022, 15, 7892. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhou, Q.; Hua, D.; Huang, Z.; Li, Y.; Jia, Q.; Gumbsch, P.; Greiner, C.; Wang, H.; Liu, W. Wear-Resistant CoCrNi Multi-Principal Element Alloy at Cryogenic Temperature. Sci. Bull. 2024, 69, 227–236. [Google Scholar] [CrossRef] [PubMed]

- Zhou, P.-F.; Xiao, D.-H.; Yuan, T.-C. Comparison between Ultrafine-Grained WC–Co and WC–HEA-Cemented Carbides. Powder Metall. 2017, 60, 1–6. [Google Scholar] [CrossRef]

- Zhou, P.L.; Xiao, D.H.; Zhou, P.F.; Yuan, T.C. Microstructure and Properties of Ultrafine Grained AlCrFeCoNi/WC Cemented Carbides. Ceram. Int. 2018, 44, 17160–17166. [Google Scholar] [CrossRef]

- Qian, C.; Li, K.; Cheng, H.; Zhang, W.; Jiang, X.; Liu, Y. Fracture Behavior of Cemented Carbides with CoNiFe Medium Entropy Alloy Binder. Int. J. Refract. Met. Hard Mater. 2021, 98, 105547. [Google Scholar] [CrossRef]

- Chen, C.-S.; Yang, C.-C.; Chai, H.-Y.; Yeh, J.-W.; Chau, J.L.H. Novel Cermet Material of WC/Multi-Element Alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 200–204. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Dong, B.; Wu, Z.; Zhou, L. Corrosion Resistance of WC-Based Cemented Carbides with 10 wt% AlxCrCoCuFeNi High-Entropy Alloy Binders. Intermetallics 2022, 151, 107738. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Liu, X.; Zhou, Z. Oxidation Behavior of Ultrafine WC-Based Cemented Carbides with AlxCoCrCuFeNi High-Entropy Alloy Binders. Ceram. Int. 2021, 47, 8498–8509. [Google Scholar] [CrossRef]

- Yao, Q.C. Study of the Wear and Corrosion Resistance of WC-HEA Cemented Carbide in Seawater Media. Master’s Thesis, Donghua University, Shanghai, China, 2024. [Google Scholar]

- Chang, S.-H.; Chang, M.-H.; Huang, K.-T. Study on the Sintered Characteristics and Properties of Nanostructured WC–15 Wt% (Fe–Ni–Co) and WC–15 Wt% Co Hard Metal Alloys. J. Alloys Compd. 2015, 649, 89–95. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, B.-H.; He, K.-J.; Zhang, W.-W.; Bai, Z.-H. Effect of Fe/Ni Ratio on the Microstructure and Properties of WC-Fe-Ni-Co Cemented Carbides. Ceram. Int. 2018, 44, 2030–2041. [Google Scholar] [CrossRef]

- Pötschke, J.; Säuberlich, T.; Vornberger, A.; Meese-Marktscheffel, J.A. Solid State Sintered Nanoscaled Hardmetals and Their Properties. Int. J. Refract. Met. Hard Mater. 2018, 72, 45–50. [Google Scholar] [CrossRef]

- Lin, C.G.; Cao, R.J.; Li, Y. The Evolution of Micro-structure of Ultra-fine Grain WC-Co Cemented Carbide Containing Cr3C2 During its Sintering Process. China Tungsten Ind. 2009, 24, 93–98. [Google Scholar]

- Poetschke, J.; Richter, V.; Holke, R. Influence and Effectivity of VC and Cr3C2 Grain Growth Inhibitors on Sintering of Binderless Tungsten Carbide. Int. J. Refract. Met. Hard Mater. 2012, 31, 218–223. [Google Scholar] [CrossRef]

- Balbino, N.A.N.; Correa, E.O.; de Carvalho Valeriano, L. Development of the 90WC-8Ni-2Cr3C2 Cemented Carbide for Engineering Applications. Int. J. Adv. Manuf. Technol. 2018, 99, 1653–1660. [Google Scholar] [CrossRef]

- Kawakami, M.; Kitamura, K. Segregation Layers of Grain Growth Inhibitors at WC/WC Interfaces in VC-Doped Submicron-Grained WC–Co Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2015, 52, 229–234. [Google Scholar] [CrossRef]

- Su, W.; Wen, Y.; Zhang, Q. Effects of Ni and Cu Additions on Microstructures, Mechanical Properties and Wear Resistances of Ultra-Coarse Grained WC–6Co Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2018, 70, 176–183. [Google Scholar] [CrossRef]

- Qiu, Y.X.; Li, N.; Zhang, W.; Wen, Y.H.; Zhang, Y.; Zhou, Y.G. WC-Co Study on Inhititor and It’s Mechanism in WC-Co Super-fine Cemented Carbides. Cem. Carbides 2006, 254–257. [Google Scholar]

- Liu, S.R. Mechanism of the Effects of TaC and Cr3C2 on Property of WC-Co Cemented Carbides. Rare Met. Mater. Eng. 1997, 26, 31–35. [Google Scholar]

- Roebuck, B.; Almond, E.A.; Cottenden, A.M. The Influence of Composition, Phase Transformation and Varying the Relative F.C.C. and H.C.P. Phase Contents on the Properties of Dilute Co W C Alloys. Mater. Sci. Eng. 1984, 66, 179–194. [Google Scholar] [CrossRef]

- Sun, Y.; Su, W.; Yang, H.; Ruan, J. Effects of WC Particle Size on Sintering Behavior and Mechanical Properties of Coarse Grained WC–8Co Cemented Carbides Fabricated by Unmilled Composite Powders. Ceram. Int. 2015, 41, 14482–14491. [Google Scholar] [CrossRef]

- Raihanuzzaman, R.M.; Xie, Z.; Hong, S.J.; Ghomashchi, R. Powder Refinement, Consolidation and Mechanical Properties of Cemented Carbides—An Overview. Powder Technol. 2014, 261, 1–13. [Google Scholar] [CrossRef]

- Ma, Q.L.; Chen, M.H.; Liu, N.; Li, Q.W.; Wang, D.F.; Cao, H. Effect of Cr3C2 Content on Microstructure and Properties of Ultra-fine WC-12%Co Cemented Carbides. Cem. Carbides 2019, 36, 29–37. [Google Scholar]

- Dong, K.L.; Liao, J.; Shi, K.H.; Diao, C.M.; Zhang, Q.W.; Jiang, J.Y. Effect of Mo2C Addition Amount on Microstructure and Properties of YG6 Fine-Grained Cemented Carbides. Rare Met. Cem. Carbides 2024, 52, 70–75. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. Microstructure and Mechanical Properties of WC–Co, WC–Co–Cr3C2 and WC–Co–TaC Cermets Fabricated by Spark Plasma Sintering. Trans. Nonferrous Met. Soc. China 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

- Chu, K.Y. Development of 21 Century’s Tool Material for Numerical Control Machine Tool. Mach. Tool. Hydraul. 2011, 39, 117–123. [Google Scholar]

- Zhang, H.J.; Zhu, H.Q.; Dong, D.W.; Wei, L.L.; Ma, Y.; Meng, Y.Y. Study on Ultracold Modification of WC-Co Alloy for Cutter Material. Hot Work. Technol. 2023, 1–7. [Google Scholar] [CrossRef]

- Wan, X.H.; Wang, C.A.; Han, H.K. Effects of Cr3C2 Content on Properties of Submicron-grained WC-10%Co Cemented Carbide for Mould. Cem. Carbides 2022, 39, 51–56. [Google Scholar]

- Qian, C.; Liu, Y.; Cheng, H.; Li, K.; Liu, B. Effect of the Carbon Content on the Morphology Evolution of the η Phase in Cemented Carbides with the CoNiFeCr High Entropy Alloy Binder. Int. J. Refract. Met. Hard Mater. 2022, 102, 105731. [Google Scholar] [CrossRef]

| Sample | Composition (wt.%) | Sinter Parameter | |

|---|---|---|---|

| WC−5Co4Ni1Fe | Cr3C2 | ||

| A | 100 | 0 | 1430 °C, 1 h |

| B | 99.8 | 0.2 | |

| C | 99.4 | 0.6 | |

| D | 99.1 | 0.9 | |

| E | 98 | 2.0 | |

| Sample | ω(Cr3C2) /% | Porosity | Uncombined Carbon | Mean Size (μm) |

|---|---|---|---|---|

| A | 0 | A00 B00 | C00/E00 | 1.28 |

| B | 0.2 | A00 B00 | C00/E00 | 0.97 |

| C | 0.6 | A00 B00 | C00/E00 | 0.9 |

| D | 0.9 | A02 B00 | C00/E00 | 0.72 |

| E | 2.0 | A04 B00 | C00/E00 | 0.54 |

| Sample | ω(Cr3C2)/% | Magnetic Saturation/% | Coercivity, Hc /(ka∙m−1) | Hardness (HRA) | TRS/MPa |

|---|---|---|---|---|---|

| A | 0 | 6.81 | 12.04 | 90.1 ± 0.11 | 3533.86 |

| B | 0.2 | 6.73 | 15.83 | 90.5 ± 0.16 | 3632 |

| C | 0.6 | 6.7 | 16.25 | 91.25 ± 0.15 | 3883.2 |

| D | 0.9 | 6.57 | 17.33 | 91.4 ± 0.2 | 3769 |

| E | 2.0 | 6.28 | 22.06 | 92.3 ± 0.12 | 1613 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Ren, D.; Xie, B.; He, R.; Geng, Z.; Zhang, Z.; Liu, Y.; Wang, D.; Zhu, Y.; Zhang, W. Effect of Cr3C2 Addition on Microstructure and Mechanical Properties of WC-CoNiFe Cemented Carbides. Metals 2024, 14, 895. https://doi.org/10.3390/met14080895

Wu J, Ren D, Xie B, He R, Geng Z, Zhang Z, Liu Y, Wang D, Zhu Y, Zhang W. Effect of Cr3C2 Addition on Microstructure and Mechanical Properties of WC-CoNiFe Cemented Carbides. Metals. 2024; 14(8):895. https://doi.org/10.3390/met14080895

Chicago/Turabian StyleWu, Jinbo, Daping Ren, Bo Xie, Rongyue He, Zhanji Geng, Zichun Zhang, Yang Liu, Dong Wang, Yanghui Zhu, and Wei Zhang. 2024. "Effect of Cr3C2 Addition on Microstructure and Mechanical Properties of WC-CoNiFe Cemented Carbides" Metals 14, no. 8: 895. https://doi.org/10.3390/met14080895

APA StyleWu, J., Ren, D., Xie, B., He, R., Geng, Z., Zhang, Z., Liu, Y., Wang, D., Zhu, Y., & Zhang, W. (2024). Effect of Cr3C2 Addition on Microstructure and Mechanical Properties of WC-CoNiFe Cemented Carbides. Metals, 14(8), 895. https://doi.org/10.3390/met14080895