Microstructure Evolution of Extruded TiAl Alloy During Vacuum Isothermal Superplastic Forging Process

Abstract

:1. Introduction

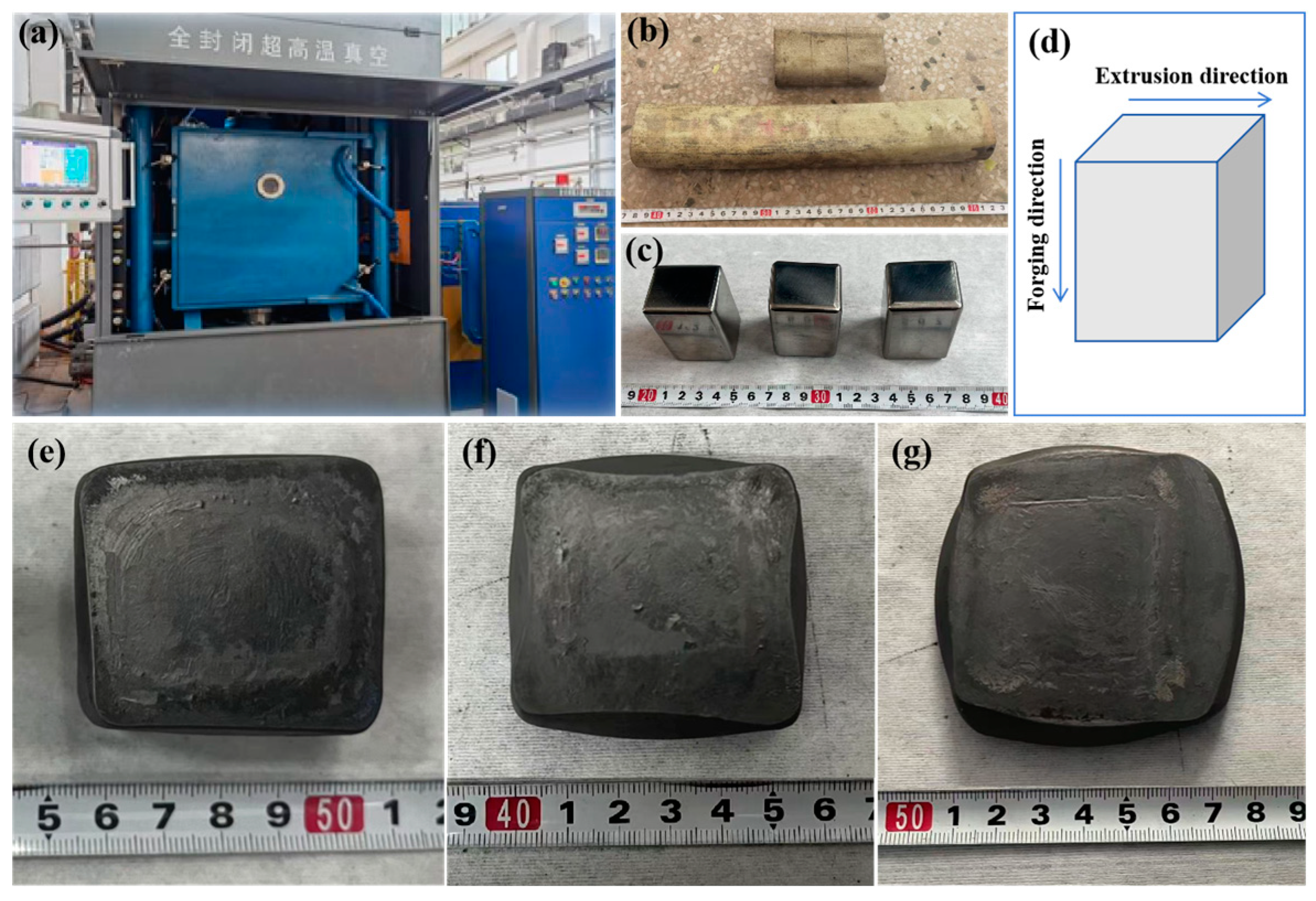

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (1)

- The TiAl alloy forgings produced at an extremely low strain rate and a lower temperature exhibited a high surface quality without cracks.

- (2)

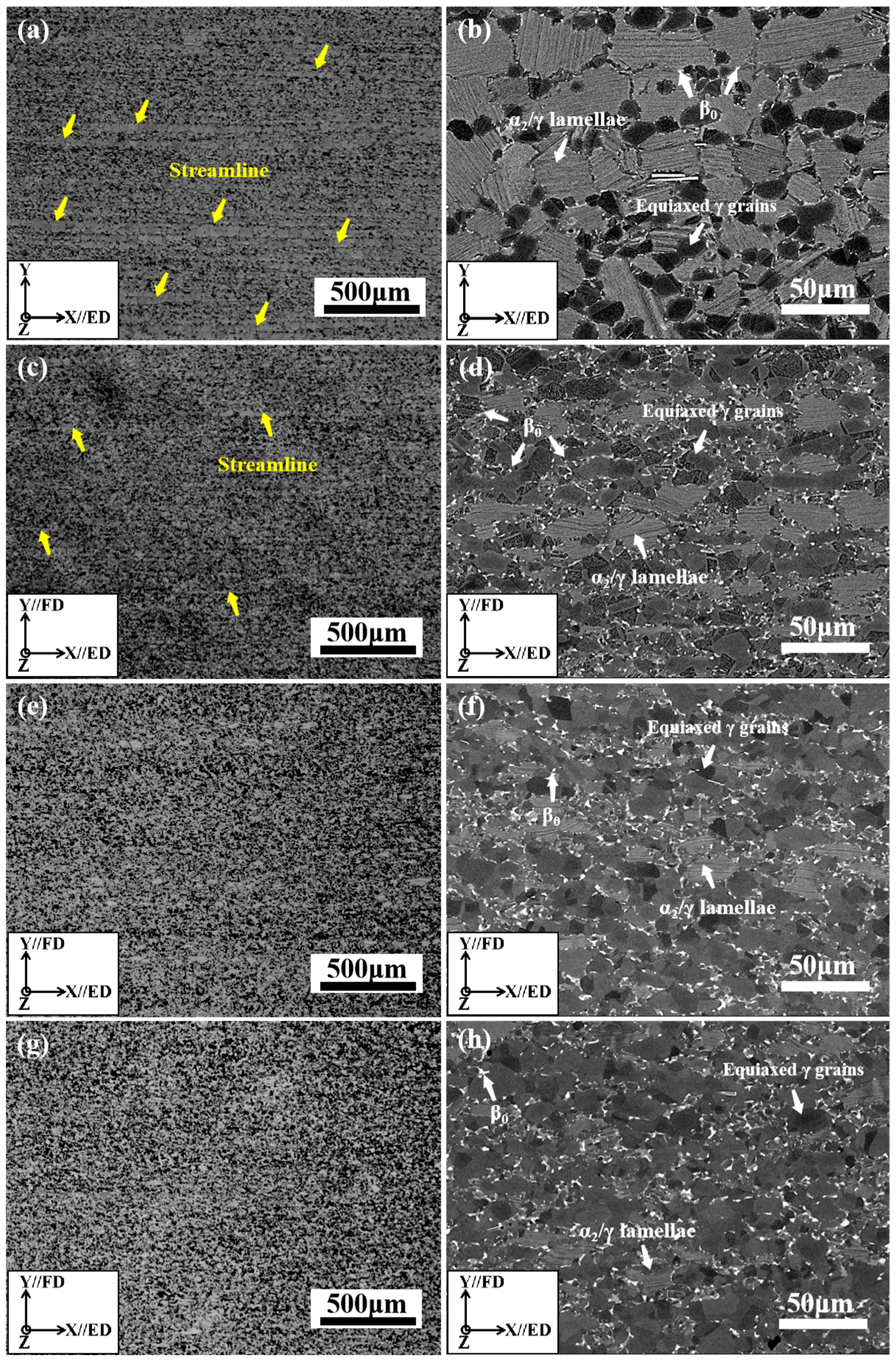

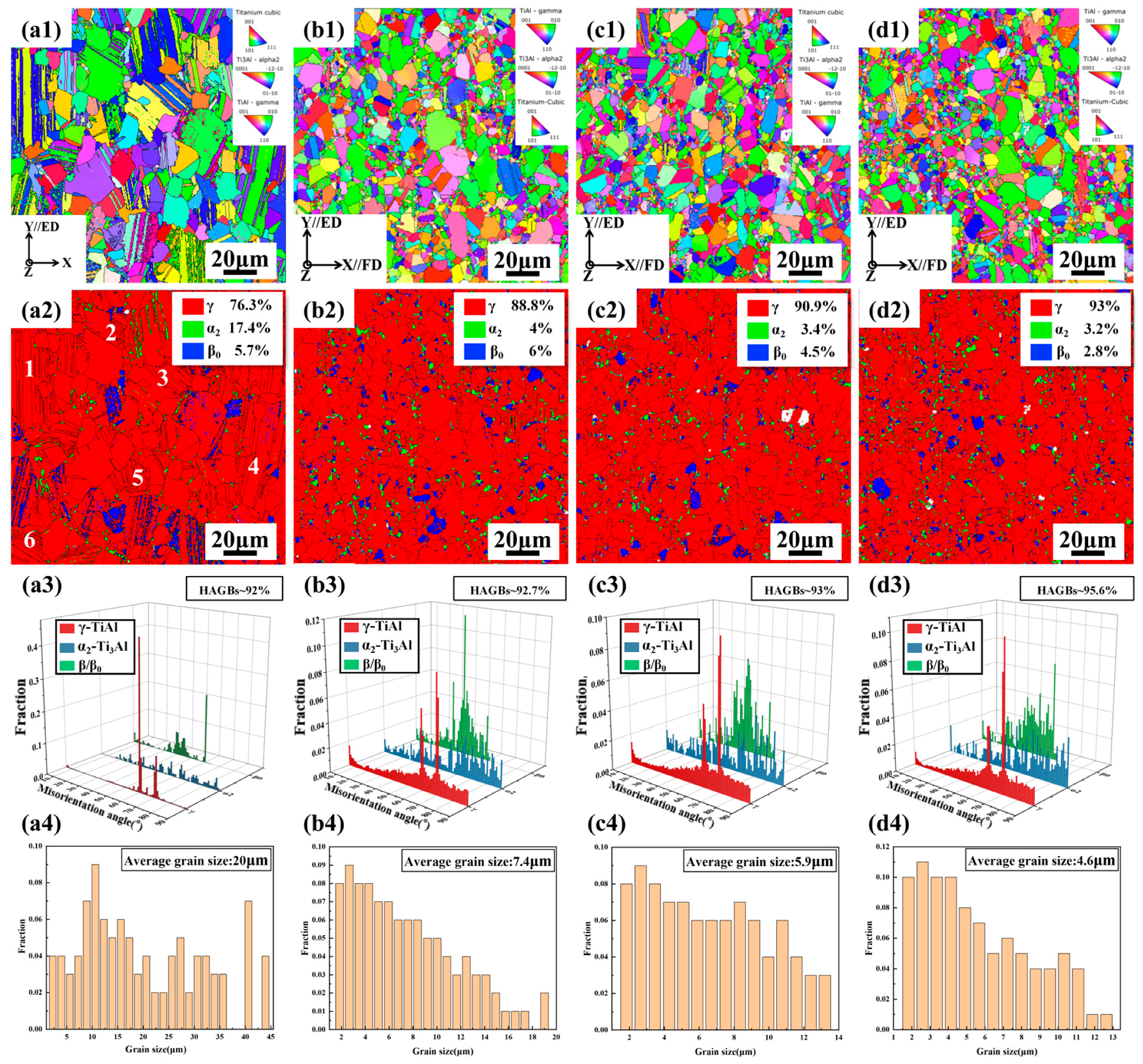

- The volume fraction of lamellar colonies and the grain size of the forged alloys were significantly reduced compared to the extruded alloy. The dynamic recrystallization process was promoted by the increase in deformation, leading to the rise in the proportion of equiaxed γ phase from 76.3% to 93% and the decrease in the volume fraction of remnant lamellar colonies from 70.26% to 8.32%. Therefore, the proportion of high-angle grain boundaries increased, and the grain size reduced from 20 μm to 4.6 μm. In addition, the type of the microstructure transitioned from NL to NG with the increased deformation.

- (3)

- During the forging process, the dynamic recrystallization occurred in soft-oriented lamellar colonies through phase boundary bulging until they decomposed completely, while hard-oriented lamellar colonies were only broken by force and retained at room temperature.

- (4)

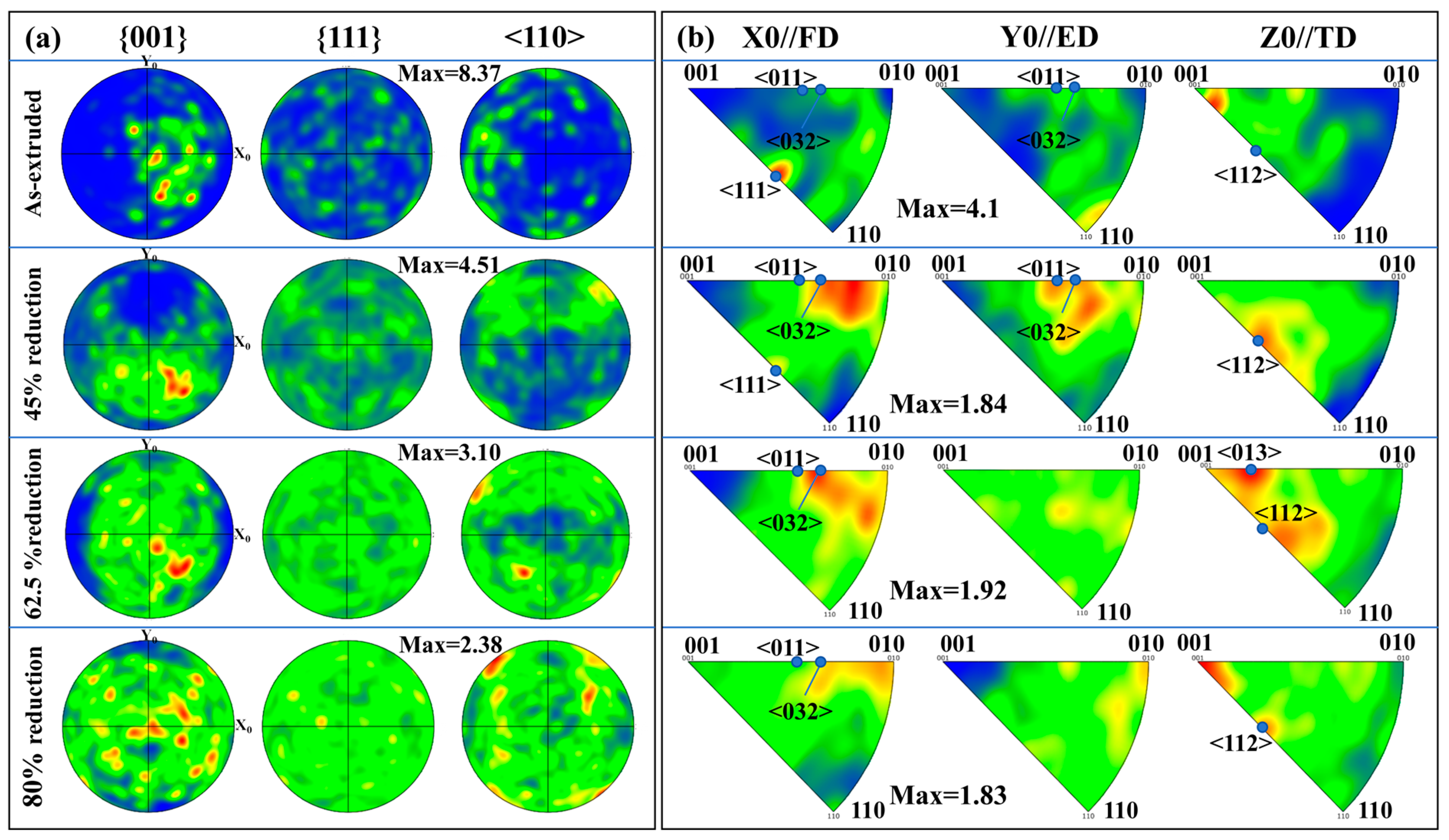

- The γ grains of the forgings exhibited a preferred orientation in the <032> face parallel to the forging direction, showing a typical characteristic of mechanical twinning.

- (5)

- The extrusion streamlines and textures were gradually destroyed with the increase in deformation, leading to a reduction in strength from 891 MPa to 722 MPa. To maintain the streamlined features and hold its strengthening effects, the forging deformation should not exceed 56.7%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sokolovsky, V.S.; Stepanov, N.D.; Salishchev, G.A. The Effect of Cellular Reaction on Mechanical Behavior and Microstructure Evolution of β-Solidified γ-TiAl Based Alloy during Hot Deformation. Intermetallics 2025, 179, 108653. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A Review of Microstructure Control and Mechanical Performance Optimization of γ-TiAl Alloys. J. Alloys Compd. 2023, 932, 167611. [Google Scholar] [CrossRef]

- Klein, T.; Usategui, L.; Rashkova, B.; Nó, M.L.; San Juan, J.; Clemens, H.; Mayer, S. Mechanical Behavior and Related Microstructural Aspects of a Nano-Lamellar TiAl Alloy at Elevated Temperatures. Acta Mater. 2017, 128, 440–450. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Ma, Y.; Ye, J.; Liu, Y. The Impact of Directional Annealing on the Microstructure and 900 °C Tensile Properties of γ-TiAl Alloy. Intermetallics 2025, 179, 108648. [Google Scholar] [CrossRef]

- Usategui, L.; López-Ferreño, I.; Echániz, T.; Sainz-Menchón, M.; Musi, M.; Clemens, H.; López, G.A. Emissivity Measurements Conducted on Intermetallic γ-TiAl-Based Alloys for Aeronautical Applications. J. Mater. Res. Technol. 2023, 27, 3170–3179. [Google Scholar] [CrossRef]

- Li, M.; Li, J.; Zhou, T.; Xiao, S.; Chen, Y.; Xu, L.; Hu, L.; Shi, L. The Investigation of Microstructure Evolution, Deformation Behavior and Processing Performance of the High Niobium Containing TiAl Alloys. Intermetallics 2021, 138, 107336. [Google Scholar] [CrossRef]

- Liang, Z.; Xiao, S.; Chi, D.; Zheng, Y.; Xu, L.; Xue, X.; Tian, J.; Chen, Y. Compressive Creep Behavior of High Nb Containing TiAl Alloy: Dynamic Recrystallization and Phase Transformation. Intermetallics 2023, 163, 108067. [Google Scholar] [CrossRef]

- Ganesan, H.; Scheider, I.; Cyron, C.J. Understanding Creep in TiAl Alloys on the Nanosecond Scale by Molecular Dynamics Simulations. Mater. Des. 2021, 212, 110282. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, S.; Pan, Y.; Xu, W.; Singh, H.; Liu, B.; Lu, D.; Wang, H.; Zhang, J.; Lu, X. Effect of Sn Addition on the Mechanical Properties and High-Temperature Oxidation Resistance of Intermetallic TiAl Alloys by First Principles Study and Experimental Investigation. J. Mater. Res. Technol. 2022, 21, 3666–3677. [Google Scholar] [CrossRef]

- Cao, S.; Han, J.; Wang, H.; Xiao, S.; Xu, L.; Chen, Y. Effects of Cycle Heat Treatment on the Microstructure and Mechanical Property of As-Cast γ-TiAl Alloy. Mater. Sci. Eng. A 2022, 857, 144053. [Google Scholar] [CrossRef]

- Ren, G.; Dai, C.; Mei, W.; Sun, J.; Lu, S.; Vitos, L. Formation and Temporal Evolution of Modulated Structure in High Nb-Containing Lamellar γ-TiAl Alloy. Acta Mater. 2019, 165, 215–227. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Advances in Gammalloy Materials–Processes–Application Technology: Successes, Dilemmas, and Future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef]

- Chen, G.; Peng, Y.; Zheng, G.; Qi, Z.; Wang, M.; Yu, H.; Dong, C.; Liu, C.T. Polysynthetic Twinned TiAl Single Crystals for High-Temperature Applications. Nat. Mater. 2016, 15, 876–881. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl Blades. Mater. Today Proc. 2015, 2, S92–S97. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, L.; Mo, X.; Nan, H.; Ding, X. Microstructure Characterization and Properties of Graphene Oxide-Reinforced TiAl Matrix Composites. Metals 2021, 11, 883. [Google Scholar] [CrossRef]

- Tetsui, T. Application of TiAl in a Turbocharger for Passenger Vehicles. Adv. Eng. Mater. 2001, 3, 307–310. [Google Scholar] [CrossRef]

- Gebauer, K. Performance, Tolerance and Cost of TiAl Passenger Car Valves. Intermetallics 2006, 14, 355–360. [Google Scholar] [CrossRef]

- Genc, O.; Unal, R. Development of Gamma Titanium Aluminide (γ-TiAl) Alloys: A Review. J. Alloys Compd. 2022, 929, 167262. [Google Scholar] [CrossRef]

- Yang, Y.; Feng, H.; Wang, Q.; Chen, R.; Guo, J.; Ding, H.; Su, Y. Improvement of Microstructure and Mechanical Properties of TiAl−Nb Alloy by Adding Fe Element. Trans. Nonferrous Met. Soc. China 2020, 30, 1315–1324. [Google Scholar] [CrossRef]

- Zheng, G.; Tang, B.; Zhao, S.; Wang, W.Y.; Chen, X.; Zhu, L.; Li, J. Evading the Strength-Ductility Trade-off at Room Temperature and Achieving Ultrahigh Plasticity at 800 °C in a TiAl Alloy. Acta Mater. 2022, 225, 117585. [Google Scholar] [CrossRef]

- Liu, N.; Niu, J.; Chen, Y.; Wang, X.; Wang, J.; Xiang, H.; Wei, D.; Chen, G. Effect of In-Situ Post-Heating on the Microstructure and Tensile Performance of TiAl Alloys Produced via Selective Electron Beam Melting. Mater. Sci. Eng. A 2023, 885, 145585. [Google Scholar] [CrossRef]

- Erdely, P.; Staron, P.; Maawad, E.; Schell, N.; Klose, J.; Mayer, S.; Clemens, H. Effect of Hot Rolling and Primary Annealing on the Microstructure and Texture of a β-Stabilised γ-TiAl Based Alloy. Acta Mater. 2017, 126, 145–153. [Google Scholar] [CrossRef]

- Niu, H.Z.; Tong, R.L.; Chen, X.J.; Zhang, T.B.; Zhang, D.L. Rapid Decomposition of Lamellar Microstructure and Enhanced Hot Workability of an As-Cast Triphase Ti–45Al–6Nb–1Mo Alloy via One-Step Alpha-Extrusion & Annealing. Mater. Sci. Eng. A 2021, 801, 140438. [Google Scholar] [CrossRef]

- Yang, G.; Xu, X.; Sun, T.; Xu, S.; Gui, W.; Zeng, J.; Mu, Y.; Liang, Y.; Lin, J. A Refined Fully Lamellar TiAl Alloy Extruded at α-Phase Region: Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2023, 888, 145804. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, V.A.; Babu, R.R.; Rao, A.G. Development of Ductile Γ+α2 Titanium Aluminide through Ingot Metallurgy Route, Thermomechanical Processing and Characterization. Mater. Sci. Eng. A 2017, 703, 124–136. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Kong, F.T.; Chen, Y.Y.; Liu, Z.Y.; Lin, J.P. Phase Transformation and Microstructure Evolution of Differently Processed Ti–45Al–9Nb–Y Alloy. Intermetallics 2012, 31, 208–216. [Google Scholar] [CrossRef]

- Tang, B.; Cheng, L.; Kou, H.; Li, J. Hot Forging Design and Microstructure Evolution of a High Nb Containing TiAl Alloy. Intermetallics 2015, 58, 7–14. [Google Scholar] [CrossRef]

- He, W.; Tang, H.; Liu, H.; Jia, W.; Liu, Y.; Yang, X. Microstructure and Tensile Properties of Containerless Near-Isothermally Forged TiAl Alloys. Trans. Nonferrous Met. Soc. China 2011, 21, 2605–2609. [Google Scholar] [CrossRef]

- Zhang, J.; Jing, Y.; Fu, M.; Gao, F. Microstructure Optimization of Ingot Metallurgy TiAl. Intermetallics 2012, 27, 21–25. [Google Scholar] [CrossRef]

- Carneiro, T.; Kim, Y.-W. Evaluation of Ingots and Alpha-Extrusions of Gamma Alloys Based on Ti–45Al–6Nb. Intermetallics 2005, 13, 1000–1007. [Google Scholar] [CrossRef]

- Fukutomi, H.; Nomoto, A.; Osuga, Y.; Ikeda, S.; Mecking, H. Analysis of Dynamic Recrystallization Mechanism in γ-TiAl Intermetallic Compound Based on Texture Measurement. Intermetallics 1996, 4, S49–S55. [Google Scholar] [CrossRef]

- Koeppe, C.; Bartels, A.; Clemens, H.; Schretter, P.; Glatz, W. Optimizing the Properties of TiAl Sheet Material for Application in Heat Protection Shields or Propulsion Systems. Mater. Sci. Eng. A 1995, 201, 182–193. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology, 1st ed.; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-3-527-31525-3. [Google Scholar]

- Singh, V.; Mondal, C.; Kumar, A.; Bhattacharjee, P.P.; Ghosal, P. High Temperature Compressive Flow Behavior and Associated Microstructural Development in a β-Stabilized High Nb-Containing γ-TiAl Based Alloy. J. Alloys Compd. 2019, 788, 573–585. [Google Scholar] [CrossRef]

- Jiang, H.; Tian, S.; Guo, W.; Zhang, G.; Zeng, S. Hot Deformation Behavior and Deformation Mechanism of Two TiAl-Mo Alloys during Hot Compression. Mater. Sci. Eng. A 2018, 719, 104–111. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Wang, Y.; Liu, B.; He, Y. Dynamic Recrystallization Behavior of an As-Cast TiAl Alloy during Hot Compression. Mater. Charact. 2014, 97, 169–177. [Google Scholar] [CrossRef]

- Zhang, W.-J.; Lorenz, U.; Appel, F. Recovery, Recrystallization and Phase Transformations during Thermomechanical Processing and Treatment of TiAl-Based Alloys. Acta Mater. 2000, 48, 2803–2813. [Google Scholar] [CrossRef]

- Inui, H.; Kishida, K.; Misaki, M.; Kobayashi, M.; Shirai, Y.; Yamaguchi, M. Temperature Dependence of Yield Stress, Tensile Elongation and Deformation Structures in Polysynthetically Twinned Crystals of Ti-Al. Philos. Mag. A 1995, 72, 1609–1631. [Google Scholar] [CrossRef]

- Cao, G.H.; Klöden, B.; Rybacki, E.; Oertel, C.-G.; Skrotzki, W. High Strain Torsion of a TiAl-Based Alloy. Mater. Sci. Eng. A 2008, 483–484, 512–516. [Google Scholar] [CrossRef]

- Mecking, H.; Hartig, C.; Kocks, U.F. Deformation Modes in γ-TiAl as Derived from the Single Crystal Yield Surface. Acta Mater. 1996, 44, 1309–1321. [Google Scholar] [CrossRef]

- Bartels, A.; Hartig, C.; Willems, S.; Uhlenhut, H. Influence of the Deformation Conditions on the Texture Evolution in γ-TiAl. Mater. Sci. Eng. A 1997, 239–240, 14–22. [Google Scholar] [CrossRef]

- Bartels, A.; Kestler, H.; Clemens, H. Deformation Behavior of Differently Processed γ-Titanium Aluminides. Mater. Sci. Eng. A 2002, 329–331, 153–162. [Google Scholar] [CrossRef]

- Liu, R.; Liu, D.; Tan, J.; Cui, Y.; Yang, R.; Liu, F.; Withey, P.A. Textures of Rectangular Extrusions and Their Effects on the Mechanical Properties of Thermo-Mechanically Treated, Lamellar Microstructure, Ti–47Al–2Cr–2Nb–0.15B. Intermetallics 2014, 52, 110–123. [Google Scholar] [CrossRef]

- Brokmeier, H.-G.; Oehring, M.; Lorenz, U.; Appel, F.; Clemens, H. Neutron Diffraction Study of Texture Development during Hot Working of Different Gamma-Titanium Aluminide Alloys. Metall. Mater. Trans. A 2004, 35, 3563–3579. [Google Scholar] [CrossRef]

| Samples | Deformation Parameters | ||

|---|---|---|---|

| Deformation Temperature (°C) | Strain Rate (s−1) | Deformation Amount (%) | |

| 1 | 1150 | 0.001 | 45 |

| 2 | 1150 | 0.001 | 62.5 |

| 3 | 1150 | 0.001 | 80 |

| Samples | Volume Fractions (%) | ||

|---|---|---|---|

| (α2/γ) Lamellar Colonies | γ Grains | β0 Grains | |

| As-extruded | 70.26 | 29.22 | 0.52 |

| As-forged, 45% | 44.71 | 52.29 | 3.0 |

| As-forged, 62.5% | 16.04 | 80.89 | 3.07 |

| As-forged, 80% | 8.32 | 88.71 | 2.97 |

| Samples | The Angles Between the Lamellar Interface and the Extrusion Direction | ||

|---|---|---|---|

| 0–10° | 10–60° | 60–90° | |

| As-extruded | 48.94% | 27.66% | 23.4% |

| As-forged, 45% | 62.96% | 37.04% | 0 |

| As-forged, 62.5% | 68.75% | 31.25% | 0 |

| As-forged, 80% | 71.43% | 28.57% | 0 |

| The Angle Between the Lamellar Boundaries and the Loading Axis | |||

|---|---|---|---|

| 0° | 31° | 90° | |

| Yield stress (MPa) | 180 | 70 | 260 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, X.; Gong, M.; Guo, Z.; Kong, F. Microstructure Evolution of Extruded TiAl Alloy During Vacuum Isothermal Superplastic Forging Process. Metals 2025, 15, 123. https://doi.org/10.3390/met15020123

Li J, Wang X, Gong M, Guo Z, Kong F. Microstructure Evolution of Extruded TiAl Alloy During Vacuum Isothermal Superplastic Forging Process. Metals. 2025; 15(2):123. https://doi.org/10.3390/met15020123

Chicago/Turabian StyleLi, Jintao, Xiaopeng Wang, Minyu Gong, Zhenyu Guo, and Fantao Kong. 2025. "Microstructure Evolution of Extruded TiAl Alloy During Vacuum Isothermal Superplastic Forging Process" Metals 15, no. 2: 123. https://doi.org/10.3390/met15020123

APA StyleLi, J., Wang, X., Gong, M., Guo, Z., & Kong, F. (2025). Microstructure Evolution of Extruded TiAl Alloy During Vacuum Isothermal Superplastic Forging Process. Metals, 15(2), 123. https://doi.org/10.3390/met15020123