Magnetic Indicator for Evaluating Cu Clustering and Hardening Effect in RPV Model Alloy

Abstract

1. Introduction

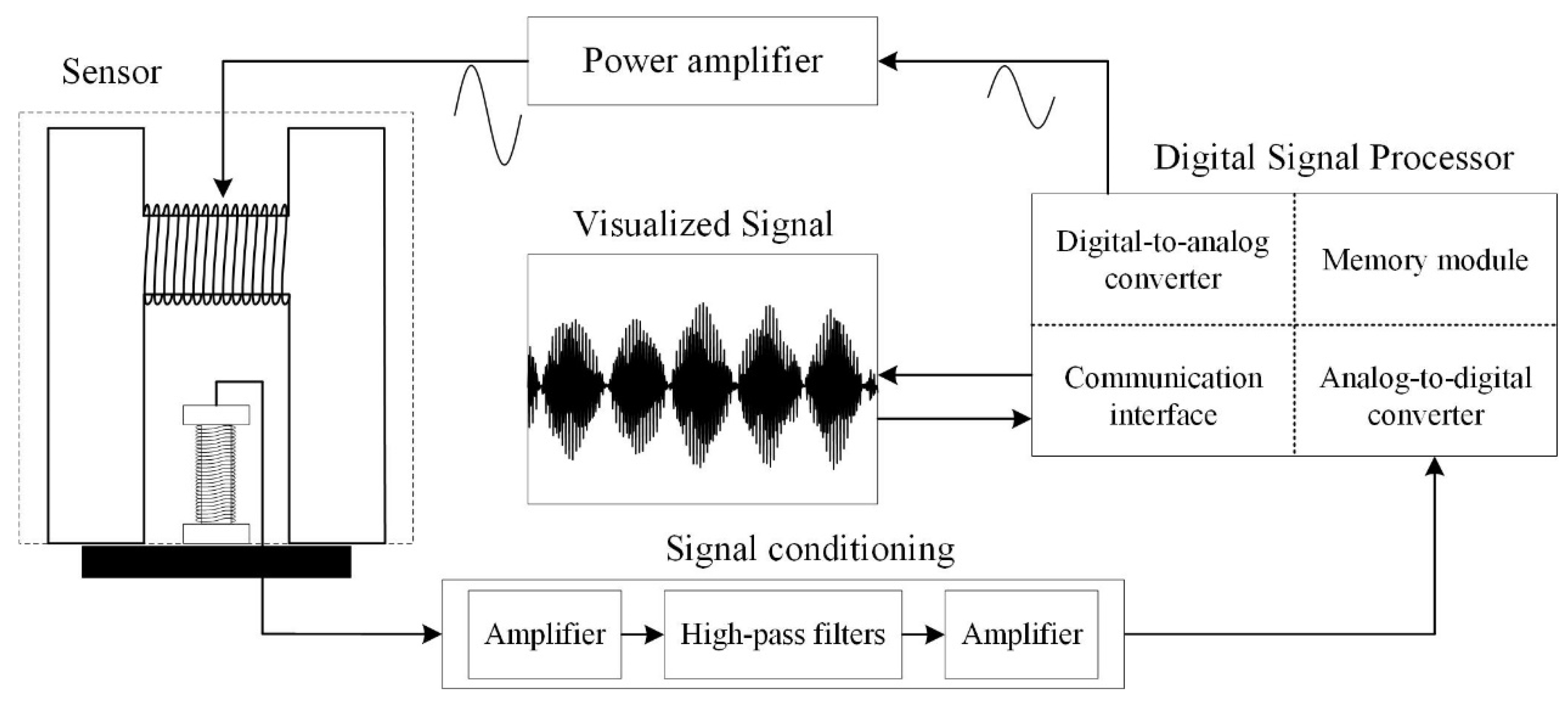

2. Experiments

3. Results and Discussion

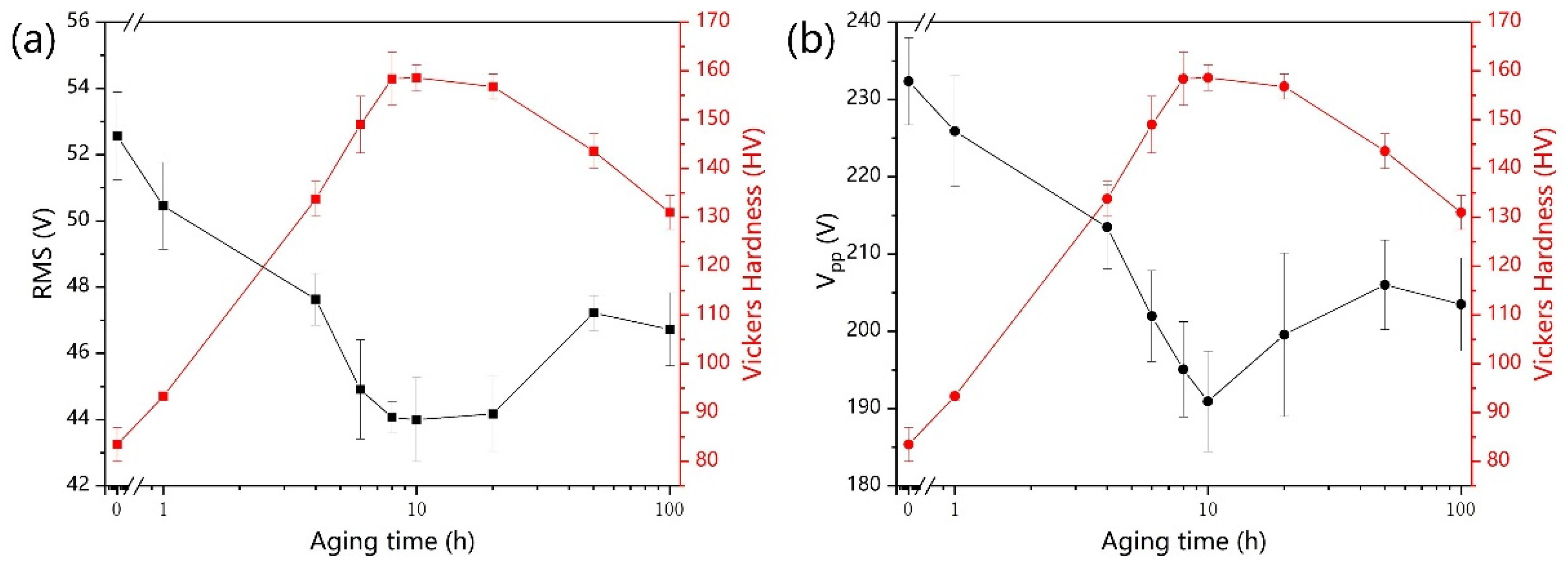

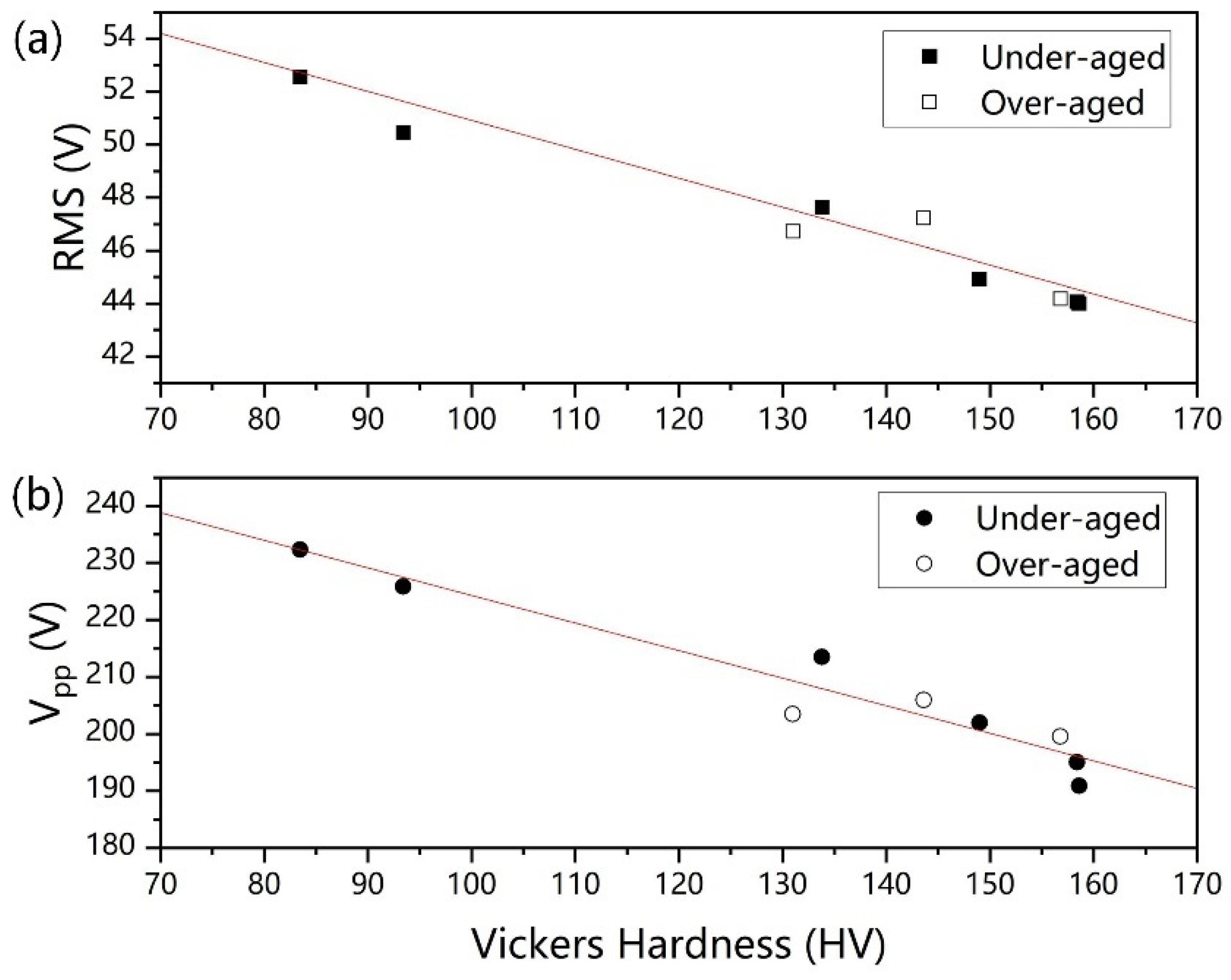

3.1. Variation of Hardness and MBN Characteristics

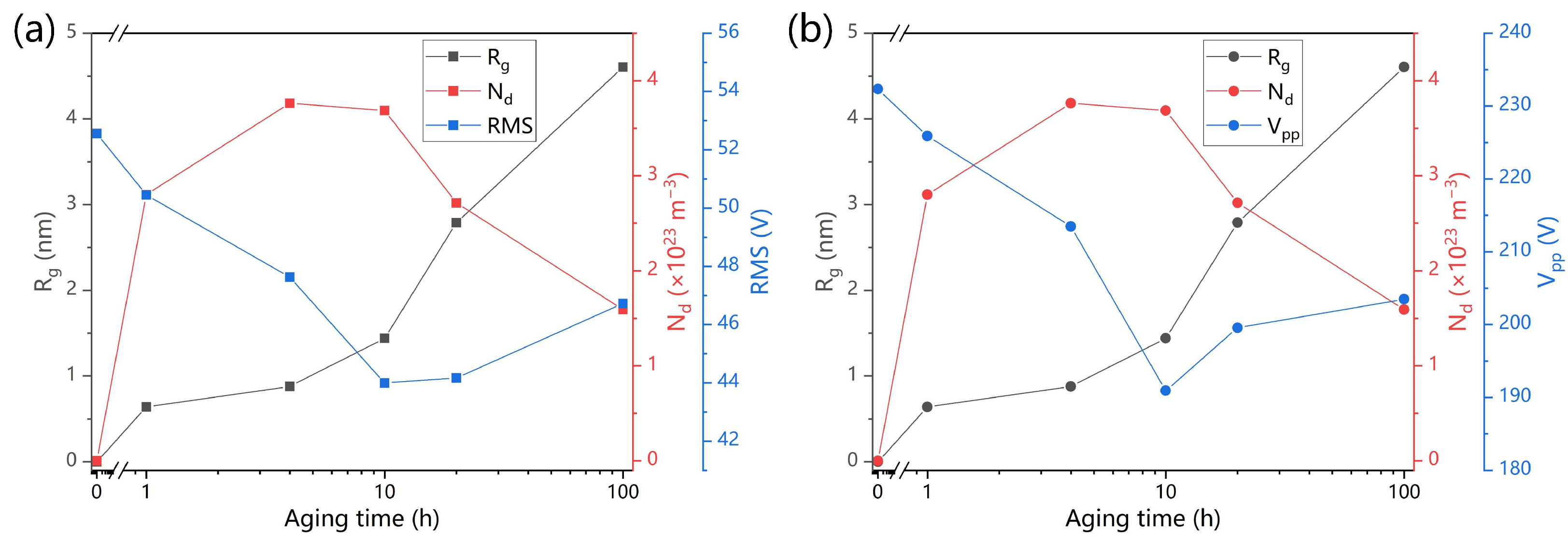

3.2. Evolution of Cu-Enriched Clusters

3.3. Correlation between MBN Signals and Clustering Behaviors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kolluri, M.; Martin, O.; Naziris, F.; D’Agata, E.; Gillemot, F.; Brumovsky, M.; Ulbricht, A.; Autio, J.M.; Shugailo, O.; Horvath, A. Structural MATerias research on parameters influencing the material properties of RPV steels for safe long-term operation of PWR NPPs. Nucl. Eng. Des. 2023, 406, 112236. [Google Scholar] [CrossRef]

- Gillemot, F. Review on Steel Enhancement for Nuclear RPVs. Metals 2021, 11, 2008. [Google Scholar] [CrossRef]

- Bohanon, B.; Wei, P.; Foster, A.; Bazar, L.; Zhang, Y.; Spearot, D.; Bachhav, M.; Capolungo, L.; Aitkaliyeva, A. A critical review of irradiation-induced changes in reactor pressure vessel steels. Prog. Nucl. Energy 2024, 174, 105276. [Google Scholar] [CrossRef]

- Gao, J.; Li, J.; Li, J.; Li, S.; Li, Z. Research progress on thermal aging of reactor pressure vessel steel. Mater. Sci. Technol. 2024. [Google Scholar] [CrossRef]

- Han, L.; Liu, Q.; Gu, J. High-resolution Transmission Electron Microscopy Characterization of the Structure of Cu Precipitate in a Thermal-aged Multicomponent Steel. Chin. J. Mech. Eng. 2019, 32, 81. [Google Scholar] [CrossRef]

- Emerson, J.N.; Marrero-Jackson, E.H.; Nemets, G.A.; Okuniewski, M.A.; Wharry, J.P. Nuclear reactor pressure vessel Welds: A critical and historical review of Microstructures, mechanical Properties, irradiation Effects, and future opportunities. Mater. Des. 2024, 113134. [Google Scholar] [CrossRef]

- Kamboj, A.; Almirall, N.; Yamamoto, T.; Tumey, S.; Marquis, E.A.; Odette, G.R. Dose and dose rate dependence of precipitation in a series of surveillance RPV steels under ion and neutron irradiation. J. Nucl. Mater. 2024, 588, 154772. [Google Scholar] [CrossRef]

- Cui, S. Modeling of Cu Precipitation in Fe–Cu and Fe–Cu–Mn Alloys Under Neutron and Electron Irradiation. Metall. Mater. Trans. A 2024, 55, 1849–1866. [Google Scholar] [CrossRef]

- Hyde, J.M.; Sha, G.; Marquis, E.A.; Morley, A.; Wilford, K.B.; Williams, T.J. A comparison of the structure of solute clusters formed during thermal ageing and irradiation. Ultramicroscopy 2011, 111, 664–671. [Google Scholar] [CrossRef]

- Styman, P.D.; Hyde, J.M.; Morley, A.; Wilford, K.; Riddle, N.; Smith, G.D.W. The effect of Ni on the microstructural evolution of high Cu reactor pressure vessel steel welds after thermal ageing for up to 100,000 h. Mater. Sci. Eng. A 2018, 736, 111–119. [Google Scholar] [CrossRef]

- Wang, D.; He, X.; Dou, Y.; Wu, S.; Jia, L.; Cao, H.; Yang, W. Effect of edge dislocation on solute-enriched clusters in reactor pressure vessel steel. Nucl. Instrum. Methods Phys. Res. Sect. B 2019, 451, 55–60. [Google Scholar] [CrossRef]

- Ahlawat, S.; Sarkar, S.K.; Sen, D.; Biswas, A. Revisiting Temporal Evolution of Cu-Rich Precipitates in Fe–Cu Alloy: Correlative Small Angle Neutron Scattering and Atom-Probe Tomography Studies. Microsc. Microanal. 2019, 25, 840–848. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Mamivand, M.; Morgan, D. Simulation of Cu precipitation in Fe-Cu dilute alloys with cluster mobility. Mater. Des. 2020, 191, 108574. [Google Scholar] [CrossRef]

- Chen, D.; Murakami, K.; Chen, L.; Li, Z.; Sekimura, N. An investigation of nucleation sites for the formation of solute clusters in ferrite Fe. Nucl. Instrum. Methods Phys. Res. Sect. B 2020, 478, 182–186. [Google Scholar] [CrossRef]

- Kuleshova, E.; Fedotova, S.; Zhuchkov, G.; Erak, A.; Saltykov, M.; Dementyeva, M.; Alekseeva, E. Degradation of RPV steel structure after 45 years of operation in the VVER-440 reactor. J. Nucl. Mater. 2020, 540, 152362. [Google Scholar] [CrossRef]

- Shu, S.; Wells, P.B.; Almirall, N.; Odette, G.R.; Morgan, D.D. Thermodynamics and kinetics of core-shell versus appendage co-precipitation morphologies: An example in the Fe-Cu-Mn-Ni-Si system. Acta Mater. 2018, 157, 298–306. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Y.; Wang, R.; Liu, W.; Liu, X. Irradiation and thermal effects on the mechanical properties and solute cluster evolution of Fe-Cu alloy. Nucl. Instrum. Methods Phys. Res. Sect. B 2022, 511, 118–122. [Google Scholar] [CrossRef]

- Scott, K.; Kim, J.-Y.; Wall, J.J.; Park, D.-G.; Jacobs, L.J. Investigation of Fe-1.0% Cu surrogate specimens with nonlinear ultrasound. NDT E Int. 2017, 89, 40–43. [Google Scholar] [CrossRef]

- Minghang, T.; Xinfu, H.; Yankun, D.; Dongjie, W.; Lixia, J. Cu Precipitate Induced Hardening in FeCu Model Alloy by Dislocation Dynamics. At. Energy Sci. Technol. 2021, 55, 1153–1162. [Google Scholar] [CrossRef]

- Vértesy, G.; Rabung, M.; Gasparics, A.; Uytdenhouwen, I.; Griffin, J.; Algernon, D.; Grönroos, S.; Rinta-Aho, J. Evaluation of the Embrittlement in Reactor Pressure-Vessel Steels Using a Hybrid Nondestructive Electromagnetic Testing and Evaluation Approach. Materials 2024, 17, 1106. [Google Scholar] [CrossRef]

- Vértesy, G.; Gasparics, A.; Uytdenhouwen, I.; Szenthe, I.; Gillemot, F.; Chaouadi, R. Nondestructive Investigation of Neutron Irradiation Generated Structural Changes of Reactor Steel Material by Magnetic Hysteresis Method. Metals 2020, 10, 642. [Google Scholar] [CrossRef]

- Rabung, M.; Kopp, M.; Gasparics, A.; Vértesy, G.; Szenthe, I.; Uytdenhouwen, I.; Szielasko, K. Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Appl. Sci. 2021, 11, 2917. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, D.; Chen, J.; Yin, L. Research on non-destructive testing of stress in ferromagnetic components based on metal magnetic memory and the Barkhausen effect. NDT E Int. 2023, 138, 102881. [Google Scholar] [CrossRef]

- Omae, K.; Yamazaki, T.; Oka, C.; Sakurai, J.; Hata, S. Stress measurement based on magnetic Barkhausen noise for thin films. Microelectron. Eng. 2023, 279, 112057. [Google Scholar] [CrossRef]

- Ren, T.Y.; Chen, G.L.; Zhang, W.M.; Qiu, Z.C. Experimental Study on the Stress of Ferromagnetic Tensile Specimen Using Magnetic Barkhausen Noise Detection. Appl. Mech. Mater. 2014, 455, 442–447. [Google Scholar] [CrossRef]

- Santa-aho, S.; Honkanen, M.; Kaappa, S.; Azzari, L.; Saren, A.; Ullakko, K.; Laurson, L.; Vippola, M. Multi-instrumental approach to domain walls and their movement in ferromagnetic steels—Origin of Barkhausen noise studied by microscopy techniques. Mater. Des. 2023, 234, 112308. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Deng, S.; Xu, B.; Li, Q.; Shu, G.; Liu, W. Changes in the magnetic and mechanical properties of thermally aged Fe–Cu alloys due to nano-sized precipitates. J. Phys. D Appl. Phys. 2016, 49, 035006. [Google Scholar] [CrossRef]

- Park, D.G.; Kishore, M.B.; Lee, D.H.; Kim, J.Y.; Jacobs, L.J.; Vertesy, G.; Son, D. A study of microstructural analysis for nondestructive evaluation of thermal annealing using magnetic properties. NDT E Int. 2017, 89, 14–18. [Google Scholar] [CrossRef]

- Hyde, J.M.; Marquis, E.A.; Wilford, K.B.; Williams, T.J. A sensitivity analysis of the maximum separation method for the characterisation of solute clusters. Ultramicroscopy 2011, 111, 440–447. [Google Scholar] [CrossRef]

- Lawitzki, R.; Stender, P.; Schmitz, G. Compensating Local Magnifications in Atom Probe Tomography for Accurate Analysis of Nano-Sized Precipitates. Microsc. Microanal. 2021, 27, 499–510. [Google Scholar] [CrossRef]

- Yeli, G.; Auger, M.A.; Wilford, K.; Smith, G.D.; Bagot, P.A.; Moody, M.P. Sequential nucleation of phases in a 17-4PH steel: Microstructural characterisation and mechanical properties. Acta Mater. 2017, 125, 38–49. [Google Scholar] [CrossRef]

- Auger, P.; Pareige, P.; Welzel, S.; Van Duysen, J. Synthesis of atom probe experiments on irradiation-induced solute segregation in French ferritic pressure vessel steels. J. Nucl. Mater. 2000, 280, 331–344. [Google Scholar] [CrossRef]

- Yin, J.; Hou, H.; Wang, J.T.; Liu, X.; Xue, F. Atomistic simulation of [100](001) crack propagation with Cu precipitates in α-iron. Int. J. Press. Vessel. Pip. 2021, 194, 104519. [Google Scholar] [CrossRef]

- Yin, J.; Hou, H.; Wang, J.-T.; Liu, X.; Xu, C.; Li, Y.; Qian, W.; Jin, X.; Wu, H.; Jia, W. Atomistic Simulation of the Interaction between the Σ9[110](221) Shear-Coupled Grain Boundary Motion and the Cu-rich Precipitates in α-Iron. Metals 2024, 14, 252. [Google Scholar] [CrossRef]

- Othen, P.; Jenkins, M.; Smith, G. High-resolution electron microscopy studies of the structure of Cu precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, T.; Yang, Y.; Liu, C. Phase field study of the copper precipitation in Fe-Cu alloy. Acta Mater. 2019, 166, 560–571. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Ghosh, G.; Vaynman, S.; Fine, M.E.; Chung, Y.-W. Aging characteristics and mechanical properties of 1600 MPa body-centered cubic Cu and B2-NiAl precipitation-strengthened ferritic steel. Acta Mater. 2014, 73, 56–74. [Google Scholar] [CrossRef]

- Wen, Y.; Hirata, A.; Zhang, Z.; Fujita, T.; Liu, C.; Jiang, J.; Chen, M. Microstructure characterization of Cu-rich nanoprecipitates in a Fe–2.5 Cu–1.5 Mn–4.0 Ni–1.0 Al multicomponent ferritic alloy. Acta Mater. 2013, 61, 2133–2147. [Google Scholar] [CrossRef]

- Jiles, D.C.; Kiarie, W. An Integrated Model of Magnetic Hysteresis, the Magnetomechanical Effect, and the Barkhausen Effect. IEEE Trans. Magn. 2021, 57, 1–11. [Google Scholar] [CrossRef]

- Santa-aho, S.; Laitinen, A.; Sorsa, A.; Vippola, M. Barkhausen Noise Probes and Modelling: A Review. J. Nondestruct. Eval. 2019, 38, 94. [Google Scholar] [CrossRef]

- Qiu, F.; Klug, M.J.; Tian, G.; Hu, P.; McCord, J. Influence of magnetic domain wall orientation on Barkhausen noise and magneto-mechanical behavior in electrical steel. J. Phys. D Appl. Phys. 2019, 52, 265001. [Google Scholar] [CrossRef]

- Lo, C. Modeling the effects of nanosized precipitates on magnetic hysteresis and Barkhausen effect signal. J. Appl. Phys. 2012, 111, 07D109. [Google Scholar] [CrossRef]

| Thermal Aging Time (h) | Mean Radius (nm) | Number Density (×1023 m−3) |

|---|---|---|

| 1 | 0.64 | 2.80 |

| 4 | 0.88 | 3.76 |

| 10 | 1.44 | 3.69 |

| 20 | 2.79 | 2.71 |

| 100 | 4.60 | 1.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, W.; Quan, Q.; Qian, W.; Bian, C.; Xu, C.; Yin, J.; Li, B.; Li, Y.; Fan, M.; Liu, X.; et al. Magnetic Indicator for Evaluating Cu Clustering and Hardening Effect in RPV Model Alloy. Metals 2024, 14, 973. https://doi.org/10.3390/met14090973

Jia W, Quan Q, Qian W, Bian C, Xu C, Yin J, Li B, Li Y, Fan M, Liu X, et al. Magnetic Indicator for Evaluating Cu Clustering and Hardening Effect in RPV Model Alloy. Metals. 2024; 14(9):973. https://doi.org/10.3390/met14090973

Chicago/Turabian StyleJia, Wenqing, Qiwei Quan, Wangjie Qian, Chuang Bian, Chaoliang Xu, Jian Yin, Bin Li, Yuanfei Li, Minyu Fan, Xiangbing Liu, and et al. 2024. "Magnetic Indicator for Evaluating Cu Clustering and Hardening Effect in RPV Model Alloy" Metals 14, no. 9: 973. https://doi.org/10.3390/met14090973

APA StyleJia, W., Quan, Q., Qian, W., Bian, C., Xu, C., Yin, J., Li, B., Li, Y., Fan, M., Liu, X., & Wang, H. (2024). Magnetic Indicator for Evaluating Cu Clustering and Hardening Effect in RPV Model Alloy. Metals, 14(9), 973. https://doi.org/10.3390/met14090973