Detrimental Effects of βo-Phase on Practical Properties of TiAl Alloys

Abstract

:1. Introduction

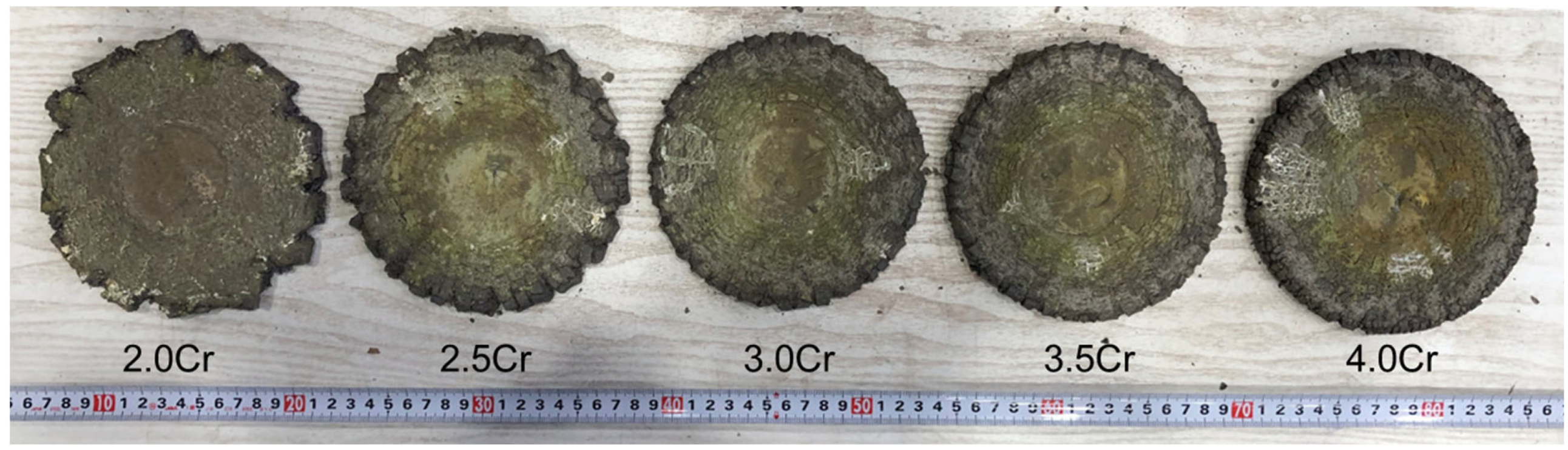

2. Materials and Methods

2.1. Materials

2.2. Methods for Evaluating Various Properties

2.2.1. Impact Resistance

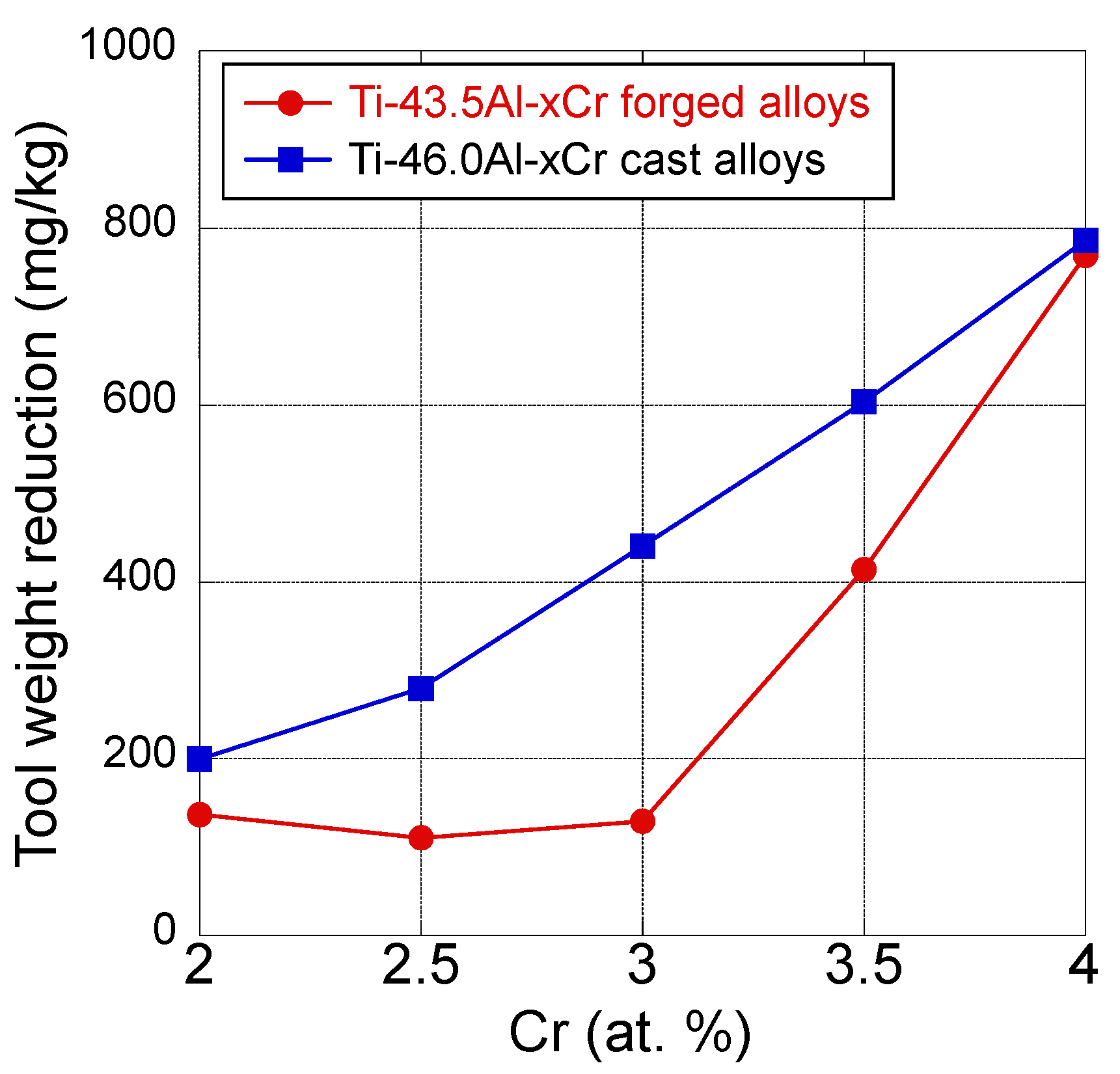

2.2.2. Machinability

2.2.3. Other Properties

3. Results

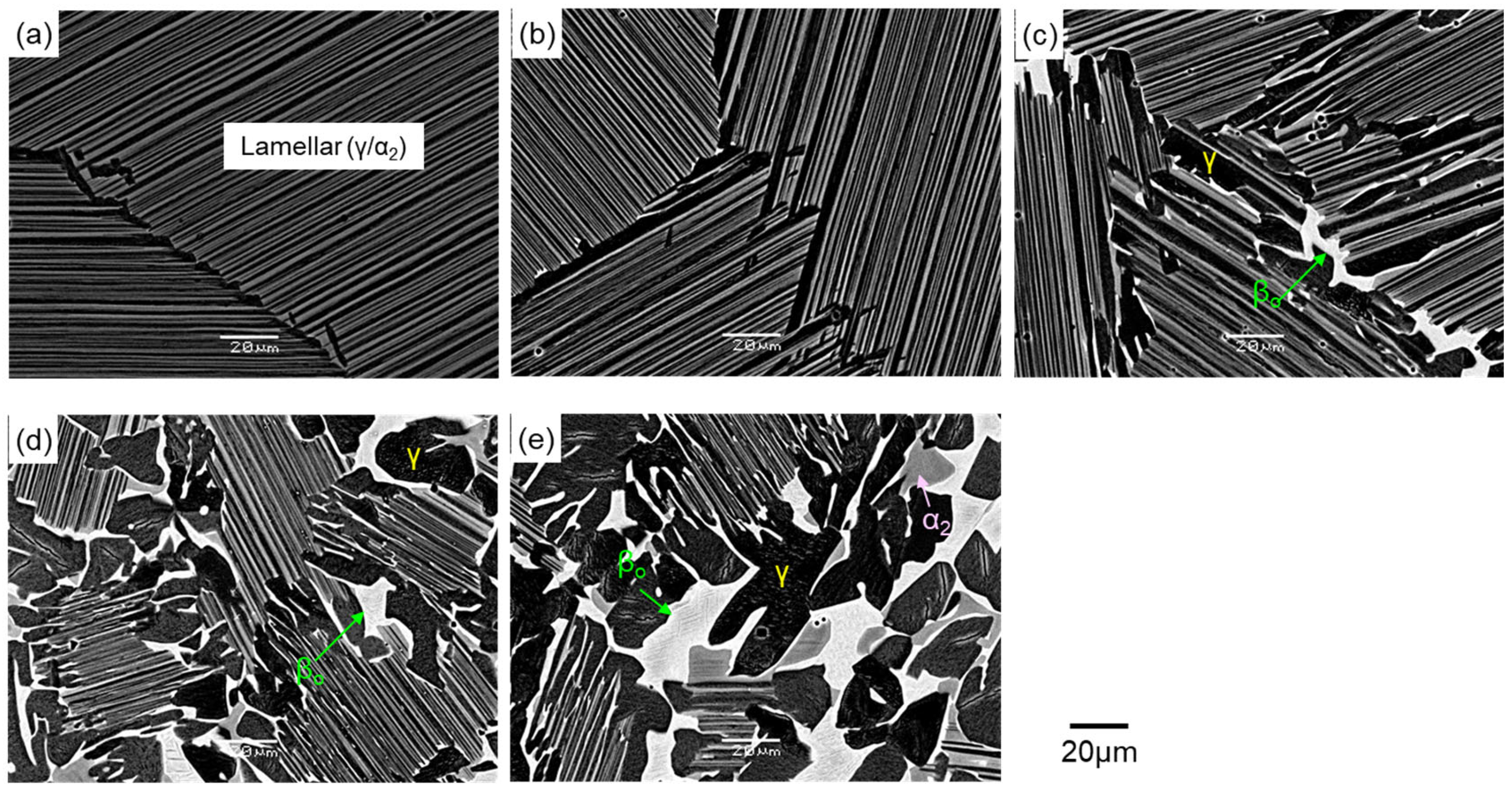

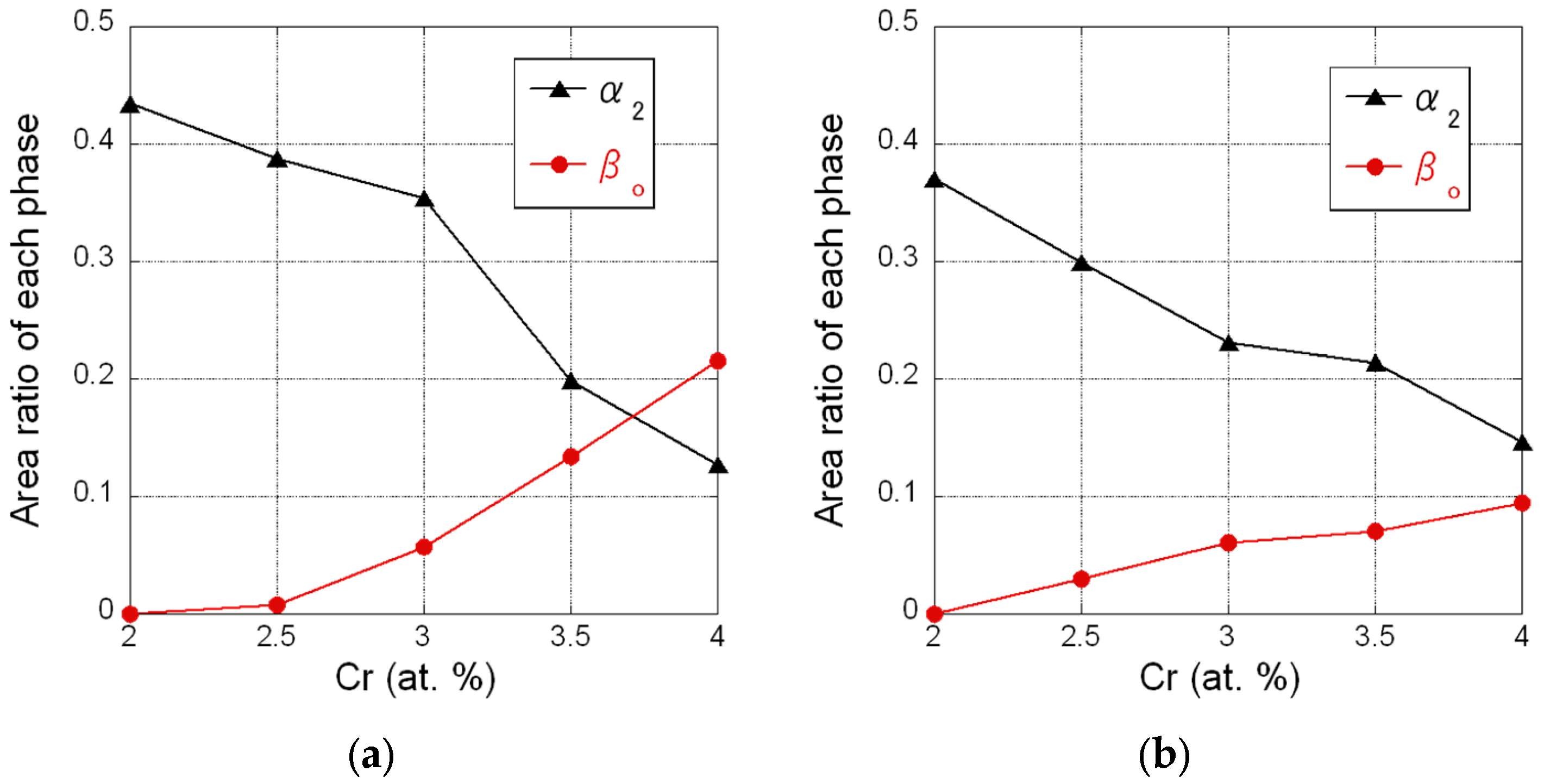

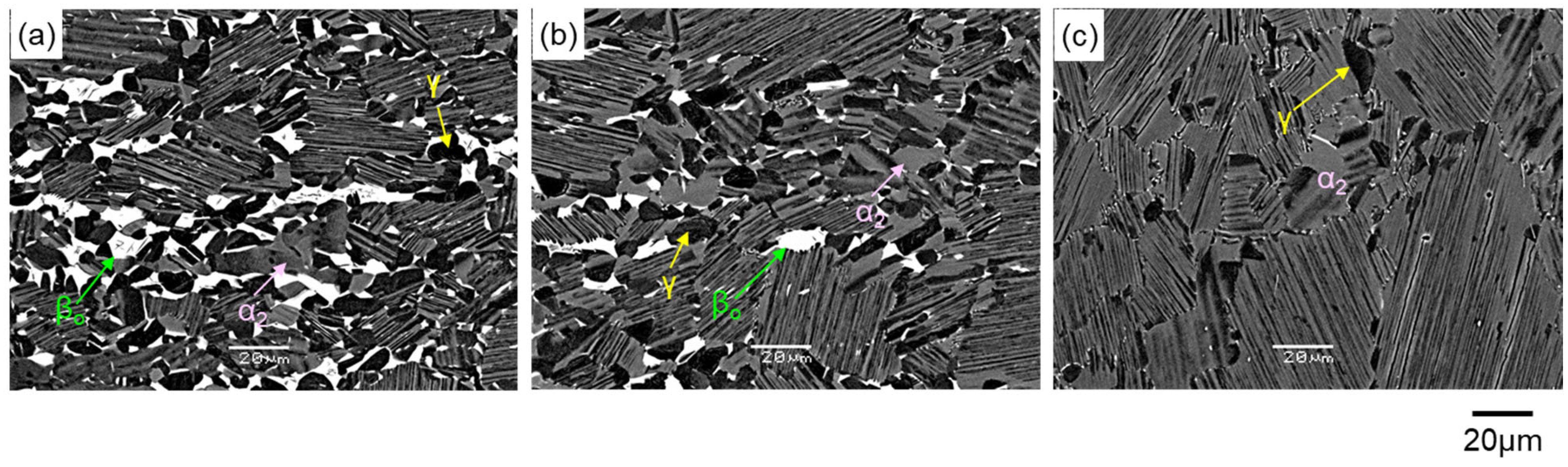

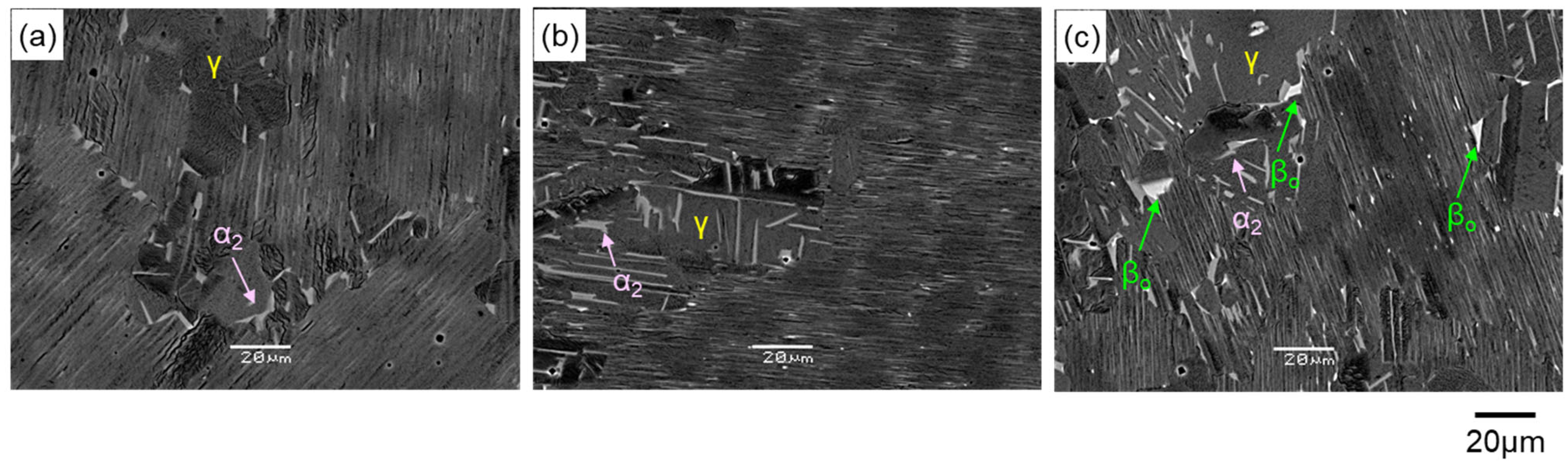

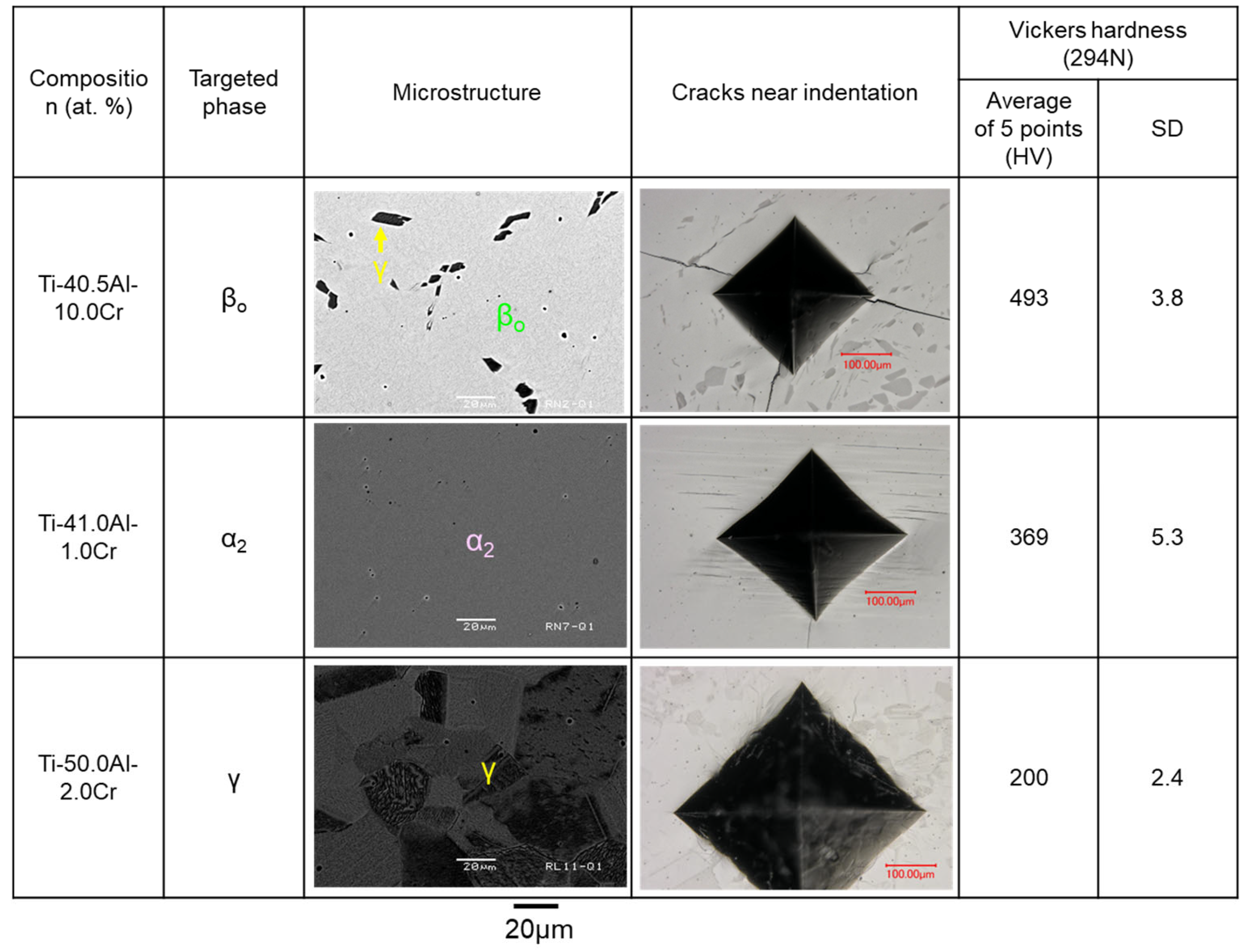

3.1. Ti–Al–xCr Ternary Forged and Cast Alloys

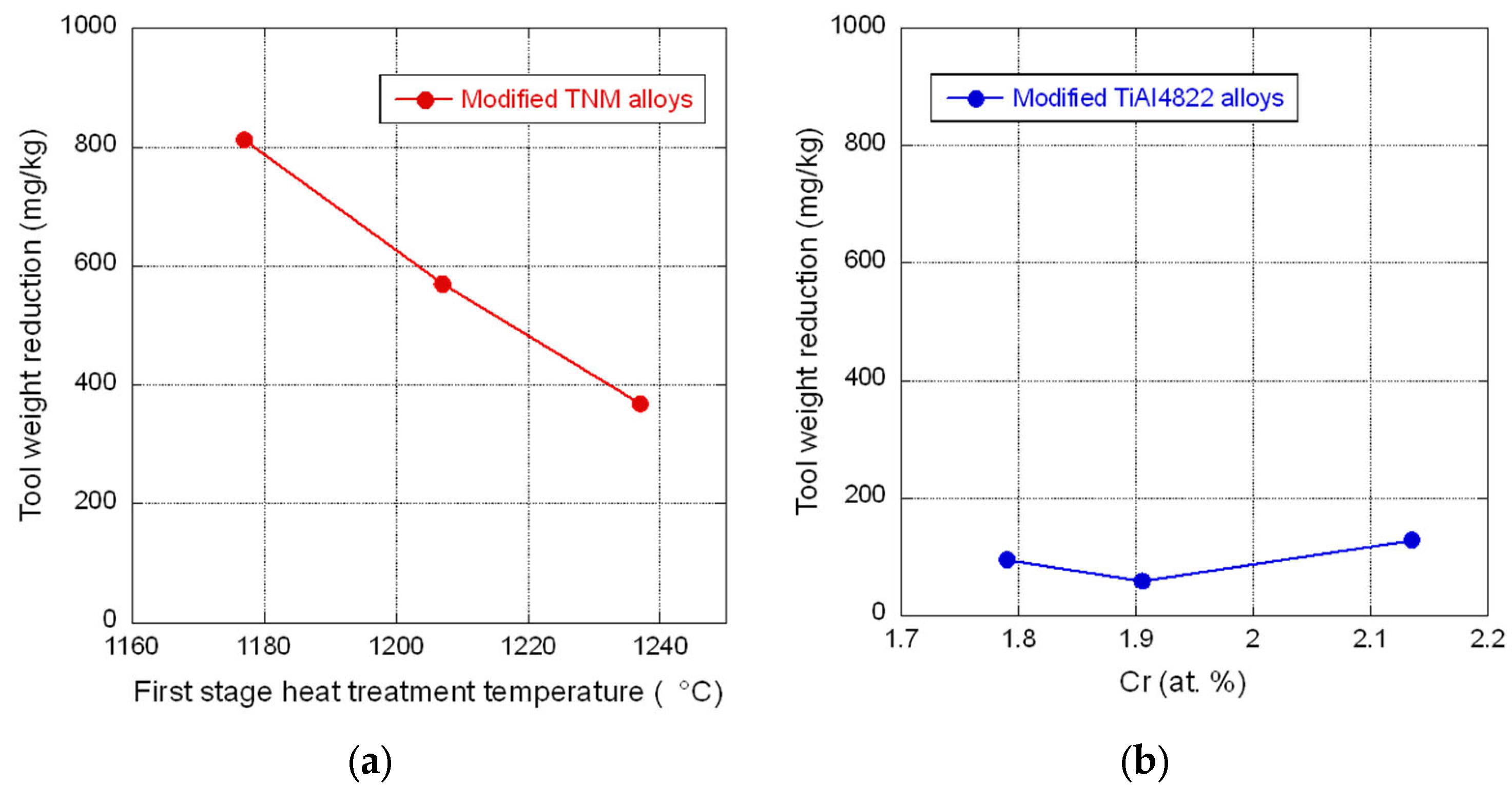

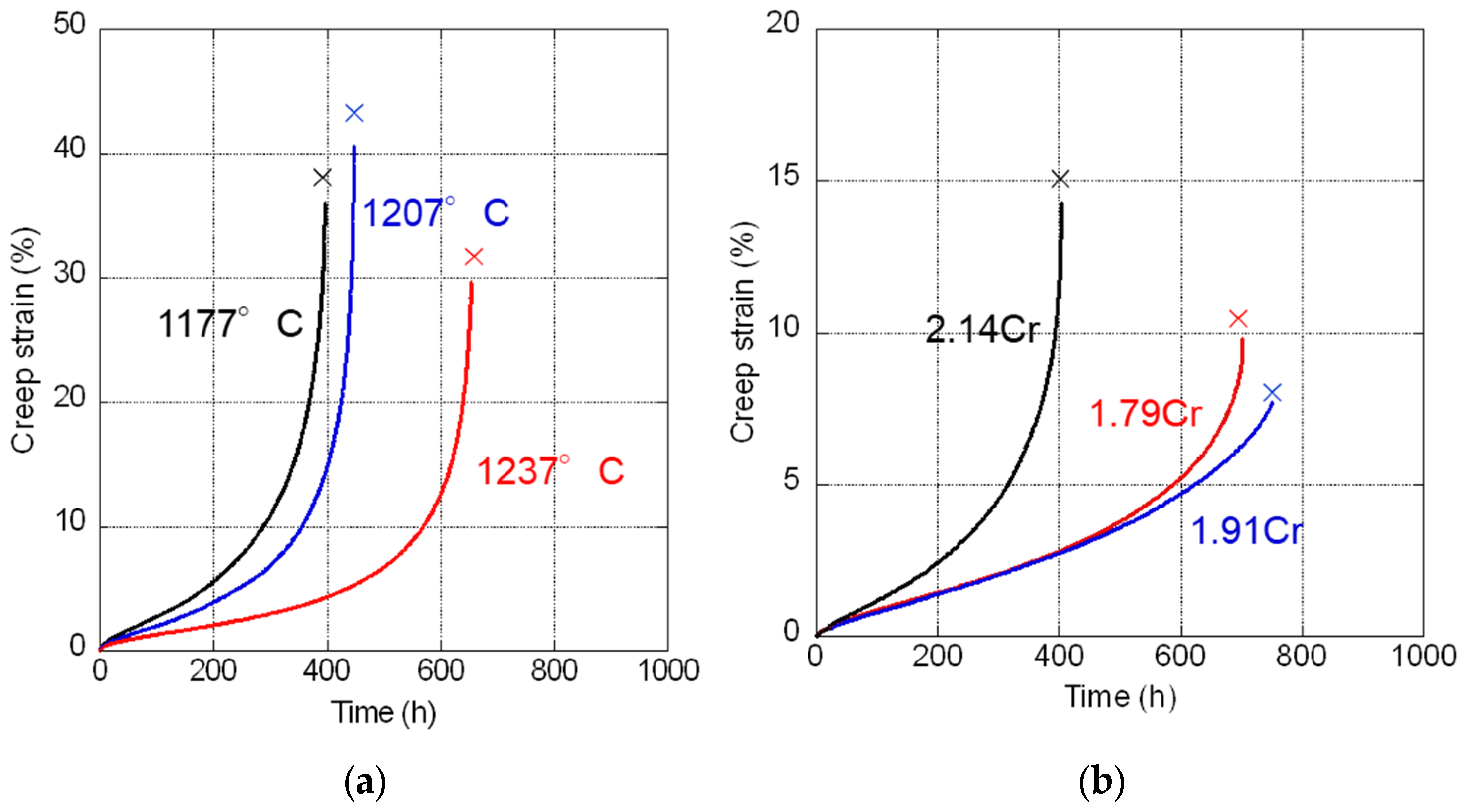

3.2. Modified TNM and TiAl4822 Alloys

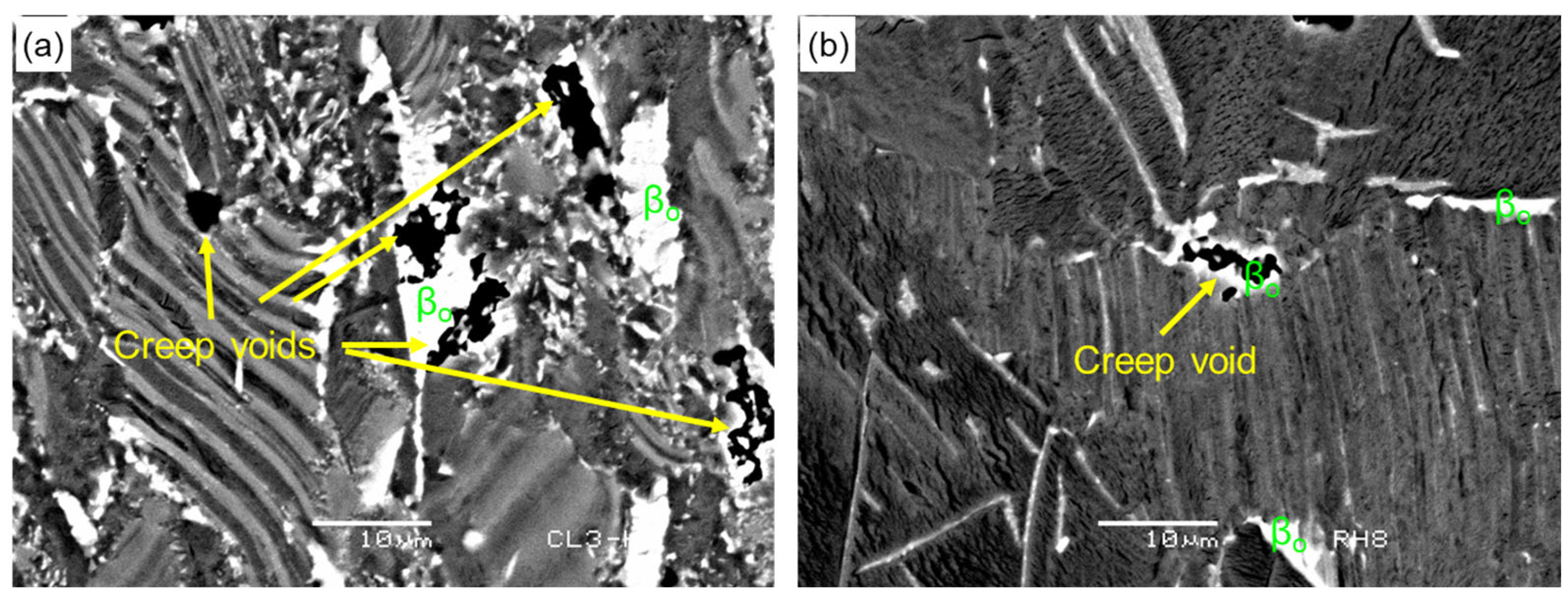

4. Discussion

4.1. Summary of the Influence of Each Phase on the Practical Properties of TiAl Alloys

4.2. Causes of Negative Effects of βo-Phase on Impact Resistance and Machinability

4.3. Assessment of Various Existing TiAl Alloys Assuming the Harmfulness of βo-Phase

4.3.1. Cast TiAl Alloys

4.3.2. Forged TiAl Alloys

5. Conclusions

- For the forged and cast Ti–Al–xCr ternary alloys, the impact resistance at RT and 700 °C, as well as the machinability, decreased significantly as the βo-phase content increased.

- The results of modified TNM and TiAl4822 alloys show that the βo-phase, present within the material, reduced the creep strength, impact resistance, and machinability.

- Although the disordered β-phase is soft at high temperatures (forging temperature), it changes to the ordered βo-phase, which is significantly more brittle and harder after cooling. Thus, the detrimental effect of the βo-phase on the impact resistance and machinability can be attributed to this change.

- An evaluation of various existing TiAl alloys developed to date with respect to the presence or absence of the βo-phase suggests that the practical properties of βo-phase-free TiAl alloys (that were developed in the distant past) are superior to those of more recent TiAl alloys that contain the βo-phase.

- Finally, it can be concluded that the βo-phase should not be included in practical TiAl alloys, especially those used for jet engine blades.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bartolotta, P.; Barrett, J.; Kelly, T.; Smashey, R. The use of cast Ti-48Al-2Cr-2Nb in jet engines. JOM 1997, 49, 48–50. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A review of microstructure control and mechanical performance optimization of γ-TiAl alloys. J. Alloys Compd. 2023, 932, 167611. [Google Scholar] [CrossRef]

- Feng, J.; Gui, W.; Liu, Q.; Bi, W.; Ren, X.; Liang, Y.; Lin, J.; Luan, B. Ti-48Al-2Cr-2Nb alloys prepared by electron beam selective melting additive manufacturing: Microstructural and tensile properties. J. Mat. Res. Technol. 2023, 26, 9357–9369. [Google Scholar] [CrossRef]

- Larsen, D.E.; Christodoulou, L.; Kampe, S.L.; Sadler, R. Investment-cast processing of XD™ near-γ titanium aluminides. Mater. Sci. Eng. A 1991, 144, 45–49. [Google Scholar] [CrossRef]

- McQuay, P.A.; Simpkins, R.; Seo, D.Y.; Bieler, T.R. Alloy and process improvements for cast gamma TiAl alloy applications. In Gamma Titanium Aluminides; Kim, Y.W., Dimiduk, D.M., Loretto, M.H., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1999; pp. 197–207. [Google Scholar]

- Shagñay, S.; Cornide, J.; Ruiz-Navas, E.M. Sliding wear behavior of intermetallic Ti-45Al-2Nb-2Mn-(at. %)-0.8vol%TiB2 processed by centrifugal casting and hot isostatic pressure: Influence of microstructure. Materials 2022, 15, 8052. [Google Scholar] [CrossRef] [PubMed]

- Koyanagi, Y.; Sumi, Y.; Takabayashi, H. Development of titanium aluminide alloy with good high temperature properties for turbine wheel. Denki Seiko 2014, 15, 121–125. (In Japanese) [Google Scholar]

- Xu, H.; Li, X.; Xing, W.; Shu, L.; Ma, Y.; Liu, K. Processing map and hot working mechanism of as-cast Ti-42Al-5Mn alloy. Adv. Eng. Mater. 2018, 20, 1701059. [Google Scholar] [CrossRef]

- Li, X.; Tang, H.; Xing, W.; Zhao, P.; Chen, B.; Ma, Y.; Liu, K. Microstructural stability, phase evolution and mechanical properties of a forged W-modified high-Mn β-γ-TiAl alloy. Intermetallics 2021, 136, 107230. [Google Scholar] [CrossRef]

- Graf, G.; Seyffertitz, M.; Spoerk-Erdely, P.; Clemens, H.; Stark, A.; Hatzenbichler, L.; Holec, D.; Burtscher, M.; Kiener, L.; Li, X.; et al. On the stability of Ti(Mn, Al)2 C14 Laves phase in an intermetallic Ti-42Al-5Mn alloy. Intermetallics 2023, 161, 107962. [Google Scholar] [CrossRef]

- Tetsui, T. Practical use of hot-forged-type Ti-42Al-5Mn and various recent improvements. Metals 2021, 11, 1361. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Klein, T.; Clemens, H.; Mayer, S. Tailoring microstructure and chemical composition of advanced γ-TiAl based alloys for improved creep resistance. Intermetallics 2018, 97, 27–33. [Google Scholar] [CrossRef]

- Yang, G.; Xu, X.; Hao, G.; Zhai, Y.; Wang, H.; Liang, Y.; Lin, J. Microstructure evolution, deformation behavior and processing performance of TNM TiAl alloy. J. Mater. Sci. 2023, 58, 5530–5551. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Hemmerdinger, J. FlightGlobal.com, FAA Orders PW1100G Low-Pressure Turbine Blade Replacement. 2019. Available online: https://www.flightglobal.com/engines/faa-orders-pw1100g-low-pressure-turbine-bladereplacement/135575.article (accessed on 24 May 2024).

- Perrut, M.; Caron, P.; Thomas, M.; Couret, A. High temperature materials for aerospace applications: Ni-based superalloys and γ-TiAl alloys. C.R. Phys. 2018, 19, 657–671. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Sallot, P.; Monchoux, J.P.; Joulie, S.; Couret, A.; Thomas, M. Impact of β-phase in TiAl alloys on mechanical properties after high temperature air exposure. Intermetallics 2020, 119, 106729. [Google Scholar] [CrossRef]

- Nakatani, M.; Shimono, A.; Yamamoto, T.; Hiyoshi, N.; Itoh, T. Low cycle fatigue properties in forged TiAl alloy Ti-43Al-5V-4Nb with triplex microstructure. J. Soc. Mat. Sci. Jpn. 2021, 70, 111–117. (In Japanese) [Google Scholar] [CrossRef]

- Tetsui, T. Identifying low-cost, machinable, impact-resistant TiAl alloys suitable for last-stage turbine blades of jet engines. Intermetallics 2024, 168, 108263. [Google Scholar] [CrossRef]

- Güther, V.; Allen, M.; Klose, J.; Clemens, H. Metallurgical processing of titanium aluminides on industrial scale. Intermetallics 2018, 103, 12–22. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Mondal, A.; Pilone, D. Production issues in the manufacturing of TiAl turbine blades by investment casting. Procedia Struct. Integr. 2020, 25, 79–87. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl blades. Mater. Today Proc. 2015, 2, S92–S97. [Google Scholar] [CrossRef]

- Gomes, F.; Barbosa, J.; Silva Ribeiro, C. Induction melting of γ-TiAl in CaO crucibles. Intermetallics 2008, 16, 1292–1297. [Google Scholar] [CrossRef]

- ATP® 610, Advanced Technical Products Supply Co., Inc. Available online: https://www.knowde.com/stores/advanced-technical-products-supply/products/atp-610 (accessed on 13 May 2024).

- Mizuta, K.; Hijikata, Y.; Fujii, T.; Gokan, K.; Kakehi, K. Characterization of Ti-48Al-2Cr-2Nb built by selective laser melting. Scr. Mater. 2021, 203, 114107. [Google Scholar] [CrossRef]

- Tetsui, T. Effect of microstructure on impact resistance and machinability of TiAl alloys for jet engine turbine blade applications. Metals 2023, 13, 1235. [Google Scholar] [CrossRef]

- Morris, M.A.; Lipe, T. ⅠCreep deformation of duplex and lamellar TiAl alloys. Intermetallics 1997, 5, 329–337. [Google Scholar] [CrossRef]

- Kumpfert, J.; Kim, Y.W.; Dimiduk, D.M. Effect of microstructure on fatigue and tensile properties of the gamma TiAl alloy Ti-46.5Al-3.0Nb-2.1Cr-0.2W. Mater. Sci. Eng. 1995, A192/193, 465–473. [Google Scholar] [CrossRef]

- Kriegel, M.J.; Pavlyuchkov, D.; Cupid, D.M.; Fabrichnaya, O.; Heger, D.; Rafaja, D.; Seifert, H.J. Phase equilibria at 1473 K in the ternary Al–Cr–Ti system. J. Alloys Compd. 2013, 550, 519–525. [Google Scholar] [CrossRef]

- Shaaban, A.; Wakabayashi, H.; Nakashima, H.; Takeyama, M. Phase equilibria among β/α/α2/γ phases and phase transformations in Ti-Al-Cr system at elevated temperatures. MRS Adv. 2019, 4, 1471–1476. [Google Scholar] [CrossRef]

- Voice, W. The future use of gamma titanium aluminides by Rolls-Royce. Aircr. Eng. Aerosp. Technol. 1999, 71, 337–340. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M.; Buque, C.; Klinkenberg, C.; Cameiro, T. Recent developments of TiAl alloys towards improved high-temperature capability. In Niobium for High-Temperature Applications; Kim, Y.W., Carneiro, T., Eds.; TMS: Pittsburgh, PA, USA, 2004; pp. 139–152. [Google Scholar]

- Couret, A.; Reyes, D.; Thomas, M.; Ratel-Ramond, N.; Deshayes, C.; Monchoux, J.-P. Effect of ageing on the properties of the W-containing IRIS-TiAl alloy. Acta Mater. 2020, 199, 169–180. [Google Scholar] [CrossRef]

- Yoshihara, M.; Miura, K. Effects of Nb addition on oxidation behavior of TiAl. Intermetallics 1995, 3, 357–363. [Google Scholar] [CrossRef]

- Donchev, A.; Mengis, L.; Couret, A.; Mayer, S.; Clemens, H.; Galetz, M. Effects of tungsten alloying and fluorination on the oxidation behavior of intermetallic titanium aluminides for aerospace applications. Intermetallics 2021, 139, 107270. [Google Scholar] [CrossRef]

- Zhao, P.; Li, X.; Tang, H.; Ma, Y.; Chen, B.; Xing, W.; Liu, K.; Yu, J. Improved high temperature oxidation properties for Mn-containing beta-gamma TiAl with W addition. Oxid. Met. 2020, 93, 433–448. [Google Scholar] [CrossRef]

- Tetsui, T. Selection of additive elements focusing on impact resistance in practical TiAl cast alloy. Metals 2022, 12, 544. [Google Scholar] [CrossRef]

- Hilleringmann, M.; Schievenbusch, J.; Zapala, P.; Bünck, M. Microstructure and mechanical properties of TNM titanium aluminide alloy after heat treatment and different cooling conditions. In Intermetallics 2021: Programme and Abstracts; Educational Center: Kloster Banz, Germany, 2021; O-TA-14; pp. 86–87. [Google Scholar]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase g-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Rittinghaus, S.-K.; Hecht, U.; Werner, V.; Weisheit, A. Heat treatment of laser metal deposited TiAl TNM alloy. Intermetallics 2018, 95, 94–101. [Google Scholar] [CrossRef]

| Composition (Mass%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Al | Nb | Cr | Cu | Fe | Ni | Si | C | O | N | H | Ca |

| Bal. | 32.6 | 4.62 | 2.64 | <0.005 | 0.023 | 0.008 | 0.014 | <0.005 | 0.07 | <0.002 | <0.002 | 0.044 |

| Composition (at. %) | Production Method | Heat Treatment Protocol | Hot Isostatic Pressing (HIP) Conditions | Charpy Impact Test Results at RT | Charpy Impact Test Results at 700 °C | |||

|---|---|---|---|---|---|---|---|---|

| Al | Cr | Mean Absorbed Energy (J/cm2) | Standard Deviation (SD) | Mean Absorbed Energy (J/cm2) | SD | |||

| 43.5 | 2.0 | Cast → hot- forging at 1330 °C | 1280 °C/ 5 h/furnace cooling (FC) | - | 5.85 | 0.57 | 10.16 | 2.22 |

| 2.5 | 5.58 | 0.57 | 11.15 | 2.60 | ||||

| 3.0 | 5.04 | 0.56 | 11.13 | 1.88 | ||||

| 3.5 | 3.70 | 0.68 | 10.35 | 1.27 | ||||

| 4.0 | 3.47 | 0.29 | 7.71 | 1.06 | ||||

| 46.0 | 2.0 | Cast | - | 1200 °C/ 4 h/ 186 MPa | 5.22 | 0.61 | 11.37 | 1.57 |

| 2.5 | 4.73 | 0.61 | 11.60 | 1.78 | ||||

| 3.0 | 4.57 | 0.75 | 11.46 | 2.24 | ||||

| 3.5 | 3.48 | 0.69 | 10.77 | 1.35 | ||||

| 4.0 | 3.25 | 0.48 | 9.22 | 1.38 | ||||

| Alloys | Composition (at. %) | Production Method | Heat Treatment Protocol | HIP Conditions | Charpy Impact Test Results at RT | Charpy Impact Test Results at 700 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Nb | Cr | Mo | B | Mean Absorbed Energy (J/cm2) | SD | Mean Absorbed Energy (J/cm2) | SD | ||||

| TNM alloy | 43.5 | 4.0 | - | 1.0 | 0.1 | Cast → hot- forging at 1330 °C | 1177 °C/3 h AC → 850 °C/6 h FC | 5.86 | 1.41 | 6.07 | 0.91 | |

| 1207 °C/3 h AC → 850 °C/6 h FC | - | 6.66 | 1.93 | 7.77 | 0.78 | |||||||

| 1237 °C/3 h AC → 850 °C/6 h FC | 8.43 | 2.21 | 8.50 | 1.30 | ||||||||

| TiAl 4822 | 47.0 | 2.0 | 1.79 | - | - | Casting | - | 1200 °C/ 4 h/186 MPa | 6.08 | 1.08 | 15.54 | 3.12 |

| 1.91 | 6.06 | 1.32 | 15.30 | 3.32 | ||||||||

| 2.14 | 4.59 | 0.98 | 12.34 | 2.05 | ||||||||

| Change in Phase Ratio | Impact Resistance | Machinability | Creep Strength | High-Temperature Fatigue Strength | |

|---|---|---|---|---|---|

| RT | 700 °C | ||||

| Increase in α2-phase (increase in lamellar structure) | Improved | Improved | Small effect | Improved [29] | Varies depending on conditions [30] |

| Increase in βo-phase | Reduced | Reduced | Reduced | Reduced | Reduced [19,20] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetsui, T.; Mizuta, K. Detrimental Effects of βo-Phase on Practical Properties of TiAl Alloys. Metals 2024, 14, 908. https://doi.org/10.3390/met14080908

Tetsui T, Mizuta K. Detrimental Effects of βo-Phase on Practical Properties of TiAl Alloys. Metals. 2024; 14(8):908. https://doi.org/10.3390/met14080908

Chicago/Turabian StyleTetsui, Toshimitsu, and Kazuhiro Mizuta. 2024. "Detrimental Effects of βo-Phase on Practical Properties of TiAl Alloys" Metals 14, no. 8: 908. https://doi.org/10.3390/met14080908

APA StyleTetsui, T., & Mizuta, K. (2024). Detrimental Effects of βo-Phase on Practical Properties of TiAl Alloys. Metals, 14(8), 908. https://doi.org/10.3390/met14080908