Analyzing Impact of Processing Parameters and Material Properties on Symmetry of Wire-Arc Directed Energy Deposit Beads

Abstract

:1. Introduction

Contributions

- A novel technique to characterize asymmetrical bead geometries.

- To the best of our knowledge, the first comparison between bead geometry asymmetry, processing parameters, and material properties.

- A multi-material analysis of the relationship between material characteristics and the degree of substrate warping caused by wire-arc DED bead deposits.

2. Background

3. Methodology

3.1. Depositing Wire-Arc DED Beads

3.2. Calculating Asymmetry

3.3. Calculating Substrate Curvature

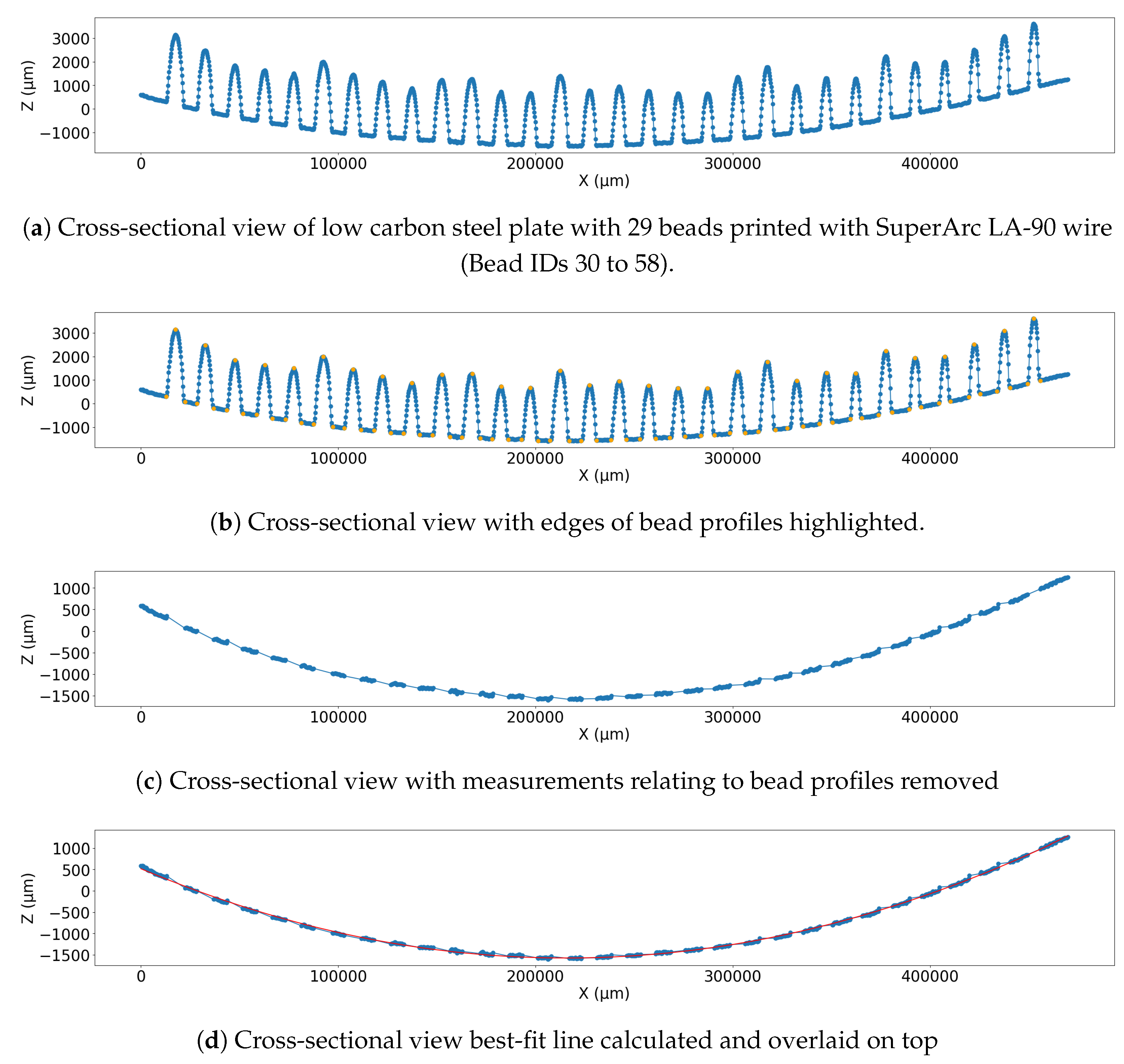

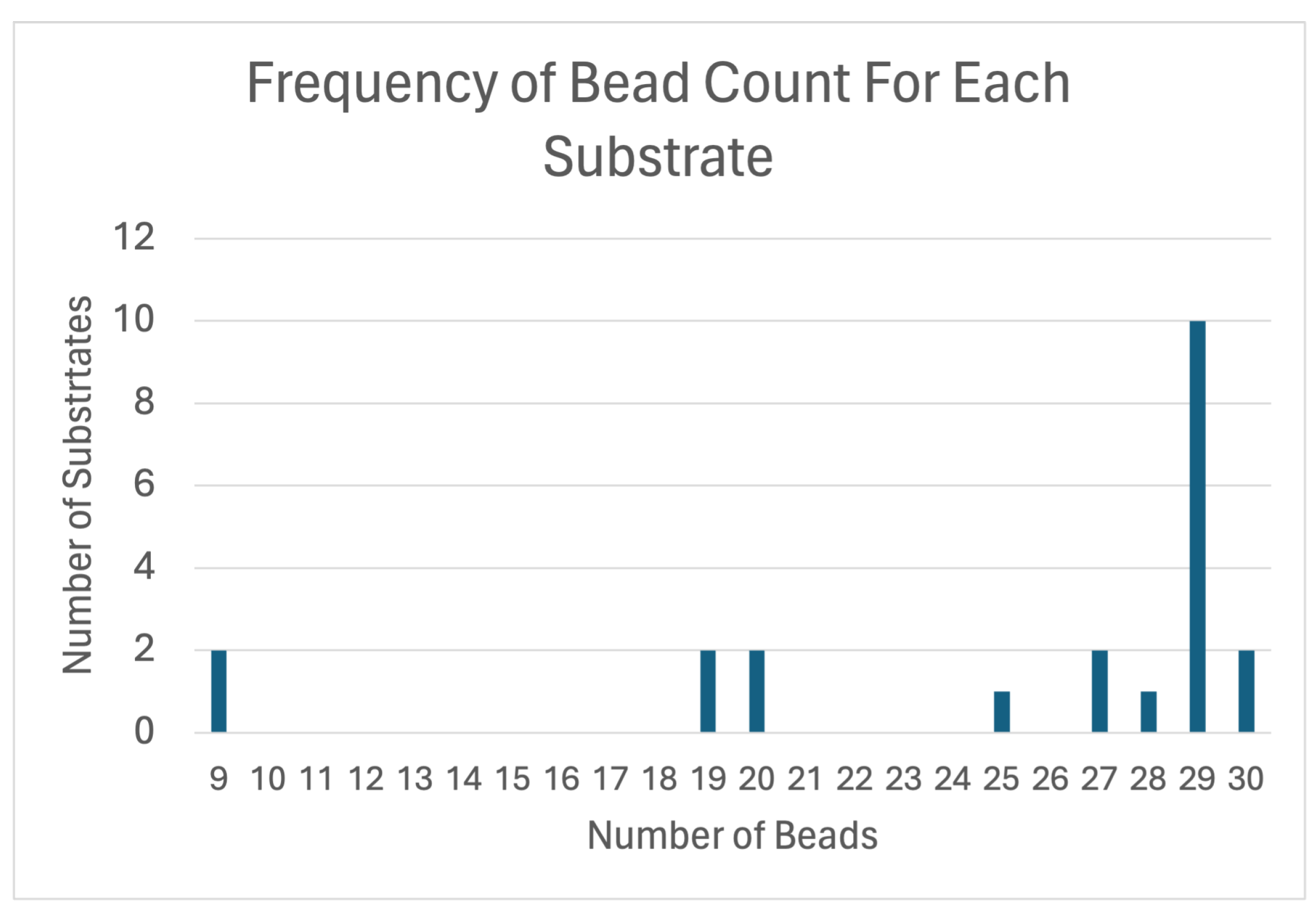

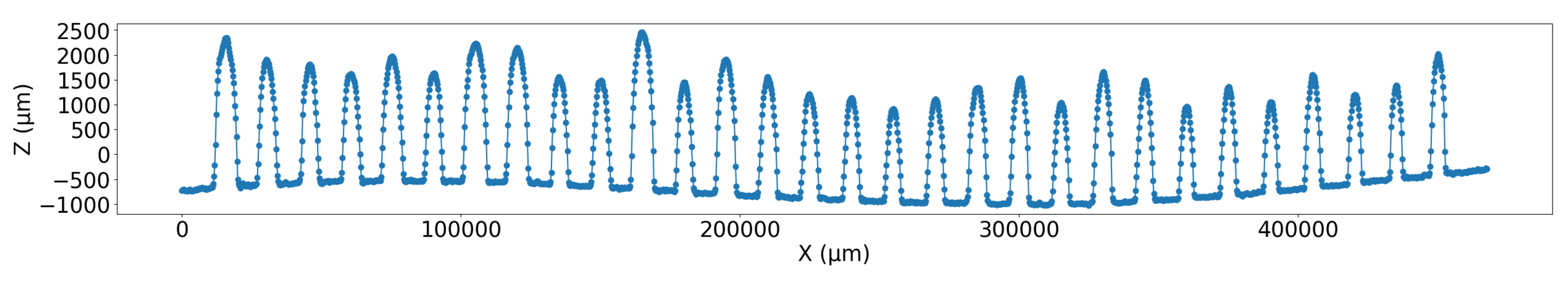

Filtering Experimental Data

3.4. Computing Thermophysical Properties

4. Results and Discussion

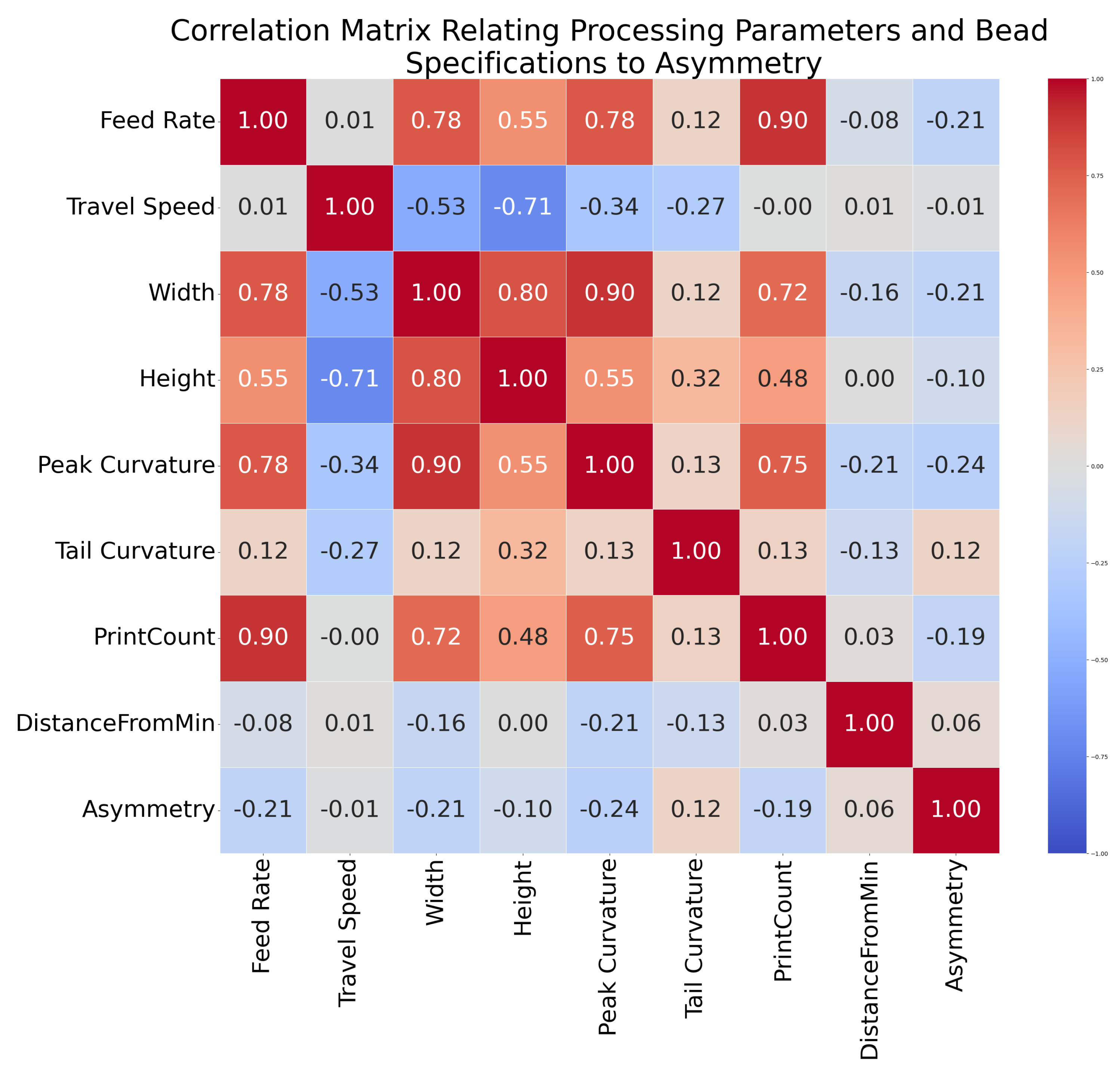

4.1. Asymmetry Measurements

4.2. Impact of Asymmetrically Deposited Beads

4.3. Substrate Warping

4.4. Impact of Substrate Warping

4.5. Utilizing Results to Improve Manufacturing

4.6. Improving Experimental Design

5. Conclusions

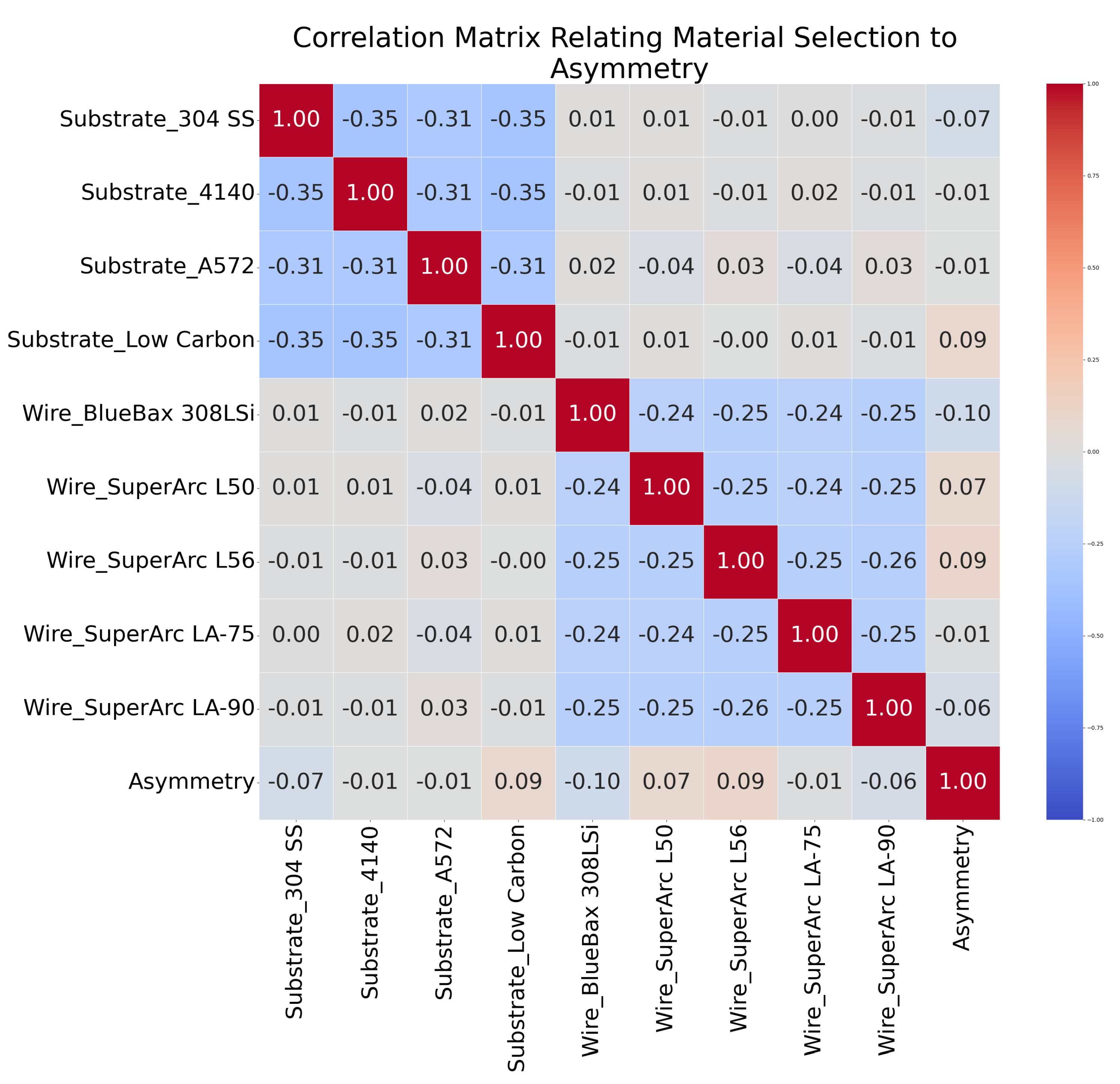

- The asymmetry of each bead was calculated using a normalized Euclidean distance equation and compared between each other using a correlation matrix, finding that none of the parameters had a particularly strong correlation with asymmetry. Peak curvature, feed rate and width had the strongest correlations with −0.24, −0.21 and −0.21, respectively.

- Correlation matrix between process parameters, physical properties and warping revealed the strongest correlation with feed rate, travel speed, substrate mean heat capacity, substrate means thermal diffusivity, wire mean heat capacity and wire means thermal diffusivity with −0.26, −0.01, 0.60, −0.67, 0.47 and −0.40, respectively.

- Heat capacity and thermal diffusivity were the most relevant features examined.

- As substrate heat capacity decreased, substrate warping increased.

- As substrate thermal conductivity increased, warping decreased.

- As substrate thermal diffusivity increased, substrate warping decreased.

- Thermal conductivity exhibits a dominating role over heat capacity to cause an increase in thermal conductivity and decrease in resultant warping.

- Increased wire feed rates caused decreased warping effects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. Addit. Manuf. Aerosp. Ind. 2019, 7–31. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S. Biomedical applications of additive manufacturing: Present and future. Curr. Opin. Biomed. Eng. 2017, 2, 105–115. [Google Scholar] [CrossRef]

- Bhatia, A.; Sehgal, A.K. Additive manufacturing materials, methods and applications: A review. Mater. Today Proc. 2023, 81, 1060–1067. [Google Scholar] [CrossRef]

- Costello, S.C.; Cunningham, C.R.; Xu, F.; Shokrani, A.; Dhokia, V.; Newman, S.T. The state-of-the-art of wire arc directed energy deposition (WA-DED) as an additive manufacturing process for large metallic component manufacture. Int. J. Comput. Integr. Manuf. 2023, 36, 469–510. [Google Scholar] [CrossRef]

- Yi, H.; Yang, L.; Jia, L.; Huang, Y.; Cao, H. Porosity in wire-arc directed energy deposition of aluminum alloys: Formation mechanisms, influencing factors and inhibition strategies. Addit. Manuf. 2024, 84, 104108. [Google Scholar] [CrossRef]

- Calignano, F.; Mercurio, V. An overview of the impact of additive manufacturing on supply chain, reshoring, and sustainability. Clean. Logist. Supply Chain. 2023, 7, 100103. [Google Scholar] [CrossRef]

- Derekar, K. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Karouanas, I.; Foteinopoulos, P.; Bikas, H.; Stavropoulos, P. A practical simulation approach for the support of wire arc DED additive manufacturing systems design. Procedia Comput. Sci. 2024, 232, 3161–3172. [Google Scholar] [CrossRef]

- Nie, Y.; Zhang, P.; Wu, X.; Li, G.; Yan, H.; Yu, Z. Rapid prototyping of 4043 Al-alloy parts by cold metal transfer. Sci. Technol. Weld. Join. 2018, 23, 527–535. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; Ramli, F.R.; Sudin, M.N.; Maidin, S. Influence of process parameters in wire and arc additive manufacturing (WAAM) process. J. Mech. Eng. (JMechE) 2021, 17, 69–78. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S.; Nath, T. A review on wire arc additive manufacturing: Processing parameters, defects, quality improvement and recent advances. Mater. Today Commun. 2022, 31, 103739. [Google Scholar] [CrossRef]

- Nagesh, D.; Datta, G. Genetic algorithm for optimization of welding variables for height to width ratio and application of ANN for prediction of bead geometry for TIG welding process. Appl. Soft Comput. 2010, 10, 897–907. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Karmuhilan, M. Intelligent process model for bead geometry prediction in WAAM. Mater. Today Proc. 2018, 5, 24005–24013. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ríos, S.; Williams, S.W.; Ramos-Grez, J.A. Comparative Evaluation of Machine Learning Regressors for the Layer Geometry Prediction in Wire Arc Additive Manufacturing. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; pp. 186–190. [Google Scholar]

- Price, S.; Judd, K.; Gleason, M.; Tsaknopoulos, K.; Cote, D.L.; Neamtu, R. Advancing Wire Arc Directed Energy Deposition: Analyzing Impact of Materials and Parameters on Bead Shape. Metals 2024, 14, 282. [Google Scholar] [CrossRef]

- Manokruang, S. Phenomenological Model of Thermal Effects on Weld Beads Geometry Produced by Wire and Arc Additive Manufacturing (WAAM). Ph.D. Thesis, Université Grenoble Alpes, Saint-Martin-d’Hères, France, 2022. [Google Scholar]

- Ali, M.H.; Han, Y.S. Effect of phase transformations on scanning strategy in WAAM fabrication. Materials 2021, 14, 7871. [Google Scholar] [CrossRef]

- Song, G.H.; Lee, C.M.; Kim, D.H. Investigation of path planning to reduce height errors of intersection parts in wire-Arc Additive manufacturing. Materials 2021, 14, 6477. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Numerical simulation of welding distortion in large structures. Comput. Methods Appl. Mech. Eng. 2007, 196, 4613–4627. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Prediction of welding distortion and residual stress in a thin plate butt-welded joint. Comput. Mater. Sci. 2008, 43, 353–365. [Google Scholar] [CrossRef]

- Fahlström, K.; Andersson, O.; Todal, U.; Melander, A. Minimization of distortions during laser welding of ultra high strength steel. J. Laser Appl. 2015, 27, S29011. [Google Scholar] [CrossRef]

- Tsai, C.L.; Park, S.C.; Cheng, W.T. Welding distortion of a thin-plate panel structure. Weld. J. N. Y. 1999, 78, 156-s. [Google Scholar]

- Ojalvo, M. Discussion of “Warping and Distortion at I-Section Joints”. J. Struct. Div. 1975, 101, 343–345. [Google Scholar] [CrossRef]

- Radaj, D. Heat Effects of Welding: Temperature Field, Residual Stress, Distortion; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Dogan, E.; Ay, M.; Kurtulmus, M.; Yukler, A.I.; Etyemez, A. Effects of welding parameters on the angular distortion of welded steel plates. Open Chem. 2022, 20, 417–423. [Google Scholar] [CrossRef]

- Lincoln, J.F. The Procedure Handbook of Arc Welding; The Lincoln Electric Company: Cleveland, OH, USA, 2000; Volume 10. [Google Scholar]

- Tseng, K.H.; Hsu, C.Y. Performance of activated TIG process in austenitic stainless steel welds. J. Mater. Process. Technol. 2011, 211, 503–512. [Google Scholar] [CrossRef]

- Murugan, N.; Gunaraj, V. Prediction and control of weld bead geometry and shape relationships in submerged arc welding of pipes. J. Mater. Process. Technol. 2005, 168, 478–487. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K. Selection of process parameters for near-net shape deposition in wire arc additive manufacturing by genetic algorithm. J. Mater. Eng. Perform. 2020, 29, 3334–3352. [Google Scholar] [CrossRef]

- Sedgwick, P. Pearson’s correlation coefficient. Bmj 2012, 345, e4483. [Google Scholar] [CrossRef]

- Little, G.; Kamtekar, A. The effect of thermal properties and weld efficiency on transient temperatures during welding. Comput. Struct. 1998, 68, 157–165. [Google Scholar] [CrossRef]

- Armentani, E.; Esposito, R.; Sepe, R. The effect of thermal properties and weld efficiency on residual stresses in welding. J. Achiev. Mater. Manuf. Eng. 2007, 20, 319–322. [Google Scholar]

- Colegrove, P.; Ganguly, S. Residual stress characterization and control in the additive manufacture of large scale metal structures. Residual Stress. 2017, 2016, 455. [Google Scholar]

| Parameter | Correlation |

|---|---|

| Feed rate | −0.26 |

| Travel speed | −0.01 |

| Substrate mean heat capacity | 0.60 |

| Substrate mean thermal diffusivity | −0.67 |

| Wire mean heat capacity | 0.47 |

| Wire mean thermal diffusivity | −0.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Price, S.; Judd, K.; Gleason, M.; Tsaknopoulos, K.; Cote, D.L.; Neamtu, R. Analyzing Impact of Processing Parameters and Material Properties on Symmetry of Wire-Arc Directed Energy Deposit Beads. Metals 2024, 14, 905. https://doi.org/10.3390/met14080905

Price S, Judd K, Gleason M, Tsaknopoulos K, Cote DL, Neamtu R. Analyzing Impact of Processing Parameters and Material Properties on Symmetry of Wire-Arc Directed Energy Deposit Beads. Metals. 2024; 14(8):905. https://doi.org/10.3390/met14080905

Chicago/Turabian StylePrice, Stephen, Kiran Judd, Matthew Gleason, Kyle Tsaknopoulos, Danielle L. Cote, and Rodica Neamtu. 2024. "Analyzing Impact of Processing Parameters and Material Properties on Symmetry of Wire-Arc Directed Energy Deposit Beads" Metals 14, no. 8: 905. https://doi.org/10.3390/met14080905