Synergistic Effect of Phase Transformation and Stress-Induced Twinning on the Antibacterial Property and Elastic Modulus of Ti-13Nb-13Zr-7Ag

Abstract

:1. Introduction

2. Experimental

2.1. Material Preparation

2.2. Phase Identification

2.3. Microstructure

2.4. Antibacterial Properties

2.5. Elastic Modulus

2.6. Corrosion Resistance

2.7. Cytotoxicity

2.8. Statistical Analysis

3. Results

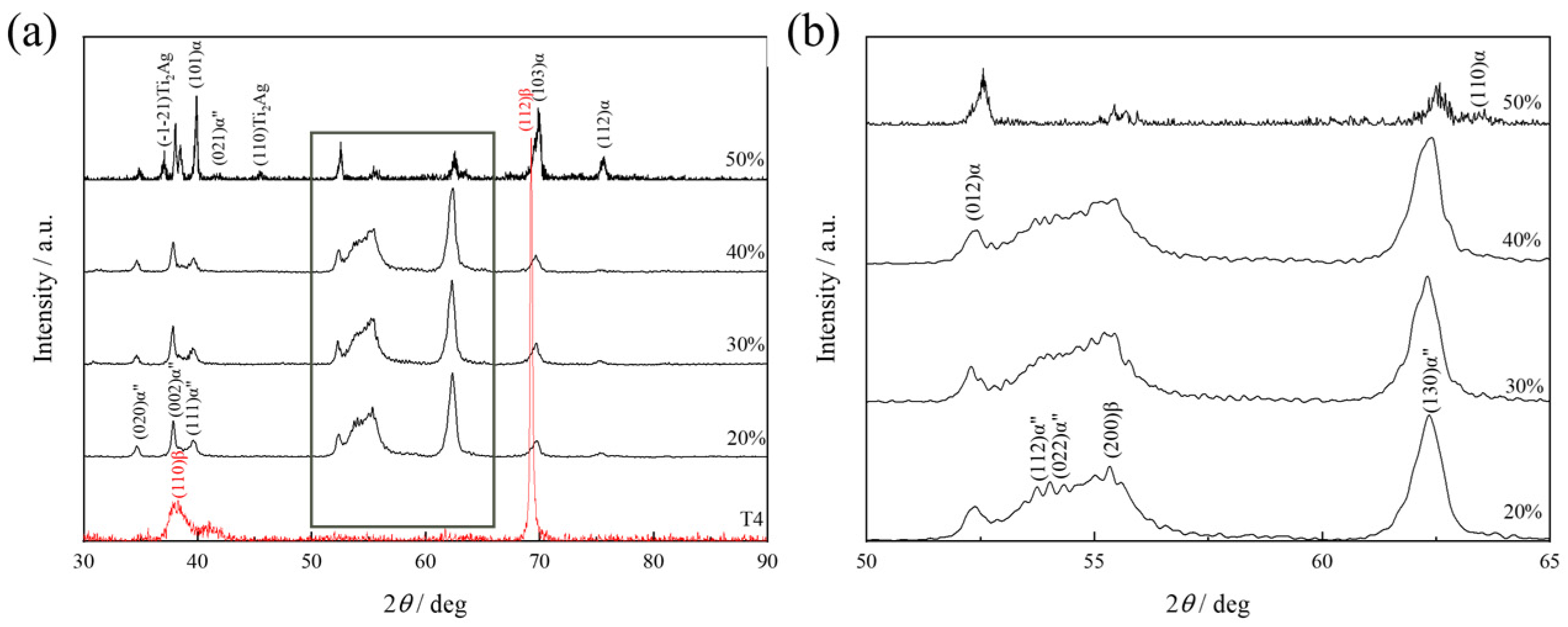

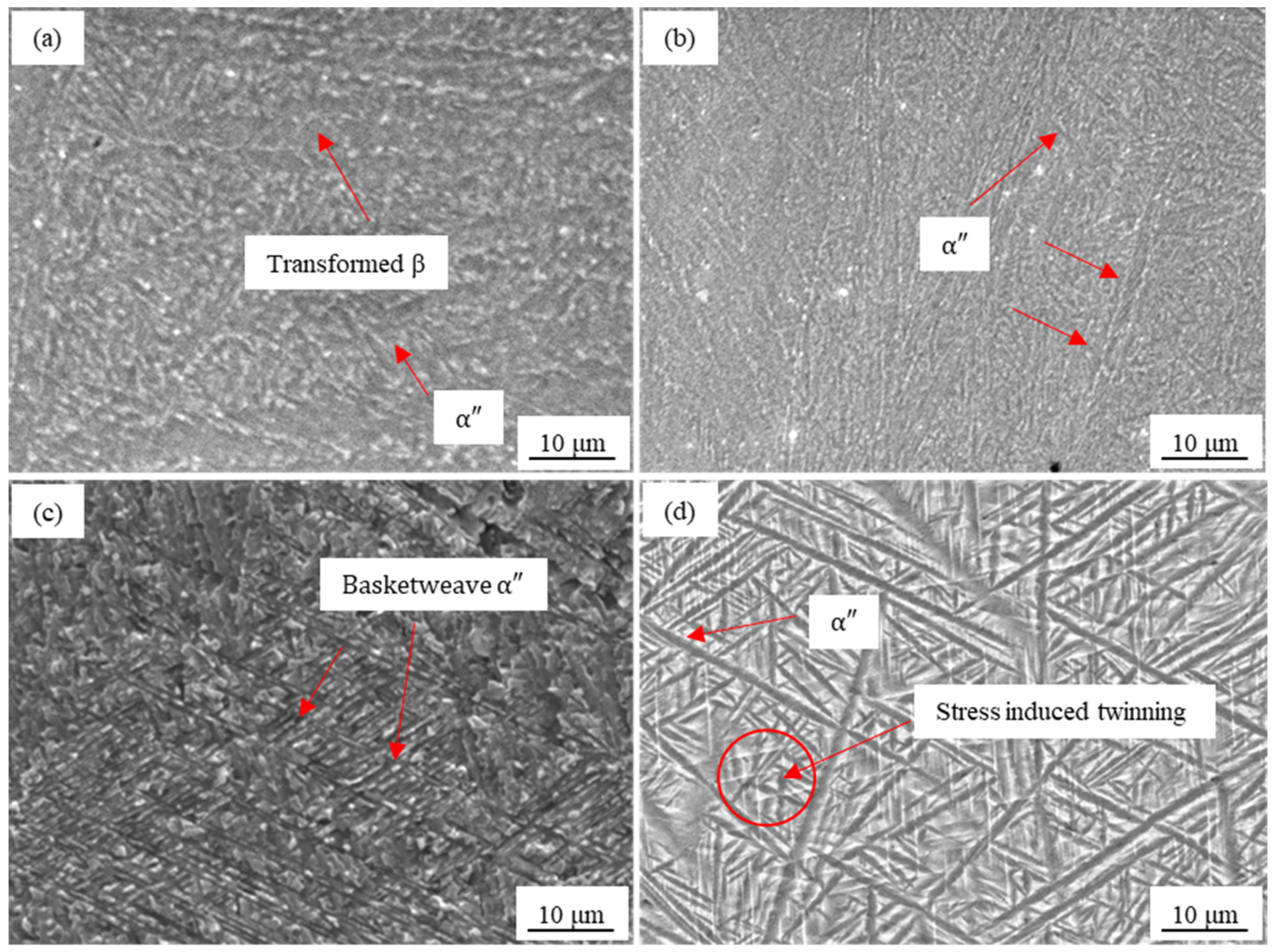

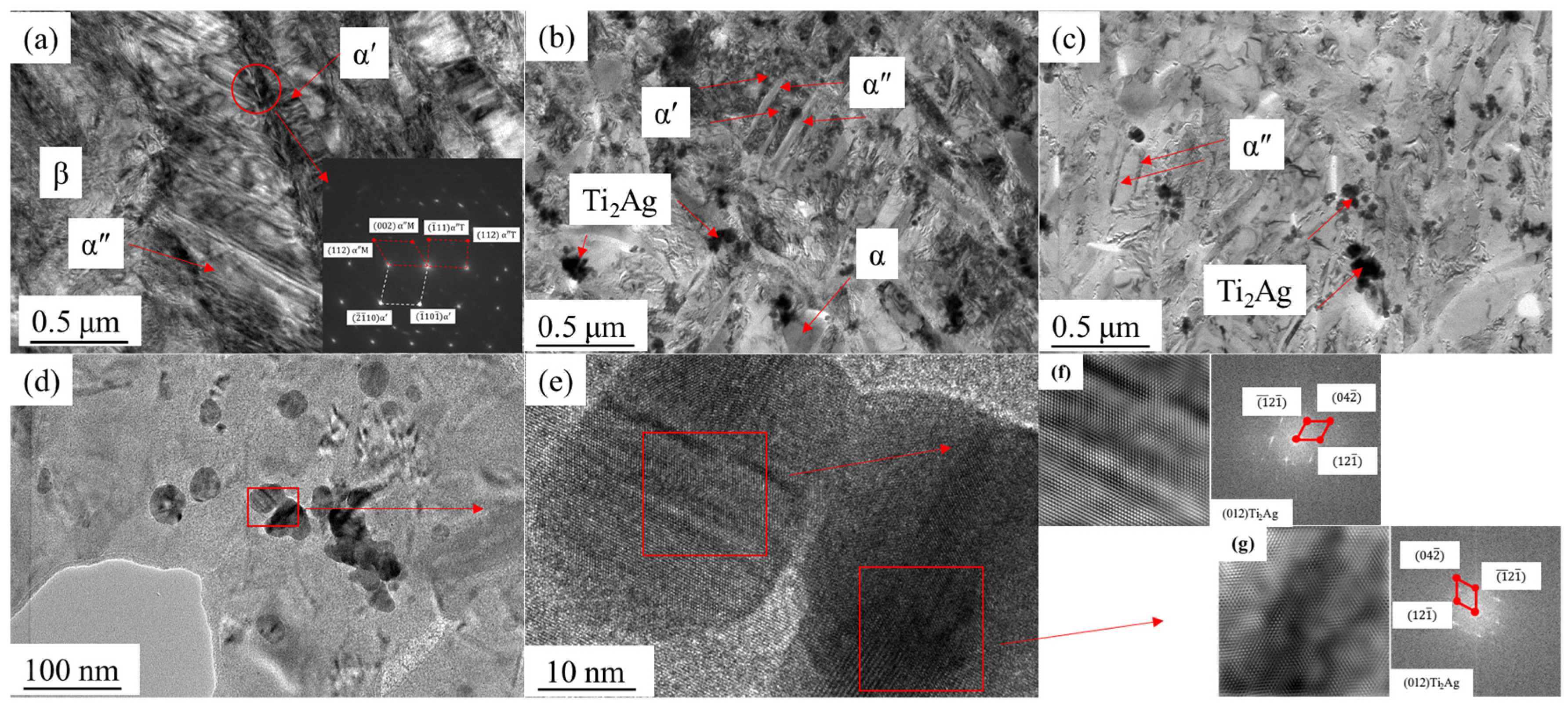

3.1. Microstructure after Pre-Deformation

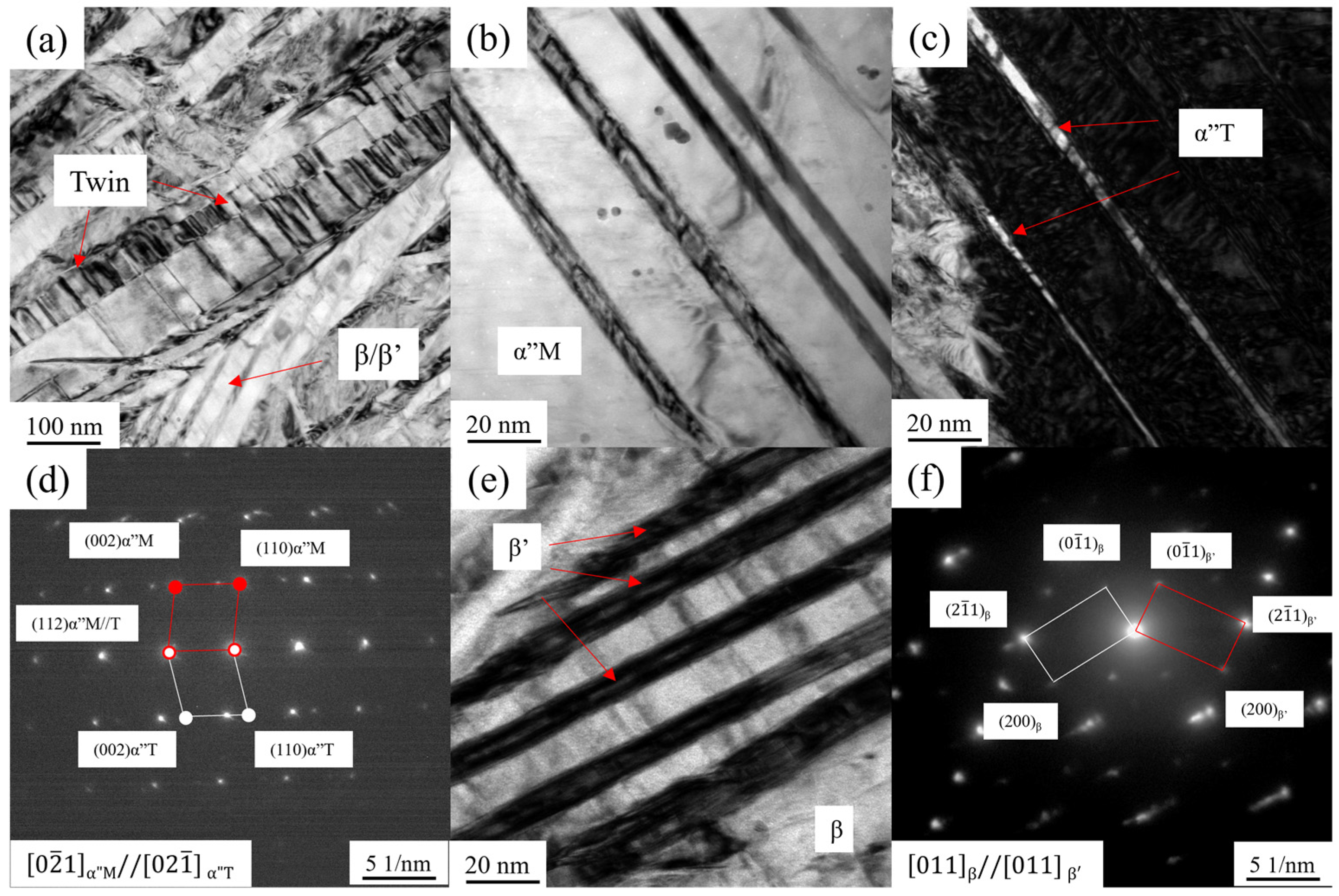

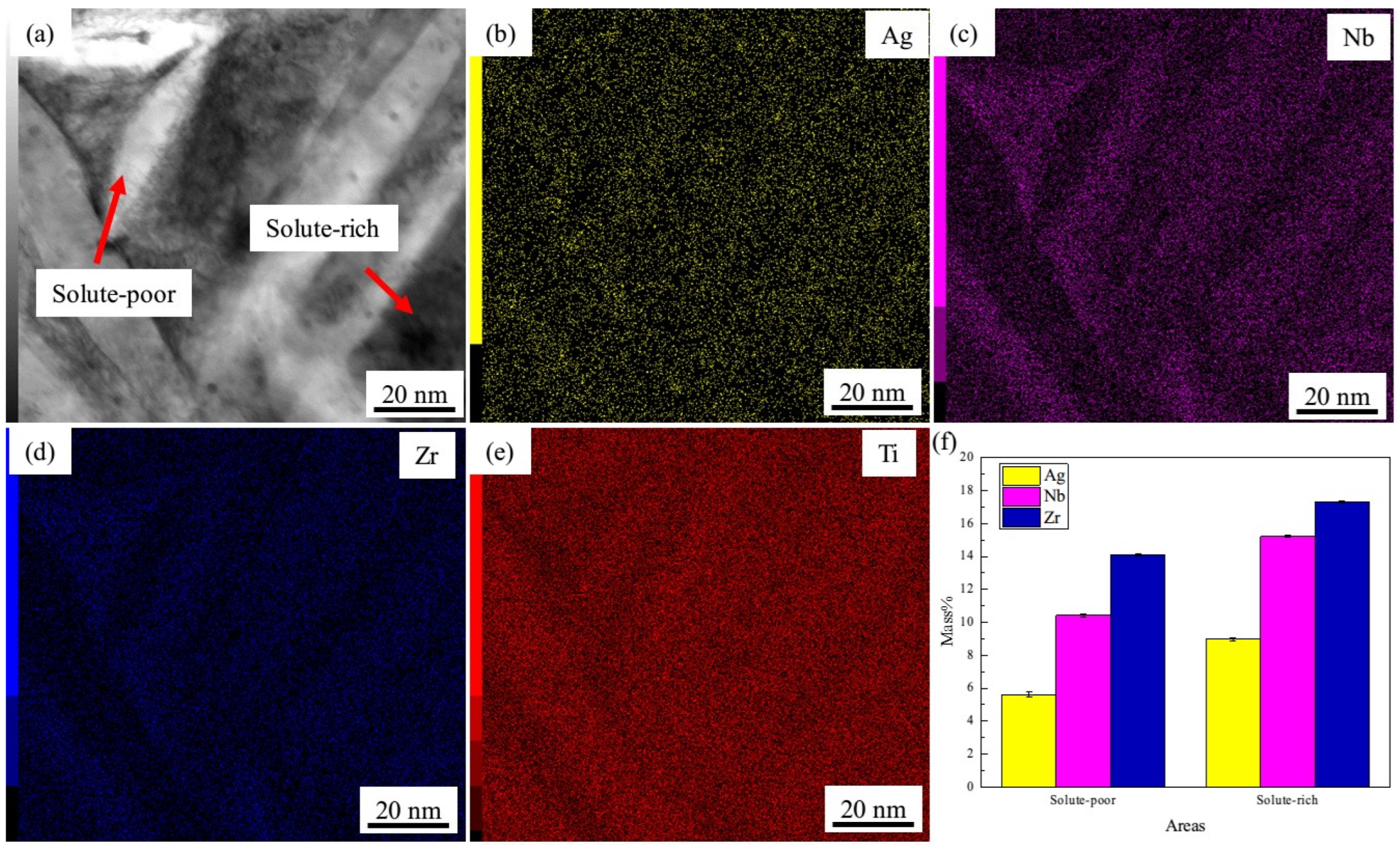

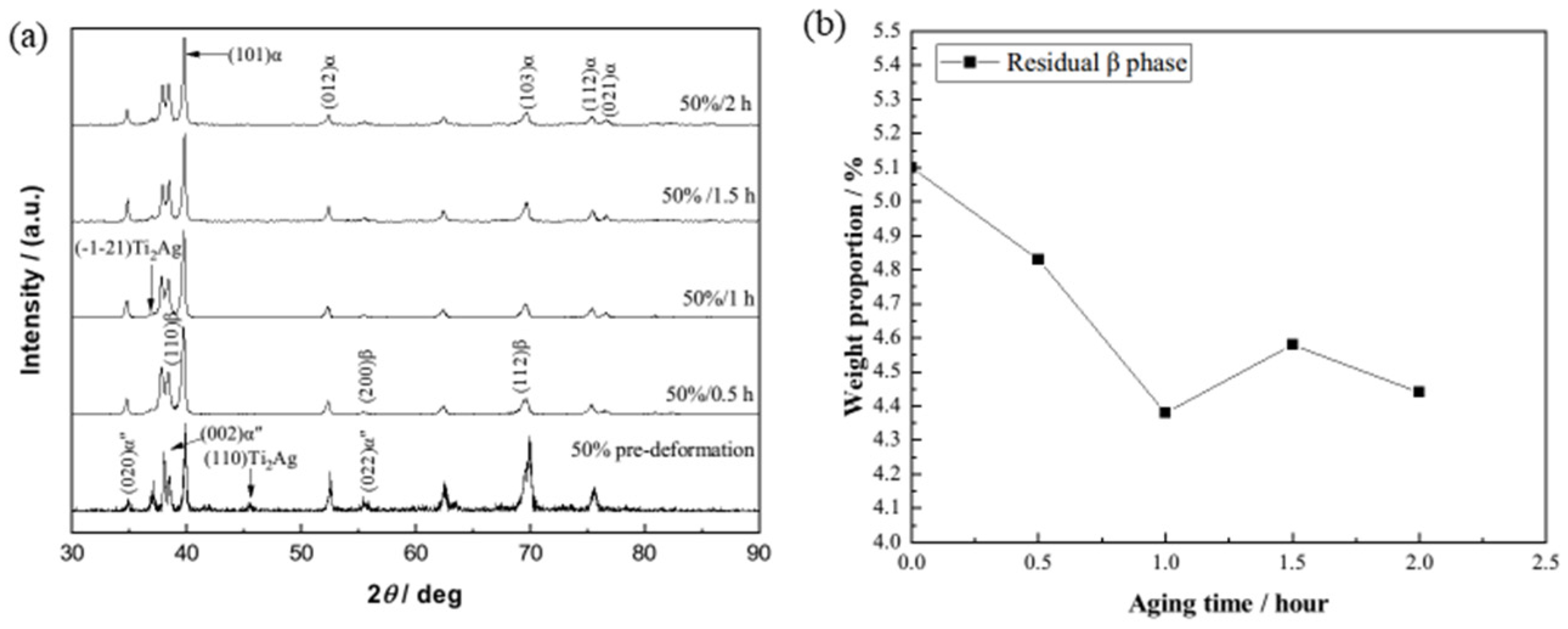

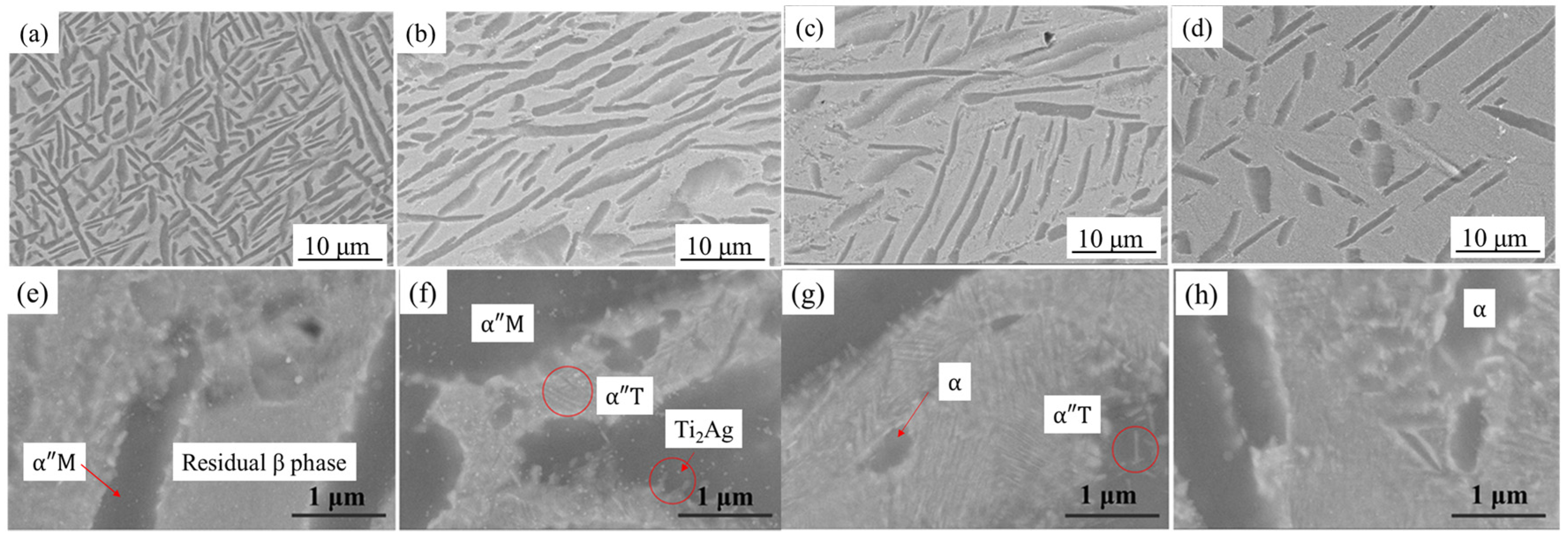

3.2. Microstructure of TNZ-7Ag with Pre-Deformation and Aging

3.3. Elastic Modulus

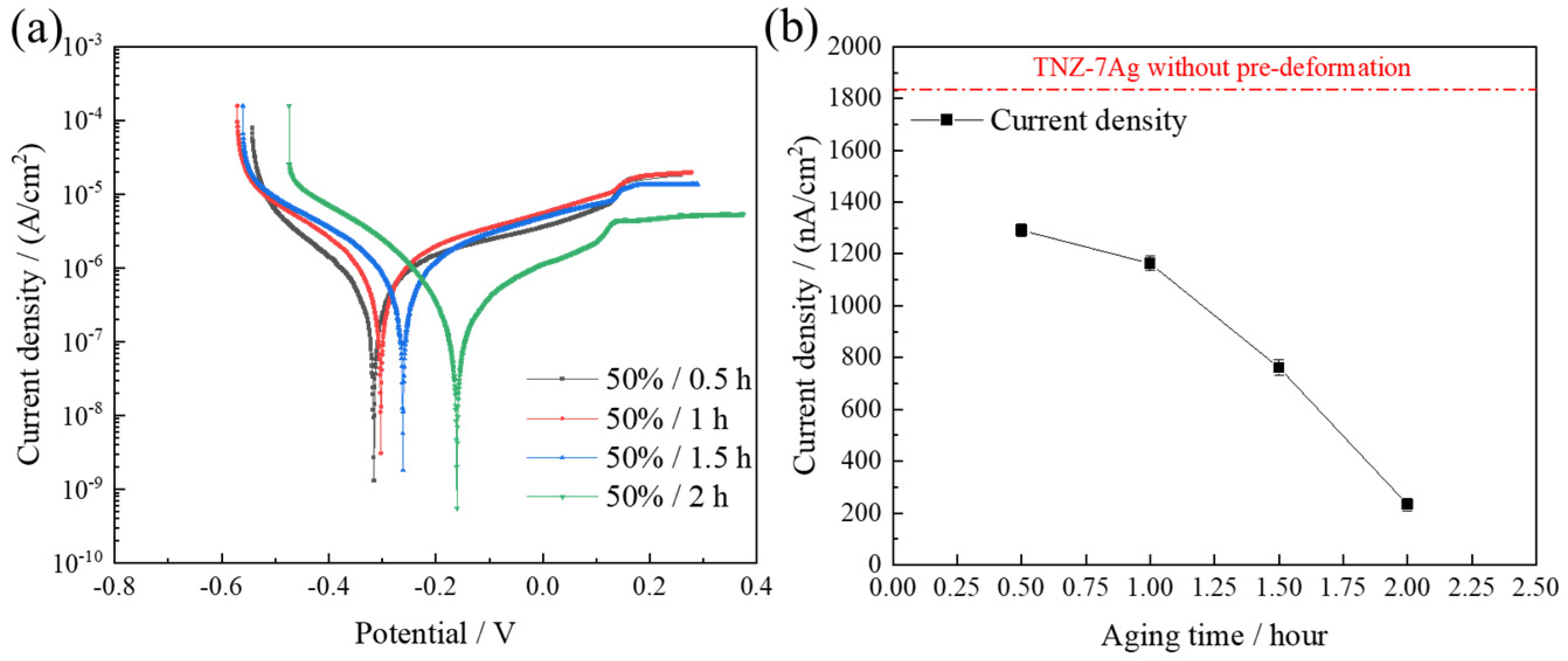

3.4. Corrosion Resistance

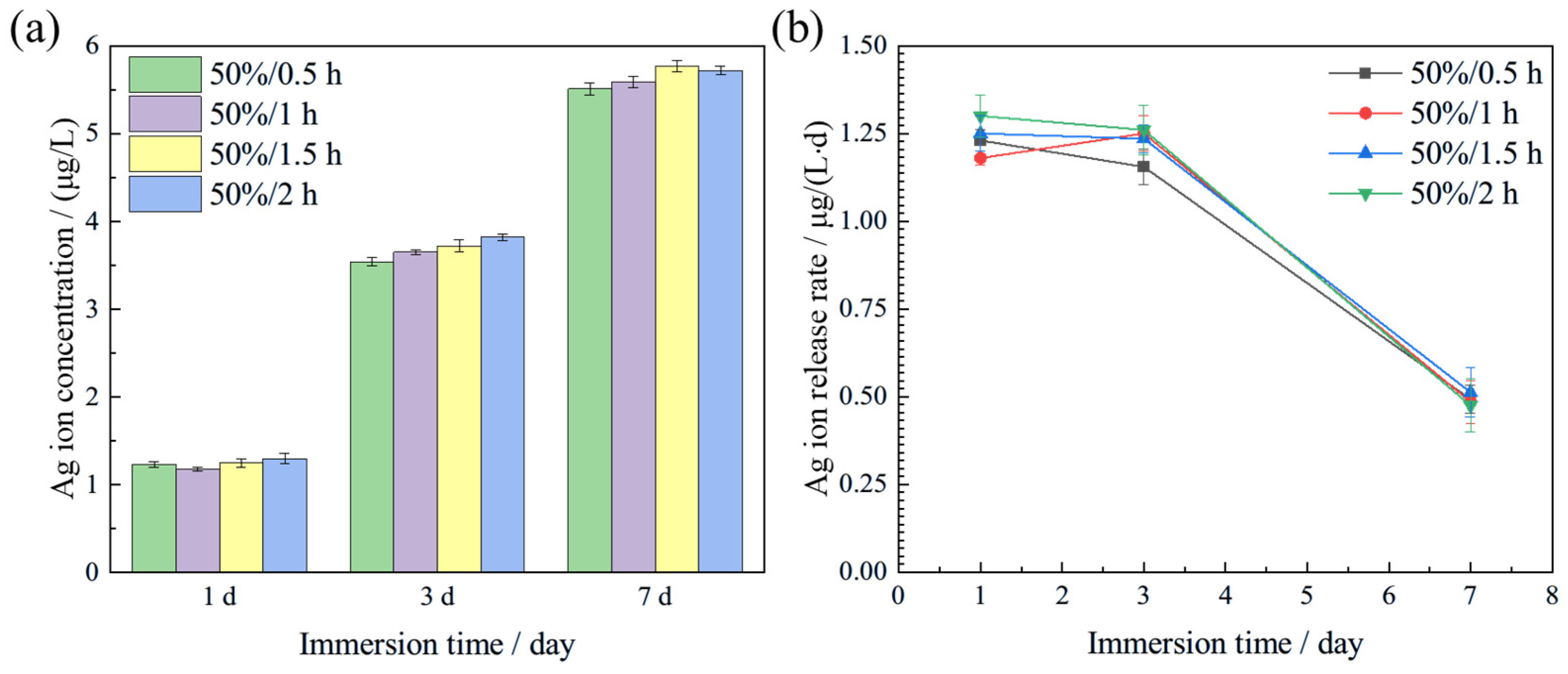

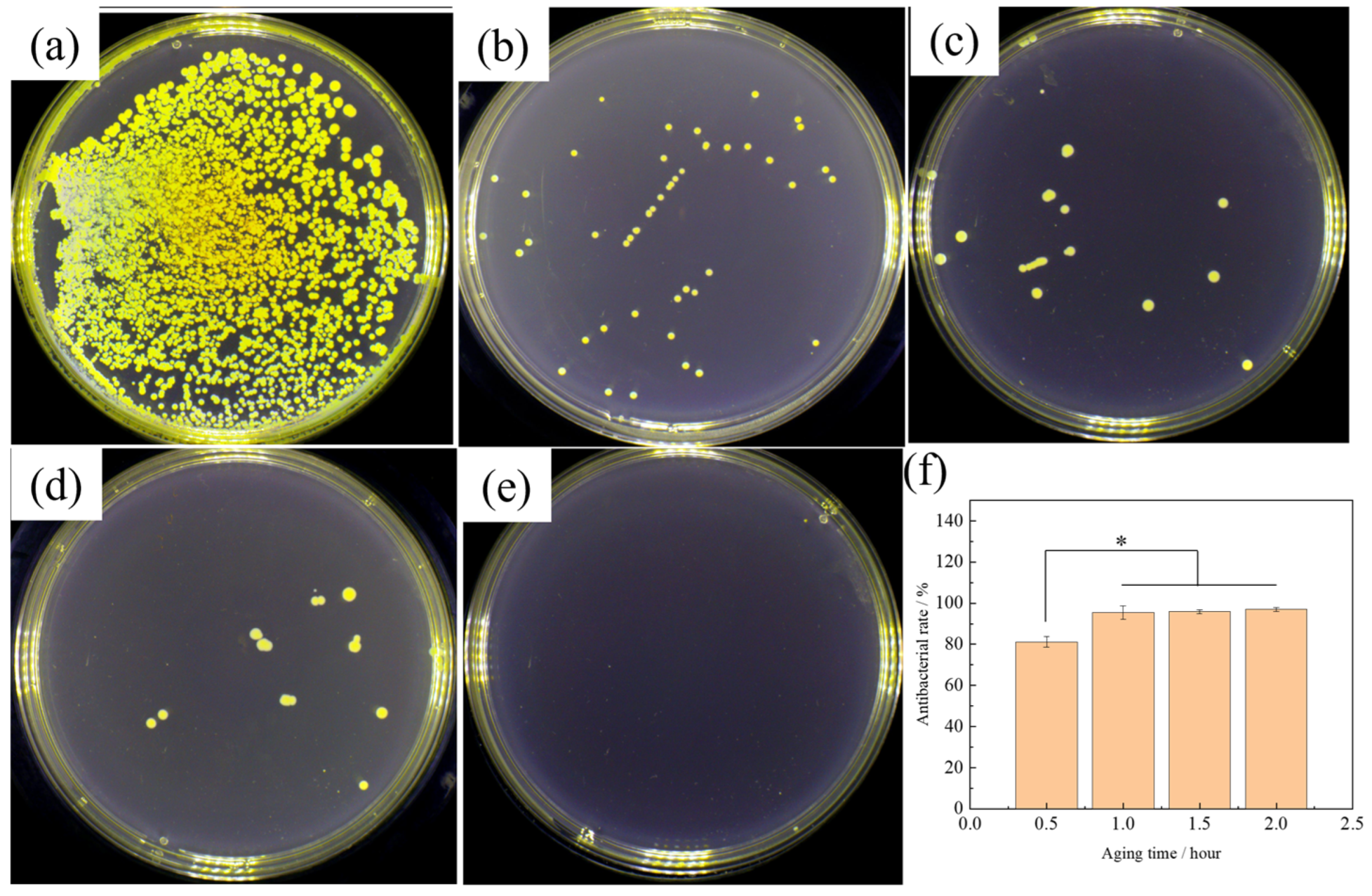

3.5. Antibacterial Properties

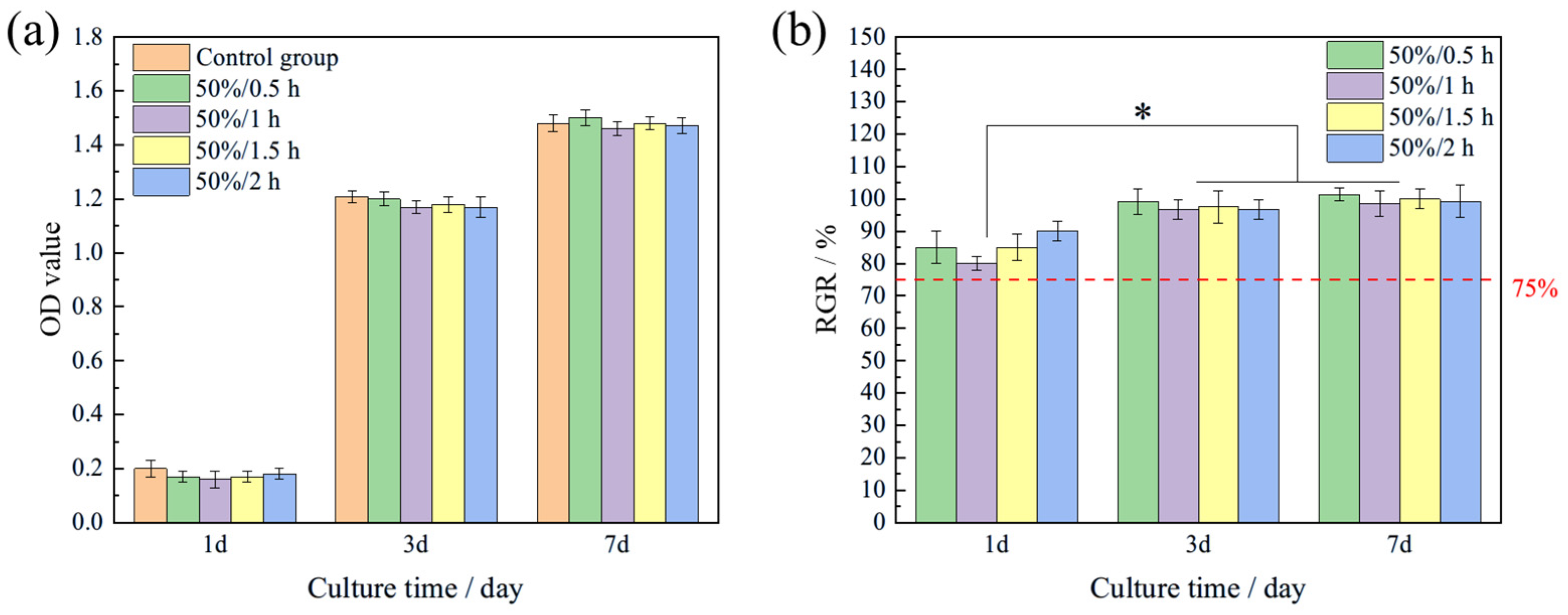

3.6. Cytotoxicity

4. Discussion

4.1. Effect of Pre-Deformation + Aging on the Microstructure

4.2. Antibacterial Properties and Elastic Modulus

4.3. Corrosion Resistance and Cytotoxicity

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, Y.; Song, Y.; Wang, L.; Wei, C.; Zhou, X.; Feng, Y. Research progress on antibacterial activity of medical titanium alloy implant materials. Odontology 2023, 111, 813–829. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Yang, L.; Zhang, L.; Han, Y.; Lu, Z.; Qin, G.; Zhang, E. Effect of nano/micro-Ag compound particles on the bio-corrosion, antibacterial properties and cell biocompatibility of Ti-Ag alloys. Mater. Sci. Eng. C 2017, 75, 906–917. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ma, Z.; Zhu, Y.; Xia, H.; Yao, M.; Chu, X.; Wang, X.; Yang, K.; Yang, M.; Zhang, Y.; et al. Toward a Molecular Understanding of the Antibacterial Mechanism of Copper-Bearing Titanium Alloys against Staphylococcus aureus. Adv. Healthc. Mater. 2016, 5, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Zhang, T.; Gong, Y.; He, Y. Silver-Containing Biomaterials for Biomedical Hard Tissue Implants. Adv. Healthc. Mater. 2023, 12, 2300932. [Google Scholar] [CrossRef] [PubMed]

- Marczewski, M.; Jurczyk, M.; Pecyna, P.; Ratajczak, M.; Gajecka, M.; Jurczyk, M.U. The Effect of 45S5 Bioglass and Ag, Cu, or Zn Addition on the Crystal Structure, Properties, and Antibacterial Effect of Bulk Ti23Zr25Nb Biocomposites. Metals 2020, 10, 1115. [Google Scholar] [CrossRef]

- Aziz, N.; Faraz, M.; Sherwani, M.A.; Fatma, T.; Prasad, R. Illuminating the Anticancerous Efficacy of a New Fungal Chassis for Silver Nanoparticle Synthesis. Front. Chem. 2019, 7, 65. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Chen, S.; Yang, M.; Liu, Y.; Liu, J. Metallic Materials for Bone Repair. Adv. Healthc. Mater. 2024, 13, 2302132. [Google Scholar] [CrossRef] [PubMed]

- Takizawa, T.; Nakayama, N.; Haniu, H.; Aoki, K.; Okamoto, M.; Nomura, H.; Tanaka, M.; Sobajima, A.; Yoshida, K.; Kamanaka, T.; et al. Titanium Fiber Plates for Bone Tissue Repair. Adv. Mater. 2018, 30, 1703608. [Google Scholar] [CrossRef]

- Mohammed, M.T.; Khan, Z.A.; Siddiquee, A.N. Beta titanium alloys: The lowest elastic modulus for biomedical applications: A review. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2014, 8, 726–731. [Google Scholar]

- Liang, S. Review of the Design of Titanium Alloys with Low Elastic Modulus as Implant Materials. Adv. Eng. Mater. 2020, 22, 2000555. [Google Scholar] [CrossRef]

- Cai, D.; Yu, Z.; Yang, L.; Nie, J.-J.; Wang, R.; Chen, D.; Zhang, E. Effect of Ag content on the microstructure and antibacterial activity of biomedical titanium alloy Ti-13Nb-13Zr-xAg (x = 7,10 wt%). Mater. Lett. 2024, 354, 135389. [Google Scholar] [CrossRef]

- Cui, S.; Liu, S.; Nie, J.; Chen, D.; Wu, X.; Qin, G.; Zhang, E. Design and preparation of a biomedical titanium alloy with low elastic modulus and high antibacterial property based on Ti-Mo-Ag system. J. Alloys Compd. 2022, 908, 164639. [Google Scholar] [CrossRef]

- Hussein, M.A.; Kumar, A.M.; Azeem, M.A.; Sorour, A.A.; Saravanan, S. Ti–30Nb–3Ag alloy with improved corrosion resistance and antibacterial properties for orthopedic and dental applications produced by mechanical alloying. J. Mech. Behav. Biomed. Mater. 2023, 142, 105851. [Google Scholar] [CrossRef] [PubMed]

- Hussein, M.A.; Azeem, M.A.; Kumar, A.M.; Saravanan, S.; Ankah, N.; Sorour, A.A. Design and processing of near-β Ti–Nb–Ag alloy with low elastic modulus and enhanced corrosion resistance for orthopedic implants. J. Mater. Res. Technol. 2023, 24, 259–273. [Google Scholar] [CrossRef]

- Fu, S.; Zhang, Y.; Qin, G.; Zhang, E. Antibacterial effect of TiAg alloy motivated by Ag-containing phases. Mater. Sci. Eng. C 2021, 128, 112266. [Google Scholar] [CrossRef] [PubMed]

- Gong, D.; Wang, H.; Wang, Q.; Li, S.; Lin, K.; Wang, Y.; Yang, R.; Hao, Y. Tuning temperature coefficient of elastic modulus by heat treatment in a compositionally-modulated Ti-Nb-based alloy. Scr. Mater. 2023, 227, 115275. [Google Scholar] [CrossRef]

- Ma, X.; Chen, Z.; Xiao, L.; Luo, S.; Lu, W. Stress-induced martensitic transformation in a β-solution treated Ti–10V–2Fe–3Al alloy during compressive deformation. Mater. Sci. Eng. A 2021, 801, 140404. [Google Scholar] [CrossRef]

- GB/T 31544-2015; Test Method for Elastic Properties of Glass at High Temperatures—Impulse Excitation of Vibration. Industrial Glass and Special Glass: Beijing, China, 2015; pp. 1–5.

- Bohner, M.; Lemaitre, J. Can bioactivity be tested in vitro with SBF solution? Biomaterials 2009, 30, 2175–2179. [Google Scholar] [CrossRef]

- GB/T 16886. 12-2005; Biological Evaluation of Medical Devices—Part 12: Sample Preparation and Reference Materials. Industrial Glass and Special Glass: Beijing, China, 2015; pp. 1–9.

- Thangaraju, P.; Varthya, S.B. Iso 10993: Biological evaluation of medical devices. In Medical Device Guidelines and Regulations Handbook; Springer: Cham, Switzerland, 2022; pp. 163–187. [Google Scholar]

- Mittler, R.; Vanderauwera, S.; Suzuki, N.; Miller, G.; Tognetti, V.B.; Vandepoele, K.; Gollery, M.; Shulaev, V.; Van Breusegem, F. ROS signaling: The new wave? Trends Plant Sci. 2011, 16, 300–309. [Google Scholar] [CrossRef]

- Su, H.-L.; Chou, C.-C.; Hung, D.-J.; Lin, S.-H.; Pao, I.C.; Lin, J.-H.; Huang, F.-L.; Dong, R.-X.; Lin, J.-J. The disruption of bacterial membrane integrity through ROS generation induced by nanohybrids of silver and clay. Biomaterials 2009, 30, 5979–5987. [Google Scholar] [CrossRef]

- Ruzic, J.; Emura, S.; Ji, X.; Watanabe, I. Mo segregation and distribution in Ti–Mo alloy investigated using nanoindentation. Mater. Sci. Eng. A 2018, 718, 48–55. [Google Scholar] [CrossRef]

- He, Q.F.; Wang, J.G.; Chen, H.A.; Ding, Z.Y.; Zhou, Z.Q.; Xiong, L.H.; Luan, J.H.; Pelletier, J.M.; Qiao, J.C.; Wang, Q.; et al. A highly distorted ultraelastic chemically complex Elinvar alloy. Nature 2022, 602, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Hardes, J.; Streitburger, A.; Ahrens, H.; Nusselt, T.; Gebert, C.; Winkelmann, W.; Battmann, A.; Gosheger, G. The Influence of Elementary Silver Versus Titanium on Osteoblasts Behaviour In Vitro Using Human Osteosarcoma Cell Lines. Sarcoma 2007, 2007, e26539. [Google Scholar] [CrossRef]

- Zhang, B.B.; Zheng, Y.F.; Liu, Y. Effect of Ag on the corrosion behavior of Ti–Ag alloys in artificial saliva solutions. Dent. Mater. 2009, 25, 672–677. [Google Scholar] [CrossRef] [PubMed]

- Tweden, K.S.; Cameron, J.D.; Razzouk, A.J.; Holmberg, W.R.; Kelly, S.J. Biocompatibility of silver-modified polyester for antimicrobial protection of prosthetic valves. J. Heart Valve Dis. 1997, 6, 553–561. [Google Scholar] [PubMed]

| Element | Nb | Zr | Ag | Ti |

|---|---|---|---|---|

| Composition/wt% | 13.2 | 12.8 | 6.5 | Balanced |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, D.; Wang, J.; Yang, L.; Xu, X.; Zhang, E. Synergistic Effect of Phase Transformation and Stress-Induced Twinning on the Antibacterial Property and Elastic Modulus of Ti-13Nb-13Zr-7Ag. Metals 2024, 14, 901. https://doi.org/10.3390/met14080901

Cai D, Wang J, Yang L, Xu X, Zhang E. Synergistic Effect of Phase Transformation and Stress-Induced Twinning on the Antibacterial Property and Elastic Modulus of Ti-13Nb-13Zr-7Ag. Metals. 2024; 14(8):901. https://doi.org/10.3390/met14080901

Chicago/Turabian StyleCai, Diangeng, Jiayu Wang, Lei Yang, Xiaocen Xu, and Erlin Zhang. 2024. "Synergistic Effect of Phase Transformation and Stress-Induced Twinning on the Antibacterial Property and Elastic Modulus of Ti-13Nb-13Zr-7Ag" Metals 14, no. 8: 901. https://doi.org/10.3390/met14080901