Influence of Ceramic Size and Morphology on Interface Bonding Properties of TWIP Steel Matrix Composites Produced by Lost-Foam Casting

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Preparation of Experimental Materials

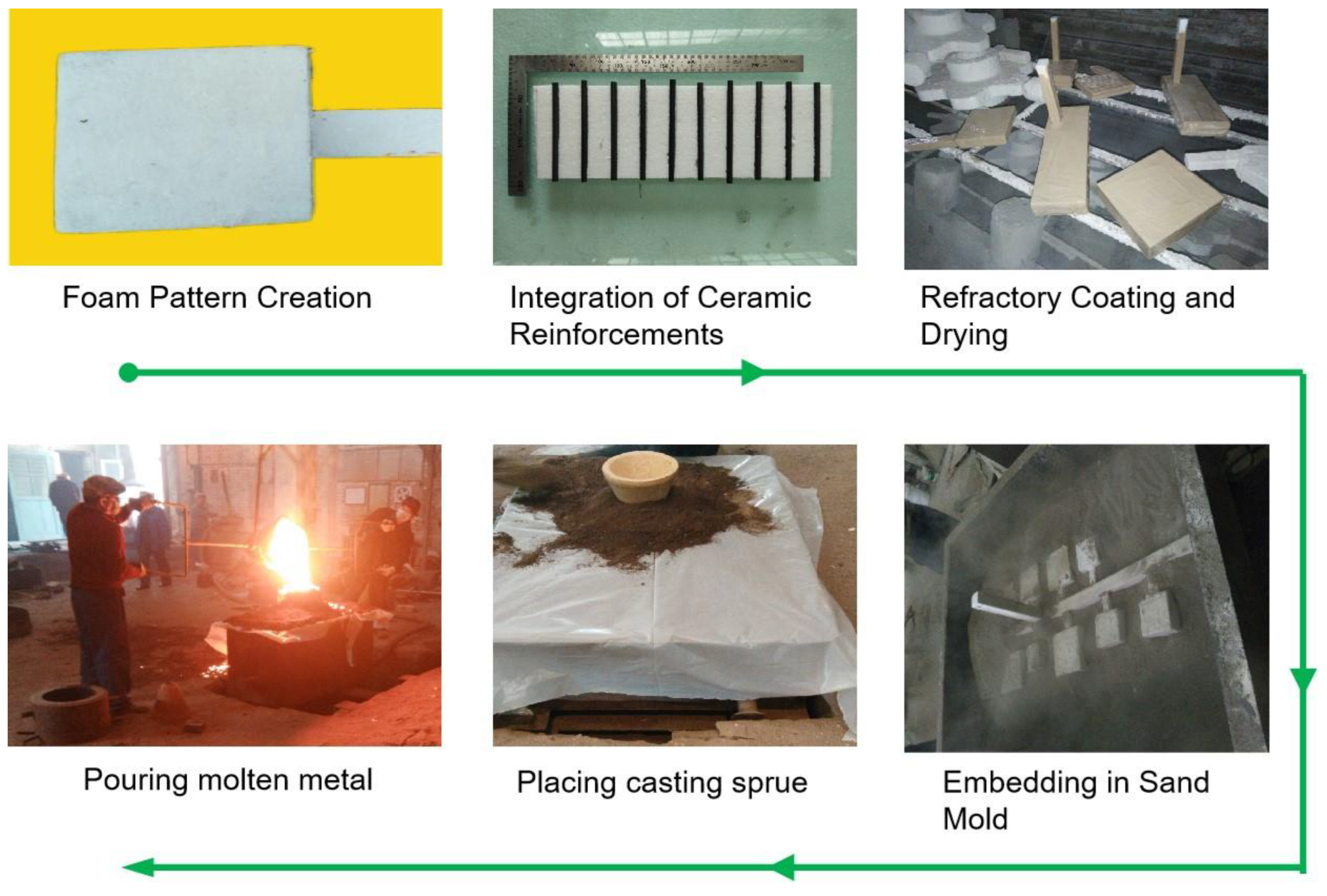

2.2. Preparation of Lost-Foam Casting Molds

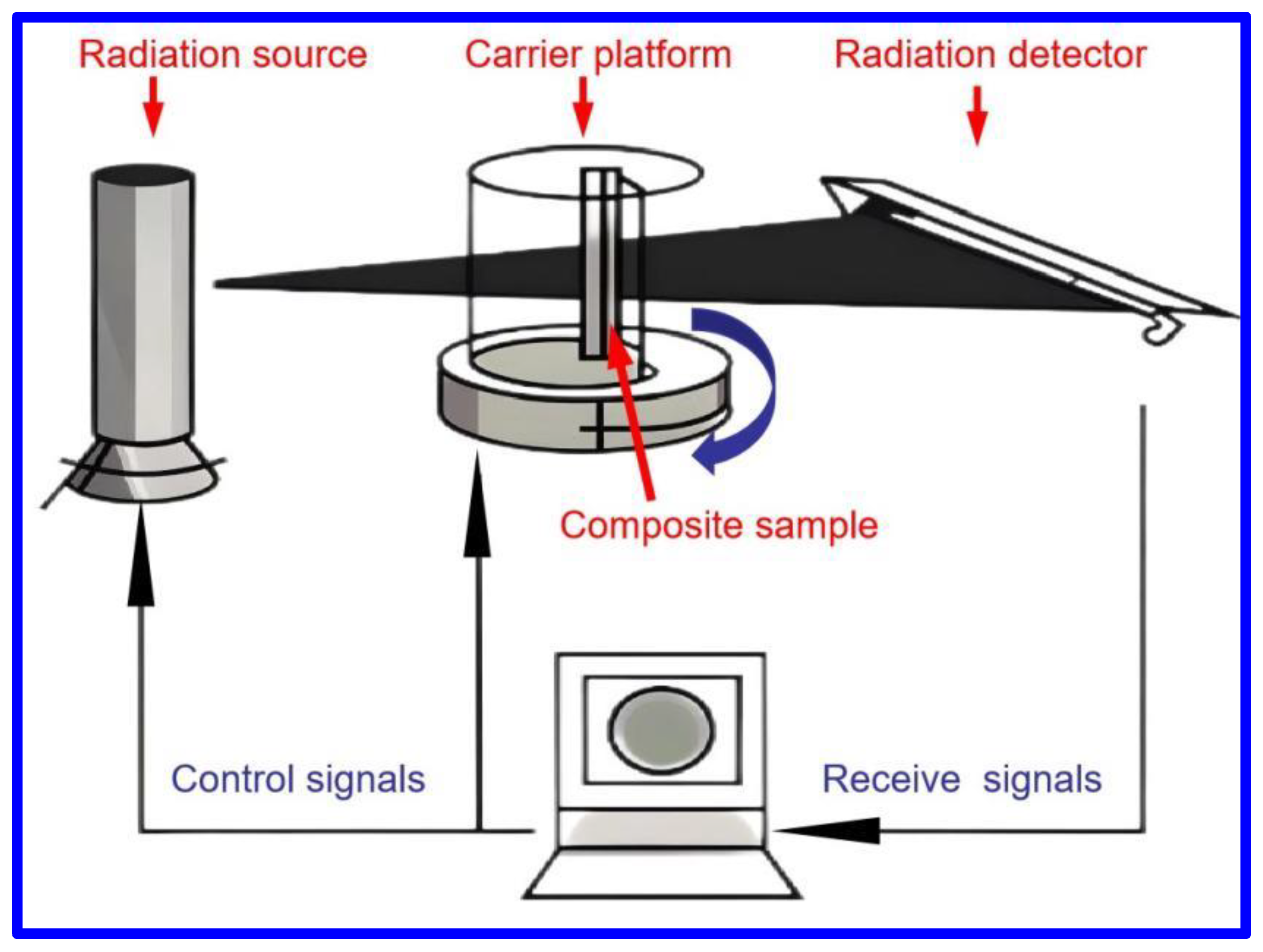

2.3. Evaluation of Ceramic and TWIP Steel Matrix Composite Performance

3. Results and Discussion

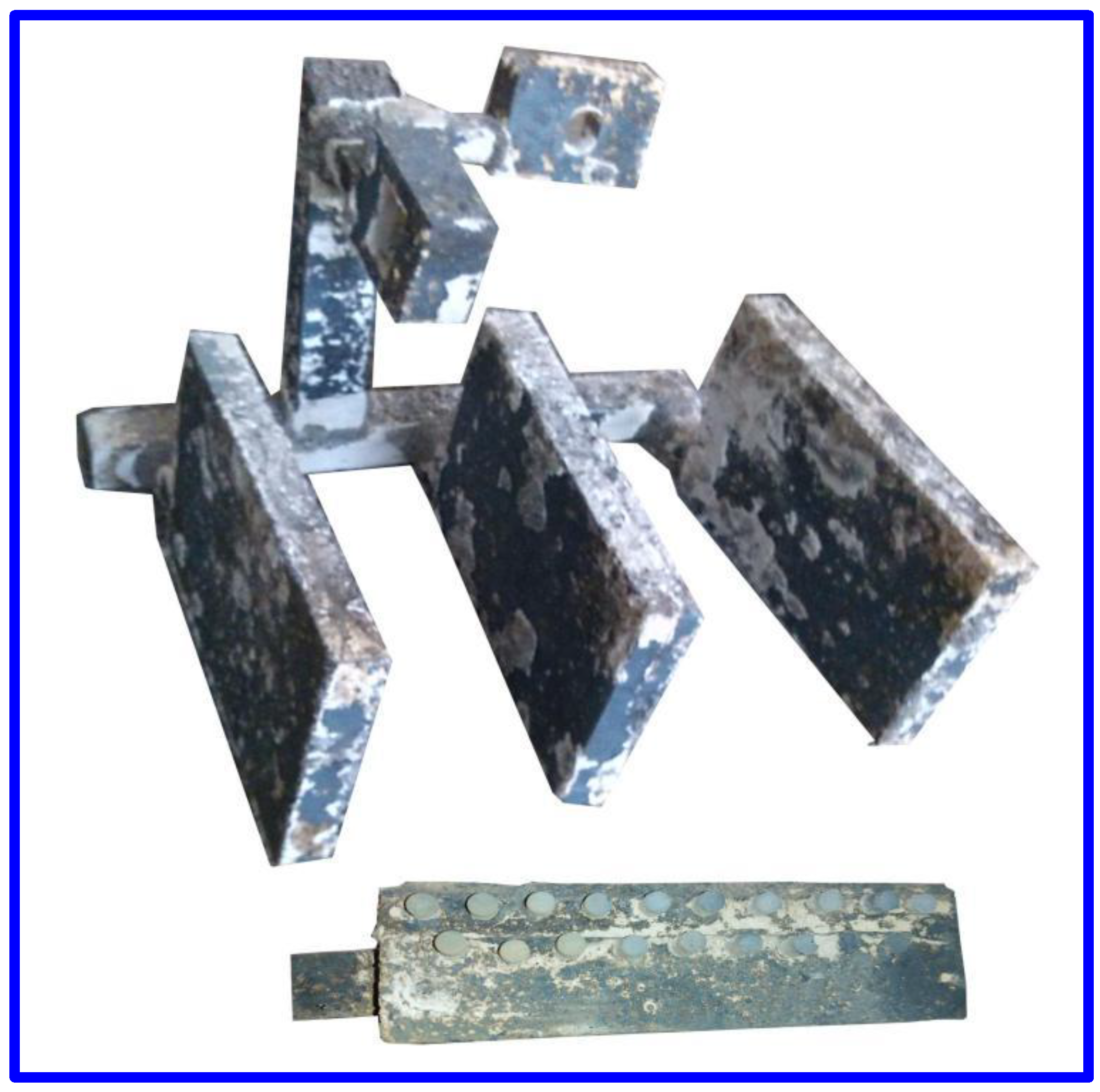

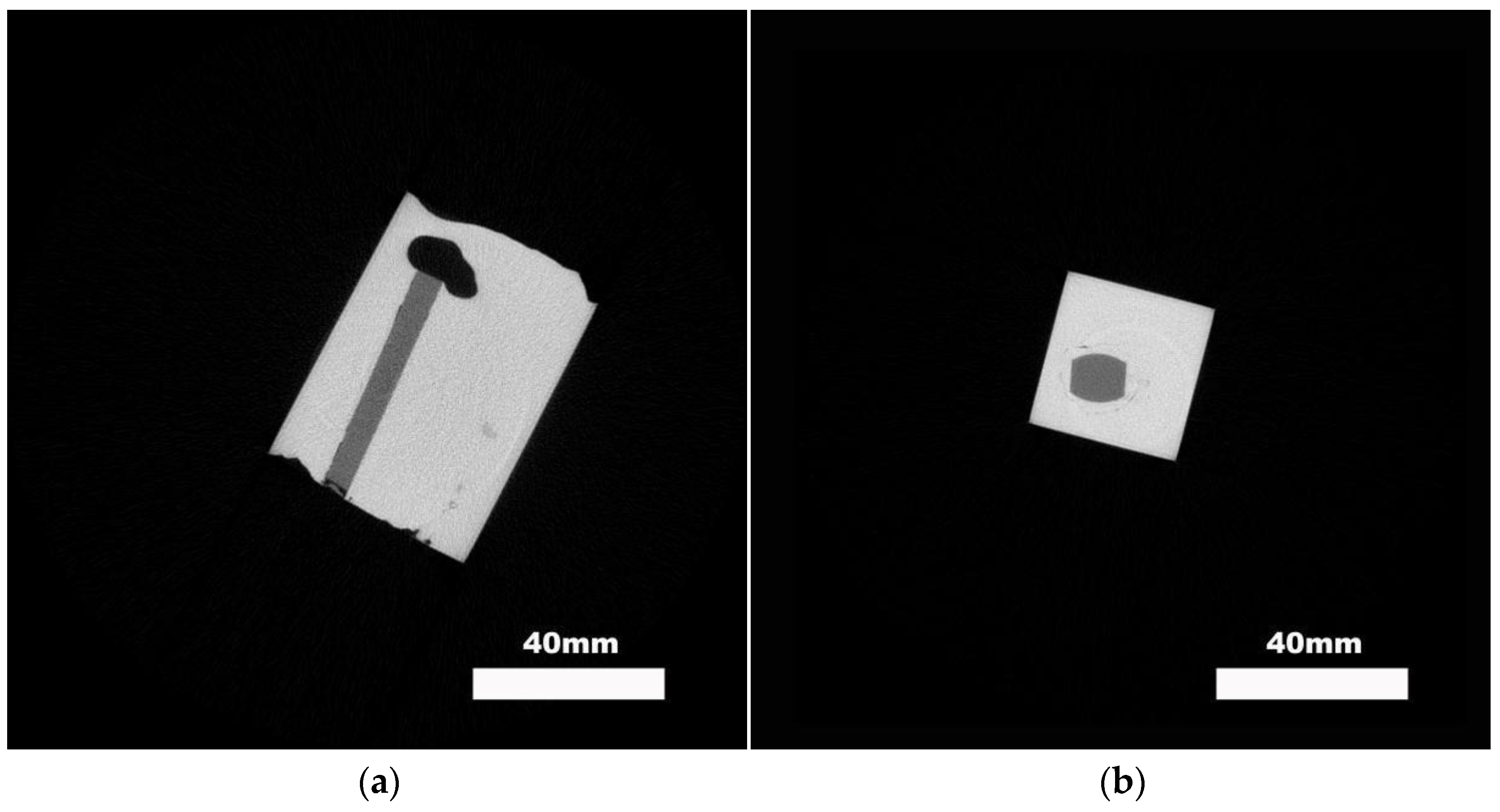

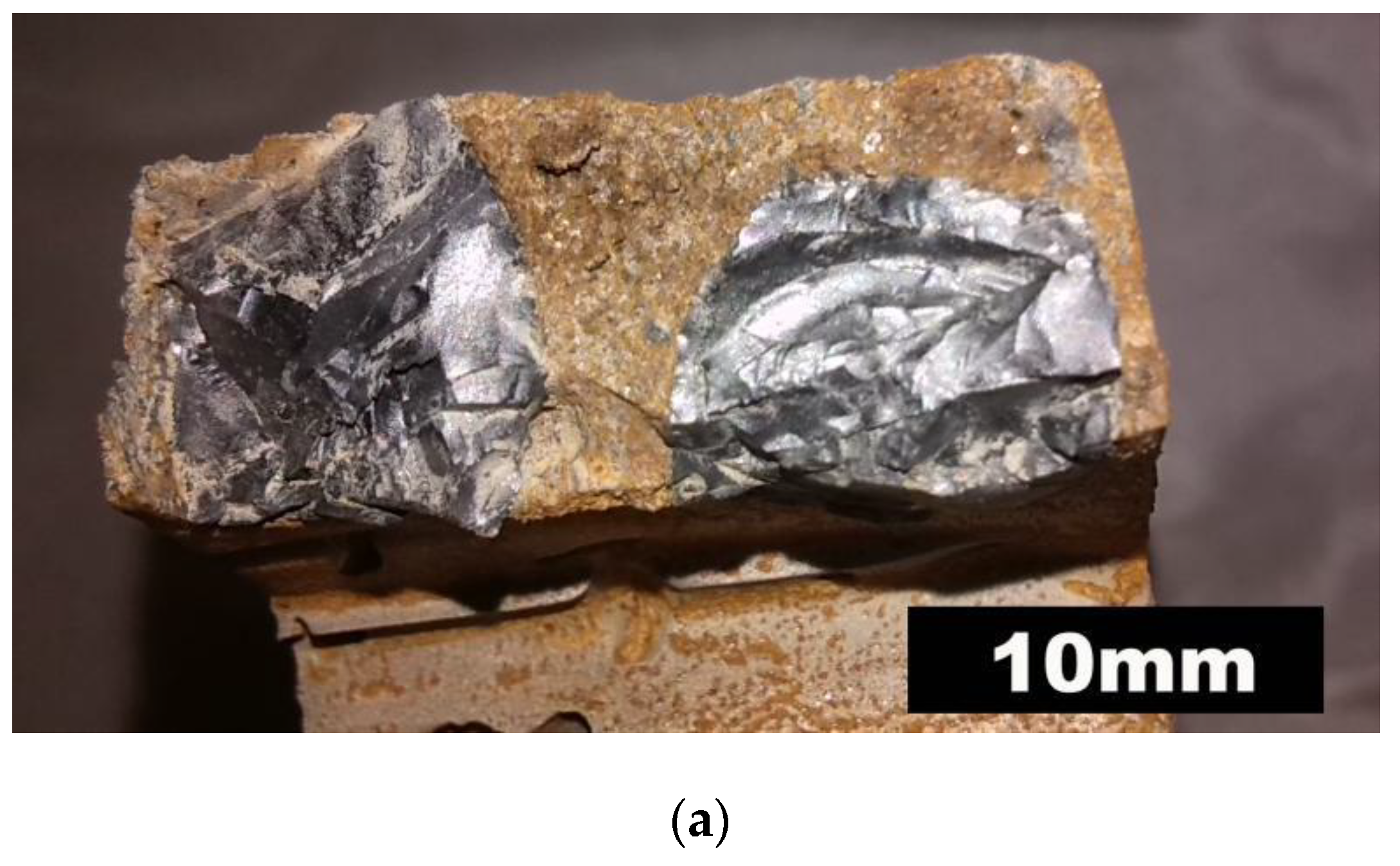

3.1. Fabrication of Ceramic-Reinforced TWIP Steel Matrix Composites

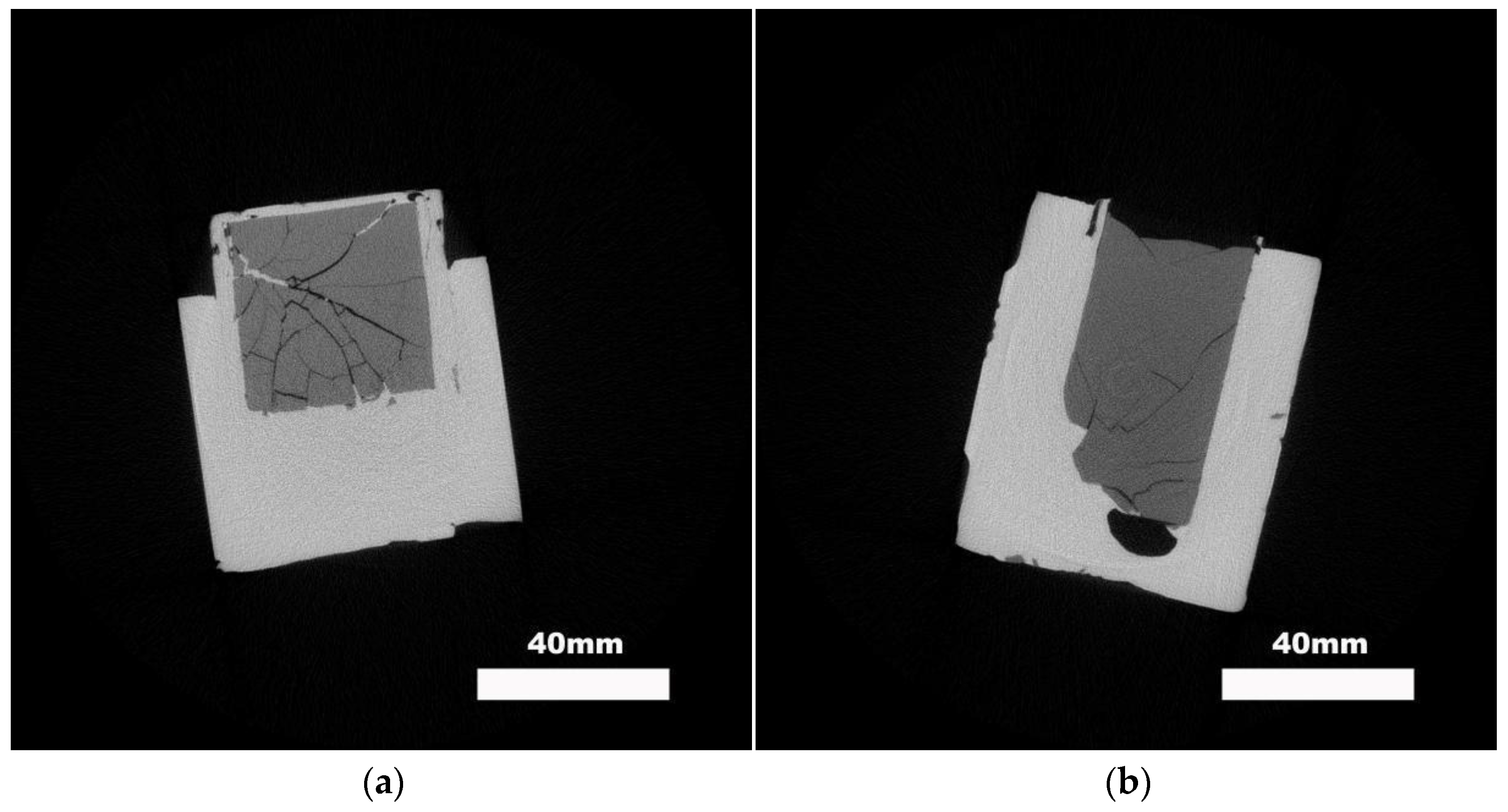

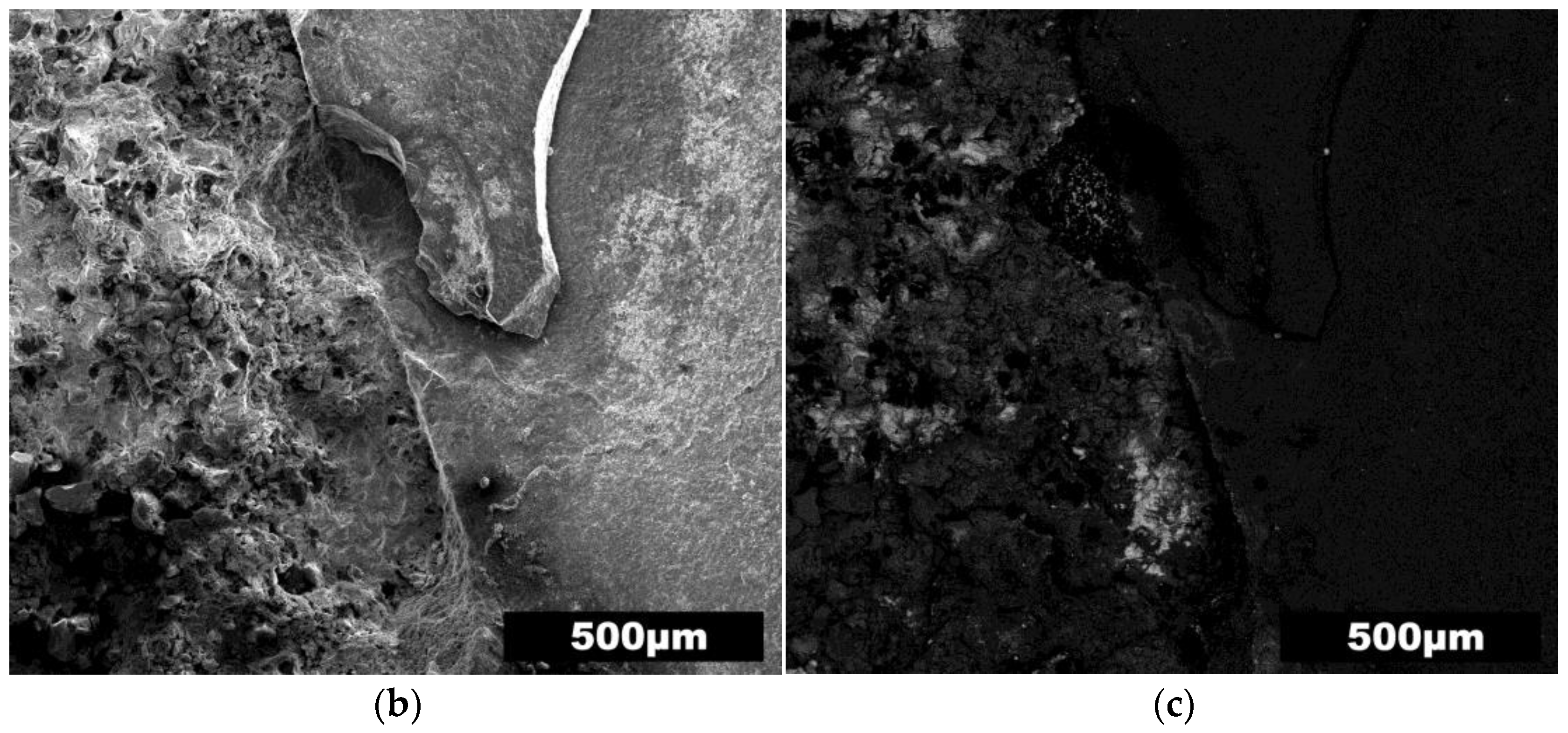

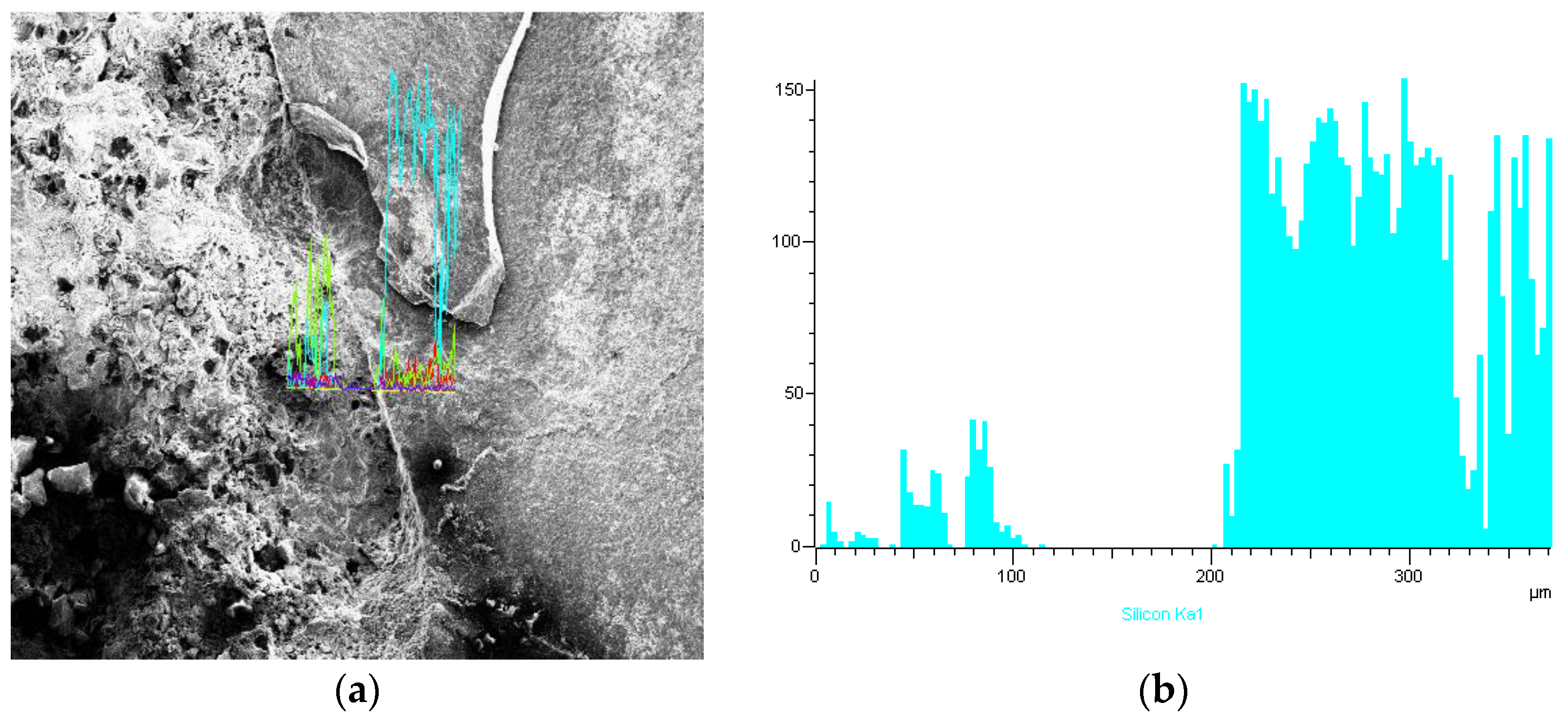

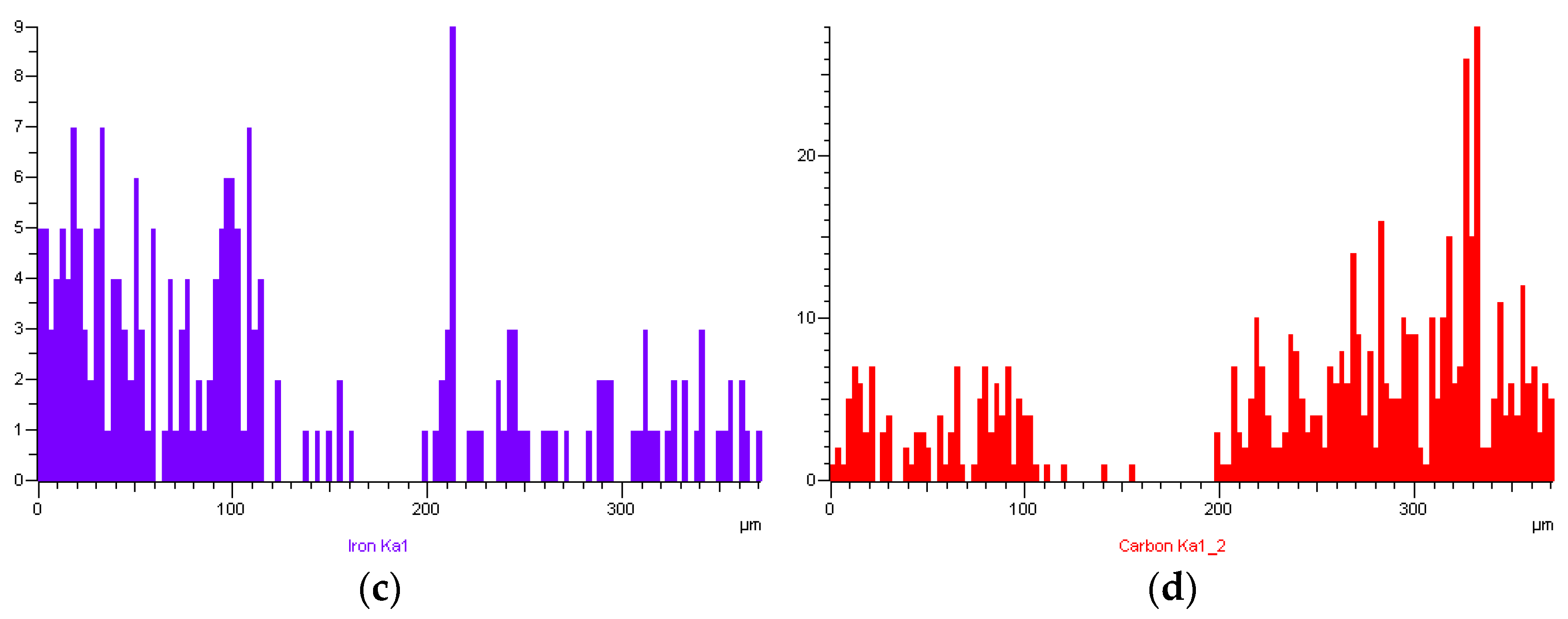

3.2. Interfacial Morphology Analysis of Large Ceramic-Reinforced TWIP Steel Matrix Composites

3.3. Analysis of the Composite Process for Large Ceramics with TWIP Matrix

4. Conclusions

- It was observed that blocky (115 × 40 × 25 mm) and flaky (40 × 40 × 5 mm) ceramic reinforcements experienced significant cracking and fragmentation during the lost-foam casting process. These defects compromised the integrity of the composite and diminished the reinforcement’s effectiveness. In contrast, rod-like (φ5 × 95 mm) and granular (φ10 × 10 mm) ceramics demonstrated superior compatibility with the TWIP steel matrix. They maintained their structural integrity, resulting in a robust and cohesive composite structure.

- The SEM and CT analyses revealed that rod-like and granular ceramics formed favorable interfacial bonding with the TWIP matrix. The microstructural examination indicated that the ceramics were well embedded within the matrix, with minimal interfacial defects.

- Smaller, more uniformly shaped ceramics, such as rods and granules, allowed better heat dissipation and reduced thermal stress. This led to fewer defects and better overall material properties. The findings underscore the importance of controlling ceramic size and shape to minimize thermal and mechanical stresses during lost-foam casting.

- Based on the comprehensive analysis, rod-like and granular ceramics emerged as the better choices for reinforcing large TWIP steel matrix composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Lee, S.; Ryu, S. Advancements and Challenges of Micromechanics-based Homogenization for the Short Fiber Reinforced Composites. Multiscale Sci. Eng. 2023, 5, 133–146. [Google Scholar] [CrossRef]

- Alhmoudi, A.; Sheikh-Ahmad, J.; Almaskari, F.; Bojanampati, S. Joining of polymer to metal using material extrusion additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 129, 3303–3319. [Google Scholar] [CrossRef]

- Sethi, D.; Acharya, U.; Kumar, S.; Shekhar, S.; Roy, B.S. Effect of Reinforcement Particles on Friction Stir Welded Joints with Scarf Configuration: An Approach to Achieve High Strength Joints. Silicon 2022, 14, 6847–6860. [Google Scholar] [CrossRef]

- Sekaran, P.R.; Ramakrishnan, H.; Venkatesh, R.; Nithya, A. Mechanical and Physical Characterization Studies of Nano Ceramic Reinforced Al–Mg Hybrid Nanocomposites. Silicon 2023, 15, 4555–4567. [Google Scholar] [CrossRef]

- Nyanor, P.; El-Kady, O.; Yehia, H.M.; Hamada, A.S.; Hassan, M.A. Effect of Bimodal-Sized Hybrid TiC–CNT Reinforcement on the Mechanical Properties and Coefficient of Thermal Expansion of Aluminium Matrix Composites. Met. Mater. Int. 2021, 27, 753–766. [Google Scholar] [CrossRef]

- Rajkumar, K.; Nambiraj, K.M.; Ramraji, K.; Khan, B.S.H. Influence of silicon filler size and concentration on thermal stability and erosion wear resistance of polymer composite. Silicon 2022, 14, 9595–9608. [Google Scholar] [CrossRef]

- Han, Y.; Liu, J.; Wang, Q.; Lin, C.; Wang, E.; Wu, W.; Zhang, M. Effect of volume fraction ratio of Ti to Al3Ti on mechanical and tribological performances of the in situ Ti–Al3Ti core–shell structured particle reinforced Al matrix composite. J. Mater. Res. 2022, 37, 3695–3707. [Google Scholar] [CrossRef]

- Bhardwaj, A.R.; Vaidya, A.M.; Meshram, P.D.; Bandhu, D. Machining behavior investigation of aluminium metal matrix composite reinforced with TiC particulates. Int. J. Interact. Des. Manuf. 2024, 18, 2911–2925. [Google Scholar] [CrossRef]

- Hwang, J.-I.; Kim, S.H.; Heo, Y.-U.; Kim, D.H.; Hwang, K.-C.; Suh, D.-W. Tempering Behavior of TiC-Reinforced SKD11 Steel Matrix Composite. Met. Mater. Int. 2018, 24, 644–651. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, D.H.; Hwang, K.-C.; Lee, S.-K.; Hong, H.U.; Suh, D.-W. Heat treatment response of TiC-reinforced steel matrix composite. Met. Mater. Int. 2016, 22, 935–941. [Google Scholar] [CrossRef]

- Chen, P.-H.; Li, Y.-B.; Li, R.-Q.; Jiang, R.-P.; Zeng, S.-S.; Li, X.-Q. Microstructure, mechanical properties, and wear resistance of VCp-reinforced Fe-matrix composites treated by Q&P process. Int. J. Miner. Met. Mater. 2018, 25, 1060–1069. [Google Scholar] [CrossRef]

- Sui, Y.; Han, L.; Jiang, Y.; Li, Z.; Shan, Q. Effects of Ni60WC25 powder content on the microstructure and wear properties of WCp reinforced surface metal matrix composites. Trans. Indian Inst. Met. 2018, 71, 2415–2422. [Google Scholar] [CrossRef]

- Kračun, A.; Jenko, D.; Godec, M.; Savilov, S.V.; Prieto, G.; Tuckart, W.; Podgornik, B. Nanoparticles Reinforcement for the Improved Strength and High-Temperature Wear Resistance of Mn-Cr Steel. Met. Mater. Trans. A 2018, 49, 5683–5694. [Google Scholar] [CrossRef]

- Zafar, H.M.N.; Nair, F. Fabrication and Microscale Characterization of Iron Matrix Composite Wires Reinforced by in situ Synthesized Iron Boride Phases. Arab. J. Sci. Eng. 2023, 48, 3909–3930. [Google Scholar] [CrossRef]

- Aslam, M.; Chandan, G.K.; Kanchan, B.K. Development of SiC Ceramic Reinforced Composite Interlayer Cladding with AISI304 Stainless Steel Wire on Low Carbon Steel Substrate Using TIG Cladding Process. Silicon 2023, 15, 7733–7743. [Google Scholar] [CrossRef]

- Sule, R.; Bayode, B.L.; Obadele, B.A.; Asante, J.K.O.; Olubambi, P.A.; Falodun, O.E. Densification and wear behavior of Cu-TiC composites via spark plasma sintering in situ degassing. Int. J. Adv. Manuf. Technol. 2022, 123, 2415–2426. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Prasad, K.; Patnaik, L. Effect of SiC and TiC Reinforcements on the Mechanical Properties of ZrB2- SiC- TiC Hybrid Composite Fabricated Through Spark Plasma Sintering. Silicon 2023, 15, 3339–3351. [Google Scholar] [CrossRef]

- Aghajani, S.; Pouyafar, V.; Meshkabadi, R.; Volinsky, A.A.; Bolouri, A. Mechanical characterization of high volume fraction Al7075-Al2O3 composite fabricated by semisolid powder processing. Int. J. Adv. Manuf. Technol. 2023, 125, 2569–2580. [Google Scholar] [CrossRef]

- Tong, Z.; Shao, W.; He, C.; He, D. Microstructure and wear resistance of in situ TiC-reinforced low-chromium iron-based hardfacing alloys. Weld. World 2024, 68, 605–620. [Google Scholar] [CrossRef]

- Lakshmikanth, B.; Jesudas, T. Influence of Stainless Steel Short Fibres as Reinforcements in Enhancing the Performance of Aluminium 7075 Alloy Matrix Composites. Trans. Indian Inst. Met. 2024, 77, 495–501. [Google Scholar] [CrossRef]

- Shavnev, A.A.; Kurbatkina, E.I.; Nyafkin, A.N.; Kosolapov, D.V. Fabrication Technologies of a Dispersion-Reinforced Metallic Composite Material Based on an Aluminum Alloy—Review. Inorg. Mater. Appl. Res. 2023, 14, 76–80. [Google Scholar] [CrossRef]

- Dong, T.-S.; Liu, J.-H.; Fang, Q.; Li, G.-L.; Zhang, J.-J. High strength bimetallic composite material fabricated by electroslag casting and characteristics of its composite interface. China Foundry 2016, 13, 389–395. [Google Scholar] [CrossRef][Green Version]

- Binesh, F.; Zamani, J.; Ghiasvand, M. Ordered Structure Composite Metal Foams Produced by Casting. Int. J. Met. 2018, 12, 89–96. [Google Scholar] [CrossRef]

- Sohn, S.S.; Song, H.; Jo, M.C.; Song, T.; Kim, H.S.; Lee, S. Novel 1.5 GPa-strength with 50%-ductility by transformation-induced plasticity of non-recrystallized austenite in duplex steels. Sci. Rep. 2017, 7, 1255. [Google Scholar] [CrossRef]

- Wang, Y.-N.; Yang, J.; Wang, R.-Z.; Xin, X.-L.; Xu, L.-Y. Effects of Non-metallic Inclusions on Hot Ductility of High Manganese TWIP Steels Containing Different Aluminum Contents. Met. Mater. Trans. B 2016, 47, 1697–1712. [Google Scholar] [CrossRef]

- Lapovok, R.; Berner, A.; Bisht, A.; Acharya, S.; Vahid, A.; Rabkin, E. Strain-induced solid-state coating of TWIP steel sheets with zinc. J. Mater. Sci. 2024, 59, 5538–5557. [Google Scholar] [CrossRef]

- Lv, W.; Gu, Y.; Huang, Y.; Cai, G.; Misra, R.D.K. An Experimental Investigation on Microstructure and Mechanical Property of Asymmetric Warm-Rolled Fe-27Mn-3Si-4Al TWIP Steel. J. Mater. Eng. Perform. 2023, 32, 6704–6716. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, S.; Zhou, Y.; Dong, J.; Ma, L.; Liu, S. Influence of aging treatment on mechanical properties and wear resistance of medium manganese steel reinforced with Ti(C,N) particles. Friction 2023, 11, 2059–2072. [Google Scholar] [CrossRef]

- Vidilli, A.L.; Coury, F.G.; Gonzalez, G.; Otani, L.B.; Amigó, V.; Bolfarini, C. Tailoring the Microstructure and Properties of Reinforced FeMnAlC Composites by In-Situ TiB2–TiC–M2B Formation. Met. Mater. Trans. A 2024, 55, 101–117. [Google Scholar] [CrossRef]

| Density (g/cm3) | Modulus of Elasticity (GPa) | Flexural Strength (MPa) | Compressive Strength (MPa) | Thermal Expansion Coefficient (10−6/°C) |

|---|---|---|---|---|

| >3.2 | >290 | >600 | >2500 | >3.1 |

| C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|

| 0.6 | 0.2 | 19 | <0.002 | <0.002 | Balance |

| Material | C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|

| Pure Iron | 0.01 | 0.06 | 0.2 | 0.012 | 0.015 | Balance |

| Medium Carbon Ferromanganese | 1.7 | 1.44 | 75 | ≤0.0046 | ≤0.137 | Balance |

| Q235 Steel | 0.2~0.3 | 0.1~0.2 | 0.17 | ≤0.04 | ≤0.04 | Balance |

| C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|

| 0.802 | 0.915 | 20.45 | 0.0045 | 0.075 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, G.; Liu, X.; Li, Z.; Wang, Q. Influence of Ceramic Size and Morphology on Interface Bonding Properties of TWIP Steel Matrix Composites Produced by Lost-Foam Casting. Metals 2024, 14, 1003. https://doi.org/10.3390/met14091003

Sun G, Liu X, Li Z, Wang Q. Influence of Ceramic Size and Morphology on Interface Bonding Properties of TWIP Steel Matrix Composites Produced by Lost-Foam Casting. Metals. 2024; 14(9):1003. https://doi.org/10.3390/met14091003

Chicago/Turabian StyleSun, Guojin, Xiaoming Liu, Zhenggui Li, and Qi Wang. 2024. "Influence of Ceramic Size and Morphology on Interface Bonding Properties of TWIP Steel Matrix Composites Produced by Lost-Foam Casting" Metals 14, no. 9: 1003. https://doi.org/10.3390/met14091003

APA StyleSun, G., Liu, X., Li, Z., & Wang, Q. (2024). Influence of Ceramic Size and Morphology on Interface Bonding Properties of TWIP Steel Matrix Composites Produced by Lost-Foam Casting. Metals, 14(9), 1003. https://doi.org/10.3390/met14091003