Phase Mapping Using a Combination of Multi-Functional Scanning Electron Microscopy Detectors and Imaging Modes

Abstract

1. Introduction

2. Materials and Experimental Methods

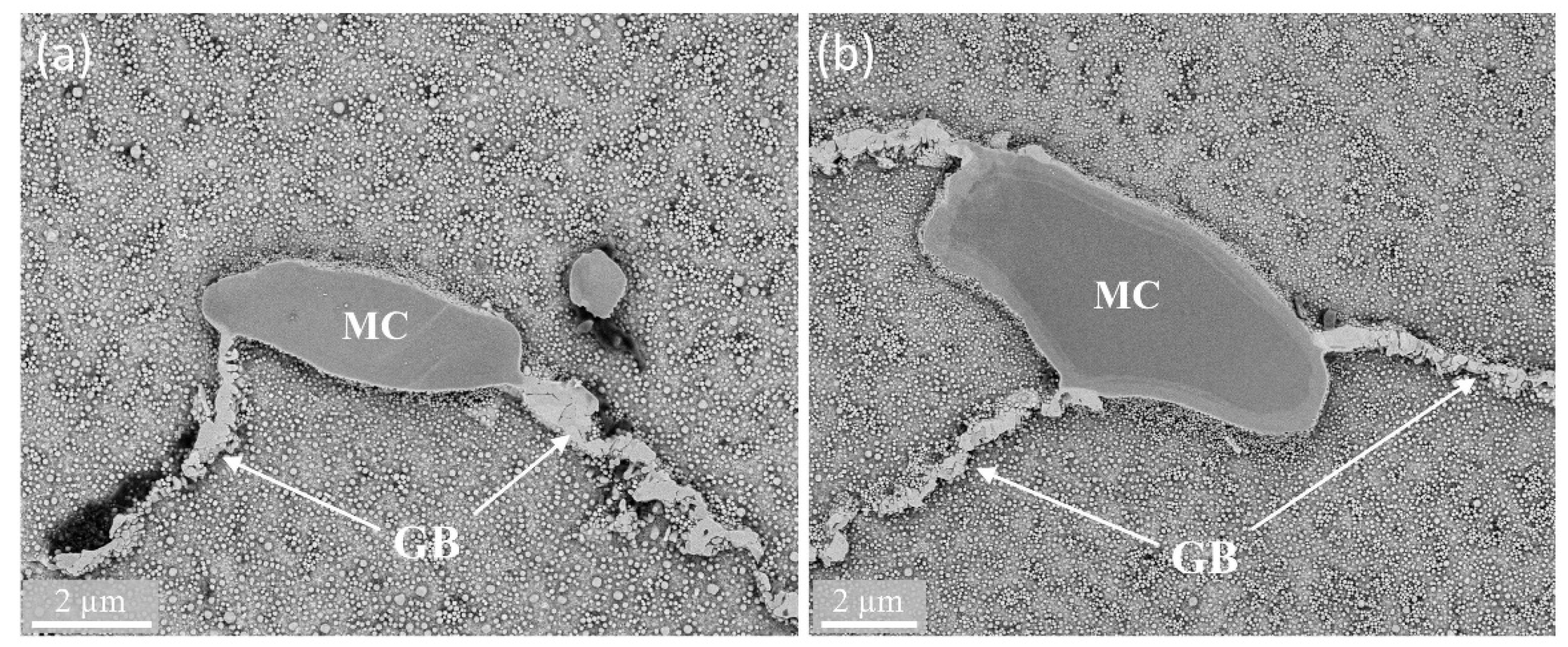

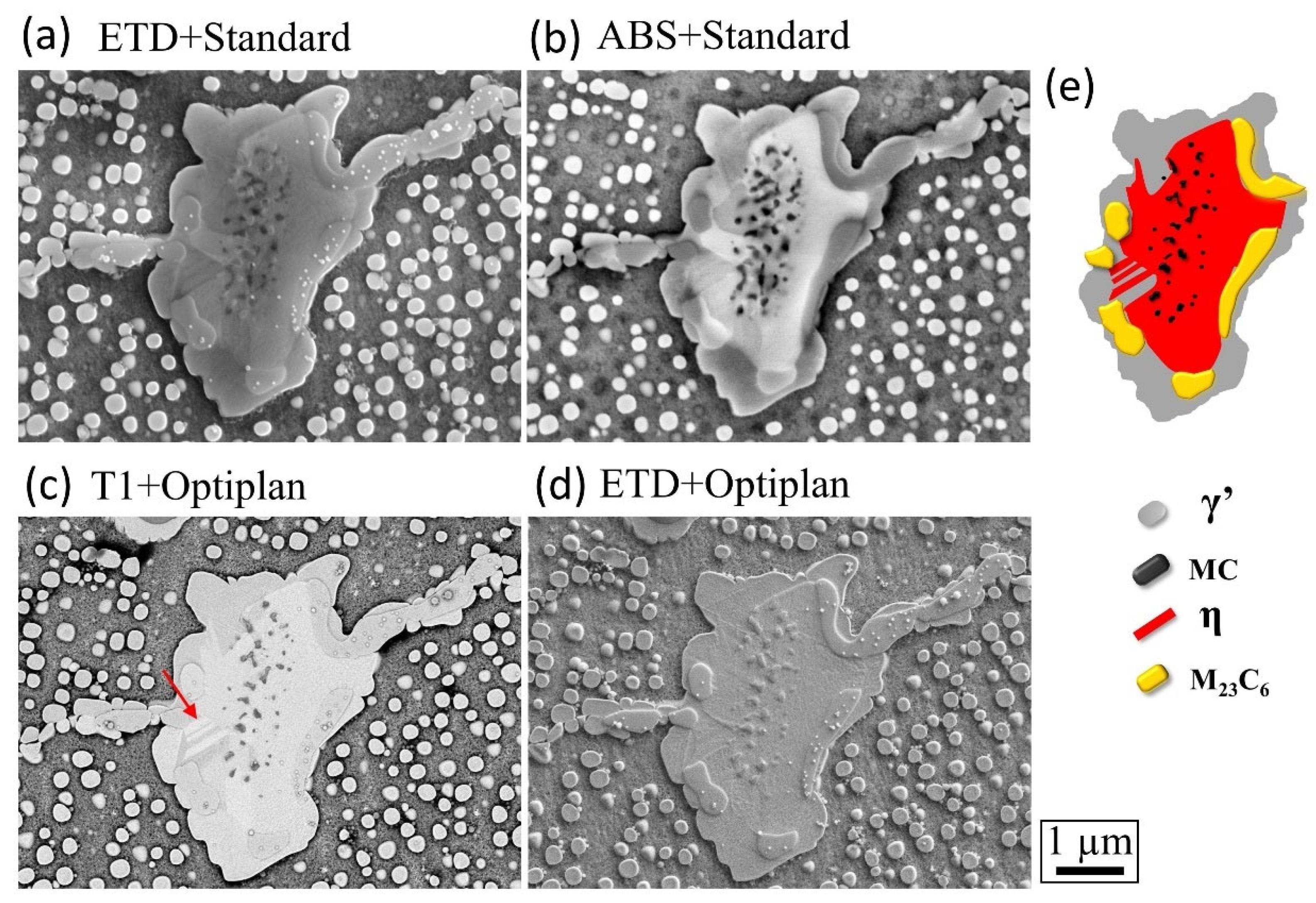

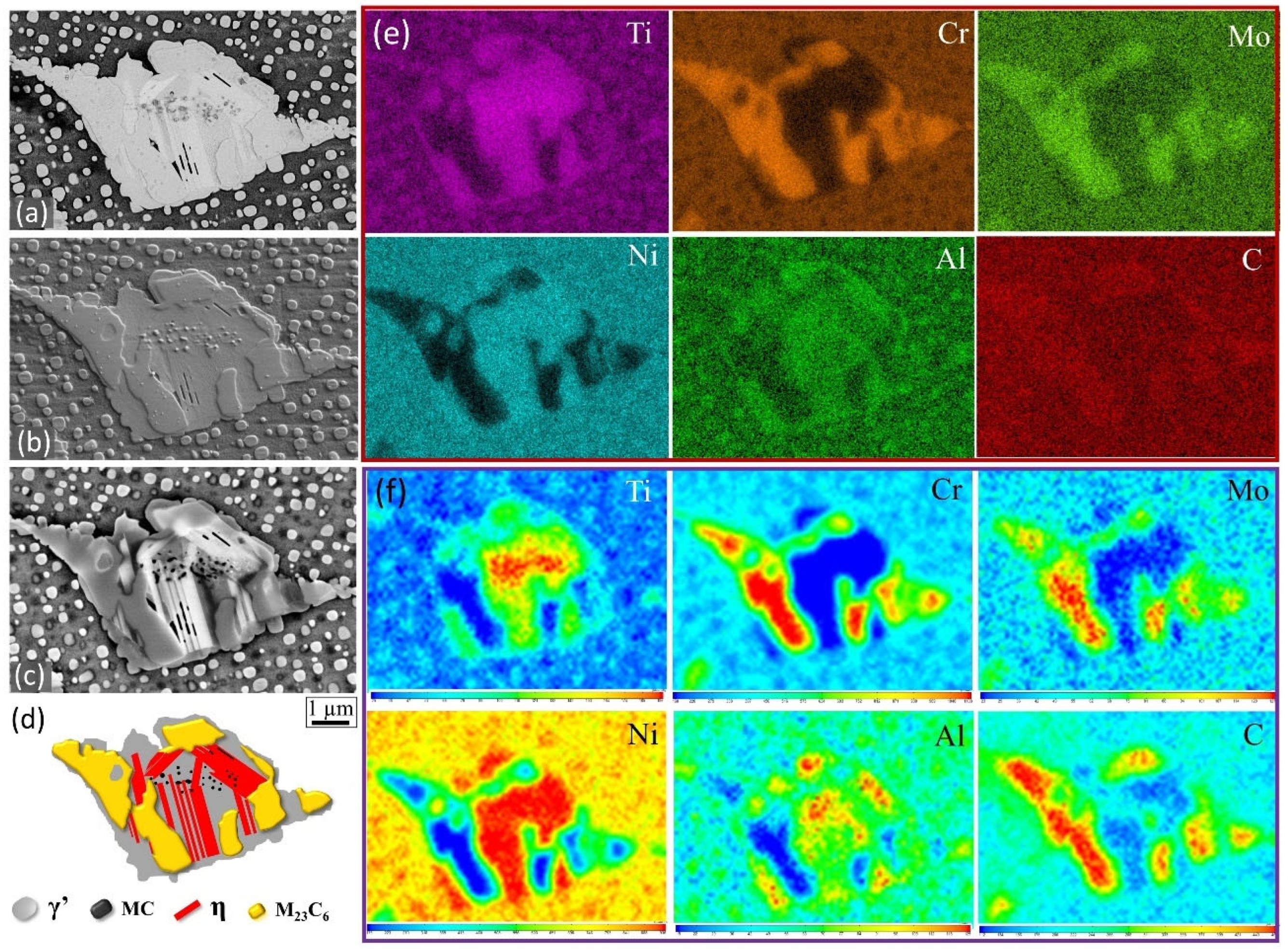

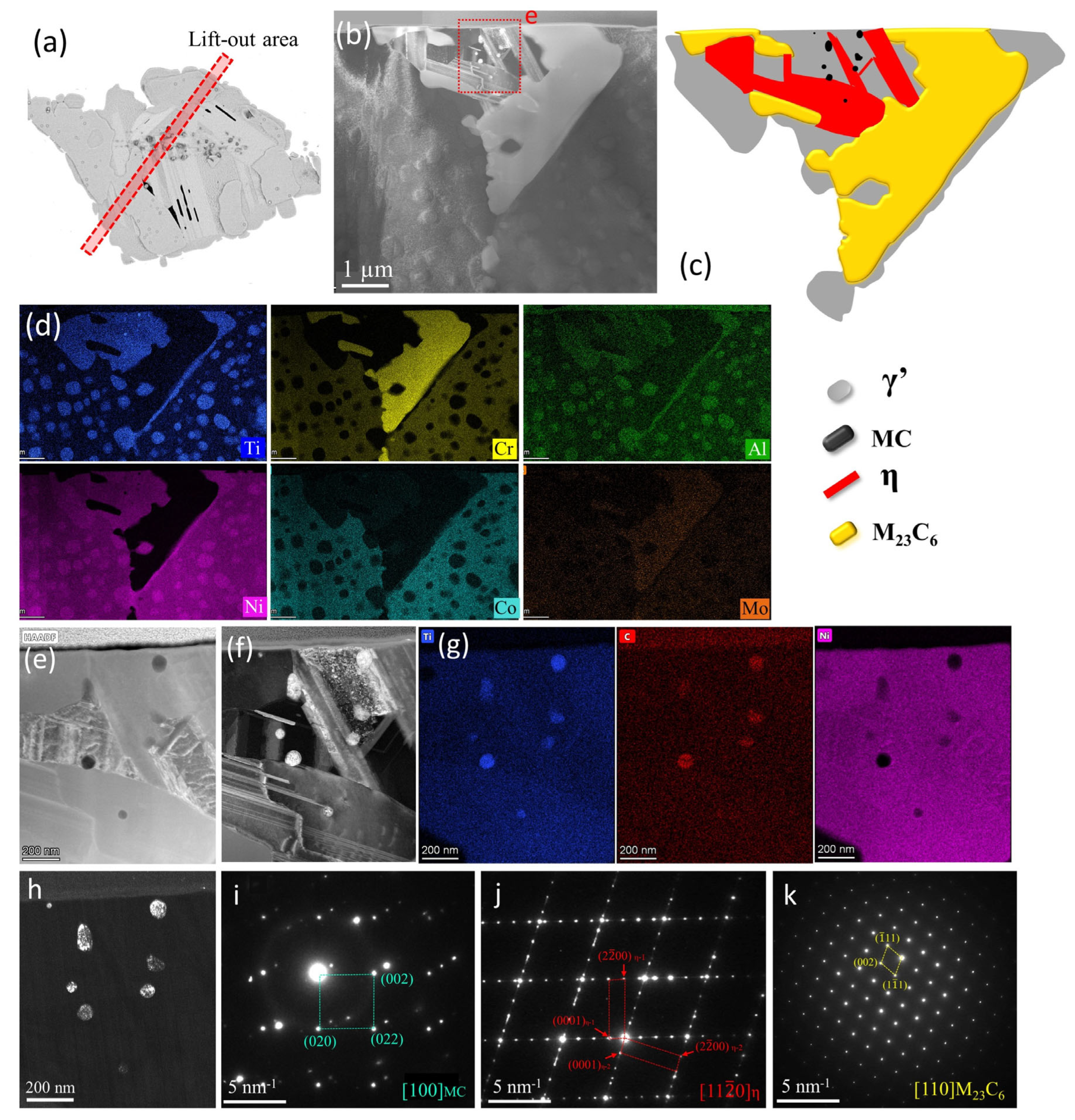

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pedroso, A.F.V.; Sousa, V.F.C.; Sebbe, N.P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Jesus, A.M.P. A Comprehensive Review on the Conventional and Non-Conventional Machining and Tool-Wear Mechanisms of INCONEL®. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Liu, G.; Kong, L.; Xiao, X.; Birosca, S. Microstructure evolution and phase transformation in a nickel-based superalloy with varying Ti/Al ratios: Part 2—Phase transformation. Mater. Sci. Eng. A 2022, 831, 142228. [Google Scholar] [CrossRef]

- Sazerat, M.; Nait-Ali, A.; Cervellon, A.; Lopez-Galilea, I.; Burlot, G.; Gillet, S.; Eyidi, D.; Joulain, A.; Villechaise, P.; Weber, S.; et al. High temperature microstructure stability of Waspaloy produced by Wire Arc Additive Manufacturing. J. Alloys Compd. 2023, 966, 171626. [Google Scholar] [CrossRef]

- Chu, D.J.; Park, C.; Lee, J.; Jung, W.S. Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys. Metals 2023, 13, 1959. [Google Scholar] [CrossRef]

- Detrois, M.; Jablonski, P.D.; Hawk, J.A. The effect of η phase precipitates on the creep behavior of alloy 263 and variants. Mater. Sci. Eng. A 2021, 799, 140337. [Google Scholar] [CrossRef]

- Lvov, G.; Levit, V.I.; Kaufman, M.J. Mechanism of primary MC carbide decomposition in Ni-base superalloys. Metall. Mater. Trans. A 2004, 35, 1669–1679. [Google Scholar] [CrossRef]

- Ge, H.; Liu, G.; Zheng, S.; Yang, Y.; Liu, K.; Ma, X. Dislocation climbing dominated decomposition and fracture of carbides in a Ni-based superalloy. Acta Mater. 2023, 246, 118669. [Google Scholar] [CrossRef]

- Liu, G.; Xiao, X.; Véron, M.; Birosca, S. The nucleation and growth of η phase in nickel-based superalloy during long-term thermal exposure. Acta Mater. 2020, 185, 493–506. [Google Scholar] [CrossRef]

- Hou, K.; Ou, M.; Xing, W.; Ma, G.; Hao, X.; Wang, M.; Ma, Y. The formation of η-Ni3Ti phase microstructure in a cast nickel-based superalloy with high Ti/Al ratio. J. Mater. Res. Technol. 2024, 29, 764–778. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, I.S.; Kim, D.H.; Jo, C.Y. Temperature dependence of MC decomposition behavior in Ni-base superalloy GTD 111. Mater. Sci. Eng. A 2008, 478, 329–335. [Google Scholar] [CrossRef]

- BGeorgin, B.M.; Viswanathan, G.B.; Welk, B.A.; Kloenne, Z.T.; Fraser, H.L. Optimizing image contrast of second phases in metal alloys. Ultramicroscopy 2021, 228, 113346. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, Í.; Simões, S. Recent Advances in EBSD Characterization of Metals. Metals 2020, 10, 1097. [Google Scholar] [CrossRef]

- Sharma, J.; Nicolaÿ, A.; De Graef, M.; Bozzolo, N. Phase discrimination between δ and η phases in the new nickel-based superalloy VDM Alloy 780 using EBSD. Mater. Charact. 2021, 176, 111105. [Google Scholar] [CrossRef]

- Münch, B.; Martin, L.; Leemann, A. Segmentation of elemental EDS maps by means of multiple clustering combined with phase identification. J. Microsc. 2015, 260, 411–426. [Google Scholar] [CrossRef] [PubMed]

- Parish, C.M.; Brewer, L.N. Multivariate statistics applications in phase analysis of STEM-EDS spectrum images. Ultramicroscopy 2010, 110, 134–143. [Google Scholar] [CrossRef] [PubMed]

- Rauch, E.; Véron, M. Automated crystal orientation and phase mapping in TEM. Mater. Charact. 2014, 98, 1–9. [Google Scholar] [CrossRef]

- Jiang, J.; Britton, T.B.; Wilkinson, A.J. Measurement of geometrically necessary dislocation density with high resolution electron backscatter diffraction: Effects of detector binning and step size. Ultramicroscopy 2013, 125, 1–9. [Google Scholar] [CrossRef] [PubMed]

| Phase Mapping Methods | Advantages | Disadvantages | Note |

|---|---|---|---|

| Imaging with different detectors and modes | Relatively quick and accurate | Proposed herein | |

| EBSD | High accuracy for large-size phases | High demand of sample surface; time consuming for scanning; limited resolution | Widely used for accurate phase mapping for bulk alloys [8] |

| SEM-EDS | Time consuming for scanning; limited accuracy | Common method for auxiliary phase identification and mapping for bulk alloys | |

| STEM-EDS | High accuracy | Difficulties in specimen preparation; time consuming for scanning; limited research areas | Common method for auxiliary phase identification and mapping for TEM foils |

| TEM-PED | High accuracy | Difficulties in specimen preparation; time consuming for scanning, limited research areas | Widely used for accurate phase for TEM foils with nanometer resolution [9] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhao, Y.; Wang, S. Phase Mapping Using a Combination of Multi-Functional Scanning Electron Microscopy Detectors and Imaging Modes. Metals 2024, 14, 899. https://doi.org/10.3390/met14080899

Liu G, Zhao Y, Wang S. Phase Mapping Using a Combination of Multi-Functional Scanning Electron Microscopy Detectors and Imaging Modes. Metals. 2024; 14(8):899. https://doi.org/10.3390/met14080899

Chicago/Turabian StyleLiu, Gang, Yonghua Zhao, and Shuai Wang. 2024. "Phase Mapping Using a Combination of Multi-Functional Scanning Electron Microscopy Detectors and Imaging Modes" Metals 14, no. 8: 899. https://doi.org/10.3390/met14080899

APA StyleLiu, G., Zhao, Y., & Wang, S. (2024). Phase Mapping Using a Combination of Multi-Functional Scanning Electron Microscopy Detectors and Imaging Modes. Metals, 14(8), 899. https://doi.org/10.3390/met14080899